Wall & Deck Mounted

Sequential Control

Thermostatic Mixer

HTMWMCP, HTMDMCP

HTMWMRS & HTMDMRS

Installation and Maintenance Instructions

In this procedure document we have endeavoured to make the

information as accurate as possible.

We cannot accept any responsibility should it be found that in

any respect the information is inaccurate or incomplete or

becomes so as a result of further developments or otherwise.

© Intatec Ltd. 2016

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: sales@intatec.co.uk

web: www.intatec.co.uk

Contents

Thank you for choosing the Inta lever operated thermostatic wall mixer.

Subject Page

Introduction 2

Technical Data 2

Components - Wall Mounted 3

Components - Wall Mounted with Removable Spout 4

Components - Deck Mounted 5

Components - Deck Mounted with Removable Spout 6

Dimensions 7

Installation 8

Operation 9

Trouble Shooting 9

Re-calibration 10

Cartridge Removal 10

Aftercare 11

Removing Spout and Disinfection 12

System Flushing Procedure 13

Sterilization Process 14

TMV3 Installation Instructions 16

Guarantee 21

© Intatec Ltd 2016

1

Introduction

This installation guide has been produced for the wall and deck mounted sequential control

mixer. These instructions cover the installation, operation and maintenance. Please read the

enclosed instructions before commencing the installation of this product, please note;

We recommend that the installation is carried out by an approved

installer.

The installation must be carried out strictly in accordance with the Water Supply (Water Fitting)

Regulations 1999 and any local authority regulations.

If in doubt we recommend that you contact WRAS - Water Regulations Advisory Scheme on

Tel: 0333 207 9030, your local water authority - details available on the WRAS website or the

Chartered Institute of Plumbing and Heating Engineers on Tel: 01708 472 791.

All products MUST be re-commissioned to suit site conditions to ensure optimum performance

levels of the product are obtained.

Check Content

Before commencing remove all components from packaging and check each component with

the contents list.

Ensure all parts are present, before discarding any packaging. If any parts are missing, do not

attempt to install your control mixer until the missing parts have been obtained.

Product Range

HTMWMCP - HTM safe touch thermostatic sequential wall mounted tap.

HTMDMCP - HTM safe touch thermostatic sequential deck mounted tap.

HTMWMRS - HTM safe touch thermostatic sequential wall mounted tap with removable spout.

HTMDMRS - HTM safe touch thermostatic sequential deck mounted tap with removable spout.

Technical Data

This Inta thermostatic mixer is suitable for installations on all types of plumbing systems, including

gravity supplies, fully pumped, modulating combination boiler, unvented water heater and

unbalanced supplies i.e. Cold Mains & Tank Fed Hot.

Max Dynamic Pressure 5 bar Min Operating Pressure 1.0 bar

Max Static Pressure 12 bar Min Inlet Temperature 10˚C

Max Inlet Temperature 85˚C Temperature Stability ±2˚C

Pre Set Factory Temp Setting 41˚C Min Temp Differential to

Max Unbalanced Pressure Ratio ensure fail-safe between hot

Without Flow Regulator 5:1 and cold supplies 10˚C

Preparation for Installation

Before starting the installation, ensure that the site conditions are suitable - see Technical Data.

The tap is supplied for wall or deck mounting as shown.

Flush the water supply pipes thoroughly prior to installation - see page 13. Do not allow debris,

PTFE tape or any metal particles to enter the mixer.

© Intatec Ltd 2016

2

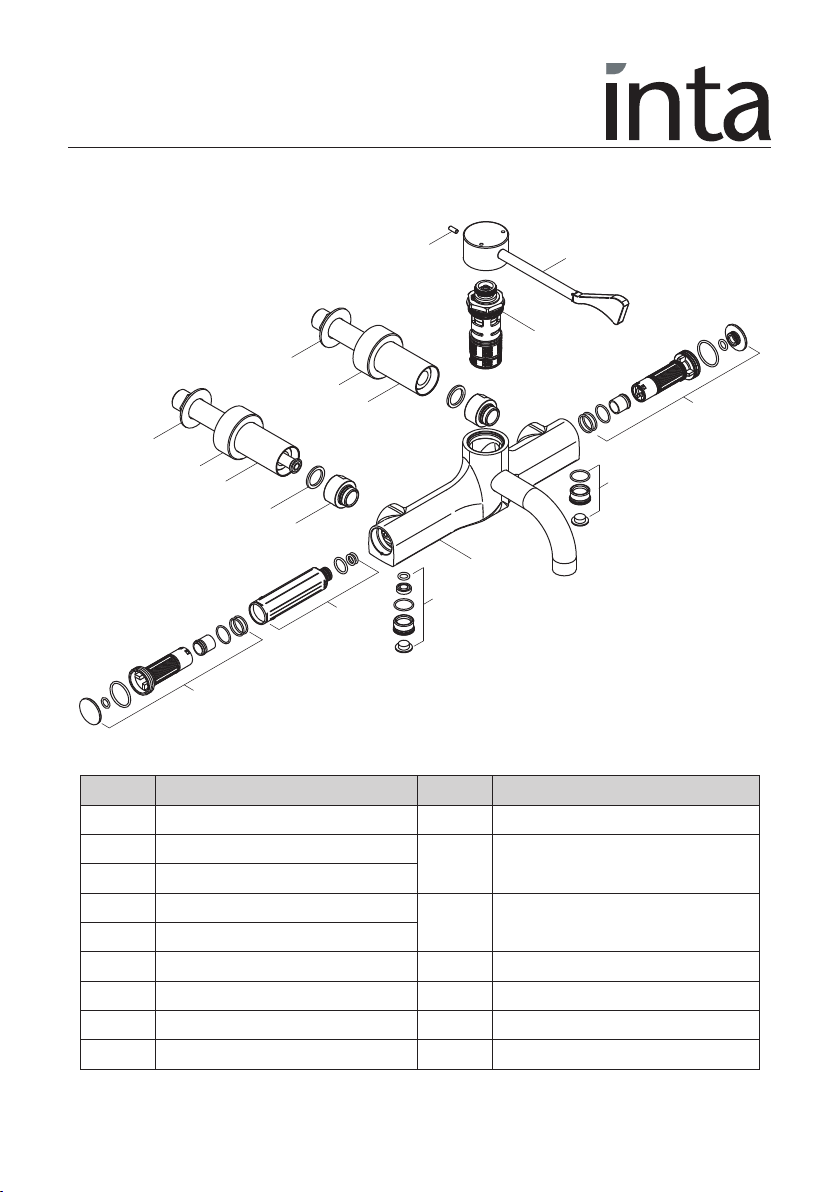

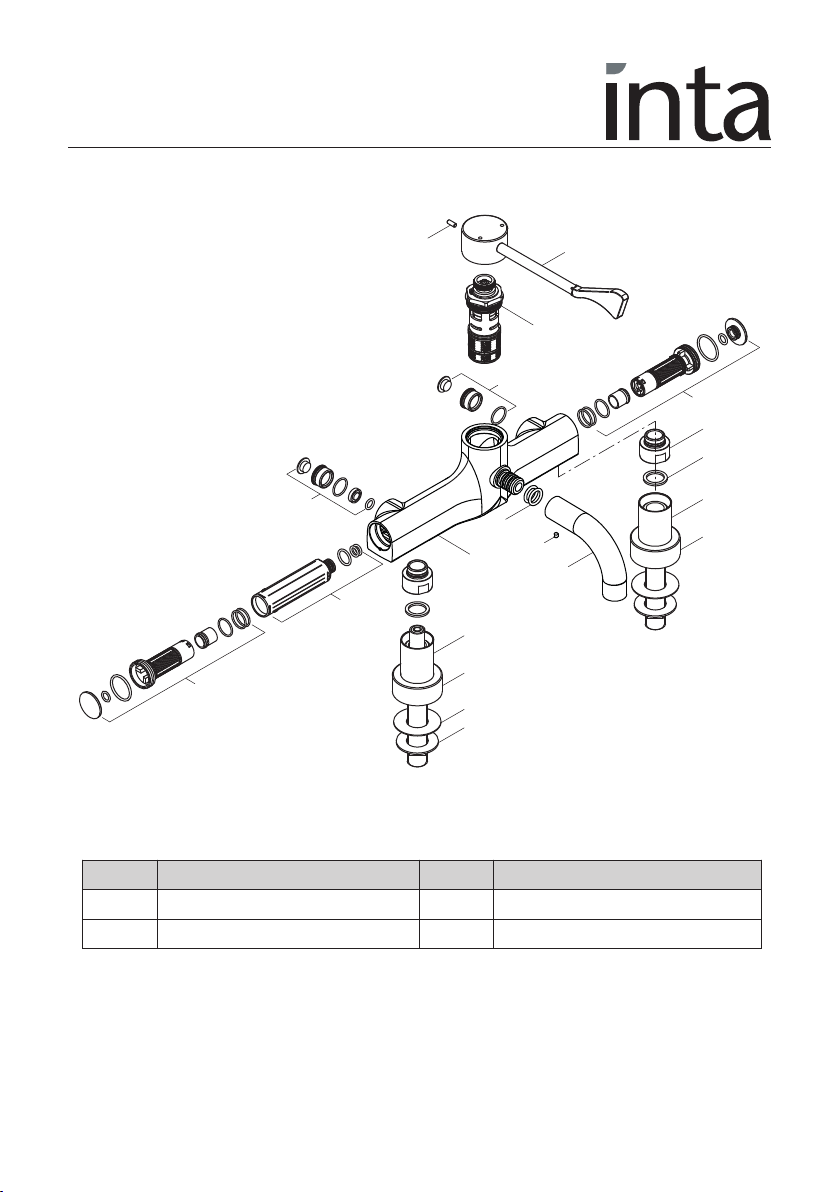

Components - Wall Mounted with Fixed Spout

1

2

3

4

5

6

5

7

8

9

11

13

14

15

15

10

12

Item Description Item Description

1 Body inc. Outlet Diffuser 10 Hot Water Insulator

2 Thermostatic Cartridge

3 Lever

4 Lever Retaining Screw

5 Concealing Plate

6 Cold Water Inlet Tail Assembly 13 Hot Water Port Blanking Assembly

7 Hot Water Inlet Tail Assembly 14 Cold Water Port Blanking Assembly

8 Sealing Washer 15 Backnut

9 Swivel Nut

Cold Water Inlet Assembly

11

including 5 l/m flow regulator

Hot Water Inlet Assembly

12

including 5 l/m flow regulator

© Intatec Ltd 2016

3

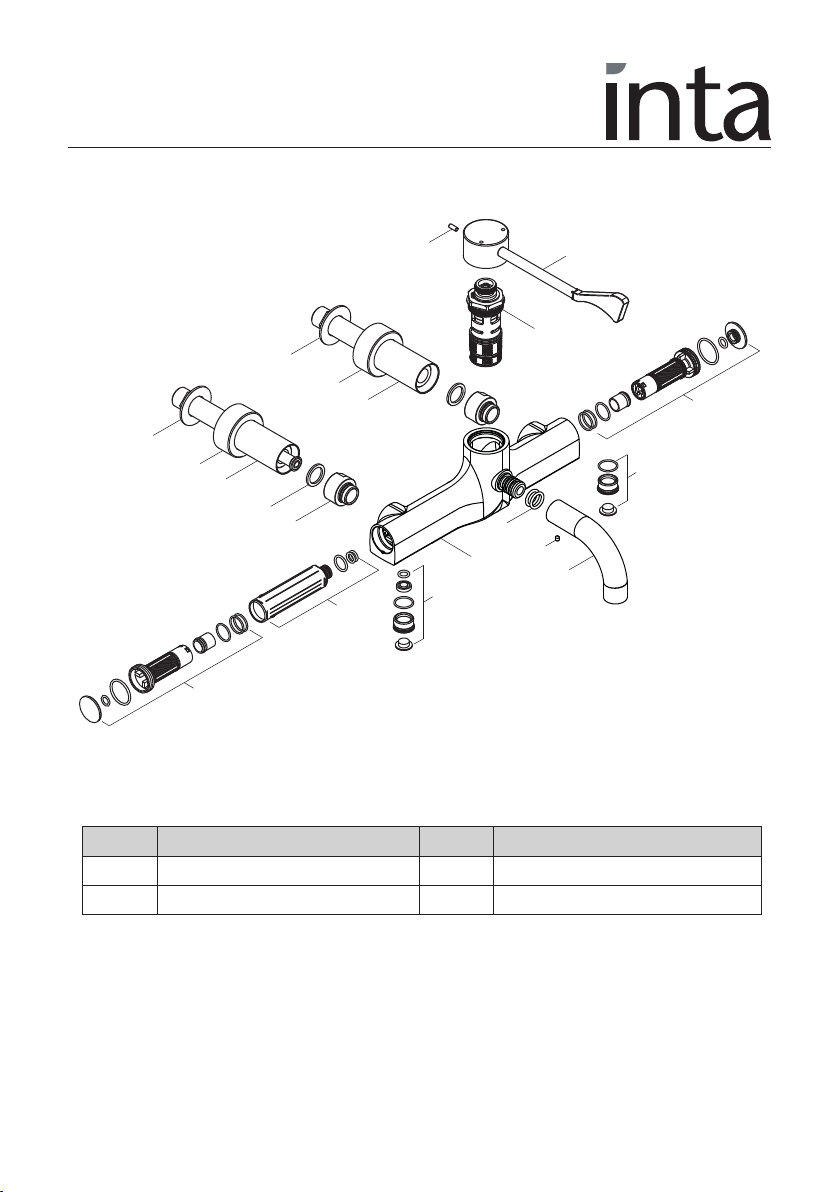

Components - Wall Mounted with Removable Spout

1

2

3

4

5

6

5

7

8

9

11

13

14

15

15

10

12

17

18

19

Additional Components - Removable Spout

Item Description Item Description

1 Body 18 Spout Retaining Screw

17 Spout 19 ‘O’ Ring

© Intatec Ltd 2016

4

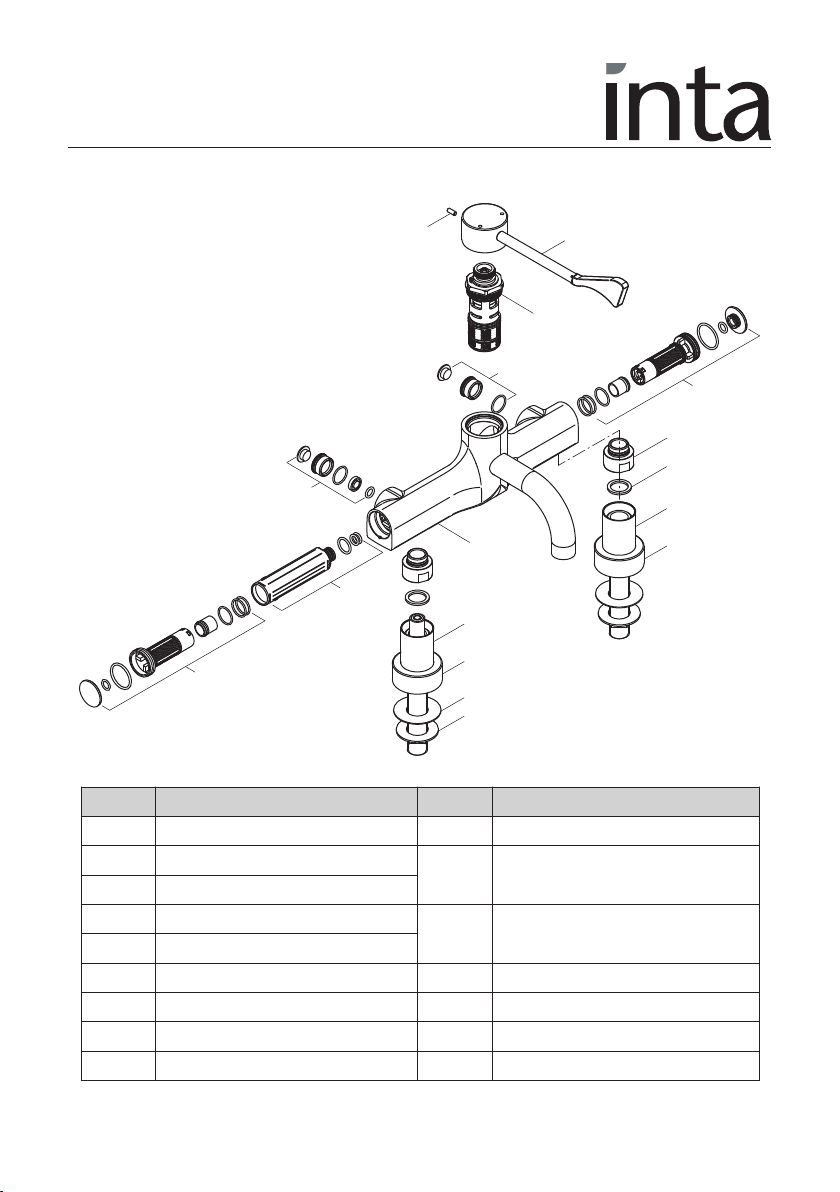

Components - Deck Mounted with Fixed Spout

1

2

3

4

11

6

5

8

9

7

5

13

14

16

15

10

12

Item Description Item Description

1 Body inc. Outlet Diffuser 10 Hot Water Insulator

2 Thermostatic Cartridge

3 Lever

4 Lever Retaining Screw

5 Concealing Plate

6 Cold Water Inlet Tail Assembly 13 Hot Water Port Blanking Assembly

Cold Water Inlet Assembly

11

including 5 l/m flow regulator

Hot Water Inlet Assembly

12

including 5 l/m flow regulator

7 Hot Water Inlet Tail Assembly 14 Cold Water Port Blanking Assembly

8 Sealing Washer 15 Backnut

9 Swivel Nut 16 Washer - Chrome

© Intatec Ltd 2016

5

Components - Deck Mounted with Removable Spout

1

2

3

4

11

6

5

8

9

7

5

13

14

16

15

10

12

17

18

19

Additional Components - Removable Spout

Item Description Item Description

1 Body 18 Spout Retaining Screw

17 Spout 19 ‘O’ Ring

© Intatec Ltd 2016

6

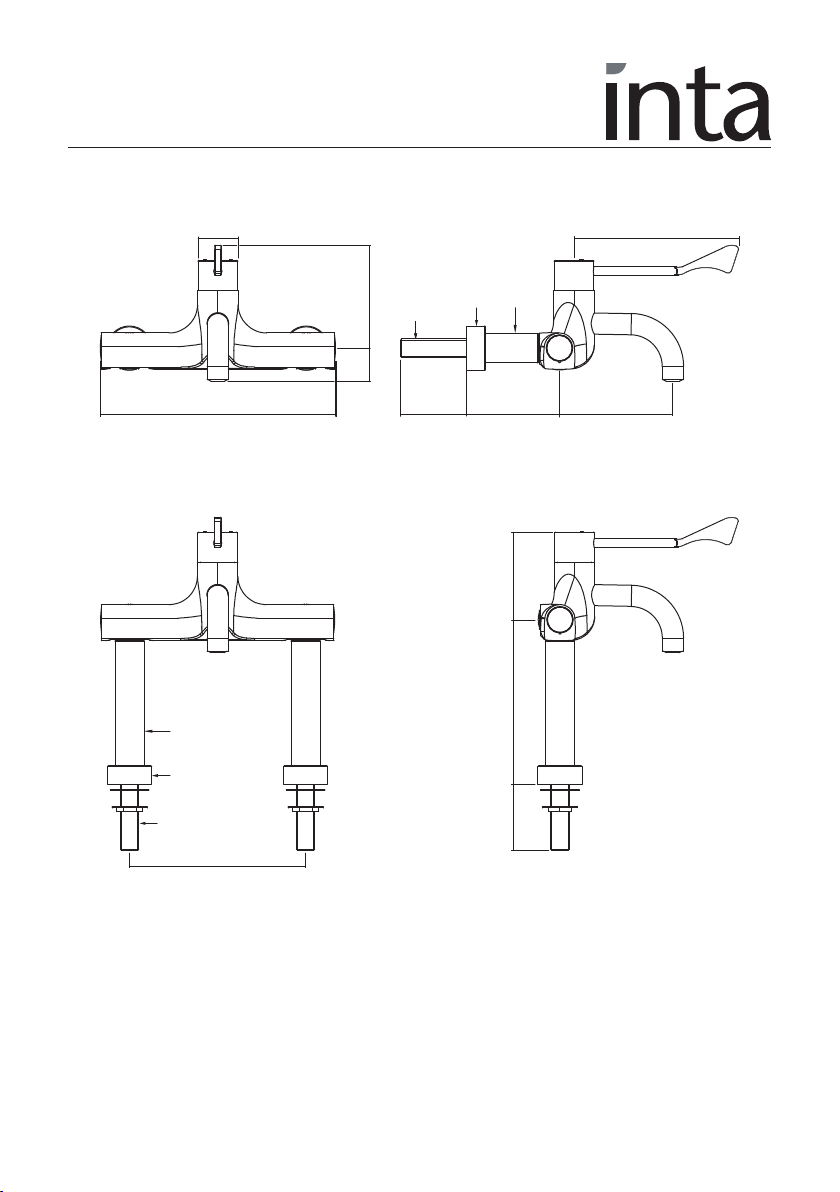

Dimensions - Wall Mounted

37

G½B

12875 105

186.5

Ø45

266

116.5

Ø50 Ø33

75

187.5

200

G½B

Ø50

Ø33

100

Dimensions - Deck Mounted

© Intatec Ltd 2016

7

Installation

Cold water

inlet tail

Sealing

washer

6

Hot water

inlet tail

7

Wall Mounting

• The tap is supplied as shown in the Components section except that the thermostatic cartridge

(2) and swivel nut connectors (9) are fitted into the body.

• Fit the concealing plates (5) onto the tailpieces (6) & (7).

• Screw the tailpiece (6) into the cold water inlet of

the tap, right hand side when facing the tap.

ATTENTION: The hot water inlet connection tail

can be identified by the brass insulator pipe that

protrudes past the connecting thread.

Care must be taken to ensure the Hot Water Inlet

Tail Assembly is connected securely into the hot

water inlet of the tap body.

• Screw the tailpiece (7) into the hot water inlet of

the tap, left hand side when facing the tap.

• For wall mounting fit the tap assembly to the

mounting panel, using the back nuts (15) and slide

the concealing plates to the panel.

• Care should be taken that the maximum panel thickness does not exceed 33mm..

• Connect the supply pipes to the tap, cold on the right, hot on the left.

• Fit the lever (3) to the tap using the grub screw (4) provided.

• Please ensure that the hydraulic installation is completed and that all check valves are open.

Deck Mounting

• Screw the tailpiece (6) into the cold water inlet of the tap, right hand side when facing the

tap.

ATTENTION: The hot water inlet connection tail can be identified by the brass

insulator pipe that protrudes past the connecting thread. Care must be taken to ensure the

Hot Water Inlet Tail Assembly is connected securely into the hot water inlet of the tap

body.

• Screw the tailpiece (7) into the hot water inlet of the tap, left hand side when facing the tap.

• For deck mounting fit the tap assembly to the basin, using the washers (16) and back nuts

(15) (supplied) and slide the concealing plates to the basin.

• Connect the supply pipes to the tap, cold on the right, hot on the left.

• Fit the lever (3) to the tap using the grub screw (4) provided.

• Please ensure that the hydraulic installation is completed and that all isolation valves are in

the open position.

© Intatec Ltd 2016

8

Off

Warm

Cold

Max. blend

temperature

(preset)

Hot Supply

Cold Supply

Operation

As the handle is rotated anti-clockwise from the off position the delivered water progresses from

cold, through warm to the pre-set maximum temperature of approximately 43˚C.

Trouble Shooting

Fault Diagnosis

Mixed water temperature is not hot enough. Ensure the hot water supply is at a constant

temperature above 60˚C.

Re-calibrate as per page 10.

Check for airlocks in the pipework.

The water goes cold during operation. Insufficient stored hot water supply.

Ensure that the boiler is still firing for combi

boilers.

Adjust the boiler control to a minimum setting

of 65˚C not necessarily the best flow rate.

Temperature is too hot or when set to Check the commissioned maximum

hot water runs cold. temperature of the valve. Check connections

to the mixer are not reversed.

Flow of water through the valve is low. Check the filters are clean and supply

pressure is above 1 bar.

No flow of water. Ensure the mixer has not fail-safed,

and check that there is water flow to the mixer

and the service valves are not closed - see

exploded drawing.

© Intatec Ltd 2016

9

Re-Calibration

A

B

A

A

B

B

Remove rings and

set water temperature

Replace rings

as shown

Rings act

as stops

The factory setting at 41˚C can be altered to suit site conditions.

Warning: Care must be taken when altering the setting as incorrect calibration can cause injury.

• Remove the grub screw.

• Lift the handle cover off.

• Re-calibrate by removing the temperature stop rings from the cartridge and set the mixed water

to the required temperature by temporarily re-fitting the control lever.

• Once the required temperature is achieved replace the two temperature stop rings on the

splined spindle of the cartridge as shown. These two rings are used to prevent the temperature

of the cartridge from being altered whilst in use. The stop rings should be locked at either end

of the operating cycle and will form a physical stop to prevent the cartridge turning (see

below)

• Refit the lever assembly and grub screw.

• Recheck the calibrated temperature

Cartridge removal

1 Unscrew the retaining screw and remove the lever.

2 The thermostatic cartridge is a single piece construction and should be unscrewed

anti-clockwise from the mixer body using a suitably sized spanner.

3 When re-installing the cartridge into the mixer body, it should be tightened to a maximum

torque of 15 Nm

© Intatec Ltd 2016

10

Aftercare

Internal bore

in flow

straightener

• With all highly polished items, care should be taken not to damage any of the external

surfaces.

• We recommend that to ensure the physical appearance of the product and component parts

that it is periodically cleaned with a soft damp cloth and a mild detergent. The use of abrasive

or solvent cleaners will damage the finish of the product.

• We recommend periodically that the flow straightener is cleaned using a suitable scaling

solvent. Check first it does not affect the plated surface.

• The internal bore of the flow straightener must be periodically wiped using a damp cloth.

• We recommend that this fitting is serviced at least once a year.

• Only use genuine spare parts, the full list is available on request by ringing the Technical

Helpline number on the back page.

Removing Spout

The HTMWMRS wall mounted and HTMDMRS deck mounted taps have a removable spout to

assist with cleaning, disinfection by immersion or sterilisation in an autoclave.

Inta recommend that a replacement spout is available as the tap should not be left without

a spout (HTMSP16XX).

Cleaning, disinfection and sterilisation is only necessary if there is evidence of solid deposits

around the outlet from the tap or a minimum of once per year.

• Ensure the isolation valve in both supplies to the tap are in the closed position and the lever is

also in the closed position to prevent water flow and potential flooding.

© Intatec Ltd 2016

11

Removing Spout

17

18

Lever in closed

position

19

• Using a suitably sized Allen key unscrew the grub screw (18) located beneath the spout.

The grub screw must be removed completely to ensure the ‘O’ rings are not damaged when

the spout is pulled away.

• Pull the spout (17) away for the body of the tap, care should be taken to prevent damage to

the chrome finish of the spout.

• Check the condition of the two ‘O’ rings (19) on the spigot of the tap body, if damaged they

must be replaced.

Once the spout has been removed disinfection or sterilisation can commence.

• The spout can be sterilised in an Autoclave following standard sterilisation procedures.

• The spout after disinfection and sterilisation should be stored in such a manner that they will not

become infected or dirty before refitting.

Refitting Spout

• When refitting the spout lubricate the two ‘O’ rings with a suitable lubricant to ease

re-assembly.

• Fit and re-tighten the grub screw (18).

• Open the isolation valve in both supplies to the tap.

• Only use genuine spare parts, the full list is available on request by ringing the Technical

Helpline number on the back page.

© Intatec Ltd 2016

12

System Flushing Procedure

A

Waste water flushed

through outlet with

hose connected

7 - Flushing

(hose not supplied)

90°

OPEN

CLOSE

1 - Move handle to closed position

Water must not pass through

the tap before completing

system flushing

2 - Ensure both isolation valves

are in the closed position

2A - Turn to closed

position

3 - Remove end cover from

the hot supply end of

the tap

1

2

4 - Carefully remove check valve

housing using the extraction

tool (HTMSP20XX) and rotating

anti-clockwise

5 - Screw in connector plug using

suitably sized spanner

6 - Attach hose connector

(HTMFLUSH)

90°

OPEN

CLOSE

6A - Turn to open

position

Hot

supply

pipework

flushed

The water system must be thoroughly flushed before attempting to commission or operate this tap to

ensure all pipework is clean and free from any debris. This system flushing procedure allows the

process to be efficiently conducted with the tap installed. Failure to carry out effective system flushing

before commissioning or operating this product could damage or limit the performance of the

product and invalidate the product guarantee.

© Intatec Ltd 2016

13

System Flushing Procedure

90°

OPEN

CLOSE

8 - Ensure the isolation valve

on the hot supply is

closed before

9 - Unscrew the connector plug using

suitably sized spanner and refit

the check valve and end cover

10 - Repeat the procedure for the

cold inlet side before opening

both isolation valves

REMOVE

1 - Move handle to open position 2 - Isolate both inlet tails

2A - Turn to the

closed position

90°

OPEN

CLOSE

3 - Remove the cover from each

inlet

4 - Remove hot and cold inlet plugs

using a 10mm Allen key

4A

Sterilization Process

NOTE: Not a replacement for chlorination

© Intatec Ltd 2016

14

Sterilization Process

5 - Fit the cold inlet plug into the hot

position and the hot into the

cold position

By carrying out the above procedure you are sterilizing the complete tap with hot water

6 - Open the ball valve on the hot

supply to start sterilization

procedure

90°

OPEN

CLOSE

6A - Turn to open

position

7 - Close the isolation

valve

90°

OPEN

CLOSE

8 - Refit the hot inlet plug into the hot position

and the cold into the cold position and refit

the covers

90°

OPEN

CLOSE

9 - Open the isolation valve

and move the handle

to the closed position

Temperature Disinfection time

60˚C

65˚C

70˚C

20 minutes

10 minutes

5 minutes

10 - Disinfection times based

on water temperature

© Intatec Ltd 2016

15

When this Mixer is used in a DO8 Application the following Instructions apply:

Introduction

This Inta Thermostatic Mixer has been specifically designed and manufactured to meet the

requirements of BS 7942: 2000 and NHS D08. The product has been independently tested

and approved as a TYPE 3 valve under the TMV3 scheme.

Technical Specification

Outlet Temperature Adjustment Range 30˚C to 50˚C

Temperature Stability ±2˚C

Maximum Hot Inlet Temperature 85˚C

Inlet Temperature Range

DO8 Working Pressure Range

Min Temp Differential (Mix to Hot) for Fail-Safe 10˚C

Max. Pressure Inlet Differential 5 : 1

Max. Flow Rate @ 1 bar Differential

Operating Pressure Range High Pressure Low Pressure

Maximum Static Pressure 10 bar 10 bar

Flow Pressure, Hot and Cold 1 to 5 bar 0.2 to 1 bar

Hot Supply Temperature 55˚C to 65˚C 55˚C to 65˚C

Cold Supply Temperature 5˚C to 20˚C 5˚C to 20˚C

55˚C to 65˚C : Hot Supply

5˚C to 20˚C : Cold Supply

0.2 to 1.0 bar : Low Pressure

1.0 to 5.0 bar : High Pressure

Ø15mm 1500 l/h (25 l/m)

Ø22mm 1700 l/h (28.3 l/m)

Application

This thermostatic mixer has been independently tested by WRc and certified as meeting the

requirements of the NHS D08 specification under the TMV3 Scheme as being suitable for use

on the following;

Code Application Range

HP-W Basin High Pressure

© Intatec Ltd 2016

16

Installation

IMPORTANT – The following instructions must be read prior to the installation of any Inta

thermostatic mixing valve.

The installer should also be aware of his responsibility and duty of care to ensure that all aspects

of the installation comply with all current regulations and legislations.

It has been brought to our attention that flushing water systems using certain chemicals may affect

the workings of the valve, which may adversely affect its performance.

We recommend that following system flushing with chemicals, mixers are checked for correct

operation.

1. It is essential that, before installing a thermostatic mixing valve, the supply conditions of the

system to which the valve is intended to be fitted are checked to confirm compliance with the

parameters as quoted within the Technical Specification above and conditions on which the

approval is granted i.e. verify supply temperatures, supply pressures, risk assessments etc

2. Consideration must be made for the possibility of multiple/ simultaneous demands being made

on the supply system whilst the thermostatic mixing valve is in use, all practical pre-cautions

must be made to ensure that the valve is not affected. Failure to make provision within the pipe

sizing etc will affect the performance of the valve.

3. The supply system to which the Thermostatic Mixing Valve is to be installed into must be

thoroughly flushed and cleaned to remove any debris (see page 13), which may be

accumulated during the installation. Failure to remove any debris will affect the performance

and the manufacturer’s warranty on the product.

4. Independent filters/check valves and isolation valves must be fitted in conjunction with the

valve. In areas that are subject to hard water, provision must be made to treat the supplies

prior the supplies entering any product.

5. The maximum flow rate of the valve will only be achieved when the supply conditions are

achieved as quoted, with a flow condition under 1 bar differential pressure.

6. This Inta thermostatic mixer has been designed to be wall mounted. It is essential that access to

the valve is not obstructed for future maintenance, that may be required to the valve or

associated fittings.

7. The connection of the hot and cold supplies must be in accordance with the instructions shown

on page 8 i.e. hot water connected to the left hand side of the valve when the nozzle is facing

you.

8. In a situation where one or both of the water supplies are excessive, it is recommended to fit a

Pressure Reducing Valve, WRAS approved product, to reduce the pressure(s) to within those

stated in the Technical Specification previously stated or a suitable flow regulator.

9. We recommend that Y pattern strainers and full bore isolation valves are installed in

conjunction with this product as close as practically possible to the location valve.

© Intatec Ltd 2016

17

Installation

10. It is essential that this product should not be installed in situations where there is a possibility of

the valve being deprived of water or where demands for water are greater than the actual

stored supplies.

11. To ensure that the performance levels of this Thermostatic Mixing Valve are maintained (in the

event of cold water failure) the temperature of the hot water supply at the point of entry to the

valve must be a minimum of 10°C above the commissioned mixed water discharge

temperature.

12. This Thermostatic Mixing Valve must not be subject to any extreme temperature variations

either during the installation or under normal operating condition

Commissioning

IMPORTANT – The following instructions must be read and understood prior to the commissioning

of a Thermostatic Mixer. If under any circumstances there are aspects to the installation/system which

do not comply with the specification laid down, the valve MUST NOT is put into operation until the

system/installation complies with our specification.

1. Ensure that the system is thoroughly cleaned and free from any debris prior to the

commissioning of the valve. (See page 10)

2. The commissioning of the temperature must be carried out using a suitably calibrated

thermometer – preferably a digital thermometer. (See page 8)

3. In the absence of other temperatures being specified we recommend that the outlet

temperatures quoted in table 1 are used, extracted from the “National Health Service –

Health Guidance Note – Safe Hot Water and Surface Temperatures”.

Table 1

Application Recommended Set Hot Water Temperature

Wash Hand Basin 41˚C

4. Each valve must be commissioned taking into consideration any fluctuations, which may

occur within the system due to simultaneous demands. It is advisable that any outlets which

are connected to the same supply as the mixing valve are opened during setting of the

mixed water temperature. It is advisable to ensure that the water temperatures are

established before any attempt to commission.

5. Once the supply temperatures are stable and the normal operating conditions are

established, the valve can be commissioned. We suggest that the following sequence is

followed when commissioning the valve:

5.1 Using the lever turn to the maximum hot setting of the tap, the mixed water temperature

should be preset (see page 8).

5.2 Measure and record the temperature of the hot and cold water supplies at the

connections to the valve.

© Intatec Ltd 2016

18

Commissioning

5.3 Measure and record the temperature of the water discharging from the valve for the

largest and smallest draw off point.

5.4 Isolate the cold water supply to the valve and monitor the mixed water temperature.

5.5 Measure and record the maximum mixed water temperature and the final temperature.

The final temperature found during the test should not exceed the values quoted in

table 2.

Table 2

Application Maximum Hot Water Temperature

Wash Hand Basin 43˚C

5.6 Record all the equipment used during the commissioning.

6. Ensure that the application, to which the valve will be used, is appropriate for the approved

designation.

7. The above information must be recorded and updated on every occasion when any work is

carried out on the valve.

In Service Testing

To ensure that the Thermostatic Mixer maintains a high level of protection, we advise the following in

service testing is followed (the same equipment used to commission the valve initially must be used in

the following tasks).

1. After a period of between 6 and 8 weeks after commissioning carry out the following.

a) Record the temperature of the hot and cold water supplies.

b) Record the temperature of the mixed water at the largest draw off flow rate.

c) Record the temperature of the mixed water at the smallest draw off flow rate.

2. If the mixed water temperature has changed significantly from the previous test results

(e.g. > 1 k), record the change and before re-setting the mixed water temperature check that:

a) All the strainers are clean

b) All the check valves are in good working order

c) The isolation valves are fully open.

© Intatec Ltd 2016

19

In Service Testing

3. If the mixed water temperature is acceptable, carry out the following:

a) Record the temperature of the hot and cold water supplies.

b) Record the temperature of the mixed water at the largest draw off flow rate.

c) Record the temperature of the mixed water at the smallest draw off flow rate.

d) Isolate the cold water supply to the mixing valve and monitor the mixed water

temperature.

e) Record the maximum temperature achieved as a result and the final temperature (the

final temperature should not exceed the values quoted in table 2)

f) Record the equipment used during these tests.

4. If during the test, paragraph 3, the mixed water temperature is greater than the values quoted

in table 2 or the maximum temperature exceeds the corresponding values from previous test

results by more than 2˚C, the tap must be serviced.

5. After a period of between 12 and 15 weeks after commissioning, carry out the sequence of

tests as described in 1, 2, 3 and 4 of this section.

6. Dependant upon the results obtained from the first two series of tests; there are a number of

possible outcomes.

a) If no significant change in the mixed water temperatures (e.g. < 1˚C) is recorded

between commissioning and step 3e above or between commissioning and 5 of this

section, the next in service testing should be carried out at a period of 24 to 28 weeks

after initial commissioning.

b) If a small change (e.g. 1 - 2˚C) in the mixed water temperature is recorded in only one

of these periods, necessitating adjustment of the mixed water temperature, then the next in

service test can be deferred to 24 to 28 weeks after commissioning.

c) If small change (e.g. 1 - 2˚C) in the mixed water temperature is recorded in both of these

periods, necessitating adjustment of the mixed water temperature, then the next in service

test can be deferred to 18 to 21 weeks after commissioning.

d) If significant changes (e.g. >2˚C) in the mixed water temperature are recorded in both

of these periods necessitating service work, then the next in service test should be carried

out at 18 - 21 weeks after commissioning.

7. The general principle to be observed after the first two or three in service tests is that the

intervals of future test should be set to those which previous tests have shown can be achieved

with no more than a small change in mixed water temperature.

8. In all areas periodic maintenance of the valve and associated fittings i.e. strainers, check

valves will ensure optimum performance levels are maintained.

9. On the inlet strainers on both the hot and cold water supply inlet can be removed for cleaning.

10. The built in check valves can be accessed in a similar way to the filters to ensure freedom and

correct seating.

© Intatec Ltd 2016

20

Guarantee

Intatec guarantees the product to be free from defects in materials and workmanship at the date

of purchase. If the product is determined to be defective at the date of original purchase due to

improper materials or workmanship and you inform us of this within the prescribed warranty

period, (five years for showering products, one year for commercial products), of the date of

purchase, Intatec will, without charge for labour or parts, repair or (at the discretion of Intatec)

replace the product or its defective parts subject to the terms and limitations below. Intatec may

replace defective products or parts with new or refurbished products or parts.

Guarantee services will be provided only if the original invoice or sales receipt (indicating the

date of purchase and supplier's name) is presented with the defective product within the

guarantee period.

The free of charge service may be refused if this information is not available. The guarantee will

not apply if the product has not been installed correctly.

This guarantee does not cover (without limitation):

• Periodic maintenance or parts replacement due to wear and tear;

• Damage or defects caused by misuse in operation;

• Installation or use of the product inconsistent with good working practice;

• Failure to maintain the product in accordance with instructions;

• Repair or attempted repair by persons who are not qualified;

• Neglect

Consumers have legal (statutory) rights under applicable laws relating to the sale of consumer

products. This guarantee does not affect statutory rights you may have or those rights that cannot

be excluded or limited, nor rights against the person from whom you purchased the product. You

may assert any rights you have at your sole discretion.

© Intatec Ltd 2016

Please leave this Manual for the User

21

Notes:

© Intatec Ltd 2016

22

E & O.E

© Intatec Ltd 2016

Please leave this Manual for the User

To activate your product warranty please visit

www.intatec.co.uk

and click on Product Registration

Intatec Ltd

Airfield Industrial Estate

Hixon

Staffordshire

ST18 0PF

Tel: 01889 272 180

Fax: 01889 272 181

email: sales@intatec.co.uk

web: www.intatec.co.uk

10-08-16

Loading...

Loading...