Doc. CV / CR 3.3

January 2018

User & Installation Manual

intarblock

MCV-N, MCV-C

BCV-N, BCV-C

MCV-I, BCV-I

intartop

MCR-N, MCR-C

BCR-N, BCR-C

2

I. Quick Start Guide

Congratulations! You have acquired a high quality cooling unit. Your INTARBLOCK and INTARTOP

units are specially designed to equip positive temperatura cold romos in the range from -5ºC (23ºF) to

+10 ºC (50ºF), and from -15ºC (5ºF) to -25ºC (13ºF), depending on the range.

Once installed, your INTARSPLIT unit can be fully operated from the remote keyboard. The control

keyboard has the following functions and characteristics.

The unit has four operation modes:

Refrigeration mode.- this is the normal operation mode. The display shows the room temperature

and by pressing the set key the target temperature is shown. During the operation the electronic

control keeps a record of the maximum and minimum room temperature ever measured, which can be

consulted at any time.

Defrost mode.- the time on time your unit will switch to the defrost mode to eliminate the frost that has

formed on the evaporator. You can also force a defrost cycle by pressing the corresponding key.

Fast cooling mode.- If you like you can activate this operation mode during the start-up of the cold

room. The unit will run continuously for the preset time in parameter “CCt”, even beyond the target

temperature.

Energy saving mode.- If you like you can activate or deactivate this operation mode to save energy

during the night or when the room will stay closed for a long time. By activating this function the target

temperature is increased according to preset value in parameter “HES”.

Press for 3 seconds

to

activate the energy

saving function

Press to switch on

and off the room light

Press for 3 seconds

to force a defrost

cycle

Press to visualise

minimum temperature

record

Press to visualise the

target temperature,

which can be modified

by pressing or

Press to visualise

maximum temperature

record

Press to turn on and

off the unit

DIGITAL DISPLAY

It shows the room

temperature.

By pressing the set key

it will show the target

temperature.

Operation LEDs

intarblock | intartop

3

Basic keyboard functions.-

To switch ON and OFF the instrument.

To switch ON and OFF the room light.

To visualise maximum room temperature record

In programming mode it increases the displayed value or explores the parameter list.

by pressing the key for 3 seconds the fast cooling cycle starts.

To visualise minimum room temperature record

In programming mode it decreases the displayed value or explores the parameter list.

To display and modify target set point; in programming mode it selects a parameter or

confirm an operation.

By holding it pressed for 3s when max or min temperature is displayed it will be erased.

By holding it pressed for 3s a manual defrost cycle starts.

By holding it pressed for 3s Energy Saving function is activated or deactivated.

II. CONTENTS

1. DESCRIPTION ........................................................................................................................ 4

2. IDENTIFICATION .................................................................................................................... 4

3. OPERATION............................................................................................................................ 5

4. OPERATION LIMITS ............................................................................................................... 6

5. COMPOSITION ....................................................................................................................... 7

6. TESTS ..................................................................................................................................... 8

7. SAFETY DEVICES .................................................................................................................. 8

8. MCV SERIES TECHNICAL FEATURES ................................................................................ 9

9. BCV SERIES TECHNICAL FEATURES ............................................................................... 11

10. MCR SERIES TECHNICAL FEATURES .............................................................................. 12

11. BCR SERIES TECHNICAL FEATURES ............................................................................... 14

12. COOLING CAPACITY R404A ............................................................................................... 15

13. COOLING CAPACITY R134a ............................................................................................... 15

14. DIMENSIONS ........................................................................................................................ 18

15. ELECTRICAL CONNECTIONS ............................................................................................. 20

16. EMERGENCY SYSTEM........................................................................................................ 21

17. SOUND PRESSURE LEVEL ................................................................................................ 21

18. TRANSPORT......................................................................................................................... 21

19. DATA PLATE ......................................................................................................................... 22

20. SAFETY RECOMMENDATIONS .......................................................................................... 22

21. INSTALLATION AND MOUNTING........................................................................................ 23

22. START-UP ............................................................................................................................. 27

23. MAINTENANCE .................................................................................................................... 28

24. REFRIGERANT LOAD .......................................................................................................... 29

25. DISPOSAL MANAGEMENT .................................................................................................. 30

26. CONTROL ............................................................................................................................. 30

27. PARAMETER LIST ................................................................................................................ 33

28. FAULT ANALYSIS ................................................................................................................. 37

29. GUARANTEE ........................................................................................................................ 40

4

1. DESCRIPTION

INTARBLOCK and INTARTOP units are monoblock refrigeration units in vertical and roof construction,

fullly tested and adjusted in Factory. They are assembled on a prelacquered galvanised steel shell and

have been designed for indoor installation, with easily removable panels to give access to fans,

refrigerant circuit, and electric board.

INTARBLOCK:

MCV Series are designed for positive temperature refrigeration applications from -5ºC (23ºF) to +10ºC

(50ºF) and consist of 12 models to cover a cooling capacity range from 0.5 kW to 3 kW

BCV Series are designed for positive temperature refrigeration applications from -15ºC (5ºF) to -25ºC

(13ºF) and consist of 9 models to cover a cooling capacity range from 0.4 kW to 2,5 kW

INTARTOP:

MCV Series are designed for positive temperature refrigeration applications from -5ºC (23ºF) to +10ºC

(50ºF) and consist of 10 models to cover a cooling capacity range from 0.5 kW to 2,5 Kw

BCR Series are designed for positive temperature refrigeration applications from -15ºC (5ºF) to -25ºC

(13ºF) and consist of 6 models to cover a cooling capacity range from 0.4 kW to 1,7 kW

- NF version – featuring axial condensation fan,

- CF version – featuring centrifugal condensation fan for ducted air extraction.

2. IDENTIFICATION

INTARBLOCK and INTARTOP series are identified according to the following nomenclature on the

product data plate.

M C V - N F - 1 024

Compressor capacity

Construction size

R-404A refrigerant

Vertical construction

Compact construction

(N) Standard (C) Centrifugal

Medium temperature

intarblock | intartop

5

3. OPERATION

INTARBLOCK and INTARTOP are refrigeration machines operating under a vapour compression

cycle.

Refrigeration cycle

The refrigeration cycle uses a phase change refrigerant fluid in a closed circuit, with the following four

steps:

Expansion: refrigerant expansion takes place in the capillary tube between high and low pressure

sections. During the expansion, liquid refrigerant cools down to the evaporating temperature.

Evaporation: In the evaporator the refrigerant evaporates under constant temperature and pressure

absorbing heat from the cold room. Once the refrigerant vapour has been fully evaporated, it is slightly

overheated beyond the evaporation temperature.

Compression: The resultant refrigerant vapour is suctioned from the evaporator by the compressor

through the suction line. The compressor compresses the refrigerant vapour up to high pressure and

temperature.

Condensation: the hot high pressure gas is desuperheated and condensed, at a constant pressure

and temperature, in the el condenser by exhausting the latent evaporation to the outer ambient. Once

the refrigerant has been fully condensed, the liquid refrigerant is overcooled beyond the condensing

temperature.

High pressure liquid refrigerant is then driven to the capillary tube, and therefore closing the circuit.

Defrost cycle

Because of the evaporator temperature can be below 0ºC (32ºF), frost is likely to deposit on the

evaporator surface through the condensation of the water vapour contained in the air. To prevent the

air flow from being obstructed with the consequently loss of performance, the instrument switches

automatically to the defrost operation mode every given period of time.

During the defrost cycle, by opening the solenoid valve, part of the hot gas from the compressor

discharge is injected into the evaporator. The evaporator temperature is rapidly increased in order to

melt the frost on it while the inside fan is off.

The defrost water is collected in the drain tray and conducted to the drain bucket. This drain bucket

contains a hot gas coil to progressively evaporate the drain water to the outer ambient.

6

4. OPERATION LIMITS

INTARBLOCK and INTARTOP units are designed for continuous operation within the following

temperature limits:

Cold Room Temperature

Ambient Temperature

Max

Min Max

Min

MCV +10 ºC (50ºF) -5 ºC (23ºF) +45 ºC (113ºF) +15 ºC (59ºF)

BCV -15 ºC (5ºF) -25 ºC (-13ºF) +45 ºC (113ºF) +15 ºC (59ºF)

MCR 10 ºC (50ºF) -5 ºC (23ºF) +45 ºC (113ºF) +15 ºC (59ºF)

BCR -15 ºC (5ºF) -25 ºC (-13ºF) +45 ºC (113ºF) +15 ºC (59ºF)

The unit should work beyond these limits only for short periods of time or during the start-up.

AP

BP

SOLENOID

VALVE

COMPRESSOR

DRAIN BUCKET

EVAPORATOR

CONDENSER

DRAIN TRAYFILTER

AP

BP

PRESSURE

REGULATOR

(only BCV/BCR)

CAPILLARY TUBE /

THERMOSTATIC

EXPANSION VALVE

intarblock | intartop

7

5. COMPOSITION

MCV / BCV units are built on a self-contained construction. The components are assembled on a steel

structure and covered with a prelacquered galvanised steel shell. It consists of:

Refrigerant circuit

§ Hermetic reciprocating compressor with internal protection, assembled on silentblocs

§ R404-A or R134a refrigerant load.

§ HP and LP pressure switches.

§ HP and LP load nipples.

§ Thermostatic expansion valve (capillary tube in medium temperature models with power lower

than 1,5 HP (R404A) and 1 HP (R134a).

§ Antiacid dehydrating filter.

§ Evaporation coil in copper tubes and aluminium fins with stainless steel drain tray.

§ Condensation coil in copper tubes and aluminium fins.

§ Solenoid valve for the hot gas bypass.

§ Water drain bucket including hot gas coil for the automatic evaporation of drain water.

Air circuits

N/I version:

§ Direct driven axial fans with single phase motor. Dynamically equilibrated blades with protection

grill.

C version:

§ Direct driven centrifugal fans with single phase motor. Dynamically equilibrated rotor.

Electric board

§ Circuit breaker protection

§ Electric control XW270K with the following elements and features:

- transformer 230 VAC / 12 VCC,

- microprocessor,

- alarm relay,

- compressor relay,

- defrost relay,

- evaporator fan relay,

- cold room light relay,

- condenser fan relay,

- door switch digital input

- H/LP pressure switch input

- inside temperature NTC probe

- outside temperature NTC probe

- defrost NTC probe

- RS485 connection,

- programming key connection,

8

- V820 keyboard.

§ Compressor permanent condenser in single phase units.

§ Compressor start relay and condenser in single phase units.

§ Ground connection for compressor and motorfans.

§ Cold room light.

§ Door microswitch connection.

§ Door microswitch (as an option).

§ Door heating cable (only for BCV and BCR models).

§ Crankcase heater (as an option).

§ Draining pipe heating cable (only for BCV y BCR models).

6. TESTS

Every INTARBLOCK and INTARTOP units have been previously checked and tested in factory

according to the following test protocol:

§ Helium leak-proof test. A leak-proof certificate is supplied upon request.

§ Refrigerant load.

§ Operation test for refrigeration and defrost modes under nominal operating conditions.

§ Safety devices checking

7. SAFETY DEVICES

INTARBLOCK and INTARBLOCK units feature the following safety devices:

§ HP and LP pressure limit switches to protect the unit against unusual pressure levels.

§ Thermal switches with automatic restart in compressor and fans to protect motor wirings from

overloads.

§ Circuit breaker protection

§ Common ground connection.

intarblock | intartop

9

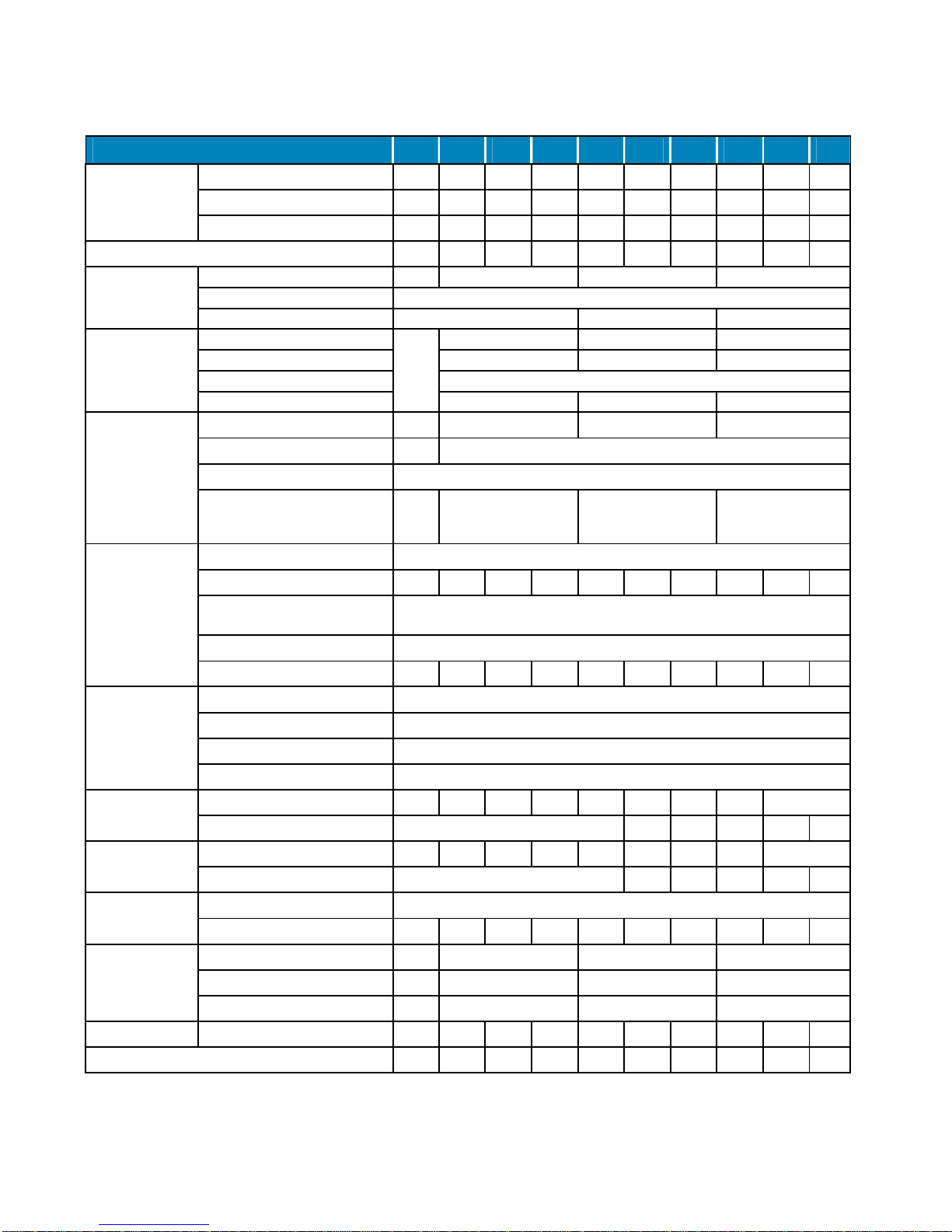

8. MCV SERIES TECHNICAL FEATURES

(1) Cooling capacity under cold room temperature of 0 ºC (32 ºF) and ambient temperature of 35 ºC (95 ºF).

(2) Total absorbed power by compressor and fans under nominal condition (axial version).

(3) As defined by RD138/2011. IF-01.

(4) Maximum absorbed current even beyond compressor operation limits (axial version).

MCV Series R404A

0008 0010 0012 1010 1012 1014 1016 1018 1024 2024 2026 2034 3034 3038

Cooling

capacity

Cooling capacity (1) (W) 610 728 808 799 930 1077 1184 1347 1468 1917 2149 2391 2690 3020

Absorbed power (2) (W) 470 570 640 649 672 804 869 1020 1175 1356 1474 1946 2070 1970

COP performance 1,30 1,28 1,27 1,23 1,38 1,34 1,36 1,32 1,25 1,41 1,46 1,23 1,30 1,53

Installed power (3) (kW) 0,53 0,73 0,86 0,75 0,82 0,98 1,10 1,38 1,68 1,68 1,89 2,63 2,63 2,35

Condenser

fan

NF version

Nominal air flow rate (m3/h)

375

575 1000 1350

Type Axial

Power (W) - r.p.m

85W @ 1300

2 x 85W @ 1300 2x70W@1300

Condenser

fan

CF version

Nominal air flow rate (m3/h)

-

575 1000 1350

Available static pressure (Pa) 45 90 120

Type Centrifugal

Power (W) 45 W 105 W 2 x 105 W

Evaporator

fan

Nominal air flow rate (m3/h) 300 550 1050 1400

Range (m) 3 4

Type Axial

Power (W) - r.p.m 47W @ 2500 62W @ 2600 2 x 62W @ 2600 2x70W@2600

Compressor

Type Hermetic reciprocating

Swept volume (m3/h) 1,16 1,54 1,79 1,64 1,96 2,32 2,65 3,18 4,21 4,21 4,52 6,01 6,01 6,60

Nominal discharge pressure

(bar rel.)

20

Nominal suction pressure (bar

rel.)

3,40

Nominal power (CV) 1/3 3/8 1/2 3/8 1/2 1/2 5/8 3/4 1 1 1 1/4 1 1/2 1 1/2 1 3/4

High

pressure

switch

Type ACB

Brand Danfoss

Model 061F8175

Cut out (bar rel.) 28

Max.

absorbed

intensity

(A)(4)

230 V / I ph / 50 Hz 4,5 5,9 6,7 5,1 6,1 6,7 7,6 8,9 11,1 11,9 12,3 16,9 17,1 N/D

400 V / III ph / 50 Hz Not available 5,7 6,5 6,7 7,9

Starting-up

intensity (A)

230 V / I ph / 50 Hz

16,3 18,8 20,2 16,9 17,9 20,9 23,5 30,9 34,4 35,2 33,7 46,7 46,9 N/D

400 V / III ph / 50 Hz Not available 19,7 24,7 24,9 17,9

Refrigerant

Type R-404A / Group L1 / GWP-100: 3922

Load (kg) 0,50 0,50 0,56 0,70 0,70 0,70 0,78 0,76 0,76 1,00 0,98 1,10 1,66 1,50

Dimensions

Length (mm)

556 854 854 879

Wide (mm) 420 400 620 735

Height (mm) 683 880 920 920

Weight (kg) 35 37 38 59 60 60 69 70 70 88 89 89 117 114

Sound pressure level db(A) 30 30 30 31 31 32 34 35 35 36 38 40 39 40

10

(1) Cooling capacity under cold room temperature of 0 ºC (32 ºF) and ambient temperature of 35 ºC (95 ºF).

(2) Total absorbed power by compressor and fans under nominal condition (axial version).

(3) As defined by RD138/2011. IF-01.

(4) Maximum absorbed current even beyond compressor operation limits (axial version).

MCV series R134a

0010 0015

1015 1026 1033 2033 2053 3053

3074

3108

Cooling capacity

Cooling capacity (1) (W) 610 794 972

1281 1454 1790 2153 2489

3239

3927

Absorbed power (2) (W)

430 530 570 810 920

1090 1460 1510

1890

2480

COP performance 1,42 1,50 1,71 1,58 1,58 1,64 1,47 1,65 1,71 1,58

Installed power (3) (kW) 0,59 0,83 0,83 1,22 1,44 1,44 2,2 2,2 2,9 4,4

Condenser fan

NY version

Nominal air flow rate (m3/h) 375 575 950 1150

Type

Axial

Power (W) - r.p.m 85 W @ 1300

1300

2x 70 W @ 1300

Condenser fan

CY version

Nominal air flow rate (m3/h) 375 575 950 1150

Available static pressure (Pa) 120

Type Centrifugal

Power (W) 180 W 220 W 2x 200W 2x 200W

Evaporator fan

Nominal air flow rate (m3/h) 300 500 950 1300

Range (m) 3 4

Type Axial

Power (W) - r.p.m 47W @ 2500 62W @ 2600

2x 62W @

2600

2x 70W @ 2600

Compressor

Type Hermetic reciprocating

Swept volume (m3/h) 2,08 3,18 3,18 4,51 5,69 5,69 9,26 9,26 12,92

Nominal discharge pressure (bar rel.) 10

Nominal suction pressure (bar rel.) 1

Nominal power (CV) 3/8 1/2 1/2 3/4 1 1

1 1/2 1 1/2

2 5

High pressure switch

Type ACB

Brand Danfoss

Model 061F6147

Cut out (bar rel.) 20

Max. absorbed

intensity (A)(4)

230 V / I ph / 50 Hz 5,9 6,9 7,0 10,7 10,9

11,17

13,77

14,19

19,74 -

400 V / III ph / 50 Hz Not available 18,5

Starting-up intensity

(A)

230 V / I ph / 50 Hz 13,2 20,7 20,7 27,0 30,0 30,0 46,0 46,0 55,0 400 V / III ph / 50 Hz Not available 65

Refrigerant

Type R-134a / Group A1 / GWP-100: 1430

Load (kg) 0,56 0,62 0,64 0,64 0,70 0,90 0,90 1,30 1,20 1,40

Dimensions

Length (mm) 306+250 340+514 340+514 365+514

Wide (mm) 420 400 620 735

Height (mm) 683 880 920 940

Weight (kg) 36 38 60 69 70 88 89 117 114 116

Sound pressure level db(A) 28 29 29 34 34 35 39 38 41 43

intarblock | intartop

11

9. BCV SERIES TECHNICAL FEATURES

(1)

Cooling capacity under cold room temperature of -20 ºC (-4 ºF) and ambient temperature of 35 ºC (95 ºF).

(2) Total absorbed power by compressor and fans under nominal condition (axial version).

(3) As defined by RD138/2011. IF-01.

(4) Maximum absorbed current even beyond compressor operation limits (axial version).

BCV Series R404A

0018

1018 1026 1034 2034 2054 2074 3074 3086 3096

Cooling capacity

Cooling capacity (1) (W)

479 489 720 866 1048 1349 1633 1930 2270 2460

Absorbed power (2) (W) 620 688 914 1136 1187 1685 2014 2380 2320 2640

COP performance 0,77 0,73 0,79 0,76 0,88 0,80 0,81 0,81 0,98 0,93

Installed power (3) (kW) 0,87 0,88 1,29 1,76 1,76 2,60 3,39 3,39 3,46 4,31

Condenser fan

NF version

Nominal air flow rate (m3/h)

375 575 1000 1350

Type Axial

Power (W) - r.p.m 85W @ 1300 2 x 85W @ 1300 2 x 70W @ 1300

Condenser fan

CF version

Nominal air flow rate (m3/h)

-

575 1000 1350

Available static pressure (Pa)

45 90 120

Type Centrifugal

Power (W) 45 W 105 W 2 x 105 W

Evaporator fan

Nominal air flow rate (m3/h) 300 550 1050 1400

Range (m) 3 4

Type Axial

Power (W) - r.p.m

47W

@

2500

62W @ 2600 2 x 62W @ 2600 2 x 70W @ 2600

Compressor

Type Hermetic reciprocating

Swept volume (m3/h) 3,18 3,18 4,57 6,01 6,01 9,25 12,91 12,91 11,80 16,70

Nominal discharge pressure (bar

rel.)

20

Nominal suction pressure (bar rel.) 1,30

Nominal power (CV) 5/8 5/8 3/4 1 1/4 1 1/4 1 3/4 2 1/2 2 1/2 3 3 1/2

High pressure

switch

Type ACB

Brand Danfoss

Model 061F8175

Cut out (bar rel.) 28

Max. absorbed

intensity (A)(4)

230 V / I ph / 50 Hz 4,8 7,2 8,4 10,9 11,7 17,7 25,7 25,9 No disponible

400 V / III ph / 50 Hz Not available 6,5 7,2 7,4 10,3 12,0

Starting-up

intensity (A)

230 V / I ph / 50 Hz 21,9 21,9 29,9 40,9 41,7 69,7 82,7 82,9 No disponible

400 V / III ph / 50 Hz Not available 24,7 29,7 29,9 26,9 33,9

Refrigerant

Type R-404A / Group L1 / GWP-100: 3922

Load (kg) 0,60 0,70 0,70 0,60 1,15 1,05 1,10 1,50 1,50 1,20

Dimensions

Length (mm) 556 854 854 879

Wide (mm) 420 400 620 735

Height (mm) 683 880 920 920

Weight (kg) 38 59 60 60 89 102 102 131 117 129

Sound pressure level db(A) 33 38 38 40 41 42 43 43 40 50

12

10. MCR SERIES TECHNICAL FEATURES

(1) Cooling capacity under cold room temperature of 0 ºC (32 ºF) and ambient temperature of 35 ºC (95 ºF).

(2) Total absorbed power by compressor and fans under nominal condition (axial version).

(3) As defined by RD138/2011. IF-01.

(4) Maximum absorbed current even beyond compressor operation limits (axial version).

MCR Series R404A

0008 0010 0012

1010 1012 1014 1016 1018 1024 2024 2026 2034

Cooling

capacity

Cooling capacity (1) (W) 612 738 838 799 930 1087 1194 1378 1478 2020 2223 2527

Absorbed power (2) (W) 470 580 650 652 672 811 880 1038 1201 1319 1425 1903

COP performance 1,30 1,27 1,29 1,23 1,38 1,34 1,36 1,33 1,23 1,53 1,56 1,33

Installed power (3) (kW) 0,53 0,73 0,86 0,75 0,82 0,98 1,10 1,38 1,68 1,68 1,89 2,63

Condenser

fan

NF version

Nominal air flow rate (m3/h) 375 575 1150

Type Axial

Power (W) - r.p.m 85 W @ 1300 rpm 120W @ 1300 rpm

Condenser

fan

CF version

Nominal air flow rate (m3/h)

-

575 1150

Available static pressure (Pa) 45

Type Centrifugal

Power (W) 45 W @ 1300 rpm 105 W @ 1300 rpm

Evaporator

fan

Nominal air flow rate (m3/h) 300 600 1150

Range (m) 3 4

Type Axial

Power (W) - r.p.m 47@ 2500 rpm 62W @ 2600 rpm

2x 62W @ 2600

rpm

Compressor

Type Hermetic reciprocating

Swept volume (m3/h) 1,16 1,54 1,79 1,64 1,96 2,32 2,65 3,18 4,21 4,21 4,52 6,01

Nominal discharge pressure (bar

rel.)

20

Nominal suction pressure (bar

rel.)

3,40

Nominal power (CV) 1/3 3/8 1/2 3/8 1/2 1/2 5/8 3/4 1 1 1 1/4 1 1/2

High pressure

switch

Type ACB

Brand Danfoss

Model 061F8175

Cut out (bar rel.) 28

Max.

Absorbed

intensity(4)(A)

230 V / I ph / 50 Hz 4,5 5,9 6,7 5,1 6,1 6,7 7,6 8,9 11,1 11,6 12,0 16,6

400 V / III ph /50 Hz Not available 5,4 6,2

Starting up

intensity (A)

230 V / I ph / 50 Hz 16,3 18,8 20,2 16,9 17,9 20,9 23,5 30,9 34,4 34,9 33,4 46,4

400 V / III ph /50 Hz

Not available 19,4 24,4

Refrigerant

Type R-404A / Group L1 / GWP-100: 3922

Load (kg) 0,50 0,50 0,50 0,80 0,70 0,80 0,83 0,76 0,86 1,10 1,05 1,10

Dimensions

Length (mm) 790 850 850

Wide (mm)

600 665 835

Height (mm) 480 385+189 468+189

Weight (kg) 62 64 65 73 73 73 82 83 83 98 99 99

Sound pressure level db(A) 30 30 30 32 32 32 34 35 35 36 38 40

intarblock | intartop

13

(1) Cooling capacity under cold room temperature of 0 ºC (32 ºF) and ambient temperature of 35 ºC (95 ºF).

(2) Total absorbed power by compressor and fans under nominal condition (axial version).

(3) As defined by RD138/2011. IF-01.

(4) Maximum absorbed current even beyond compressor operation limits (axial version).

MRC series R134a 0010 0015 1015 1026 1033 2033 2053 2074

Cooling capacity

Cooling capacity (1) (W) 605 788 999 1265 1502 1911 2352 2940

Absorbed power (2) (W) 430 530 580 930 1050 1210 1670 1830

COP performance 1,41 1,48 1,72 1,36 1,43 1,58 1,41 1,61

Installed power (3) (kW) 0,83 0,83 1,22 1,44 1,44 2,2 2,9

Condenser fan

NF version

Nominal air flow rate (m3/h) 375 575 1000

Type Axial

Power (W) - r.p.m 85 W @ 1300 120 W @ 1300

Condenser fan

CF version

Nominal air flow rate (m3/h) 375 575 1000

Available static pressure (Pa) 120

Type Centrifugal

Power (W) 180 W 220 W 2x 200 W

Evaporator fan

Nominal air flow rate (m3/h) 300 600 1150

Range (m) 4

Type Axial

Power (W) - r.p.m

47W @ 2500

62W @ 2600 2x 62W @ 2600

Compressor

Type Hermetic reciprocating

Swept volume (m3/h) 2,08 3,18 3,18 4,51 5,69 5,69 9,26 12,92

Nominal discharge pressure (bar rel.) 10

Nominal suction pressure (bar rel.)

1

Nominal power (CV) 3/8 1/2 1/2 3/4 1 1 1 1/2 2

High pressure switch

Type ACB

Brand Danfoss

Model 061F6147

Cut out (bar rel.) 20

Max. Absorbed intensity(4)(A)

230 V / I ph / 50 Hz 5,94 6,94 7,00 10,70 10,90 11,17 13,7 11,77

400 V / III ph /50 Hz Not available

Starting up intensity (A)

230 V / I ph / 50 Hz 16 22 22 29 30 30 46 55

400 V / III ph /50 Hz Not available

Refrigerant

Type R-134a / Grupo A1 / PCA-100: 1430

Load (kg) 0,46 0,50 0,70 0,70 0,60 1,00 1,00 1,10

Dimensions

Length (mm) 790 850 850

Wide (mm) 600 665 835

Height (mm) 330+100 385+135 469+135

Weight (kg) 62 65 73 82 83 98 99 110

Sound pressure level db(A) 30 30 28 34 34 35 39 41

14

11. BCR SERIES TECHNICAL FEATURES

(1) Cooling capacity under cold room temperature of 0 ºC (32 ºF) and ambient temperature of 35 ºC (95 ºF).

(2) Total absorbed power by compressor and fans under nominal conditions.

(3) As defined by RD138/2011. IF-01.

(4) Maximum absorbed current even beyond compressor operation limits (axial version)

BCR Series R404A 0008 1018 1026 1034 2034 2054 2074

Cooling capacity

Cooling capacity (1) (W) 515 502 734 876 1102 1443 1689

Absorbed power (2) (W) 630 671 928 1160 1297 1830 2147

COP performance

0,81 0,75 0,79 0,76 0,85 0,79 0,79

Installed power (3) (kW) 0,87 0,88 1,29 1,76 1,76 2,60 3,39

Condenser fan

NF version

Nominal air flow rate (m3/h) 375 575 1150

Type Axial

Power (W) - r.p.m

85 W @ 1300 rpm 120 W @ 1300 rpm

Condenser fan

CF version

Nominal air flow rate (m3/h)

-

575 1150

Available static pressure (Pa) 45

Type Centrifugal

Power (W) 45 W @ 1300 rpm 105 W @ 1300 rpm

Evaporator fan

Nominal air flow rate (m3/h) 300 600 1150

Range (m) 3 4

Type Axial

Power (W) - r.p.m

47 W @

2500rpm

62 W @ 2600 rpm 2 x 62 W @ 2600 rpm

Compressor

Type Hermetic reciprocating

Swept volume (m3/h) 3,18 3,18 4,57 6,01 6,01 9,25 12,91

Nominal discharge pressure (bar

rel.)

20

Nominal suction pressure (bar rel.) 1,30

Nominal power (CV) 5/8 5/8 3/4 1 1/4 1 1/4 1 3/4 2 1/2

High pressure

switch

Type ACB

Brand Danfoss

Model 061F8175

Cut out (bar rel.) 28

Max. absorbed

intensity (A)

230 V / I ph / 50 Hz 4,8 7,2 8,4 10,9 11,4 17,4 25,4

400 V / III ph / 50 Hz Not available 6,21 6,91

Starting-up

intensity (A)

230 V / I ph / 50 Hz 21,9 21,9 29,9 40,9 41,4 69,4 82,4

400 V / III ph /50 Hz Not available 24,4 29,4

Refrigerant

Type R-404A / Grupo L1 / PCA-100: 3260

Load (kg) 0,64 0,75 0,75 0,80 1,20 1,00 1,10

Dimensions

Length (mm) 790 850 850

Wide (mm) 600 665 835

Height (mm) 480 385+189 468+189

Weight (kg) 65 83 84 84 135 145 145

Sound pressure level db(A) 33 38 38 40 41 42 43

intarblock | intartop

15

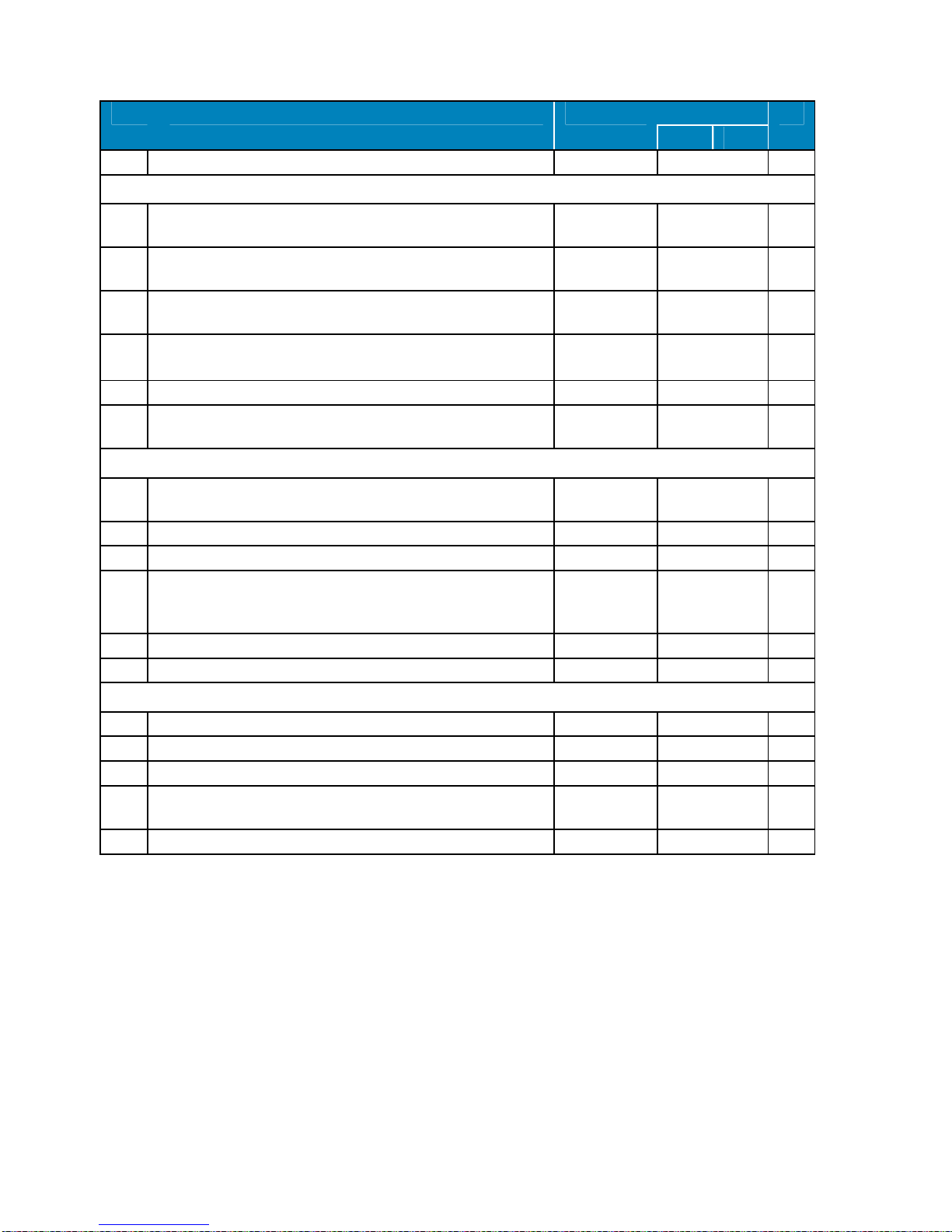

12. COOLING CAPACITY R-404A

§ MCV series

Capacity (W)

Cold room temperature

-5 ºC 0 ºC +5 ºC +10 ºC

MCV series

Cooling

capacity

(W)

Absorbed

power (W)

Cooling

capacity

(W)

Absorbed

power (W)

Cooling

capacity

(W)

Absorbed

power (W)

Cooling

capacity

(W)

Absorbed

power (W)

Ambient Temp: 35 ºC

0008

502 446 610 470 738 506 860 534

0010

604 533 728 570 871 624 1012 666

0012

568 619 808 676 961 706 1118 759

1010

630 613 801 649 966 683 1157 722

1012

767 631 930 672 1118 714 1317 763

1014

893 756 1077 804 1270 858 1485 920

1016

985 800 1184 869 1386 939 1615 1018

1018

1138 940 1347 1020 1570 1104 1806 1200

1024

1207 1049 1468 1175 1739 1305 2039 1450

2024

1554 1245 1917 1356 2296 1464 2726 1579

2026

1795 1368 2149 1474 2526 1584 2945 1707

2034

1996 1805 2391 1946 2801 2102 3247 2282

3034

2230 1925 2690 2070 3200 2220 3730 2390

3038

2500 1830 3020 1970 3580 2110 4220 2270

§ BCV series

Capacity (W)

Cold room temperature

-25 ºC -20 ºC -15 ºC

MCV series

Cooling capacity

(W)

Absorbed power

(W)

Cooling capacity

(W)

Absorbed power

(W)

Cooling capacity

(W)

Absorbed power

(W)

Ambient Temp: 35 ºC

0018

379 565 479 620 591 694

1018

383 611 489 668 655 747

1026

548 802 720 914 877 1015

1034

668 986 866 1136 1023 1254

2034

793 1196 1048 1334 1297 1463

2054

963 1592 1349 1832 1655 2026

2074

1338 1931 1633 2161 1963 2405

3074

1430 2070 1930 2380 2320 2660

3086

1630 2000 2270 2320 2810 2560

3096

1890 2280 2460 2640 3040 2970

16

§ MCR Series

Capacity (W)

Cold room temperature

-5 ºC 0 ºC +5 ºC +10 ºC

MCR Series

Cooling

capacity

(W)

Absorbed

power (W)

Cooling

capacity

(W)

Absorbed

power (W)

C

ooling

capacity

(W)

Absorbed

power (W)

Cooling

capacity

(W)

Absorbed

power (W)

Ambient Temp.: 35 ºC

0008

508 455 612 470 720 521 851 547

0010

621 537 738 580 901 629 1055 681

0012

701 598 838 650 1012 712 1163 766

1010

630 617 801 652 966 682 1157 727

1012

767 637 930 672 1118 717 1317 772

1014

916 761 1087 811 1275 867 1479 929

1016

1005 811 1194 880 1402 953 1628 1031

1018

1161 957 1378 1038 1579 1118 1828 1211

1024

1217 1070 1478 1201 1782 1335 2062 1462

2024

1625 1201 2020 1319 2402 1409 2888 1527

2026

1849 1324 2223 1425 2646 1531 3077 1648

2034

2080 1768 2527 1903 2987 2059 3380 2190

§ BCR Series

Capacity (W)

Cold room temperature

-25 ºC -20 ºC -15 ºC

BCR Series

Cooling

capacity (W)

Absorbed power

(W)

Cooling capacity

(W)

Absorbed power

(W)

Cooling capacity

(W)

Absorbed power

(W)

Ambient Temp:

35 ºC

0018

405 570 515 630 618 700

1018

407 618 502 671 664 752

1026

565 813 734 928 908 1039

1034

699 1015 876 1160 1051 1287

2034

840 1157 1102 1297 1366 1433

2054

1116 1617 1443 1830 1733 2005

2074

1425 1932 1689 2147 2088 2416

intarblock | intartop

17

13. COOLING CAPACITY R-134a

· Serie MCV

Capacity (W)

Cold room temperature

0 ºC +5 ºC +10 ºC

MCV Series

Cooling

capacity (W)

Absorbed

power (W)

Cooling

capacity (W)

Absorbed

power (W)

Cooling

capacity (W)

Absorbed

power (W)

Ambient Temp: 35 ºC

0010

610 437 758 477 907 508

0015

794 532 961 587 1139 642

1015

972 572 1199 622 1453 672

1026

1281 812 1565 892 1859 972

1033

1454 922 1743 1012 2037 1112

2033

1790 1099 2163 1184 2573 1274

2053

2153 1464 2609 1634 3103 1809

3053

2489 1515 3103 1700 3743 1870

3074

3239 1895 3938 2145 4667 2400

3108

3927 2485 4725 2790 5539 3145

· Serie MCR

Capacity (W)

Cold room temperature

0 ºC +5 ºC +10 ºC

MCR Series

Cooling

capacity (W)

Absorbed

power (W)

Cooling

capacity (W)

Absorbed

power (W)

Cooling

capacity (W)

Absorbed

power (W)

Ambient Temp: 35 ºC

0010

605 432 751 471 902 505

0015

788 530 956 577 1134 640

1015

999 580 1231 673 1490 691

1026

1265 930 1549 884 1853 970

1033

1502 1050 1817 1067 2153 1176

2033

1911 1210 2363 1210 2846 1347

2053

2352 1670 2882 1689 3455 1855

2074

2940 1830 3560 1945 4211 2147

18

14. DIMENSIONS

CV-N-C Models

CV-I Models

Dimensions (mm) A B C D E F G H

1 series

340 330 1060 400 514 115 380 335

2 series

340 330 1100 620 514 115 600 335

3 series

365 470 1100 735 514 115 710 475

Dimensions (mm) A B C D E F G H I J K L M

Exhaust

duct

0 series

306 510 683 420 250 50 405 515 n/a Ø 150

1 series

340 330 880 400 514 122 380 335 75 41 295 13 233 Ø 150

2 series

340 330 920 620 514 122 600 335 75 36 523 13 233 Ø 150

3 series

365 470 920 735 514 122 710 475 75 41 611 22 356 2x Ø 150

PLUG-IN FRAME

DROP FRAME

Centrifugal Box

only in 0 series

intarblock | intartop

19

CR-N Models

CR-C Models

Dimensions (mm) A B C D E F G H I Exhaust duct

0 series

480 600 430 330 790 375 100 435 380 Ø 150

1 series

574 665 582 385 850 379 135 588 385 Ø 150

2 series

677 835 756 469 850 379 135 762 385 Ø 150

ROOF FRAME

20

15. ELECTRICAL CONNECTIONS

Before connecting the unit to the electrical supply, make sure that the electrical board is in good

conditions and please follow the following recommendations:

§ Consult the electrical schema supplied by manufacturer.

§ Only use electrical cables of the appropriate characteristics and capacity according to the following

table. Notice that single phase units have a three-wire supply and three phase units have a fivewire supply, being always the ground wire in green-yellow colour.

MCV - MCR 0008 0010 0012 1010 1012 1014 1016 1018 1024 2024 2026 2034 3034 3038

Power supply

220-I-50

2 x 1,5 mm² + T

2 x 2,5 mm² +

T

Power supply

400-III-50

4 x 1,5 mm² + T

Cold room light

2 x 1 mm² + T

Door

microswitch

2 x 1 mm²

Remote

controller

2 x 1 mm²

BCV - BCR 0018 1018 1026 1034 2034 2054 2074 3074 3086 3096

Power supply 220-I-50

2 x 1,5 mm² + T

2 x 2,5 mm² + T 2 x 4 mm² +

T

Power supply 400-III-50

4 x 1,5 mm² + T

Cold room light

2 x 1 mm² + T

Door microswitch

2 x 1 mm²

Remote controller

2 x 1 mm²

Power supply 220-I-50

2 x 1 mm²

§ Always install the appropriate protection device on the supply line. In case that more than one unit

is installed, always provide separate protection devices for each of the installed units.

§ Electrical wires section in power supply wiring is to be calculated according to the electrical data

provided by manufacturer in data plate, power supply wires length, wires type, etc.; always

according to electrical regalement.

§ Optionally install a door switch on the end of the supplied cable or close the end of the cable.

§ Install the room light in the supplied cable.

intarblock | intartop

21

16. EMERGENCY SYSTEM

The electronic regulation of the units involves control routines and emergency alarms for the following

causes:

§ Probe failure.

§ Too high and too low room temperature.

§ Too high or too low refrigerant pressure.

§ Too high ambient temperature

§ Electronic control failure

§ Opened door.

Once a failure an external alarm is activated, and the unit turns into emergency operation mode.

17. SOUND PRESSURE LEVEL

Sound pressure level should be observed once the unit is installed. To do so, the environment, the

type of building and the rest of the solid elements should be considered on the noise transmission. It is

recommended to deploy an expert study if necesary.

INTARBLOCK and INTARTOP units include low noise components. The following chart indicates

sound pressure levels calculated at 10 m from the source in open field distribution (directivity = 1):

18. TRANSPORT

Handle the unit with care to prevent damages during its transport. Please follow the following

instructions:

§ Always handle the unit in vertical position.

§ Never pile up the units during transport.

§ Never pile up the units during storage.

§ Use a forklift or a pallet jack to handle the unit.

§ Keep the unit on its pallet until its final destination.

Packaging dimensions (mm) L W H Weight

CV series 0 610 460 823 44 Kg

CV series 1 905 440 1065 76 Kg

CV series 2 905 660 1105 108 Kg

CV series 3 940 795 1105 137 Kg

CR series 0 870 660 655 77 Kg

CR series 1 920 820 700 100 Kg

CR series 2 920 985 780 162 Kg

A

L

H

A

L

H

22

19. DATA PLATE

All All units are identified with the following data plate. In all communications with the manufacturer

please indicate the serial number.

20. SAFETY RECOMMENDATIONS

The start-up of the unit and its reparation must be carried out by qualified personnel.

To minimise the risk of accidents during the installation, start up or maintenance tasks, below

instructions must be followed.

It is mandatory to observe the recommendations and instructions as shown in manufacturer manuals,

plates and specific instructions. It is also mandatory to observe law and regulations.

Before operating on the unit, verify that the general supply is disconnected to avoid

electrical shocks.

Refrigerant leaks may cause:

§ Suffocation due to oxygen displacement in the atmosphere, narcotic effect or heart

arrhythmia.

Ensure that the working area is properly ventilated.

§ Eye irritations or burns may be caused if refrigerant comes into contact with the skin.

Use a safety mask and a pair of gloves. Avoid any contact between the refrigerant and

the skin and mind any sharp end of the unit.

intarblock | intartop

23

In case of accident due to refrigerant inhalation follow the following instructions:

§ Move the victim where it could breathe fresh air. The victim should lay on its back or its shoulder.

§ Call emergency services if needed.

In case of eye injures due to refrigerant splatters:

§ Never rub the eyes. In case contact lenses are used, you must take them out.

§ Eyes should be kept open and washed with plenty of water.

§ The victim should be taken to an emergency medical service

In case of burn due to contact with the skin

§ Wash with plenty of running water the affected part and take out the clothes while water is applied

on.

§ Never cover the affected parts with cloth, bandages or oil.

21. INSTALLATION AND MOUNTING

The final emplacement of the unit will affect the good performance of the unit. For an optimal

performance, please follow the following recommendations:

§ During the reception of your unit, please verify that it is free from any transport damage. Otherwise

indicate the perceived damages on the receipt.

§ Install the unit in a room with good ventilation and away from heat sources.

§ Keep clean the surroundings of the unit to facilitate the air intake and exhaust, and make sure the

air does not reflow.

INTARBLOCK units are designed for wall mounting directly onto the cold room panel. To do so, cut

out the indicated frame on the wall panel, depending on the type of mounting.

§ Drop mounting (except series 0).-

1. Before assembling the cold room, cut out the corresponding frame for the unit structure and

drill the hole for the drain pipe in the specified position.

2. Remove the drain pipe from the drain tray. To do so screw out the side cover of the inner part

and release the end of the tube.

3. Place the unit before assembling the roof of the cold room.

4. Place the drain pipe through the hole in the panel. Then, replace the roof panel.

24

§ Plug in mounting.- on an existing cold room or new one:

1. Cut out the indicated frame on the wall panel.

2. Place the unit into the wall frame with the supplied isolating block.

§ Fix the unit to the wall panel by mean of 6 through screws of Ø 6 mm metric as indicated on the

drawing. For the drop mounting, two hang-in holes are available for Ø 8 mm metric.

INSULATING

PAD

RECOMMENDED

SEPARATION

1 000 mm

RECOMMENDED

SEPARATION

> 500 mm

COLD

ROOM

LIGHT

DOOR MICROSWITCH

DRAIN PIPE

RECOMMENDED

SEPARATION

1 000 mm

RECOMMENDED

SEPARATION

> 500 mm

COLD

ROOM

LIGHT

DOOR MICROSWITCH

SIDE

COVER

DOOR HEATER (Only BCV)

DOOR HEATER (Only BCV)

intarblock | intartop

25

Dimensions (mm) A B C D E F G H

CV series 0 (plug-in mounting)

400

+0 +5

117 ±1 135 ±1 n/a 511 +5

Dimensions (mm) A B C D E F G H

CV series 1 375

+0 +5

469 ±1 125 ±1 726.5

±1

34.5 +5 122 ±1 208 ±2 330 +5

CV series 2 595

+0 +5

509 ±1 235 ±1 766.5

±1

30.5 +5 222 ±1 208 ±2 330 +5

CV series 3 692

+0 +5

369 ±1 292 ±1 766.5

±1

39.5 +5 267.5

±1

356 ±2 470 +5

CCØ6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø

6

52

± 1

159

± 1

C

C

H 72

+3

CCBACCØ6Ø6Ø

6

Ø8Ø

8

G

AØ2

PLUG-IN MOUNTING

DROP MOUNTING

E

2

+2

FFD

12

5

± 1

26

§ Centrifugal fan installation.- for CV-CF models.

1. Fix the unit to the cold room wall before installing the centrifugal fan.

2. Take out the side panels of the centrifugal box to access the fixing screws.

3. Screw the centrifugal box to the refrigeration unit and connect the fan electrical wiring.

4. Re install the side panels.

The INTARTOP unit series are specially designed for roof mounting. To do so, please follow below

steps:

§ Before assembling the roof of the cold room, cut out the roof frame as indicated in the plan and

dimensions chart (page 16)).

§ Once the cold room is assembled, place the unit on the roof.

§ In some operation conditions (e.g. intenstive use in wet environmment, air infiltrations, etc.), it

could be possible that the unit is not able to evaporate all condensing water. In that case, install a

draining pipe in the drain bucket to a permanent draining point.

§ Finally seal with silicon the gap between the unit and the wall panel.

To ensure good working conditions and easy access for maintenance, please keep free

the recommended separation around the unit.

Condensation air ducts (CV-C and CR-C models)

§ Units of CV-C and CR-F series feature a centrifugal condensation fan to be ducted. It is

recommended to duct the air extraction. Optionally, it is also recommended to duct the air suction

through semi-flexible ducts in aluminium or rigid ducts in PVC plastic, steel or fibreglass.

§ Failing a detailed calculation, the following chart shows the recommended dimensions according

to the duct type, for an equivalent total length of 20 m and both air intake-outtake grilles.

RECOMMENDED

SEPARATION

MINIMUM 650 mm

COLD

ROOM

LIGHT

DOOR

MICROSWITCH

RECOMMENDED

SEPARATION 5

00 mm

CONTROL PAD WIRING

DOOR

HEATER

POWER

SUPPLY

intarblock | intartop

27

CV/CR -C

Air flow

m³/h

A.s.p.

Pa

Recommended duct dimensions (mm)

Semi-flexible Rigid (PVC or steel)

CV 0 series

375 120

Ø 200 Ø 150

CV 1 series

575 120

Ø 250

< 20 m: Ø 150

>20 m: Ø 200

CV 2 series

950 120

Ø 315 Ø 200

CV 3 series

1250 120

Ø 315 Ø 250

CR 0 series

375 120

Ø 200 Ø 150

CR 1 series

575 120

Ø 250

< 20 m: Ø 150

>20 m: Ø 200

CR 2 series

1150 120

Ø 315 Ø 200

§ It is recommended a minimum length duct, avoiding placing unnecessary turns. Failing a detailed

calculation, it can be supposed that a 90º turn, with no internal radio, is equivalent to 5 m length.

§ If air intake is not ducted, an air intake adequate to the room should be planned.

§ It is not recommended the use of flexible ducts due to pressure loss, being only acceptable in case

of straight and very short stretches. If so, an aluminium semi-flexible duct as indicated diameters is

recommended.

22. START-UP

Before starting the unit,plese check that the unit is properly fixed on its supports and the electrical

connections are properly installed. If you have worked on the unit, take care not to forget tools or any

objects inside, that there is no gas leak and that assembly-connection are properly done.

Before starting up or after a stand-by periods, activating the crankage heater (when included) at

twelve hours in advance is recommended. Otherwise, the compressor must be warmed up in a

different way to ensure the refrigerant-oil separation. This operation is important, specially when

starting-ups in low ambiance temperatures.

Connect the electrical supply and switch on the unit with room door closed. The display will show the

room temperature and after the time as specified for Ods parameter the compressor will start.

Set the cold room temperature set point and wait until the cold room temperature reaches the set

point. The high temperature alarm will not be activated until the time of dAO parameter is elapsed.

Once the target temperature is reached, initialise the record of maximum and minimum temperature as

indicated in thism anual. You may check that auxiliary devices work properly:

§ Room light.- turn on and off the room light.

§ Door switch.- check that the compressor and fans stop when opening the door.

Force a manual defrost cycle to check this operation mode. make sure that the evaporation coil gets

clean and that the unit stays within the normal operating parameters without activating any safety

device.

Depending on the application you may need to modify defrost parameters, such as time

period between two consecutive defrost cycles, defrost cycle duration or termination

temperature. To do so, pay attention to the defrost cycles during normal operation.

28

Finally you can easily test the proper operation of some of the safety devices such as:

§ Open door alarm.- by leaving the door open beyond indicated in doA parameter.

§ High pressure switch or high temperature alarm.- by intentionally obstructing the air intake of

condenser.

§ Low pressure switch or Low temperature alarm.- by intentionally obstructing the air intake of

evaporator.

23. MAINTENANCE

INTARBLOCK and INTARTOP units are self-contained equipment not requiring specialised

maintenance. Nevertheless, to keep your unit in an optimal working state, we recommend to

periodically carrying out the following preventive maintenance tasks.

During the maintenance tasks, switch off the power supply and use gloves to avoid any

possible cut.

§ External cleaning.- To keep your unit free from dust and dirtiness, simply pass a wet cloth over the

cover. Do not use neither solvents nor detergents.

TORNILLOS

FIJACION

CARCASA

B

ATERIA DE

CONDENSACION

§ Condenser cleaning.- During the normal operation the dust and dirtiness will deposit on the coil

surface and will obstruct the air flow. Periodically, and depending on the surroundings, the

condenser should be cleaned. To do so, remove the external cover of the unit by removing the

side screws. Use compressed air blowing from inside or a vacuum cleaner to remove dirtiness on

the coil. Alternatively use a brush from the outer face of the coil. Do not force the fins to avoid

deformation.

§ Cleaning the evaporator (CV).- Remove any of the side covers of the evaporator block by

removing front and side screws. Blow air from outside or brush on the inner side to remove the

dirtiness on the coil.

SCREWS IN THE

COVER SIDE

SCREWS IN THE

COVER SIDE

EVAPORATION COIL

DRAIN TRAY

CONDENSER COIL

SIDE SCREWS

FIXING THE

EXTERNAL COVER

intarblock | intartop

29

§ Cleaning the evaporator (CR).- Remove the evaporator cover panel from inside cold room.

Deplace the cover to a side to access the coil. Blow or brush to clean it.

§ Drain tray.- To clean the drain tray you can use commercial detergents. In that case, make sure to

remove the detergent from the drain bucket inside the condensation block. To do so you can clean

the bucket with water. For CR units it is posible to dissasemble the evaporator box to access the

condenser coil and the drain tray. To do so, unscrew the box from the condenser and from the

lower section.

Following repair tasks should only be carried out by qualified personnel.

§ Replacement of any electrical part in the unit

§ Any modification of mechanical parts

§ Any operation on the refrigerant circuit

§ Any modification on the protection devices, control panel, control switches.

The maintenance tasks shown in this manual do not exclude any maintenance task in regulations and

laws.

24. REFRIGERANT LOAD

INTARBLOCK units are specifically designed for R404A refrigerant. The use of any other refrigerant in

the unit invalidates its guarantee.

Any operation related to the load, removal or replacement of refrigerant must always be carried out by

qualified personnel and never by the user. Please refer to technical refrigeration manuals for such

operations.

Units must always be loaded with R404A refrigerant in liquid phase through the HP nipple, in the exact

quantity indicated on the data plate.

GRILLE

CONDENSATION

COIL

EVAPORATOR

COVER PANEL

EVAPORATOR

EVAPORATOR

COIL

SIDE SCREWS

TRAY

30

25. DISPOSAL MANAGEMENT

After the installation dispose the packaging and pallet in an environmentally friendly manner and

according to your regulations. When disposing your unit or any of its parts, do it through an authorised

waste management company according to laws and regulations.

26. CONTROL

The unit is managed by a electronic board and a control keyboard with the following operating modes:

Refrigeration mode

The refrigeration operation mode is driven by a thermostatic control according to the room temperature

and a temperature target fixed by the user. Thus, when the room temperature is greater than the

temperature target, plus a pre-set differential, the compressor starts and stops when the room

temperature reaches the target temperature.

During the operation mode the display shows the room temperatura. Target temperature can be

shown by pressing the

key and can be modified by pressing

and .

To protect the compressor from successive starts, short cycle timing is inbuilt.

Fast cooling mode

The fast freezing operation mode can be activated or deactivated by pressing the key

for 3

seconds. During this operation mode the compressor works continuously for a preset period as

configured through the “CCt” parameter.

Defrost mode

After every preset period (fixed by the parameter “Idf”) the unit executes a defrost cycle. The unit is

preset on a defrost mode controlled through the inner coil temperature. In this mode, when the

evaporator coil reaches a certain temperature (as predefined value through the parameter “dtE”), or

after certain time (as predefined value through the parameter “MdF”). After a defrost cycle the unit

stays idle for the drain time (preset time through the parameter “Fdt”) to allow the evacuation of all

defrosted water.

The unit is configured to stop fans during the defrost cycle (parameter “FnC”)

After the defrost cycle and during the beginning of the normal refrigeration mode, the evaporator fan

remains stopped for the time defined by parameter “Fnd”.

Room light

Room light can be switched on and off through the key .

Keyboard

It consists of a display of 3 digits and a 7 key keyboard with LEDs to indicate operation mode and

alarms.

intarblock | intartop

31

To display and modify target set point; in programming mode it selects a parameter or confirm an operation.

By holding it pressed for 3s when max or min temperature is displayed it will be erased.

To see the max. stored temperature; in programming mode it browses the parameter codes or increases the

displayed value. By holding it pressed for 3s the fast freezing cycle is started.

To see the min stored temperature; in programming mode it browses the parameter codes or decreases the

displayed value.

By holding it pressed for 3s the defrosting is started.

Switch ON and OFF the cold room light.

By holding it pressed for 3s Energy Saving function is started or stopped.

Switch ON and OFF the auxiliary output.

Operation LEDs

LED Status

Description

Compresor LED

On The compressor is running

Flashing

Antyshort cycle safety device on. Pressure switch/es opened

(pressure

switch).

Fan LED

On The fan is running

Flashing

Programming

(flashing along with Compresor LED)

Defrosting LED

On The defrost is enable

d Flashing

Defrost is finished. Drip time in progress

Fast-cooling LED

On

The Fast Freezing cycle is enabled

Digital display

Unit On/Off

Energy saving mode key

Cold room Light switch

Defrosting key

Min temperature key

Target temperatura and

validation key

Max. Temperature and fast

-

cooling mode key

Compressor LED

Fast-cooling mode LED

Defrosting LED

Fan LED

Alarm LED

32

Keyboard functions

§ To switch off the unit.-

1. hold pressed

for 5 seconds and the display will show "OFF".

§ To show maximum temperature record.-

1. press

2. the display will show the value together with “Hi”.

3. press or wait 5 seconds to restore the normal display.

§ To show minimum temperature record.-

1. press

2. the display will show the value together with "Hi".

3. press or wait 5 seconds to restore the normal display.

§ To restart the minimum and maximum temperature record.-

1. while maximum or minimum temperature record is shown,

2. press the key set until the message “rST” is shown.

Do not forget to restart temperature records at the first start-up of the unit.

§ To show and modify target temperature.-

1. press set and the target temperature will be shown

2. the corresponding LED will begin to flash

3. press

or

to modify its value.

4. to store the new value press set or wait for 10 seconds.

§ To force a manual defrost cycle.-

1. press

for 2 seconds.

§ To access Pr1 parameter list, user parameters.-

1. press set and

simultaneously for some few seconds,

2. fan and compressor leds will flash,

3. the display will show the first parameter.

§ To access Pr2 parameter list, installer parameters.-

1. access Pr1 list,

2. select parameter “Pr2” and press set,

3. the display will show the message “PAS” followed by ”0 - -“.

4. press and

to modify the flasshing digit and confirm its value by pressing set, to enter

the password 321.

§ To modify a parameter.-

1. enter the parameter list,

2. select the parameter by pressing

or

and press set to visualise its value.

intarblock | intartop

33

3. press or

to modify its value.

4. press set to confirm then ew value and jump to the next parameter.

5. to exit the programming mode press set and or wait for 15 seconds.

§ To lock the keyboard.-

1. press and for 3 s.

2. the message “POF” will be shown and only the set point and temperature records can be

consulted.

3. To unblock the keyboard press and for 3 s.

27. PARAMETER LIST

Code Description Range Default List

MT BT

REGULATION

SET

Set Point. LS ÷ US 0 ºC -20 ºC

Hy

Set Point differential. 0,1 ÷ 25,5 ºC 2,0 ºC Pr1

LS

Minimum set point

-50,0 ºC ÷

SET

-5 ºC -25 ºC Pr2

US

Maximum set point. SET ÷ 110,0 ºC 10 ºC -15 ºC Pr2

Od

S

Time in which functions excluding light are not allowed from

starting-up.

0 ÷ 255 min 1 min Pr2

AC

Antishort cycle delay 0 ÷ 30 min 2 min Pr1

CCt

Fast freezing mode time (minutes)

0 ÷ 23 h 50

min

0h

30 min

2h

30 min

Pr2

Con Time interval during which the compressor is working after probe

default

0 ÷ 255 min 15 min Pr2

CO

F

Time interval during which the compressor is stopped due to

probe default

0 ÷ 255 min 15 min Pr2

DISPLAY

CF

Temperature measurement unit. ºC - ºF ºC Pr2

rES

Resolution integer/decimal point (only if CF = ºC):

in (integer) = 1 ºC ; de (decimal) = 0,1 ºC.

in - de de Pr1

Lod

PARÁMETER NOT AVAILABLE FOR THIS MODEL P1, P2, P3, 1r2

P1 Pr2

rEd

Remote display:

P1=room probe ; P2=evap. probe ; P3=ambient probe ; 1r2=P1-

P2.

P1, P2, P3, 1r2

P1 Pr2

DEFROSTING

tdF

Defrost type. (DO NOT MODIFY).

rE=electrical heater ; rT=off time ; in=hot gas injection

rE, rT, in in Pr1

EdF

Defrosting mode: in=Standar ; Sd=SmartDefrost

in - Sd in Pr2

SdF

set point for Smart Defrost.

-30,0 ÷ 30,0

ºC

0,0 ºC Pr2

dtE

Defrosting finalization temperature.

-50,0 ÷ 110,0

ºC

20,0 ºC Pr1

34

Code Description Range Default List

MT BT

IdF

Interval between defrosting cycles. 1 ÷ 120 h 3 h Pr1

Md

F

Maximum defrosting legth.

0 ÷ 255 min 15 min Pr1

dFd

Display during defrost:

rt=real temperature ; it=last recorded temperature ; Set=set point

; dEF= “dEF” message ; dEG= “dEG”message.

rt, it,Set, dEF,

dEG

it Pr2

dAd

Delay after defrosting to display cold room temperature 0 ÷ 255 min 15 min Pr2

dSd

Defrosting start delay. 0 ÷ 99 min 0 min Pr2

Fdt

Time defrosting end to compressor starting-up (draining time). 0 ÷ 60 min 2 min 3 min Pr2

dP

O

Displayed if defrosting after starting-up.

n - y n Pr2

dAF

Defrost delay after fast freezing.

0 ÷ 23 h 50

min

2,0 h Pr2

FANS

FnC Fans operating mode: With compressor (C) / always on (O) /

during defrosting (y=yes / n=no).

C-n, C-y, O-n,

O-y

C-n Pr2

Fnd

Fans operation delay after defrosting. 0 ÷ 255 min 3 min 4 min Pr2

FSt

Fans stop temperature.

-50,0 ÷ 110,0

ºC

10 ºC 0 ºC Pr2

ALARMS

ALC

Temperature alarm configuration (ALU and ALL):

rE=relative ; Ab=absolute.

rE - Ab rE Pr2

ALU

Maximum temperature alarm

rE: -50,0 ÷ 110,0

ºC

Ab: 0,0 ÷ 50,0 ºC

5,0 ºC Pr1

ALL

Minimum temperature alarm

rE: -50,0 ÷ 110,0

ºC

Ab: 0,0 ÷ 50,0 ºC

5,0 ºC Pr1

AFH

Temperature alarm and fan differential 0,1 ÷ 25,5 ºC 2,0 ºC Pr2

ALd

Temperature alarm delay. 0 ÷ 255 min 0 min Pr2

dAO

Delay of temperature alarm after starting up.

0 ÷ 23 h 50

min

3 h 4 h Pr2

EdA

Alarm delay at the end of the defrosting 0 ÷ 255 min 30 min Pr2

dot

Delay of temperature alarm after closing the door 0 ÷ 255 min 30 min Pr2

doA

Delay of opened door alarm 0 ÷ 255 min 15 min Pr2

rrd

outputs restart after doA alarm n - y y Pr2

AL2

Condenser low temperature alarm -50,0 ÷ Au2 ºC

-40 ºC Pr2

Au2

Condenser high temperature alarm

AL2 ÷ 110,0

ºC

52 ºC Pr2

ALH

Differential of condenser low temperature alarm (AL2). 0,1 ÷ 25,5 ºC 5 ºC Pr2

AtH

Differential of condenser high temperature alarm (Au2). 0,1 ÷ 25,5 ºC 3 ºC Pr2

Ad2

Condenser temperature alarm delay 0 ÷ 255 min 0 Pr2

dA2

Condenser temperature alarm eclusion at starting up 0 ÷ 23h 50 min

0 Pr2

tbA

Alarm signal silencing by pressing a key. n - y y Pr2

intarblock | intartop

35

Code Description Range Default List

MT BT

nPS

Pressure switch activation number 0 ÷ 15 10 Pr2

ANALOGUE INPUTS

Ot

Thermostat probe calibration

-12,0 ÷ 12,0

ºC

0 Pr1

OE

Evaporator probe

-12,0 ÷ 12,0

ºC

0 Pr2

O3

Condenser probe calibration

-12,0 ÷ 12,0

ºC

0 Pr2

P2P

Evaporator probe presence:

n=no (defrosting by time) ; y=sí (desescarche por tiempo y Tª)

n - y y Pr2

P3P

Condenser probe presence: n=no ; y=yesí n - y y Pr2

HE

S

Temperature increase during the Energy Saving cycle -30,0 ÷ 30,0

ºC

2 ºC Pr2

DIGITAL INPUTS

odc When door is open, switches off the compressor (CPr), fan (Fan),

both (F_C), or non of them (no)

no, Fan, CPr,

F_C

F_C Pr2

I1P

Door micriswitch polrity. CL=Closed; OP=Opened CL - OP OP Pr2

I2P

Pressure switches polarity: CL=Closed; OP=Opened CL - OP OP Pr2

I2F

Digital input 2 configuration: PAL=Pressure switches.

EAL, bAL,

PAL, dFr,

AUS, Es, onF

PAL Pr2

did

Digital input alarm relay 0 ÷ 255 min 60 Pr2

oP2

External alarm polarity: cL=closed ; oP=Opened. cL - oP cL Pr2

OTHERS

Adr

Serial address. 1 ÷ 247 1 Pr1

rEL

Software release solo lectura 8.4 Pr2

Ptb

Dixell map code. solo lectura 2 Pr2

Prd Probe display values: thermostat “Pb1”, evaporator “Pb2” and

condenser “Pb3”.

Pb1, Pb2, Pb3 solo lectura Pr2

Pr2

Access Pr2 parameter list.

Pr1

Configurable digital input

The unit has two digital inputs. One of them is always configured as a door switch. The other one is

preset as a pressure switch (PAL value assigned to parameter “I2F”). If during the interval time set by

“did” parameter, the pressure switch has reached the number of activation of the “nPS” parameter,

the “PAL” pressure alarm message will be displayed. When the digital input is ON the compressor is

always OFF.

The digital inputs polarity depends on “I1P” and “I2P” parameters: CL indicates the digital input is

activated by closing the contact; OP indicates the digital input is activated by opening the contact.

36

External communication

By mean of the TTL connector it is possible to connect the unit through a ModBUS-RTU compatible

net to a XWEB300 monitoring system. Same TTL input is used to download or upload parameter data

from a “Hot key”.

Alarm signals

Message Cause Output

P1

Thermostat probe failure Alarm output ON; Compressor according to parameters “COn” and “COF”

P2

Evaporator probe failure Alarm output ON; Other outputs unchanged

P3

Ambient probe failure Alarm output ON; Other outputs unchanged

HA

Maximum temperatura alarm Alarm output ON; Other outputs unchanged

LA

Minimum temperatura alarm Alarm output ON; Other outputs unchanged

EE

Data orm emory failure Alarm output ON; Other outputs unchanged

dA

Door switch alarm Alarm output ON; Other outputs unchanged

PAL

Pressure switch alarm Alarm output ON; Other outputs OFF

CSd

Condenser alarm Alarm output ON; Other outputs unchanged

EAL

Delete of electronic board data Alarm output ON

Alarm recovery

Depending on the entered option in parameter “tBA”, alarm signals are turned off by pressing any key

or when the alarm cause ceases.

Probe alarms: “P1” (probe1 faulty), “P2” and “P3” automatically stop 10s after the probe restarts

normal operation.

Temperature alarms “HA” and “LA” automatically stop as soon as the thermostat temperature returns

to normal values or when the defrost starts.

Door switch alarm “dA” stops as soon as the door is closed.

Pressure alarm “PAL” is recovered by switching OFF the instrument.

intarblock | intartop

37

28. FAULT ANALYSIS

Syptom

Cause

Solution

The unit does not turn on

a) faulty power supply

b) wrong connection of remote keyboard

a) Check protections, fuse, etc.

b) Check connection and polarity

The compressor does

not start up, LED

compressor is on

a) faulty power supply

b) faulty contactor

c) internal klixon is open

d) Compresor full of liquid

a

) Check protections, fuse, etc.

b) Replace

c) Wait for recovery and check compressor

intensity

d) Plug in the unit to activate crankase heater

(when included) and wait several hours before

switching on. Load-unload circuit alternatively

The compressor do

esn

’t

start. Compressor led

flashing

a) faulty power supply

b) faulty contactor

c) internal klixon is open

a)

Check pressure value and/or check safety

devices (pressure switches) by checking

continuity in board connectors. Look for the

cause:

àLP switch closed: switch on-off the unit

à faulty pressure switches: identify and

replace.

b) Wait and/or check AC parameter

c) check electrical continuity in board terminals

The compressor stops

some few seconds after

having started. The

motor produces an

intermittent noise and the

internal klixon is opened.

a) Low supply voltage

b) Faulty starting kit (check the starting relay)

(only single-phase units)

c) Blocked compresor

d) Blocked compresor

e) Liquid slug (the starting up was posibly

done without connecting the crankage heater

with sufficient time

a)

Check the power supply and look for the

voltage drop

b) Replace compressor and start kit (only

single-phase unit)

c) Check oil level and oil return to the

compressor through the suction line. If needed

install oil traps or remake the suction line.

d) Replace compressor

e) Plug in the unit to activate crankase heater

(when included) and vacuum for a time.

Reload and start-up the unit

Repetitive compressor

starts and stops

a) if the compressor LED is flashing

b) if the compressor LED is on (opened klixon)

c) Too small regulation differential or too

powerful unit for the room size, or empty room

without any thermal inertia.

a) Check pressures and/or safety chain to look

for the activated device.

à HP pressure switch: condenser is blocked,

poor ventilation, too much refrigerant, high

room temperature, faulty control of condensing

temperature, etc.

à LP pressure switch: connect the

manometer to HP&LP switches and bypass

refrigerant from high pressure to low pressure

sectors. Then find out the reason (frost, leak,

condensation control, valves, etc

b) V Check oil level and oil return to the

compressor through the suction line. If needed

install oil traps or remake the suction line.

c) Increase regulation differential (parameter

Hy)

38

Syptom

Cause

Solution

The unit runs but the

room temperature does

not goes down

a) Faulty room temperature probe

b) Too often defrost cycles

c) Too small unit for the room size

d) Insufficient air-flow

e) The condenser is dirty or obstructed

a) Check the pr

obe value and calibrate

through parameters, check probe connections,

or replace probe.

b) Check defrost parameters

c) Recalculate the necessary power

d) Check air flow (rate, reflow, outlets)

e) Clean it

The unit froze the

product, even in case of

positive temperature set

point

a)

Faulty room temperature probe

a)

Check wiring and parameter

Prd (

Pb1

),

replace probe and/or adjust Ot parameter

The unit works but loses

too much temperature

before restarting

a)

Regulation differential (parameter

Hy

) too

high

a) Decrease regulation differential (parameter

Hy) by 2 ºC.

The evaporator gets too

much frost and the drain

tray overflows

a)

Too low evaporation pressure

b) Blocked drain-pipe

c) Cold room leak-proof fault

d) The door is opened too often, or there is too

much humidity

a)

Check pressure and find out the reason

b) Check draining pipe heater (for LT models)

and replace or connect the heater to continous

supply, set higher slope. Verify the heater is

placed all long the draining-pipe for LT

models)

c) Check continuity of steam barrier and seal

the joints. Check door leak-proof

d) Increase defrosting frequence

Condenser Alarm

CSd

or

pressure alarm PAL

Too high condensation

pressure

(HP Pressure switch

activates)

a) Insufficient air flow or air reflo

w in

condenser

b) Faulty condenser fan

c) Too high room temperature

d) Too dirty and obstructed condenser

e) Excess of refrigerant load

f) Air inside refrigerant circuit

a) Check air flow (rate, reflow, outlets)

b) Repair or replace

c) Check target temperature

d) Clean condenser and air intakes

e) Check and replace refrigerant load

f) Evacuate and replace refrigerant

Pressure alarm

PAL

Too low evaporation

pressure (LP pressure

switch activates)

Ice block in evaporator

a) Insufficient airflow in evap

orator.

b) Faulty evaporator fan

c) Evaporator is always iced

d) Frozen drain pipe

e) Obstructed refrigerant filter (different inlet

and outlet temperatures)

f) lack of refrigerant (leakage)

g) Too low condensation pressure

h) Faulty solenoid valve

i) Faulty expansion valve

a) Clean air intakes

b) Repair or replace

c) Check defrost and defrost parameters.

Increase defrost frequency

d) Check drain heater and replace if necesary

(for low temperature units)

e) Change refrigerant filter

f) Repair leakage, replace refrigerant load

g) Too low ambient temperature, too high

airflow rate, check and adjust condensation

parameters (only for split units) or replace the

unit

h) Repair or replace

i) Check posible humidity inside the circuit

intarblock | intartop

39

Syptom

Cause

Solution

The condenser fan

works inttermitently and

subsequently the

pressure switch turns off

the unit.

a) Condensation control is not working

properly (only for split units)

a) Compare

Pb3 value by checking with a

reliable thermometer, check probe isolation,

replace probe and isolate it properly. Check

HP and LP values performance during starting

up, stop fan and modify ALH and AL2

parameters if neccesary

Evaporator fan does not

work.

Blocked evaporator

(frost)

a) LED ON and power in board connectors

à

faulty electrical supply connection or faulty

motorfan

B) LED off à wrong Pb2 probe value à

faulty probe or wrong probe wiring

a)

Check electrical conexión or c

hange

motorfan.

b) Check probe wiring or replace probe

Noisy compressor

a) Loose compressor

b) Low oil level

c) Faulty compressor

a) Check silentbloc screws

b) Add oil to the recommended level

c) Replace

Noisy unit

a) Unit is installed without noise insulation

a) Install insulating layer or supports under the

unit

Defrost mode doesn’t

work

a) Faulty heater or solenoid valve

b) Electrical fault.

c) Faulty evaporator probe

d) Wrong defrost parameters

e) Faulty solenoid valve (only for hot gas

defrosting units)

a) Repair or replace

b) check contactor and fuse

c) Check value Pb2, check connections,

replace

d) Check and adjust defrost parameters

e) Repair

P1 alarm and/or default

thermostat reading

Probe value is lower than cold room

temperature. The value decresases quickly

when the unit is operating

b) Room temperature probe faulty or wiring

faulty

a) wrong wiring between co

ld room

temperatura probe and evaporator probe

b) check probe wiring (electrical connection

between units for Split systems). Replace

probe

P2 alarm

a)

Evaporator probe faulty or wiring faulty

a) Check probe wiring (electrical interconexion

for split units). Replace probe

P3 alarm

a)

Condenser probe faulty

a)

Check probe wiring. Replace probe

dA

alarm

a)

open door micro

-

switch

a)

Check wiring and door switch or

electrical

bridge.

BAL alarm and/or

EAL

alarm

a)

Misconfigured

board

and/or

board

defau

lt a)

Check

board

configuration. Check

I2F=PAL

parameter value and/or replace board

The unit does not work

and the keyboard shows

the temperature value

and "---" alternatively

a)

Wrong voltage

a)

Check phase

connection

for three

-

phase