Page 1

GE

Reduce inventory and part number requirements, reducing asset

Grid Solutions

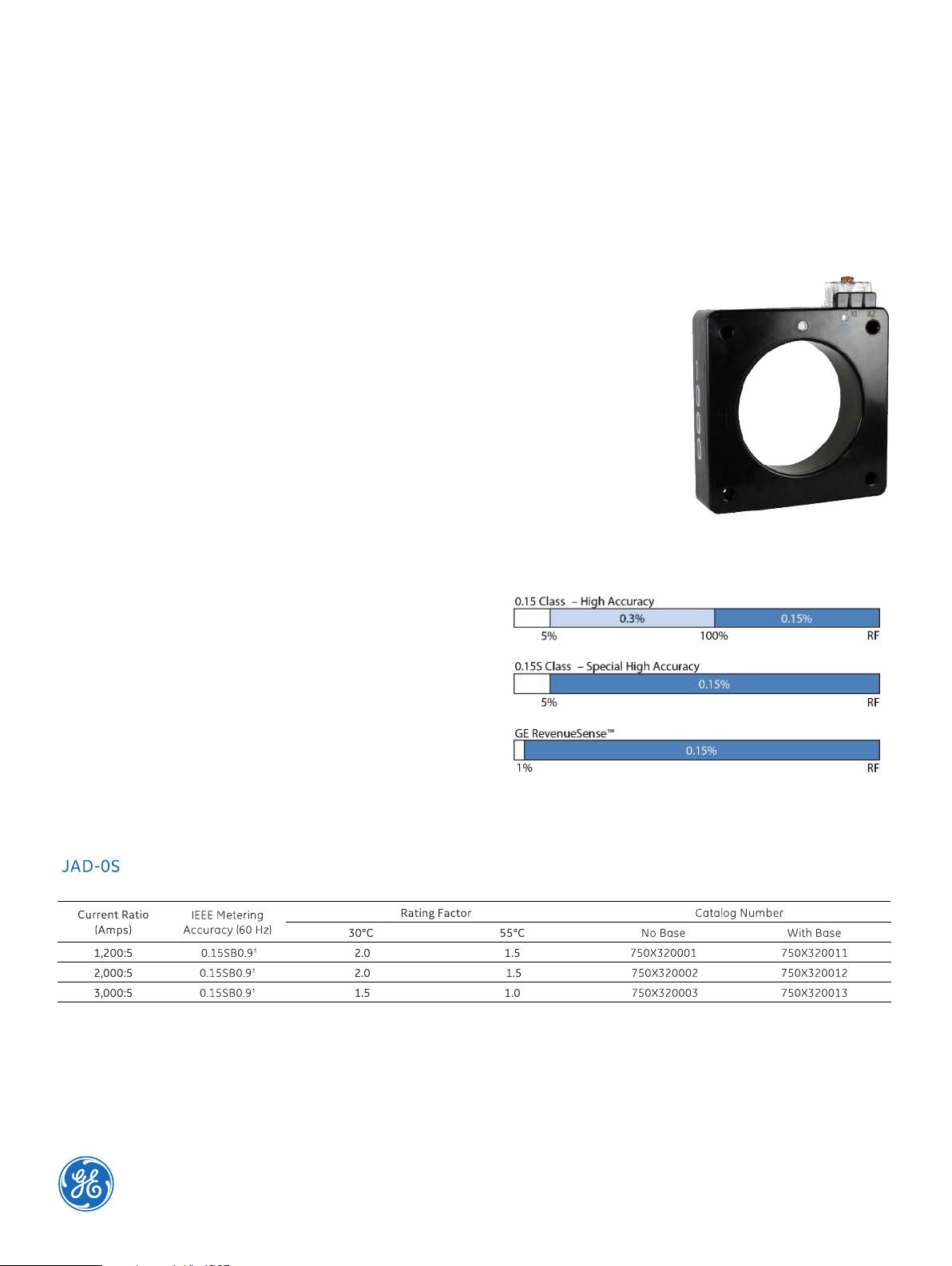

Model JAD-0S RevenueSenseTM

Revenue Metering Current Transformer

Application

RevenueSenseTM is a revenue metering current transformer which

maintains IEEE 0.15 accuracy class from 1 % of rated current up

through rating factor. This is accomplished using the specialized

amorphous core material which minimizes electrical core losses.

The result is an extremely accurate CT that can maintain high

accuracy over a extended range of current. Model JAD-0S is

designed for indoor service, and is available in bar-type or windowtype designs.

Features

Voltage Class: 0.6 kV

Frequency: 50-60 Hz

Window Size: 5.75”

Insulation Level: 10 kV BIL

Application: Indoor/Outdoor

Benefits

Maximize revenue metering accuracy with special high accuracy

rating extended beyond IEEE requirements

Simplify CT selection and billing multipliers, improving

productivity and minimizing risk of error

and operational costs

Unit Selection

(1) Exceeds IEEE definition for special high accuracy. Maintains 0.15 Accuracy from 1% to Rating Factor.

(2) Primary-bar options available upon request. Contact GE for more details.

(3) Other designs available, upon request. Contact GE for more details.

Page 2

top of the unit. The nominal current rating is marked on both sides

orientation and allow the transformer to be supported in a vertical

The transformer can be mounted in any position. An optional base

Secondary terminals are tin plated brass, compression type with a

Weight

Transformer, Window Type 13 lbs

Primary Bar, add 4 lbs

Mounting Base, add 2 lbs

Reference Drawings

Outline 0121C34994

Primary Bar Assembly 0821C35021

Base Assembly 0221A36647

Construction and Insulation

The core and coil assembly is encapsulated in resin within a

molded case. The case is molded with GE Valox thermoplastic

polyester resin. This tough material has excellent electrical and

mechanical properties over a wide temperature range, has low

water absorption and is resistant to oil and a variety of chemicals.

The polyurethane resin filling completely encapsulates the

winding, leads and terminals to form a waterproof unit.

Core and Coils

The core is manufactured with high-efficiency material that

reduces energy losses, allowing for higher accuracy over a wider

range. The secondary winding is made of heavy enameled copper

wire evenly distributed around the core for maximum accuracy

and resistance to stray fields from adjacent conductors.

Terminals

0.275” diameter cross-hole for wiring and a 1/4-28 clamp screw. A

shorting device is provided and interlocked to the terminal cover.

The terminal cover is made of a clear plastic. Provision is made for

sealing the cover..

Polarity

Primary and secondary polarity marks H1 and X1 are molded into

the case.

Nameplates

The nameplate is laser engraved aluminum and is attached to the

of the unit in large numerals.

Primary Conductor

Removable primary bars are formed from 1/4”x 4”tin-plated, flat

copper bar, with 1/4”spacing between bars on multiple bar

assemblies. The bars are retained by insulated and ventilated end

caps, which permit the bars to be rotated to any desired

primary arrangement. A potential connector is provided adjacent

to one end cap. Primary bars are available in 11 7/8”and 14

1/4”lengths, each provided with four bolt holes at each end.

Baseplate and Mounting

plate is available, made of stainless steel. It is attached to the

transformer with two bolts.

Maintenance

These transformers require no maintenance, other than

occasional cleaning, if installed where air contamination is severe.

Grid-AIS-L4-ITI_Model_JAD_OS-1384-2017_07-EN. © Copyright 2017. General Electric Company

and Instrument Transformers LLC reserve the right to change specifications of described

products at any time without notice and without obligation to notify any person of such changes.

Loading...

Loading...