Page 1

EVOLVE Manual Pipettes Operating instructions

900-00010-00_V00

Page 2

Declaration of conformity

INTEGRA Biosciences Corp. –

Hudson, NH, USA

declares on its own responsibility that the devices

comply with:

Hudson, New Hampshire, USA - March 15, 2016

Description Models

EVOLVE Manual

Pipettes

3011, 3012, 3013, 3015, 3016, 3018, 3019, 3022, 3024, 3025,

3026, 3032, 3034, 3035, 3036

EU Directives (DoW: Date of Withdrawal) Before DoW DoW After DoW

Restriction of Hazardous Substances 2011/65/EU

EU Regulations

Registration, Evaluation, Authorisation and Restriction of Chemicals

(REACH)

1907/2006

Piston-operated volumetric apparatus - Part 2: Piston pipettes ISO 8655-2

George Kalmakis

VP Operations

Page 3

EVOLVE Manual Pipettes – Operating instructions V00

www.integra-biosciences.com 3

Table of Contents

Chapter 1 Introduction

1.1 Symbols used...................................................................................5

1.2 Intended use.....................................................................................5

1.3 Safety notes .....................................................................................6

Chapter 2 Description of the device

2.1 Scope of delivery..............................................................................7

2.2 Overview of the EVOLVE Manual Pipettes ......................................7

Chapter 3 Installation

3.1 Optional color coded plunger cap.....................................................8

3.2 Changing the Plunger Spring ...........................................................8

Chapter 4 Operation

4.1 Setting the volume..........................................................................10

4.2 Attaching and removing GripTip pipette tips .................................. 10

4.3 Pipetting .........................................................................................11

4.3.1 Aspirating and Dispensing ..................................................11

4.3.2 Reverse mode.....................................................................12

4.3.3 Proper pipetting techniques ................................................13

4.4 Troubleshooting..............................................................................14

Page 4

EVOLVE Manual Pipettes – Operating instructions V00

4 INTEGRA Biosciences AG

Chapter 5 Maintenance

5.1 Cleaning .........................................................................................15

5.2 Single channel lower end disassembly ..........................................15

5.2.1 Disassembly........................................................................15

5.2.2 Reassembly ........................................................................18

5.3 Sterilization.....................................................................................20

5.3.1 Autoclaving the disassembled components........................20

5.4 Servicing.........................................................................................21

5.4.1 Shipping to INTEGRA Biosciences.....................................21

5.4.2 Changing O-rings of tip fittings............................................21

5.4.3 Lubrication ..........................................................................22

5.5 Calibration ......................................................................................23

5.5.1 Materials .............................................................................23

5.5.2 Definitions ...........................................................................23

5.5.3 Test conditions and environment ........................................24

5.5.4 Pre-wetting of tips ...............................................................24

5.5.5 Leak test .............................................................................25

5.5.6 Obtaining the actual volume ...............................................26

5.5.7 Calculation of accuracy and precision ................................27

5.5.8 Adjusting EVOLVE Manual Pipettes...................................28

5.6 Equipment disposal ........................................................................29

Chapter 6 Technical Data

6.1 Environmental conditions ...............................................................30

6.2 Pipette specifications......................................................................30

6.3 Z Correction Factors.......................................................................32

Chapter 7 Accessories and Consumables

7.1 Accessories ....................................................................................33

7.2 Consumables .................................................................................33

Imprint................................................................................................... 36

Page 5

EVOLVE Manual Pipettes – Operating instructions V00 Introduction

www.integra-biosciences.com 5

1 Introduction

These operating instructions contain all the information required for installation, operation

and maintenance of the EVOLVE Manual Pipettes. This chapter informs about the

symbols used in these operating instructions, the intended use of the EVOLVE Manual

Pipettes and the general safety instructions.

1.1 Symbols used

The operating instructions specifically advise of residual risks with the following symbols:

W

ARNING

This safety symbol warns against hazards that could result in injury. It also

indicates hazards for machinery, materials and the environment.

It is essential that you follow the corresponding precautions.

C

AUTION

This symbol cautions against potential material damage. Follow the

instructions.

N

OTE

This symbol identifies important notes regarding the correct operation of the

device and labor-saving features.

1.2 Intended use

EVOLVE Manual Pipettes are intended to be used in a laboratory for aspirating and

dispensing liquids in the volume range of 0.2–5000 µl using GripTip pipette tips.

Page 6

EVOLVE Manual Pipettes – Operating instructions V00 Introduction

6 INTEGRA Biosciences AG

1.3 Safety notes

EVOLVE Manual Pipettes comply to the recognized safety regulations and is safe to

operate. EVOLVE Manual Pipettes can only be operated when in perfect condition and

while observing these operating instructions.

The device may be associated with residual risks if it is used or operated improperly by

untrained personnel. Any person operating the EVOLVE Manual Pipettes must have read

and understood these operating instructions, and particularly, the safety notes, or must

have been instructed by supervisors so that safe operation of the device is guaranteed.

Repairs may only be performed by INTEGRA Biosciences AG or by an authorized aftersales service member.

Parts may be replaced with original INTEGRA Biosciences parts only.

Regardless of the listed safety notes, additional applicable regulations and guidelines of

trade associations, health authorities, trade supervisory offices, etc. must be observed.

Please visit our website www.integra-biosciences.com

on a regular basis for up to date

information regarding REACH classified chemicals contained in our products.

W

ARNING

When handling dangerous substances, comply with the material safety data

sheet (MSDS) and with all safety guidelines such as the use of protective

clothing and safety goggles.

CAUTION

Do not immerse the EVOLVE Manual Pipettes in liquid. The fluid can damage

internal parts. Avoid pipetting of liquids whose vapors could attack the

materials PA (polyamide), POM (polyoxymethylene), FPM (fluor-rubber),

NBR (nitrile-rubber), CR (chloroprene), silicone. Corrosive vapors could also

damage metallic parts inside the device.

N

OTE

Prolonged exposure of the EVOLVE Manual Pipettes to UV-light can cause

discoloration and/or yellowing of the pipette housing. However, this will not

affect the performance of the device in any way.

Page 7

EVOLVE Manual Pipettes – Operating instructions V00 Description of the device

www.integra-biosciences.com 7

2 Description of the device

2.1 Scope of delivery

• EVOLVE Manual Pipette

• Multipurpose Tool

• Replacement Plunger Cap

• Quick Start Guide

• Replacement O-rings (for 200 μl, 1000 μl and 5000 μl models)

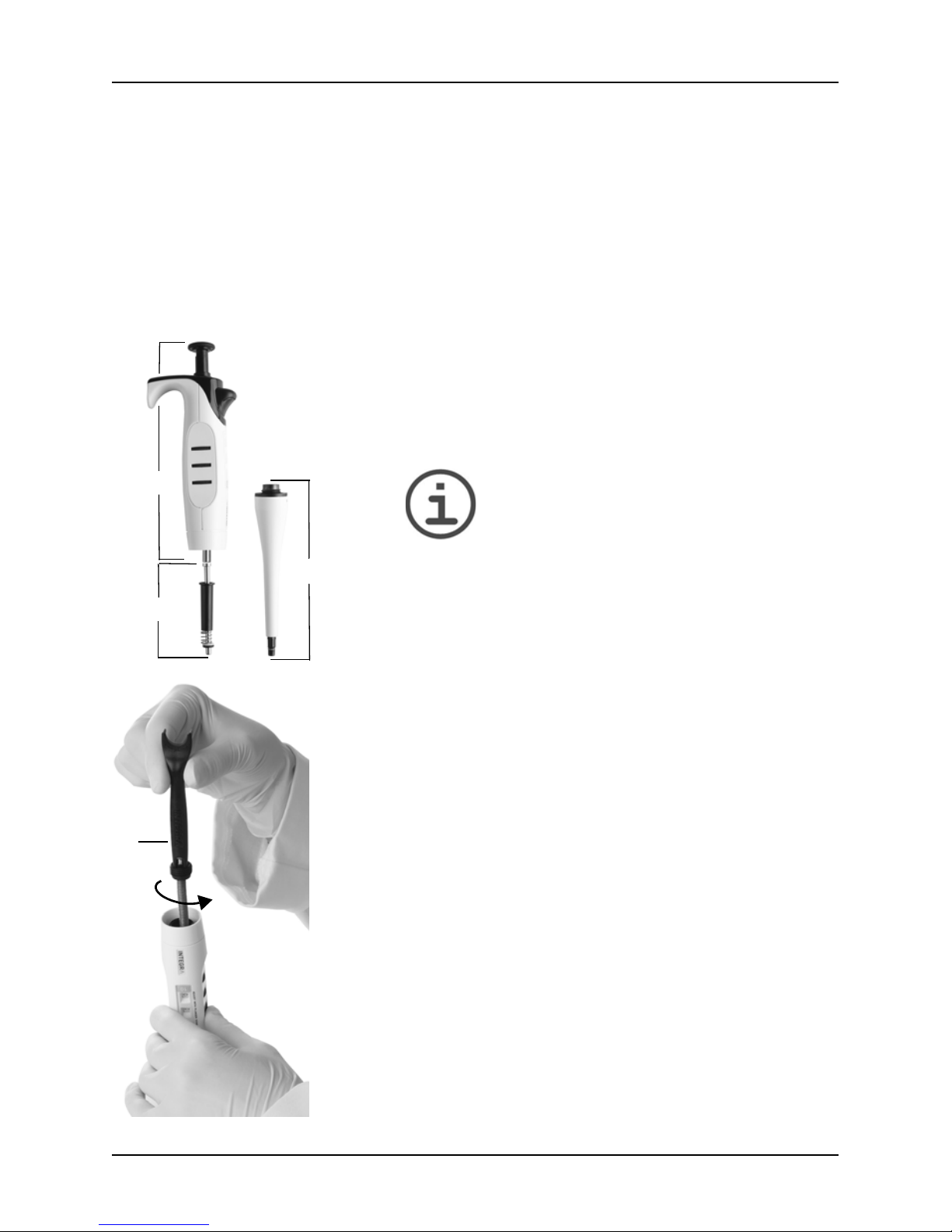

2.2 Overview of the EVOLVE Manual Pipettes

1 Plunger Cap

2 Plunger, to pipette

3 Tip Ejector

4 Finger Hook

5 Adjustment Dials, to set volume

6 Volume Window

The color of the volume indicator label matches

GripTip box insert

7 Ejector Sleeve

8 Tip Fitting

1

2

4

6

3

5

7

8

Page 8

EVOLVE Manual Pipettes – Operating instructions V00 Installation

8 INTEGRA Biosciences AG

3 Installation

3.1 Optional color coded plunger cap

If desired, replace black plunger cap with optional color coded plunger cap.

3.2 Changing the Plunger Spring

The plunger spring installed inside the pipette is the light spring option. You can exchange

with a heavier plunger spring to achieve more control of the plunger movement.

1) Unscrew the Cylinder Assembly (a) and

separate the Piston Assembly (b, models 2–

200 µl) or Piston (model 1000 µl) from the upper

part of the pipette (c). It is held in place by a small

magnet.

N

OTE

5000 µl piston and cylinder assembly is

removed as one piece.

2) Set the pipette to the maximum setting. The

maximum setting is higher than the maximum

volume.

3) Put the two teeth of the Multipurpose Tool (d)

vertically into the slots of the black opening inside

at the bottom of the pipette‘s body (c). Rotate

counterclockwise until the plunger spring

assembly (e) is released.

a

b

c

d

Page 9

EVOLVE Manual Pipettes – Operating instructions V00 Installation

www.integra-biosciences.com 9

CAUTION

Validate or calibrate your pipette after reassembly.

4) To install the optional spring assembly, screw the

plunger spring assembly (e) clockwise into the

upper part of the pipette using the Multipurpose

Tool.

5) Re-attach the Piston assembly/Piston. Screw

clockwise to attach the Cylinder Assembly (a) to

the body of the pipette.

e

Page 10

EVOLVE Manual Pipettes – Operating instructions V00 Operation

10 INTEGRA Biosciences AG

4 Operation

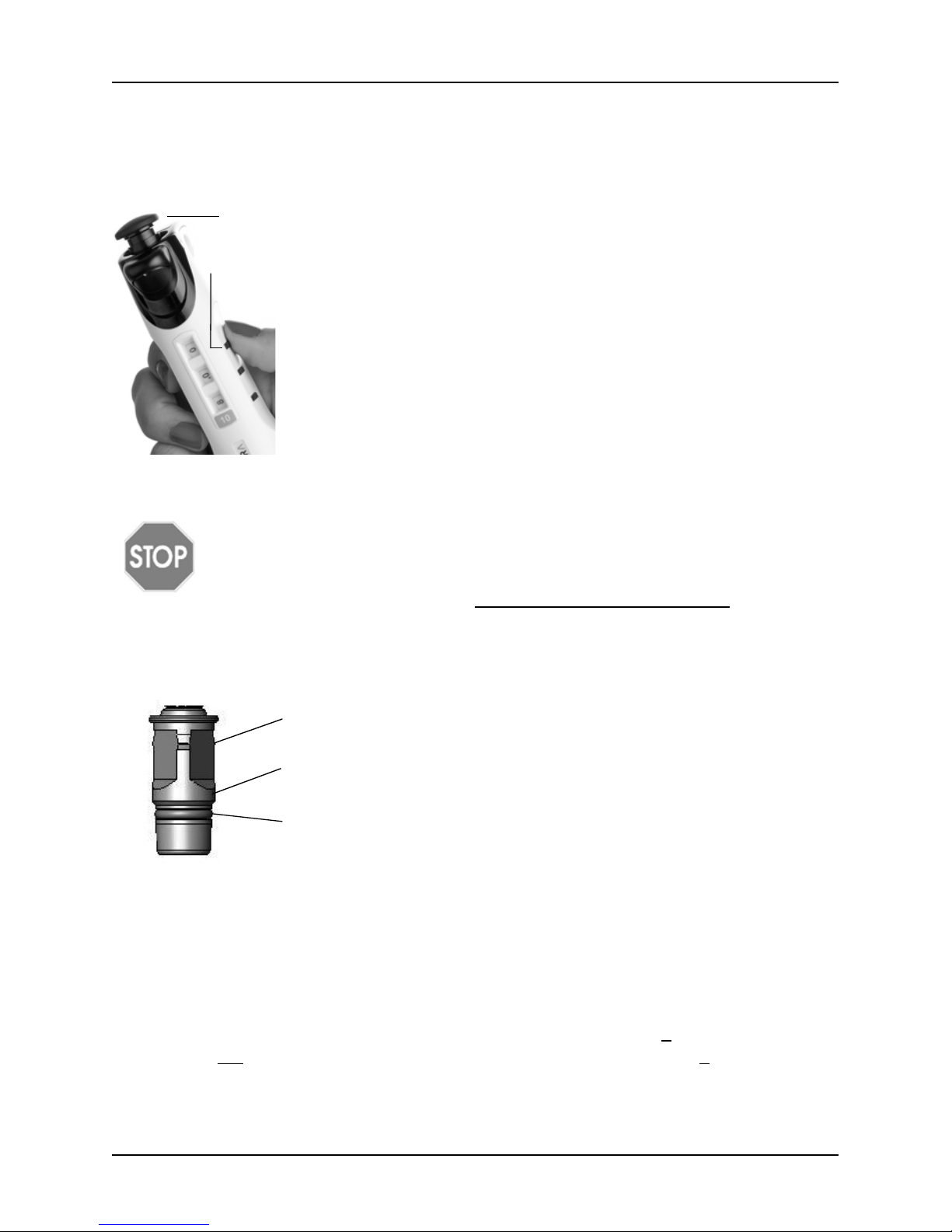

4.1 Setting the volume

4.2 Attaching and removing GripTip pipette tips

CAUTION

T o ensure optimal performance of your EVOL VE Manual Pipettes always use

GripTips of correct size which have been designated for the use with the

EVOLVE Manual Pipettes, see “7.2

Consumables” on page 33.

The unique GripTip system of the EVOLVE Manual Pipettes reduces attachment and

ejection forces, ensures a perfect fitting to prevent the tips from falling off and to provide

a perfect seal. On a multichannel pipette all tips sit on the same height.

Attach the tips:

When loading tip(s), press the pipette into the appropriate GripTip(s) until you hear and

feel a click indicating that a seal has been achieved. Once you feel the click, stop applying

pressure. When loading GripTip pipette tips using a multichannel pipette, slowly rock the

pipette from one side to the other side to ensure the proper seal is achieved.

Discard your used tips:

If liquid is in the tips, empty them by pressing down the Plunger (2

) to the second stop

(see section 4.3

). Tips are easily removed by pressing the Tip Ejector (3).

1) To set the desired pipetting volume press down the Plunger (a)

and rotate slightly clockwise to unlock the volume dials.

2) Spin the Adjustment Dials (b) until the desired volume is

shown in the Volume Window.

3) Slightly rotate and slowly release the Plunger (a) to lock the

volume.

a

b

A rim inside the GripTips snaps over the multi-lobes and ensures

firm attachment of the tips.

A shoulder provides a positive stop to prevent over tightening of the

tips. Without hammering, the tip is either on or off but nothing in

between.

O-ring provides forgiving and robust seal surface for the pipette tip.

Page 11

EVOLVE Manual Pipettes – Operating instructions V00 Operation

www.integra-biosciences.com 11

4.3 Pipetting

The Plunger can be pushed down to two different stops:

For detailed recommendations for pipetting see also “4.3.3

Proper pipetting techniques”

on page 13.

4.3.1 Aspirating and Dispensing

To aspirate and dispense liquid perform the following steps:

1) Top position: Varies depending on volume setting.

2) First stop: Fixed calibrated position for aspirating and

dispensing.

3) Second Stop: To blowout the residual liquid.

Aspirate

1) With GripTip(s) attached, push down the Plunger (2

) to the first

stop.

2) Place GripTips in liquid. Hold the pipette vertically or in an angle

of max. 20° throughout the entire pipetting process and immerse

the GripTip(s) just below the surface of the liquid (2–3 mm).

3) Slowly return Plunger to the top position. For higher volumes

(>200 μl), follow the liquid level by moving the pipette down.

4) Remove the GripTip(s) from liquid.

Dispense

5) To dispense the liquid, push the Plunger (2

) down to the first

stop.

6) If there is any residual liquid in tip, a blowout

should be

performed by pressing the Plunger to the second stop.

7) Remove the GripTips from vessel and release Plunger.

1

2

3

Page 12

EVOLVE Manual Pipettes – Operating instructions V00 Operation

12 INTEGRA Biosciences AG

4.3.2 Reverse mode

Viscous samples should be aspirated and dispensed at slower speeds and in reverse

pipetting mode:

Aspirate

1) Fully push down the Plunger (2

) to the second stop.

2) Immerse the GripTip(s) in the liquid, let the Plunger slowly

release to the upper position and wait shortly until the liquid is

fully aspirated.

Dispense

3) To dispense, press the Plunger (2

) slowly down to the first stop

and wait a few seconds to dispense the liquid.

4) Remove the GripTip(s) from the target vessel.

5) To expel the excess liquid press the Plunger to the second

stop.

Page 13

EVOLVE Manual Pipettes – Operating instructions V00 Operation

www.integra-biosciences.com 13

4.3.3 Proper pipetting techniques

INTEGRA Biosciences recommends the following techniques for enhancing pipetting

results. These techniques are consistent with ISO standard 8655-2.

• It is best to immerse the GripTips just below the surface of the liquid (2–3 mm) to allow

the desired volume to be aspirated. If the tip is immersed too deep, the risk of carryover is increased due to liquid drops clinging to the outer surface of the tip.

• Press and release the plunger with consistent speed and smoothness.

• Always prewet GripTips. After loading tips onto your pipette, aspirate and dispense the

full volume 2-3 times to coat the inside of pipet tips. Pre-wetting ensures that the liquid

and air inside the tips are at equal temperature and the dead air space is humidified.

Neglecting to perform a pre-wet can result in a smaller delivery volume in the first few

dispenses.

• EVOLVE Manual Pipettes are air displacement pipettes. To properly dispense liquids,

ensure that the pipette tip is at a 0–20° angle. After each dispense, you must touch

GripTips against the vessel wall or liquid. This process is referred to as “touching off”

or “tip touch” and prevents liquid from clinging to the pipette tips.

• Air displacement pipettes show the best performance between 35% and 100 % of the

nominal volume.

• Viscous samples should be aspirated and dispensed at slowest speeds to ensure

accurate pipetting. In addition, pipetting should be performed in a reverse mode.

• For pipetting liquids with high vapor pressures (such as methanol or ethanol), use relatively fast pipetting speeds and avoid prolonged pauses after aspiration.

• Calibrate based on fluid type. EVOLVE Manual Pipettes are tested and calibrated at

the factory for use with distilled water at room temperature. It may be necessary to recalibrate your EVOLVE Manual Pipettes if the liquid to be used has different physical

properties (specific gravity and vapor pressure) than water.

W

ARNING

Avoid pipetting for extended periods. To minimize the risk of repetitive strain

injury, include pauses of several minutes.

Use filtered GripTips to pipette corrosive or biohazardous liquids. The filter

prevents vapors and aerosols from corroding or contaminating the cylinder

assembly.

Page 14

EVOLVE Manual Pipettes – Operating instructions V00 Operation

14 INTEGRA Biosciences AG

4.4 Troubleshooting

Problem Probable cause Remedy

Leaking. • Tip incorrectly attached.

• Foreign particles between tip

and tip fitting.

• Damaged red O-ring.

• Attach a new tip.

• Clean tip fitting. Attach new tips.

• Change the O-ring, see 5.4.2

.

• If leak persists, contact service.

Dispense results

are inaccurate.

• Unsuitable calibration for

liquid class.

• Improper pipetting

techniques.

• Recalibrate with the liquids in

question.

• Adjust aspiration and dispense

speed depending on liquid:

- High viscosity liquids may

require calibration.

- High vapor pressure liquids

may require pre-wetting.

- Refer to proper pipetting

techniques section 4.3.3

Not dispensing/

aspirating.

• Piston stuck or not

connected.

• Internal seal is damaged.

• Contact service.

Droplets on the

tips.

• Temperature of liquid differs

from that of air inside the tips.

• Liquid of low viscosity and

high vapor pressure.

• Touch off was not performed.

• Pre-wet tips up to 3 times.

• Increase dispensing speed.

• Perform a touch-off.

Page 15

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 15

5 Maintenance

5.1 Cleaning

The materials used on the exterior of the EVOLVE Manual Pipettes support regular

cleaning intervals. Clean the external components with a lint-free cloth lightly soaked with

mild soap solution in distilled water or with a 70 % dilution of Isopropyl or Ethanol. Never

use acetone or other solvents.

W

ARNING

Do not immerse the entire pipette into a cleaning solution or spray cleani ng

solution directly onto the exterior body of the pipette.

If the pipette is exposed to corrosive vapors, e.g. from concentrated acids, or if liquid

enters the internals, disassemble the lower part of the pipette and clean the internal parts

with distilled water or with a 70 % dilution of Isopropyl or Ethanol. Follow the instructions

below for disassembly, also necessary for trouble shooting and autoclaving.

5.2 Single channel lower end disassembly

5.2.1 Disassembly

Disassemble the lower part of the single channel pipette as follows:

Models of all sizes:

1) Unscrew counterclockwise to remove the

Cylinder Assembly (a) from the pipette.

2) Slide the Cylinder Assembly (a) down from the

pipette body. This exposes the Piston Assembly

(b, models 2–200 µl) or Piston with mounted

Cup Seal (m, model 1000 µl).

a

b

Page 16

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

16 INTEGRA Biosciences AG

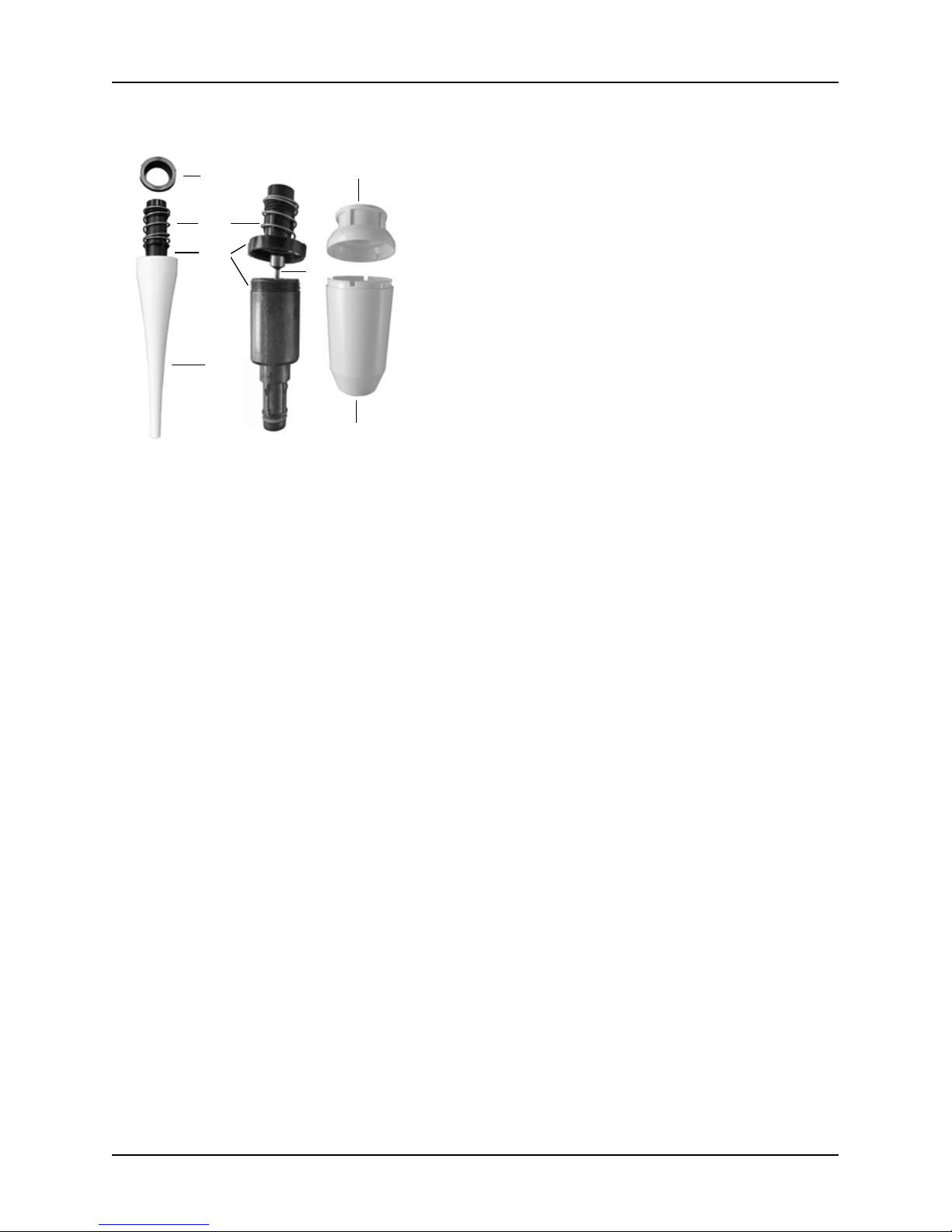

Models 2–20 µl:

3) Slide the following components from the Piston (h):

•

O-Ring

(black, g)

and Seal

(white, f)

Assembly

• Lower Seal Retainer (white, e)

• Seal Retainer Spring (d)

• Seal Retainer (white, c)

Set these components aside or place them in an

autoclave pouch.

Models 100 µl and 200 µl:

3) Slide the following components from the Piston (h):

•

O-Ring

(black, g)

and Seal

(white, f)

Assembly

• Seal Retainer Spring (d)

• Seal Retainer (black or white, c)

Set these components aside or place them in an

autoclave pouch.

100 µl 200 µl

Models 2–1000 µl:

4) Separate the Piston (h) from the upper part of the

pipette. The Piston is held in place by a small

magnet.

f

c

d

h

e

g

f

d

c

h

g

f

d

c

h

g

h

Page 17

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 17

Models of all sizes:

6) Remove the Ejector Spring (j).

7) Set all components of the lower part aside or place them in an autoclave pouch.

Cylinder Assemblies (a): Models 2–1000 µl:

5) With the Cylinder Assembly (a) in hand, turn

counterclockwise to remove the black Snap Ring

(i). Pullout the black Cylinder (k) from the white

Ejector Sleeve (l).

Model 5000 µl:

5) Put your fingernails into the gap of the white

Ejector Sleeve (l) and pull off the Ejector Sleeve

Cap (n). With the black Cylinder (k) in hand

unscrew the upper part. Remove the Piston (h)

with mounted Cup Seal (m).

2–1000 µl

5000 µl

k

j

i

l

h

l

n

Page 18

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

18 INTEGRA Biosciences AG

5.2.2 Reassembly

Before reassembling the pipette, check each component for lint or dust particles. It is

recommended to replace the O-Ring (black, g) and Seal (white, f) or Cup Seal (m).

1) Lightly lubricate the Piston, O-Rings and Seals (see “5.4.3

Lubrication” on page 22).

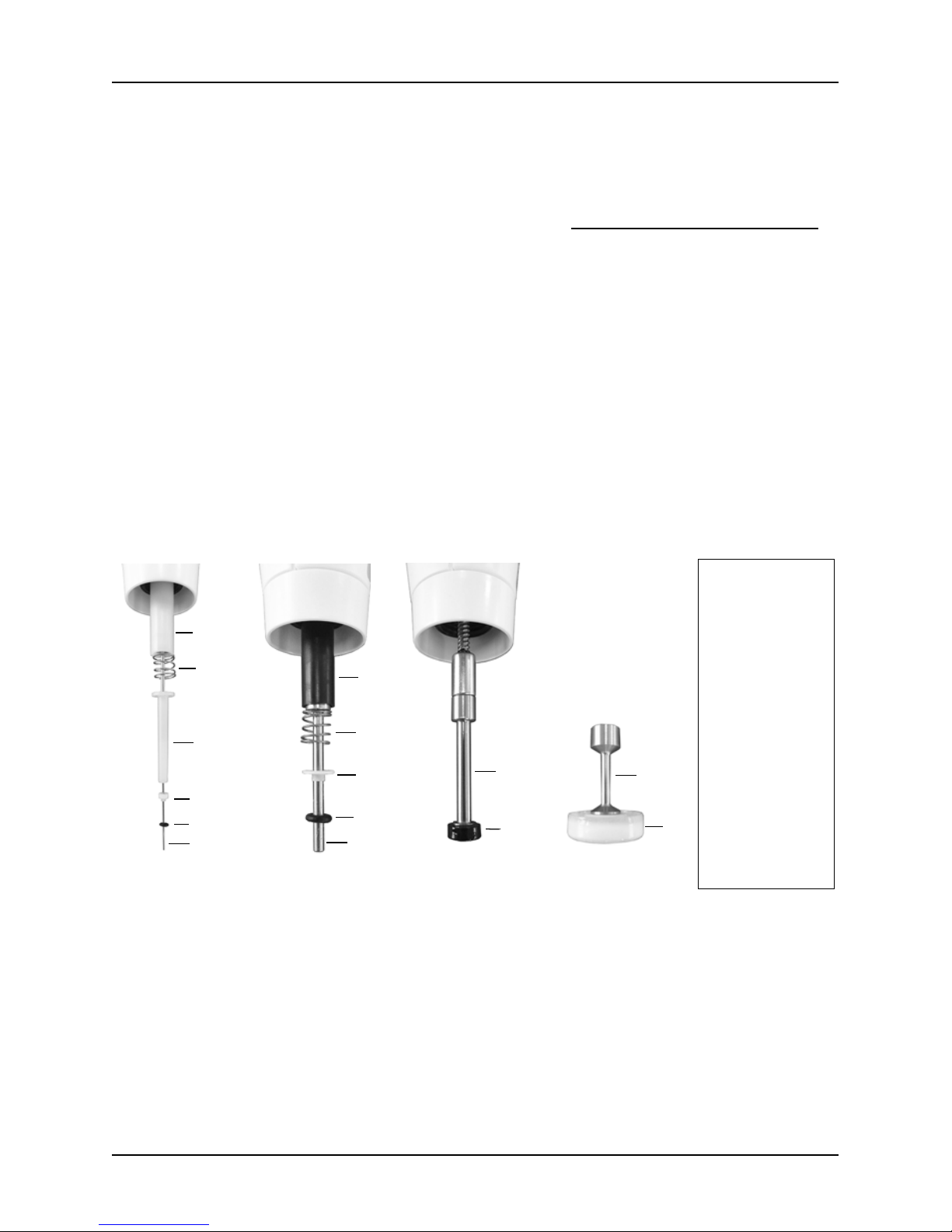

Models 2 µl –1000 µl:

2) Position the Piston (h) at the small magnet to connect the Piston to the upper part of

the pipette.

Models 2 µl – 200 µl:

3) Slide the Seal Retainer (c) onto the Piston and up into the pipette. The end of the Seal

Retainer that has an extended edge (lip) faces the upper part of the pipette.

4) Slide the Seal Retainer Spring (d) onto the Piston. It rests against the Seal Retainer.

Slide the Lower Seal Retainer (e, 2, 10, 20 µl only) onto the Piston.

5) Slide the lightly lubricated

O-Ring

(black, g)

and Seal

(white, f)

Assembly onto the

Piston. The white Seal is closest to the Seal Retainer Spring. Be sure the black O-Ring

is securely slided into the white Seal.

Piston Assemblies (models 2–200 µl) and Pistons with Cup Seal (1000 µl, 5000 µl):

c: Seal

Retainer

d: Seal

Retainer

Spring

e: Lower Seal

Retainer

f: O-Ring

g: Seal

h: Piston

m: Cup Seal

2, 10, 20 µl 100, 200 µl 1000 µl 5000 µl

g

c

d

h

e

f

f

d

c

h

g

h

m

m

h

Page 19

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 19

Models of all sizes:

6) Slide the Ejector Spring (j) onto the top of the black Cylinder (k).

Models of all sizes:

10) Screw clockwise to attach the Cylinder Assembly (a) to the body of the pipette.

Perform a leak test (see “5.5.5

Leak test” on page 25) and validate pipetting volumes after

reassembly.

Cylinder Assemblies (a): Models 2 µl – 1000 µl:

2–1000 µl

5000 µl

7) Slide the Cylinder (k) into the white Ejector Sleeve (l).

8) Position the black Snap Ring (i) over the Cylinder (k) at

the top of the Ejector Sleeve (l). Turn the sleeve

clockwise until the Snap Ring snaps into place and

secures the Cylinder in the Cylinder Assembly.

9) Slide the Cylinder Assembly (a) over the Piston (h).

Model 5000 µl:

7) Push the Cup Seal (m) of the Piston (h) into the top of

Cylinder‘s lower part (k) and screw on the upper part of

Cylinder (k).

8) Ensure that the four noses (o) of the Ejector Sleeve Cap

(n) point to the openings (p) of the Ejector Sleeve (l) and

re-attach the cap.

k

j

i

l

n

h

o

p

Page 20

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

20 INTEGRA Biosciences AG

5.3 Sterilization

If the surface of the EVOLVE Manual Pipettes have been in contact with biohazardous

material, they must be decontaminated in accordance to good laboratory practice. Wipe

the clean surface with a lint-free cloth, lightly soaked e. g. with the following disinfectants:

• Ethanol 70 %

• Microcide SQ 1:64

• Glutaraldehyde solution 4%

• Virkon solution 1-3%

Follow the instructions provided with the disinfectants.

It is not recommended to autoclave the EVOLVE Manual Pipettes. If autoclaving is

required, only the lower assembly of the EVOLVE single channel pipettes can be

autoclaved.

W

ARNING

Service is required after autoclaving the EVOLVE Manual Pipettes!

Do not autoclave the entire unit. Multichannel pipettes can NOT be

autoclaved, they might be damaged!

As-found calibration (measurement report, indicating “before” data) is not

possible after autoclaving!

5.3.1 Autoclaving the disassembled components

Place the disassembled components (see 5.2.1) into steam autoclave in an autoclave

pouch:

You may autoclave the components at 121°C, 1 bar overpressure for 20 minutes.

C

AUTION

Service is required after autoclaving the EVOLVE Manual Pipettes!

Single channel 2–1000 µl: Single channel 5000 µl:

Page 21

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 21

5.4 Servicing

5.4.1 Shipping to INTEGRA Biosciences

For any service or repairs, please contact your local service technician.

WARNING

If working with infectious materials, e. g. human pathogens, the EVOLVE

Manual Pipettes need to be decontaminated before sending them to service

and the declaration on the absence of health hazards must be signed. T his

is necessary to protect service personnel.

5.4.2 Changing O-rings of tip fittings

200 µl, 1000 µl and 5000 µl EVOLVE Manual Pipettes feature tip fittings with red O-rings.

This O-ring is used to seal against the inside wall of GripTips and provides a robust seal.

O-rings are made of durable silicone. If necessary, e.g. in case of a leakage due to

damaged O-ring, you can replace these O-rings. A set of spare O-rings can be ordered

separately, see “7.2

Consumables” on page 33.

W

ARNING

Avoid mechanical damage of the tip fittings.

For 200 µl or 1000 µl pipettes, slide the Multipurpose Tool

sidewards onto the tip fitting until the O-ring (a) builds a loop.

Remove the O-ring with plastic tweezers.

For 5000 µl pipettes, simply use plastic tweezers to remove the Oring.

Slide a new O-ring over the tip fitting (b).

a

a

b

Page 22

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

22 INTEGRA Biosciences AG

5.4.3 Lubrication

The internal seals and O-rings are subject to wear. An undamaged thin lubricant film is

important to keep the seals tight. The lubricant recommended depends on the EVOLVE

pipette size, see “7.2 Consumables” on page 33:

Single channel 2 µl– 200 µl models:

Use Fluorocarbon Gel (#100-00136-50) to lightly lubricate the

piston (a) without components (c, d) slid onto. Put a drop of grease

onto your fingers, lubricate the black O-ring (b) and slide it over the

white seal (c).

Single channel 1000 µl and 5000 µl models:

Use the Super-O-Lube (#100-00135-50) to lightly lubricate the

outer ring of the Cup Seals (d, e). Do not lubricate the bottom of Cup

Seals.

b

c

a

d

e

Page 23

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 23

5.5 Calibration

The EVOLVE Manual Pipettes are factory tested and calibrated under environmentally

controlled conditions using a gravimetric procedure in accordance with ISO 8655

standards. For the accuracy and precision specifications, see “6.2 Pipette specifications”

on page 30.

For information regarding calibration service, please contact your local dealer.

5.5.1 Materials

• Precision balance with 0.01 mg readability

• ASTM Class 2 or OIML E2 test weights

• Evaporation trap for balance

• Weighing vessel (optimally the height-to-diameter ratio is at least 3:1)

• Measurement equipment for temperature, humidity and atmospheric pressure

• Distilled water (Grade 3 according to ISO 3696)

• New non-filtered GripTips matching the pipette volume (see section 7.2

)

• 1 beaker with distilled water

5.5.2 Definitions

Blow-out: Discharges any residual liquid from the pipette tip.

Blow-in: After the blow-out, the piston moves back into home position. This causes a

slight intake of air (or liquid if tips remain in the liquid).

Two step blow-out: To avoid an early blow-in, keep the plunger pressed after dispensing,

remove the tips from liquid and then release the plunger.

Pre-wet: The action of pre-coating the inside of the liquid contacting parts with a thin film

of the same liquid. Additionally, it equilibrates humidity of the air space inside tip and the

pipette.

Touch off: Touching the pipette tip against the surface liquid or side of well-plate to

release any sample liquids that might be on the end of the pipette tip.

Page 24

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

24 INTEGRA Biosciences AG

5.5.3 Test conditions and environment

Tests and calibrations should be performed in conditions and environment according to

ISO 8655-6 standard.

• Temperature needs to be between 18–25°C and remain constant (±0.5 °C) throughout

the calibration.

• Optimal relative humidity of the environment is >50% and around the dispensing position 80%.

• GripTips, pipettes and distilled water need to be in the calibration laboratory for at

least 2 hours prior to calibration to reach temperature equilibrium with the environment.

• The balance must be validated using reference weights before and after a measuring

series. A low and high volume weight should be used. E.g.:

100 g (Mettler Toledo, #11119250)

10 g (Mettler Toledo, #11119220)

1 g (Met tle r Toled o, #11119190)

10 m g (M ett ler Tol edo, #1111 913 0)

C

AUTION

Always use new, pre-wetted GripTips for leak test and calibration.

5.5.4 Pre-wetting of tips

Pre-wet new GripTips three times prior to starting tests and calibrations. This is required

every time a tip is changed.

1) Set the pipette to aspirate full volume.

2) Attach a new unused GripTip which correspond to the volume range of the pipette

directly from the rack without touching the tip by hand.

3) Use a separate waste container for pre-wet dispenses.

4) Push down the Plunger to the first stop. Aspirate by releasing with medium speed.

5) Dispense: Keep the Plunger pressed to the first stop until all liquid is expelled.

At the end of the third cycle push the Plunger to the second stop, remove the tip from the

liquid and then release the Plunger to perform a two-step blowout.

Page 25

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 25

5.5.5 Leak test

It is recommended to perform a leak test every 3 months or when errors occur.

1) Prewet tips as described above.

2) Set the EVOLVE Manual Pipettes to aspirate full volume.

3) Push down the Plunger to the first stop. Aspirate full volume by releasing with medium

speed and verify liquid level is not decreasing during 10 seconds while GripTips are

still in distilled water.

4) Remove the GripTips from the liquid and hold the pipette at a 20° angle. Wait for 20

seconds.

a) Observe whether liquid droplets are forming at the end of the GripTips.

b) On a multichannel pipette, verify liquid level is even across all channels.

5) Immerse GripTips approximately 2 mm into distilled water and push and release the

Plunger to mix six times.

a) Observe whether air bubbles are forming when dispensing.

b) On a multichannel pipette, check whether the levels stay approximately on the

same level across all channels.

6) At the end push the Plunger to the second stop and remove the tip from the liquid

before releasing.

Signs indicating a leak

1) During the mix cycle in the leak test, the liquid level of 1 channel is decreasing.

N

OTE

A decreasing liquid level at aspiration could be an indication of a slow leak.

Performing a retest at 10 mixes may help identify a slow leak.

2) Liquid is left in a tip after the last dispense during the leak test.

3) One or more channels show air bubbles during the mix cycle in the leak test.

4) Droplets are forming when holding the pipette in the air for 20 seconds, even if a prewet was performed.

5) The liquid levels are not equal on all channels after aspiration.

If the pipette is leaking, change O-rings (see 5.4.2

) and lubricate pistons (see 5.4.3) or

contact your service technician.

Page 26

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

26 INTEGRA Biosciences AG

5.5.6 Obtaining the actual volume

INTEGRA certifies the pipettes at 10 %, 50% and 100 % of the nominal value. For each

volume 5 measurements are taken from all channels.

General

1) Always use new, unused GripTips, also when changing the test volume (e.g. from

200 µl to 20 µl).

2) Always pre-wet (section 5.5.4

) when using a new GripTip. For a low volume

measurement, first set the maximum volume for the pre-wet and then change to the

volume to be measured.

3) After dispensing, perform a touch off to make sure no liquid remains on the tip.

Gravimetric testing

1) Write down the ambient temperature and air pressure.

2) Set the pipette to the high test volume.

3) Perform a pre-wet, see 5.5.4

.

4) The first and second dispense to the balance should not be recorded. After each

dispense re-tare the balance.

5) Aspirate the Target volume of water keeping the pipette in a vertical to 20-degree

position while immersing the pipet tip 2–3 mm below the surface of the water. When

withdrawing the tip from the liquid, gently wipe the tip against the side wall of the vessel

to remove any liquid from the outside of the pipet tip.

6) Start the first measurement. Always pipet directly into the liquid of the weigh container

on the balance. At the end push the Plunger to the second stop and hold the plunger

pressed until the pipette is removed again from the weigh vessel to perform a 2-step

blowout. Record the weight from the balance.

7) After completing the 5 high volume measurements, continue with the mid and low test

measurements by repeating steps 3–6.

Page 27

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 27

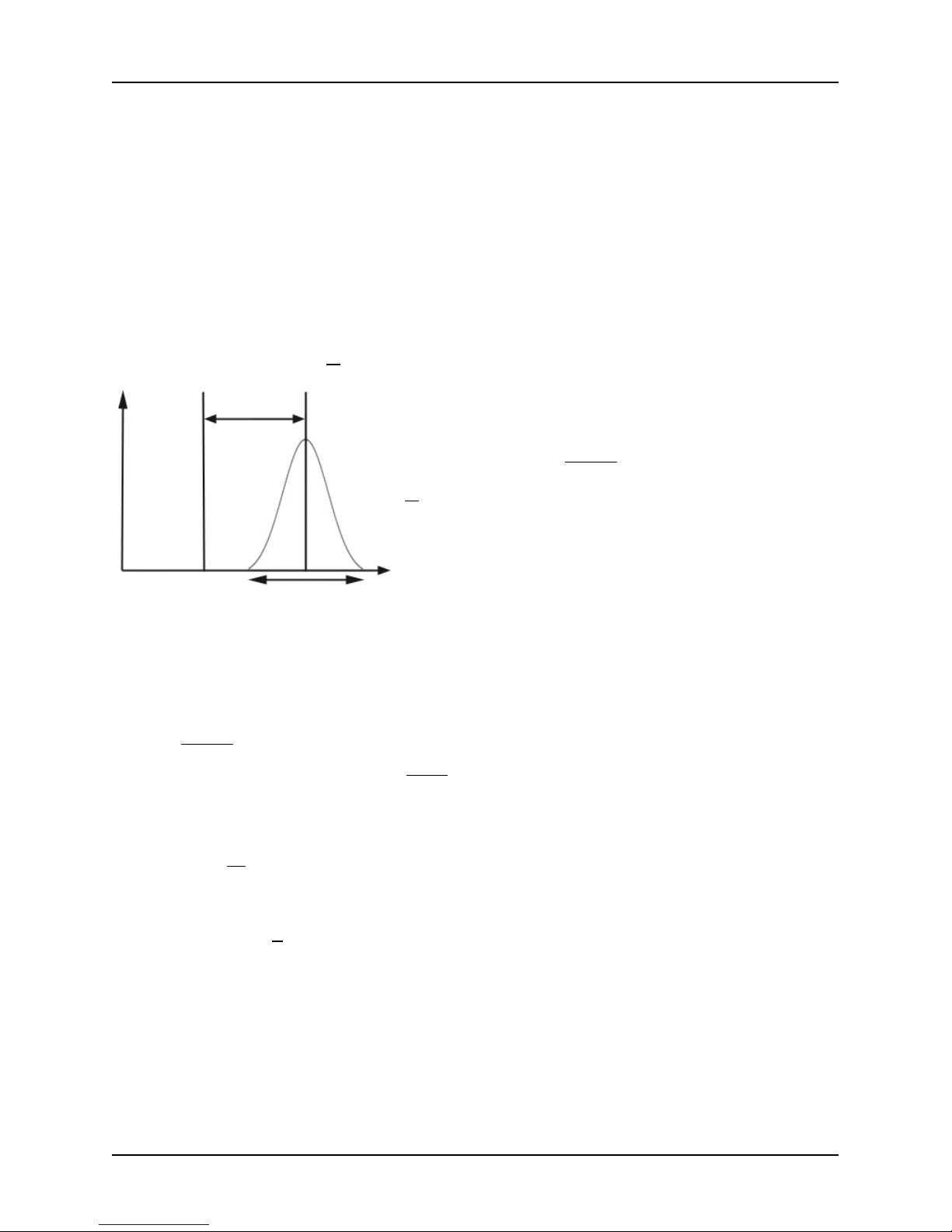

5.5.7 Calculation of accuracy and precision

Accuracy

The ability of a pipette to aspirate or dispense the exact volume desired. It indicates the

proximity of measurement results to the true value. Accuracy is also know as systematic

error and as the name indicates, can be corrected/calibrated.

Precision, coefficient of variation (CV)

Precision indicates the repeatability or reproducibility of the measurement. It is also called

random error and is therefore an unpredictable error, which can not be corrected/

calibrated.

Conversion of the mass to volume

The values obtained by balance readings are in grams. These values need to be

converted to micro liters using the Z correction factor. It takes into account the water

density and air buoyancy during weighing at the corresponding test temperature. To

determine the correct Z factor, find the intersection between temperature and air pressure

in Table 6.3

6.3. Round up temperature and air pressure values.

Multiply each weight

m

i

obtained in 5.5.6 with the corresponding Z factor:

Add together the volumes

V

i

delivered, divide the sum by n (e.g. n = 5) to calculate the

mean volume

V (in millilitres or micro litres) delivered at the test temperature, which is the

Actual Volume:

The following symbols are used throughout this text:

V

s

= Selected test or target Volume

m

i

= Measured Liquid Weight (g)

Z = Z factor, see 6.36.3

V

i

= Converted Volume (ml or µl)

V = Actual mean Volume (ml or µl)

n = Number of measurements

Tar ge t V

s

Accuracy

Precision

V

Actual

V

i

m

i

Z=

V

1

n

---

V

i

i 1=

n

=

Page 28

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

28 INTEGRA Biosciences AG

Calculation of systematic error (accuracy)

The systematic error

e

s

can be calculated using the following equation with V

s

being the

selected test volume:

or in percent:

Calculation of random error (precision %)

To calculate the random error as the repeatability standard deviation s

r

, use the following

equation:

The random error can also be expressed as a percentage, by the coefficient of variation

CV, using equation:

If the pipette is properly calibrated, the Target volume

V

s

should equal the Actual volume

V within the accuracy specifications of the pipette.

5.5.8 Adjusting EVOLVE Manual Pipettes

Compare the calculated accuracy and precision values with the corresponding pipette

specifications given in section 6.2

.

The industry standard is to test and present specifications using neat transfers. This is

aspirating and dispensing the same volume.

In case a EVOLVE Manual Pipette has not met the calibration specifications it needs to be

adjusted. This can be corrected with the Multipurpose Tool.

e

s

VV

s

=

e

s

100 VV

s

V

s

-----------------------------------

=

s

r

ViV–

2

i 1=

n

n 1–

-------------------------------=

CV 100

s

r

V

----

=

Page 29

EVOLVE Manual Pipettes – Operating instructions V00 Maintenance

www.integra-biosciences.com 29

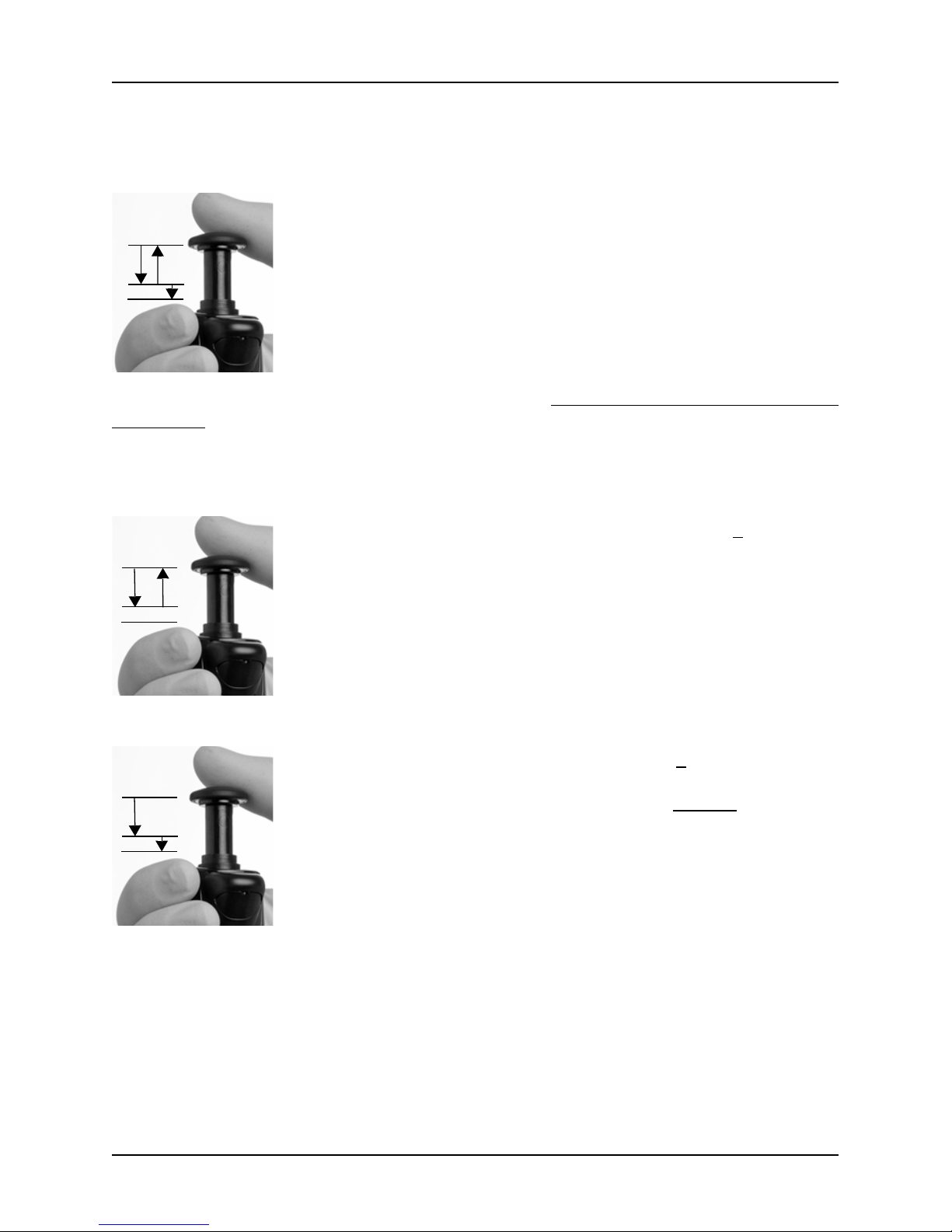

Put the two teeth of the Multipurpose Tool into the slots on the top of the pipette.

N

OTE

Validate the new volume set by repeating the gravimetric testing.

c)

5.6 Equipment disposal

The EVOLVE Manual Pipettes must not be disposed of with unsorted municipal

waste.

Dispose of the EVOLVE Manual Pipettes in accordance with the laws and

regulations in your area.

Rotate clockwise to increase the volume (slight turn up to a full turn).

Rotate counterclockwise to decrease the volume (slight turn up to a

full turn).

Page 30

EVOLVE Manual Pipettes – Operating instructions V00 Technical Data

30 INTEGRA Biosciences AG

6 Technical Data

6.1 Environmental conditions

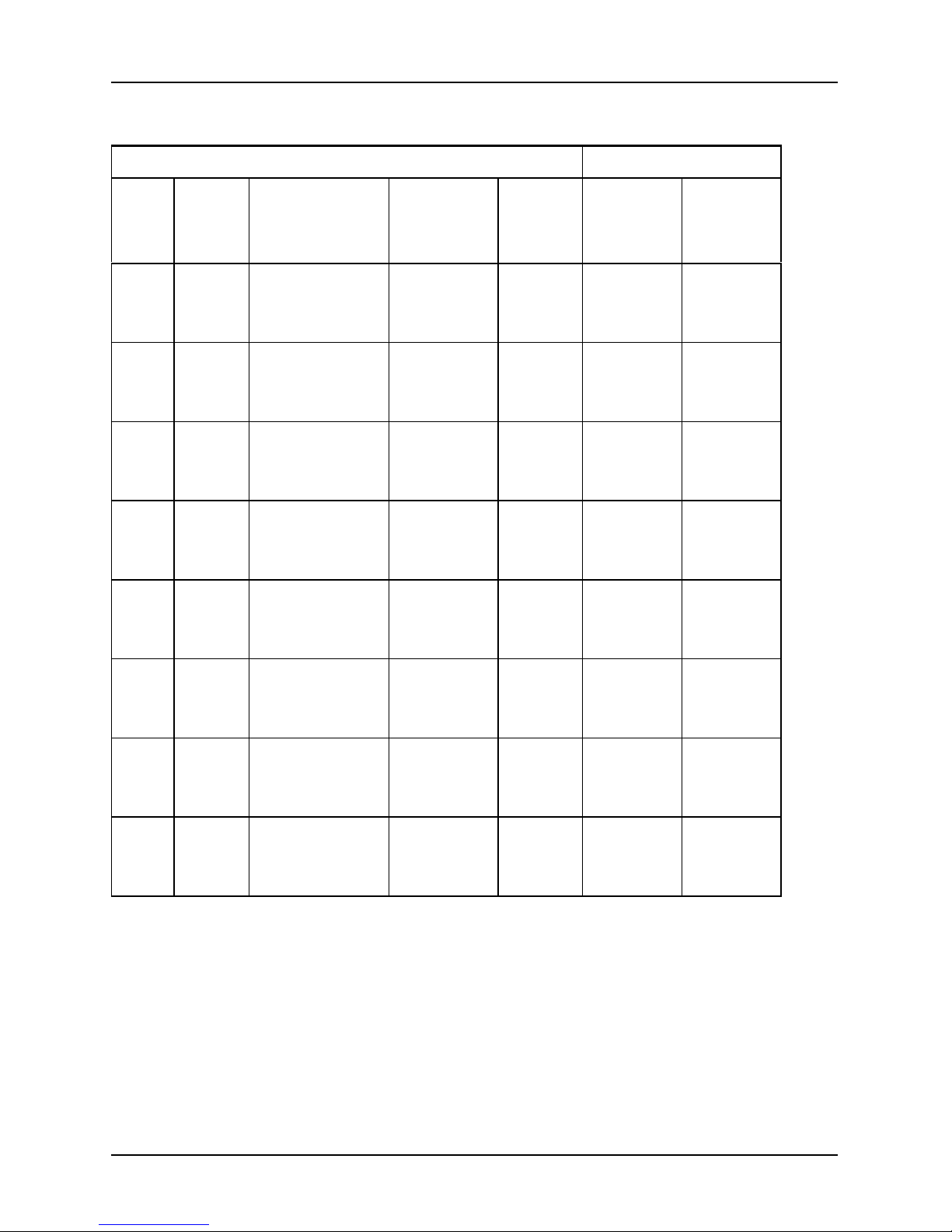

6.2 Pipette specifications

Precision = Coefficient of Variation.

Operation

Temperature range 5–40 °C

Humidity range Max. rel. humidity 80% for temperatures up to 31°C,

decreasing linearly to 50% rel. humidity at 40°C.

Altitude range <2000 m

EVOLVE Manual Pipettes Manufacturer

Chan-

nel

Part

No.

Volume Ran ge

(µl)

Volume

Increments

(µl)

Test

Volume

(µl)

Accuracy

(±%)

Precision

(≤%)

1 3011 0.2–2 0.001 0.2 12 6

12.81.6

21.8 1

1 3012 1–10 0.01 1 2.5 1.8

51.50.8

10 1 0.5

1 3013 2–20 0.01 2 5 2

10 1.6 0.5

20 1 0.35

1 3015 10– 100 0.1 10 3 1

50 0.8 0.35

100 0.8 0.2

1 3016 20– 200 0.1 20 2.2 0.9

100 0.8 0.3

200 0.7 0.18

1 3018 100– 1000 110030.6

500 0.8 0.3

1000 0.8 0.2

1 3019 500– 5000 5 500 2.2 0.7

2500 0.8 0.3

5000 0.6 0.18

Page 31

EVOLVE Manual Pipettes – Operating instructions V00 Technical Data

www.integra-biosciences.com 31

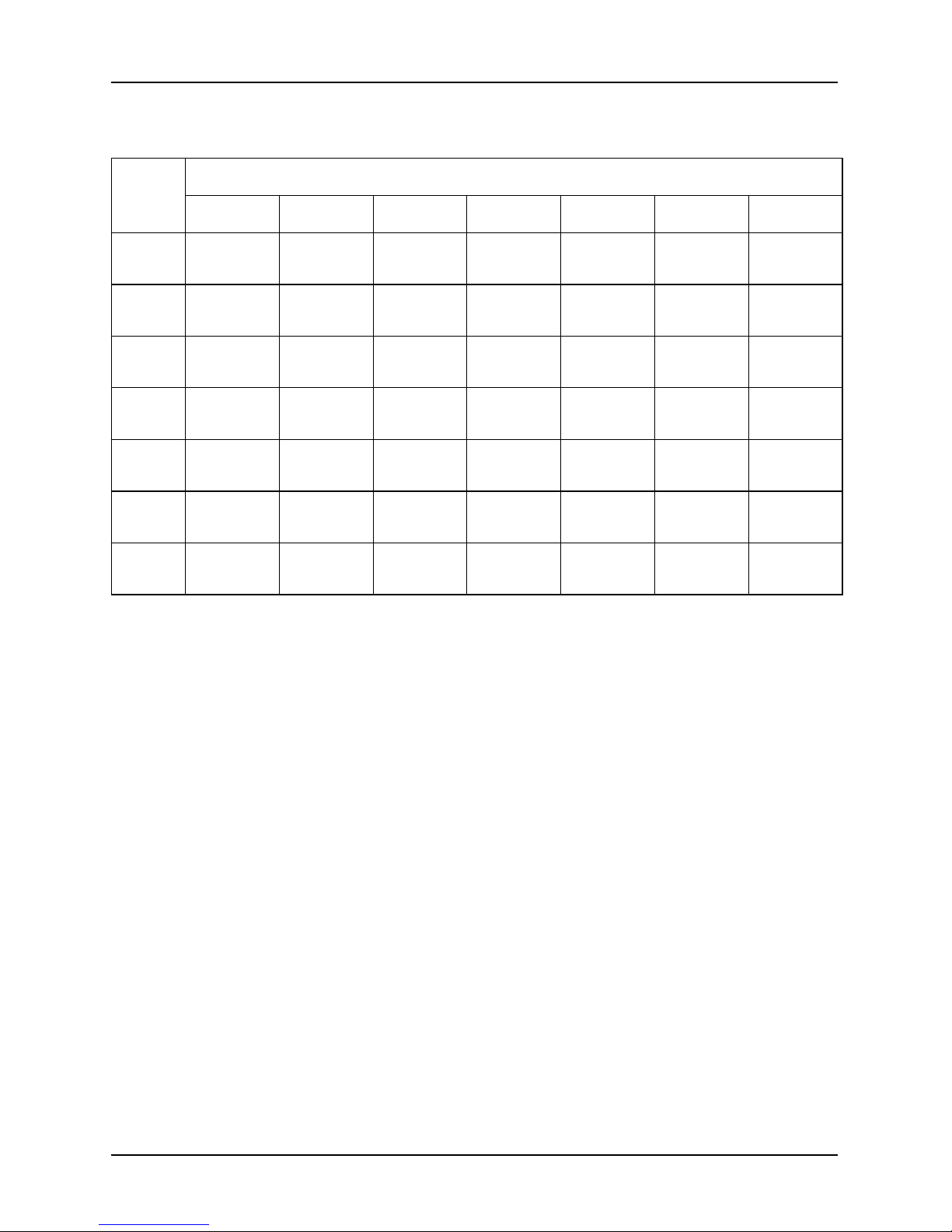

The multichannel pipettes’ specifications represent the performance of all channels

of the pipettes.

Precision = Coefficient of Variation.

EVOLVE Manual Pipettes Manufacturer

Chan-

nel

Part

No.

Volume Ran ge

(µl)

Volu me

Increments

(µl)

Test

Volume

(µl)

Accuracy

(±%)

Precision

(≤%)

83022 1–10 0.01 1 8.5 7

543

10 2 1.2

83024 5–50 0.05 5 4 2

25 2 1

50 1.2 0.5

83025 10–100 0.1 10 3.75 2

50 1.7 0.8

100 1.2 0.5

83026 20–200 0.1 20 4 1.3

100 1.5 0.5

200 1.2 0.4

12 3032 1–10 0.01 1 8.5 7

543

10 2 1.2

12 3034 5–50 0.05 5 4 2

25 2 1

50 1.2 0.5

12 3035 10– 100 0.1 10 3.75 2

50 1.7 0.8

100 1.2 0.5

12 3036 20– 200 0.1 20 4 1.3

100 1.5 0.5

200 1.2 0.4

Page 32

EVOLVE Manual Pipettes – Operating instructions V00 Technical Data

32 INTEGRA Biosciences AG

6.3 Z Correction Factors

Z values in microliters per milligram

Temp.

(°C)

Air Pressure (kPa)

80 85 90 95 100 101.3 105

18.0

18.5

1.0022

1.0023

1.0023

1.0024

1.0023

1.0024

1.0024

1.0025

1.0025

1.0025

1.0025

1.0026

1.0025

1.0026

19.0

19.5

1.0024

1.0025

1.0025

1.0026

1.0025

1.0026

1.0026

1.0027

1.0026

1.0027

1.0027

1.0028

1.0027

1.0028

20.0

20.5

1.0026

1.0027

1.0027

1.0028

1.0027

1.0028

1.0028

1.0029

1.0028

1.0029

1.0029

1.0030

1.0029

1.0030

21.0

21.5

1.0028

1.0030

1.0029

1.0030

1.0029

1.0031

1.0030

1.0031

1.0031

1.0032

1.0031

1.0032

1.0031

1.0032

22.0

22.5

1.0031

1.0032

1.0031

1.0032

1.0032

1.0033

1.0032

1.0033

1.0033

1.0034

1.0033

1.0034

1.0033

1.0034

23.0

23.5

1.0033

1.0034

1.0033

1.0035

1.0034

1.0035

1.0034

1.0036

1.0035

1.0036

1.0035

1.0036

1.0036

1.0037

24.0

24.5

1.0035

1.0037

1.0036

1.0037

1.0036

1.0038

1.0037

1.0038

1.0037

1.0039

1.0038

1.0039

1.0038

1.0039

Page 33

EVOLVE Manual Pipettes – Operating instructions V00 Accessories and Consumables

www.integra-biosciences.com 33

7 Accessories and Consumables

7.1 Accessories

7.2 Consumables

General Part No.

EVOLVE Pipette Multipurpose Tool

(for calibration, o-ring removal and plunger spring exchange)

3200

EVOLVE Pipette Shelf Hook, 1/pack 3210

EVOLVE Pipette Shelf Hook, 5/pack 3211

Linear Stand for manual/electronic pipettes 3215

Replacement Plunger Caps (5/pack) Part No.

Black for use with any pipette 3220

Purple for use with 2 µl, 10 µl, 20 µl manual pipettes 3221

Yellow for use with 50 µl, 100 µl manual pipettes 3222

Green for use with 200 µl manual pipettes 3223

Blue for use with 1000 µl manual pipettes 3224

Orange for use with 5000 µl manual pipettes 3225

EVOLVE Control Spring Assembly Part No.

for single channel pipettes 2, 10, 20, 100, and 200 µl only 3230

O-rings for tip fittings Part No.

200 μl,

(300 μl)

Replacement kit 24/pack 100-00027-50

1000 μl,

(1250 μl)

Replacement kit 24/pack 100-00028-50

5000 μl Replacement kit 10/pack 100-00029-00

Lubricant for pipettes and O-rings Part No.

Lube Parker Super-O-Lube, Silicone based, 50 g / 2 oz, for single

channel 1250 µl and 5000 µl pipettes

100-00135-50

Grease Grease Nye Fluorocarbon Gel 807, 5 g / 0.2 oz, for single

channel 12.5 µl, 125 µl and 300 µl pipettes

100-00136-50

Page 34

EVOLVE Manual Pipettes – Operating instructions V00 Accessories and Consumables

34 INTEGRA Biosciences AG

GripTips for all INTEGRA Manual and Electronic Pipettes Part No.

Purple

LONG:

2 μl,

10 μl,

(12.5 μl),

20 μl

Bulk pack, 1 bag of 1000 tips, non-sterile, LONG 4401

5 inserts of 384 tips, non-sterile, LONG, GREEN CHOICE 4402

5 racks of 384 tips, non-sterile, LONG 4403

5 racks of 384 tips, sterile, LONG 4404

5 racks of 384 tips, sterile, filter, LONG 4405

5 inserts of 384 tips, pre-sterilized, LONG, GREEN CHOICE 4406

Purple:

2μl,

10 μl,

(12.5 μl),

20 μl

Bulk pack, 1 bag of 1000 tips, non-sterile 4411

5 inserts of 384 tips, non-sterile, GREEN CHOICE 4412

5 racks of 384 tips, non-sterile 4413

5 racks of 384 tips, sterile 4414

5 racks of 384 tips, sterile, filter 4415

5 inserts of 384 tips, pre-sterilized, GREEN CHOICE 4416

Yellow:

50 μl,

100 μl,

(125 μl)

Bulk pack, 1 bag of 1000 tips, non-sterile 4421

5 inserts of 384 tips, non-sterile, GREEN CHOICE 4422

5 racks of 384 tips, non-sterile 4423

5 racks of 384 tips, sterile 4424

5 racks of 384 tips, sterile, filter 4425

5 inserts of 384 tips, pre-sterilized, GREEN CHOICE 4426

Green:

200 μl,

(300 μl)

Bulk pack, 1 bag of 1000 tips, non-sterile 4431

5 inserts of 96 tips, non-sterile, GREEN CHOICE 4432

5 racks of 96 tips, non-sterile 4433

5 racks of 96 tips, sterile 4434

5 racks of 96 tips, sterile, filter 4435

5 inserts of 96 tips, pre-sterilized, GREEN CHOICE 4436

Blue:

1000 μl,

(1250 μl)

Bulk pack, 1 bag of 500 tips, non-sterile 4441

5 inserts of 96 tips, non-sterile, GREEN CHOICE 4442

5 racks of 96 Tips, non-sterile 4443

5 racks of 96 Tips, sterile 4444

5 racks of 96 Tips, sterile, filter 4445

5 inserts of 96 tips, pre-sterilized, GREEN CHOICE 4446

Page 35

EVOLVE Manual Pipettes – Operating instructions V00 Accessories and Consumables

www.integra-biosciences.com 35

Orange:

5 ml

Bulk pack, 1 bag of 250 tips, non-sterile 4451

5 racks of 48 Tips, non-sterile 4453

5 racks of 48 Tips, sterile 4454

5 racks of 48 Tips, sterile, filter 4455

Individually wrapped, 100 tips per case, sterile 4456

GripTips for all INTEGRA Manual and Electronic Pipettes Part No.

Page 36

EVOLVE Manual Pipettes – Operating instructions V00

36 INTEGRA Biosciences AG

Imprint

© 2016 INTEGRA Biosciences AG

All rights to this documentation are reserved. In particular the rights of reproduction,

processing, translation and the form of presentation lie with INTEGRA Biosciences AG.

Neither the complete documentation nor parts thereof may be reproduced in any way, or

stored and processed using electronic media or distributed in any other way without the

written consent of INTEGRA Biosciences AG.

This operating instruction manual has part number 900-00010-00, the version is V00.

EVOLVE and GripTip are trademarks of INTEGRA Holding, Switzerland.

Manufacturer

Customer service

Please contact your local INTEGRA Biosciences representative.

To find out name and address of your local representative go to

www.integra-biosciences.com

.

Further information and operating instructions in other languages are available on

www.integra-biosciences.com

or on request info@integra-biosciences.com.

INTEGRA Biosciences AG

CH-7205 Zizers, Switzerland

T +41 81 286 95 30

F +41 81 286 95 33

INTEGRA Biosciences Corp.

Hudson, NH 03051, USA

T +1 603 578 5800

F +1 603 577 5529

info@integra-biosciences.com

www.integra-biosciences.com

Loading...

Loading...