Inta VR994CP Quick Start Manual

VVRR999944CCPP VVaannddaall RReessiissttaanntt SShhoowweerr HHeeaadd

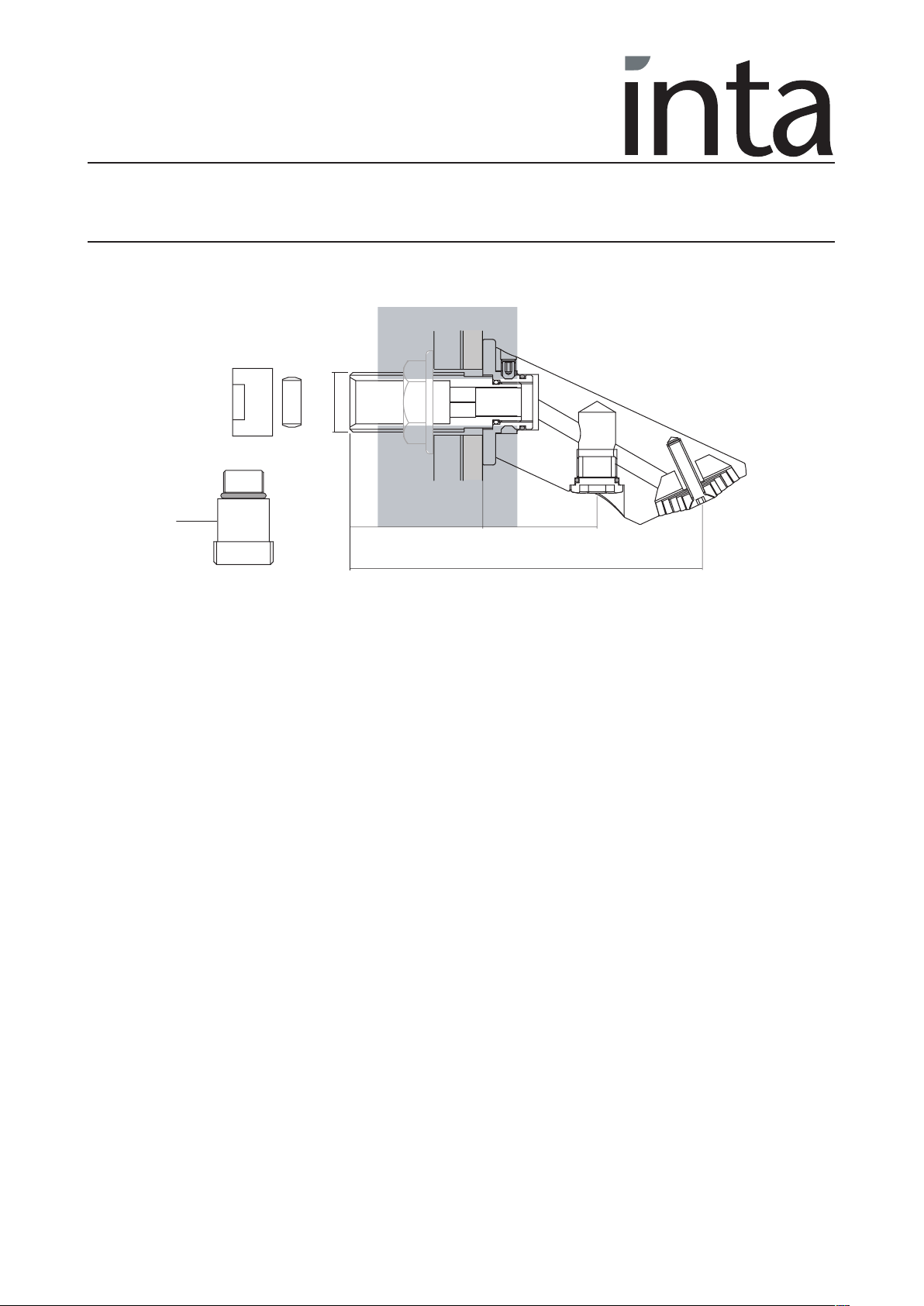

RReeaarr aanndd BBoottttoomm CCoonnnneeccttiioonnss

CCoonncceeaalleedd IInnssttaallllaattiioonn

/2B

1

G

Exposed

Inlet

OOppeerraattiinngg CCoonnddiittiioonnss

Max. Operating Pressure 10 bar

Min. Operating Pressure 0.2 bar

Max. Inlet Temperature 65˚C

LLooccaattiioonn

For ease of servicing always mount on a tiled wall

or similar water proof surface, never tile up to the

shower head.

Choose the position of the shower to suit the

tallest user.

The shower must not be positioned where it will

be subjected to freezing condition

CCoonncceeaalleedd IInnssttaallllaattiioonn IInnssttrruuccttiioonnss

The shower head is always dispatched configured

for concealed pipework.

The installation shown is typical for a tiled stud

wall.

Drill a hole through the wall 24mm in diameter.

40mm46.5mm

124.4mm

Using the back nut secure the shower arm to the

wall, do not over tighten

Connect the copper supply pipe to the pipe

connector using using the olive and compression

nut, tighten to make a water tight joint.

Straight or angled swivel connectors with a fibre

washer (tap connector) can also be used

Turn on the water supply and check joints for

leakage, tighten or re-make the joint until water

tight.

AAfftteerrccaarree

With all highly polished items, care should be

taken not to damage any of the external surfaces.

To maintain the appearance of the shower head

periodically it should be cleaned with a soft damp

cloth and a mild detergent.

The use of abrasive or solvent cleaners will

damage the finish of the product and should not

be used.

The shower head can be mounted to the wall

using a back nut (not provided) or by screws as

the exposed installation.

IInnttaatteecc LLiimmiitteedd,, AAiirrffiieelldd IInndduussttrriiaall EEssttaattee,, HHiixxoonn,, SSttaaffffss,, SSTT1188 00PPFF

0011888899 220077220000

© Intatec Ltd 2008

Te

l:

Fax:

0011888899227711117722

email:

ssaalleess@@iinnttaatteecc..ccoo..uukk

VVRR999944CCPP VVaannddaall RReessiissttaanntt SShhoowweerr HHeeaadd

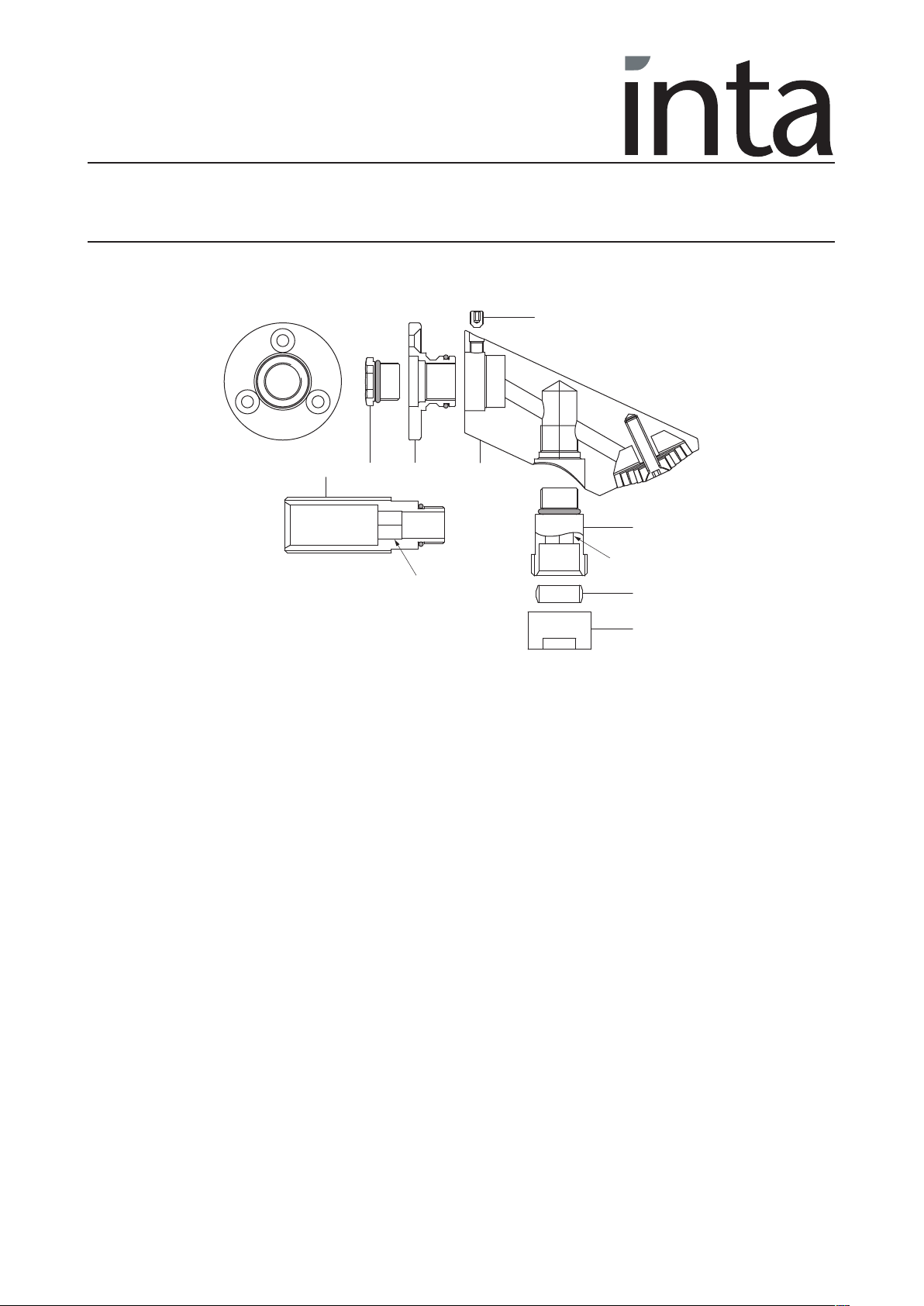

RReeaarr aanndd BBoottttoomm CCoonnnneeccttiioonnss

EExxppoosseedd IInnssttaallllaattiioonn

3

45

EExxppoosseedd IInnssttaallllaattiioonn IInnssttrruuccttiioonnss

For exposed pipework the configuration of the

shower needs to be changed.

Care needs to be taken not to damage the

highly polished surfaces during the modification.

Separate the body (1) from the backing plate (2)

by unscrewing the set screw (3) and pulling

apart.

Unscrew the pipe connector (4), using the

hexagonal section, from the back plate (2) using

a 10mm Allen key.

Lubricating the ‘O’ rings which a mild detergent

or silicone grease will ease assembly.

Unscrew the plug (5) from the body using a

10mm Allen key and screw into the backing

plate and tighten, taking care not to damage the

‘O’ ring and tighten to make a water tight joint.

Hexagon

12

6

Hexagon

7

8

Using the backing plate (2) as a template mark

the position for the three fixing holes.

Drill and plug to suit the fixing screws supplied

which are suitable for most brick walls.

If the wall is plaster board or soft building block

use special wall plugs obtainable from most DIY

stores.

Position the backplate on the wall and secure in

position using the screws provided.

Push the body onto the backplate taking care not

to damage the ‘O’ ring seal and re-tighten the

socket set screw to hold in position, do not over

tighten.

Connect the supply pipe using the olive (7) and

compression nut (8) as shown and check the

joint for leakage.

Screw the exposed inlet pipe connector (6) into

the body taking care not to damage the ‘O' ring

and tighten to make a water tight joint.

IInnttaatteecc LLiimmiitteedd,, AAiirrffiieelldd IInndduussttrriiaall EEssttaattee,, HHiixxoonn,, SSttaaffffss,, SSTT1188 00PPFF

0011888899 220077220000

© Intatec Ltd 2008

Te

l:

Fax:

0011888899227711117722

email:

ssaalleess@@iinnttaatteecc..ccoo..uukk

Loading...

Loading...