Page 1

Intan CLAMP System

Intan CLAMP System

Voltage/Current Clamp

User Guide

16 September 2016; updated 14 May 2019

Features

♦ Complete, miniaturized patch clamp amplifier system

with small digital headstages using revolutionary

CLAMP microchips from Intan Technologies

♦ Voltage clamp operation with low current noise floor:

< 3 pA

♦ Current clamp operation with low voltage noise floor:

< 20 µV

♦ Fast transient capacitance compensation: 0-20 pF

range; bridge balance in current clamp mode

♦ Automated measurement of pipette / seal resistance

and cell membrane parameters

♦ Clamp operation controlled by software and/or external

analog voltage command signals

♦ Small headstage size: 6.1 cm × 2.8 cm × 2.0 cm (not

including pipette holder)

♦ Standard threaded Teflon pipette electrode connector

♦ Standard dovetail for mounting to micromanipulator

♦ All-digital interface cable is immune to noise pickup

♦ Standard USB interface to host computer

♦ Free, open-source, multi-platform GUI software

www.intantech.com ● info@intantech.com 1

over 5 kHz bandwidth with highest sensitivity

rms

over 10 kHz bandwidth

rms

Description

The Intan Technologies CLAMP patch clamp amplifier

system allows users to perform signal channel or multichannel patch clamp electrophysiology or electrochemistry

experiments using the revolutionary new Intan CLAMP

voltage/current clamp chips.

The Intan CLAMP system incorporates all analog circuitry

and many digital control blocks in close proximity to the

electrode, resulting in a miniaturized “headstage” that is

actually a complete patch clamp amplifier. Thanks to the

integration of nearly all patch clamp circuit elements onto a

single silicon chip, the Intan-powered patch clamp amplifier

is smaller than traditional analog headstages that perform

only a small fraction of the total amplification task.

The Intan digital CLAMP headstages are interfaced to the

Intan CLAMP Controller which coordinates the operation of

the voltage/current clamps as well as sampling auxiliary

digital and analog signals in synchrony with the measured

electrophysiological signals. The interface cables are purely

digital with independently isolated grounds, making them

immune to noise pickup or signal degradation.

The Intan CLAMP Controller connects to a host PC via a

standard USB bus, and operates using free, open-source

software.

Page 2

Intan CLAMP System

System Architecture and Theory of Operation

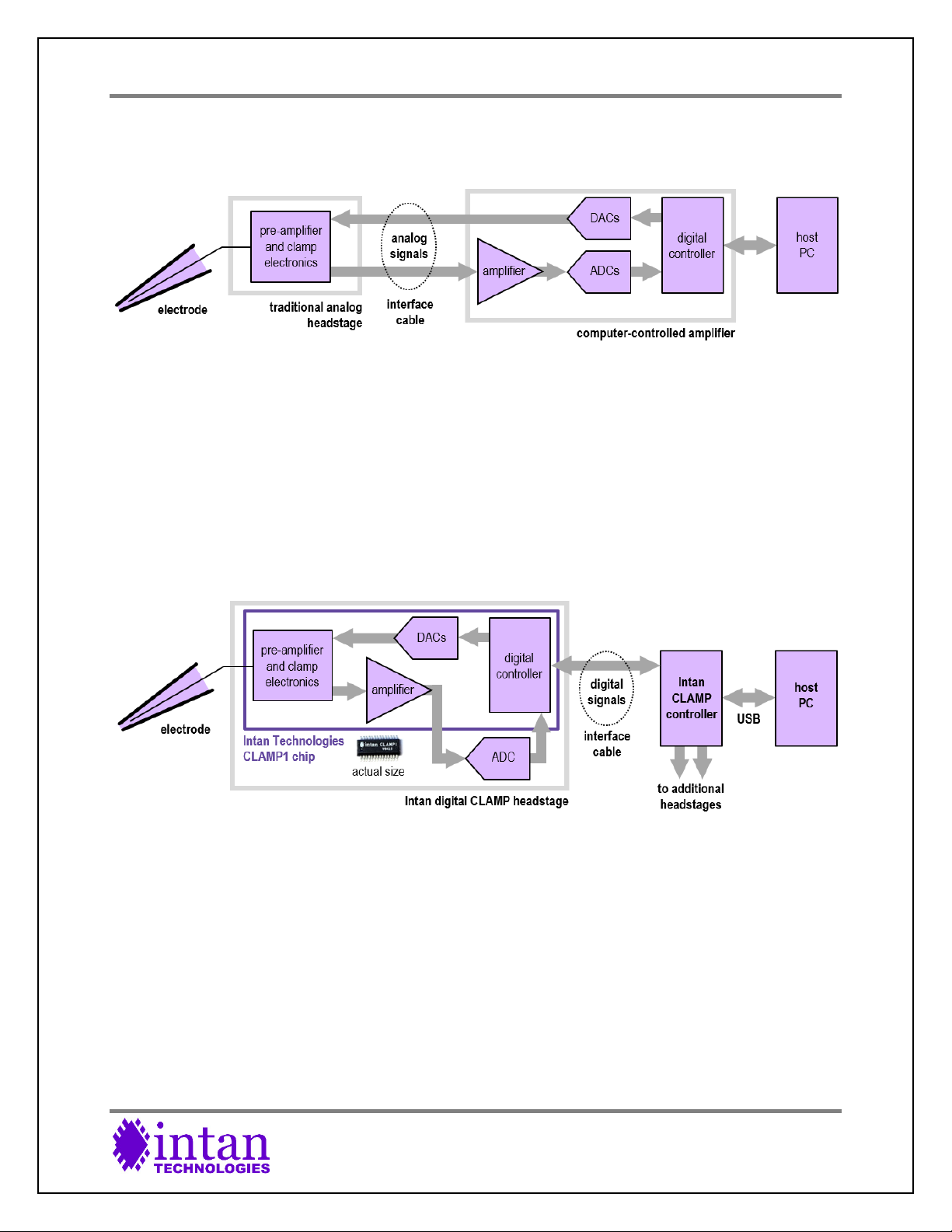

Traditional Analog Patch Clamp Amplifier

The diagram above shows the major functional components of a traditional patch clamp amplifier system. A traditional analog

headstage module contains sensitive analog electronics that act as a pre-amplifier with voltage clamp and current clamp capability.

In voltage clamp mode, the headstage measures the electrode current and converts this to a proportional small voltage. In current

clamp mode, the headstage buffers the electrode voltage but provides no additional amplification. Voltage and current clamp

control is provided by analog voltages that convey the desired clamping levels.

The headstage is connected to a remote computer-controlled amplifier via a shielded interface cable that carries small analog

voltages (typically in the millivolt range) and is thus susceptible to noise pickup. The amplifier module / digitizer consists of one or

more rack-mounted boxes that contain additional analog amplifiers, analog-to-digital converters (ADCs), digital-to-analog

converters (DACs), and a digital controller that coordinates control of these devices. The amplifier module and digitizer are

interfaced to a host PC that sequences particular experiments and records the measured data.

Intan Digital Patch Clamp Amplifier

The CLAMP chips from Intan Technologies combine all analog circuitry and many digital control blocks on a single chip, permitting

the construction of Intan-powered digital headstages (see diagram above). A small circuit board containing an Intan CLAMP

chip and a small number of support components form a complete patch clamp amplifier with a purely digital interface. The Intan

digital “headstage” is actually a complete, miniaturized patch clamp amplifier. Thanks to the integration of nearly all patch

clamp circuit elements onto a single silicon chip (see “actual size” inset above), the Intan-powered patch clamp amplifier is smaller

than many traditional analog headstages that perform only a small fraction of the total amplification task.

The digital interface cable uses a standard serial communication protocol (Serial Peripheral Interface, or SPI) and is no longer

susceptible to noise pickup. Sensitive analog signals are digitized at the source, not several meters away. The purely digital

interface makes it easy to electrically isolate each headstage and eliminate ground loops. The need for a large computer-controlled

amplifier module is completely eliminated, replaced by an Intan CLAMP controller that can easily control multiple digital

headstages simultaneously.

To preserve legacy “external command” and “signal monitor” functions associated with traditional patch clamp systems, the Intan

CLAMP controller incorporates ADCs and DACs to allow for real-time control of voltage and current clamp via analog voltages (in

addition to software clamp control), and real-time monitoring of measured and/or clamp voltages/currents via analog signals.

www.intantech.com ● info@intantech.com 2

Page 3

Intan CLAMP System

The voltage clamp operates over a wide range with steps as

The current clamp produces currents up to ±127 nA and

steps as small as 5 pA. Intracellular voltages may be

. The plot below shows the intracellular

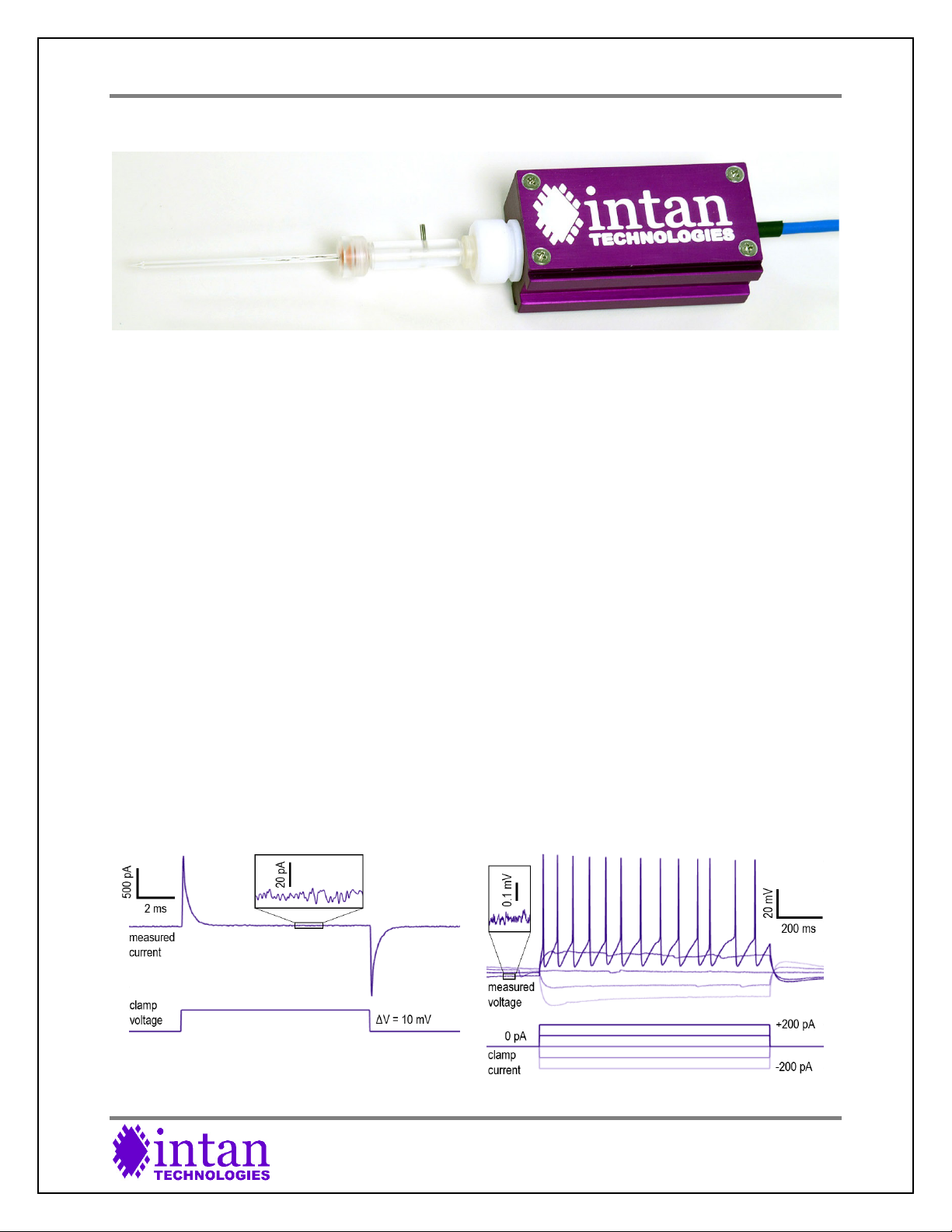

Intan CLAMP Headstages

An Intan CLAMP headstage is shown above with a pipette holder and glass pipette attached (not included). Intan headstages

mate with thread-mounted pipette holders that are compatible with Axon amplifiers. Pipette holders sold by Molecular Devices

(the 1-HL-U), Warner Instruments (the Q series), and other companies may be used with Intan headstages. Glass pipettes must

be custom made with a pipette puller shortly before recording.

Each headstage has standard 0.7” (17.8 mm) wide dovetail connectors on the side and the bottom. These mate with

micromanipulators from companies such as Sutter Instruments to permit precision positioning and movement of the headstage.

The rear side of the headstage has a receptacle for a 1-mm diameter grounding pin. This should be used to tie the headstage to

a grounding point near the experiment. Intan headstages are electrically isolated from the controller and from earth ground; this

can prevent noise pickup caused by unintentional ground loops. If a Faraday cage is used, it should be connected to the black

I/O GND binding post on the rear panel of the controller. Some experimentation may be needed to find the optimal grounding

scheme for a particular patch clamp rig.

The blue interface cable delivers ±3.3V power to the headstage and provides a digital serial interface between the headstage and

the controller. These SPI (serial peripheral interface) cables use low-voltage differential signaling (LVDS) with twisted-pair wires

for noise-free operation. Each Intan CLAMP headstage comes with a 6-foot (1.8-meter) interface cable. Additional SPI interface

cables may be purchased from Intan and daisy-chained to span longer distances.

Each headstage contains a small circuit board with an Intan CLAMP1 chip that performs all voltage and current clamping and

voltage and current sensing (see previous page). The detailed operation of this microchip is described in the Intan CLAMP

Voltage/Current Amplifier Chip Datasheet, available from the Downloads page of the Intan website.

The figures below show actual data obtained using an Intan CLAMP system.

small as 2.5 mV. A low noise floor (below 3 pA

sensitive range) allows tiny currents to be resolved. The plot

below shows a cell membrane test:

in the most

rms

observed across a wide ±300 mV range with a noise floor

below 20 µV

potential of a neuron during current injection:

rms

www.intantech.com ● info@intantech.com 3

Page 4

Intan CLAMP System

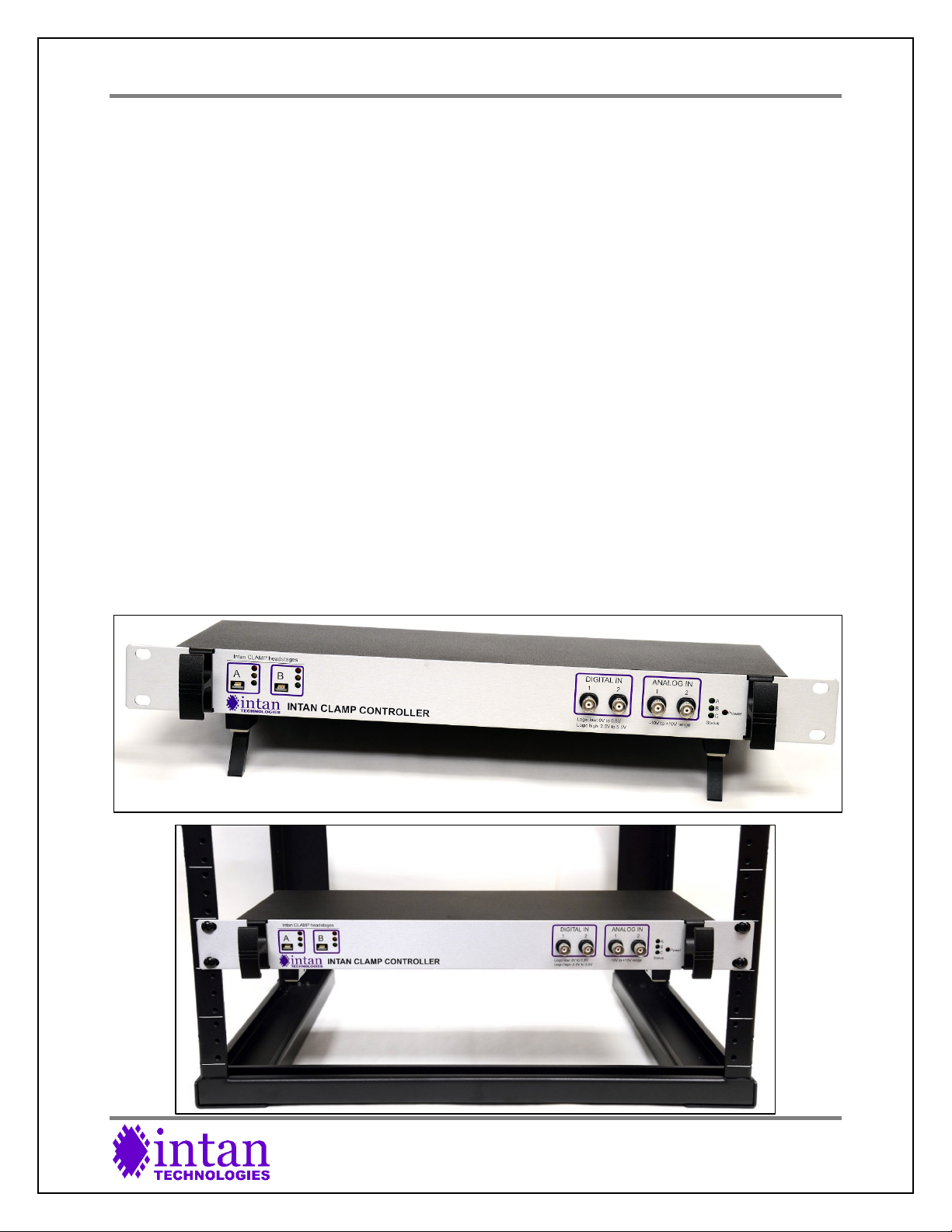

Controller Hardware

Front Panel

The front panel of the Intan CLAMP Controller provides connection ports for Intan CLAMP headstages as well as auxiliary digital

and analog inputs. From left to right:

• Intan CLAMP headstage ports: These ports, labeled A and B, provide connection points for up to two headstages via

12-wire digital SPI (serial peripheral interface) cables. Each headstage port is electrically isolated from the controller

and from earth ground. Indicator lights provide information on the status of each port: green and yellow LEDs show that

proper voltage supplies are being provided for each headstage. Red LEDs are activated when the software recognizes

a headstage plugged into a port.

• Digital inputs: Two BNC sockets are provided for recording digital signals in synchrony with the headstage signals.

The digital inputs accept TTL-level signals. Any voltage between 0V and +0.8V is read as a digital “low”. Any voltage

between +2.0V and +5.5V is read as a digital “high”. Voltages delivered to these sockets should not exceed the range

of 0V to +5.5V. These signals may be used to record discrete events associated with an experiment.

• Analog inputs: Two BNC sockets are provided for recording general-purpose analog signals, or for controlling the

headstages using externally provided analog waveforms. Signals are digitized with 16-bit ADCs over a range of -10.24V

to +10.24V. Voltages delivered to these sockets should not exceed this range.

• Status indicators: Status indicator A is illuminated when the CLAMP Controller software has successfully connected

to the unit. Status indicator B is controlled by DIGITAL IN 1; status indicator C is controlled by DIGITAL IN 2. These

LEDs can be used to monitor the status of digital signals that are recorded in synchrony with the patch clamp amplifiers.

• Power indicator: This red LED is illuminated when the Intan CLAMP Controller is powered.

Rear Panel

The rear panel of the Intan CLAMP Controller provides auxiliary output lines as well as other ports and switches. From left to right:

• Analog outputs: Two BNC sockets are provided for monitoring measured signals or clamp signals from CLAMP

headstages. The headstages communicate with the controller using purely digital signals, but 16-bit DACs are used to

reconstruct analog signals with desired scaling factors. The control software allows users to route selected signals to

any analog output ports. These ports have a -10.24V to +10.24V voltage range.

• Audio line out jack: This standard 3.5-mm stereo phone jack allows users to connect an audio amplifier to the controller

and listen to the signals routed to the two analog output ports. ANALOG OUT 1 is connected to the left channel;

ANALOG OUT 2 is connected to the right channel. This port cannot drive speakers directly; an audio amplifier should

be used, and the volume should be adjusted carefully to ensure that excessive levels are not delivered to speakers.

• High-speed port: This connector is reserved for future use.

• I/O expansion port: This connector is used to add an Intan I/O Expander. This board is described in the next section.

It provides six additional analog inputs and outputs and 14 additional digital inputs and outputs for more complex

experiments. Signals on this port are digital and serially encoded, and are not easily accessed without the I/O Expander.

www.intantech.com ● info@intantech.com 4

Page 5

Intan CLAMP System

• CONFIG switches: Configuration switches 1-3 are reserved for future use. Switch 4 (CONFIG4) is used to select the

voltage level of the digital output ports (see next item). With CONFIG4 in the down position, 3.3V digital signals are

generated. With CONFIG4 in the up position, 5.0V digital signals are generated.

• Digital outputs: Two BNC sockets produce either 3.3V or 5.0V digital signals (see previous item) that can be

synchronized with software-generated voltage clamp or current clamp waveforms.

• USB port: A USB 2.0 port provides two connection to a host computer running the control software.

• Sample clock out: This port generates a digital square wave proportional to the headstage sampling rate when the

headstages are active. While the software acquires data with a sampling rate of 50 kS/s, the headstages are actually

sampled at 200 kS/s to reduce noise, so this port produces a 200 kHz square wave during operation. The voltage level

of this signal is set by the CONFIG4 switch.

• Mark out: This port generates digital pulses marking the onset and offset of voltage clamp or current clamp waveforms.

The voltage level of this signal is set by the CONFIG4 switch.

• I/O GND: This binding post is connected to the controller system ground used by all analog and digital inputs and

outputs. This is the preferred ground to use for Faraday cage and other shielding connections.

• Chassis GND: This binding post is connected to the controller chassis and to the grounding conductor of the AC power

socket.

• Power switch and fuse holder: The unit uses two standard 1A 250V 5x20mm slow blow fuses that can be replaced

by opening the fuse holder to the right of the power switch. The power cord must be removed to access the fuses.

• AC power socket: The controller is powered by 90-260V AC power, and is compatible with international voltage levels.

A US-style power cord is supplied with the controller. International customers must use an adapter to accommodate

non-US power sockets. The center grounding conductor must be connected to earth ground to avoid electric shock

hazards.

Mounting

The Intan CLAMP controller can be rack mounted on a standard 19” instrument rack using provided hardware, or it can be used

on a bench top by folding out the feet on the bottom of the case:

www.intantech.com ● info@intantech.com 5

Page 6

Intan CLAMP System

Intan I/O Expander

Intan Technologies offers an optional I/O Expander (sold separately) that provides an additional six analog inputs and outputs and

an additional 14 digital inputs and outputs. This unit is shown below:

Front Panel

The front panel of the Intan I/O Expander provides auxiliary digital and analog inputs, and analog outputs. From left to right:

• Analog outputs: Two analog outputs for monitoring measured signals or clamp signals from CLAMP headstages. (Four

more analog outputs are provided on the rear panel.) These ports have a -10.24V to +10.24V voltage range.

• Digital inputs: Six BNC sockets are provided for recording digital signals in synchrony with the headstage signals.

(Eight more digital inputs are provided on the rear panel.)

• Analog inputs: Six BNC sockets are provided for recording analog signals, or for controlling the headstages using

externally provided analog waveforms. Signals are digitized with 16-bit ADCs over a range of -10.24V to +10.24V.

• Power indicator: This red LED is illuminated when the Intan I/O Expander is powered. The I/O Expander receives low-

voltage DC power over an interface cable from the controller.

Rear Panel

The rear panel of the Intan I/O Expander provides auxiliary input and outputs lines. From left to right:

• Interface port: This connector is used to interface with the main controller unit.

• Analog outputs: Four analog outputs for monitoring measured signals or clamp signals from CLAMP headstages. (Two

more analog outputs are provided on the front panel.) These ports have a -10.24V to +10.24V voltage range.

• Digital outputs: Six BNC sockets produce either 3.3V or 5.0V digital signals that can be synchronized with software-

generated voltage clamp or current clamp waveforms. The CONFIG4 switch on the main Intan controller selects the

voltage level used by these ports.

• Digital inputs 9-16: Eight additional digital inputs are provided on screw terminal blocks. System ground connections

are also provided on the ends of the terminal block.

• Digital outputs 9-16: Eight additional digital outputs are provided on screw terminal blocks. System ground connections

are also provided on the ends of the terminal block. The CONFIG4 switch on the main Intan controller selects the

voltage level used by these ports.

www.intantech.com ● info@intantech.com 6

Page 7

Intan CLAMP System

Software Installation

Before attaching the Intan CLAMP Controller to a computer,

first install the drivers provided on the Intan website. (If you

have already installed drivers for other Intan USB-linked

products, you do not need to reinstall these drivers.) After

installing the drivers, connect the CLAMP Controller to the

computer using the supplied USB cable, plug in the

Controller, and turn on the power switch on the rear panel.

Windows users may download the compiled CLAMP UI

(User Interface) software from the Intan website. The

executable, DLL files, and

the same directory. To run the software, double click the

executable.

Plug in at least one CLAMP headstage to one of the ports

on the front panel and start the software. The software takes

a few seconds to calibrate the attached headstages and

then opens two windows: a Control Window (see right) and

a Data Display Window (see below).

If any errors show up when the software is run the first time,

these can be corrected by installing the

Redistributable Packages for Visual Studio 2013 and the

Visual C++ Redistributable Packages for Visual Studio 2015

from Microsoft.

main.bit file should be kept in

Visual C++

the Record button is enabled. Clicking this button starts

data acquisition and saves the data to a file. Auxiliary data

from all ANALOG IN, DIGITAL IN, and DIGITAL OUT ports

are also saved unless the Save Auxiliary I/O item in the

Options menu is unchecked.

Control Window

Run and Run Once: These buttons start data acquisition

and display the measured and clamp data in real time

without saving data to disk. The Stop button halts data

acquisition. All data are acquired at 50 kSamples/s.

Select Base Filename: This button opens a dialog that

prompts the user to select a path and filename for saved

data files. A time and date stamp will be added to all saved

data files. Once a valid base filename has been selected,

Port Tabs: Clicking on these tabs (i.e., Port A, Port B)

selects headstages attached to the ports on the front panel

of the Intan CLAMP Controller. Each headstage may be

configured independently with its own holding levels, clamp

mode, capacitance compensation settings, etc. A softwaregenerated voltage clamp or current clamp waveform may

only be run on one headstage at a time; all other headstages

run in holding mode, but measurements are made on all

headstages simultaneously. Any external commands

www.intantech.com ● info@intantech.com 7

Page 8

Intan CLAMP System

coming from ANALOG IN channels will be applied to all

enabled headstages (see External Command Tab below).

Capacitance Compensation: This control enables and

adjusts the fast transient capacitance compensation circuit

in each headstage which is used to cancel pipette

capacitance. Capacitance compensation is typically

performed when the electrode is in the bath but prior to cell

contact. It may be refined after a gigaseal has been

obtained. See the Capacitance Compensation section

below for more details.

Status: This indicator shows the current clamp status of the

selected headstage.

Voltage Clamp Controls

Clicking on the Voltage Clamp tab displays the following

voltage clamp controls:

Pipette Offset: When a pipette electrode is placed in an

electrolytic solution, a small DC potential is generated by the

interface of dissimilar materials. This control allows the user

to adjust the pipette offset to null out this built-in potential.

Pipette offset should be nulled after the electrode is placed

in solution but prior to contact with a cell. If the Auto button

is clicked, the pipette offset will be adjusted to minimize

measured current. The lock can be clicked to prevent this

value from being changed accidentally.

The pipette offset may be adjusted manually by clicking on

the blue voltage indicator and turning the mouse scroll

wheel, moving the cursor keys up or down, or typing a

number.

Holding Voltage: This control sets a baseline clamp voltage

that is superimposed on all other voltage clamp commands.

After breaking into a cell, this is typically set close to -70 mV

to match the intracellular potential and prevent large

currents from flowing into or out of the cell.

Voltage Clamp Command: These buttons allow the user to

select between different types of voltage clamp waveforms.

Holding Only can be used to monitor spontaneous activity

in a cell. Seal Test produces a repeating voltage step, and

is typically used to monitor the pipette resistance as a

gigaseal is being formed or to estimate cell parameters (see

below). Resistance is similar to Seal Test, but adds a

running plot of resistance vs. time so that resistance trends

may be monitored visually. Multi-Step generates multiple

voltage clamp steps and superimposes the plots. Arbitrary

generates a waveform specified by a user file (see Arbitrary

Waveform Specification below for details).

Current Measurement Range: This control allows the user

to select the range of the current that is sensed by the

headstage: ±5 nA, ±10 nA, ±100 nA, or ±1000 nA. Using

the smallest acceptable range minimizes the noise floor.

Cell Parameters: If this box is checked, the passive cell

parameters R

resistance), and C

(series resistance), RM (membrane

S

(membrane capacitance) will be

M

estimated by fitting an exponential curve to the measured

voltage clamp data (see Estimating Membrane Parameters

below for details). Unchecking this box will “freeze” these

values.

Zap: This button must be enabled by clicking the lock icon.

Clicking the Zap button produces a brief, high voltage pulse

(typically 1 V) that can be used to break into a cell once a

gigaseal has been established (although most researchers

use pressure pulses to break the membrane). The

parameters of the zap pulse can be adjusted by clicking on

the blue numerical display.

Plot total Vclamp: Checking this box adds a second plot on

the Clamp Voltage graph in the lower half of the Data Display

Window. The primary plot shows the voltage clamp

waveform generated by the Voltage Clamp Command

controls above. The second plot shows the total voltage

clamp waveform applied by the headstage, which is a linear

superposition of the software-defined voltage clamp

command, the pipette offset, and any external command

delivered to an ANALOG IN port, if this option is enabled

(see External Command Tab below).

Plot Vcell: Checking this box adds a plot to the Clamp

Voltage graph in the lower half of the Data Display Window

that shows the cell voltage V

, which is defined as the

cell

clamp voltage minus the voltage drop across the series

resistance. This voltage drop is the series resistance (R

S

multiplied by the instantaneous measured electrode current.

The Intan CLAMP System does not allow for series

resistance compensation in voltage clamp mode, but

observing V

can allow users to manually compensate for

cell

some aspects of the voltage drop across the series

resistance and perhaps adjust the voltage clamp waveforms

to yield the desired voltage at the cell.

Current Clamp Controls

Clicking on the Current Clamp tab displays the following

current clamp controls:

Pipette Offset: See “Voltage Clamp Controls” for a

description of this control.

Holding Current: This control sets a baseline clamp current

that is superimposed on all other current clamp commands.

This can be used to bias the cell to a desired intracellular

potential or suppress spontaneous activity. The Zero

Current button may be clicked to set the holding current to

zero quickly.

Current Clamp Command: These buttons allow the user to

select between different types of current clamp waveforms.

Holding Only can be used to monitor spontaneous activity

in a cell. Tuning produces a repeating current step, and can

www.intantech.com ● info@intantech.com 8

)

Page 9

Intan CLAMP System

be used to tune the bridge balance (see below). Multi-Step

generates multiple current clamp steps and superimposes

the plots. Arbitrary generates a waveform specified by a

user file (see Arbitrary Waveform Specification below for

details).

Current Clamp Range: This control allows the user to

select the range and resolution (i.e., step size) of the current

clamp. The current-output DAC that generates the

headstage clamp current has a range of ±127 steps. The

step size can be 5 pA, 50 pA, 0.5 nA, or 1 nA.

Bridge Balance: Series resistance compensation may be

performed in current clamp mode using this control.

Checking this box enables bridge balance, where the

voltage drop across the series resistance of the pipette is

subtracted from the voltage measurements. The default

value of series resistance is the last measurement of R

made in voltage clamp mode (see Cell Parameters above),

but this value can be adjusted here to minimize step artifacts

observed during Tuning current clamp pulses (see the

Bridge Balance section below for more details).

Buzz: This button must be enabled by clicking the lock icon.

Clicking this button modulates the capacitance

compensation circuitry to produce small AC current pulses

that may assist in forming a membrane seal around sharp

intracellular electrodes. The parameters of the buzz pulse

can be adjusted by clicking on the blue parameter display.

S

recording. To control headstages using only the external

commands, select Holding Only in the software clamp

commands and run the system.

Multiple headstages may be controlled simultaneously using

external command signals. Voltage waveforms may be

generated using legacy hardware (e.g., NIDAQ boards) and

connected to ANALOG IN ports to generate clamp control.

Plot total Iclamp: Checking this box adds a second plot on

the Clamp Current graph in the Data Display Window. The

primary plot shows the current clamp waveform generated

by the Current Clamp Command controls above. The

second plot shows the total current clamp waveform applied

by the headstage, which is a linear superposition of the

software-defined current clamp command and any external

command delivered to an ANALOG IN port, if this option is

enabled (see below).

Other Controls

Display Resistance: Checking this box enables real-time

display of the measured pipette resistance. This can be

used when establishing a gigaseal. Average “best fit” lines

used to calculate resistance are superimposed on the

measured waveform in the Data Display Window when this

feature is enabled.

Analog/Digital I/O Tabs

External Command Tab: Controls in this tab allow the user

to control the voltage clamp or current clamp in real time via

external command signals from any of the ANALOG IN

ports. Voltage clamp and current clamp scaling factors may

be selected for each headstage. The external command is

superimposed on any software-defined clamp command,

and only takes effect when the system is running or

Signal Out Tab: Controls in this tab allow the user to route

the measured voltage or current signal to any of the

ANALOG OUT ports for monitoring on an oscilloscope or

speaker. (The ANALOG OUT 1 and 2 signals are connected

to the left and right channels of the AUDIO LINE OUT jack

on the rear panel.) Voltage and current scaling factors can

be selected here as well. DACs in the Intan CLAMP

Controller reconstruct an analog waveform from the digital

www.intantech.com ● info@intantech.com 9

Page 10

Intan CLAMP System

headstage data in real time. Note: Any low-pass Bessel

filtering or bridge balancing is not applied to these

waveforms as these operations are performed in software.

Clamp Out Tab: Controls in this tab allow the user to

produce an analog waveform corresponding to the clamp

command signal on any of the ANALOG OUT ports. Voltage

and current scale factors can be selected here for voltage

clamp or current clamp commands. DACs in the Intan

CLAMP Controller reconstruct an analog waveform from the

digital clamp commands sent to the headstage.

Marker Out Tab: When a voltage clamp or current clamp

waveform is active, a digital signal on the MARK OUT port

on the rear panel of the Intan CLAMP Controllers goes high

when the clamp waveforms departs from the holding level.

This signal may also be routed to any of the DIGITAL OUT

ports using controls in this tab. Note: If a signal is routed to

a DIGITAL OUT port, then it will be saved in the auxiliary I/O

file.

Data Display Window

Low-Pass Filter: This control selects the cutoff frequency

th

for a 4

voltages and currents.

-order Bessel low-pass filter applied to measured

Save Displayed: This button is enabled by selecting a base

filename in the Control Window. When the button is clicked,

the data visible in the Data Display Window are saved to

disk.

Clear: The button clears the plots in this window.

Capacitance Compensation

Each CLAMP headstage supports pipette capacitance

cancellation in the range of 0-20 pF. In practice fast

transient capacitance compensation is usually tuned when

the pipette is placed into bath, before contact with a cell is

made. As shown in the plot below, a voltage clamp step is

applied to the electrode and the capacitance compensation

is adjusted to eliminate the transient peaks in the measured

current. The pipette resistance is easily measured during

this procedure as well by checking the Display Resistance

box. Note that excessive capacitance compensation can

cause increased noise levels and instability.

Autoscale: This box may be unchecked to enable manual

control of the plotting axes. Axes may be adjusted by

clicking and dragging along the axis (see figure below),

using the cursor keys, the page up/down keys, or other keys

described in the Keyboard Shortcuts dialog accessible

through the Help menu in the Control Window.

Overlay multi-steps: When multi-step clamp commands

are selected, the results from each voltage clamp or current

clamp step are superimposed on top of one another unless

this box is unchecked.

Estimating Membrane Parameters

In whole-cell patch clamp electrophysiology, the electrode is

electrically connected to the inside of a cell as shown in the

diagram below. The tiny opening in the cell membrane

creates a large access resistance R

pipette resistance R

can have a value in the tens of megohms. To first order the

cell’s membrane behaves as a capacitance C

the tens of picofarads) with some parallel resistance R

(typically in the hundreds of megohms) in series with a

reversal potential V

to -90 mV). These membrane parameters, as well as the

series resistance R

voltage clamp measurement and checking the Cell

Parameters box.

. The resulting series resistance RS

P

(usually in the range of -30 mV

R

, can be estimated using a simple

S

which adds to the

A

(typically in

M

M

www.intantech.com ● info@intantech.com 10

Page 11

Intan CLAMP System

Note that the electrode parasitic capacitance CP is not

shown in the diagram below because it is assumed that this

element has already been cancelled by the fast transient

capacitance compensation circuitry prior to cell contact.

After breaking into a cell, the voltage clamp is typically set to

a value near the cell’s expected resting potential (e.g., -70

mV) to prevent the activation of voltage-gated ion channels.

A small voltage step is applied around this potential (e.g., a

step from -70 mV to -60 mV) and the resulting current is

measured. The plot below shows a typical clamp voltage

profile and measured current waveform. The current takes

the form of a decaying exponential with a time constant τ:

·exp(-t/τ) + I1. (These exponential current peaks are

i(t) = I

0

much wider and slower than the “fast transient” peaks

caused by uncompensated pipette capacitance)

The Intan CLAMP system does not support series

resistance compensation in voltage clamp mode, but the

Plot VCell control (see Voltage Clamp Controls above) can

be used to estimate the true cell potential by subtracting the

voltage drop across the series resistance in real time. The

user may then adjust the voltage clamp parameters to

produce the desired voltage in the cell.

Bridge Balance

When applying current clamp pulses through real electrodes

connected to cells, the measured membrane potential is

distorted by an artifact caused by the voltage drop across

the electrode. Referring to the diagram below, we would like

to apply a current signal I

voltage V

equal to the intracellular potential V

elec

However, the clamp current flows through a series

resistance R

access resistance R

is equal to I

comprised of the pipette resistance RP and the

S

. This leads to a voltage offset ΔV that

A

.

clamp·RS

and measure an electrode

clamp

.

cell

Enabling Cell Parameters causes an exponential curve to

be fit to the data and the membrane parameters R

can be estimated, along with the series resistance R

and CM

M

.

S

Traditional patch clamp instruments sometimes use positive

feedback circuits to reduce the effects of the series

resistance R

in voltage clamp mode. (The measured

S

current flowing through the electrode creates a voltage drop

across R

, causing the voltage in the cell to be slightly

S

different from the clamp voltage.)

The plot above shows an example of this phenomenon for a

simple clamp current that starts at zero and pulses to I

Luckily, the intracellular potential V

the measured electrode voltage V

can be recovered from

cell

by subtracting the

elec

clamp current (at every instant in time) multiplied by R

stim

S

which was previously measured using the Cell Parameters

www.intantech.com ● info@intantech.com 11

.

,

Page 12

Intan CLAMP System

tool. In the old days of purely analog instrumentation, this

subtraction was performed using an analog circuit in a

technique called bridge balance or series resistance

compensation. With modern computing power it is much

easier to perform this subtraction after the electrode voltage

has been digitized. The Bridge Balance tool in the Current

Clamp tab performs this function. In practice, the exact

value of series resistance should be adjusted while applying

small current pulses to eliminate the voltage jump shown in

the figure above.

Note that the clamp current is exactly the same with or

without bridge balance enabled; the stimulation experienced

by the cell is not affected, only the interpretation of the

measured data.

Arbitrary Waveform Specification

Users may define arbitrary voltage clamp or current clamp

waveforms by creating CSV (comma separated values) text

files listing all clamp levels and durations comprising the

waveform.

Arbitrary waveform files must end in the .arb prefix, and the

first line of the file must read

waveform or

with the second line of the text file, each line specifies a

voltage or current clamp level and a time duration that this

clamp level should be held. Clamp levels are specified in

integer steps. (Smooth changes in clamp levels must be

approximated by “stair steps”.)

The standard voltage clamp step size is 2.5 mV, but if 2x

Voltage Clamp Mode is enabled in the Options menu, the

step size is 5.0 mV (see next section for details). The

voltage clamp level can range between -255 and +255

steps. The current clamp step size is set by the Current

Clamp Range control in the Current Clamp tab. The step

size can be 5 pA, 50 pA, 0.5 nA, or 1 nA. The current clamp

level can range between -127 and +127 steps.

The duration each clamp level is held is specified by a

positive integer in the range of 1 to 65535. The actual

duration is calculated by multiplying this number by

20 microseconds (i.e., 1 / 50 kHz), so a value of 25000

signifies 500 milliseconds, for example. The maximum

value of 65535 sets a duration of 1.31 seconds; if longer

holding times are needed then repeated commands must be

used.

The clamp level and duration are specified by two numbers

separated with a comma. For example, to define a voltage

clamp waveform that holds at zero for 20 ms, then steps to

+20 mV for 40 ms, and then steps to -30 mV for 10 ms, the

.arb file would be:

ARBI for a current clamp waveform. Starting

ARBV for a voltage clamp

ARBV

0,1000

8,2000

-12,500

The total length of an arbitrary waveform specification is

limited to approximately 16000 lines.

By default, the MARK OUT digital signal for an arbitrary

waveform will go high for any nonzero clamp level. More

sophisticated digital signals can be specified by appending

two additional binary numbers (i.e., 0 or 1) to each line. The

first number signals when the MARK OUT signal should go

high. The second number signals when the optional

DIGITAL OUT signal (controlled by the Marker Out tab)

should go high.

Adding to the previous example, if we wanted MARK OUT

to go high during the +20 mV clamp level and the selected

DIGITAL OUT signal to go high during the -30 mV clamp

level, we would use the following file:

ARBV

0,1000,0,0

8,2000,1,0

-12,500,0,1

2x Voltage Clamp Mode for FSCV

The Intan CLAMP chip in each headstage uses an on-chip

DAC to generate a clamp voltage. The voltage level of this

DAC is set by an 8-bit magnitude variable and 1-bit sign

variable. In the normal mode of operation, this DAC has

2.5 mV steps, giving a total voltage clamp range of

±637.5 mV, which is more than enough range for cellular

patch clamp experiments. By selecting the 2x Voltage

Clamp Mode from the Options menu, the DAC step size is

doubled to 5.0 mV, producing a range of ±1.275 V.

This wide voltage clamp range permits the Intan CLAMP

Controller to be used in fast-scan cyclic voltammetry (FSCV)

or other electrochemistry applications. In FSCV

experiments, voltages typically in the range of -0.4 V to

+1.3 V are swept rapidly across graphite electrodes while

the current is measured. (The Arbitrary Waveform function

can be used generate FSCV voltage clamp signals.)

Background currents on the order of 1 µA are subtracted

from baseline readings, and the resulting residual current

variations – typically less than 10 nA in magnitude – indicate

the presence of various neurotransmitters or other

chemicals.

When the 2x Voltage Clamp Mode is enabled, all clamp

voltages generated by the headstages are 2x larger than

they appear in the software. The controls and display axes

do not reflect this 2x increase. However, the MATLAB code

used to read saved data files (see next section) does

www.intantech.com ● info@intantech.com 12

Page 13

Intan CLAMP System

recognize data saved with the 2x mode enabled and

automatically adjusts voltage clamp waveforms to reflect the

true voltages.

www.intantech.com ● info@intantech.com 13

Page 14

Intan CLAMP System

Importing Recorded Data into MATLAB

Intan Technologies provides an open-source m-file (read_Intan_CLP_file.m) for importing data recorded from the CLAMP

Controller software into MATLAB. Make sure you have the latest version of this m-file to ensure compatibility with the newest

version of the control software. Running this m-file brings up a file selector dialog with which the user locates and selects the

desired .clp data file. The m-file then loads and parses the data file and returns a data structure containing the clamp and measured

waveforms, time vectors, and settings.

The CLAMP Controller software creates a new subdirectory each time data is saved. The directory has a name consisting of the

base filename specified by the user followed by a date stamp and a time stamp:

this subdirectory, a separate file is saved for each headstage, with a letter designating the headstage port. An additional file

designated AUX contains waveforms from the ANALOG IN, DIGITAL IN, and DIGITAL OUT ports sampled in synchrony with the

headstages. (If this file is not needed it can be disabled by unchecking the Save Auxiliary I/O item in the Options menu.) A typical

set of saved data files might have the following names:

myexperiment_A_160916_142731.clp

myexperiment_B_160916_142731.clp

myexperiment_AUX_160916_142731.clp

Following is a transcript of a typical MATLAB session loading a recorded data file and looking at the data structure:

>> clear

>> d = read_Intan_CLP_file;

Reading Intan Technologies CLAMP Data File, Version 1.0

File contains 0.360 seconds of data sampled at 50.00 kS/s.

>> d

d =

Header: [1x1 struct]

Data: [1x1 struct]

>> d.Data

ans =

Measured: [1x18000 single]

Time: [1x18000 double]

Clamp: [1x18000 single]

TotalClamp: [1x18000 single]

>> subplot(2,1,1); plot(d.Data.Time, d.Data.Measured);

>> subplot(2,1,2); plot(d.Data.Time, d.Data.Clamp);

The time vector is contained in the variable Data.Time, with units of seconds. Corresponding waveform data are stored in the

Data.Measured, Data.Clamp, and Data.TotalClamp. The Clamp waveform contains the software clamp signal

vectors

(in volts or amps) while

TotalClamp includes the pipette offset and any external commands delivered by ANALOG IN channels.

basefilename_YYMMDD_hhmmss. Within

The

Header structure contains information on sampling rates, the Bessel filter cutoff frequency, recently measured cell

parameters, and other settings.

If an auxiliary I/O file is loaded, the

>> d.Data

ans =

Time: [1x18000 double]

DigitalIn: [1x18000 uint16]

DigitalOut: [1x18000 uint16]

ADC: [8x18000 double]

>> plot(d.Data.Time, d.Data.ADC(2,:))

Data structure will be different:

www.intantech.com ● info@intantech.com 14

Page 15

Intan CLAMP System

The DigitalIn and DigitalOut vectors are 16-bit unsigned integers encoding all DIGITAL IN and DIGITAL OUT values.

(The Intan CLAMP Controller has two DIGITAL IN lines and two DIGITAL OUT lines; the Intan I/O Expander can be added to gain

access to all 16 signals.) For example, if DIGITAL IN 1 and DIGITAL IN 7 are both high and all other digital inputs are low, then

the value of

The time vectors in the auxiliary I/O files and individual headstage data files are identical.

DigitalIn at that point in time will be 2

0

+ 26 = 1 + 64 = 65.

www.intantech.com ● info@intantech.com 15

Page 16

Intan CLAMP System

intan

TECHNOLOGIES, LLC

Related CLAMP Documentation

The following supporting datasheets may be found at

http://www.intantech.com/downloads:

♦ Intan CLAMP Voltage/Current Amplifier Chip

Datasheet

Pricing Information

See www.intantech.com for current pricing. All price

information is subject to change without notice. Quantities

may be limited. All orders are subject to current pricing at

time of acceptance by Intan Technologies. Additional

charges may apply for international purchases and

shipping.

Contact Information

This datasheet is meant to acquaint scientists and engineers

with the general characteristics of the Intan CLAMP system

developed at Intan Technologies. We value feedback from

potential end users.

For more information, contact Intan Technologies at:

www.intantech.com

info@intantech.com

© 2016-2019 Intan Technologies, LLC

Information furnished by Intan Technologies is believed to be accurate and reliable. However, no responsibility is assumed by Intan

Technologies for its use, nor for any infringements of patents or other rights of third parties that may result from its use. Specifications

subject to change without notice. Intan Technologies assumes no liability for applications assistance or customer product design.

Customers are responsible for their products and applications using Intan Technologies components. To minimize the risks

associated with customer products and applications, customers should provide adequate design and operating safeguards.

Intan Technologies’ products are not authorized for use as critical components in life support devices or systems. A critical component

is any component of a life support device or system whose failure to perform can be reasonably expected to cause the failure of the

life support device or system, or to affect its safety or effectiveness.

www.intantech.com ● info@intantech.com 16

Loading...

Loading...