Page 1

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

1/196

Lift controller

MLC 8000

Operating manual

INTEC GmbH

Ingenieurservice

Ringstraße 3

04827 Gerichshain Tel.: 034292-862-30

Germany Fax: 034292-862-33

www.intecgmbh.com E-Mail: info@intecgmbh.com

Page 2

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

2/196

© 2016 INTEC GmbH Ingenieurservice. All rights reserved.

This manual and the product described within are protected by Copyright rights under the

reservation of all rights for the INTEC GmbH Ingenieurservice. According to copyright laws,

this manual may not be copied in whole or service engineer without written permission from

INTE C GmbH Ingenieurservice in part, except in the normal course of use of the product or

for creating backup copies. However, this exemption does not extend to copies that are

created by third parties and sold to or in other manner transferred to. However, the entire

material purchased (with all backup copies) can be sold to third parties, be handed over to

or provided on loan. According to the provisions of the Act, the production of a translation

also falls under the definition of copying.

The INTEC GmbH Ingenieurservice accepts no responsibility or guarantee for the

content of this manual. It rejects all implied warranties of merchantability or eligibility

for a particular purpose.

The INTEC GmbH Ingenieurservice is not legally responsible for errors contained within or

for any indirect or consequential damages in connection with the transfer, performance, or

use of this manual. The INTEC GmbH Ingenieurservice reserves the right to revise this

manual from time to time without pre notice and to make changes to the content.

The operation is not allowed in the US and countries of similar laws.

Page 3

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

3/196

Version number:

The present description is based on the software version 1.39 of the main board HSE.

Due to new requirements in the lift cont r ol field, a continuous development of the lift

controller MLC 8000 is taking place. While compatibility with older software versions

will always be preserved, so that the present description stays also applicable to

newer or older versions of the control. There might be some features in newer

versions of this specification which are not included, as well as some features of this

description which might not carried out yet in older control versions.

Page 4

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

4/196

Frequently used abbreviations

General terms:

LC

Landing call

AWG

Absolute encoder

Position measurement system that can measure

the actual position of the lift immediately after

switching on; there is no reference travel required

In the lift controller MLC 8000, a measuring

system with magnetic tape and reading unit with

integrated CAN-bus interface is typically used.

CAN

Controller Area Network

In the lift controller MLC 8000 used bus system,

with which the individual components are

interconnected

COP

Car Operation Panel

Car operating panel

VVVF

Variable Voltage Variable

Frequency

AC motor speed controller, used in modern lifts

to control the main motor

ID

Identifier

Number that clearly identifies a module on the

CAN bus

CC

Car call

Car call

LCD

Liquid Crystal Display

Type of graphical display

LED

Light Emitting Diode

LS

Light screen

Light barrier

LOP

Landing Operation Panel

Outer panel

SL

Safety line (safety circuit)

Control modules and other modules:

ASE

Antriebssteuereinheit

drive control unit; PCB for controlling the drive

(e.g. VVVF) via the CAN bus

CBC

CAN Bus Coupler

see CBK; Designation is used only when using

the main board MCU

CBK

CAN Bus Koppler

Assembly used to divide the CAN bus for large

lifts or lift groups in several physically separate

Page 5

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

5/196

segments

CDU

Car Distribution Unit

see FVE; Designation is used only when using the

main board MCU

CPA

CAN Positioning Adapter

see PSE; Designation is used only when using

the main board MCU

DCU

Drive Control Unit

see ASE; Designation is used only when using

the main board MCU

DSE

Diagnose- und

Serviceeinheit

Mobile handheld terminal for diagnostics and

service

ESE

Etagensteuereinheit

Name of a control assembly which is connected

on shaft bus (CAN bus) for connection of landing

calls, special items / outputs or serves as a car

position indicator.

As ESE differ ent modules can be used

- UEA

- LCI16

- MS3-C

- PMA

- LCD-047

- LCD-057

FVE

Fahrkorb- Verteilereinheit

Car unit (usually on the car roof or in the car

operating panel)

HHT

Hand-Held Terminal

see DSE; Designation is used only when using

the main board MCU

HSE

Hauptsteuereinheit

Main assembly of the lift controller; usually

installed in the control cabinet

LCI16

Liquid Crystal Indicator

LCD Module with CAN-Bus connection and 8

inputs / outputs (can be used in the cabin or

outside the panel)

LCM

Lower Correction Magnet

Switching point (magnet) of the lower pre-limit

switch LPLS; Designation is used only when

using the main board MCU

LCU

Landing Control Unit

see ESE; Designation is used only when using

the main board MCU

LPLS

Lower Prelimit Switch

see VU; Designation is used only when using the

main board MCU

Page 6

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

6/196

LSI

Lower Signaler

see SGU; Designation is used only when using

the main board MCU

MCU

Main Control Unit

Main assembly of the controller; usually installed

in the control cabinet

MS3-C

Car position indicator 2 digits + arrow (dot matrix

5 * 7) with CAN-Bus connection and 7 inputs /

outputs (can be used in the cabin or outside the

panel). Not used for new installations

MSI

Middle Signaler

see SGM; Designation is used only when using

the main board MCU

PCU

Panel Control Unit

see TSE; Designation is used only when using the

main board MCU

PMA

Punktmatrixanzeige

Car position indicator 2 digits + arrow (dot matrix

5 * 7) with CAN-Bus connection and 8 inputs /

outputs (can be used in the cabin or outside the

panel)

PSE

Positionssteuereinheit

Positioning (adapter assembly between

incremental and CAN bus)

RSI

Reference Signaler

see SGE; Designation is used only when using

the main board MCU

SDS

Slow Down Switch

see SGV; Designation is used only when using

the main board MCU

SGE

Signalgeber zum Eichen

Reference or calibration switch SGE; is used as

reference point for the positionin

SGM

Signalgeber mitte

Center door zone switch (also leveling switch,

usually bistable magnetic switches, inductive or

capacitive switches)

SGO

Signalgeber oben

upper door zone switch (usually bistable

magnetic switches, inductive or capacitive

switches)

SGU

Signalgeber unten

lower door zone switch (usually bistable magnetic

switches, inductive or capacitive switches)

SGV

Signalgeber Verzögern

Slow down switch to switch to levelling speed if

arriving the target floor

SRU

Safety Relais Unit

Safety assembly for advanced door opening and

Page 7

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

7/196

re-levelling with open car doors; is used only

when using the main board MCU

TSE

Tableausteuereinheit

Name of a control assembly which is connected

on control bus (CAN bus) inside the car panel for

connection of car calls, special items / outputs or

serves as a car position indicator.

As TSE different modules can be used

- UEA

- LCI16

- MS3-C

- PMA

- LCD-047

- LCD-057

UCM

Upper Correction Magnet

Switching point (magnet) of the upper pre-limit

switch UPLS; Designation is used only when

using the main board MCU

UEA

Universelle Ein-/Ausgabe-

Baugruppe

Universal input / output module; control Module

with CAN-Bus connection and 8 inputs / outputs;

Available in 2 versions:

- UEA.1: inputs / outputs to 0V switching

- UEA.2: inputs / outputs to 24V switching

The UEA can be used depending on the

configuration for various purposes:

- As ESE for connection of landing calls

- TSE to connect the car calls

- As ASE for controlling the drive unit

- As PSE for connecting an incremental

encoder via CAN

UPLS

Upper Prelimit Switch

see VO; Designation is used only when using the

main board MCU

USI

Upper Signaler

see SGO; Designation is used only when using

the main board MCU

VU

Vorendschalter unten

lower prelimit switch; used as reference point for

the positioning

VO

Vorendschalter oben

upper prelimit switch; used as reference point for

the positioning

Page 8

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

8/196

Inhalt

0. Preliminary ............................................................................................................ 10

1. Introduction ........................................................................................................... 11

1.1 Operation of the Lift Controller MLC 8000 and Parameter Input ..................................11

1.2 Keyboard commands .................................................................................................12

1.3 Password protection (Code) ........................................................................................14

1.3.1 Menu code ............................................................................................................14

1.3.2 Parameter code ....................................................................................................14

1.3.3 Exceptions ............................................................................................................14

1.4 Hardware encoding .....................................................................................................15

2. Menu structure ...................................................................................................... 16

3. Commisioning ....................................................................................................... 76

3.1 Setup Mode .................................................................................................................76

3.2 Testing of individual input and output functions ...........................................................76

3.3 Setup of car doors .......................................................................................................76

3.4 Teach-in ......................................................................................................................76

3.4.1 Starting normal operation for lifts with magnetic switch positioning .......................76

3.4.2 Teach-in procedure by lifts with incremental encoder ............................................77

3.4.3 Teach-in procedure by lifts with absolute encoder .................................................77

3.5 Flush correction ...........................................................................................................78

3.5.1 Flush correction by car operation panel COP ........................................................78

3.5.1 Flush correction by keypad of HSE or handheld terminal DSE ..............................79

4. Error diagnosis ..................................................................................................... 79

4.1 General procedure for troubleshooting ........................................................................79

4.2 LED indicators .............................................................................................................79

4.3 Initial troubleshooting using state display 1 .................................................................80

4.4 Error stack ...................................................................................................................80

4.5 Error counter ...............................................................................................................82

4.6 Behavior of the controller in case of error ....................................................................83

4.7 Internal error counter ...................................................................................................83

4.8 Error warning ...............................................................................................................83

4.9 Hardware test of the individual controller boards .........................................................84

4.10 Troubleshooting at CAN bus faults ............................................................................85

4.11 Apparent errors by anti misuse detection or special functions ...................................87

4.12 Troubleshooting at the interface to external components...........................................87

4.13 Fault output ...............................................................................................................88

4.14 Error messages .........................................................................................................89

4.15 Error messages during teach-in procedure .............................................................. 107

5. Travel commands and Door commands via keypad (HSE or handheld terminal) 109

5.1 Travel commands ...................................................................................................... 109

5.2 Door commands by keypad ....................................................................................... 110

5.3 Door commands by inspection switches .................................................................... 110

6. Test of the safety functions of the lift control (Technical inspection) ................... 111

6.1. Automated Test ........................................................................................................ 111

6.1.1 Testing the safety circuit for moving with open doors .......................................... 111

6.1.2 Testing the trip time monitoring ........................................................................... 112

6.1.3 Testing the final limit switches ............................................................................. 112

6.1.4 Overspeed .......................................................................................................... 113

6.1.5 Testi ng the safety gear ........................................................................................ 113

6.1.6 Testi ng the mot or brake ...................................................................................... 114

Page 9

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

9/196

6.1.7 Testing the monitoring inputs for motor brake (roped lifts) or valves (hydraulic lifts)

.................................................................................................................................... 115

6.1.8 Testing the contactor monitoring (Contactor drop off control) .............................. 116

6.1.9 Uncontrolled movement ...................................................................................... 116

6.2. Conventional Test .................................................................................................... 117

6.2.1 Testing the safety circuit for moving with open doors .......................................... 117

6.2.2 Testing the trip time monitoring ........................................................................... 117

6.2.3 Testing of parking trip to lowest floor by hydraulic lifts ......................................... 117

6.2.4 Testing of emergency light .................................................................................. 117

6.2.5 Testing the final limit switche s ............................................................................. 117

6.2.6 Testing the traction (driving ability) ...................................................................... 118

6.2.7 Testing the speed monitoring .............................................................................. 118

7. Parameters of lift controller ................................................................................. 119

7.1 Saving parameters .................................................................................................... 119

7.2 Parameter backup ..................................................................................................... 119

7.3 Changing parameters ................................................................................................ 119

7.4 Changing of parameter “Floor name” ........................................................................ 120

7.5 Transferring parameters when replacing defective modules ...................................... 120

7.6 Parameters for freely programmable inputs and outputs ........................................... 121

7.7 Functions for free programmable inputs and outputs ................................................. 123

7.7.1. Input functions .................................................................................................... 123

7.7.2. Output functions ................................................................................................. 135

8. Setting the node ID ............................................................................................. 148

9. Group control ...................................................................................................... 148

9.1 Principle of Group control .......................................................................................... 148

9.2 Parameter synchronization within a lift group ............................................................ 150

10. State display ..................................................................................................... 151

10.1 State display 1 (General overview) .......................................................................... 151

10.2 State display 2 (Door state) ..................................................................................... 152

10.3 State display 3 (Timer values) ................................................................................. 153

10.4 State display 4 (Position and Speed) ....................................................................... 153

10.5 State display 5 (Emergency evacuation) ................................................................. 154

Appendix 1. Technical specifications ...................................................................... 155

Appendix 1.1 Module MCU ............................................................................................. 155

Appendix 1.2 Module HSE .............................................................................................. 159

Appendix 1.3 Module FVE 1.1 / FVE 2.1 ......................................................................... 164

Appendix 1.4 Module FVE 1.2 ......................................................................................... 170

Appendix 1.5 Module UEA .............................................................................................. 175

Appendix 1.6 Module PMA .............................................................................................. 178

Appendix 1.7 Module LCI16 ............................................................................................ 180

Appendix 1.8 Module TVE ............................................................................................... 183

Appendix 1.9 Module CBK .............................................................................................. 185

Appendix 1.10 Module SRU ............................................................................................ 187

Appendix 1.11 Module LCD-047 ..................................................................................... 188

Appendix 1.12 Module LCD-057 ..................................................................................... 191

Appendix 1.13 Handheld terminal ................................................................................... 196

Page 10

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

10/196

0. Preliminary

The main board of the lift controller MLC 8000 exists in 2 different versions:

- HSE board with integrated safety circuit and socket for modem or Ethernet interface

- MCU board without integrated safety circuit

The two boards also differ from each other in the external form; the functioning and

integrated application are still largely identical.

Depending on the main board used the name of the other boards differ from each other ,as

well as some specific control switches.

Mainly the board HSE is used, so that the present description relates also to this board.

Basically, the present description is also applicable to control systems in which the MCU

board is used.

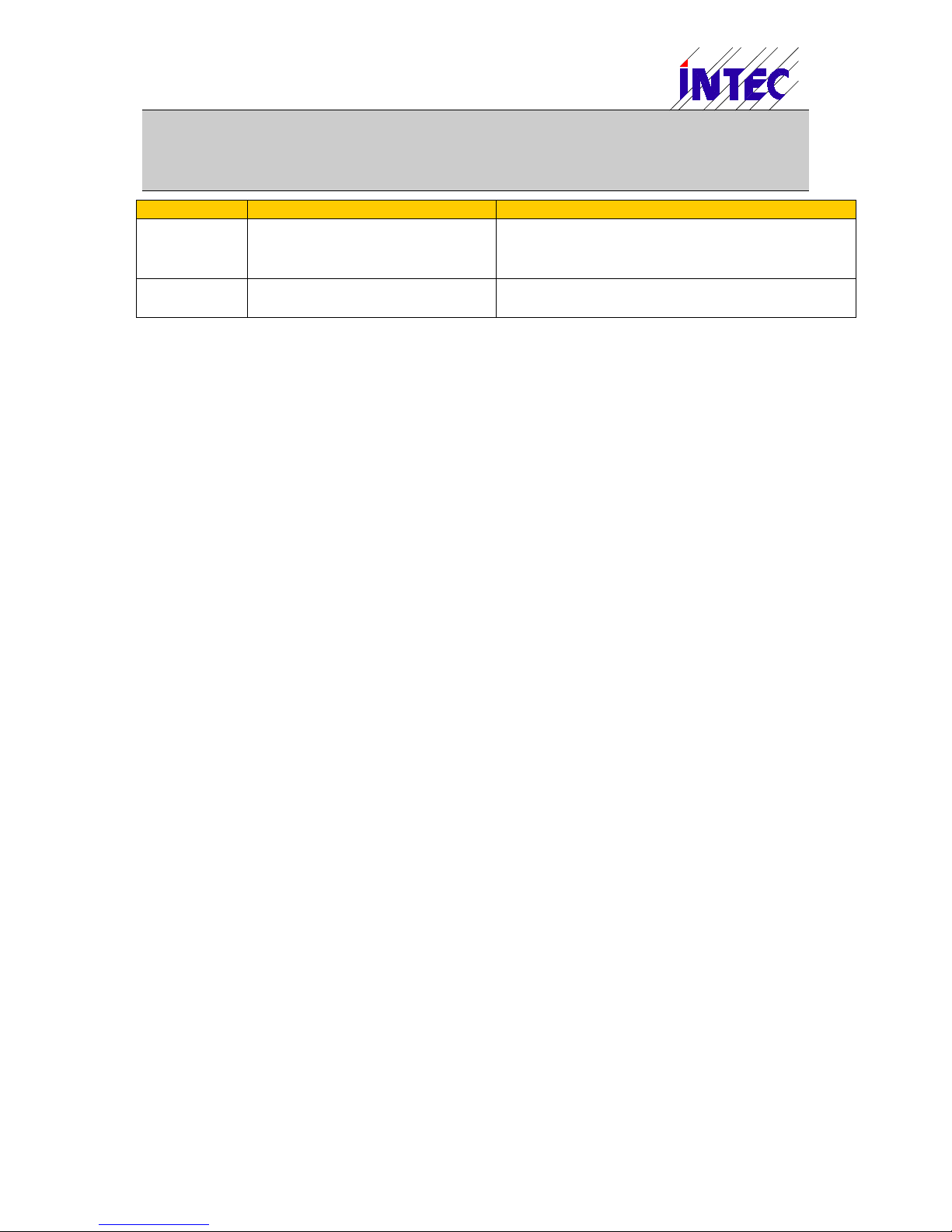

Following is a list with the various names by the HSE or MCU:

Board

Main board HSE

Main board MCU

Car board

FVE

CDU

Boards in the car operating panel

TSE

PCU

Boards in landing operating panel

ESE

LCU

Safety circuit

Integrated safety

relays KH5, KH6 a

nd

KH7

SRU

Drive control board

ASE

DCU

Positioning unit

PSE

CPA

Diagnosis unit

DSE

HHT

CAN bus coupler

CBK

CBC

Double-AWG (for moving with open door)

AWG2

SAF

AWG2 adaptor board (Double-AWG)

PSE2

POS2

Lower prelimit switch

VU

LPLS

Switching point of lower prelimit switch

VU

LCM

Upper prelimit switch

VO

UPLS

Switching point of upper prelimit switch

VO

UCM

Door zone switch (Level switch)

SGM

MSI

Lower door zone switch

SGU

LSI

Upper door zone switch

SGO

USI

Slow down switch

SGV

SDS

Correction switch (Reference switch)

SGE

RSI

Relay on the main board

KH11-16, KH41-42

KM1-8

Emergency relay on the main board

KH31

KM-CA

Inputs of the main board

E1-8 (BR, U2, MAX,

U1, MIN, RHEin,

Auf, Ab)

IM1-8

Page 11

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

11/196

1. Introduction

1.1 Operation of the Lift Controller MLC 8000 and Parameter Input

The operation of the lift controller MLC 8000 can be handled either from the keypad and LCD

display located on the HSE, or with a mobile handheld terminal DSE.

HSE and handheld terminal have an LCD display with 16 * 4 characters and a keypad using

the following keys:

- Number keys 0 to 9

- Cursor keys ↑ and ↓

- ENTER key ↵

- ESC key

The handling of the HSE and the handheld terminal is very simple. With the cursor keys ↑

and ↓ a menu item in the LCD display can be selected. Pressing ENTER

↵ the selected

menu item starts. Either a function is activated or a submenu is called.

With the ESC key a function may be terminated or you can leave a submenu.

The entire menu structure is described in more detail in the section "Menu structure".

The handheld terminal DSE is connected via the CAN bus to the lift controller and can be

inserted and withdrawn during operation. Currently located on both the HSE and on the FVE

appropriate connectors. Additionally, it is possible to insert at any point corresponding

adapters on both the control bus and on the shaft bus.

After connecting the hand-held terminal to the lift controller first following display appears

(example):

** INTEC GmbH **

Lift controller

Connect to HSE

1 2 3

If the handheld terminal was connected to the control bus (e.g. FVE), then only the number 1

is displayed on the bottom line. Pressing ENTER

↵ the connection is made to the lift

controller. Further operation of the hand-held terminal is then identical to the operation of the

HSE.

If the hand-held terminal was connected into the shaft bus of an lift group, then the group

numbers of all HSE modules will appear within the group. By pressing the corresponding

number button it can be selected, with which lift of the group the connection has to be done

(by pressing ENTER

↵ always the lift 1 is selected).

If, after you connect the handheld terminal, in the bottom line no number appears, then the

CAN data transmission between handheld terminal and lift controller is disturbed.

If the CAN connection gets disturbed while working with the handheld terminal, then following

display appears on the LCD screen of the handheld terminal :

Page 12

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

12/196

Lost connection

to HSE!

Continue with

any key!

By pressing ENTER ↵, the connection, if possible, can be reestablished.

1.2 Keyboard commands

For experienced users, there is next to the menu the so called keyboard commands used in

the operation of the lift controller, where a lot of time can be saved.

Certain functions or menu items can be selected by pressing the keyboard commands

directly, by passing the menu structure.

Each keyboard command consists of a sequence of digits that are acknowledged by

pressing the ENTER key

↵. The time interval between 2 consecutive keys must not be

greater than 3 seconds, otherwise the previously operated keys are invalid and the key

command must be started from the beginning. Operated key will be shown in the LCD

display on the bottom left

The keyboard commands can be used anytime, regardless of what is shown on the LCD

display of the lift controller or the hand-held terminal.

Only in a few menu items or functions the keyboard commands are disabled, for example, in

the menus "Travel commands" and "Door commands" or the "Hardware test".

The following table lists all the keyboard commands .

Kommando

Bedeutung

Hinweise

0 ↵

State display 1

Main screen

1 ↵

Open door 1

2 ↵

Open door 2

3 ↵

Open door 3

4 ↵

Close all doors

5 ↵

Enable /Disable door lock

6 ↵

Enable /Disable landing calls

7 ↵

Test drives on / off

8 ↵

Menu "Travel movement"

9 ↵

Save all parameters

0 0 ↵

Menu "Basic settings"

0 1 ↵

"Out of service" indication on/off

0 0 0 ↵

Menu "General parameters"

0 0 1 ↵

Menu "Timer parameter"

0 1 2 ↵

Menu "Error stack"

0 1 3 ↵

Menu "Error count"

0 1 5 ↵

Clear error stack

Page 13

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

13/196

Kommando

Bedeutung

Hinweise

0 1 6 ↵

Clear error count

0 1 7 ↵

Clear operating time counter

0 1 8 ↵

Clear trip counter

1 0 0 ↵

Start Teach in trip

1 x x ↵

Car call for floor xx

(for all doors)

e.g.: 105 ↵ = Car call floor 5

115 ↵ = Car call floor 15

1 x x y ↵

Car call for floor xx,

Door y

e.g.: 1051 ↵ = Car call floor 5, door 1

1152 ↵ = Car call floor 15, door 2

2 x x ↵

Landing call up direction for floor

xx

(for all doors)

e.g.: 205 ↵ = Landing call up floor 5

215 ↵ = Landing call up floor 15

Landing calls without door are only valid for the

actual lift of a lift group.

2 x x y ↵

Landing call up direction for floor

xx

Door y

e.g.: 2051 ↵ = Landing call up floor 5,

door 1

2153 ↵ = Landing c all up floor 15,

Door 3

Landing calls with door are handled by each lift

of a group.

3 x x ↵

Landing call down direction for

floor x x

(for all doors)

e.g.: 305 ↵ = Landing call down floor 5

315 ↵ = Landing call down floor 15

Landing calls without door are only valid for the

actual lift of a lift group.

3 x x y ↵

Landing call down direction for

floor x x

Door y

e.g.: 3052 ↵ = Landing call down floor 5,

door 2

3153 ↵ = Landing call down floor 15,

door 3

Landing calls with door are handled by each lift

of a group.

4 0 0 ↵

Hardware test HSE

4 0 1 ↵

Bus node test FVE, ASE and

PSE

4 0 2 ↵

Hardware test TSE boards

4 0 3 ↵

Hardware test ESE boards

4 0 4 ↵

Test group connection

4 0 5 ↵

Switch to English languag e

4 0 6 ↵

Switch to German language

4 0 7 ↵

Switch to Dutch language

4 9 0 ↵

Menu "Technical check"

5 x x ↵

Emergency call floor xx

(for all doors)

e.g.: 505 ↵ = Emergency call floor 5

515 ↵ = Emergency call floor 15

6 x x ↵

Advanced call floor xx

(for all doors)

e.g.: 605 ↵ = Advanced call floor 5

615 ↵ = Advanced call floor 15

7 x x ↵

Special call floor xx

(for all doors)

e.g.: 705 ↵ = Special call floor 5

715 ↵ = Special call floor 15

8 x x ↵

Set output HSE

• 1: Relay KH11

• 2: Relay KH12

e.g.: 805 ↵ = Output 5 (KH15) activated

Page 14

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

14/196

Kommando

Bedeutung

Hinweise

• 3: Relay KH13

• … to Relay KH42

• 9: Output KH5

9 x x ↵

Switch off output HSE (siehe

above)

e.g.: 905 ↵ = Output 5 (KH15) deactivated

1.3 Password protection (Code)

The lift controller MLC 8000 has a two-stage access protection (code number). If access

protection is enabled, then when you start the menu structure (pressing ENTER

↵) you will

be asked to enter a numeric code.

Within the control 2 different access codes (Menu code, parameter code) can be stored.

These can be activated, changed or disabled (by setting the codes to 0) in the menu item

"Change password".

After entering a valid password access for 15 minutes is enabled, then the access is blocked

again and the State display 1 (main screen) is displayed.

The access time of 15 minutes starts again when:

- a key is pressed on the HSE or the hand-held terminal

- the lift is in "Teach in mode"

- The menu item "Travel commands" was started

- The menu item "Door command" was launched

- The m enu item "Basic settings" was started

1.3.1 Menu code

If the menu code is activated, the menu structure can only get started if the corresponding

code has been entered.

1.3.2 Parameter code

If the parameter code is activated, the following actions can be performed only when the

appropriate code has been entered:

- Changing parameters

- Teach-in trip

- Door movements with keyboard

- Drive movement on keyboard

- Basic settings

- Group synchronization

1.3.3 Exceptions

Regardless of the preset or entered code following actions can always be carried out:

- Display of state images

- Input of calls over short commands

- Start menu "Technical check" with short command 490 ↵

Page 15

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

15/196

1.4 Hardware encoding

Upon customer request all control modules can be fitted with a custom specific coding. Only

modules with identical hardware encoding can work together in an lift controller. Thus, if, for

example, a TSE board was connected with other hardware encoding of such the system, this

module will be "ignored" completely (it appears the error message "Wrong Code TSE xxx" in

the error stack HSE).

In the default state, the entire system is unprotected and control modules can be freely

interchanged.

Page 16

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

16/196

2. Menu structure

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

Parameter

General paramet.

No.

Lift number (for information only)

Lift type

Rope / Hydraulic

Bottom floor

Bottom floor

Top floor

Top floor

Group size

Number of lifts per group (1 … 8)

Group number

Number of lift within a group (1 … 8)

Car door numb.

Car door number (1 … 3)

Main floor

Main floor

Park floor

Park floor

(Note: Starting with version 1.32z this parameter is in a separate

submenu "Special parameter" - "Parking trip")

Type

Collecting control / Single call control

Setup ready

This value is set to "Yes" if setup is completed. As long as this value

is set to "No", all position values are invalid and the lift does not

handle trips (only electrical recall operation and inspection possible)

Push control

If set to "Yes" lift is working as a "Push control", ie, the lift only goes

as long as special pushs are pressed (also called Deadman control).

Note: As of version 1.36m HSE, this parameter is in the submenu

"special parameters" - "Push control "

Call config.

If set to "Yes" special "call tables" (see "Special parameter") are

activated. If the lift arrives a floor by a landing call, only car calls

enabled for this landing call ("Call table" will be handled.

A maximum of 5 different call configurations can be set. Switching

between the Call configurations occurs only when all doors are closed

and (if available), the presence sensor signals "Car empty" signals

that no one is inside the car anymore.

In principle, up to 5 "logical" lifts can be created for one "real" lift , in

which only floors or entrances within this "logic" lift can be

approached.

Page 17

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

17/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

The function can be activated by this parameter as well as with an

input ("Special function" - "Call configuration").

Doors locked

By setting "Yes" never 2 car doors open at the same time.

Note: Inside the menu item "Special parameters" it is possible to

select, whether the "door lock" is also active in the various Special

drive modus .

Ref.run speed

Choice of driving speed for reference run to the SGE magnet or the

prelimit switch

Ref. floor

Last floor before reference switch SGE when driving in the upward

direction (= floor below the reset switch)

Ref. floor ↑

Last floor in upward direction before top prelimit switch VO

Ref. floor ↓

Last floor in downward direc t ion before bottom prelimit switch VU

Diving

Behavior of the lift when the car is between 2 floors (eg after switching

on, after a failure, etc.):

VO / VU: The lift always moves to one of the prelimit switches (VO/VU).

Next Floor: The lift always travels to the nearest floor

Pos.type

Type of positioning:

- CAN Encoder: (Incremental encoder with CAN interface)

- Encoder (Encoder mechanical connected to car).

This setting must also be selected if the motor encoder is used for the

position, but the door zone is not additionally monitored by "real"

door zone switch SGO / SGU

- Motor encoder (using the motor encoder; always in connection with

"real" door zone switches SGO / SGU)

- Switch (position via a magnetic switchs)

- Absolute (Absolut encoder

- Double-AWG (Double absolute encoder for driving with open doors

without any additional magnetic switch)

- Limax Safe: Special absolute encoder with integrated safety

functions (e.g. replacement of final limit switchs)

Adv.door op.

Advanced door opening (door opening while lift is arriving) (yes/no)

v Adv.door

Speed limit to open door if lift is arriving (advanced door opening)

Pos.Adv.door

Position to open door if lift is arriving (advanced door opening)

Releveling

Re-levelling with open doors (yes/no)

Rel.at Call

Re-levelling if new call available (yes/no)

LC mode

Handling of new landing call in actual floor:

Page 18

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

18/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

- reopen: re-opens the door if new landing call is pressed

- ignore: if the lift already starts door closing while the new landing

call was presses the lift controller will continue closing the door and

handle this call later

- other lift (only for group of lifts): If a new landing call is pressed

another lift of the group will go to this floor even if there is alrady a lift

with open doors located in this floor

Vane length

Length of the door zone (area where the door zone switch SGM is

turned on)

Only if this parameter is entered correctly, the control values can

specify in mm or mm/s (the lift controller calculates the relation

between resolution of incremental encoder and "real length in mm)

If the vane length is not identical in all floors, the vane langth on the

2nd floor length must be entered here.

Cl.calls[mm]

Distance in mm from the target floor, in which the calls for this floor

will be cleared (lamp off). When set to "0", the calls are cleared in the

moment the lift starts slowing down

(Note: Clearing a call before the lift slows down is not possible.)

Level zone ↑

Position in mm above floor level where the lift starts re-levelling (only

if parameter "Relevelling" is set to "yes")

Note: When positioning via the motor encoder and magnetic

switches the leveling zone is formed by the switch SGO / SGU. This

parameter is of no significance in this case.

Level zone ↓

See above; position below floor level

Incr./m

Resolution of position encoder related to travel distance in mm.

This parameter is automatic calculated during set-up trip (setting of

parameter "Vane length" - see above - must be correct!)

If the lift has only 2 floors this parameter must be calculated and set

manually.

v nominal

Rated speed ( for speed monitoring)

v relevel

Relevelling speed ( for speed monitoring)

v brake

For manual evacuation through brake opening via UPS in case of

power failure (machine room-less lifts): Upon reaching this speed the

control allows the mechanical brake to come up again ("interval

braking" for speed limit)

Top limit

Distance of the upper final limit swit c h above top floor. This parameter

is used exclusively for the detection of errors if the lift is on the top

floor and the primary safety circuit (SL1) fails. If the lift is above this

Page 19

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

19/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

position, it detects error "SL final limit"; otherwise at fault "SK

missing". This parameter is used for hydraulic lift, which has to stop

operation if the lift was at top final limit.

Bot.limit

See above; position of bottom limit switch

SL door test

If set to "Yes", according to EN81-20 the shaft door safety circuit is

checked after each trip (if the doors are completely openend).

For this the safety unit for door zone bypass is activated for a short

time and so power is switched to safety circuit input SL4.

At the same time safety circuit input SL3 must not have power,

otherwise the safety circuit shaft door is defective or bypassed. In this

case the lift controller goes out of operation and sets the error

message " SL shaftdoor on".

Descr.

For these parameters, values or text may be entered for informative

purposes.

Thus, for example, better assignment can be done when the parameter

set is stored on the PC.

Manuf.

Year

Set.date

Traction

Nom.Ld.[kg]

Timer parameter

Parktime[s]

If the lift is not used for this time the lift will go to the specified parking

level.

(Note: as of version 1.32z these parameters aredisplayed in a separate

submenu "Special parameter" - "Parking trip")

Triptime[s]

Monitoring of travel movement according to EN81

Carlight[s]

Time to turn off the car light, when the lift parks with closed doors at a

floor

Waitt.CC[s]

Time until door closing when the lift has approached a floor due to a

car call (not for main floor; see below)

Waitt.LC[s]

Time until door closing when the lift has approached a floor due to a

landing call (whether simultaneously a car call existed).

(not for main floor; see below)

Waitt.nC[s]

If the lift is on a floor and there is no further call, then the lift closes

after this time the doors after that time (unless "Parking with open

door" is set; see Door parameters)

(not for main floor; see below)

Page 20

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

20/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

Wt.CC Main[s]

Time until door closing when the lift has approached a floor due to a

car call (just for main floor; see above)

Wt.LC Main[s]

Time until door closing when the lift has approached a floor due to a

landing call (whether simultaneously a car call existed).

(just for main floor; see above)

Wt.nC Main[s]

If the lift is on a floor and there is no further call, then the lift closes

after this time the doors after that time (unless "Parking with open

door" is set; see Door parameters)

(just for main floor; see above)

Doorstop[s]

Time Door Stop push stays active until pressed

Wt.Start[ms]

Start delay after closing of the safety circuit of the shaft doors

("Debouncing")

Wt.door[s]

Max. w aiting time for safety circuit doors when starting

Errdelay[s]

Waiting time between the occurrence of an error and further reactions

of the lift controller (call canceling, setting the fault relay, sending an

error message via the remote data transmission, etc.)

Drive parameter

General

Drive

Selection of interface between lift controller and drive unit:

- Standard: control of the drive only via relays of the main board

- CAN-Lust: Inverter "Lust" connected by CAN bus

- CAN-ASE: Using an ASE board (UEA) as interface to lift controller

- CAN-Open: Inverter interface according to CANopen Lift (DSP 417)

- Em.RS485: Emerson inverter connected by RS485

Star/D. [ms]

Changeover time star / delta (hydraulic lifts)

Startdel[ms]

Delay between switching on running contactors and setting control

signals (only if parameter "Sign.delayed" (see below) is set to "Yes" at

the same time)

Brakedel[ms]

Delay between setting control signals and switching on brake

contactor

Brakeoff[ms]

Delay between switching off the control signals and brake contactor

Offdel. [ms]

Delay between switching off brake contactor and main / direction

contactor

Stopdel.[ms]

Delay between switching off all contactors and direction + enable

signals

Stop [ms]

Waiting time after shutdown of all control signals and contactors until

Page 21

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

21/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

the next action (e.g. opening the doors or starting a new journey)

Sl.start[ms]

Delay when switching on the slow-start contactor if switching from

fast to slow. If, for example, used for pole-changing motors where in

the supply line of the slow winding-up resistors are connected.

If the lift starts directly at slow speed , then the starting contactor is

activated immediately.

Contact.[ms]

Max. waiting for contactor supervising input (while switching on and

switching off contactors)

Braket. [ms]

Max. waiting for brake supervising inputs (while switching on and

switching off the brake)

Ready=1 [ms]

Only if "Ready" signal from drive exist: Max. waiting time for "Ready"

signal

Brake=1 [ms]

Only if "Brake" signal from drive exist: Max. waiting time for "Brake"

signal

Mov. =1 [ms]

Only if "Moving" (Speed > 0) signal from drive exist: Max. waiting time

for "Moving" signal

Brake=0 [ms]

Only if "Brake" signal from drive exist: Max. waiting time for "Brake"

signal of at trip end

Ready=0 [ms]

Only if "Ready" signal from drive exist: Max. waiting time for "Ready"

signal of at trip end

Error [ms]

Delay between activation of an error signal from the drive and

response of the lift controller

Sign.delayed

No: main contactors and speed signals are activated at the same time

Yes: speed signals are activated delayed (see above parameter

"Startdel [s].)

Pos.mode

Special mode for lifts with CANopen drive, where the inverter selects

the optimum driving speed itself. Notably, the arrival behavior and

travel time are optimized, especially for short floors.

Other Requirements: Positioning with CAN open interface

Quickstart

By Quick Start the motor is already energized and the brake is

released while the doors close. So the delay time is minimized during

starting.

For the function Quick Start a safety circuit for moving with open

doors is necessary.

Note: While starting the movement the door lock bypass (safety

circuit) is switched off. So it is necessary to adjust the parameter

"Wt.start[ms]" (see "Timer parameter" above) in a way, that the safety

circuit of the doors is really closed in the moment the door lock

bypass is switched off; otherwise the error "SL off trip" occurs.

Page 22

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

22/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

Qu.delay[ms]

Waiting time between starting of door closing and starting the quick

start procedure (drive on).

If the lift is equipped with a CANopen Lift door this parameter may be

set to 0 (see also next parameter below).

Qui.door[mm]

Only if the lift is equipped with CANopen lift doors: Door position

where Quick start is activated

Vent.time[s]

Switch off delay of car ventilatorafter trip end

Relev.[ms]

Delay time for relevelling [ms].

Relevelling is only started if cabin is outside level zone for this time.

So, a possible oscillation of the cabin is avoided at the flush position.

Speeds

Only for CANopen lift drives:

With this parameters the actual lift speed in mm/s is assigned to the

different functional speeds:

Speed signals

For all other drives:

With this parameters it is defined which speed signal outputs will be

set for the different functional speeds:

vRL

Re-levelling speed

V0

Arrival speed

V1

Intermadiate speed 1 (for short floor distances)

V2

Intermadiate speed 2 (for short floor distances)

V3

Nominal speed

vI

Normal Inspection speed

vIS

Slow Inspection speed

vR

Fast Electrical recall operation speed

vRS

Slow ( normal) Electrical recall operation speed

vEE(UPS)

Evacuation speed (UPS-Evacuation)

vHu

Lift with holding bolts: Up speed from holding bolts

vHd

Lift with holding bolts: Down speed to holding bolts

vZ1

Additional intermadiate speed 1

vZ2

Additional intermadiate speed 2

Drive specific

Menu item only for CANopen Liift drives: Here you can directly set

parameters of the drive (usually VVVF).

The meaning of each parameter is in the operating manual of the drive.

Page 23

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

23/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

Read from drive

The drive-specific parameters (see above) are each stored in both the

drive and in the lift controller. For the operation of the lift, the

parameters in the drive and control need to be the same

(synchronous) . If the parameters are changed in the lift controller,

then they are automatically sent also to the drive (synchronized).

However, if you change parameters directly on the CANopen lift drive,

then the changes need to be transferred manually with this menu item

from the drive to the lift controller.

Write to drive

If a CAN open drive has been replaced, then the drive parameters can

be sent with this menu item to the new drive, ie, the drive must not be

customized manually before.

In addition, this menu option is required if within the lift controller

drive-specific parameters (see above) were changed while the drive

(VVVF) was not switched on (not "available") .

Positions/Imp.

All red marked parameters are automatically measured during the

setup trip and do not need to be changed.

Dec./stop dist.

Gemessene Brems- und Anhaltewege

Dec. v3 ↑

Braking distance for speed v3 in the upward direction

Dec. v3 ↓

Braking distance for speed v3 in the downward direction

Dec. v2 ↑

Braking distance for speed v2 in the upward direction

Dec. v2 ↓

Braking distance for speed v2 in the downward direction

Dec. v1 ↑

Braking distance for speed v1 in the upward direction

Dec. v1 ↓

Braking distance for speed v1 in the downward direction

Stop ↑

Stopping distance in the upward direction

Stop ↓

Stopping distance in the downward direction

Dec.vZ2 ↑

Braking distance for speed vZ2 in the upward direction

Dec.vZ2 ↓

Braking distance for speed vZ2 in the downward direction

Dec.vZ1 ↑

Braking distance for speed vZ1 in the upward direction

Dec.vZ1 ↓

Braking distance for speed vZ1 in the downward direction

Min.Dist.v3

Minimum distance between start and target floor to start with nominal

speed v3

Min.Dist.v2

Minimum distance between start and target floor to start with reduced

Page 24

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

24/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

speed v2

Min.Dist.v1

Minimum distance between start and target floor to start with reduced

speed v1

Min.Dist.vZ2

Minimum distance between start and target floor to start with reduced

speed vZ2

Min.Dist.vZ1

Minimum distance between start and target floor to start with reduced

speed vZ1

Dec. vI ↑

Braking distance for inspection speed vI in the upward direction

Dec. vI ↓

Braking distance for inspection speed vI in the downward direction

Stop vI ↑

Stopping distance for inspection speed in the upward direction

Stop vI ↓

Stopping distance for inspection speed in the downward direction

Stop vN ↑

Stopping distance for relevelling speed in the upward direction

Stop vN ↓

Stopping distance for relevelling speed in the downward direction

Stop vAh

Stopping distance if moving with vAh in upward direction (lift with

holding bolts

Stop vAs

Stopping distance if moving with vAs in downward direction (lift with

holding bolts

Floor positions

Floor distances

Distance between 2 floors

Fl. 1- 2

Fl. 2- 3

… Floor height

Absolute floor position

1.Floor

B ottom floor = 0

2.Floor

… SGM Positionen

Measured switching points of the door zone switch SGM

1.Floor ↑

switching point above 1st floor

1.Floor ↓

switching point below 1st floor

2.Floor ↑

…

Page 25

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

25/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

2.Floor ↓

…

… … SGO/SGU Position

Measured switching points of the door zone switches SGO/SGU

1.Floor ↑

switching point SGO above 1st floor

1.Floor ↓

switching point SGU below 1st floor

2.Floor ↑

…

2.Floor ↓

…

… …

Shaft doors

Landing door positions in each floor

1.Floor

Shaft doors in 1st floor

2.Floor

Shaft doors in 2nd floor

…

…

Door releases

Enabling / disabling of individual shaft doors and/or complete levels

depending on the actual operation mode

Normal run, CC

Released doors for car calls during normal operation

1.Floor

Released doors in 1st floor

2.Floor

"

… " Normal run, LC

Released doors for landing calls during normal operation

1.Floor

Released doors in 1st floor

2.Floor

"

… " Auto call funct.

Released doors in operation mode „Automatic calls"

1.Floor

Released doors in 1st floor

2.Floor

"

… " Clock run 1, CC

Released doors in operation mode „Clock run 1“

1.Floor

Released doors in 1st floor

Page 26

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

26/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

2.Floor

"

…

"

Clock run 1, LC

Released doors in operation mode „Clock run 1“

1.Floor

Released doors in 1st floor

2.Floor

"

…

"

Clock run 2, CC

Released doors in operation mode „Clock run 2“

1.Floor

Released doors in 1st floor

2.Floor

"

… " Clock run 2, LC

Released doors in operation mode „Clock run 2“

1.Floor

Released doors in 1st floor

2.Floor

"

… " Clock run 3, CC

See above, up to clock run 5

… Special run

Released doors in operation mode „Special run“

1.Floor

Released doors in 1st floor

2.Floor

"

… " VIP run

Released doors in operation mode „VIP run“

1.Floor

Released doors in 1st floor

2.Floor

"

… " Emergency run

Released doors in operation mode „Emergency run“

1.Floor

Released doors in 1st floor

2.Floor

"

…

"

Page 27

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

27/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

Fire evac. run

Released doors in case of fire detection

1.Floor

Released doors in 1st floor

2.Floor

"

… " Firemen run

Released doors for fireman trip

1.Floor

Released doors in 1st floor

2.Floor

"

…

"

Hazard transport

Released doors for hazard transportation mode

1.Floor

Released doors in 1st floor

2.Floor

"

…

"

Door park mode

If parking with open doors is enabled (see Door parameters), then here

it can be set individually for each floor, which doors should remain

open when the lift is on the equivalent floor.

1.Floor

Opened doors if lift is on 1st floor

2.Floor

Opened doors if lift is on 2nd floor

… …

Door parameter

Parameters for up to 3 car doors

Gener.door para.

Cl.push

Operation of the door-close button

No delay: the door-close button is immediately active at the beginning

of the door opening, ie, the opening of the door can be interrupted by

pressing the door-close button and the door closes immediately

delayed.: button is not active until the door was fully open

Op.push D1

Operation of the door-open button for car door 1

all: open all the doors of the relevant floor.

last: The last opened doors will open again

enabled: All released doors according to the operation mode will be

opened (see parameter "Door releases" above)

Op.push D2

Operation of the door-open button for car door 2 (see above)

Op.push D3

Operation of the door-open button for car door 3 (see above)

Page 28

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

28/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

Dr.closeD1

autom.: The lift controller closes the door automatically when a new

call has been approached or when the parking position is to be taken.

Push: The door is only closed after operating the door-close button

Dr.closeD2

Door close mode for door 2; see above

Dr.closeD3

Door close mode for door 3; see above

Forced Cl.

Ignore light screen when lift is outside the door zone (yes / no)

Door 1 parameter

Parameter for 1st car door

Door type

Standard: Door is controlled by digital signals

CANopen: Door drive with CANopen lift interface

Open park.

allow: Lift is parked with open doors

forbid: Lift is parked with closed doors

Revolv.door

yes: shaft doors on the door side 1 are revolving doors

Lightscr.[s]

time indication how long the door remains open after the reopening by

light screen interruption

Rev.open [s]

time indication how long the door remains open after the reopening by

force limitation (reversing switch)

Nudging[*2s]

If the light screen is interrupted continuously, then the door is closed

after this time anyway (forced door closing). Here, the closing occurs

with reduced force or speed; in addition, it will sound (if available), an

acoustic signal.

Note: The nudging time is entered in 2s increments. If for example the

numerical value 20 is entered, the forced closing starts after 40s.

Entering the value 0 disables this feature.

Opentime [s]

Door opening time

This parameter has, depending on the type of door, 2 different

meanings:

- For doors with door-open-limit-switch the lift controller monitors if

the door is fully opened at the latest after this time. The time must be

chosen in this case so long, that the door has opened securely within

that time.

- For doors without door-open-limit-switch the lift controller assumes

that the door is fully opened after that time. Here, then, the time should

be entered which actually the door requires to open.

Closetime[s]

Door closing time

The lift controller monitors whether the doors are closed at the latest

after this time.

Open attempts

Number of door open attemps

If the door can't properly open in a floor, the lift can be operated with a

Page 29

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

29/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

new call to another floor. This process can only be repeated according

to the number set here. If the door cannot be opened after that

number of attemps, the lift goes out of service.

If the value 0 is set, there is an unlimited number of opening attempts.

Closeattempts

Number of door close attemps

Here it is set how often the lift controller tries to close the door before

the lift goes out of service.

If the value 0 is set, there is an unlimited number of closing attempts.

Rev.del.[ms]

Waiting time between changing the direction of the movement of the

door

Cls.delay[s]

Waiting time between a door closing command of the liift controller

and the actual closing of the door.

Within this waiting time, for example, a warning (acoustic / optical

signal) can take place

Relays

Switching status of the door close relay after the door is completely

closed or of the door open relay after the door is fully opened.

- both on: The door close relay remains on after the door is completely

closed; the door open relay remains energized after the door is fully

opened

- both off: Once the door is fully opened or closed, the door close

relay and door open relay are switched off

- Open on: The door open relay remains energized after the door is

fully opened; but the door close relay is switched off after the door is

completely closed.

- Close on: The door close relay remains energized after the door is

fully closed; but the door open relay is switched off after the door is

completely opened.

MaxCl.Rel[s]

Only relevant if the "relay" parameter (see above) is set to "both on",

or "Close on":

Here a maximum time can be set for the door close relay to remain

switched on. At standstill, the relay switches off after this time (e.g. to

prevent overheating the door motor)

If this value is set to 0, then the door close relay is always turned on

when the door is closed.

MaxOp.Rel[s]

Only relevant if the "relay" parameter (see above) is set to "both on",

or "Open on":

Here a maximum time can be set for the door open relay to remain

switched on. At standstill, the relay switches off after this time (e.g. to

prevent overheating the door motor)

If this value is set to 0, then the door open relay is always turned on

Page 30

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

30/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

when the door is opened.

Max.LS [s]

If the light screen is constantly interrupted, then an error message will

be set after this time.

Entering the value of 0 this feature is disabled.

Ramp off

never: The door ramp magnet remains constantly energized while the

door is closed.

always: The door ramp magnet is always switch off at standstill after a

time delay (see parameter"Max. ramp" below).

betw.fl.: If the lift stands between 2 floors (outside the door zone), then

the door ramp magnet is turned off after a time delay (see

parameter"Max. ramp" below)

Ramp

with door: The door ramp magnet is switched off when the door-

opening gets started

after door: The door ramp magnet is switched off when the car door is

fully opened..

Rampdel.[ms]

Delay time between closing the revolving door and switching off of

door ramp magnet (debouncing)

Ramp off[ms]

Delay time between turning off the door ramp magnet and opening the

car door. This ensures that the car door is unlocked safely before

opening.

Add.R.on[ms]

The additional door ramp magnet is activated while the door is

opening or closeing (mechanical unlocking of the door). With this

parameter, a waiting time can be adjusted between the activation of

the additional door ramp magnet and the beginning of the door

opening or door closing.

Add.Roff[ms]

With this parameter a waiting period can be adjusted between end of

door opening or door closing and the switching off the additional door

ramp magnet.

Max.Ramp [s]

Max. time the door ramp magnet is switched on while the lift is

standstill (only if parameter „Ramp off“ = Always" or. "Between

floors" - see above)

Door 2 parameter

Parameter for 2nd car door

…

See car door 1 parameter above

Door 3 parameter

Parameter for 3rd car door

…

See car door 1 parameter above

Floor name

Names of the floors (for floor level indicator).

This setting is only relevant if the indicator is controlled directly via

the CAN bus.

Page 31

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

31/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

1.Floor

1st floor designation (eg, 'GF' or '0')

2.Floor

2nd floor designation

…

ESE disp.alloc.

Assignment of a floor level indicator to one of the lifts inside a lift

group.

ESE 1.1 Lift

Specifies, from which Lift the actual floor position is displayed at the

floor level indicator with node ID 1, branch number 1 (ESE1.1)

…

…

ESE64.8 Lift

Specifies, from which Lift the actual floor position is displayed at the

floor level indicator with node ID 64, branch number 8 (ESE64.8)

Mandatory PCBs

Setting, which TSE or ESE modules are necessary for the operation of

the lift

Mandatory TSE

TSE 1

If set to "Yes" the lift goes to error state ("PCB fault") if the TSE1 does

not work or does not exist. If set to "No," the lift continues operation

even without TSE1 and only a warning ("Maintenance") flashes in the

display.

TSE 2

… Mandatory -ESE

See TSE above

ESE 1.1

ESE 1.2

…

ESE 64.8

HSE in-/outputs

Function of the inputs and outputs of the mainboard HSE

HSE Inputs

1:

Function of input 1 of HSE

… …

15:

Function of input 15 of HSE

HSE Outputs

1:

Function of output 1 of HSE

…

…

Page 32

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

32/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

8:

Function of output 8 of HSE

FVE in-/outputs

Function of the inputs and outputs of the car unit FVE

FVE Inputs

1:

Function of input 1 of FVE

…

…

28:

Function of input 28 of FVE

FVE Outputs

1:

Function of output 1 of FVE

…

…

16:

Function of output 16 of FVE

ASE in-/outputs

Function of the inputs and outputs of the drive control unit ASE

ASE Inputs

1:

Function of input 1 of ASE

… …

8:

Function of input 8 of ASE

ASE Ouputs

1:

Function of output 1 of ASE

… …

8:

Function of output 8 of ASE

TSE in-/outputs

Function of the inputs and outputs of the car panel unit TSE

TSE 1

TSE 1 Inputs

1:

Function of input 1 of TSE1

… …

8:

Function of input 8 of TSE1

TSE 1 Outputs

1:

Function of ouput 1 of TSE1

…

…

Page 33

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

33/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

8:

Function of ouput 8 of TSE1

TSE 2

TSE 2 Inputs

1:

Function of input 1 of TSE2

…

…

8:

Function of input 8 of TSE2

TSE 2 Outputs

1:

Function of ouput 1 of TSE2

…

…

8:

Function of ouput 8 of TSE2

…

Add PCB

With this menu item another car panel unit TSE can be added (max.

16).

Finally the new TSE is only added if at least 1 input or output function

is defined for this TSE.

Node ID

Set node ID of new TSE board

Add TSE

Add TSE board with the defined node ID (see above)

Remove PCB

With this menu item an unused car panel unit TSE will be deleted (it

will delete all input-output functions of the TSE)

Node ID

Node ID of the TSE which will be deleted

Remove TSE

TSE to be deleted with the above entered number

Copy PCB

Copy all parameters of one TSE to another

Source ID

Number of TSE, of which the parameters are to be copied

Target ID

Number of TSE, to which the parameters are to be copied

Copy parameter

Copy parameters from source to destination TSE

ESE in-/outputs

Function of the inputs and outputs of the landing panel unit ESE

ESE 1.1

ESE 1.1 Inputs

…

1:

Function of input 1 of ESE1, branch 1

…

…

Page 34

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

34/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

8:

Function of input 8 of ESE1, branch 1

ESE 1.1 Outputs

1:

Function of output 1 of ESE1, branch 1

… …

8:

Function of output 8 of ESE1, branch 1

…

ESE 64.8

ESE64.8 Inputs

1:

Function of input 1 of ESE64, branch 8

… …

8:

Function of input 8 of ESE64, branch 8

ESE64.8 Outputs

1:

Function of output 1 of ESE64, branch 8

… …

8:

Function of output 8 of ESE64, branch 8

Add PCB

With this menu item another landing panel unit ESE can be added

(max. 512).

Finally the new ESE is only added if at least 1 input or output function

is defined for this TSE.

Node ID

Set node ID of new ESE board

Branch No.

Set branch number of new ES E board

Add ESE

Add ESE board with the defined node ID and branch number (see

above)

Remove PCB

With this menu item an unused landing panel unit ESE will be deleted

(it will delete all input-output functions of the ESE)

Node ID

Node ID of the ESE which will be deleted

Branch No.

Branch numnber of the ESE which will be deleted

Remove ESE

Remove ESE with the above entered node ID and branch number

Copy PCB

Copy all parameters of one ESE to another

Source ID

Node ID of ESE, of which the parameters are to be copied

Page 35

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

35/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

Target ID

Node ID of ESE, to which the parameters are to be copied

Source Branch

Branch number of ESE, of which the parameters are to be copied

Target Branch

Branch number of ESE, to which the parameters are to be copied

Copy parameter

Kopieren der Parameter von Quell- zu Ziel-ESE

Special param.

Parameters for special control functions

Special run adj.

Parameters for special trips

Finish trip

ja: The actual trip is first finished before the special drive mode is

started.

nein: The lift stops at the next possible floor and goes as fast as

possible in special drive mode.

CC Prior.[s]

After the lift has approached a floor by a special landing call, the lift

waits the time which is set . Then he goes, if no special trips in the car

operating panel were activated back to normal operation.

CC if active

yes: Special car calls can only be entered if the special drive mode is

activated via a switch inside the car.

no: Special car calls can be entered within the time "CC enable" (see

below); there is no additional activation switch required

CC enable[s]

After the lift has approached a floor by a special landing call or a

special trip input has been activated inside the car, special trips can

be started within this time by pressing any car calls. After this time, all

calls are locked again until the special trip input is activated again

inside the car.

f this value is set to 0, then special trips can be started via the car calls

without time limitation.

->normal [s]

After the lift has finished the special trip, the lift returns back to

normal operation after this time, except a new special car call has

been entered inside this time.

Land.CC canc.

yes: All car calls are deleted after the lift has approached a floor by a

special landing call.

no: The lift will keep all already entered car calls and will handle them

once the lift returned back to normal operation.

LC disable

yes: All landing calls are deleted and blocked when the lift is in special

run mode.

no: Existing landing calls are already stored and new landing calls are

taken , but only approached once the lift has returned to normal

operation.

CarC.canc.

on: All car calls are deleted when the special trip switch inside the car

Page 36

INTEC GmbH

22/12/2016 Lift controller MLC 8000

Operating manual V2.0

36/196

1. Menu level

2. Menu level

3. Menu level

4. Menu level

Description

is turned on.

off: All car calls are deleted when the special trip switch inside the car

is turned off.

on+off: All car calls are deleted when the special trip switch inside the

car is turned on or turned off.

no: Car calls will not be deleted when the special trip switch inside the

car is turned on or turned off.

Max. CC no.

Max. Number of special car calls that can be entered in the special trip

mode at the same time.

If this value is set to 0, then the number of special car calls is not

limited.

All.norm.CC

yes: If the lift is in special trip mode, but special car calls currently

disabled (see above), then new pressed car calls will be stored as

standard car call and will be handled once the lift went back to normal

operation.

no: If the lift is in special trip mode, but special car calls currently

disabled (see above), then all car calls completely disabled.

Call no door

yes: Lift will go to a floor by a special car call, even if non of the called

doors in this floor are enabled.

no: Lift will ignore special car calls, if non of the called doors in this

floor are enabled.

Park doors

Enabled: If starting park state (no new call is pressed; see Timer

parameter above) all enabled door will stay open

Called: If starting park state (no new call is pressed; see Timer

parameter above) all doors opened by last call will stay open.

Doors locked

If setting to "yes" never 2 or more car doors will stay open at the very

same time in special trip mode.

VIP run adj.

Parameters for VIP run

…

See parameter for special run above