Page 1

FT & RT

TEST SWITCHES

KEY BENEFITS

The FT Switches and FT Test Plugs have all the features necessary for applications involving the measurement of individual

currents and voltages to facilitate testing of substation instrumentation and protection devices from the front of the panel.

The make before-break current short circuit feature allows test personnel the convenience of isolating equipment from current

transformer circuits.

Voltage measurements can be made directly on the FT Switch without disturbing existing connections. There is a test clip provision

located on the top of each pole that allows connection with standard spring clip test leads.

APPLICATIONS

FT Test Switches:

The ITI FT Test Switches and Test Plugs provide a safe, simple, immediate and reliable method to isolate equipment and measure

system current and voltage during field testing and commissioning.

RT Rack Mount Test Switches:

RT Switch assemblies for rack and switchboard mounting permit convenient isolation of switchboard relays, meters and

instruments. RT racks allow quick and easy multi-circuit testing by conventional test methods and for faster installation into

switchgear.

FEATURES

FT Test Switch:

• Built with a maximum of ten individual poles, of potential,

current, and current shorting switch units

• Switches can be assembled in a variety of different

arrangements to match customer requirements

• FT Test plugs are used in conjunction with the FT Switches

to enable easy measurement, calibration, verification or

maintenance of relays, meters and instruments

• UL / cUL E101598

Protection:

• With the cover in place, a meter type seal can be placed

through either of the cover studs of the FT Switch to

prevent unauthorized access

• Standard black cover mounts only when all switches are

in the closed position

• A clear cover is available that can be installed with the

switchblades in the open or closed position

Energy

g

RT Rack Mount Test Switches:

• RT Switches accommodate three FT switches mounted

on a 19” wide steel mounting panel (Brushed aluminum

available)

• Provides up to 30 terminals with three FT combinations

• Color and finish can be customized

• Optional rack heights for label applications

• Each panel is supplied with the hardware to mount the RT

assembly to the 19” rack enclosure

• The RT assembly will support an FT style test plug

• Full-length clear cover is standard. Full length black cover,

individual clear covers, and individual black covers are

available

• UL / cUL E101598

Protection:

• Once the full-length clear cover on the RT switch is

installed, it prohibits access to some of the rack mounting

screws

• Individual clear covers offer additional protection

consistent with common testing procedures to ensure

only correct switch is exposed during testing

1

Page 2

FT & RT Test Switches

FT PAGE.pdf 1 1/24/2012 11:35:32 AM

FT Specifications

Rating

The standard FT switch is rated at 600 volts and 30 Amps. The

Switch meets or exceeds all requirements of ANSI / IEEE Standard

C37.90 and is UL and cUL recognized.

Mounting

FT Switches are designed for semi-flush mounting on the front of

switchboard panels, facilitating inspection and accessibility.

Drilling Plan - Inches

Fasteners

Captive fasteners are made of molded plastic with a threaded brass

insert for easy cover installation and removal.

Switch Poles

FT Switches are available in configuration of 1 to a maximum of

10 individual poles or switch units. Each pole identified by letter (A

thru J), which is visible along the top of the base from left to right.

The individual switch units are of knife blade type. There are three

different types of switch units available: potential, current, and

current shorting.

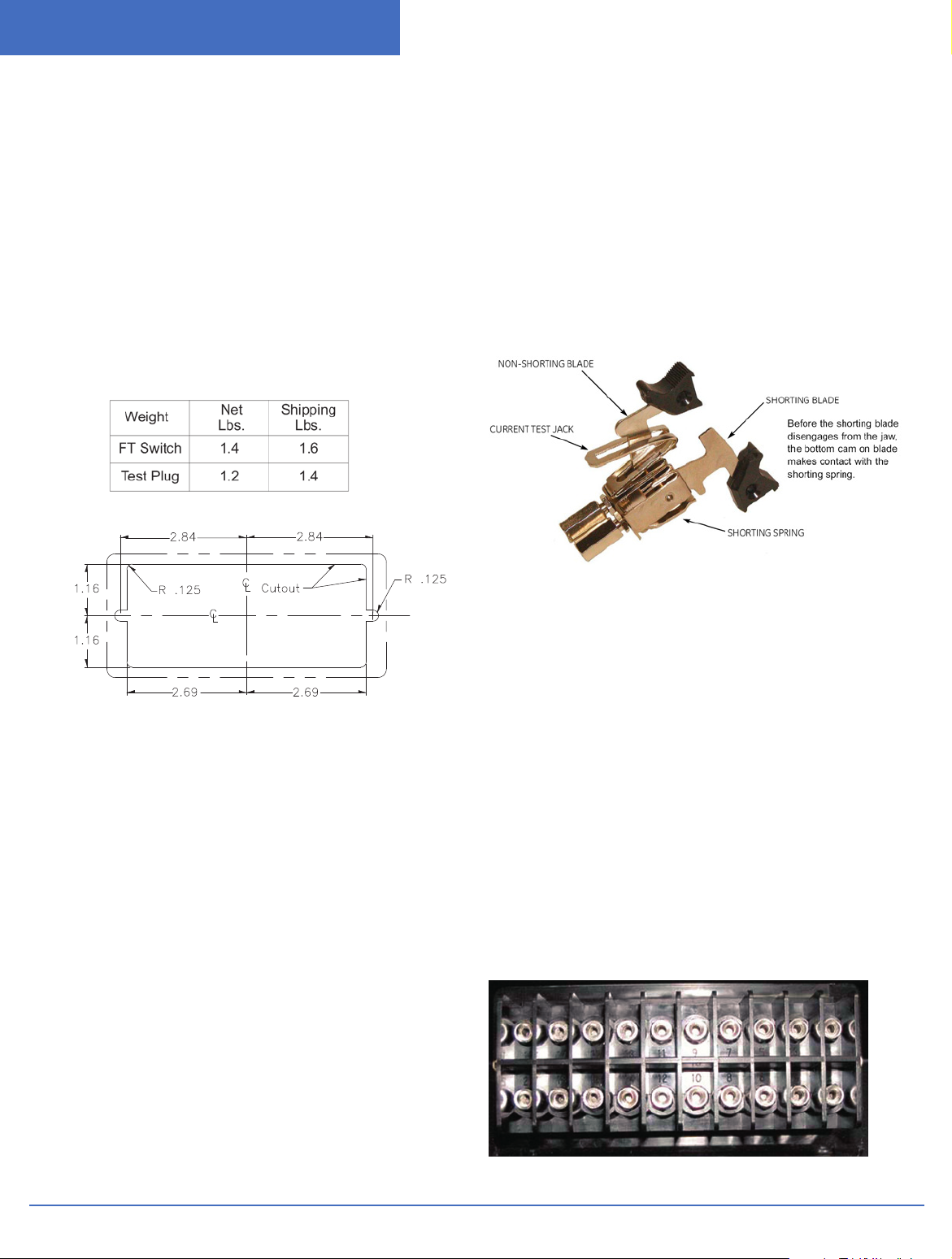

Blade assembly of two position pole “C-C” (outside of base)

FT Switch Construction

The base of the FT Switch is made of black electrical grade plastic

material which provides a tough insulated enclosure. Barriers are

molded into the base (front and rear) to separate the switch units

from one another. The barriers provide insulation between poles and

ample space between terminals.

Cover

FT Switches come with a black opaque cover or a clear see-through

cover. Switch covers provide a tough insulated enclosure for the

switch and are made from plastic material. The clear cover affords

the user the option of leaving switch handles in the open position

and replacing the cover while maintaining the provision for a meter

type seal when some or all switch handles are in the open position.

This feature allows the user to service electrical equipment while still

complying with OSHA lockout/tag-out procedures. The clear cover

can be ordered separately for retrofit to existing FT Switches. RT

racks come standard with a full length clear cover and can be sealed

with a meter seal.

Switch Handles

Switch handles are made of a molded plastic insulating material

typically black in color. Red handles can be supplied by replacing

the “P” with “T” for potential handles and replacing “C” with “R” for

current handles. Additional colors are available upon request.

Each handle has a dovetail indentation to hold a circuit identification

label (by others). Knife blade switches can be operated independently

or ganged together with a horizontal interlocking bar (see page 4).

A hole runs through the middle of each switch handle to allow

insertion of interlocking bars. 2 to 10 switch handles can be

mechanically tied together.

Terminals

Connection terminals are located at the rear of the switch and can

be either screw or stud type. Terminals are numbered 1 thru 20 for

easy identification. Each pair of numbered terminals is associated

with a matching pole designated by a letter on the front of the switch.

FT switch terminals 1 thru 20 (rear view)

222

Page 3

FT & RT Test Switches

FT Test Plugs

The Test Plug with a maximum of 10 positions is designed to match

the pole configuration of specific styles of FT Switches. Not every

switch configuration is suitable to accept a Test Plug. For available

styles, see switch selection tables.

10-Pole “In-Service Series” Test Plug Inserted into FT Test Switch

In-Service Series Test Plug

Provision is made only on current poles with shorting springs to

automatically short-circuit current transformer circuits when the

knife switches are opened prior to inserting the Test Plug.

This Test Plug is typically used to connect devices measuring the

currents and voltages being applied to the switchboard relays, meters

and instruments without interrupting or short-circuiting the circuit.

Only the current test switches with the current jack must be opened

before inserting the Series Test Plug. Connections to the test plug must

be made before inserting the test plug into the FT Switch. Before

inserting the Test Plug, all switchblades that are opposite bi-conductor

paddles must be placed in the full open position.

Single Pole Current Test Plug with Open

Secondary CT Protection

• HelpsreduceriskofhighvoltagesassociatedwithopenCT

secondary

• Reducesrisksduetooperatorerror,incorrectequipmentsettings

and deviation from correct test procedures

• Addssafetyforoperatorsandtechnicians

• Providesasimple,fastandreliablemethodtoisolateandservice

installed meters, relays and CT’s

How it works

If a CT opens during operation:

• TestplugshortstheCTsecondarytohelpreducetheriskofover-

voltage conditions for personnel and equipment

• RedLEDprovidesvisualindicationofanopenCTsecondary

circuit causing an over-voltage condition

Features

• Ergonomichand-helddesignallowsin-servicecurrent

measurement with an ammeter

• Ratings:600V,20Acontinuous

• LEDindicationofover-voltageprotectionoperation

• DesignedforusewithITIFTtestswitch

• AvailablewithorwithoutCTopensecondaryprotection

• ANSI/IEEEC37.90standards

10-Pole “In-Service Series” Test Plug

Ordering Information:

Catalog Number Open Circuit CT Protection

SPTP-01 Yes

SPTP-02 No

333

Page 4

FT & RT Test Switches

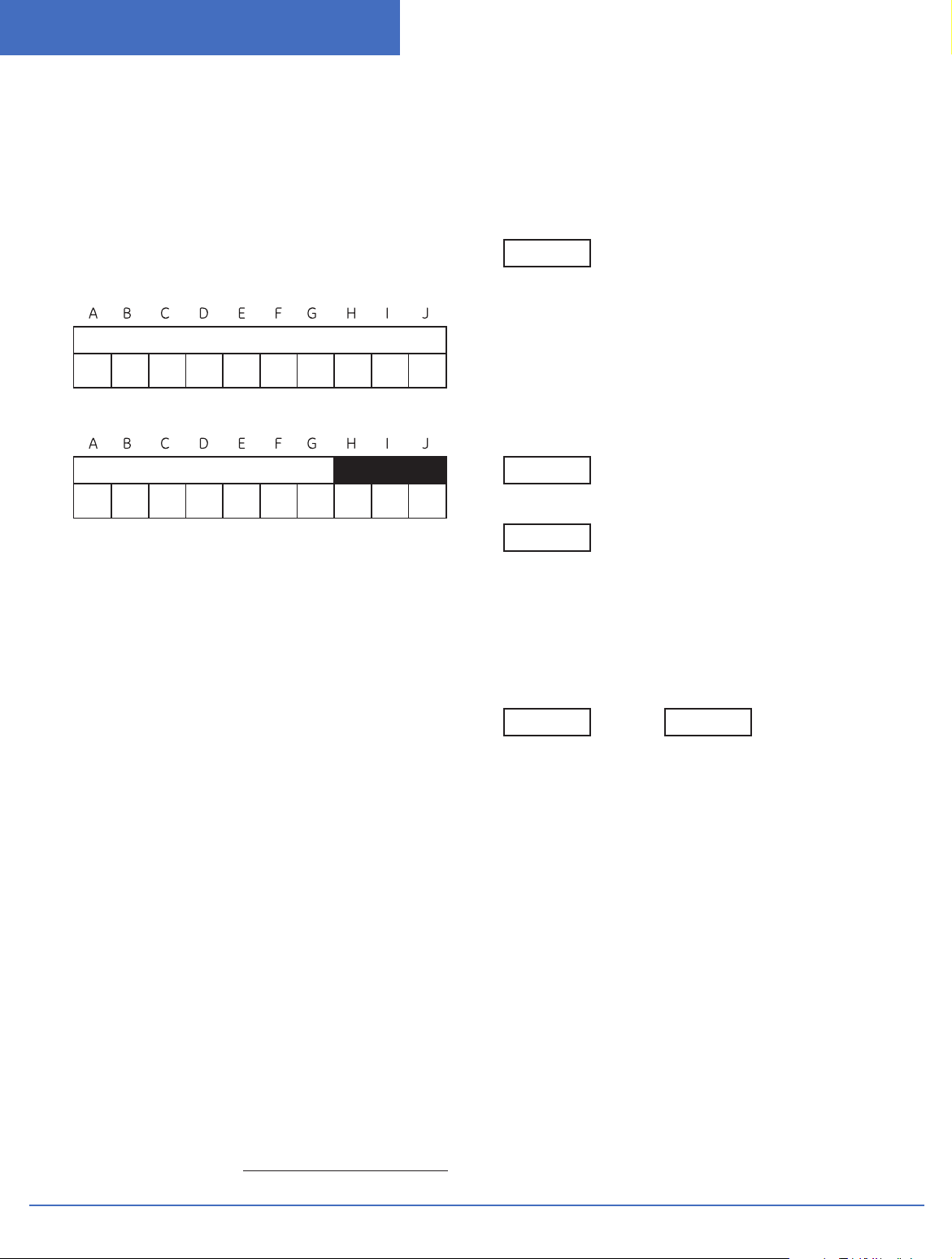

Non Standard FT Style Switch Selector

Step 1

• TheSwitchbodycansupport1to10polesinslotmarkedA

through J

• Enteraletterfromthelegend.Leaveunusedslotsblank

Position:

Excample:

P C - - C R C R - - R P P P

Legend:

P=Potential, Black

T=Potential, Red

C=Current, Non-shorting, Black

C-C or C-C-C- or C-C-C-C = Current , Shorting, Black

R = Current, Non-shorting, Red

R-R, R-R-R, R-R-R-R = Current, Shorting, Red

Additional colors available - See page 11

(Note: Some functions will require more than one slot in the

switch body)

Step 2

(Optional)

If a tie bar is required then check this box

and draw a dark heavy line over the poles to be joined.

(In the example shown in Step 1 positions H, I and J will operate

together.)

Step 3

Select a cover style

Clear (installs over open and closed switch blades)

Black (installs over closed switch blades only)

Step 4

Select a rear terminal type

Screws (Standard) Studs (Optional)

FACTORY USE ONLY

Catalog Number Assignment

444

Page 5

Catalog Number for FT Style Switches

FT C - 074 S

Cover

Black -------- (Blank)

Clear -------- C

Configuration

See website,

GEDigitalEnergy.com

Also on pages 8-11

Terminals

Screws ------ (Blank)

Studs -------- S

FT & RT Test Switches

Catalog Number for RT Style Rack Mount Switches

2 3

1

4

Left Center Right

5 6

8 9 10 11 12 13 14

7

R T 2 G G 0 6 6 0 8 4 1 2 5

RT-19” Rack

Terminal

Connectors

*Screw ---------- T

Stud ----------- S

Panel Height (ref pg 7)

2 - 2 rack unit centered

3 - 3 rack unit centered

X - 3 rack unit low

H - 3 rack unit high

4 - 4 rack unit low

5 - 4 rack unit centered

6 - 4 rack unit high

Color

*ANSI 61 ------- G

ANSI 70 ------- A

Brush Al ------- B

Black ------- X

Cover

Full Length Clear ------------------ G

3 Individual Clear Covers --------- A

3 Individual Black Covers --------- B

Position # (As viewed from front)**

Left

Center

Right

000 = Blank

* Denotes standard features

** See pages 8 thru 11 for 3 digit codes or go to “Configure a FT Switch” at GEDigitalEnergy.com/ITI

555

Page 6

FT & RT Test Switches

Dimensional Drawing - Type FT Test Switch

Black cover and threaded stud terminals

Clear cover and screw terminals

Typical FT Switch Connection Schematic using an FT-076 switch

666

Page 7

Dimensional Drawing - Type RT Mounting Racks

FT & RT Test Switches

777

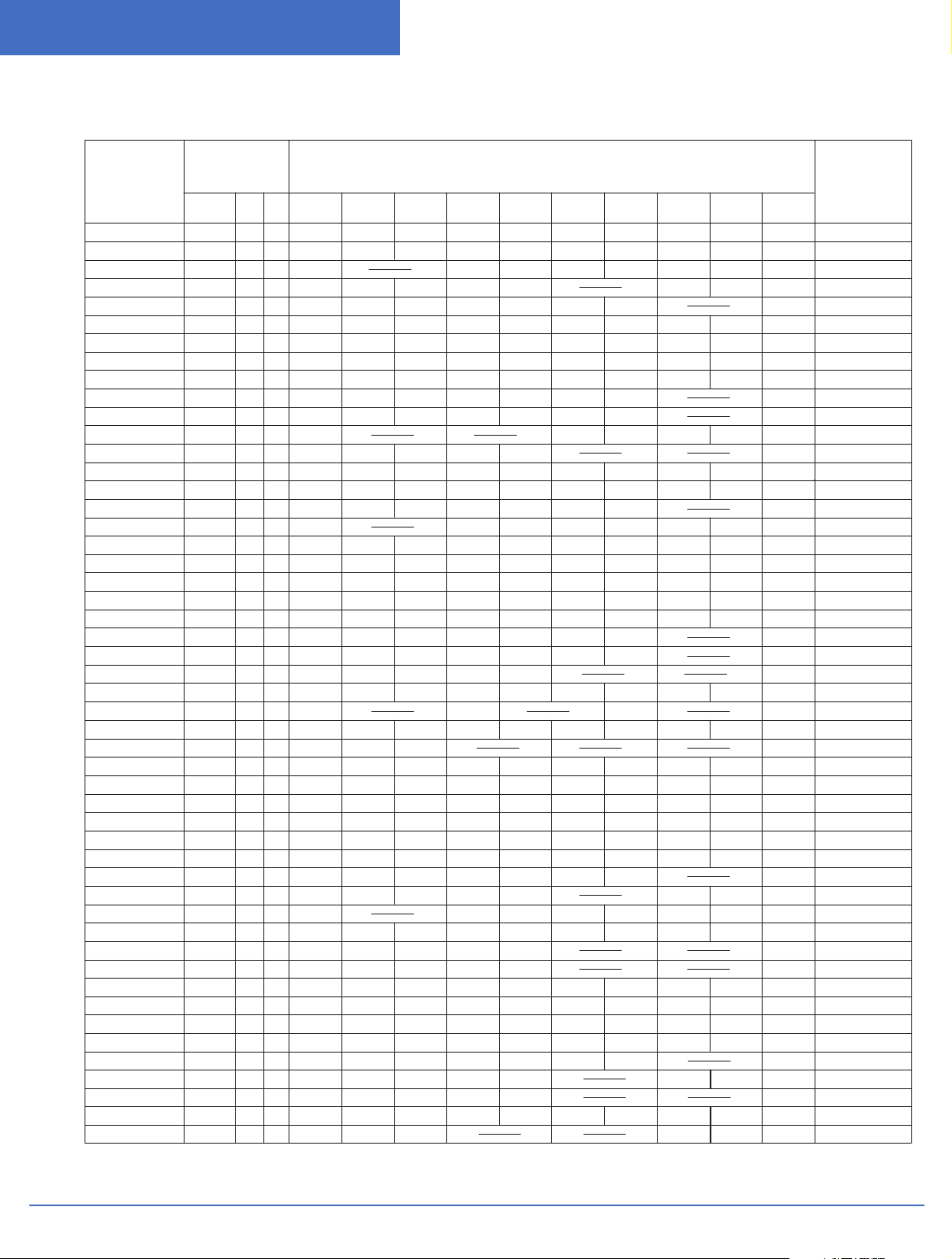

Page 8

FT & RT Test Switches

Configuration Selection Chart

INDIVIDUAL

FT SWITCH

NUMBER

-001

-002

-003

-004

-005

-006

-007

-008

-009

-010

-011

-012

-013

-014

-015

-016

-017

-018

-019

-020

-021

-022

-023

-024

-025

-026

-027

-028

-029

-030

-031

-032

-033

-034

-035

-036

-037

-038

-039

-040

-041

-042

-043

-044

-045

-046

-047

-048

-049

-050

POLES

TOTAL

2

2

2

2 0

2

4

4

4

V

A

2

0

0

2

0

2

2

0

2

4

0

4

0

4

0

4 04

2

4

22P

2

4

0

0

5

3

3

1

0

6

6

6

4

3

2

0

0

0

0

0

7

7

7

7

7

5

5

5

4

3

3

3

8

8

6

6

4

4

4

4

4

0

2

2

4

5

0

0

0

2

3

46P

6

6

6

6

0

0

0

0

0

2

2

2

3

4

4

4

0

0

0

2

2

4

4

4

4

4 0

5

5

5

5

5

6

6

6

6

6

6

6

6

6

6

6

7

7

7

7

7

7

7

7

7

7

7

7

8

8

8 8

8

8

8

8

8 44 P

P=POTENTIAL

A

P

B

P

C

P

P

P

P

P

P

P

C

C

P

P

P

P

P

C

C

C

P

P

P

P

P

P

P

C

C

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

C

P

P

P

C

P

P

P

P

P

P

P

P

P

P

P

P

SWITCH CONFIGURATION

C=CURRENT (NON-SHORTING)

*

C

D

E

P

C

P

PP

C C

C C

C

C

C P

C

C

P

P

C

C

P

P

C

C

C

C

C

C

P

P

P

P

P

P

P

P

P

C

P

P

C

P

C

C

C

C

C

P

P

P

P

C

P

C

P

P

P

P

P

P

P

C

P

P

P

P

P

P

C

C

C

C-C=CURRENT (SHORTING)

*

F

G

H

I

J

TEST PLUG

NUMBER

TP-109

P

TP-109

TP-106

C

C

C

C

P

P

P

P

P

P

PP

C

C

C

C

P

TP-107

TP-101

TP-109

TP-109

TP-109

TP-109

TP-101

TP-101

TP-108

C

C C

C

P

C

P

C

P

P

P

C

C

C

P

P

P

P

P

P

P

C

C

C

C

C

C

C

C

C

C

C

C

C

P

C

C

C

C

P

P

P

P

P

P

P

P

P

P

C

C

C

P

P

C

C

C

C

C

C

C

C

P

P

P

P

PP

C

C

C

C

C

C

C

P

C

CC

P

P

C

C

C

C

C

C

C

P

P

P

P

C

P

P

P

C

C

P

P

P

P

C

P

C

P

PC

P

P

P

P

P

P

C

P

P

P

P

P

P

P

P

P

P

P

P

P

P

TP-102

TP-109

TP-101

TP-108

TP-109

TP-109

TP-109

TP-101

TP-102

TP-102

TP-103

TP-109

TP-109

TP-109

TP-109

TP-109

TP-101

TP-107

TP-106

TP-113

TP-102

TP-102

TP-109

TP-109

TP-109

TP-101

TP-106

TP-102

TP-110

888

Page 9

Configuration Selection Chart

FT & RT Test Switches

INDIVIDUAL

FT SWITCH

NUMBER

-051

-052

-053

-054

-055

-056

-057

-058

-059

-060

-061

-062

-063

-064

-065

-066

-067

-068

-069

-070

-071

-072

-073

-074

-075

-076

-077

-078

-079*

-080

-081

-082

-083

-084

-085

-086

-087

POLES

TOTAL V A

8

8

8

8

8

8

8

8

9

9

9

9

9

9

9

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

3L

10

10

-088

-089

-090

-091

-092

-093

-094

-095

-096

-097

10

10

9

8

6

6

8

9

9

-098 10 4 6

-099 10 4 6

-100 10 10 0

SWITCH CONFIGURATION

P=POTENTIAL

A B C D E F GHI J

4

4

P

4

4

2

6

2

6

7

1

0

0

0

9

9

6

5

5

3

0

9

8

7

6

6

6

6

4

4

3

2

2

2

1

0

0

4

2

4

2

0

9

2

6

4

0

3

3

P

8

C

8

8

0

P

0

P

3

P

4

P

4

P

6

P

9

C

0

P

1

C

P

2

3

P

4

P

4

P

4

P

4

C

6

P

6

P

7

P

8

P

8

P

8

C

9

C

10

C

10

C

T T T T T T T T T

0

6

P

8

C

7

L

6

P

8

P

10

C

P

0

6

CCC

0

P

2

P P P PC C

C

8

6

P

6

P

C

C

C

C

C

P

P

P

P

P

P

C

P

P

P

P

P

P

C

C

P

P

C

C

C

C

C

P

C

C

P

P

C

P

P

C

P

P

C C

C

C C C C C T T T T

C=CURRENT (NON-SHORTING)

*

C

P

C

C

C

C

C

P

P

P

P

C

P

P

P

P

P

P

C

C

P

C

C

C

CC

C

C

C

P

C

C

P

C

C

P

P P P

P

P P

C

C

C

C

C

C

C

C

C

C

C

C

P

P

P

P

P

P

P

P

C C

C

P

P

P

P

P

C

P

C

C

C

P

P

P

P

P

C

P

P

C

CPCC

C

C

C

C

C

C

CC

C

C

C

P

C

C

C

C

C

C

L C

C

C

C C

C

C C C C

P

C

C

C

C

P

P

C

C

C

C

P

P

P P

P

C

P P

P P

P

C

C

C

C

C

C

C

C

C

C

C

C L

C C

C

P P P P P

C

P

C C CC CC

P

C

C

C

C

C

C

C C C C P P P P

C-C=CURRENT (SHORTING)

*

P

C

C

C

C

C

PPC CC CCC

C

C

C

C

C

C

C

C

C

C

C

C

P

P

P

P

C

C

C

P

C

C

C

C

P

P

C

C

C

C C

C

P

P

C

C

P

C

C

C

C

C

C

C

C

C

C C

C

P

P

C

C

C

C

C

P

C

C

C

C

CC

C

C

C

C

C

C

C

P

P

C

C

C

C

C

P

C

C

C

C

P P

C

C

C

C

P

C C

C

C

C

C

P

C

C

P

C C

CP C

P

P

P

C

P

P

P

P

PC

P

P

P

P

P

P

P

P

P

PC CP

P

P

P

P

C

C

T

C

P

C

C

TEST PLUG

NUMBER

TP-105

TP-102

TP-108

TP-108

TP-111

TP-111

TP-109

TP-109

TP-102

TP-102

TP-103

TP-109

TP-101

TP-102

TP-104

TP-105

TP-112

TP-111

TP-111

TP-112T

TP-114

TP-114

TP-115

P PPP P P P T TP

999

Page 10

FT & RT Test Switches

Configuration Selection Chart

INDIVIDUAL

FT SWITCH

NUMBER

-101

-102

-103

-104

-105

-106

-107

-108

-109

-110

-111

-112

-113

-114

-115

-116

-117

-118

-119

-120

-121

-122

-123

-124

-125

-126

-127

-128

-129

-130

-131

-132

-133

-134

-135

-136

-137

-138

-139

-140

-141

-142

-143

-144

-145

-146

-147

-148

-149

-150

SWITCH CONFIGURATION

TOTAL

10

10

9

10

7

3

10

9

2

6

POLES

V A

10

0

9

8

0

3

4

3

2

0

P=POTENTIAL C=CURRENT (NON-SHORTING)

A B C D E F G H I J

T

0

10

RRR RRRR RRR

0

TTT T T T TTT

2

*

P

P P PPPP PT

PPP P C C P PPP

7

C-C=CURRENT (SHORTING)

*

C CC CC CC

0

P P P

6

6

P P P C C C C C C

C

C C C C C

0

6

C

C C C C C

10 10 0 PPP P P T P TP P

10 10 0 P PPPP PPPP T

10

10 10 0 TTT T T T TTT

8 P C C C C CC CC T

2

T

10 10 0 P P P T T PPPP P

10 10 0 P PPPPPT T P P

10 2 8 C C CC CC CC

10

8 CC CP C CC CC T

2

T T

8 8 0 T T P PPPPP

10 10 0 T T P P PPPP T T

10 6 4 P P C P CPCPC P

10

8 TT CC CC CC CC

2

10 6 4 CC C TC TTTTT

TTTTTT066

10 4 6 PP PP RR RR RR

10 10 0 O O OOOOOO O O

10 2 8

C C C CCC B P P

C

10 4 6 PPPP RR RR RR

10 4 6 PPPP OOOO O O

10 6 4 PPPP P PR R R R

6 6 0 PPPPPP

10 2 8 R R R R P RP RRR

10 10 0

8 4 4 P P RRR R PP

10 0 10 R R RRRR R R RR

10 2 8

PP R

R RR RR RR

4 0 4 R RRR

10 10 0 PPPP PPP TTT

10 8 2 C

10 1 9 CC CC C CC C TC

10 4 6 PP T CC CC CC T

10 10 0

P P P

P044

10 10 0 TT T TTTT TTT

P00101 PP PP PTTTT

TEST PLUG

NUMBER

TP-109

TTT

T

TT

TP-109

TP-109

TP-111

TP-109

TTTTT066 T

PPPTT077 PP

TTTT044

TP-109

TP-109

TP-109

TP-111

TP-111

TP-109

TP-109

TP-111

TP-109

TP-109

TP-109

TP-112

TP-109

TP-112

TTPPPPP PPP

RRRRR808 RRR

TTTTT066 T

TC TTTTTTT

TPPPP TTTTT

101010

Page 11

Configuration Selection Chart

FT & RT Test Switches

INDIVIDUAL

FT SWITCH

NUMBER

-151

-152

-153

-154

-155

-156

-157

-158

-159

-160

-161

-162

-163

-164

-165

-166

-167

-168

-169

-170

-171

-172

-173

-174

-175

-176

-177

-178

-179

-181

-182

-183

-184

-185

-186

-187

-188

-189

-190

SWITCH CONFIGURATION

POLES

TOTAL V A

10

10

2

10103

P=POTENTIAL C=CURRENT (NON-SHORTING)

A B C D E F G H I J

P

0

P CC CC CC P

8

7

*

C C

P

P T P P T P PT

CC CC CC

C-C=CURRENT (SHORTING)

*

10 4 6 P CC CC C PC PP

10 10 0 P T PPP PPPP T

10 10 0 P T PPP PPP T T

P T PPP P P T T T

01010

10 10 0 P T T P P PPP T T

10 10 0 P T T P P P P T T T

10 10 0 P T T P PPT T T T

10 10 0 P T T P P TTT T T

10 10 0 P T T P TTTT T T

10 10 0 P TTT T P T T T T

10 10 0 P TTT TTTT T T

10 10 0 P T P P T PPPP T

10 10 0 P TTT T PPPP P

8 0 8 R

R RR RR RR

8 4 4

10 8

C

2

PPP PPPP PC

R RR RR RR

10 10 0 Y Y YYYYY YYY

10 1 9 P

CC CC C CC CC

10 10 0 PPT T TTTT T T

5 1 4 C C P C C

10 6 4 C

10 4 6 TTTT C

C CC CC

10 10 0 P T PPP PPP T P

10 0 10 CC CC CCC CC C

10 0 10 CCCCCC CC CC

C6401 CC C

PPPPC C

10 10 0 BBBB BBBB T P

10 10 0 TTTT T T PPP P

10 10 0 TTTT P PPPP P

10 4 6

10 4 6

10 4 6

10 6 4 P

T

P

C C

C C T

P P P P

C CC CC

C CC

C

PPPC

C C T C C T

C C C

TEST PLUG

NUMBER

TP-111

TCPP

TP-111

TP-111

PRPRPRPR

TT8201 R

TP-111

TP-109

PPP00101 PT T TTTT

YO00101 YYYYO OOO

TP-109

TP-109

CC CT P PPT P

TP-109

TP-109

TP-109

TP-109

TTTT

TP-112

T

C

P = POTENTIAL- black handle

T = POTENTIAL- red handle

C = Current Non-shorting - black handle

R = Current Non-shorting - red handle

C-C = Current shorting - black handle

R-R = Current shorting - red handle

O = POTENTIAL- orange handle

Y = POTENTIAL- yellow handle

G = POTENTIAL- green handle

B = POTENTIAL- blue handle

CO = Current Non-shorting - orange handle

CY = Current Non-shorting - yellow handle

CG = Current Non-shorting - green handle

CB = Current Non-shorting - blue handle

CW = Current Non-shorting - White handle

CO-CO = Current shorting - orange handle

CY-CY = Current shorti

ng - yello

w handle

CG-CG = Current shorting - green handle

CB-CB = Current shorting - blue handle

CW-CW = Current shorting - white handle

W = POTENTIAL- white handle

* = SHORT CIRCUIT WITHOUT JAW OR BLADE AT POSITION "H"

= FT-079 and FT-085 *APPEAR SIMILAR EXCEPT THAT FT-079 IS SHORT CIRCUIT WITHOUT JAW OR BLADE AT POSITION "H"

Note: Selection Chart does not include all possible configurations

111111

Loading...

Loading...