Page 1

ETSM / ETSU

Installation and

Operation Manual

Manual

Page 2

Page 3

Copyright © July 2018 INSYS MICROELECTRONICS GmbH

Any duplication of this manual is prohibited. All rights on this documentation and

the devices are with INSYS MICROELECTRONICS GmbH Regensburg.

Trademarks

The use of a trademark not shown below is not an indication that it is freely avai la-

ble for use.

MNP is a registered trademark of Microcom Inc.

IBM PC, AT, XT are registered trademarks of International Business Machine Corporation.

INSYS®, VCom®, e-Mobility LSG® and e-Mobility PLC® are registered trademarks of

INSYS MICROELECTRONICS GmbH.

Windows™ is a registered trademark of Microsoft Corporation.

Linux is a registered trademark of Linus Torvalds.

Publisher:

INSYS MICROELECTRONICS GmbH

Hermann-Köhl-Str. 22

D-93049 Regensburg, Germany

Phone: +49 941 58692 0

Fax: +49 941 58692 45

E-mail: info@insys-icom.com

Internet: http://www.insys-icom.com

Date: Jul-18

Item: 10019946

Version: 1.0

Language: EN

Page 4

Content

4

Jul-18

1 Preface ............................................................................... 6

1. 1 Defects Liability Terms....................................................................... 6

1. 2 Feedback ....................................................................................... 6

1. 3 Marking o f Warnings and Notes ........................................................... 7

1. 4 Sy mbols and the Formatting in this Manual ............................................. 8

2 Safety ................................................................................ 9

2. 1 Intended Use .................................................................................. 9

2. 2 Per missible Technical Limits .............................................................. 10

2. 3 Responsibilities of the Operator .......................................................... 10

2. 4 Qualification of the Personnel ............................................................ 10

2. 5 Instructions for Tran sport and Storage.................................................. 10

2. 6 Marking s on the Product .................................................................. 11

2. 7 Environmental Protection ................................................................. 11

2. 8 Safety Instructions for Electrical Installation ........................................... 12

2. 9 General Safety Instructions ............................................................... 12

3 Using Open Source Software .................................................. 14

3. 1 General Infor mation ........................................................................ 14

3. 2 Special Liab ility Regulations .............................................................. 15

3. 3 Used Open -Source So ftware ............................................................. 15

4 Version History ................................................................... 16

5 Device Variants ................................................................... 17

6 Scope of Delivery ................................................................ 18

7 Technical Information ........................................................... 19

7. 1 Technical Data............................................................................... 19

7.1.1 Physical Features ................................................................................ 19

7.1.2 Technologica l Features.........................................................................20

7. 2 Connections and display elements ...................................................... 20

7.2.1 Connecting the connectors ..................................................................23

8 Assembly .......................................................................... 24

9 Commissioni ng, Operation and Configuration ETSU....................... 26

Page 5

Contents

Jul-18 5

10 Commissioni ng, Operation and Configuration ETSM ...................... 27

10 .1 Commissioning.............................................................................. 27

10 .2 Operation via the web interface .......................................................... 28

10 .3 Supported Switch Configuration ......................................................... 30

10.3.1 Ethernet Ports ..................................................................................... 30

10.3.2 Port Mirroring ......................................................................................32

10.3.3 Link Aggreg ation................................................................................. 33

10.3.4 VLAN .................................................................................................. 34

10 .4 Device Diagno sis ........................................................................... 36

10.4.1 LED display ......................................................................................... 36

10.4.2 Failure conditions ................................................................................ 36

10.4.3 Fault contact ....................................................................................... 37

10.4.4 Traps................................................................................................... 38

10.4.5 Diagnosis services............................................................................... 39

10.4.6 Digital input .........................................................................................42

10.4.7 Log files .............................................................................................. 43

10 .5 S ystem Access Settings ................................................................... 44

10.5.1 IP addre ss ........................................................................................... 44

10.5.2 Power supply ...................................................................................... 44

10.5.3 Administration port ............................................................................. 45

10.5.4 Password change ................................................................................ 45

10.5.5 Configuration files ............................................................................... 46

10 .6 Configuration via USB flash drive ........................................................ 47

10.6.1 Function.............................................................................................. 47

10.6.2 Perfor ming the configuration............................................................... 47

10 .7 F ir mware update ............................................................................ 48

10.7.1 Firmware update via web interface ...................................................... 48

10.7.2 Firmware update via USB flash drive ................................................... 49

11 Maintenance, Repair and Troubleshooting .................................. 50

11 .1 Maintenance ................................................................................. 50

11 .2 Troubl eshooting............................................................................. 50

11 .3 Repair ......................................................................................... 50

12 Waste Disposal ................................................................... 51

12. 1 Repurchasing of Legacy Syste ms........................................................ 51

13 Declaration of Conformity ...................................................... 52

14 Tables and Diagrams ............................................................ 53

14 .1 List of Tables ................................................................................ 53

14 .2 List of Diagra ms............................................................................. 53

15 Index ............................................................................... 54

Page 6

Preface

ETSM / ETSU

6

1 Preface

This manual allows for the safe and efficient use of the product. The manual is part

of the product and must always be stored accessible for installation, commissioning and operating personnel.

1.1 Defects Liability Terms

A usage not according to the intended purpose, an ignorance of this documentation, the use of insufficiently qualified personnel as well as unauthorised modifications exclude the liability of the manufacturer for damages resulting from this. The

liability of the manufacturer ceases to exist.

The regulations of our Delivery and Purchasing Conditions are effective. These can

be found on our website (www.insys-icom.de/imprint/) under “General Terms and

Conditions“.

1.2 Feedback

We are permanently improving our products and the associated technical documentation. Your feedback is very helpful for this. Please tell us what you like in particular on our products and publications and what can be improved from your point

of view. We highly appreciate your suggestions and will include them in our work

to support you and all our customers. We are looking forward to any of your feedback.

Please send an e-mail to support@insys-tec.de.

We'd like to know your applications. Please send us a few headwords that we

know the applications you solve using products of INSYS icom.

Page 7

ETSM / ETSU

Preface

7

1.3 Marking of Warnings and Notes

Symbols and Key Words

Danger!

Risk of severe or fatal injury

One of these symbols in conjunction with the key word

Danger indicates an imminent danger. It will cause death

or severe injuries if not avoided.

Warning!

Personal injury

This symbol in conjunction with the key word Warning

indicates a possibly hazardous situation. It might cause

death or severe injuries if not avoided.

Caution!

Sli ght injury and / or material damage

This symbol in conjunction with the key word Caution

indicates a possibly hazardous or harmful situation. It

might cause slight or minor injuries or a damage of the

product or something in its vicinity if not avoided.

Note

Imp rovement of the application

This symbol in conjunction with the key word Note

indicates hints for the user or very useful information. This

information helps with installation, set-up and operation of

the product to ensure a fault-free operation.

Page 8

Preface

ETSM / ETSU

8

1.4 Symbols and the Formatting in this Manual

This section describes the definition, formatting and symbols used in this manual.

The various symbols are meant to help you read and find the information relevant

to you. The following text is structured like a typical operating instruction of this

manual.

Bold print: This will tell you what the following steps w ill result in

After that, there will be a detailed explanation why you could perform the

following steps to be able to reach the objective indicated first. You can

decide whether the section is relevant for you or not.

An arrow will indicate prerequisites which must be fulfilled to be able to

process the subsequent steps in a meaningful way. You will also learn

which software or which equipment you will need.

1. One individual action step: This tells you what you need to do at this

point. The steps are numbered for better orientation.

A result which you will receive after performing a step will be marked

with a check mark. At this point, you can check if the previous steps

were successful.

Additional information which you should consider are marked with a

circled "i". At this point, we will indicate possible error sources and tell

you how to avoid them.

➢

Alternative results and steps are marked with an arrow. This will tell

you how to reach the same results performing different steps, or what

you could do if you didn't reach the expected results at this point.

Page 9

ETSM / ETSU

Safety

9

2 Safety

The Safety section provides an overview about the safety instructions, which must

be observed for the operation of the product.

The product is constructed according to the currently valid state-of-the-art technology and reliable in operation. It has been checked and left the factory in flawless

condition concerning safety. In order to maintain this condition during the service

life, the instructions of the valid publications and certificates must be observed and

followed.

It is necessary to adhere to the general safety instructions must when operating the

product. The descriptions of processes and operation procedures are provided with

precise safety instructions in the respective sections in addition to the general

safety instructions.

Moreover, the local accident prevention regulations and general safety regulations

for the operating conditions of the device are effective.

An optimum protection of the personnel and the environment from hazards as well

as a safe and fault-free operation of the product is only possible if all safety instructions are observed.

2.1 Intended Use

The product may be used for the following purposes:

• Usage and mounting in an industrial cabinet.

• Switching and data transmission functions in machines according to

the machine directive 2006/42/EC.

• Usage as data transmission device for a PLC.

The product may not be used for the following purposes and used or operated under the following conditions:

• Controlling or switching of machines and systems, which do not

comply with the directive 2006/42/EC.

• Usage, controlling, switching and data transmission of machines and

systems, which are operated in explosive atmospheres.

• Controlling, switching and data transmission of machines, which may

involve risks to life and limb due to their functions or when a

breakdown occurs.

Page 10

Safety

ETSM / ETSU

10

2.2 Permissible Technical Limits

The product is only intended for the use within the permissible technical limits

specified in the data sheets.

The following permissible limits must be observed:

• The ambient temperature limits must not be fallen below or

exceeded.

• The supply voltage range must not be fallen below or exceeded.

• The maximum humidity must not be exceeded and condensate

formation must be prevented.

• The maximum switching voltage and the maximum switching current

load must not be exceeded.

• The maximum input voltage and the maximum input current must not

be exceeded.

2.3 Responsibilities of the Operator

As a matter of principle, the operator must observe the legal regulations, which are

valid in his country, concerning operation, functional test, repair and maintenance

of electrical devices.

2.4 Qualification of the Personnel

The installation, commissioning and maintenance of the product must only be performed by trained expert personnel, which has been authorised by the plant operator. The expert personnel must have read and understood this documentation and

observe the instructions.

Electrical connection and commissioning must only be performed by a person, who

is able to work on electrical installations and identify and avoid possible hazards independently, based on professional training, knowledge and experience as well as

knowledge of the relevant standards and regulations.

2.5 Instructions for Transport and Storage

The following instructions must be observed:

• Do not expose the product to moisture and other potential hazardous

environmental conditions (radiation, gases, etc.) during transport and

storage. Pack product accordingly.

• Pack product sufficiently to protect it against shocks during transport

and storage, e.g. using air-cushioned packing material.

Check product for possible damages, which might have been caused by improper

transport, before installation. Transport damages must be noted down to the shipping documents. All claims or damages must be filed immediately and before installation against the carrier or party responsible for the storage.

Page 11

ETSM / ETSU

Safety

11

2.6 Markings on the Product

The identification plate of the product is either a print or a label on a face of the

product. Amongst other things, it can contain the following markings, which are

explained in detail here.

Observe manual

This symbol indicates that the manual of the product contains

essential safety instructions that must be followed implicitly.

Dispose waste electronic equipment environmentally

compatible

This symbol indicates that waste electronic equipment must be

disposed separately from residual waste via appropriate collecting

points. See also Section Disposal in this manual.

CE marking

By applying a CE marking, the manufacturer confirms that the

product complies with the European directives that apply productspecific.

UL marking

By applying a UL marking, the manufacturer confirms that the

product complies with the obligatory safety requirements.

Appliance Class II - double insulated

This symbol indicates that the product complies with Appliance

Class II

Appliance Class III - protection by extra low voltage

This symbol indicates that the product complies with Appliance

Class III

2.7 Environmental Protection

Dispose the product and the packaging according to the relevant environmental

protection regulations. The Waste Disposal section in this manual contains notes

about disposing the product. Separate the packaging components of cardboard

and paper as well as plastic and deliver them to the respective collection systems

for recycling.

Page 12

Safety

ETSM / ETSU

12

2.8 Safety Instructions for Electrical Installation

The electrical connection must only be made by authorised expert personnel according to the wiring diagrams.

The notes to the electrical connection in the manual must be observed. Otherwise,

the protection category might be affected.

The safe disconnection of circuits, which are hazardous when touched, is only ensured if the connected devices meet the requirements of VDE T.101 (Basic requirements for safe disconnection).

The supply lines are to be routed apart from circuits, which are hazardous when

touched, or isolated additionally for a safe disconnection.

An easily accessible isolation device that disconnects all lines must be installed

prior to commissioning of the device to be able to isolate it completely from power

supply.

2.9 General Safety Instructions

Caution!

Electrostatic discharges may damage the product!

Damage of the product.

Observe the general safety precautions when handling

electrostatic-discharge-sensitive parts.

Caution!

Incomplete voltage isolation!

Damage of the product.

To isolate the voltage from the device, disconnect any

supply circuit with its respective isolation device if a

redundant power supply is used.

Caution!

Moisture and liquids from the environment may seep into

the interior of the product!

Fi re hazard and damage of the product.

The product must not be used in wet or damp

environments, or in the direct vicinity of water. Install the

product at a dry location, protected from water spray.

Disconnect the power supply before you perform any work

on a device which may have been in contact with

moisture.

Page 13

ETSM / ETSU

Safety

13

Caution!

Short circuits and damage due to improper repairs and

modifications as well as opening of maintenance areas!

Fi re hazard and damage of the product.

It is not permitted to open the product for repair or

modification.

Caution!

Overvoltage and voltage peaks from the mains supply!

Fi re hazard and damage of the product due to overvoltage .

Install suitable overvoltage protection.

Caution!

Damage due to chemicals!

Ketones and chlorinated hydrocarbons dissolve the plastic

housing and damage the surface of the device.

Never let the device come into contact with ketones (e.g.

acetone) or chlorinated hydrocarbons, such as

dichloromethane.

Page 14

Using Open Source Software

ETSM / ETSU

14

3 Using Open Source Software

3.1 General Information

Our product ETSM / ETSU contains, amongst others, so-called open-source software that is provided by third parties and has been published for free public use.

The open-source software is subject to special open-source software licenses and

the copyright of third parties. Basically, each customer can use the open-source

software freely in compliance with the licensing terms of the respective producers.

The rights of the customer to use the open-source software beyond the purpose of

our product are regulated in detail by the respective concerned open-source software licenses. The customer use the open-source software freely, as provided in

the respective effective license, beyond the purpose that the open-source software

gets in our product. In case there is a contradiction between the licensing terms for

our product and the respective open-source software license, the respective relevant open-source software license takes priority over our licensing terms, as far as

the respective open-source software is concerned by this.

The use of the used open-source software is possible free of charge. We do not demand usage fees or any comparable fees for the use of the open-source software

contained in our product. The use of the open-source software in our product by

the customer is not part of the earnings we achieve with the contractual compensation.

All open-source software programs contained in our product can be taken from the

available list. The most important open-source software licenses are listed in the Licenses section at the end of this publication.

As far as programs contained in our product are subject to the GNU General Public

License (GPL), GNU Lesser General Public License (LGPL), Clarified Artistic License

or another open-source software license, which regulates that the source code

must be made available, and if this software is not already delivered in source code

on a data carrier with our product, we will send you this at any time upon request.

If it is required to send this on a data carrier, the sending will be made against payment of a cost compensation of € 10,00. Our offer to send the source code upon

request ceases automatically 3 years after delivery of our product to the customer.

Requests must be directed to the following address, if possible under specification

of the serial number:

INSYS MICROELECTRONICS GmbH

Hermann-Köhl-Str. 22

93049 Regensburg, Germany

Phone +49 941 58692 0

Fax +49 941 58692 45

E-mail: support@insys-icom.de

Page 15

ETSM / ETSU

Using Open Source Software

15

3.2 Special Liability Regulations

We do not assume any warranty or liability, if the open-source software programs

contained in our product are used by the customer in a manner that does not comply any more with the purpose of the contract, which is the basis of the acquisition

of our product. This concerns in particular any use of the open-source software

programs outside of our product. The warranty and liability regulations that are provided by the respective effective open-source software license for the respective

open-source software as listed in the following are effective for the use of the

open-source software beyond the purpose of the contract. In particular, we are not

liable, if the open-source software in our product or the complete software configuration in our product is changed. The warranty granted with the contract, which is

the basis of the acquisition of our product, is only effective for the unchanged

open-source software and the unchanged software configuration in our product.

3.3 Used Open-Source Software

The following open-source software is being used in the product:

Software/project

Version

Li censes

FreeRTOS

7.0.0

GPL2 + MODIFIED BY the FreeRTOS

exception

ASF

3.21.0/3.18.1

Atmel ASF license

IwIP

1.4

BSD

exTLS

1.5.2

BSD

Page 16

Version History

ETSM / ETSU

16

4 Version History

Version

Modification

1.0

Release

Page 17

ETSM / ETSU

Device Variants

17

5 Device Variants

This manual describes two different variants of the INSYS icom switch. These are:

• Unmanaged Switch ETSU-E100

• Lite-managed Switch ETSM-E100

If the devices are different, this will be mentioned explicitly in the respective

sections.

Page 18

Scope of Delivery

ETSM / ETSU

18

6 Scope of Delivery

The scope of delivery includes all accessories listed below. Please check if all

accessories are included in the box. If a part is missing or damaged, please contact

your distributor.

• Switch

• Quick Installation Guide

• Safety Instructions

The scope of delivery does not include optional accessories. The following parts are

available from your distributor or INSYS icom:

• Din rail power supply units

Page 19

ETSM / ETSU

Technical Information

19

7 Technical Information

7.1 Technical Data

7.1.1 Physical Features

All specified data was measured with nominal input voltage, at full load, and an

ambient temperature of 25 ℃. The limit value tolerances are subject to the usual

variations.

Physical Feature

Value

Operating voltage

9.6 V … 60 V DC

18 V … 30 V AC

Power consumption (V = 9.6 … 24 V)

(V = 60 V)

typ. 2.4 W / max. 2.65 W

typ. 3.9 W / max. 4.2 W

Level digital input

HIGH level = 11 ... 30 V

LOW level = 0 ... 5 V

Contact open condition: LOW

Current consumption input at HIGH

potential

Max. 4 mA at 24 V, 10 mA at 30 V

Fault contact (NO), max. switch voltage

60 V (DC) / 30 V (AC)

Fault contact (NO), max. current load

1 A at 60 V DC / 30 V AC

Weight

300 g

Dimensions (Width x Depth x Height)

65 mm x 49 mm x 105 mm

(depth with connector)

Temperature range

-40 °C … 70 °C (operation)

-40 °C … 85 °C (storage)

Maximum permissible humidity

10 … 95% non-condensing

IP rating

Housing IP20, connectors IP40

Ta b le 1: ETSM/ETSU – physical features

Page 20

Technical Information

ETSM / ETSU

20

7.1.2 Technological Features

Te chnological Feature

Description

6-port Ethernet switch

10/100 Mbit/s full/half duplex auto sense;

automatic detection of "crossover" or "patch"

wiring.

USB interface

USB 2.0 host; socket type A, max. 500 mA

Ta b le 2: ETSM/ETSU – technological features

7.2 Connections and display elements

Fig u re 1: ETSM / ETSU – connections and display elements

Page 21

ETSM / ETSU

Technical Information

21

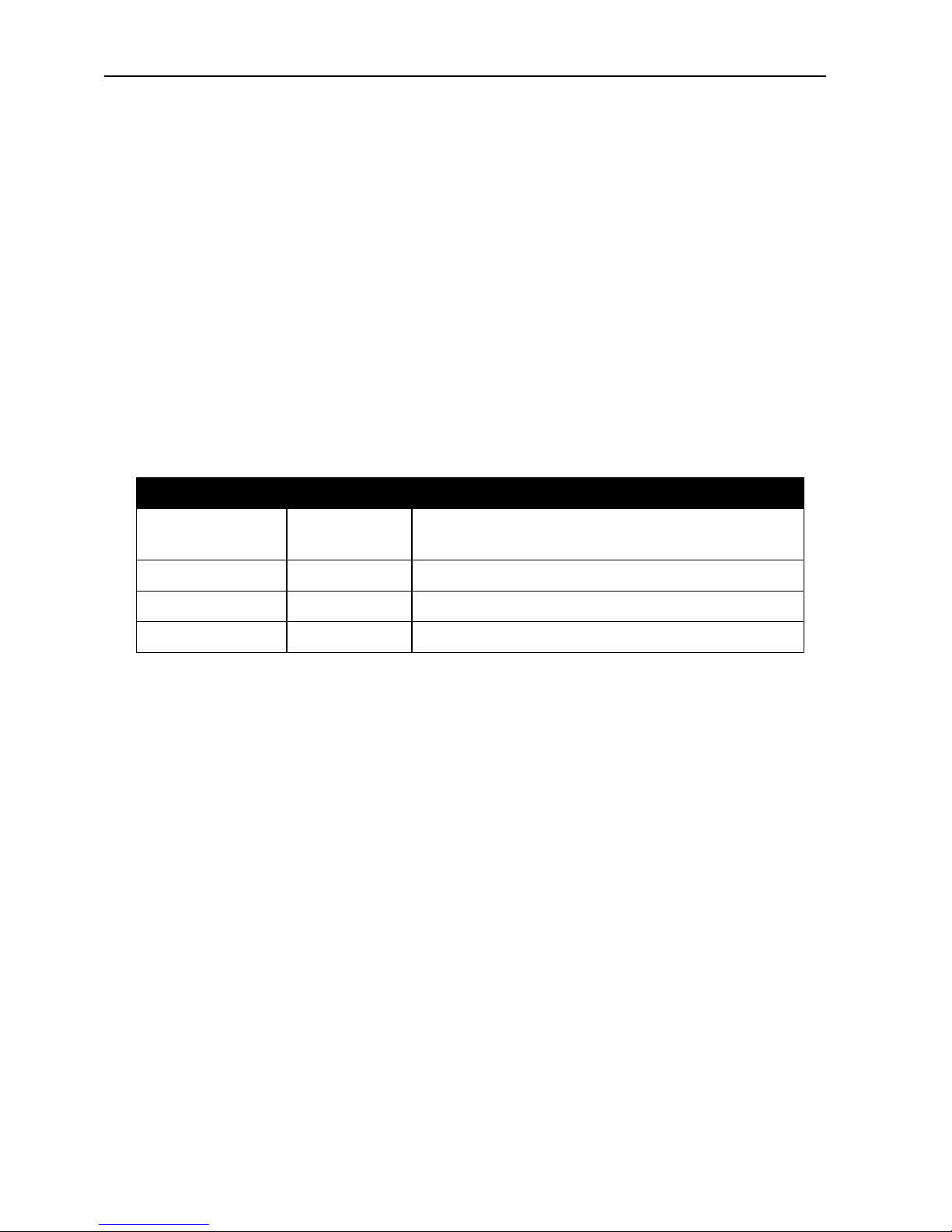

Item

Designation

Description

1

V1

Power supply, redundant positive terminal 1

2

GND

Ground

3

Fault

Fault contact, potential-free (ETSM only)

4

DI+

Digital input, positive connection (ETSM only)

5

DI-

Digital input, negative connection (ETSM only)

6

Fault

Fault contact, potential-free (ETSM only)

7

GND

Ground

8

V2

Power supply, redundant positive terminal 2

Ta b le 3: ETSM / ETSU – push-in termina l connector connections

Fig u re 2: ETSM / ETSU – USB socket (ETSM only)

Item

Designation

Description

1

VBUS

+5 V

2

D-

Data -

3

D+

Data +

4

GND

Ground

Ta b le 4: ETSM / ETSU – USB socket connections (ETSM only)

Page 22

Technical Information

ETSM / ETSU

22

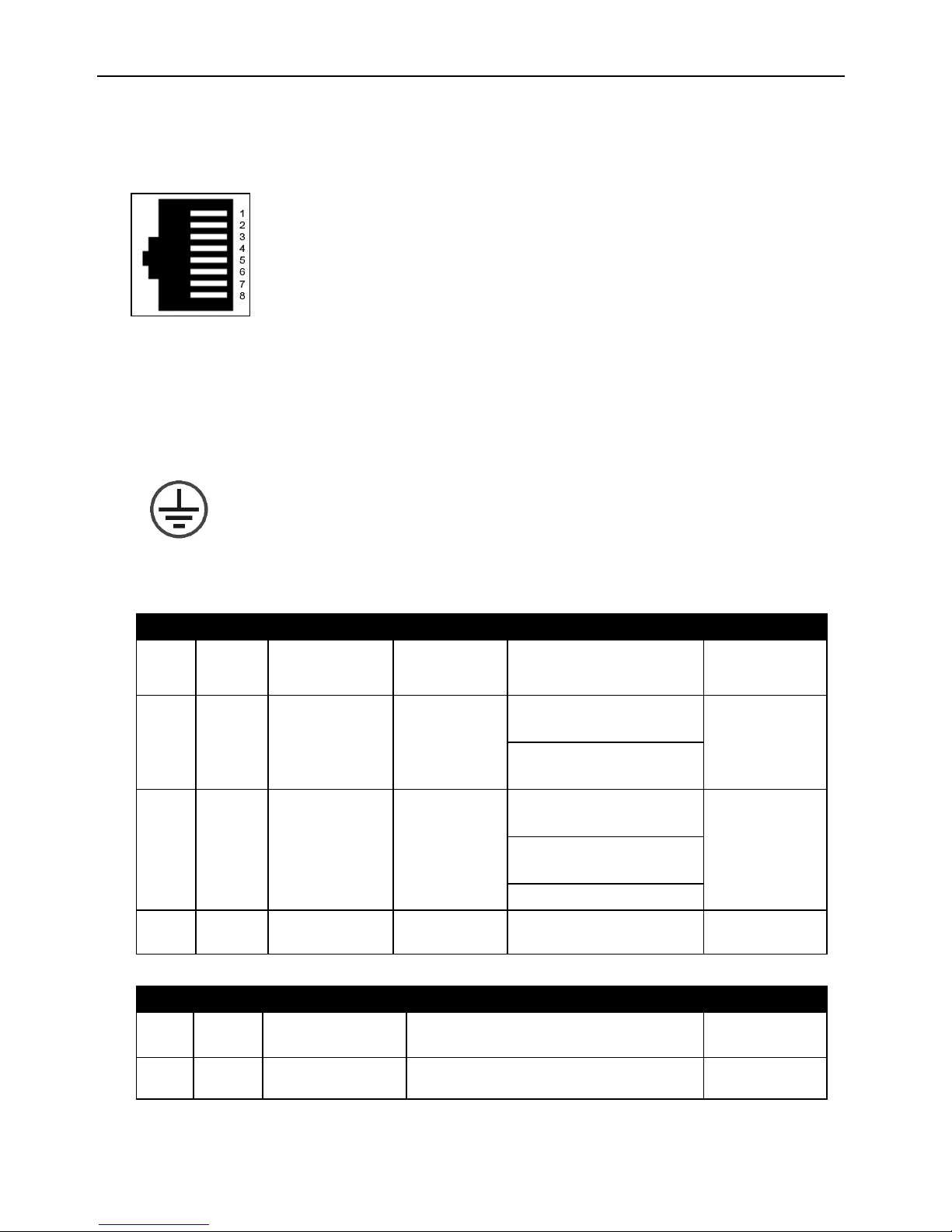

1

TX+

Data TX+

2

TX-

Data TX-

3

RX+

Data RX+

4

n/c

not connected

5

n/c

not connected

6

RX-

Data RX-

7

n/c

not connected

8

n/c

not connected

Fig u re 3: ETSM / ETSU – Ethernet port connections

Grounding connection

Fig u re 4: ETSM / ETSU – grounding connection

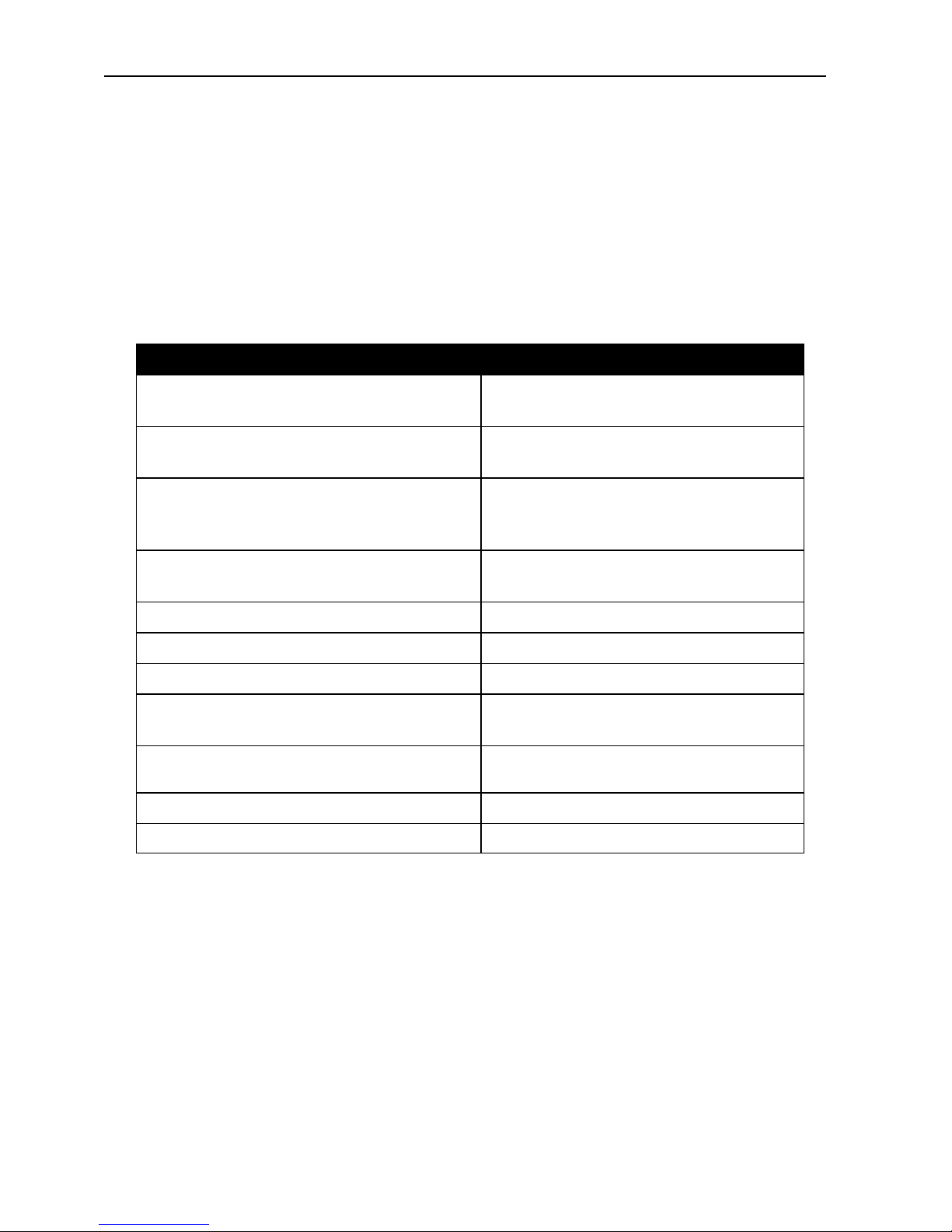

The variants ETSM and ETSU have different display elements.

LE D

Colour

Function

off

blinking

on

PWR

green

Supply

not

sufficient

Error

sufficient

MOD

green

Operating

mode

not ready

for

operation

USB interface in

device mode (1 Hz)

ready for

operation

Firmware update

(10 Hz)

ERR

red

Error

no error is

present

configuration file

invalid (1 Hz)

system error

or over temperature

fault contact active

(10 Hz)

supply failure (30 Hz)

DI

green

Digital input

inactive

active

Ta b le 5: ETSM – mea ning of t he display elements

LE D

Colour

Function

off

on

V1

green

Supply V1

not connected / sufficient

sufficient

V2

green

Supply V2

not connected / sufficient

sufficient

Ta b le 6: ETSU – meaning of the display elements

Page 23

ETSM / ETSU

Technical Information

23

Each switch port has a green and a yellow LED.

LE D

Colour

Function

off

blinking

on

LA

green

Link / Activity

not connected

Data traffic

connected

SP

yellow

Data rate

10 Mbit/s

100 Mbit/s

Ta b le 7: ETSM / ETSU – meaning of the display elements at the Ethernet port

7.2.1 Connecting the connectors

The wires are contacted maintenance-free in the connector via screw terminal.

The permissible wire cross-sections can be found in the following tables.

Wire

Cross-section

Nominal cross-section

2.5 mm²

Rigid

0.2 – 2.5 mm²

Flexible

0.2 – 2.5 mm²

Flexible with end sleeve

0.25 – 2.5 mm²

Ta b le 8: Permissible wire cross-sections for connectors

Page 24

Assembly

ETSM / ETSU

24

8 Assembly

This section describes how to mount the switch to a DIN rail, connect the

power supply and uninstall it again. Observe the instructions in the "Safety"

section of this manual, in particular the "Safety Instructions for Electrical

Installation" for that purpose unconditionally.

Caution!

Moisture and liquids from the environment may seep into

the interior of the device!

Fi re hazard and damage of the product.

The device must not be used in wet or damp

environments, or in the direct vicinity of water. Install the

device at a dry location, protected from water spray.

Disconnect the power supply before you perform any work

on a device which may have been in contact with

moisture.

Caution!

The device could be destroyed if the wrong power supply

is used!

If the device is operated with a power supply that supplies

a voltage exceeding the permissible operating voltage, it

will be destroyed.

Make sure that you use the suitable power supply. Refer to

the Technical Data section for the proper voltage range.

Mounting the device to the DIN rail

How to mount the switch to a DIN rail:

1. Place the device at the DIN rail Hook the upper DIN rail groove into

place behind the upper edge of the DIN rail.

2. Fold down the device perpendicular to the DIN rail until the lower

DIN rail groove latches in the DIN rail.

3. Connect the grounding cable to the grounding connection of the

device.

The switch is now readily mounted.

Page 25

ETSM / ETSU

Assembly

25

Connecting the power supply

The device has already been mounted to the DIN rail.

The power supply is connected and switched off.

1. Remove the push-in terminal connector from the switch.

2. Connect the ground lead of the power supply to the terminal "GND"

of the terminal connector.

3. Connect the positive lead of the power supply to the terminal "V1" of

the terminal connector.

4. Fasten the push-in terminal connector at the switch again.

The switch is now connected to the power supply.

Disconnecting the power supply

The device is mounted to the DIN rail.

The power supply is connected and switched off.

1. Remove the push-in terminal connector from the switch.

The switch is disconnected from the power supply.

Removing the device from the DIN rail

How to uninstall the switch from a DIN rail in a switch cabinet:

The power supply of the switch cabinet is switched off and secured against

being switched on accidentally.

The push-in terminal connector, the grounding connection and all Ethernet

cables at the device are disconnected.

1. Push the device slightly down to compress the retaining spring and

swing it away from the DIN rail.

2. Un-hook the device and take it off perpendicularly to the DIN rail.

The switch is now detached.

Page 26

Commissioning, Operation and Configuration ETSU

ETSM / ETSU

26

9 Commissioning, Operation and Configuration

ETSU

The unmanaged Switch ETSU does not require any configuration and is ready for

operation directly upon switching it on.

Page 27

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

27

10 Commissioning, Operation and Configuration

ETSM

10.1 Commissioning

The lite-managed switch ETSM is delivered pre-configured. The factory configuration is set such that after powering the switch, the device transmits data to all

Ethernet ports immediately. The following settings are set as default:

• Web interface IP address: 192.168.0.2

• Web interface user name: admin

• Web interface password: password

• Web interface access: via any Ethernet

port

• Ethernet ports: activated

• Auto-Negotiation: activated

• VLAN, QoS, port mirroring: deactivated

• Link aggregation: deactivated

• Fault contact: Normally Open

• Fault contact events: V1 or V2 fault; over

temperature

• TRAP protocol: UDP

• TRAP IP address: 192.168.0.1:4321

• TRAP events: V1 or V2 fault; over

temperature, internal fault

• Logging function: activated

Proceed as follows for commissioning:

1. Connect the power supply

2. Connect the PC / notebook to one of the Ethernet ports of the device

3. The connected PC / notebook must have the following network settings:

• Fix IP address: 192.168.0.1

• Subnet mask: 255.255.255.0

4. Start a web browser and enter the IP address of the device

5. Perform the desired configuration of the device

6. Connect the switch with your network devices

Page 28

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

28

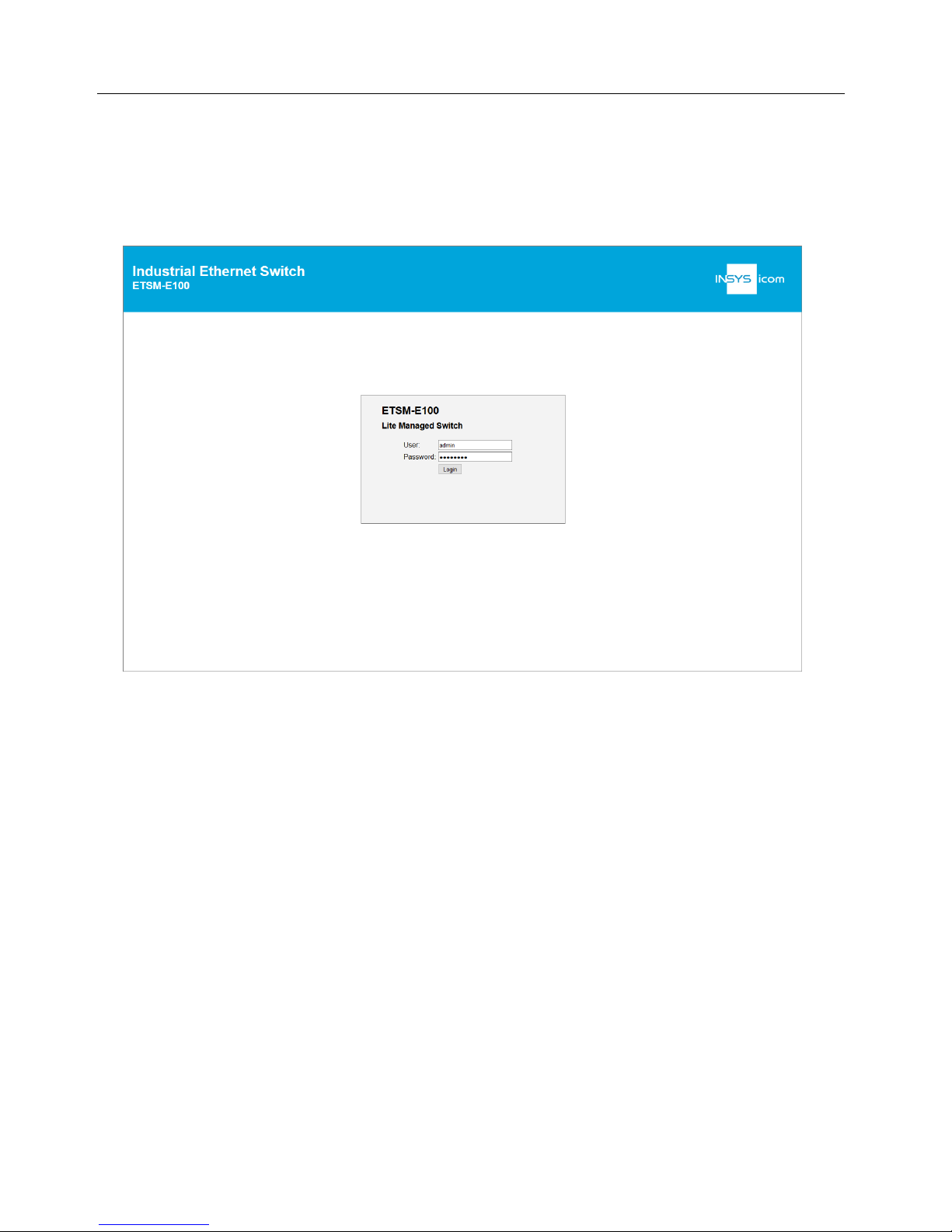

10.2 Operation via the web interface

The configuration via the web interface allows you to change the device settings

via the network. The IP address of the switch must be entered in the web browser

to get access. The default IP address is 192.168.0.2.

To get access to the system, the user must authenticate himself. This takes place

using a user name and a password. Subsequently, the web interface will be loaded

The pre-configured access data are:

• User: admin

• Password: password

If broadcast packets are sent permanently through the switch in the

network, it may happen that the web interface cannot be accessed.

Page 29

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

29

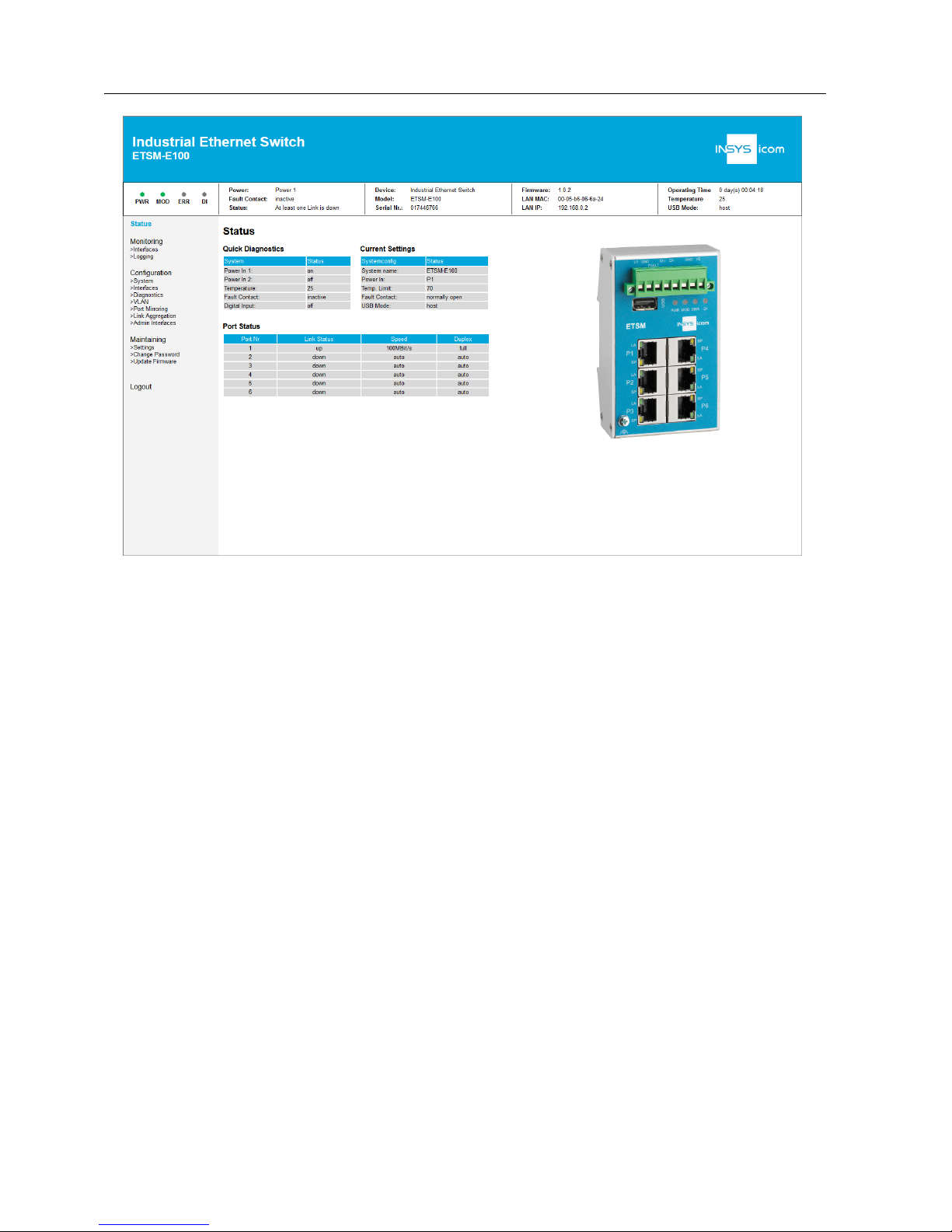

The left and upper part of the web interface will be displayed on all pages..

The left area is used for navigation and divided into the categories Monitoring, Configuration and Maintaining. Monitoring shows the states of various parts of the system. The Configuration are allows you to change settings and the Maintaining area

allows you to save configurations or upload firmware updates.

The current page is highlighted.

The status bar at the top of the web interface shows the most important information of the system and updates every 10 seconds. There you can find the LED

indications of the device, the power supply state, the fault contact state, information about the last error, the temperature and the system uptime.

After logging in, the dashboard appears which shows a detailed overview and provides initial information on the state of the network ports already. In addition, this

page contains a graph showing the connections of the device.

Page 30

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

30

10.3 Supported Switch Configuration

10.3.1 Ethernet Ports

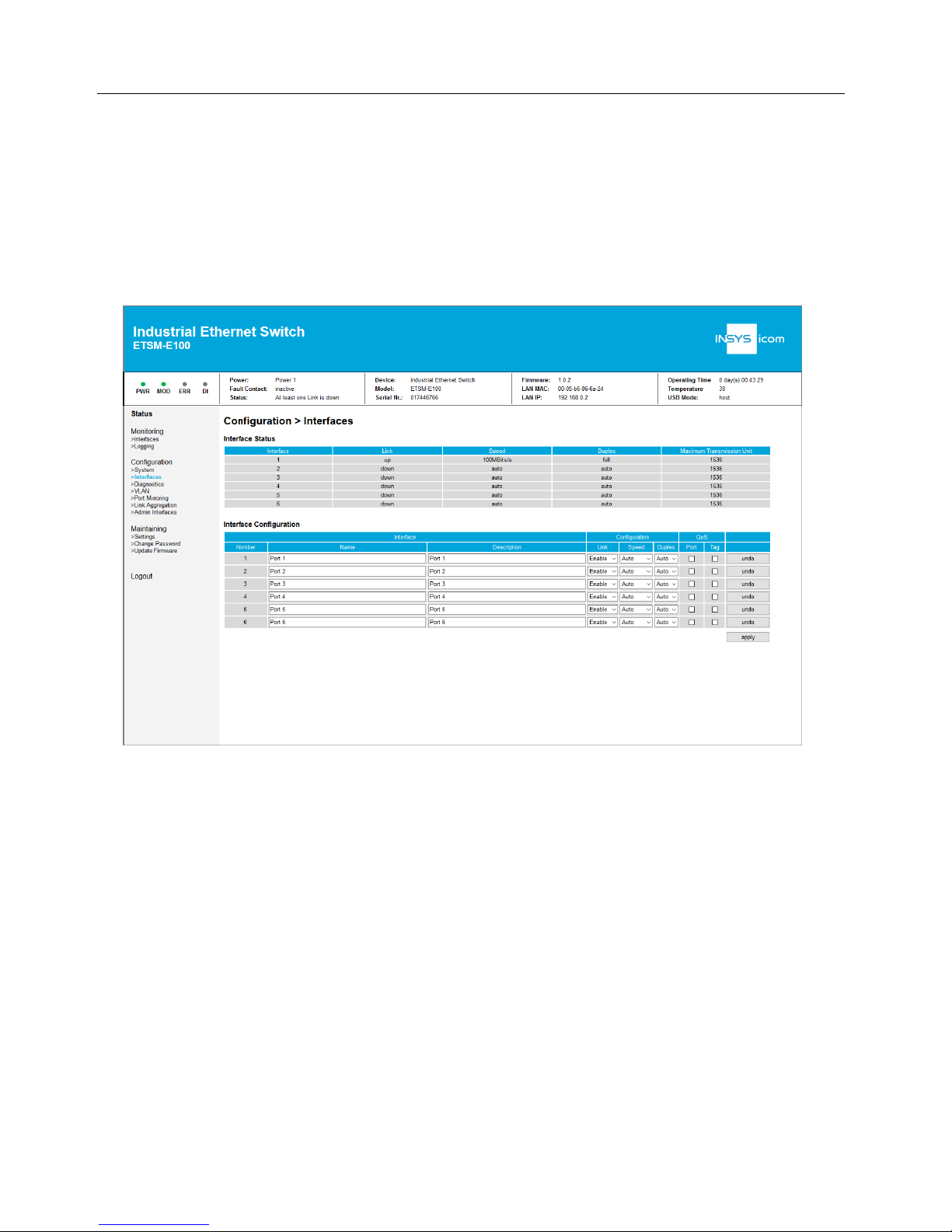

The setting of the Ethernet ports is carried out in the web interface under

Configu-

ration > Interfaces

. The page contains two tables. The top shows the state of the

interfaces. The table below can be used to change the settings.

Page 31

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

31

The following settings are available for each port:

Op tion

Value

Description

Name

Name of the interface (max. 64 characters, no semicolon or line wrap)

Description

Description of the interface (max. 64 characters, no

semicolon or line wrap)

Link

Enable

Port activated

Disable

Port deactivated

Speed

100 MBit

Port set to 100 MBit

10 MBit

Port set to 10 MBit

Auto

Port uses auto-negotiation to negotiate the speed

Duplex

Full

Port uses full duplex

Half

Port uses half duplex

Auto

Port uses auto-negotiation to negotiate the duplex

setting

QoS

Port

All incoming packets arriving at an accordingly

configured port are prioritized.

Tag

Only packets with TOS (type of service) or PCP (priority code point) field higher than 3 are prioritized.

Ta b le 9: ETSM – port settings

Ports can be activated or deactivated using "Link Status". Deactivating

unneeded ports is recommended if a link-down event shall be monitored.

Auto-negotiation will negotiate the highest possible speed that is also supported by

the connected destination device. In case that auto-negotiation is not used, the

configuration for speed and duplex must be made for both network participants to

enable communication.

If the speed or duplex mode is set to "auto", this means that both

values are set to "auto".

Changes can be transmitted to the switch by clicking the "Apply" button. The

"undo" button can be used to read back the current configuration.

Deactivating administration ports is not possible due to security reasons.

Therefore, these must be deactivated as administration ports first.

QoS (Quality of Service allows to prioritize network traffic. The switch supports two

different procedures.

Port-based QoS can be activated on maximum 4 ports. Frame-based

QoS has no such limitations.

Page 32

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

32

10.3.2 Port Mirroring

Port mirroring (or port monitoring) allows to duplicate network traffic to an observation port and analyse it there. The incoming and outgoing traffic can be duplicated independently per port.

The settings for port mirroring are made in the web interface under

Configuration >

Port Mirroring

.

Port mirroring can be activated or deactivated in the left table (default: deactivated).

The observation port (destination port) is also configured here.

The table on the right defines the ports from which incoming and/or outgoing traffic will be mirrored to the destination port.

The settings are transmitted using the "set" button.

Page 33

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

33

10.3.3 Link Aggregation

Link aggregation (also known as port trunking) allows to bundle several ports to enable a higher redundancy or data throughput between two devices.

The link aggregation settings are made in the web interface under

Configuration >

Link Aggregation

.

Each interface can be assigned to Group A, Group B or no group (none).

The settings are transmitted to the device using the "submit" button.

A maximum of 2 groups are supported. The connected device must

also be configured for link aggregation.

Page 34

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

34

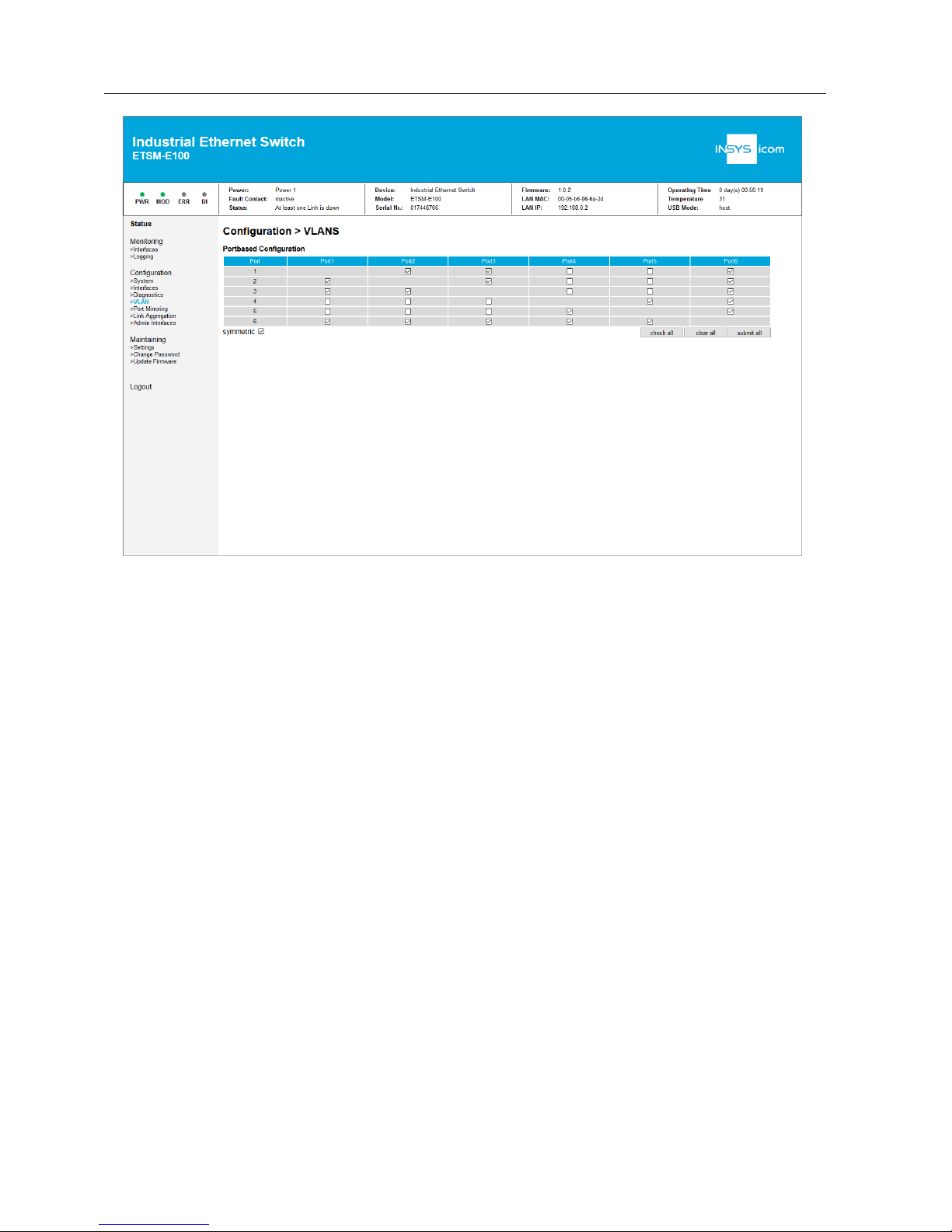

10.3.4 VLAN

VLANs allow to segment a network and operate this like several small networks.

VLANs can be configured in the web interface under

Configuration > VLAN

.

The configuration options are very flexible; connections between all ports and in

each direction can be permitted or prohibited.

This is specified in the table as follows: Packets that arrive at one of the ports at the

left are only forwarded to ports which are checked in this line.

In most cases, the switching options for incoming and outgoing traffic are symmetrical. To activate symmetric features, check "symmetric" below the table.

To apply all settings, click on "submit all".

In order to accelerate the setting effort, "check all" or "clear all" can be

used to select all or no interfaces. The transfer of the settings to the

switch must always be made in addition.

The following image shows the configuration of two VLAN networks consisting of

ports 1, 2, 3 or 4, 5. Port 6 exists in both networks.

Therefore, ports 1, 2, 3 cannot communicate with the ports 4, 5. Port 6 can communicate with each of the other ports.

Page 35

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

35

If different VLANs are connected with cables, problems with data

transfer may occur. It is recommended to combine the respective

VLANs.

Page 36

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

36

10.4 Device Diagnosis

10.4.1 LED display

A quick diagnosis of the device is possible using the LED display.

The LED display and the respective failure conditions are described in the connec-

tions and display elements section.

10.4.2 Failure conditions

The system detects faults and errant events and signals it to the user. The following

states are detected:

Fa ult code

Designation

Description

0 - No fault

2

Power

Selected power supply is under the necessary voltage (refer to Power supply under System Access Settings)

4

Temperature

The configured alarm value of the temperature has

been exceeded

8

Link down

Activatd network port has no data connection

64

Config

Loaded configuration file is invalid

32, 64, 128

Internal

Internal device fault

256

DI1

Digital input has triggered

Ta b le 10: E TSM – Failure conditions and code s

The upper status bar of the web interface shows the actual status as text. The status codes are sent as trap messages. If several faults occur simultaneously, the

sum is displayed.

Example: A status code of 10 means power (2) and link down (8).

In case a failure condition occurs, messages can be output via fault contact and

traps.

Page 37

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

37

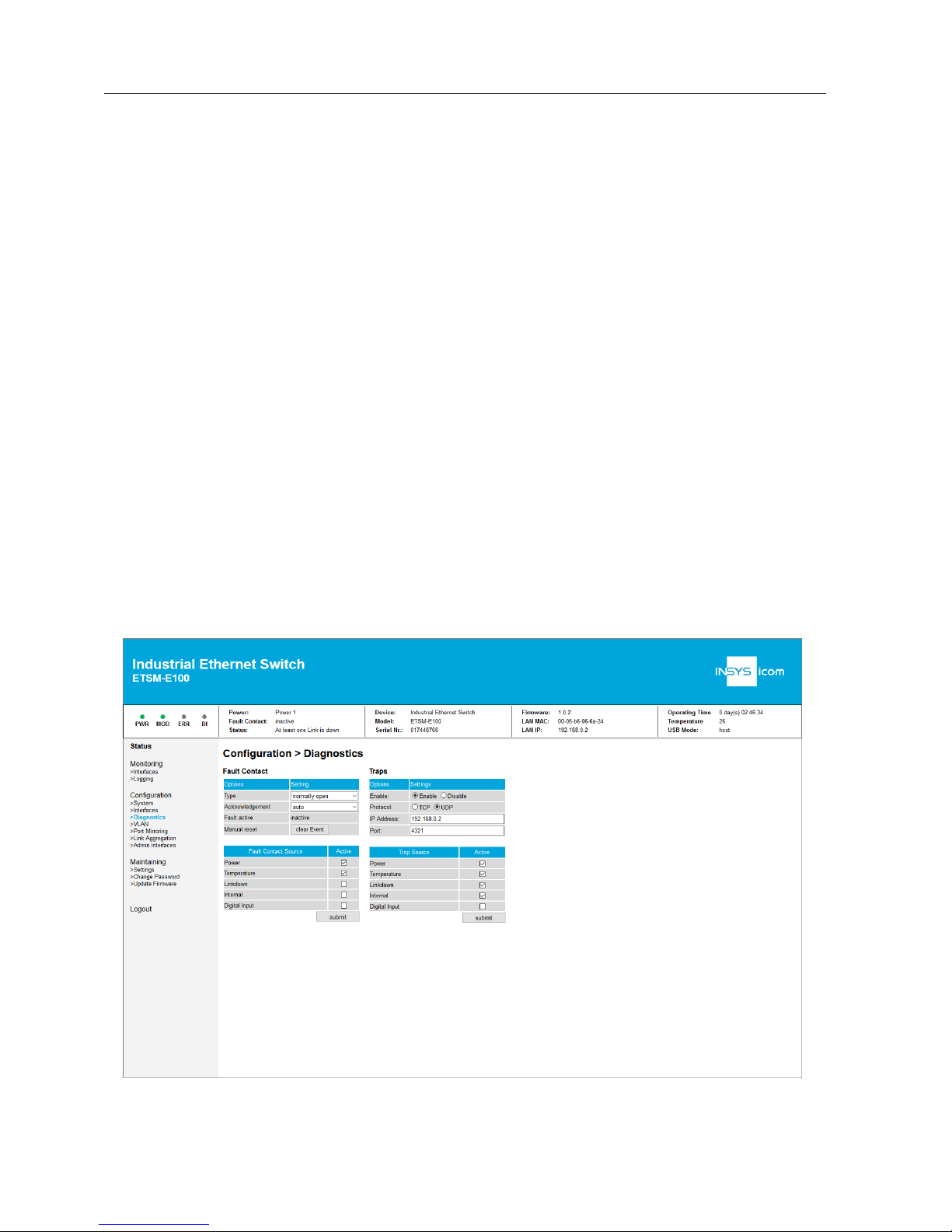

10.4.3 Fault contact

The fault contact is used to signal occurring failure conditions. Devices that process

this message can be connected to the fault contact.

The configuration of the Fault Contact is performed in the web interface under

Con-

figuration > Fault Contact

. Different events can be configured as trigger for the

fault contact:

• Power (active as default)

• Temperature (active as default)

• Link down

• Internal

• Digital input

Moreover, the reset behaviour of the fault contact can be configured:

• "automatic": The fault contact will be reset automatically (inactive) if the

problem that caused the trigger does not exist any more.

• "manual": The fault contact will be reset automatically (inactive), as soon as

the button "reset" is clicked in the web interface. If there are one or more

active trigger events, the fault contact remains active.

The electrical properties and the connection of the fault contact are described in

Technical Data.

Page 38

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

38

10.4.4 Traps

Traps are used to signal failure conditions of the device. Traps are data packets that

are sent to a configured network address via the network. This allows a monitoring

at the destination address.

The content of the data packet consists of two bytes which contains the current

failure condition code (refer to failure conditions).

Please note that these are no SNMP traps, but specific failure codes.

The following settings can be made in the web interface under

Configuration >

System

:

• Activate / deactivate traps (default: activated)

• Protocol: TCP, UDP (default: UDP)

• Destination IP address (default: 192.168.0.1)

• Destination port: (default: 4321)

One or more of the following failure conditions can be configured as trigger of the

traps:

• Power (active as default)

• Temperature (active as default)

• Link down (active as default)

• Internal (active as default)

• Digital input

Page 39

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

39

10.4.5 Diagnosis services

The diagnosis services allows to perform an automated diagnosis via network.

SNMP and Modbus TCP are available for this. The services are configured under

Diagnosis in

Configuration > Diagnostics.

All services do not support authentication. Therefore, it is

recommended to use them only if required.

10.4.5.1 SNMP

The SNMP service allows to read device information via network.

The device supports SNMPv1 get and getnext requests. The change of settings us-

ing set messages is not supported.

The requests must be sent to the IP address of the device and the standard SNMP

port 161.

The read community is public.

The following MIB-II groups are available and can be requested using get and get-

next:

• System Group (1.3.6.1.2.1.1)

• Interfaces Group (1.3.6.1.2.1.2)

• Address Translation Group (1.3.6.1.2.1.3)

• IP Group (1.3.6.1.2.1.4)

• ICMP Group (1.3.6.1.2.1.5)

• TCP Group (1.3.6.1.2.1.6)

• UDP Group (1.3.6.1.2.1.7)

• SNMP Group (1.3.6.1.2.1.11)

The System Group outputs all data that is configured in the web interface under

Configuration > System

.

Page 40

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

40

10.4.5.2 Modbus TCP

Modbus TCP allows to read the status of the network and the device.

The Modbus TCP server is accessible on Modbus TCP standard port 502.

The Modbus TCP server can only serve one client at once.

Only read commands to input registers (function code 4) are supported. The read

command consists of 16 bit words. The following memory map shows the available data of the switch. The address consists of the start address 30001 (decimal)

and an offset. When reading out using an INSYS Device App (icom Data Suite or

Monitoring App) the addresses in the

INSYS-Adr. (dec)

column must be used as

register address for an input register. Names and description are ASCII-coded and

one word contains two characters. Not used characters are filled with 0x00.

The offsets are displayed as hexadecimal figures in the following table.

Offset

(he x)

Le ngth

(dec)

Description

Mea ning

INSYSAd r.

(dec)

0x0000

1 word

Vendor ID

(0xFFFF)

29999

0x0001

1 word

Unit ID (0x01)

30000

0x0002

1 word

Product Code

(0x003)

30002

0x0010

20 word

Vendor Name

30015

0x0030

20 word

Product Name

30047

0x0051

2 word

Firmware Version

30080

0x0053

2 word

Firmware Release Date

WORD 1: DD-HH

WORD 2: YY-MM

30082

0x0055

3 word

Ethernet Mac

Example Mac:

00:11:22:33:44:55:66

WORD 1: 11 22

WORD 2: 33 44

WORD 3: 55 66

30084

0x0058

1 word

Power 1

0x0000: Off

0x0001: On

30087

0x0059

1 word

Power 2

0x0000: Off

0x0001: On

30088

0x005A

1 word

Fault LED

0x0000: Off

0x0001: On

30089

Page 41

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

41

Offset

(he x)

Le ngth

(dec)

Description

Mea ning

INSYSAd r.

(dec)

0x005B-

0x007F

Invalid range

Can not be requested

3009030126

0x0080

1 word

DI 1

0x0000: Off

0x0001: On

0xFFFF: No Di

30127

0x0081

1 word

DI 2

0x0000: Off

0x0001: On

0xFFFF: No Di

30128

0x0082

1 word

DO 1

0x0000: Off

0x0001: On

0xFFFF: No Do

30129

0x0083

1 word

DO 2

0x0000: Off

0x0001: On

0xFFFF: No Do

30130

0x0084-

0x008F

Invalid range

Can not be requested

3013130142

0x0090

4 word

Product Serial

Number

30143

0x0095-

0x009F

Invalid range

Can not be requested

3014830158

0x1000

1 word /

port

Port Status

0x0000 => Link down

0x0001 => Link up

0x0002 => Disable

0xFFFF: No port

34095

0x1100

1 word /

port

Port Status

0x0000: 10M-Half

0x0001: 10M-Full

0x0002: 100M-Half

0x0003: 100M-Full

34351

0x1400

1 word /

port

Port description

Description (ASCII format)

35119

Ta b le 11: E TSM – Modbus offsets

It is possible to read multiple registers at once. However, it is to be observed that

no invalid ranges are contained since the request will then be answered with a failure.

Page 42

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

42

10.4.6 Digital input

The device has a digital input. Any other device can be connected to it as far as the

electrical specifications are complied with. The electrical properties and the connection of the fault contact are described in Technical Data.

A level change at the digital input is detected by the switch. It will be indicated by

the DI-LED and in the web interface.

In addition, a trap message can be sent. Moreover, the digital input can be configured as a trigger source of the fault contact.

It can be configured in the web interface under

Configuration > System

to which

level changes the digital input shall react:

• Rising edge

• Falling edge

• Disabled

If one edge is causing the event, the other edge will deactivate the event again.

Page 43

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

43

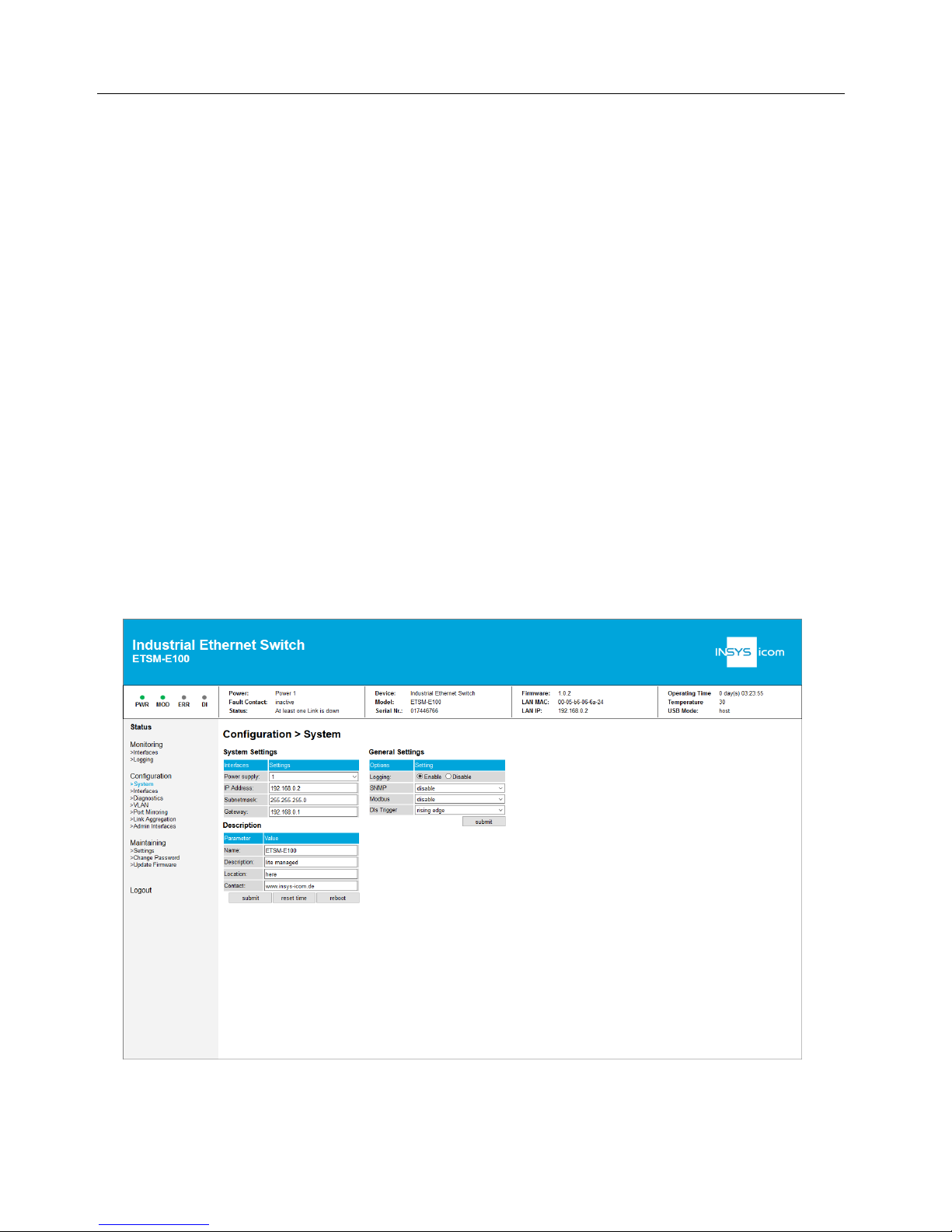

10.4.7 Log files

The device can record events and write them to log files. These contain system status, messages as well as events caused by the user.

The following log file settings can be made in the web interface under

Configura-

tion > System

in the

General Settings

section.

• enable / disable, default: enable

The log entries are displayed in the web interface under

Monitoring > Logging

. The

following table is an example of the log entries.

Ti me

Typ e

Description

0 day(s) 00:00:00

device

power on

0 day(s) 00:00:00

fault contact

inactive

0 day(s) 00:00:00

device

booted

0 day(s) 00:00:01

interface

interface 6 link up

0 day(s) 00:00:10

user

web interface login

0 day(s) 00:00:30

user

configuration file loaded

0 day(s) 00:00:30

fault contact

inactive

Ta b le 12: E TSM – log entries

The log file can also be downloaded from the device. To download the current log,

the

Download Current Log

button is available in the web interface under

Monitor-

ing > Logging

.

If a log file reaches a size of 1 MB, logging will continue in a new log

file with incremented number. The file with the highest number in its

name has the newest log entries therefore.

The internal memory has capacity for two such files. If they are full,

the first will be deleted and number of the other will be decremented

and a a new file will be written.

All log files can be copied to an USB flash drive under

Maintaining > Settings

using

"Copy to USB", "Logging Files".

Page 44

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

44

10.5 System Access Settings

10.5.1 IP address

The configuration of the IP address is performed in the web interface under

Config-

uration > System.

The IP address, the subnet mask and the gateway can be configured there and transmitted to the device using the "submit" button. The default settings are:

• IP address: 192.168.0.2

• Subnet mask: 255.255.255.0

• Gateway: 192.168.0.1

Changes of these settings become active after a restart of the system first. The system can be restarted using the "reboot" button.

10.5.2 Power supply

The power supply settings are in the web interface under

Configuration > System

.

It is possible to configure whether power is supplied via input V1 (1), input V2 (2) or

redundant via both inputs (1+2). Default setting is 1. In case no sufficient voltage is

present at the configured input (or at one of the inputs in case of setting 1+2), a

fault will be triggered.

Page 45

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

45

10.5.3 Administration port

Access to the web interface of the device can be blocked on certain ports in order

to limit device access.

This can be configured in the web interface under

Configuration > Admin Inter-

faces.

Deactivated ports cannot be configured for administration. This shall

avoid that the user locks out himself.

It is recommended to deactivate all unused ports, because the

management functions cannnot be reached any more under high

network load.

10.5.4 Password change

The password can be changed via the web interface or using an USB flash drive.

10.5.4.1 Web interface

The password can be configured under

Maintaining > Change Password

. The new

password must be entered twice for this due to reasons of security. Then, the password can be changed using the "change password" button.

10.5.4.2 USB

Alternatively, the password can also be chamged via USB. An USB flash drive is

necessary for this. It has to be prepared as described in the following section.

In order to change the password, an authentication file is required. This file must

have the name "newpassword.pass", the content is the new user name and new

password. The format requirements are described in the next section.

The following conventions apply for the password:

• at least 5 characters

• max. 16 characters

• no special characters, no umlauts

After plugging in the USB flash drive, the password will be changed automatically

without restart. If a web interface session is still active, the session becomes invalid

and the user will be logged out automatically.

Page 46

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

46

10.5.5 Configuration files

The whole system configuration can be managed using configuration files.

This can be made in the web interface under

Maintaining > Settings.

The following

functions are supported:

• Saving the configuration:

o to an USB flash drive ("config.cfg")

o as download to a PC

• Loading and applying the configuration files:

o from an USB flash drive ("config.cfg")

o as upload from a PC

• Loading the factory default settings

Configuration files can also be loaded and applied automatically from a

plugged USB flash drive (refer to next section).

Page 47

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

47

10.6 Configuration via USB flash drive

10.6.1 Function

The used USB flash drive must only have one partition and be forma tted with FAT.

The versions FAT12, FAT16 and FAT32 are supported.

New data from an USB flash drive are only applied automatically if it is able to authenticate with a valid user name and password. Therefore, an authentication file

named "userpassword.pass" must be present on the USB flash drive.

An authentication file must be present on the USB flash drive for a

configuration using the USB flash drive.

The authentication file must be an ASCII-coded text file without formatting. The

first line must contain the user name and the second line the password.

The directory structure of the USB flash drive must look like that:

• userpassword.pass

• log

o logfile1.log

o logfile2.log

o …

• configuser

o config.cfg

o confignew.cfg

• newpassword.pass

• OSYS_TQPRODUCT_Rxx.bin

10.6.2 Performing the configuration

To change the configuration of the switch, a valid configuration file must be present in the folder "configuser" of the USB flash drive. The configuration file must be

named "confignew.cfg". After plugging in the USB flash drive into the switch, the

device will load the new configuration file automatically and apply it after successful authentication.

Page 48

Commissioning, Operation and Configuration

ETSM

ETSM / ETSU

48

10.7 Firmware update

A firmware update can be made using the web interface. Optionally, a firmware update can be made using USB flash drive.

As long as a firmware update is running, the supply voltage must not

be interrupted.

This may take some time and can be seen on the System Status LEDs.

A firmware file which is compatible with the device is necessary for the firmware

update.

Never change the name of the firmware file.

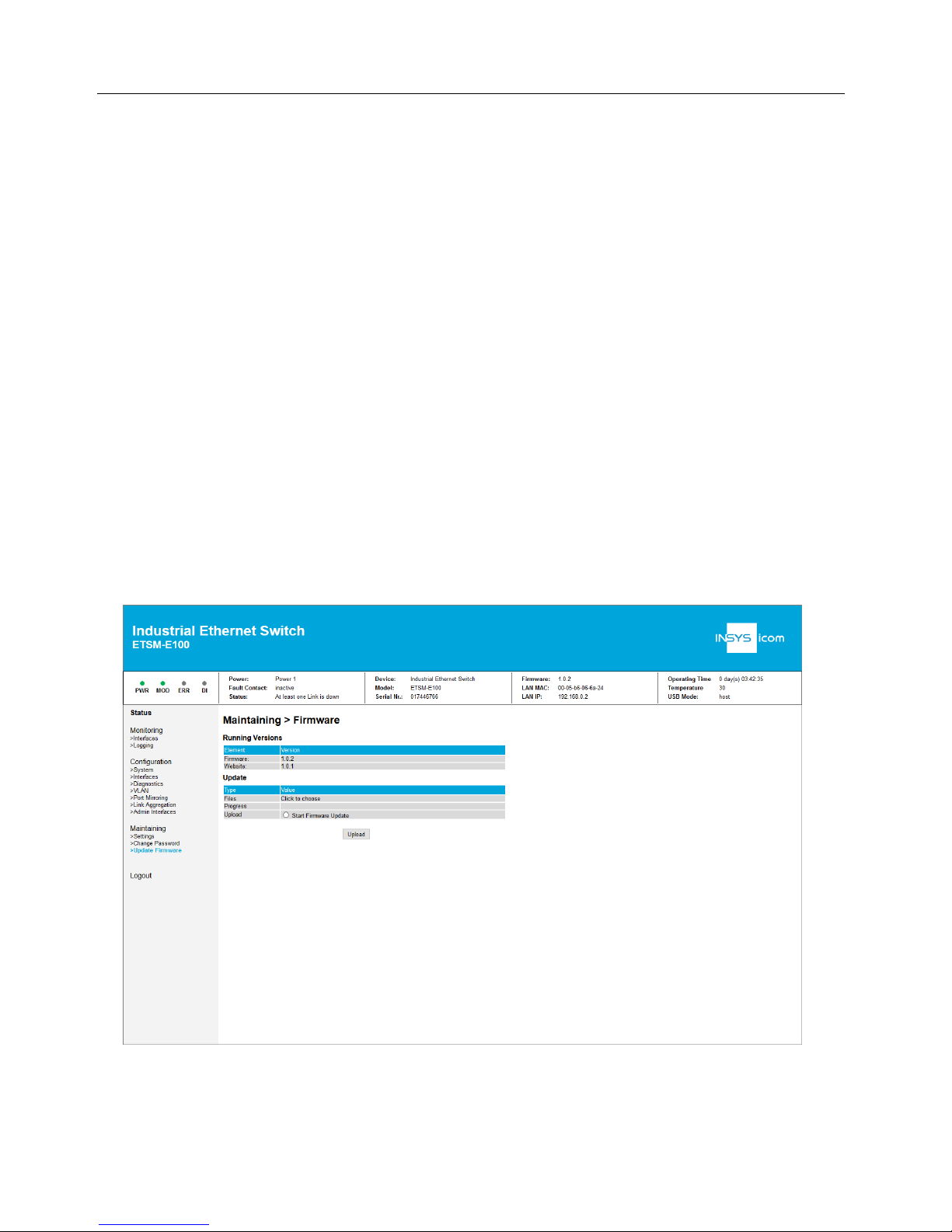

10.7.1 Firmware update via web interface

The respective option is available under

Maintaining > Update Firmware

. The firm-

ware file can be selected in pop-up window after selecting

Start Firmware Update

.

Then, the firmware can be transmitted to the device using the "upload" button. It

will start automatically.

Page 49

ETSM / ETSU

Commissioning, Operation and Configuration

ETSM

49

10.7.2 Firmware update via USB flash drive

To install a firmware update via an USB flash drive, an USB flash drive that can be

authenticated must be used (refer to respective section). An authentication file has

to exist on the USB flash drive. The firmware file must also be in the root directory.

The firmware update will start automatically after the USB flash drive is connected

to the device. During this process, the MOD LED will flashes as described in the

connections and display elements section.

Page 50

Maintenance, Repair and Troubleshooting

ETSM / ETSU

50

11 Maintenance, Repair and Troubleshooting

11.1 Maintenance

The product is maintenance-free and does not require special regular maintenance.

11.2 Troubleshooting

If a failure occurs during the operation of the product, you will find troubleshooting

tips in the "Knowledge Base" on our web site (http://www.insysicom.de/knowledge/). If you need further support, please contact your reseller or

INSYS icom. You can contact our support team via e-mail under support@insystec.de.

11.3 Repair

Send defect devices with detailed failure description to the source of supply of your

device. If you have purchased the device directly from INSYS icom, send the device

to: INSYS MICROELECTRONICS GmbH, Hermann-Köhl-Str. 22, 93049 Regensburg.

Before dispatching the device:

• Backup the configuration on the device and any other stored data if required.

Caution!

Short circuits and damage due to improper repairs and

modifications as well as opening of products.

Fi re hazard and damage of the product.

It is not permitted to open the product for repair or

modification.

Page 51

ETSM / ETSU

Waste Disposal

51

12 Waste Disposal

12.1 Repurchasing of Legacy Systems

According to the new WEEE guidelines, the repurchasing and recycling of legacy

systems for our clients is regulated as follows:

Please send those legacy systems to the following address, carriage prepaid:

Frankenberg-Metalle

Gaertnersleite 8

D-96450 Coburg

Germany

This regulation applies to all devices which were delivered after August 13, 2005.

Please consider possible stored passwords or security certificates

before disposing the device. It is recommended to block possible

existing access rights for the device (e.g. on your VPN server) and

reset the device to default settings (if possible), before passing it on or

disposing it.

Page 52

Declaration of Conformity

ETSM / ETSU

52

13 Declaration of Conformity

Hereby, INSYS Microelectronics GmbH declares that herein described device types

are in compliance with Directives 2014/30/EU and 2011/65/EU. The full text of the

EC Declaration of Conformity is available under the following Internet address:

www.insys-icom.com/manual

Page 53

ETSM / ETSU

Tables and Diagrams

53

14 Tables and Diagrams

14.1 List of Tables

Table 1: ETSM/ETSU – physical features ............................................................ 19

Table 2: ETSM/ETSU – technological features..................................................... 20

Table 3: ETSM / ETSU – push-in terminal connector connections ........................ 21

Table 4: ETSM / ETSU – USB socket connections (ETSM only) ............................ 21

Table 5: ETSM – meaning of the display elements .............................................. 22

Table 6: ETSU – meaning of the display elements ............................................... 22

Table 7: ETSM / ETSU – meaning of the display elements at the Ethernet port ..... 23

Table 8: Permissible wire cross-sections for connectors ...................................... 23

Table 9: ETSM – port settings ............................................................................ 31

Table 10: ETSM – Failure conditions and codes .................................................. 36

Table 11: ETSM – Modbus offsets ..................................................................... 41

Table 12: ETSM – log entries ............................................................................. 43

14.2 List of Diagrams

Figure 1: ETSM / ETSU – connections and display elements ................................ 20

Figure 2: ETSM / ETSU – USB socket (ETSM only) .............................................. 21

Figure 3: ETSM / ETSU – Ethernet port connections ............................................ 22

Figure 4: ETSM / ETSU – grounding connection ................................................. 22

Page 54

Index

ETSM / ETSU

54

15 Index

Accessories................................... 18

Additional information ..................... 8

Alternative results............................ 8

Assembly ...................................... 24

Auto-negotiation ........................... 31

Breakdown...................................... 9

Checkmark...................................... 8

Commissioni ng ............................. 27

Configuration file ........................... 46

Defects liability terms ...................... 6

Diagnosis .................................36, 39

Digital input .................................. 42

DIN rail ....................................24, 25

Electrical installation ...................... 12

Environment ............................12, 24

Environmental Protection ............... 11

Ethernet port ................................. 30

Explosive atmosphere ...................... 9

Failure conditions .......................... 36

Fault contact ............................19, 37

Firmware update ........................... 48

Formatting ...................................... 8

General safety instructions ............. 12

Ground ......................................... 21

Housing ........................................ 13

Humidity ....................................... 19

Intended Use................................... 9

Interface ....................................... 13

IP rating ........................................ 19

Key word ........................................ 7

LED display ................................... 36

Link Aggregation ........................... 33

Liquids .....................................12, 24

Log files ........................................ 43

Marking .......................................... 7

Modbus TCP ................................. 40

Modification ............................ 13, 50

Moisture ................................. 12, 24

Open Source ................................. 14

Operating voltage .......................... 19

Overvoltage ................................... 13

Overvoltage protection ................... 13

Password ...................................... 45

Permissible limit ............................ 10

Personnel ...................................... 10

Port mirroring ................................ 32

Power consumption ....................... 19

Preface ........................................... 6

Prerequisites ................................... 8

Qualification .................................. 10

Quality of Service........................... 31

Recycling ...................................... 51

Removal........................................ 24

Repair ..................................... 13, 50

Repurchasing ................................ 51

Responsibilities of the operator....... 10

Safety ............................................. 9

Scope of Delivery........................... 18

Short-cut ................................. 13, 50

SNMP ........................................... 39

Storage ......................................... 10

Switch .......................................... 20

Switch cabinet............................... 25

Symbol ....................................... 7, 8

Transport ...................................... 10

Traps ............................................ 38

Usage ............................................. 9

USB ................................... 20, 45, 47

VLAN ............................................ 34

Water spray............................. 12, 24

Web interface .......................... 28, 44

Wiring........................................... 24

Page 55

Loading...

Loading...