Page 1

DOSE IT Operating instructions

171250_V08

Page 2

Declaration of conformity

INTEGRA Biosciences AG –

7205 Zizers, Switzerland

declares on its own responsibility that the device

complies with:

Zizers, November 4, 2016

Description Model

DOSE IT P910 171 000

EU Directives (DoW: Date of Withdrawal) Before DoW DoW After DoW

Low Voltage Equipment 2006/95/EC 20.04.2016 2014/35/EU

Electromagnetic Compatibility 2004/108/EC 20.04.2016 2014/30/EU

Restriction of Hazardous Substances 2011/65/EU

Waste Electrical and Electronic Equipment 2012/19/EU

EU Regulations

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH)

1907/2006

Ecodesign - Power supplies 278/2009

Standards for EU

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements.

EN 61010-1: 2010

Electrical equipment for measurement, control and laboratory use EMC requirements.

EN 61326-1: 2013

Standards for Canada and USA

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements.

CAN/CSA-C22.2

No. 61010-1

Safety requirements for electrical equipment for measurement,

control and laboratory use - General requirements.

UL 61010-1

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Part 15 of the

FCC Rules

Class A

Elmar Morscher

CEO

Thomas Neher

Quality Manager

Page 3

DOSE IT – Operating instructions V08

www.integra-biosciences.com 3

Table of contents

Chapter 1 Introduction

1.1 Intended use ..................................................................................5

1.2 Symbols used.................................................................................5

1.3 Safety notes ...................................................................................6

Chapter 2 Description of the device

2.1 Scope of delivery............................................................................7

2.2 Overview of the DOSE IT...............................................................7

Chapter 3 Installation

3.1 Power supply connection ...............................................................9

3.2 Retort rod and filling arm (optional)................................................9

Chapter 4 Operation

4.1 Selection and loading of the tubing ..............................................10

4.2 Parameter settings.......................................................................13

4.3 Adjusting the dispensing program................................................15

4.4 Calibrating the pump ....................................................................18

4.5 Performing the dispensing process..............................................19

4.6 Working in Pump mode................................................................19

4.7 Using the double pumphead configuration (optional)...................20

4.8 Process documentation (optional)................................................21

4.9 Using the foot and benchtop switch .............................................22

4.10 Remote control by a PC .............................................................22

Chapter 5 Maintenance

5.1 Cleaning and servicing.................................................................23

5.2 Decontamination ..........................................................................23

5.3 Leak Test .....................................................................................23

5.4 Disposal .......................................................................................24

Chapter 6 Technical data

6.1 Environmental conditions.............................................................25

6.2 Specifications ...............................................................................25

6.3 Current consumption depending on input voltage........................25

6.4 Chemical compatibility .................................................................26

Page 4

DOSE IT – Operating instructions V08

4 INTEGRA Biosciences AG

Chapter 7 Accessories and consumables

7.1 Consumables ...............................................................................27

7.2 Spare part ....................................................................................28

7.3 Accessories..................................................................................29

Imprint .................................................................................................30

Page 5

DOSE IT – Operating instructions V08 Introduction

www.integra-biosciences.com 5

1 Introduction

1.1 Intended use

This is a general-purpose laboratory instrument. Any use of this instrument in a medical

or IVD setting is the sole responsibility of the user.

The programmable peristaltic pump DOSE IT is designed for pumping and dispensing

liquids in a volume range of 0.1 ml to 9999 ml using silicone tubings.

If the DOSE IT is used in a manner not specified by INTEGRA, the protection provided by

the DOSE IT may be impaired.

1.2 Symbols used

This operating instruction manual makes specific reference to residual dangers using the

symbols shown below.

1.2.1 Hazard warnings in these operating instructions

W

ARNING

This safety symbol advises of hazards that could result in injury or death.

It also indicates hazards for machinery, materials, and the environment.

It is essential that you follow the relevant precautions.

C

AUTION

This symbol cautions about potential material damage or data loss in a

microprocessor controller. Follow the instructions.

N

OTE

This symbol identifies important notes regarding the correct operation of the

device and labor-saving features.

1.2.2 Hazard warnings on the device

R

OTATING COG WHEELS

Risk to squash your fingers.

Page 6

DOSE IT – Operating instructions V08 Introduction

6 INTEGRA Biosciences AG

1.3 Safety notes

The DOSE IT conforms to the state of technology and the recognized safety rules, and is

operationally safe. Operate the DOSE IT when in perfect conditions only and observing

this user manual.

Residual dangers can emanate from the device if it is used or operated incorrectly by

untrained personnel. All persons entrusted with operation of the DOSE IT must have read

and understood this user manual and, in particular, the safety notes, or must have been

instructed by their superior such that they are able to operate the device without danger.

Please observe the danger references on the device.

Do not carry out any conversion work or alterations on the device.

Irrespective of the safety instructions set out here, applicable provisions and regulations

must be observed in addition; for example, GLP, GMP, FDA, of the employer's liability

insurance associations, of the health authorities and of the trading standards authorities.

Please visit our website www.integra-biosciences.com

on a regular basis for up to date

information regarding REACH classified chemicals contained in our products.

Page 7

DOSE IT – Operating instructions V08 Description of the device

www.integra-biosciences.com 7

2 Description of the device

2.1 Scope of delivery

• DOSE IT P910 peristaltic pump

• Silicone tubing, autoclavable, 4 mm inner diameter (ID)

• 2x Aspiration/dispensing tubes 10 cm, stainless steel, 4 mm ID,

one end dented

• Aspiration tube 35 cm, stainless steel, 4 mm ID, one end dented

• Tube collar

• AC adapter

• Operating Instructions

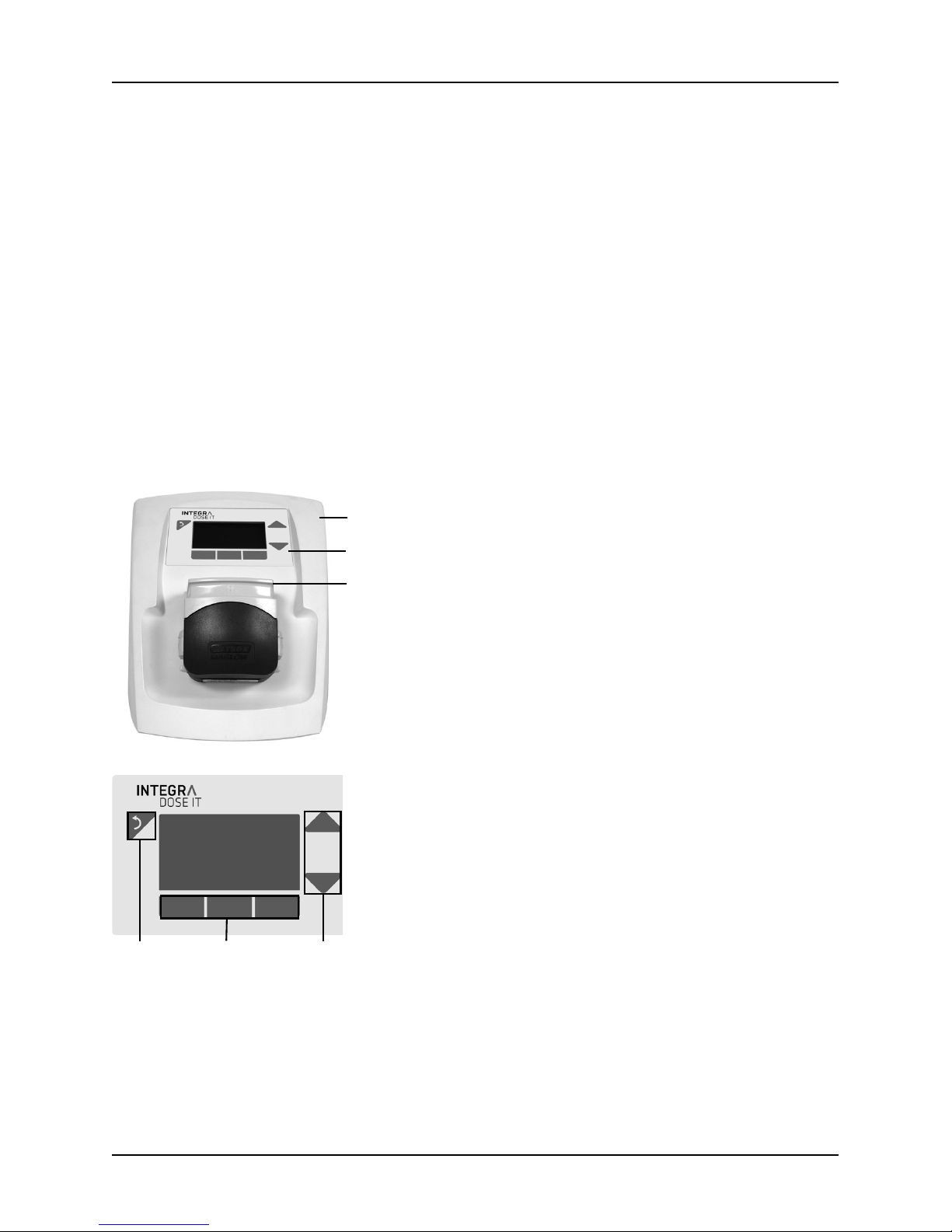

2.2 Overview of the DOSE IT

Front view

1Housing

2 Operating panel with display and keypad

3 Pumphead

Operating panel

4 Back-key

5 Function keys

6 Arrow keys

4

5

6

Page 8

DOSE IT – Operating instructions V08 Description of the device

8 INTEGRA Biosciences AG

Rear view

7 Screw threads for fixation of the retort rod

8 Handhold

9 Connections and mains switch (see below)

78 9

Connections and mains switch

10 RS-232 interface for connection with serial printer

11 RS-232 interface for service connection

12 AUX connection for controlling a second DOSE IT

13 Mains switch

14 Connection for foot switch, benchtop switch,

MEDIAJET or external relay contact (potential free,

normally open, 3.5 mm jack plug) for remote control

15 Mains connection socket

10

11

12

13

14

15

Page 9

DOSE IT – Operating instructions V08 Installation

www.integra-biosciences.com 9

3 Installation

The DOSE IT is a ready-to-use peristaltic pump that requires only a minimal installation

procedure. It shall be installed on a planar surface, in a dry and dust-free environment.

N

OTE

Before proceeding with the installation compare the contents of the package

with the list “2.1

Scope of delivery” on page 7. Should something be missing

or should you find a faulty component, please contact your local INTEGRA

Biosciences representative.

3.1 Power supply connection

Connect the AC adapter cable to the DOSE IT mains connection socket and plug it to the

electricity mains.

W

ARNING

The supply voltage must meet the requirements of the AC adapter:

100 - 240 VAC, 50 - 60 Hz.

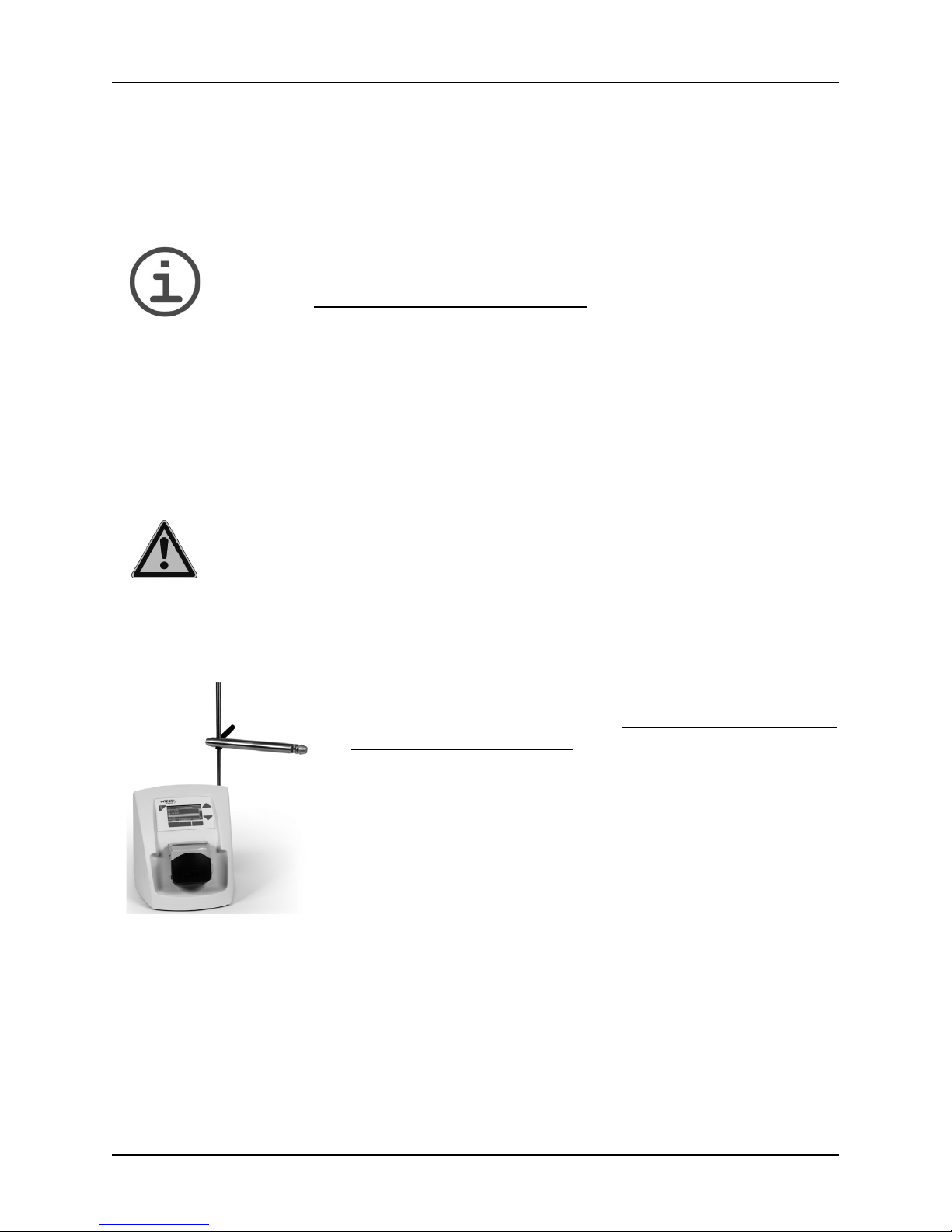

3.2 Retort rod and filling arm (optional)

Fix the retort rod with the two screws on the rear side, using

a Phillips screwdriver (PH2), see "

Screw threads for fixation

of the retort rod" on page 8.

Mount the filling arm onto the rod and tighten it with the side

lever in order to prevent it from moving during dispensing.

Page 10

DOSE IT – Operating instructions V08 Operation

10 INTEGRA Biosciences AG

4 Operation

The DOSE IT operates in different modes: DISPENSE mode for distribution of a defined

volume into containers and PUMP mode for continuous pumping of liquids. In addition,

customized applications can be defined (software version 2.0 and higher).

4.1 Selection and loading of the tubing

4.1.1 Tubing selection

The pumphead of the DOSE IT is compatible with differently sized tubing allowing the user

to dispense a wide range of dose volumes. The main criteria for the choice of tubing are

the speed and precision requirements of a specific application. The larger the inner

diameter (ID) of the tubing, the faster but less precise is the dispensing.

As a reference for selecting the appropriate inner diameter of the tubing, typical volume

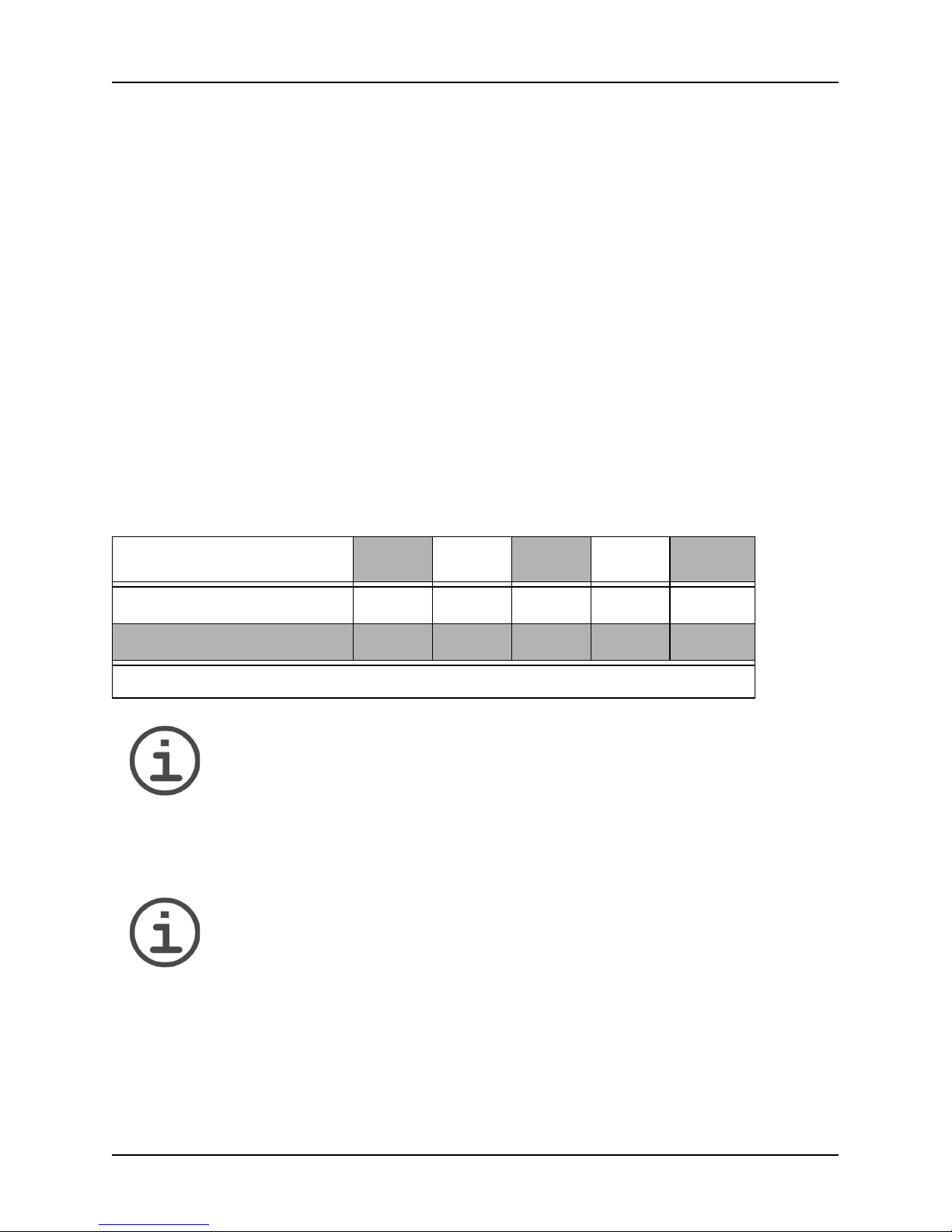

and speed values for different tubing sizes are listed in Table 1.

N

OTE

The indicated volume values relate to the specified reproducibility and not to

the actual limits of the system. The values have been determined

experimentally and may vary slightly depending on the experimental set up.

Compatibility with the pumphead and specified reproducibility can be guaranteed for

original INTEGRA Biosciences’ tubing only.

N

OTE

8 mm ID tubing is only recommended for the “PUMP” program mode (for

accuracy reasons, drips between the aliquots and draw backs in the tubing

may be a problem).

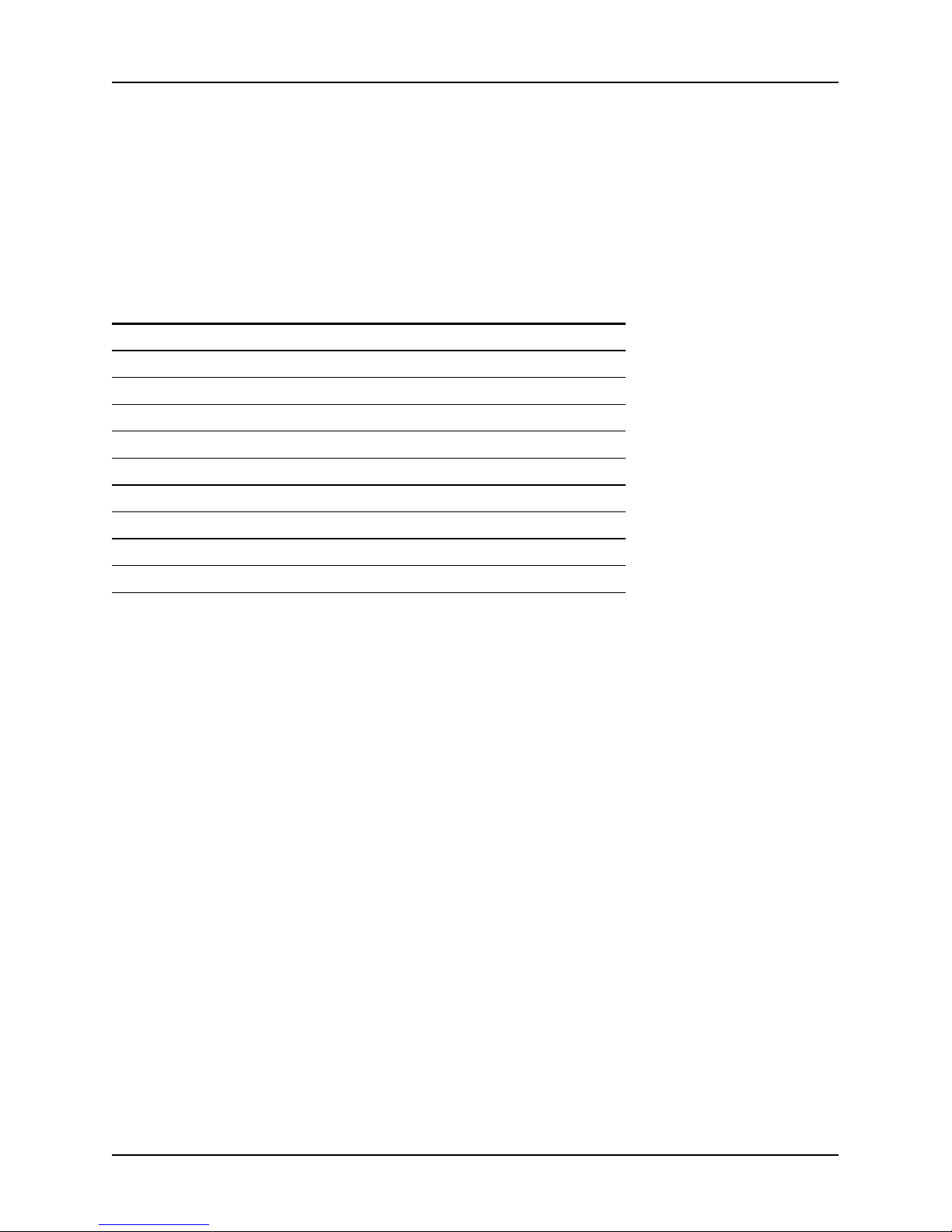

Table 1: Typical volume and speed values

Tubing inner diameter (ID) 1 mm 2 mm 3 mm 4 mm 6 mm

Volume (ml) at CV* < 1 % > 0.5 > 1 > 3 > 7 > 15

Speed range (ml / min) 0.6 – 52 2.1 – 203 4.8 – 475 8.4 – 837 16 – 1634

* Coefficient of variation.

Page 11

DOSE IT – Operating instructions V08 Operation

www.integra-biosciences.com 11

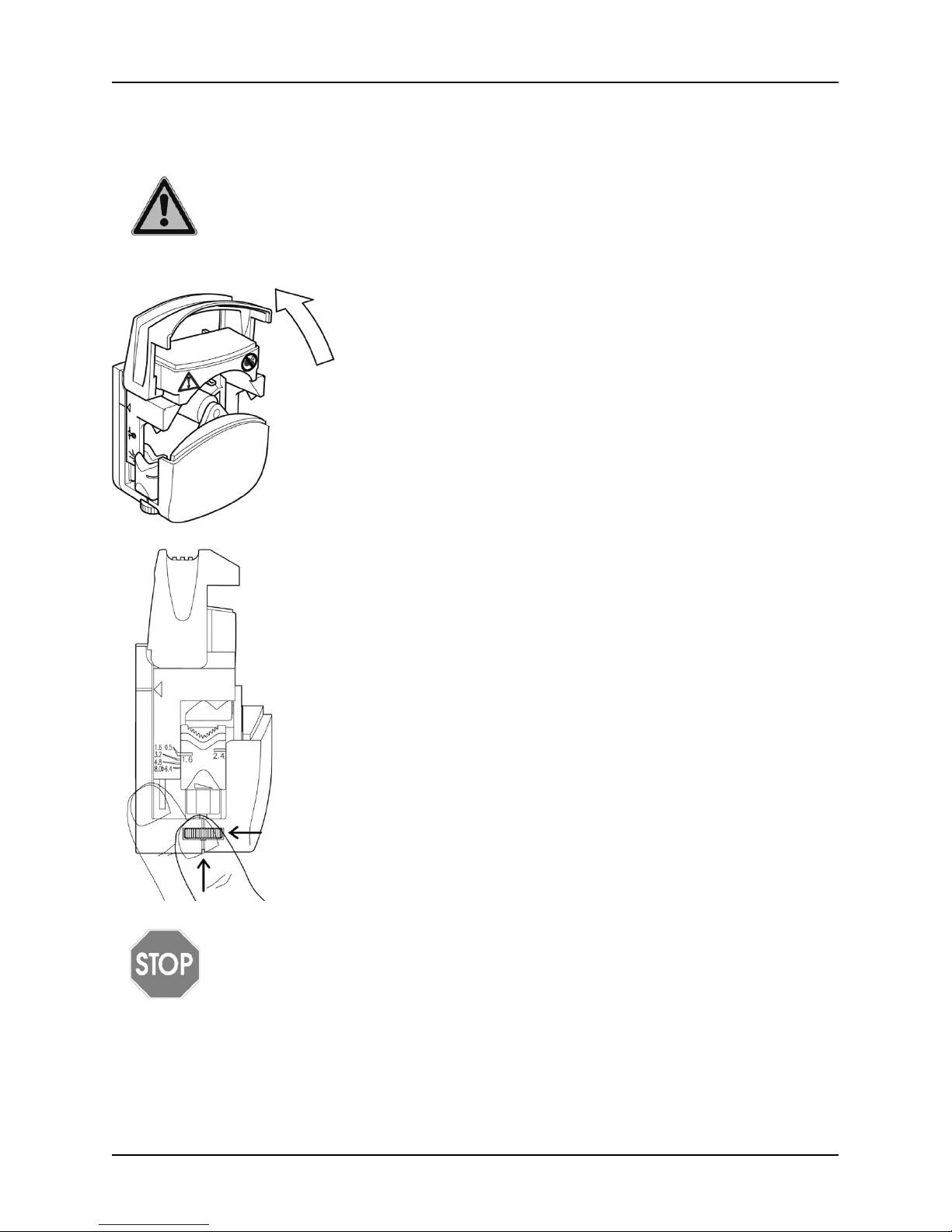

4.1.2 Loading of the tubing in the pumphead

W

ARNING

Always switch off the DOSE IT when loading the tubing and when

manipulating the open pumphead.

C

AUTION

Do not adjust the tubing clamps according to the scale on the pumphead

sides because the tubing will be unnecessarily squeezed and might be

damaged. Also the pumping precision will be diminished. Use instead the

adjustments described in Table 2.

1 Open the pumphead

2 Adjust the tubing clamps

The jagged, V-shaped tubing clamps on both sides of

the pumphead need to be adjusted and guarantee that

the tubing does not slip when the rotor turns. The tubing

clamps are set by adjusting the finger screws in such a

way as to match the diameter of the tubing.

Page 12

DOSE IT – Operating instructions V08 Operation

12 INTEGRA Biosciences AG

Table 2: Adjustments of the clamps for differently sized tubing

4.1.3 Connecting the dispensing and aspiration tubes

Clamp Tubing ID 1.6-marking of clamps

1 mm between 3.2 and 4.8 scale values

2 mm matches the 4.8 value on the scale

3 mm matches the 6.4 value on the scale

4 – 8 mm Completely open the clamps as shown beside.

Turn the finger screws right till the stop position.

3 Insert the tubing

Place the tubing over the rollers and center it so that it

comes out of the pump head over the clamps on both

sides. Close the pumphead and make sure that the tubing exits the pumphead unhindered and bending downwards. The tubing must not be bent upwards or towards

the front or back.

The aspiration/dispensing tubes delivered with the

DOSE IT facilitate the dosing process and are fitted on

the end of the tubing. The aspiration tube is dented on

one end in order to guarantee a free flowing of the liquid

entering the tubing. Make sure not to insert the dented

end of the aspiration tube into the silicone tubing.

The tube collar can either be screwed on the aspiration

tube to weigh it down or to the dispensing tube as a

spacer for use with a clamp.

Dented end

Tube collar

Aspiration/

dispensing

tube

Silicone tubing

Page 13

DOSE IT – Operating instructions V08 Operation

www.integra-biosciences.com 13

4.2 Parameter settings

4.2.1 System parameters

4.2.2 Program parameters

Some parameters described are not displayed in every program mode.

System-Parameter Description

Language Set the desired language.

Time/Date Set time and date.

Display contrast Change the contrast of the display.

Access code Provides user access restrictions to parameters.

Info General information on the unit:

• Version of the software

• Version of the electronics

• Serial number.

Parameter Description Range Default

Name Allows to name the program with up to 16

alphanumeric symbols. Press the arrow keys

simultaneously to delete the program name.

--

Type Defines the program mode: “P

UMP” for continu-

ous pumping of a liquid, “D

ISPENSE” for the

dosing of liquids, or “C

USTOMIZE” to create a

customized application.

Dispense

Pump

Customize

Dispense

Tubing-ID

(mm)

Defines the Inner Diameter (ID) of the tubing. 1.0 – 8.0 mm 4.0 m m

Flow rate

(ml/min)

Allows to set the pump speed. The flow rate

depends on the tubing inner diameter.

Time

(h min s)

Defines the duration of the pumping. Entering

0 h 0 min 0 s puts the unit in continuous operation, which is represented by the infinite symbol

(.

1'' – 9 h 59' 59''1h

Volume Defines the volume of a dose in the dispensing

mode.

0.01 – 9999 ml 10 ml

Repetitions Defines the number of doses in the dispensing

mode. Entering 0 results in an unlimited number of doses, which is represented by the

infinite symbol (.

1 – 999

20

Page 14

DOSE IT – Operating instructions V08 Operation

14 INTEGRA Biosciences AG

Customize mode

The ‘Customize’ mode allows to program a customized application consisting of up to 20

single steps:

Pause Defines the duration of the interval between

doses in the dispensing mode. If switching to

manual, the dispensing of a dose has to be

activated manually.

0.1– 99.9 s,

manual

1.0 s

Direction Defines the rotational direction of the rotor and

hence the flow direction. / C W m e a n s c l o c k wise, / CCW means counter-clockwise.

/ C W

/ C C W

/ C W

Dispense

direction

Defines the rotational direction for the step type

“D

ISPENSE”. For the step type “ASPIRATION” the

rotor rotates oppositely.

/ C W

/ C C W

/ C W

No. of

heads

Defines the number of pump heads. 1, 2 1

Step 1–20 Defines single steps of a customized applica-

tion.

1–20 -

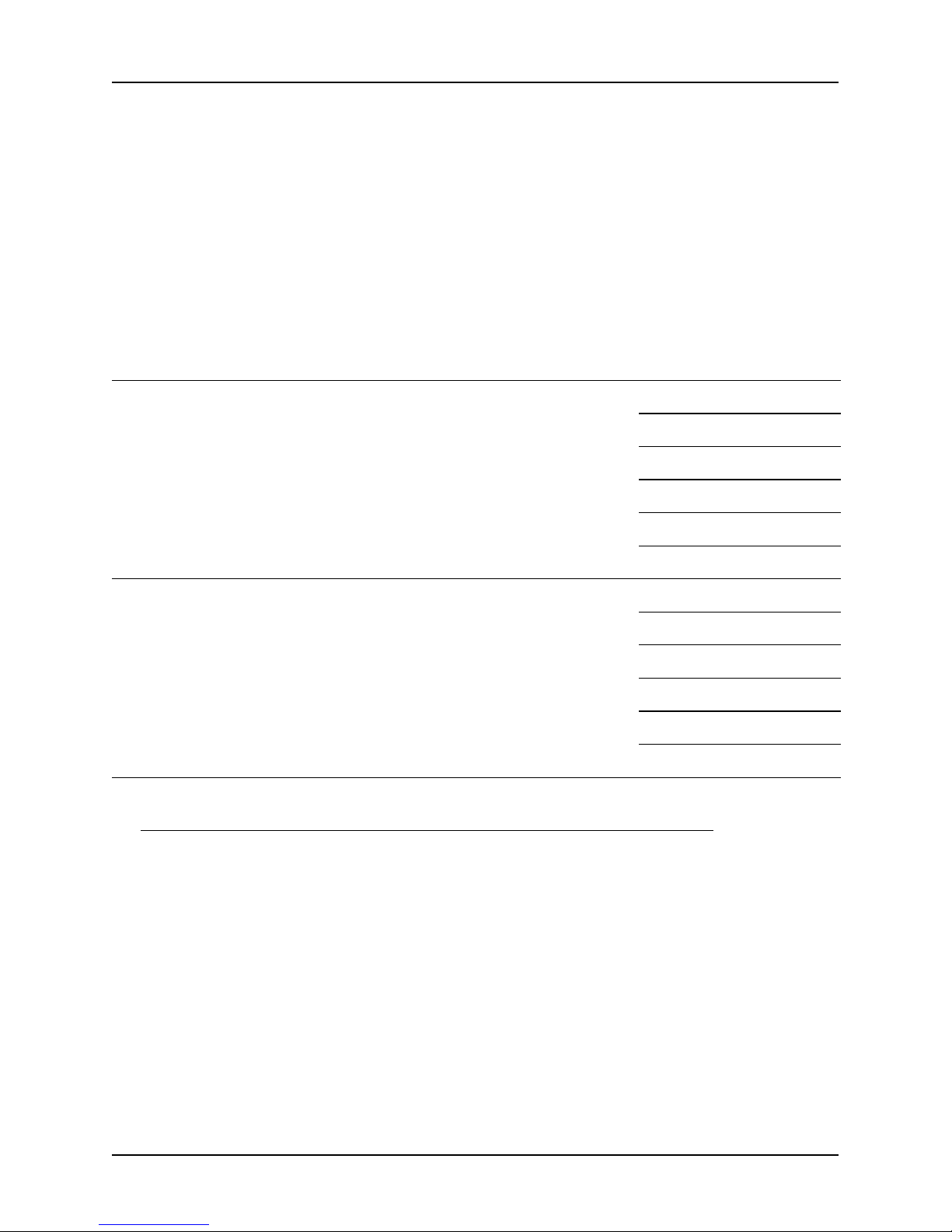

Step Description Parameter

Dispense Defines the dosing of liquids analog to the program mode

“Dispense”. The rotational direction is defined by the

parameter “Dispense direction’.

Volume

Repetitions

Flow rate

Pause

Dispense

Ramp

Defines dispensing with accelerating or decelerating

speed, needed e.g. for density gradients. Just define the

start and end flow to ramp the dispensing speed up or

down. If the start flow is identical to the speed of the previous step, and the pause of the previous step is set to manual, the liquid can be dispensed without pause.

Volume

Repetitions

Pause

Start flow

End flow

Aspirate Defines the aspiration of liquids analog to the program

mode “Dispense” with opposite rotational direction.

Volume

Repetitions

Flow rate

Pause

Aspirate

Ramp

Defines the aspiration of liquids with accelerating or decelerating speed. Just define the start and end flow to ramp

the aspirating speed up or down. If the speed of the following step is identical to the end flow, and the pause is set to

manual, the DOSE IT continues without pause.

Volume

Repetitions

Pause

Start flow

End flow

Parameter Description Range Default

Page 15

DOSE IT – Operating instructions V08 Operation

www.integra-biosciences.com 15

4.3 Adjusting the dispensing program

4.3.1 Choosing the language

N

OTE

Because it is easiest to operate the DOSE IT by following the instructions on

the screen, please select the language you are most familiar with.

Pump Defines continuous pumping of a liquid. Direction

Flow rate

Time

Wait Defines the duration of the interval between two steps.

Manual mode means that the next step has to be activated

manually.

1'' – 9 h 59' 59''

manual

Cycles Defines the number of cycles of a sequence. A cycle

always initiates a return back to a defined step, e.g. step 1.

You can define several cycles within your customized

sequence.

Number of

cycles

1 –999,

Goto step ¥

- No operation, used as default setup of step. -

Step Description Parameter

1 Switch on the DOSE IT by pressing the mains switch at

the back.

The A

PPLICATIONS window appears. The first four

programs in the application list are already pre-defined

with default values.

2 Press SYSTEM to access the SYSTEM window and set the

language of your choice by accessing the LANGUAGE

menu.

In the S

YSTEM window you can also set the display

contrast, the date and the time, and an access code, if

required.

Page 16

DOSE IT – Operating instructions V08 Operation

16 INTEGRA Biosciences AG

4.3.2 Access code

The DOSE IT system and parameter settings can be protected by a code, if activated

(Access code required ON). Before any parameter changes can be performed, an access

code must be entered. A standard user can only run defined programs.

Select the A

CCESS CODE window and enter the default access code “3473” by typing the

appropriate key until the correct number appears on the screen. Press the back-key.

4.3.3 Setting the dispensing parameters

N

OTE

The DOSE IT has a memory capacity for storing 20 programs, all of which

can be configured according to your specific applications.

1 Select the line “Access code required” and press

C

HANGE. Use the arrow keys to select “Access code

required: ON” and press S

AVE.

2 For changing the Access code select this line and press

S

AVE.

3 Change the default access code to your personal code,

if required. Enter the numbers by the arrow keys and

select the digit with the function keys (, ). Keep this

code in a save place. Press S

AVE.

1 Press the back-key to exit the SYSTEM window and to

return to the A

PPLICATION window. Press PARAMETER to

configure the program that is backlit.

2 Use the arrow keys to select the listed parameters and

press C

HANGE to set different values.

All parameters and their values are described in “4.2.2

Program parameters” on page 13.

Page 17

DOSE IT – Operating instructions V08 Operation

www.integra-biosciences.com 17

4.3.4 Defining a customized program

The following example of a customized program can be used to fill 10 density gradient

tubes. The careful and continuous dispensing without pauses prevents stirring up of

layers.

Parameter Value Description of settings

Name Density

gradient

Allows to name your customized program.

Tubing-ID 3.0 mm Define the inner diameter of the tubing inserted.

Dispense

Direction

/ C W Define the rotational direction of the rotor, e. g. clock-

wise.

No. of heads 1 Define the number of pump heads installed.

Step 1: Dispense Volume: 2.5 ml

Repetitions: 1

Pause: manual (here without pause)

Flow rate: 3.8 ml/min (i.e. speed: 4.0 rpm).

Step 2: Dispense

Ramp

Volume: 12.5 ml

Repetitions: 1

Pause: manual (here without pause)

Start flow: 3.8 ml/min (i.e. speed: 4.0 rpm)

End flow: 22.8 ml/min (i.e. speed: 24.0 rpm).

Step 3: Wait Manual, i.e. the next cycle starting with step 1 has to be

activated manually by pressing N

EXT STEP.

Step 4: Cycles Number of cycles: 10

Goto step: 1.

The figure depicts the

customized program

described above.

Page 18

DOSE IT – Operating instructions V08 Operation

18 INTEGRA Biosciences AG

4.4 Calibrating the pump

NOTE

The calibration procedure tunes the pump to deliver a precise output. The

output of the pump is determined by the tubing's inner diameter; therefore a

calibration is necessary for tubing with different inner diameter. Also calibrate

the pump after changing the fluid to be pumped. It is recommended to

calibrate the pump at regular intervals to maintain its precision.

I

MPORTANT NOTE

A calibration value is stored for each of the 20 programs that can be saved.

Therefore a calibration for each of the 20 programs is necessary, even when

the tubing inner diameter remains the same. Within each program, only the

last calibration value is saved, hence calibrate whenever there is a change in

the viscosity of the pumped liquid, of the flow rate or of the tubing inner

diameter.

Each step within a customized program has to be calibrated separately.

1 Select a program and press START to access the

program window. Put the tubing end with the aspiration

tube in the liquid that has to be dispensed and press

P

RIME to fill the tubing with liquid without bubbles.

2 Press the CALIBRATE button to enter the calibration

dialogue window and DOSING to obtain a calibration

sample. To reduce the measurement error it is possible

to obtain up to ten such dosing samples (by repeatedly

pressing the D

OSING button).

3 After one or more calibration samples have been

dispensed and measured, press the C

ONTINUE button

and enter the measured volume (CHANGE button). To

end the calibration procedure press CONTINUE.

Page 19

DOSE IT – Operating instructions V08 Operation

www.integra-biosciences.com 19

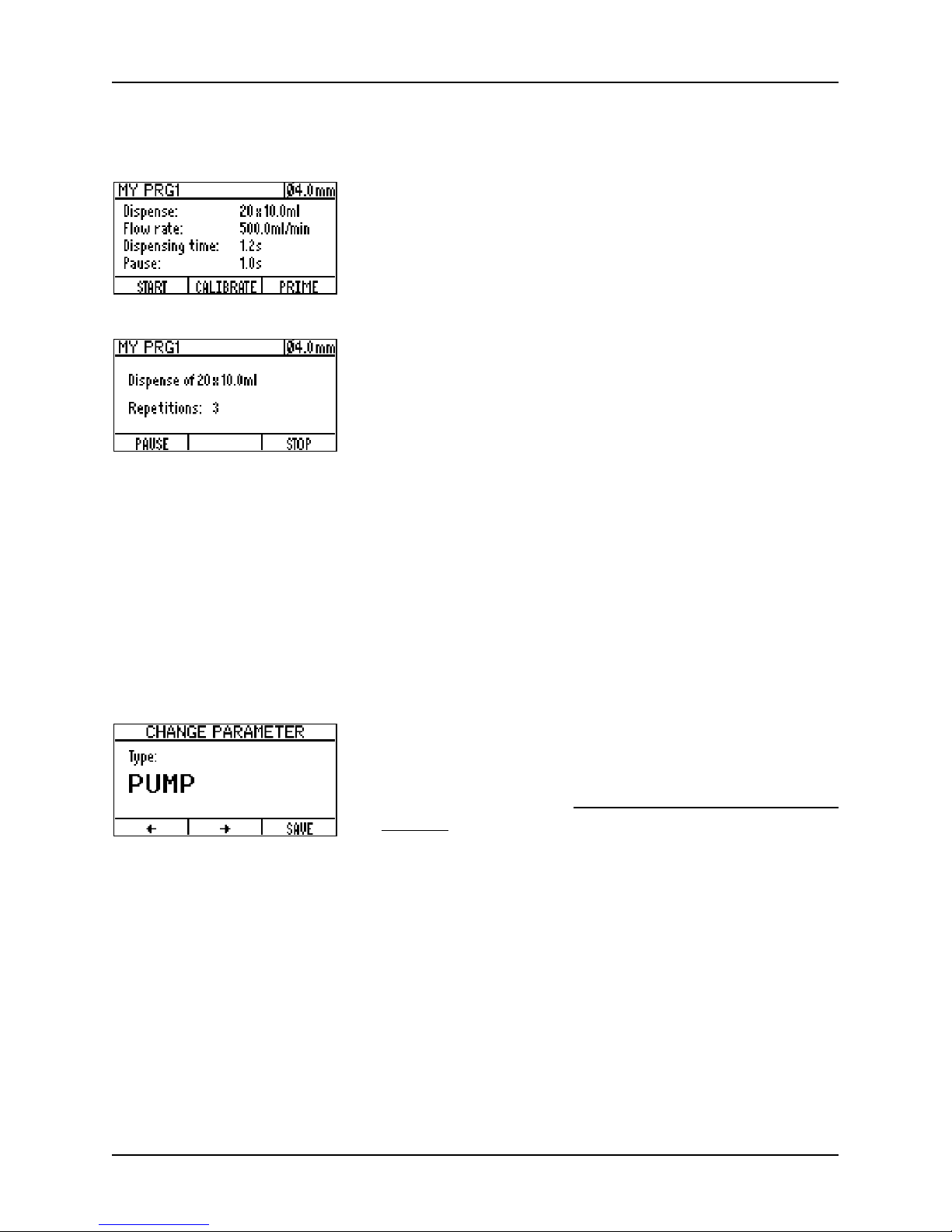

4.5 Performing the dispensing process

4.6 Working in P

UMP mode

1 In the APPLICATION window select a program and press

S

TART to access the program window. Press PRIME to fill

the tubing with liquid until no more bubbles are in the

tube and calibrate if necessary.

To begin dispensing, press S

TART.

2 While dispensing, there are two possibilities to interrupt

the process:

• P

AUSE – the process is interrupted after completing

the dispensing of the current dose.

• S

TOP – the process is interrupted immediately.

After interruption, the process can either be continued, aborted or parameters can be

changed (the latter is not possible in the customize mode). If parameters have been

changed, the user is asked to either save or discard the changes before exiting the

program.

The completion of the program is announced by a beep and a message appears on the

screen.

To continuously pump a liquid instead of dispensing it,

change the T

YPE-parameter from DISPENSE to PUMP. To

set the other parameters follow the instructions described above and in “4.2.2 Program parameters” on

page 13.

The calibration procedure in P

UMP mode works as described above. Note that the

calibration volume is indicated in the calibration window and that it varies depending on

the tubing size and on the selected flow rate.

To use a pumping program, follow the instructions on the screen. Note that you can

change the flow rate without interrupting the pumping by using the arrow keys (not

possible within customized mode).

Page 20

DOSE IT – Operating instructions V08 Operation

20 INTEGRA Biosciences AG

4.7 Using the double pumphead configuration (optional)

The DOSE IT can be used with a double pumphead and the corresponding 8 mm ID tubing

set (171 088) when it is necessary to quickly dispense large volumes. The double

pumphead configuration also reduces flow pulsation.

W

ARNING

Always switch off the DOSE IT when assembling the double pumphead

configuration.

Be aware of the sharp edges of the pumpheads when assembling them and when opening

and closing the first pumphead for tubing insertion.

When placing the tubing set (171 088) into the double pumphead assembly, gently stretch

the tubing so that inside the pumphead the tubing is taut (avoid loading the tubing in a

loose, slackened way).

W

ARNING

Visually inspect the tubing set Y-pieces for the absence of cracks in the glass.

Cracked Y-pieces may burst during operation and shall not be used.

In the affected programs, change the parameter “No. of heads” before using the double

pumphead configuration.

1 Open the pumphead to gain access to the two fixation

screws and unscrew the pumphead from the housing

using an Allen key # 3.

2 Fix the extension pumphead (171 090) to the housing

using the screws obtained after removing the original

pumphead.

Fixation screws

3 Assemble the two pumpheads by locking the original

pumphead onto the extension pumphead. When turning

the original pumphead in place, ensure that the lock

mechanism engages with an audible click.

Important: The rollers of the two pumpheads must be

out of phase in order to avoid excessive strain on the

motor (torque limits) and to obtain a reduction in flow

pulsation.

Page 21

DOSE IT – Operating instructions V08 Operation

www.integra-biosciences.com 21

4.8 Process documentation (optional)

To document the dispensing and pumping performed with a DOSE IT, relevant data can

be recorded either on paper or in an electronic text file. The following data – exemplified

by a dispensing program – are recorded:

• At the start of the process

========================================

DOSE-IT (SN:00000000)

***Start dispense

Date/time: 02.11.2006/18:01

***Program settings

Name: MY PRG1

Tubing-ID: 4.0mm

Volume: 10.0ml

Repetitions: 20

Pause: 1.0s

Flow rate: 500.0ml/min

Direction: CW

No. of heads: 1

========================================

• After calibration

========================================

DOSE-IT (SN:00000000)

***Calibration done

Date/time: 02.11.2006/18:05

Tubing-ID: 4.0mm

========================================

• At the end of the process

========================================

DOSE-IT (SN:00000000)

***End dispense

Date/time: 02.11.2006/18:02

Repetitions: 20

***Program settings

Name: MY PRG1

Tubing-ID: 4.0mm

Volume: 12.0ml

Pause: 1.0s

Flow rate: 500.0ml/min

Direction: CW

No. of heads: 1

========================================

Note: This parameter

has been changed

during the process.

Page 22

DOSE IT – Operating instructions V08 Operation

22 INTEGRA Biosciences AG

Printing on paper occurs automatically when a label printer is connected to the RS - 232

(2) port of the DOSE IT. INTEGRA Biosciences recommends the EPSON TM-U220 matrix

printer and your local INTEGRA dealer can assist you to connect this printer.

To generate an electronic text file, connect a PC to the RS - 232 (2) port of the DOSE IT

via a crossed female-female RS - 232 cable and record the process data using the

HyperTerminal software installed on your PC.

RS - 232 (2) interface settings:

Transmission speed:......... 9600 bps

Databits:............................ 8 bits

Parity:................................ No

Stopbits: ............................ 1

Handshake:....................... Xon / Xoff

4.9 Using the foot and benchtop switch

The optional foot switch or benchtop switch can be used for hands-free operation. There

are no specific setting needed, just connect one of the switches.

Depending on program mode and step, the switch can be used instead of the S

TART,

PAUSE or STOP key. However, the keys will still work, even if a switch is connected.

In D

ISPENSE mode, set the PAUSE parameter to manual. The first pedal/button pulse starts

the set number of doses, the next pulse will pause the process, and so on until the process

is completed.

In P

UMP mode, the pump starts with the first pedal/button pulse (=START). With the next

pulse it stops (=STOP) and so on.

4.10 Remote control by a PC

Remote operation can be performed by simulating the foot switch, e. g. with a PC and an

input/output interface box as described above for the foot switch.

Page 23

DOSE IT – Operating instructions V08 Maintenance

www.integra-biosciences.com 23

5 Maintenance

5.1 Cleaning and servicing

WARNING

Always switch off the DOSE IT and disconnect it from the mains when

carrying out maintenance work.

If the DOSE IT gets soiled, it can be cleaned with a cloth moistened with soapy water or

with a 70 % solution of Ethanol.

Regular servicing of the DOSE IT by a qualified partner of INTEGRA Biosciences is

recommended.

5.2 Decontamination

The aspiration/dispensing tubes, tube collars and silicone tubing contacting the liquid can

be autoclaved at 121°C, 1 bar overpressure for at least 20 minutes. Silicone may become

brittle after extensive autoclaving. Replace the tubings if they are damaged.

If the surface of the DOSE IT has been in contact with biohazardous material, it must be

decontaminated in accordance to good laboratory practice. Do not spray directly on the

instrument but use a lint-free cloth, lightly soaked with a disinfectant and wipe dry directly

after decontamination. Never use acetone or other solvents! Follow the instructions

provided by the disinfectant manufacturer.

5.3 Leak Test

It is recommended to perform a leak test about every 3 months or when dosing errors

occur. A leak test will reveal worn or defect tubing or pumphead.

Procedure:

1) Load a silicone tubing in the pumphead.

2) Position the dispensing end of the tubing below the pumphead height into a container.

3) Put the aspiration tube in liquid and press P

RIME to fill the tubing completely without

any bubbles.

4) Lift the aspirating end of the tubing as high as possible above the pumphead. The

system is tight, if the liquid level do not decrease and no liquid flow out of the lower

dispensing end.

The moving parts of the pumphead should be

checked from time to time for freedom of movement.

Occasionally lightly grease the lever (1) and the

rollers (see image) with Teflon lubrication oil.

The rotor shaft runs on sealed bearings which do not

require lubrication.

1

Page 24

DOSE IT – Operating instructions V08 Maintenance

24 INTEGRA Biosciences AG

If the system is leaking, you have to check whether the tubing or the pumphead is worn:

Repeat the leak test with a new tubing (only use original INTEGRA tubings, see “7.1

Consumables” on page 27).

• If system is tight, the tubing was worn and the problem is solved.

• If the system is still leaking, the pumphead is worn (e.g. lever loose, mechanical play)

and need to be replaced, see “7.2 Spare part” on page 28

.

N

OTE

Work around until a new pumphead is available: Put a rubber band (5 to

8 mm wide) around the pumphead to help holding it fully closed during operation. Repeat the leak test to confirm that the work around works.

5.4 Disposal

The DOSE IT is labeled with the “crossed-out bin” symbol to indicate that this

equipment must not be disposed of with unsorted municipal waste. Instead,

it is your responsibility to correctly dispose of your waste equipment by handing it over to an authorized facility for separate collection and recycling. It is

also your responsibility to decontaminate the equipment in case of biological,

chemical, and/or radiological contamination so as to protect from

health hazards the persons involved in the disposal and recycling of equipment.

For more information about where you can drop off your waste equipment for recycling,

please contact your local dealer from whom you originally purchased the product or your

local council.

By doing so, you will help conserve natural resources and you will ensure that your waste

equipment is recycled in a manner that protects human health and the environment.

Thank you!

Page 25

DOSE IT – Operating instructions V08 Technical data

www.integra-biosciences.com 25

6 Technical data

6.1 Environmental conditions

6.2 Specifications

6.3 Current consumption depending on input voltage

Operation

Temperature range 5–35 °C

Humidity range Max. rel. humidity 80 % for temperatures up to 31 °C,

decreasing linearly to 50 % rel. humidity at 40 °C.

Altitude range < 2000 m

Dose volume 0.01 ml – 9999 ml

Flow rate 0.6 ml / min – 5 l / min

Tubing inner diameter 1 – 8 mm

Tubing wall thickness 1.5 mm

Materials Housing: Polyurethane

Base plate, rear panel: stainless steel

Membrane keypad: Polyester

Tubing: Silicone

Pump head body rear: Polypropylene

Pump head body front: IXEF

Pump head tube clamps: Nylon

Pump head roller: Nylatron

Dimensions (H x W x D) 203 x 210 x 191 mm

Weight 3.5 kg

Interfaces 2 x RS-232

Electricity supply Input: 100 – 240 VAC, 50 / 60 Hz

Output: 46.6 – 49.4 VDC, 70 W

Current consumption

Input voltage Standby

Operation with

1 or 2 pump heads

Pause mode

100 VAC 45 mA 260 mA 280 mA

230 VAC 15 mA 120 mA 130 mA

Page 26

DOSE IT – Operating instructions V08 Technical data

26 INTEGRA Biosciences AG

6.4 Chemical compatibility

A particular advantage of peristaltic pumps is that the fluid remains enclosed inside the

tubing. Even chemical aggressive liquids can be transferred without the risk of damaging

parts of the pump as long they are compatible with the silicone tubing. The table below

rates the compatibility of silicone to a few of the chemicals commonly used in laboratories.

INTEGRA Biosciences AG assumes no liability for the information contained in the table.

Compatibility ratings for silicone tubing:

A = good, little to minor effects (0-5 % volume swell).

B = fair, moderate effects, not recommended for continuous use (5-10 % volume swell).

C = critical, not recommended (10 % or greater volume swell).

To determine the compatibility silicone to a chemical not listed in the table, please consult

one of the several tables available on the internet, e. g. Watson Marlow with material

Pumpsil (silicone).

It is the responsibility of the users to ensure the chemical compatibility. Before using a

critical chemical, immerse a short piece of the tubing in a closed container of the chemical

for 48 hours. Check the tubing for sings of swelling, softening, discoloration, embrittlement

or any other attack.

Chemical Rating

Acetic acid CH3COOH B

Acetone C3H6O C

Acetonitrile C2H3N C

Dimethyl sulfoxide DMSO A

Ethanol C2H5OH B

Hydrochloric acid 33 % HCl C

JAVEL NaClO A

Phenol C6H5OH C

Sodium carbonate Na2CO3 A

Sodium hydroxide 50 % NaOH B

Page 27

DOSE IT – Operating instructions V08 Accessories and consumables

www.integra-biosciences.com 27

7 Accessories and consumables

There are a number of accessories and options that adapt the DOSE IT to particular

application requirements and working environments.

7.1 Consumables

7.1.1 Silicone tubing

ID

1

(mm)

1. ID = inner diameter

Part No.

length 2.5 m, autoclavable,

wall thickness 1.5 mm.

1 171 021

2 171 022

3 171 023

4 171 024

6 171 026

8 171 028

2

2. only for pumping applications

length 25 m, (bulk roll), autoclavable,

wall thickness 1.5 mm.

1 171 031

2 171 032

3 171 033

4 171 034

6 171 036

8 171 038

2

Page 28

DOSE IT – Operating instructions V08 Accessories and consumables

28 INTEGRA Biosciences AG

7.1.2 Aspiration/dispensing tubes

7.1.3 Tube collars

7.2 Spare part

ID (mm) Part No.

Aspiration/dispensing tube, length 10 cm,

stainless steel, one end dented.

1 171 051

2 171 052

3 171 053

4 171 054

6 171 056

8 171 058

Aspiration/dispensing tube, length 35 cm,

stainless steel, one end dented.

4 171 064

6 171 066

8 171 068

ID (mm) Part No.

Used as weight for the aspiration tube or

as clamp spacer for the dispensing tube.

See also “4.1.3

Connecting the dispensing

and aspiration tubes” on page 12.

1 – 3 171 071

4 – 6 171 074

Part No.

Pumphead 313D 103 520

Page 29

DOSE IT – Operating instructions V08 Accessories and consumables

www.integra-biosciences.com 29

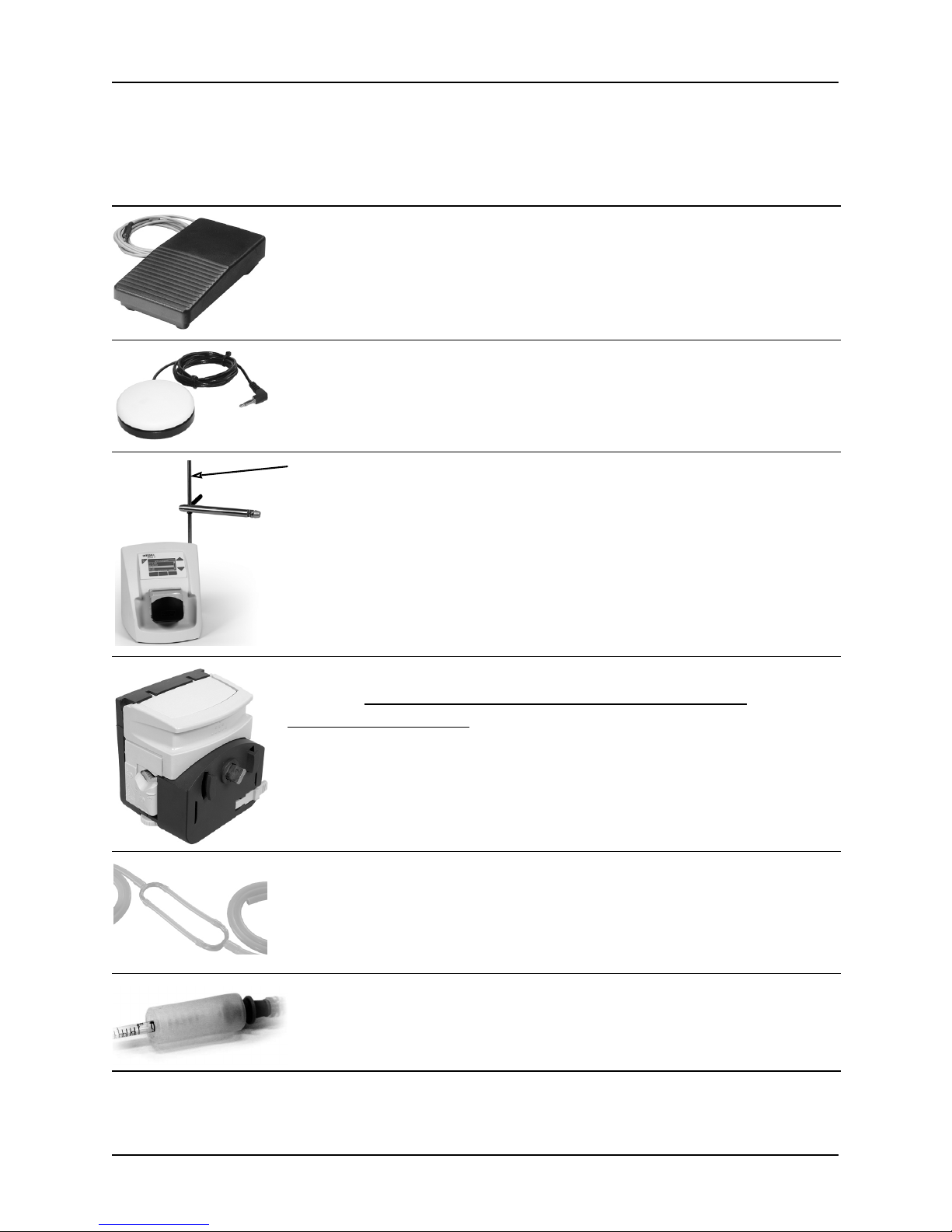

7.3 Accessories

Part No.

Foot switch. 143 200

Benchtop switch. 171 081

Retort rod with filling arm. 171 091

Extension pumphead for double pumphead assembly.

See also “4.7 Using the double pumphead configuration

(optional)” on page 20.

171 090

Silicone tubing set for double pumphead (ID 8 mm), total

length 3 m, autoclavable, incl.

• 2 short silicone tubings (ID 8 mm)

• 2 Y-pieces made of glass

• 2 long silicone tubings (ID 10 mm)

171 088

Pipette-tubing connector, for connecting pipettes to

2-6 mm inner diameter silicone tubing, autoclavable,

5-pack

171 077

Page 30

DOSE IT – Operating instructions V08

30 INTEGRA Biosciences AG

Imprint

© 2018 INTEGRA Biosciences AG

All rights to this documentation are reserved. In particular the rights of reproduction,

processing, translation and the form of presentation lie with INTEGRA Biosciences AG.

Neither the complete documentation nor parts thereof may be reproduced in any way, or

stored and processed using electronic media or distributed in any other way without the

written consent of INTEGRA Biosciences AG.

This operating instruction manual has the part number 171 250, version number V08. It

applies to firmware version 2.02 or higher until a newer revision is released.

Manufacturer

Customer service

Please contact your local INTEGRA Biosciences representative.

To find out name and address of your local representative go to

www.integra-biosciences.com

.

Further information and operating instructions in other languages are available on

www.integra-biosciences.com

or on request (info@integra-biosciences.com).

INTEGRA Biosciences AG

CH-7205 Zizers, Switzerland

T +41 81 286 95 30

F +41 81 286 95 33

INTEGRA Biosciences Corp.

Hudson, NH 03051, USA

T +1 603 578 5800

F +1 603 577 5529

info@integra-biosciences.com

www.integra-biosciences.com

Loading...

Loading...