Inta IntaKlean Series, IntaKlean IKMF22, IntaKlean IKMF28 Installation & Servicing Instructions Manual

IntaKlean

Installation & Servicing Instructions

IKMF22 and IKMF28

In this procedure document we have endeavoured to make the

information as accurate as possible.

We cannot accept any responsibility should it be found that in

any respect the information is inaccurate or incomplete or

becomes so as a result of further developments or otherwise.

© Intatec Ltd. 2012

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: sales@intatec.co.uk

web: www.intatec.co.uk

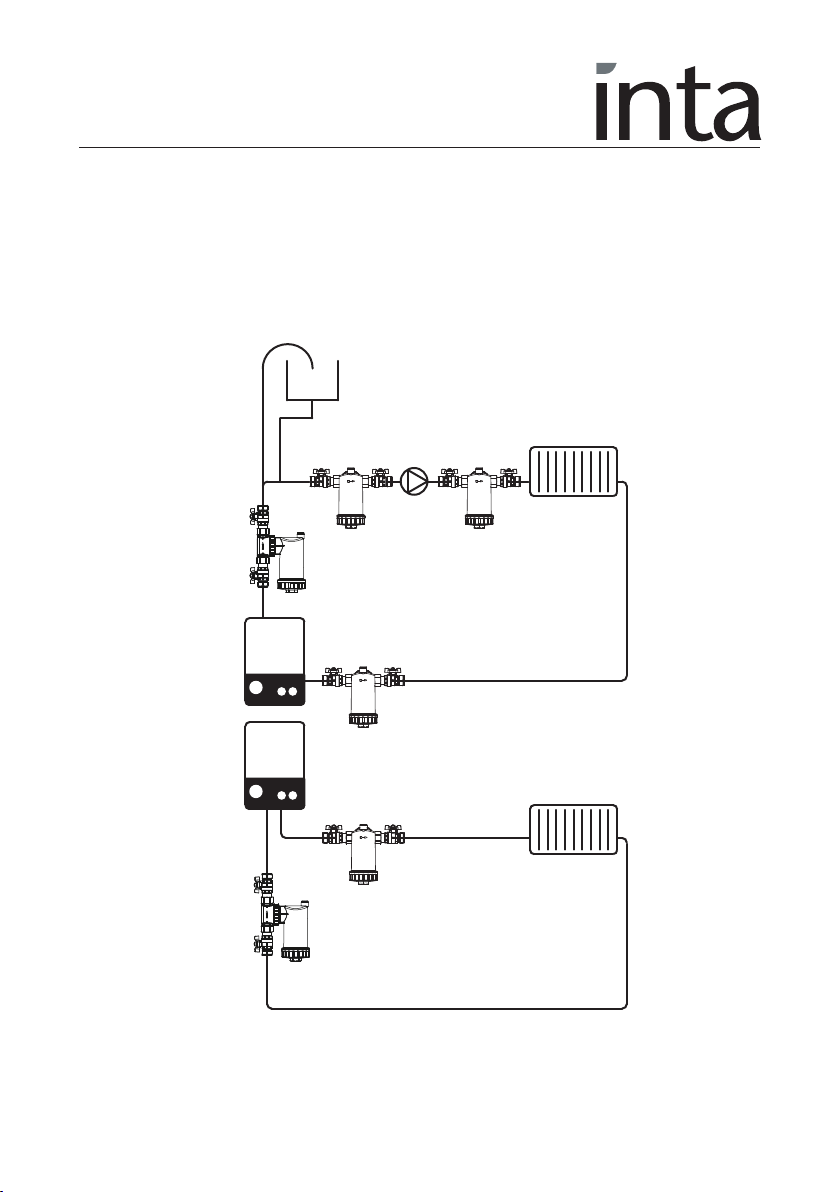

B

A

BB

Return

Return

Combi/Sealed System

Open Vented System

Header Tank

Vent

Pipe

û

ü

ü

In both diagrams, position A is best practice

whilst B is suitable

A

INSTALLATION

The IntaKlean triple action filter is suitable for installation on any central heating system

and can be fitted anywhere in any orientation.

For best performance and filter protection however, we recommend that the IntaKlean

is installed on the return leg of the circuit, between the last radiator and the boiler to

gain the maximum advantage of the IntaKlean’s vortex technology.

© Intatec Ltd 2012

1

INSTALLATION

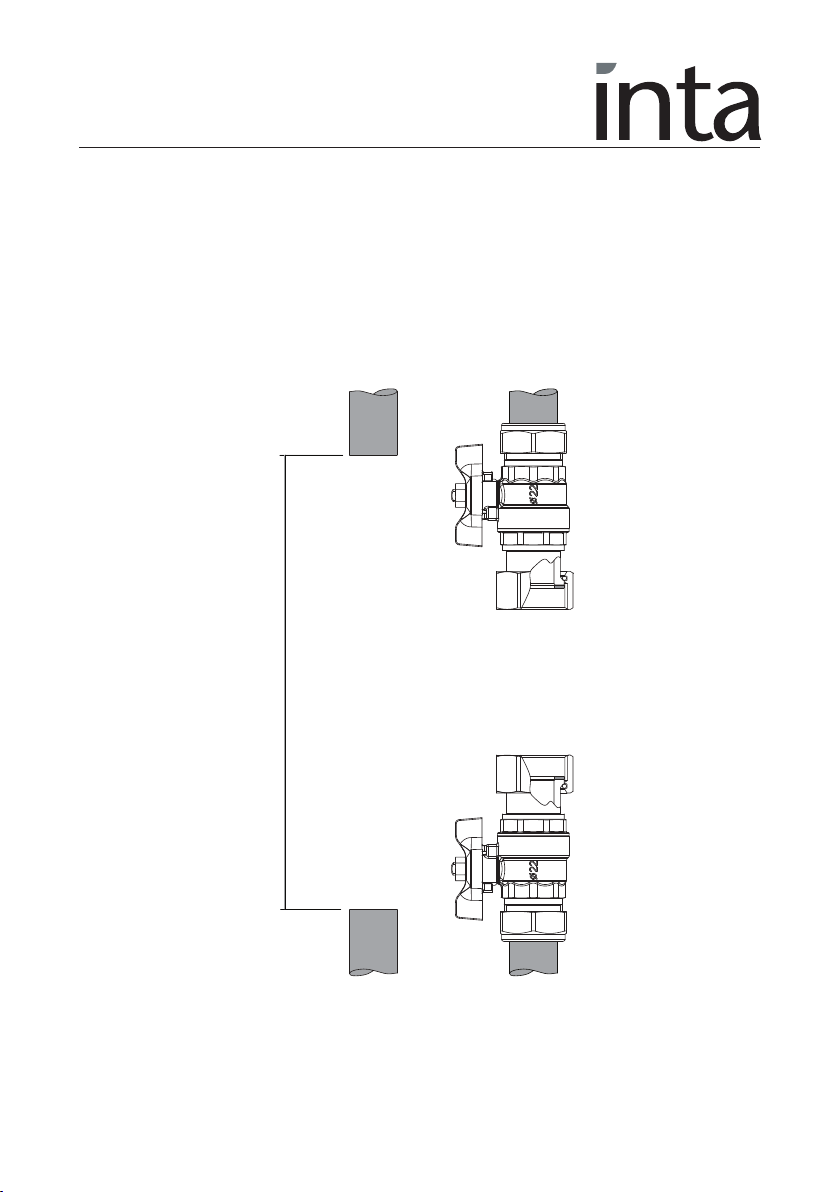

Ø22 Size =216 Ø28 Size = 231

Ensure that the system is suitably drained down and all system pressure has been

released.

On open vented systems, make sure that the feed and expansion tank is either isolated

or “tied up”.

When siting the IntaKlean ensure that the collection vessel is positioned to allow access

and removal of the bottom cover, withdrawl of the magnetic element and venting air.

Having removed the prescribed section of pipework, make sure that the open ends of

both pieces are free of debris and ready to receive the nut and olive. Fit both isolation

valves but do not tighten fully.

© Intatec Ltd 2012

2

INSTALLATION

Sealing

Washer

Slip the collection vessel between the isolation valves making sure that the sealing

washers are fitted and that the flow direction arrow on the body is pointing in the same

direction as the flow.

The air vent must be at the top of the collection vessel and the cover at the bottom.

Hand tighten the valves to the collection vessel before fully tightening.

WARNING: Over tightening the connection to the collection vessel can cause

irreparable damage to the vessel.

Fully tighten the compression joint on the ball valves.

The installation is now complete.

To change to the horizontal pipe configuration, loosen the retaining nut to the body

and then rotate the body to the desired orientation before re-tightening the joint.

© Intatec Ltd 2012

3

COMMISSIONING

The commissioning procedure should be carried out as follows;

• Open the lower isolation valve to the IntaKlean – leave the upper most isolation

valve closed.

• Making sure that all open ends of the system are closed, begin to refill the system.

• Bleed radiators as required.

• Open the air vent on the IntaKlean and bleed the air until water starts to flow.

Close the air vent.

• Open the upper isolation valve and fill the remaining volume of the system.

• Open the air bleed again to ensure all air has been removed from the filter.

N.B. – Air may continue to be present in system pipework for a small period as the

central heating is run after installation of the IntaKlean. We recommend that you check

the air bleed again to ensure that all air has been purged from the system.

CLEANING AND SERVICING

Prior to cleaning the IntaKlean, ensure that the working environment is safe.

Inta recommend that the boiler is switched off and that the system is allowed to cool to

ambient temperature before commencing any maintenance works.

Isolate the IntaKlean by closing the two ball valves and opening the air vent.

Carefully unscrew the cover.

Water will gradually begin to flow from the cover as it is unscrewed further.

Ensure that this water is collected in a suitably sized container and that the surrounding

area is protected to prevent water damage.

Once the flow of water has stopped, the collection vessel is empty.

Completely remove the cover and carefully withdraw the magnet and plastic sheath.

Remove the metal filter screen.

Remove the white plastic sheath from the magnet over a sink or container.

Clean the sheath with clean water and rinse the cap thoroughly under the tap.

Rinse the metal filter screen in clean water and check for signs of damage; replace if

damaged.

© Intatec Ltd 2012

4

Magnetic

Core

Plastic

Sheath

‘O’ring

Metal

Screen

Cover

Container

CLEANING AND SERVICING

Check the ‘O’ ring seal for signs of damage, replace if damaged.

Re-assemble in the reverse order, check joints for signs of leakage before

recommissioning following the procedure in the COMMISSIONING section.

© Intatec Ltd 2012

5

ADDING WATER TREATMENT

To add water treatment chemicals via the IntaKlean, first ensure the system is

appropriately isolated then close the upper ball valve leaving the lower valve open.

Drain a suitable volume of water from a drain point at the lowest part of the central

heating system. Ensure a sufficient amount of water is drained to allow space for the

volume of chemicals required.

The IntaKlean has a large 500ml dosing capacity, which in most cases, should prove

sufficient.

When the IntaKlean is empty, using an appropriate tool, remove the air vent from the

top of the collection vessel.

Insert a funnel into the open aperture and dose the system accordingly.

Re-commission the system as per the previous instructions in the COMMISSIONING

section.

© Intatec Ltd 2012

6

NOTES

Please Leave this Manual for the User

E & O.E

© Intatec Ltd 2012

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: sales@intatec.co.uk

web: www.intatec.co.uk

17-10-12

Loading...

Loading...