Encompass Current Sensor

Model JCR-0W 600V, 10kV BIL, 100-1000A

Window Diameter 2.00”

APPLICATION

Designed for both indoor and outdoor service.

Suitable for operating meters and instruments,

on both single-phase two-wire circuits and

polyphase circuits.

WEIGHT

(approximate)

Transformer,

Low Base ............4.0 lbs

High Base ............5.0 lbs

REFERENCE DRAWINGS

Outline ......0121C36111

INSULATION LEVEL

0.6kV; BIL 10kV full wave

FREQUENCY

50-60 Hz

JCR-0W DATA TABLE

Current

Ratio

(Amps)

Pri : Sec

ANSI Accuracy Class, 60

Hz

Burden Per ANSI 0.3 B0.2

Window

Size

(Inside Diameter)

Continuous Thermal Current

Rating Factor

Catalog Number

Without Base

@ 30oC Amb. @ 55oC Amb.

With Secondary

Hardware and Cover

Without Secondary

Hardware and Cover

250:5 100:2 to 1000:20 2.0” 4.0 3.0 750X134608 750X134611

With Low Base

250:5 100:2 to 1000:20 2.0” 4.0 3.0 750X134609 750X134612

With High Base

250:5 100:2 to 1000:20 2.0” 4.0 3.0 750X134610 750X134613

GEA-13375

250 250

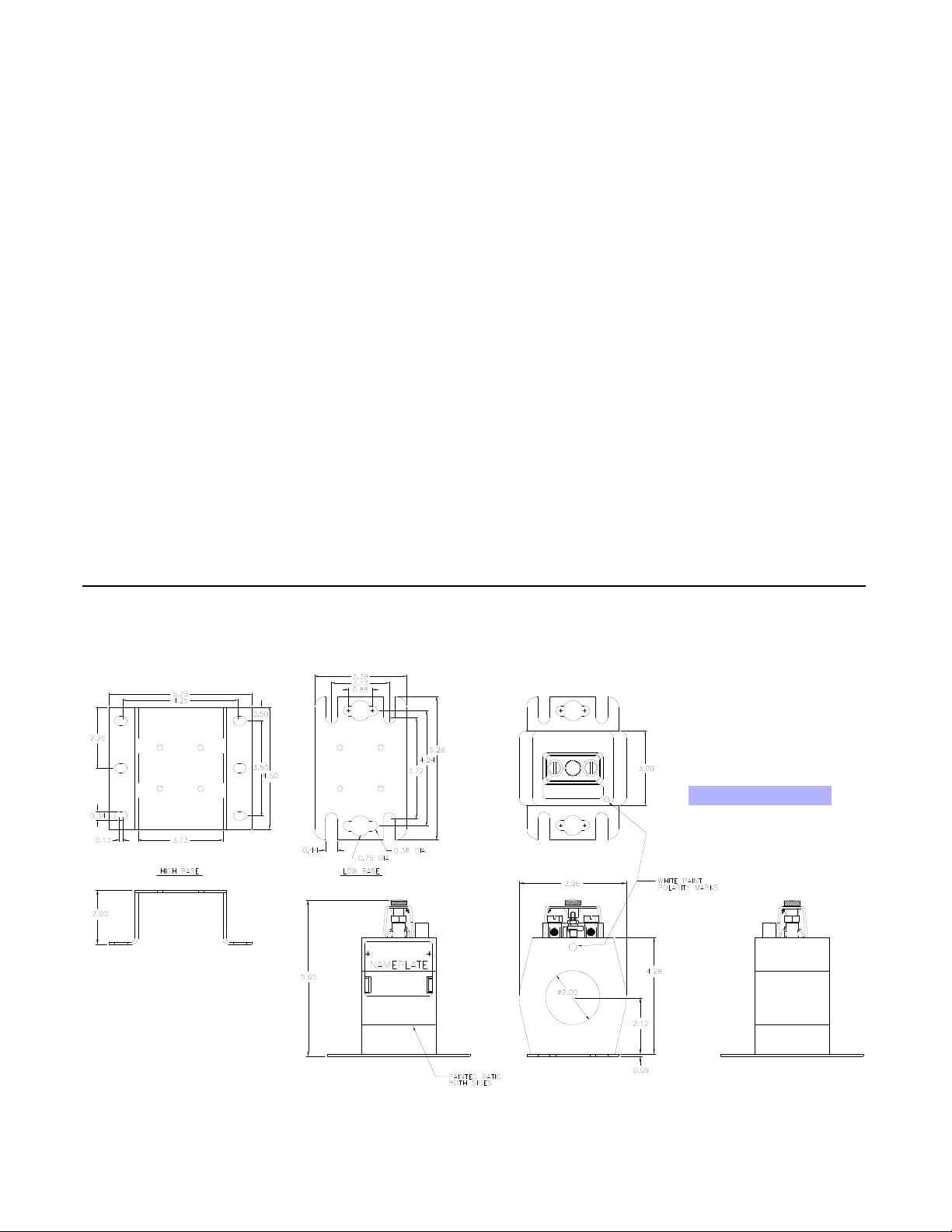

JCR-0W Dimensions

Construction and Insulation

The core and coil are encapsulated in a polyurethane resin.

This material has excellent electrical and mechanical

properties over a wide temperature range and is resistant to

oil and a variety of chemicals.

Core and Coils

The core is made from high quality grain oriented silicon

steel, annealed under rigidly controlled factory conditions.

The secondary winding is made of heavy enameled

copper wire. The secondary windings are evenly

distributed around the core for maximum accuracy and

resistance to stray fields from adjacent conductors.

Terminals

Secondary terminals are tin plated brass, compression type

with a 0.275” diameter cross-hole for wiring and a 1/4-28

clamp screw. A shorting device is provided and interlocked to

the terminal cover. The terminal cover is made of a clear

plastic. Provision is made for sealing the cover.

Polarity

The H1 polarity mark is molded into the transformer body,

above the window at one end. The X1 polarity mark is also

molded into the body adjacent to the secondary terminal.

Both are also identified with a white dot .

Primary Window

The window has ample size to accommodate cables of

current-carrying capacity equal to or greater than the

transformer’s thermal current rating.

Nameplates

The nameplate is laser engraved aluminum. It is attached to

the top of the unit and has provision for attaching the user’s

identifying tag. The nominal current rating is on both faces of

the unit in large numerals.

Baseplate and Mounting

The transformer can be mounted in any position and may be

suspended from the bus-bar or cable. It has provision for

attaching two optional bases. Bases are made from stainless

steel. The high base increases the transformer height by 2

inches and meets the dimensions specified in ANSI C12.11

Maintenance

These transformers require no maintenance, other than

occasional cleaning, if installed where air contamination is

severe.

Data subject to change without notice

Loading...

Loading...