The subject of this document is the exclusive property of ITW Test and Measurement It alia S.r.l. - INSTRON CEAST Division. This

document or any part thereof must not be reproduced in any form, nor information contained therein disclosed to third parties nor

methods, procedures or test described therein performed, without the written permision of ITW T est and Measurement Italia S.r .l.

- INSTRON CEAST Division.

CEAST 9300 Series

Droptower Impact Systems

CEAST 9340

INSTRUCTIONS for USE

and MAINTENANCE

7510.000MN1r

ed. 1 rev. 1

Page 2 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

CONTENTS

LEGEND ...................................................................................................................................... 7

1. GENERAL INFORMA TION...................................................................................................... 8

1.1 EQUIPMENT DESCRIPTION .............................................................................................................11

1.1.1 INTRODUCTION ................................................................................................................................................ 11

1.1.2 MODULARITY .................................................................................................................................................... 11

1.1.3 DIFFERENCE BETWEEN INSTRUMENTS....................................................................................................... 11

1.1.4 MAIN PARTS OF INSTRUMENT ....................................................................................................................... 11

1.1.5 OPTIONS ........................................................................................................................................................... 13

1.2 TECHNICAL CHARACTERISTICS .................................................................................................... 14

1.2.1 LAYOUT .............................................................................................................................................................. 16

1.3 SAFETY ............................................................................................................................................. 17

2. CONDITIONS OF USE .......................................................................................................... 18

2.1 AUTHORIZED PERSONNEL ............................................................................................................. 18

2.2 NORMAL USE CONDITIONS ............................................................................................................ 19

2.3 ABNORMAL SITUATIONS................................................................................................................. 20

3. OPERATOR WORK STATION .............................................................................................. 21

2.4 SHIELDS............................................................................................................................................ 21

2.5 RESIDUAL RISKS.............................................................................................................................. 21

4. TRANSPORT AND MOVEMENT .......................................................................................... 22

4.1 LIFTING AND HANDLING ................................................................................................................ 22

4.1.1 MOVEMENT IN PACKAGING ............................................................................................................................ 22

4.1.2 MOVEMENT OF THE INSTRUMENT ................................................................................................................ 22

4.1.3 WEIGHT OF THE MAIN PARTS........................................................................................................................ 23

4.2 CHECK FOR POSSIBLE DAMAGE...................................................................................................23

4.3 STORAGE.......................................................................................................................................... 23

5. MOUNTING AND DISMANTLING.......................................................................................... 24

5.1 DISMANTLING THE PACKAGING CASE............................................................................................................. 24

6. INST ALLA TION...................................................................................................................... 25

6.1 SPACE AND ENVIRONMENT REQUIREMENTS ............................................................................. 25

6.1.1 SPACE................................................................................................................................................................ 25

6.1.2 ENVIRONMENT ................................................................................................................................................. 25

6.1.3 SERVICES .......................................................................................................................................................... 25

6.2 POSITIONING ................................................................................................................................... 26

6.2.1 SURFACE LOAD IN STATIC CONDITION ........................................................................................................ 26

6.2.2 LOAD ON SLAB ................................................................................................................................................. 27

6.2.3 INSTALLATION PROCEDURE .......................................................................................................................... 28

6.3 LEVELLING........................................................................................................................................ 32

6.4 STABILITY ......................................................................................................................................... 33

6.5 CLEANING......................................................................................................................................... 33

6.6 MATERIALS AND PRODUCTS ......................................................................................................... 33

7. START-UP ............................................................................................................................. 34

7.1 INSTRUMENT, CEAST DAS 8000 JUNIOR/CEAST 16000 AND PC CONNECTION....................... 34

7.2 ELECTRICAL SERVICE CONNECTION ........................................................................................... 34

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 3

7.3 PNEUMATIC SERVICE CONNECTION ............................................................................................ 35

7.4 CRYOGENIC SERVICE CONNECTION ............................................................................................ 36

8. USE........................................................................................................................................ 38

8.1 SAFETY STANDARDS ...................................................................................................................... 38

8.2 COMPONENT IDENTIFICATION ...................................................................................................... 39

8.2.1 SAFETIES AND THEIR LOCATIONS ................................................................................................................ 41

8.3 COMMANDS...................................................................................................................................... 43

8.4 OPERATIONS.................................................................................................................................... 44

8.4.1 KEY FUNCTIONS ............................................................................................................................................... 44

8.4.2 PROGRAM ......................................................................................................................................................... 45

8.5 PROGRAM START - UP.................................................................................................................... 47

8.5.1 NAVIGATION THROUGH THE PROGRAM MENUS ........................................................................................ 48

8.5.2 MAIN MENU ....................................................................................................................................................... 50

8.5.3 SET TEMPERATURE ......................................................................................................................................... 51

8.5.4 LOAD PARAMETERS ........................................................................................................................................ 51

8.5.5 MODIFY PARAMETERS .................................................................................................................................... 52

8.5.6 SAVE PARAMETERS......................................................................................................................................... 56

8.5.7 RESULTS ........................................................................................................................................................... 56

8.5.8 UTILITY .............................................................................................................................................................. 57

8.5.9 INPUT PASSWORD ........................................................................................................................................... 58

8.5.10 CYCLE COUNTER ........................................................................................................................................... 59

8.5.11 FW VERSION ................................................................................................................................................... 59

8.5.12 MODIFY PASSWORD ...................................................................................................................................... 60

8.5.13 CLOCK ............................................................................................................................................................. 60

8.5.14 LANGUAGE ...................................................................................................................................................... 61

8.5.15 SERVICE .......................................................................................................................................................... 61

8.5.16 SHUTTER MOVING ......................................................................................................................................... 62

8.5.17 STRIKER RELEASE ........................................................................................................................................ 62

8.5.18 MOVE TO HEIGHT .......................................................................................................................................... 63

8.5.19 VISUALIZE SENSORS ..................................................................................................................................... 63

8.5.20 VISUALIZE I/O ................................................................................................................................................. 64

8.5.21 EMERGENCIES SYNOPTIC ............................................................................................................................ 64

8.5.22 ERROR CODES IN THE PROGRAM .............................................................................................................. 64

8.6 PREPARING THE INSTRUMENT FOR TESTING ............................................................................ 65

8.6.1 REPLACEMENT OF THE STANDS ................................................................................................................... 65

8.6.2 REPLACEMENT OF THE SPECIMEN FIXTURES............................................................................................ 66

8.6.3 REPLACEMENT OF THE STRIKER HOLDER.................................................................................................. 74

8.6.4 REPLACEMENT OF THE WEIGHTS ................................................................................................................ 76

8.6.5 REPLACEMENT OF STRIKER .......................................................................................................................... 78

8.6.6 REPLACEMENT OF THE STRIKER EXTENSION............................................................................................ 81

8.6.7 REPLACEMENT OF THE STRIKER’S HEADS (interchangeable head type) ................................................... 82

8.7 PREPARING THE INSTRUMENT FOR TENSILE-IMPACT TEST ONLY.......................................... 86

8.7.1 PROGRAM SETTING ........................................................................................................................................ 86

8.7.2 REPLACEMENT OF THE FIXED HEIGHT VICE SUPPORT STAND ............................................................... 88

8.7.3 REPLACEMENT OF THE PIEZOELECTRIC FORCE SENSOR ....................................................................... 90

8.7.4 REPLACEMENT OF THE INSTRUMENTED VICE FOR TENSILE-IMPACT.................................................... 92

8.7.5 REPLACEMENT OF THE TENSILE-IMPACT SPECIMEN ................................................................................95

8.7.6 REPLACEMENT OF STRIKER FOR TENSILE-IMPACT TESTS ...................................................................... 97

8.8 SUPPORT STANDS CODES 7520.350 AND 7520.351 FOR PLATES OF FIBER REINFORCED

POLYMERS ........................................................................................................................................ 98

8.8.1 INTRODUCTION ................................................................................................................................................ 98

8.8.2 COMPONENTS IDENTIFICATION .................................................................................................................... 98

Page 4 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

8.8.3 DISASSEMBLY AND ASSEMBLY OF THE SUPPORT STANDS ...................................................................... 99

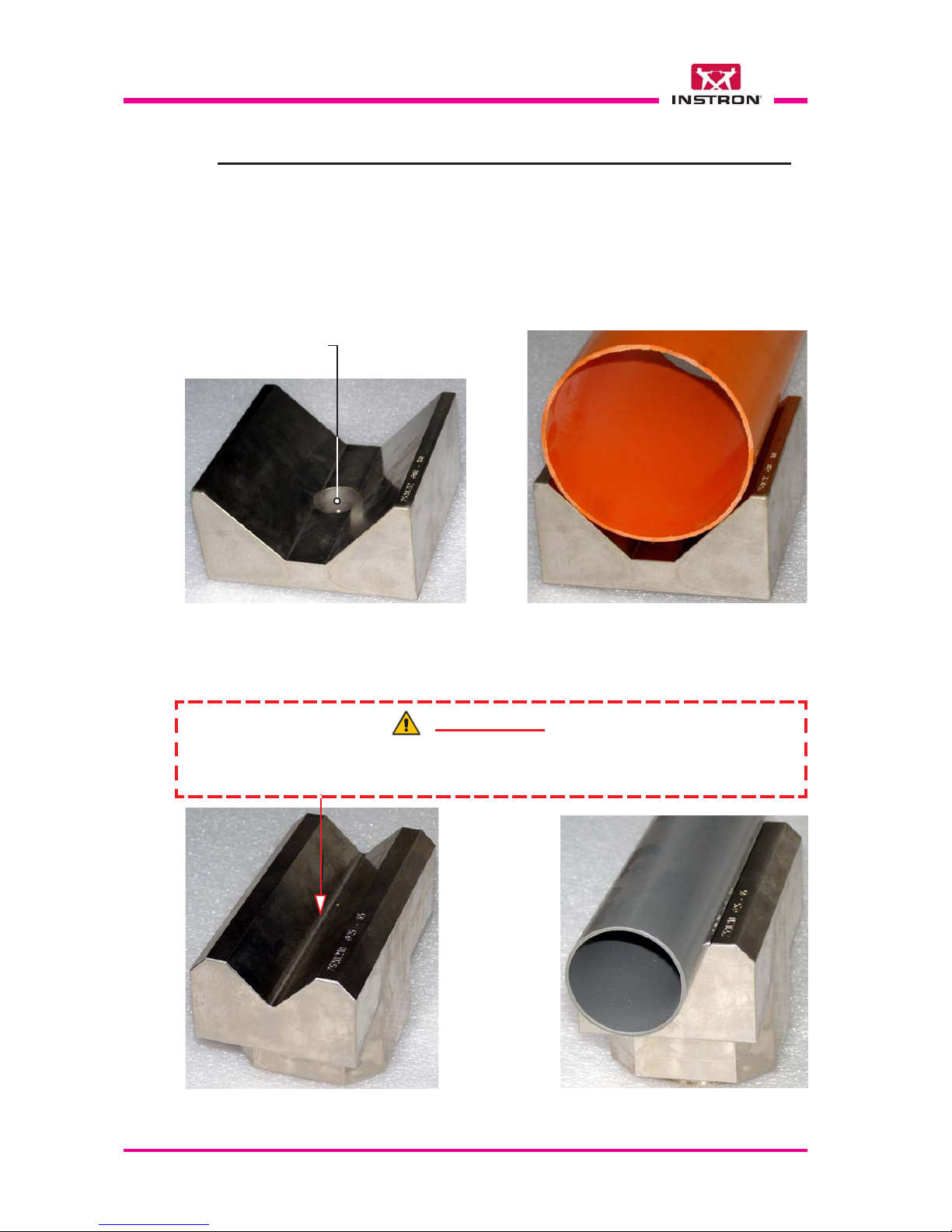

8.9 SPECIAL-PURPOSE TOOLING FOR IMPACT TESTS ON PIPES ................................................ 100

8.9.1 INTRODUCTION .............................................................................................................................................. 100

8.9.2 SUPPORTS ...................................................................................................................................................... 100

8.9.3 SPECIAL HEADS FOR STRIKER.................................................................................................................... 102

8.10 CARRY OUT TEST........................................................................................................................ 103

8.10.1 OPERATING SEQUENCE OF AN INSTRUMENTED TEST ......................................................................... 103

8.11 SCREENS SHOWN DURING TEST.............................................................................................. 104

8.11.1 TEST START .................................................................................................................................................. 104

8.11.2 TEST IN PROGRESS..................................................................................................................................... 104

8.11.3 TEST END ...................................................................................................................................................... 105

9. MAINTENANCE ................................................................................................................... 106

9.1 SAFETY STANDARDS, GENERAL PROCEDURE ......................................................................... 106

9.2 FUSES REPLACEMENT ................................................................................................................. 107

9.3 CLEANING AND DRYING METHODS ............................................................................................ 109

9.4 PROCEDURE FOR LOADING FIRMWARE UPDATES...................................................................110

9.4.1 CONNECTION ................................................................................................................................................. 110

9.4.2 PREPARATION OF THE LOADING PROGRAM ............................................................................................. 110

9.4.3 LOADING ......................................................................................................................................................... 113

9.4.3.1 LOADER UPGRADE ..................................................................................................................................... 114

9.4.3.2 FIRMWARE UPGRADE ................................................................................................................................ 114

9.4.4 DISCONNECTION ........................................................................................................................................... 115

9.4.5 INSTRUMENT FIRMWARE CHECK ................................................................................................................ 115

9.5 REPLACEMENT OF THE IMPACT ROLLERS.................................................................................116

9.6 GREASING THE STRIKER RELEASING MECHANISM..................................................................117

9.7 LUBRICATING THE GEARING CHAIN ............................................................................................118

9.8 VERIFYING THE GEARING CHAIN TIGHTENING .........................................................................119

10. SPARE PARTS .................................................................................................................. 120

10.1 LIST OF RECOMMENDED SPARE PARTS................................................................................. 120

10.1.1 CEAST 9340 7515.000 AND 7516.000.......................................................................................................... 120

10.2 LIST OF SPARE PARTS FOR TECHNICAL ASSISTANCE........................................................... 121

10.2.1 CEAST 9340 CODE 7515.000 AND 7516.000 .............................................................................................. 121

10.2.2 ENVIRONMENTAL CHAMBER 7510.011 ...................................................................................................... 124

10.2.3 STRIKER ANTIREBOUND SYSTEM CODE 7510.002 ................................................................................. 125

11. TRAINING .......................................................................................................................... 126

11.1 GENERAL INFORMATION ............................................................................................................ 126

12. WIRING DIAGRAMS.......................................................................................................... 127

13. PNEUMATIC DIAGRAMS.................................................................................................. 148

APPENDIX A - CEAST 9340 PART LIST................................................................................ 151

APPENDIX B - TOOLING........................................................................................................ 154

APPENDIX C - TOOLING FOR TENSILE IMPACT TEST ONLY ........................................... 160

APPENDIX D - STRIKERS TECHNICAL FEATURES ............................................................ 161

APPENDIX E - INPUT LIST..................................................................................................... 165

APPENDIX F - OUTPUT LIST................................................................................................. 167

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 5

APPENDIX G - ERROR CODES LIST .................................................................................... 1 69

APPENDIX H - STRIKER ANTIREBOUND SYSTEM ............................................................. 178

Page 6 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

PRINT DATE: MARCH 02, 2010

REVISION TOPIC:

REVISION: 1

EDITION: 1

- Changed the legal name of the firm from "Instron" to "ITW Test and Instrument Italia S.r.l. - INSTRON

CEAST Division" where necessary.

- Appendix G: changed “Instron Service” with “Authorized Service” in the tables of Error Codes Lists,

pages 168, 172, 173 and 174.

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 7

LEGEND

X

Perform the operations indicated by this symbol.

Additional information, observations, explanations and recommendations.

Potential danger of extremely risky situation for life or health .

Beware of potential danger to the operator and/or risk of equipment damage.

These symbols are used to focus the attention of the operator on the most important or critical

points provided in this document.

Page 8 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

1. GENERAL INFORMATION

Description: CEAST 9340

Manufacturer: ITW Test and Instrument Italia S.r.l. - INSTRON CEAST

Division

Type: Droptower Impact System

Code: the code number of the instrument can be found on the ID

plate (on the rear panel)

Registration: the registration number of the equipment can be found on

the ID plate (on the rear panel)

Electric Service: 230 V / 50 Hz - single phase

Identification

Conformity

Field of

application

Authorized

Service

Centers

Contact your nearest Instron CEAST Division Sales and Service office or

contact your local distributor: a list of Instron CEAST Division offices is

available on our websites: www.ceast.com and www.instron.com.

Markings

The plate with the CE marking and the identification information is located

on the rear panel of the instrument (see the figure below).

Indication

of danger

due to

electric

shock

On the instrument there are plates with various danger signals. These

plates act to advise the user and the maintenance personnel of the type of

danger that exists in the local area next to the plate.

Physical contact with parts of the equipment that have electrical current

can cause immediate death or permanent wounds. Safety protection, fixed

panels, flaps or doors that have this signal can be removed or opened only

and exclusively by “Maintenance Personnel, qualified or trained” after disconnecting the instrument from the electrical service and removing the

plug from the electrical socket.

The equipment is used for instrumented and not instrumented impact tests

on plates, films specimens and tridimensional parts of thermoplastic materials.

See the “Conformity Declaration” attached

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 9

Indication

of danger

due to low

temperature

WARNING !

The liquid nitrogen tank must be handled with extreme care.

Nitrogen in the liquid state has a temperature of -196 °C and it is therefore very

dangerous.

The user must not stand in front of the discharge valves of tank when regulat-

ing the pressure or touch with his bare hands the top central part of the tank as

there could be a risk of burns.

During the tank filling and handling operations

it is compulsory to wear ther-

mally insulated gloves and other protective clothes.

The room in which the nitrogen is used must be well ventilated to avoid envi-

ronment saturation problems (lowering of the oxygen percentage) with a risk of

suffocation.

The liquid nitrogen tank (option) is supplied on request and it must be used

only for low temperature tests with the Resilvis instruments code 7526.000.

Emissions

Acoustic emission level:

without Additional Energy System < 70 dB (A)

with Additional Energy System < 110 dB (A) (for less than 1 second)

Page 10 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

HAZARD IDENTIFICATION

Nitrogen is colourless, odourless, non-flammable, non-irritating and non-toxic gas.

It is classified as a Simple Asphyxiant under OSHA regulations.

Can cause suffocation by reducing oxygen available for breathing.

Breathing very high concentration of vapour can cause dizziness, shortness of

breath, unconsciousness, or even death.

There are no currently Occupational Exposure Limit Values for this component

but it is recommended to maintain oxygen levels at or above 19,5%.

Use only in a well ventilated place.

Local exhaust system of 1200 m

3

/hour is recommended

to prevent high nitrogen concentration when use the CEAST 9340

equipped with the environmental chamber.

Avoid direct inhalation of undiluted gas.

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 11

1.1 EQUIPMENT DESCRIPTION

CEAST 9340 is a droptower impact system used for instrumented and not instrumented

test on plates, films specimens and tridimensional parts, according to the requirements

prescribed in the standards: ISO 179-2, ISO 180, ISO 3127, ISO 6603-1, ISO 6603-2,

ISO 7765-2, ASTM D 256, ASTM D 2444, ASTM D 3763, ASTM D 5628, ASTM D 6110,

ASTM D 7136, ASTM D 7192, ASTM E 23, PR-EN 6038, AIRBUS AITM 1.0010 and

other equivalent standards.

1.1.3 DIFFERENCE BETWEEN INSTRUMENTS

••

••

• CEAST 9340 code 7515.000: it is equipped with a standard chamber for tests at

ambient temperature;

••

••

• CEAST 9340 code 7516.000: it is equipped with an environmental chamber for speci-

mens conditioning at temperatures: - 50 °C to 100 °C.

The environmental chamber is cooled through the expansion of liquid nitrogen taken

from an external tank or from the laboratory's nitrogen line (N

2

) if available. The nitro-

gen flows inside the chamber through pipes endowed with capillary holes.

The chamber is heated by means of heating resistances.

The uniformity of the temperature is assured through an electric fan which recircu-

lates air and nitrogen inside the chamber.

The temperature sets by the operator is automatically controlled by a temperature

regulator. This device receives the signal from a temperature probe located inside

the chamber and, depending on whether the requirement is for cold or hot, it enable

a solenoid valve to open the nitrogen inlet or the electric heating resistance.

1.1.2 MODULARITY

1.1.1 INTRODUCTION

CEAST 9340 has been designed and manufactured with a concept of modularity. In fact

the instruments is pre-arranged for an easy and quick addition and connection of all

options at a later date.

1.1.4 MAIN PARTS OF INSTRUMENT

Instrument consists of the following parts:

••

••

• Turret: it is the upper part of the instrument, secured to the test chamber by screws.

Inside the turret is housed:

- Automatic striker recovery/releasing system: it is used to moves the striker at

the correct height and to release it for impact test on the specimen.

-Striker holder: it joints mechanically the striker to the recovery/releasing sys-

tem. Moreover it can contains one or more weights used to increase the impact

mass.

The striker holder can be of two different types: light (for masses 1 to 3.5 kg,

striker included) or standard (for masses: 3 to 37 kg, striker included).

Page 12 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

••

••

• Test chamber: see para. 1.1.3.

Both chambers (standard and environmental) can be equipped with different stands,

such as:

- Fixed Height Stand;

- Adjustable Height Stand;

Many other stands are available according to the Client needs.

- Automatic clamping device: it clamps the specimen on the support before the

striker impact.

••

••

• Control box: it is the box attached to the right side of turret and it is provided of the

following parts:

- Power ON: it is a push-button to energize the instrument;

- Emergency: it is used only when an emergency condition arises.

When this button is pressed it cuts off the electrical power to the instrument.

To re-energize the instrument, disengage the Emergency button (half a turn in

clockwise direction) and re-press the Power ON push-button.

- Alphanumeric keypad with LCD display: it is used to program and manage the

tests.

It allows to enter all the test parameters required to carry out the automatic

impact cycle and to recall the results on display at the cycle end.

The instrument memory is able to store up to 25 sets of test parameters.

-Striker: it is used to strike the specimen surface when the impact test is carried out.

Striker can be of two different types:

Non-instrumented: it is used for a simple statistical check of the material impact

strenght (visual check of the specimen: broken/not broken).

Instrumented: it provide full details of the impact event from initial contact to

final breaking of the specimen by recording the force/time curve of the entire

impact event through a data acquisition system connected to a PC.

Data acquisition system (option) at which the instrumented striker is connected

can be of two different types: CEAST DAS 8000 Junior or CEAST DAS 16000.

The number identifies the max. number of points acquired during the impact

event.

For further details about strikers see the Appendix B attached to this manual.

-Striker antirebound system (option): it stops the striker after impact to avoid its

rebound on the specimen. This system intervenes only in case of striker rebound.

-Residual energy absorbers: they are used to damp the striker residual energy

after impact and they are placed on the turret base at the left and right sides.

-Impact and rebound velocity optical detector: it is used to measure the velocity of the striker just

before the impact and to activate the striker antirebound

system in case of striker rebound.

It consists of a photocell fixed with a bracket to the turret structure and a flag

fixed to the striker holder. When the striker holder is released for test, the flag

pass through the photocell interrupting the light-ray two time consecutively.

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 13

1.1.5 OPTIONS

Options code

Environmental chamber, temperature range: -50 to 100 (already included in the

instrument code 7516.000)

7510.011

Striker antirebound device

7510.002

Standard striker holder (3 to 37 kg) with combinable weights

7510.021

Light striker holder (1 to 3.5 kg) with combinable weights

7510.022

Set of additional weights for standard striker holder (no. 3 masses, 5 kg each)

7510.026

Fixed height stand for specimen support (single impact).

Max. specimen thickness 25 mm

7520.031

Adjustable height stand for specimen support (single impact).

Max. specimen thickness 195 mm

7520.035

Note: the table above summarises only the main options. Many other options are available such as: strikers, specimens supports, adapters, etc..

Page 14 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

1.2 TECHNICAL CHARACTERISTICS

Instr umen t Co de 7515.000 7516.000

Functional Characteristics

Drop height range [mm] 30 to 1100

Mass range [kg] light striker holder 1 to 3.5

standard striker holder 3 to 22

standard striker holder

and additional masses

3 to 37

Speed range [m/s] 0.77 to 4.64

Energy range [J] light striker holder 0.3 to 37

standard striker holder 0.89 to 237

standard striker holder

and additional masses

0.89 to 400

Test temperature [°C] ambient - 50 to 100, selectable

by increments of 1 °C

Temperature control - by Pt 100 sensor and

PID thermoregulator

Over temperature control - by safety thermostat

Heating system - by electric resistances

Cooling system - by liquid nitrogen

Average heating speed - 1 °C / minute

Average cooling speed - 4 °C / minute

Impact and rebound velocity measured by optical detector

Striker position measured by digital encoder

Specimen clamping on support by clamping device, pneumatically actuated

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 15

Instrument Code 7515.000 7516.000

Technical Data

Electric Power Supply

Voltage [V] - Phases - Frequency [Hz] 230 - Single phase - 50/60

Total installed power [W] 600

3200

Fuses see attached wiring diagrams

Earth path in accordance with local regulations

Pneumatic Air Supply (compressed air)

Pressure at instrument inlet [bar] 10 max.

Working pressure [bar] 5

Liquid Nitrogen Supply

Pressure at instrument inlet [bar] - 7 max.

Working pressure [bar] - 1.2

Consumption at - 40 °C [kg/h] - 4

Consumption to cool from 23 to - 40 °C [kg] - 6

Overall Dimensions

Instrument (W x D x H) [mm] see 1.2.1 Layout drawing

Inner Dimensions

Test chamber (W x D x H) [mm] 490 x 450 x 565 370 x 300 x 495

Connection see 1.2.1 Layout drawing

Weight

Instrument [kg] 340 400

Paint

Grey RAL 7035 - Fuchsia RAL 4006

Page 16 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

1.2.1 LAYOUT

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 17

1.3 SAFETY

••

••

• The instrument is supplied with fixed and movable shields.

The fixed ones (fastened with screws) are located to the sides and rear of the turret

and rear of the environmental chamber (option) to prevent anyone accessing the

interior.

The hinge-mounted movable shields (hinge-mounted) are provided with safety

microswitches and are located at the front of turret and test chamber and allow the

operator to access the work areas for routine operations. When these shields are

opened, the safety microswitches disable operation of movable parts and heating/

cooling systems.

••

••

• The instrument is controlled by keys located on the keypad of the control box or by

the PC.

••

••

• The instrument can only be used by trained, qualified and authorized personnel.

••

••

• The responsibility for the various activities, for the operation of the instrument, must

be clearly established as indicated in the following chapter and therefore respected.

••

••

• If the electric cable is damaged or cut, it must be replaced.

••

••

• For all of the work to be done regarding: installation, start-up, tooling, use, modifica-

tion conditions of use, and work instructions, the procedures indicated in this manual

must be followed.

••

••

• This manual must always be accessible, so that it can be consulted in case of doubts

about the correct conditions of use of the instrument.

Page 18 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

2. CONDITIONS OF USE

2.1 AUTHORIZED PERSONNEL

After receiving all necessary instructions contained within this manual, only the following professionals may work on this instrument:

OPERATOR

The Operator of the CEAST 9340 must have a specific qualification from a recognized

school for analogous apparatus, or under the guidance of expert personnel. The operator can perform only the operations indicated and specified in this manual, following the

instructions herein. The instrument should not be used by un-expert personnel.

MECHANIC

The Mechanic must have general experience on test equipment and specific experience with the CEAST 9340 or analogous instrument. The mechanic can perform only

the operations indicated and specified in this manual, following the instructions herein.

ELECTRICIAN

The Electrician must have general experience with switch boxes and electronic components and have specific experience on the CEAST 9340 control box or similar instruments. The electrician can perform only the operations indicated and specified in this

manual, following the instructions herein.

SAFETY MANAGER

The Safety Manager is responsible for the protection and prevention of corporate risks,

according to the indications of the International Standards. The Safety Manager must

ensure that all personnel who operate the instrument have received the instructions

contained in this manual for their position including installation and start-up.

MANUFACTURER

For all operations not expressly foreseen in this manual and assigned to one of the

above professional figures, it is necessary to contact ITW Test and Instrument Italia

S.r.l. - INSTRON CEAST Division. The aforementioned operations can only be performed by ITW T est and Instrument Italia S.r.l. - INSTRON CEAST Division, or under

authorization and according to the instructions provided by ITW Test and Instrument

Italia S.r.l. - INSTRON CEAST Division, by specialized personnel at the user’s location, who are qualified Mechanics or Electricians.

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 19

The instrument, subject of this manual, must be used only and exclusively to carry out

impact tests on plates, films and tridimensional parts of thermoplastic materials.

All of the operations for preparation of the instrument for carry out tests, and those

performed at the end of the tests (e.g.: specimen replacement, chamber cleaning, etc.),

must be manually performed by the operator.

Maintenance and instrument regulation (e.g.: replace fuses, installation of additional

modules, etc.) must be performed by persons who are qualified mechanics or electricians (see the chapter on maintenance).

The instrument is sent to the customer in two separate parts: turret and test chamber;

the USER must provide for the positioning and assembling of these parts in the laboratory, and their connection to the electric/pneumatic facilities.

After 20,000 hours of work, and in any case not longer than 10 years, a complete overhaul of the apparatus by ITW Test and Instrument Italia S.r.l. - INSTRON CEAST Division is necessary in order to continue to use it safely. The cost of overhaul are the

responsibility of the CUSTOMER.

2.2 NORMAL USE CONDITIONS

Page 20 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

2.3 ABNORMAL SITUATIONS

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

ÖÖ

ÖÖ

Ö

It is absolutely necessary that the instrument be used in the conditions prescribed

in this instruction manual; no modifications to the instrument or its safeties are

permitted, nor is its use in abnormal conditions.

Below the USER is advised of a few of the recommendations to avoid abnormal

conditions of use; in any case any other condition of use that is not expressly

foreseen by this manual must be avoided.

Run the instrument only if it is installed in the prescribed position (vertical).

Avoid that people other than the operator can use the instrument while it is func-

tioning.

Do not put objects between the striker and the base plate of the turret and on the

specimen support when the instrument is running.

Do not touch the materials inside the environmental chamber during testing at

high or low temperature. Always wear thermally insulated gloves.

Do not operate the instrument if the protections are removed or not properly

fitted.

Do not remove or alter the position of the safety microswitches or the tempera-

ture sensors (with enviromental chamber only) installed on the instrument.

Do not climb on or get on top of the instrument.

Do not put material in the test chamber that differs from that prescribed (

use only

plates, films and tridimensional parts of thermoplastic materials).

Do not operate the instrument with the fixed shields dismantled or incorrectly

mounted.

Should the CUSTOMER install a tool or sp are p art on the instrument that has not

been supplied by ITW T est and Instrument Italia S.r .l. - INSTRON CEAST Division,

he must verify that the safety measures are maintained. Regardless, in this case

ITW T est and Instrument It alia S.r .l. - INSTRON CEAST Division does not assume

the responsibility for any eventual damages derived from the use of the aforementioned part.

The instrument must not be installed or operated in a

corrosive or explosive

environment.

Do not wash the instrument with water jets or flammable materials (e.g.: diesel

fuel, gasoline, solvents, etc.).

ÖÖ

ÖÖ

Ö

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 21

2.4 SHIELDS

It is absolutely necessary that the

instrument operates with all of the

shields always closed. The fixed

shields must always be mounted

and permanently blocked.

2.5 RESIDUAL RISKS

The operators pay particular attention to the points indicated in

the figures.

Do not touch the materials

inside the environmental

chamber during tests at

hight/low temperature.

Use thermally insulated

gloves

DANGER OF BURNS

Do not put hands or objects where

indicated by the arrows

DANGER OF CRUSHING

Mobile shield

(doors)

Fixed

shields

Risk of fingers

crushing during

the weights

replacement

DANGER OF

CRUSHING

Risk of weights

falling during the

weights replace-

ment

DANGER OF

INJURY

Pneumatic cylinders of clamping plate

remain pressurized also in case of

power cut off avoiding the clamping

plate lowering

Operator at work station

The operator must always work in

such a manner to have easy access

to the commands, and at the same

time have complete visibility of the

instrument.

3. OPERATOR WORK STATION

Page 22 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

Transportation may be done with the instrument “visible” or enclosed in special packaging (e.g.: wooden crates).

T ransportation is normally performed by TRANSPOR TERS, who are the CUST OMER’S

responsibility.

The instrument is normally transported in a crate and packed in horizontal position.

During transport the crate, containing the instrument, must be firmly held down with

cables or straps in order to impede movement.

The means of transport and lifting must always be done according to the given indications

by trained personnel (e.g.: warehouse personnel, forklift workers, or crane workers).

4. TRANSPORT AND MOVEMENT

4.1 LIFTING AND HANDLING

4.1.2 MOVEMENT OF THE INSTRUMENT

X

The instrument is equipped with six eyebolts (four on the upper part of the turret and two

on the lower right side of the test chamber) that are used to lift it by ropes and a forklifts.

Leaves the pallet on the floor of the laboratory. Move and place the instrument in vertical position following the procedure described in chapter 6.2.3 Installation Procedure.

When the instrument is in vertical position, use always the four eyebolts (on the upper

part of the turret) to lift and move it in the laboratory.

During movement of the instrument, proceed slowly

4.1.1 MOVEMENT IN P ACKAGING

When the instrument is moved in crates, it

is necessary to use a forklift or pallet-mover .

The lifting points for the forks of the forklift

are indicated in the figure to the right.

The weight of the crate containing the instrument is approximately 550 kg. Lifting machinery must therefore be

able to lift these loads.

X

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 23

4.2 CHECK FOR POSSIBLE DAMAGE

X

X

X

On reception of the goods, it is necessary to perform a visual inspection of the packaging and instrument in order to identify any damage sustained during transport and movement.

If the packaging is damaged, immediately send by fax to ITW Test and Instrument Italia

S.r.l. - INSTRON CEAST Division the details of the damage sustained; or, indicate the

damages directly on the transport document and send this via fax to ITW Test and

Instrument Italia S.r.l. - INSTRON CEAST Division.

If the instrument or accessories should be damaged or missing, it is imperative to not

continue with the installation, but to notify ITW Test and Instrument Italia S.r.l. - INSTRON

CEAST Division immediately via fax of the anomaly found, and to agree with the former

the action to be taken.

4.3 STORAGE

Should the instrument need to be stored until a later date, the environment must be the

same as that for work.

If there are any storage requirements that should require special packaging, they must

be requested from ITW Test and Instrument Italia S.r.l. - INSTRON CEAST Division.

4.1.3 WEIGHT OF THE MAIN PARTS

The table below indicates the approximate weight of the CEAST 9340 instruments and

they can help the warehouse personnel or forklift workers in the choise of the hoister or

forklift appropriate.

Instrument Weight [kg]

9340 code 7515.000

(with standard test chamber)

340

9340 code 7516.000

(with environmental test chamber)

400

Page 24 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

X

5. MOUNTING AND DISMANTLING

X

X

X

X

X

The instrument is handled completely assembled.

Therefore there are no assembly and/or disassembly operations to carry out before

handling.

Should the USER need to dismantle one or more parts for which the procedure is not

included in this manual, it is imperative that ITW T est and Instrument Italia S.r.l. - INSTRON

CEAST Division be contacted for authorization and the procedure.

Every operation of mounting/dismantling done by the USER, not foreseen in this manual

nor authorized by ITW Test and Instrument Italia S.r.l. - INSTRON CEAST Division, will

be considered altering and will result in the compromise of the safety functions and

guarantee of the instrument.

Should the instrument be transported packaged in a

crate, it is necessary to:

a) Transport the crate to the place of installation. The

floor must be perfectly flat and capable of support a

weight of 1000 kg/m

2

(see para. 6.2.2).

Note: put on protective glasses before removing

straps.

b) Cut the straps.

c) Remove the screws or nails of the lid and remove it.

d) Remove the screws or nails of the walls and remove

them.

e) Remove the packing material.

f) Unscrew the screws and nuts and remove the brack-

ets that fastening the instrument to the pallet (see

figures on para. 6.2.3).

g) Continue with the handling of the instrument accord-

ing to the instructions in chapter 4.1.2.

A

X

B

C

Crate overall dimensions [mm]

and gross weight [kg]

A = 130;

B = 277;

C = 87;

Weight = 550 kg approx.

Walls

Lid

Pallet

5.1 DISMANTLING THE P ACKAGING CASE

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 25

6. INSTALLATION

6.1 SPACE AND ENVIRONMENT REQUIREMENTS

6.1.1 SP ACE

6.1.2 ENVIRONMENT

6.1.3 SERVICES

Installation of the instrument must be performed according to the instructions, by trained

qualified personnel, Mechanics or Electricians as specified according to the needs.

The instrument will work according to the technical parameters foreseen if it is correctly

placed, stably, in a laboratory on the floor that is able to hold the instrument weight.

Before installing the instrument, determine the correct place to position it. Remember

that it is necessary to consider the following requirements: space restraints, absence of

vibrations, temperature, humidity and atmosphere (not corrosive, not polluted, not ex-

plosive).

The spatial dimensions of the instrument are indicated in paragraph 1.2.1. Remember

to leave adequate space all around the instrument (about 1 meter) and on top of it

(about 1 meter) to allow the access of maintenance personnell.

The instrument must be installed in a controlled temperature and humidity laboratory. If

this is not possible, it should be located in a clean environment where the temperature

range is between 15°C and 35°C with relative humidity (RH%) ≤ 85 % (without conden-

sation).

The location determined for the installation of the instrument must have an electrical socket

according to the information on the ID plate of the instrument (see chapter 1) and a pneu-

matic air supply line (see paragraph 1.2) able to delivery compressed air with pressure 7 to

10 bar.

Page 26 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

6.2 POSITIONING

The instrument will function according to the technical parameters foreseen if it is correctly positioned vertically on a planar surface.

Note: the calculation of the surface load of each foot is performed in the most conservative manner for an instrument with all options.

An instrument (with environmental chamber) weighs approximately 400 kg, when it is

equipped with a full set of additional weights (37 kg) and with a specimens support (20

kg), the total weight becomes 457 kg approx. (4483 N).

6.2.1 SURF ACE LOAD IN STATIC CONDITION

The surface on which the instrument is placed must be

able to hold a minimum weight

of 1.5 kg/cm2 (15 N/cm2) at the

location of each foot.

A

B

C

Standard foot (x 4)

View from the top

Front side

Suggestions: place the instrument on the ground floor of reinforced-concrete

and far from other instruments for vibration problem.

Weight of instrument equipped with thermostatic chamber, additional weights set and

fixed height stand [kg]

457

Distance between feet: A; B [cm] 69; 51

No. o f rest fe et 4

Diameter of each rest foot: C [cm] 10

Surface of one rest foot [square cm] 78.5

Weight exerted on one rest foot [kg] (considering uniform weight distribution) 115

Weight-to-Surface Ratio on one rest foot [kg/square cm] 1.5

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 27

6.2.2 LOAD ON SLAB

The slab on which the instrument is placed must be able

to hold at least 1000 kg/m

2

(10000 N/m2)

LOAD ON SLAB IN STATIC CONDITION

(for storage)

The slab on which the instrument is placed must be able

to hold at least 2000 kg/m

2

(20000 N/m2)

LOAD ON SLAB IN DYNAMIC CONDITION

(load calculated for tests in the worse condition

using materials very tough)

Page 28 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

6.2.3 INST ALLATION PROCEDURE

X

Should the instrument be transported packaged in a crate, it is necessary to:

a) Transport the crate to the place of installation. The floor must be perfectly flat and

capable of support a weight of 1000 kg/m

2

(see para. 6.2.2).

b) Dismantling the packaging case following the instructions of para. 5.1.

c) Remove the screws (x 6) and brackets (x 6) fastening the instrument to the pallet

(Fig. 1 and detail).

Fig. 1

Bracket (x 6)

Screw (x 6)

X

X

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 29

d) Reeve the ropes through the four eyebolts as shown (arrows) in the details of Fig. 2.

e) Place the ropes on the forks of two forklifts or bridge cranes.

Fig. 2

X

X

Page 30 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

f) Lift the instrument and remove the pallet below (Fig. 3).

g) Continue to lift the instrument to the (Fig. 4) driving it opportunely until it touches the

floor with two feets (take care do not damage the feets during this operation) and

then with all four feet (vertical position).

Fig. 3

Fig. 4

X

X

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 31

Fig. 5

Fig. 6

h) Lower the forks of the forklifts and remove the ropes from the eyebolts (Fig. 5).

i) Remove the two eyebolts on the right side of the instrument.

j) Remove the two support brackets from the sides of the instrument (Fig. 6).

k) When the instrument is in vertical position, use always the four eyebolts (on the

upper part of the turret) to lift and move it in the laboratory.

X

X

X

X

Page 32 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

Spirit level

(longitudinal

position)

Crosshead

guide column

Spirit level

(transversal

position)

Fig. 1 Fig. 2

Notes:

- Figs. 1 and 2 show the spirit level placed against the guide column to visually inspect

the verticality of the instrument on the longitudinal and trasversal positions.

- Fig. 3 shows a forklift under the instrument base. It must be used to lift (only 2 or 3 cm)

the instrument before turn the feet for levelling. When the feet are adjusted, lower the

instrument and check again the level. If necessary, lift and lower the instrument and

adjust the feet height more times until the instrument is levelled.

- Fig. 3 detail A, shows the adjustable foot in normal position (exagonal lock nut tighten

against the instrument frame).

- Fig. 3 detail B, shows the adjustable foot in levelling position (exagonal lock nut tighten

against the foot exagonal nut).

a) Open the turret door.

b) Place the spirit level against a guide column (Fig 1). Visually inspect the verticality of

the instrument.

c) If it is not correct, turn the feet on instrument right side using the adjustable wrench.

d) Change the position of the spirit level (Fig 2). Visually inspect the verticality of the

instrument.

e) If it is not correct, turn the feet on instrument front using the adjustable wrench.

f) Repeat instructions from paragraph b) to f) included, up to reach the level required.

g) Once levelled, check that the four feet are in contact with the floor.

The instrument is provided for with four adjustable support feet (see figures) for levelling. To perform this operation, follow instructions in the paragraphs below:

X

X

X

X

X

X

X

6.3 LEVELLING

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 33

6.4 STABILITY

The instrument is stable if placed with all four feet touching a planar surface.

6.5 CLEANING

6.6

MATERIALS AND PRODUCTS

The instrument does not require cleaning with protective substances (e.g.: grease or oil

on the surfaces). In any case, should it become dirty during installation, clean the sur-

faces with a soft cloth and non-corrosive and not dangerous detergent that will not

damage the painted surfaces. In any case all safety indications provided by the manu-

facturer of the cleaning solutions must be followed.

The instrument is primarialy constructed from: iron, steel, aluminium, copper, light alloys

and thermal insulation (for environmental chamber only) not containing asbestos.

External parts of the environmental chamber are painted. The maximum external tem-

perature that can be reached by these parts is approximately 40°C, a temperature at

which the paint does not emit toxic vapors or fumes.

Cables and electric components meet the international standards.

The disposal of the materials must be done by the CUSTOMER, according to the local

environmental laws of the COUNTRY in which the instrument is located.

Don’t Litter. Recycle.

It is the responsibility of the CUSTOMER to verify that the floor is able to

carry the weight of the instrument (see paragraph 6.2.1).

Fig. 3

(detail B)

Adjustable

wrench

Foot exagonal nut

Exagonal lock nut

Fig. 3

(detail A)

Forklift

Fig. 3

Page 34 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

7.2 ELECTRICAL SERVICE CONNECTION

O OFF

I ON

Main switch

Power cord

with plug

Authorized Personnel: Electricians

a) Verify that the voltage and frequency of the line conform to those indicated on the

instrument tag (see chapter 1).

b) Verify that the main switch of the instrument is in the "O" position (OFF).

c) Insert plug of power cord into the laboratory mains outlet and close mains safety

switch (wall mounted).

X

X

X

7. START-UP

7.1 INSTRUMENT, CEAST DAS 8000 JUNIOR/CEAST 16000 AND

PC CONNECTION

X

This chapter provides the instructions that must be followed to make the instrument

operative before starting any testing.

Authorized Personnel: Operator

Connect the cables as shown in the figures below.

CEAST 9340,

rear view, left side

CEAST DAS 16000,

rear view

Personal Computer,

rear view

Instrumented Striker

(Strain-gauge sensor)

Photocell output

signal cable

T o the USB port

Striker

signal cable

CEAST 9340

movements

signal cable

T o the RS 232

serial port

T o the trigger

connector

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 35

7.3 PNEUMATIC SERVICE CONNECTION

X

X

X

X

Authorized Personnel: Operator

a) Connect the air filtering group of the instrument (see figure below) to a compressed

air line, with a pressure not greater than 10 bar.

For the connection, use flexible plastic hose provided with a standard fitting (for

pneumatic line) to the end.

b) Lift the knob of the pressure regulator to release the safety.

c) Turn the knob and adjust the pressure to 5 bar on the pressure gauge.

d) Lower the knob to insert the safety.

Note: the on-off valve can be used to close the compressed air inlet to the instrument

and in the mean time to discharge the pneumatic circuit of the instrument without disconnect the air delivery pipe.

When the on-off valve is in “Closed” position the knob can be padlocked. This solution

ensures the maximum safety of the personnel during the maintenance interventions.

Pressure regulator

(knob)

Compressed air inlet

(press. 10 bar max.)

Pressure gauge

(pressure to be set at 5 bar)

ON/OFF valve

(knob)

Slot for padlock

Page 36 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

7.4 CRYOGENIC SERVICE CONNECTION

Authorized Personnel: Operator

Note: the liquid nitrogen tank (optional) is supplied on request and must be used only

for low temperature tests on instruments equipped with the environmental chamber.

Avoid direct inhalation of undiluted gas.

Use only in a well ventilated place.

Local exhaust system of 1200 m

3

/hour is recommended

to prevent high nitrogen concentration when use the CEAST 9340

equipped with the environmental chamber.

WARNING !

The liquid nitrogen tank must be handled with extreme care.

Nitrogen in the liquid state has a temperature of -196 °C and it is therefore very

dangerous.

The user must not stand in front of the discharge valves of tank when regulat-

ing the pressure or touch with his bare hands the top central part of the tank as

there could be a risk of burns.

During the tank filling and handling operations

it is compulsory to wear ther-

mally insulated gloves and other protective clothes.

The room in which the nitrogen is used must be well ventilated to avoid envi-

ronment saturation problems (lowering of the oxygen percentage) with a risk of

suffocation.

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 37

Solenoid

valve

Rear view of

environmental chamber

X

Liquid Nitrogen Supply:

- Pressure: 1.2 bar to 1.5 bar;

- Consumption at - 40 °C: 4 [kg/h];

- Consumption to cool the chamber from 23 to - 40 °C: 6 [kg].

Connect the nitrogen tank to the pipe fitting of the CEAST 9340 using the flexible hose

provided with the tank or connect the CEAST 9340 to the nitrogen line of the laboratory.

The delivery pressure must be set between 1.2 and 1.5 bar.

Note: the tank is provided with its own User's Instructions, which contain all the informa-

tion needed to operate it.

Nitrogen inlet.

Press.:1.2 to 1.5 bar.

Pipe fitting:

3/8” GAS - UNI 338

Flexible

hose

Nitrogen

flow

adjusting

valve

Insulated liquid nitrogen tank,

60 Lt (option)

Pressure

gauge

Page 38 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

8. USE

8.1 SAFETY STANDARDS

The general safety norms outlined in the introduction pages of this manual are

valid.

All work procedures that would compromise the safety of the instrument must be

avoided.

The OPERATOR must ensure that no unauthorized personnel work on the instrument.

The OPERATOR is obliged to check the instrument at least once per work shift to

ensure that there is no visible external damage. Any eventual secondary modifications (including work methods) that compromise the safety must be immediately reported.

The instrument can be used only if it is in perfect condition.

The user must follow all instructions and checks in order to guarantee the cleanli-

ness and visibility of the work station where the instrument is located.

The protections may not be removed or altered.

Should there be damage or breakdown of a component, the instrument must be

removed from use until it is once again in perfect working order. If during inst allation, repair or maintenance it is necessary to dismantle the instrument, for safety

reasons it must be removed from service, following with precision the relative instructions. At the end of the intervention, the instrument must be immediately reassembled and checked for correct functioning .

For safety reasons, it is forbiden to change

or modify any part or portion of the instrument

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 39

8.2 COMPONENT IDENTIFICATION

In the following pages, a number of figures of the instrument can be found with identification of the main parts.

Fig. 1 - CEAST 9340 7515.000.

General view

Fig. 2 - CEAST 9340 7516.000.

General view

Turret

Test

chamber

Environmental

test chamber

Control

box

Page 40 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

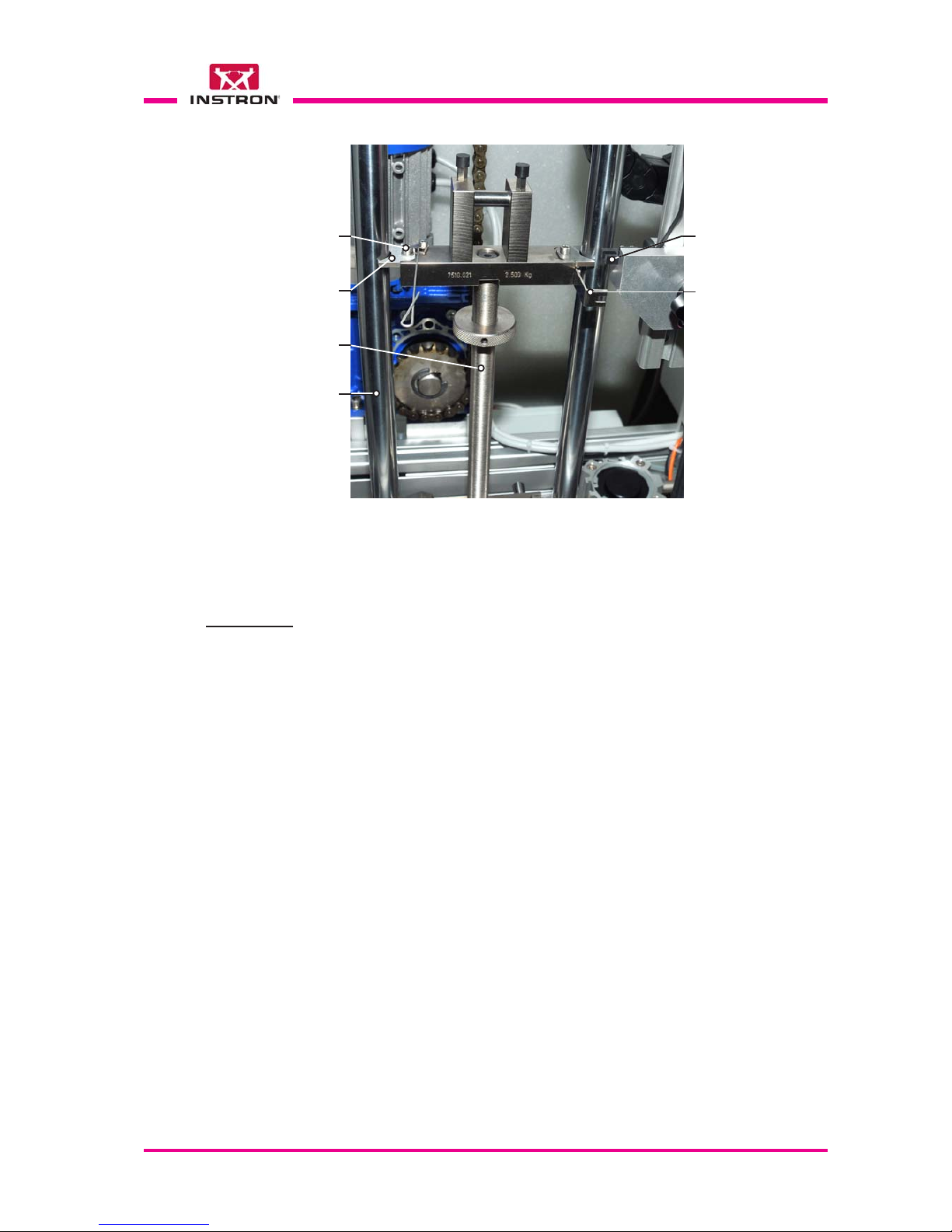

Fig. 3 - View inside turret

Striker lifter (crosshead)

(Automatic striker

recovery/releasing

system)

Photocell

(Optical detector for

impact and rebound

velocity measuring

system)

Flag (Impact and

rebound velocity

measuring system)

Combinable weights

Striker holder

Instrumented striker

Absorber block (x 2)

Ring nut

(Weights locking)

Striker antirebound

system (option)

Dumper (x 2)

(Oleodynamic residual

energy absorbers)

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 41

8.2.1 SAFETIES AND THEIR LOCATIONS

The instrument is equipped with the following safety devices:

1) - Safety thermostat: it intervenes should the temperature of the environmental cham-

ber go over the maximum allowable temperature (over 100°C), cutting the electric

service to the heating resistances. This component is located in the electric box rear

the environmental test chamber.

2) - Safety switch on turret door: this switch is located in the turret near the door lock.

Normal operating condition (Power ON push-button already pressed ).

When you open the door:

• Power ON push-button remains switched on.

• All systems inside the turret are disabled.

• All systems inside the environmental chamber remains enabled.

When you close the door:

• After a few seconds all systems inside the turret are enabled.

3) - Safety switch on standard chamber door (for instruments without environmental

chamber): this switch is located in the chamber near the door lock.

Normal operating condition (Power ON push-button already pressed).

When you open the door:

• Power ON push-button remains switched on.

• All systems inside the turret are disabled.

When you close the door:

• After a few seconds all systems inside the turret are enabled.

4) - Safety switch on environmental chamber door: this switch is located in the chamber

near the door lock.

Normal operating condition (Power ON push-button already pressed).

When you open the door:

• Power ON push-button remains switched on.

• All systems inside the turret are disabled.

• All systems inside the environmental chamber are disabled.

When you close the door:

• After a few seconds all systems inside the turret and the environmental chamber

are enabled and the previous operating conditions are restored.

Page 42 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

5) - Upper and lower limit switches for the automatic striker recovery system: they

intervene and stop the stroke of the striker lifter in the two directions of motion.

These components are located in the turret.

6) - ON-OFF valve: is used to close the compressed air inlet to the instrument and in

the mean time to discharge the pneumatic circuit of the instrument without disconnect the air delivery pipe.

When the on-off valve is in “Closed” position the knob can be padlocked. This solution ensures the maximum safety of the personnel during the maintenance interventions. This component is located rear the instrument.

7) - Pressure switch: it intervene and cut off the power to the instrument when the

pressure of the compressed air goes down below 5 bar.

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 43

8.3 COMMANDS

Main Switch

Located underneath of the control box, it

turns ON (I) or OFF (O) the voltage to the

instrument.

O OFF

I ON

Control box

••

••

• Power ON push-button: enable the auxil-

iary circuits of the instrument and switch

on the light inside the button.

••

••

• Emergency-Stop push-button: under

emergency conditions, it allows immediately to shut off the power to the auxiliary

circuits of instrument.

To restore the controls, rotate the button

about half a turn clockwise, in order to

disengage it from the locked position.

The instrument stays off until the Power

ON push-button is pressed again.

••

••

• "Keypad and Display": the man/machine

interface occurs through the use of the

keyboard and the display . These two components are closely connected and they

are used to program the tests, to command the motorized devices of instrument, to show the results of the test performed and the messages for the operator in case of problems or errors.

The large liquid crystal display allows up

to 80 characters to be shown on 4 rows.

Page 44 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

8.4 OPERATIONS

8.4.1 KEY FUNCTIONS

Here you will find the list of the single keys and next to each one a brief description of

the function it performs.

SPACE1D E F3G H I

4

M N O6P Q R S

7

W X Y Z

9

DESCRIPTION OF FUNCTION

KEY

During Data Input In the Menus During Test

Open and close the specimen

clamping device

Type the alphanumeric characters indicated on the key.

Not activated

Type the alphanumeric characters indicated on the key

Not activatedType the alphanumeric char-

acters indicated on the key

Move UP the striker holder

cross lifter

Not activatedType the alphanumeric charac-

ters indicated on the key

ENTERENTER

ENTER

Delete the last character typed

Confirm the Data lnput

Move DOWN the striker holder

lifter

Page through the default inputs on the display

(e.g.: Y/N)

Select the function where the

cursor is located

Interrupt the test

Not activated

Not activated

Not activated

Return to the previous page /

return to the first page if it is

hold pushed. Skip a function

Type the alphanumeric characters indicated on the key

Not activated

Type the decimal point and the

following character:

_

0

HOME

A B C

2

UP

T U V

8

CLAMP

J K L

5

DOWN

.

PRINT

CANC

STOP

BACK

Page through the data lists on

the display (with autoscroll)

Not activatedNot activated

Start a test or a function

Not activated

Not activated

START

Not activatedNot activated

Not activated

Not activated

Bring the instrument at HOME

Not activated

Not activated

Not activated

Note: in order to enter a numeral on the display, you must only press the key with the

corresponding number. To enter a letter of the alphabet you must continue to

press the key with the corresponding letter until it is shown in the display (the

same method used by mobile phones).

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 45

The programming of the tests is done by typing in the parameters using the keyboard in

the order that they are shown on the display.

After the test cycle is started, the program performs the measurements requested, acquires the data, elaborates it, and automatically supplies the results.

The results obtained can be seen in real time on display.

Note: to facilitate the understanding of the program structure there follows a flowchart

showing its functions in hierarchical order. Each block is identified with the writing

Vid. (Screen) and a progressive number, XXX, that follows the order of appearance on the screen of the display. This order is followed in order to present the

figures during the description of the program.

8.4.2 PROGRAM

Page 46 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

Menu

Utility

Vid. 1.6

Menu

Service

Vid. 1.7

Initial

Screen

Vid. 0

MAIN

MENU

Vid. 1

Start-Up

Screen

Vid. 0.0

Menu

Load

Parameters

Vid. 1.2

Menu

Set

Temperature

Vid. 1.1

Menu

Modify

Parameters

Vid. 1.3

Menu

Save

Parameters

Vid. 1.4

Menu

Results

Vid. 1.5

Parameters

Vid. 1.3 a

Parameters

(other)

Vid. 1.3 b

Input

Password

Vid. 1.6.1

Cycle

Counter

Vid. 1.6.2

FW

Version

Vid. 1.6.3

Modify

Password

Vid. 1.6.4

Clock

Vid. 1.6.5

Language

Vid. 1.6.6

Striker

Release

Vid. 1.7.2

Move to

Height

Vid. 1.7.3

Visualize

Sensors

Vid. 1.7.4

Visualize

I/O

Vid. 1.7.5

Modify

Configuration

Vid. 1.7.6

Modify

Cal.

Parameters

Vid. 1.7.7

Shutter

Moving

Vid. 1.7.1

Representation of the program structure (firmware) in hierarchical order

*

*

(*) Menus used by Service Personnel of ITW Test

and Measurement Italia S.r.l. - INSTRON CEAST

Division only

CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev. 1 - Page 47

Vid. 0 - Initial Screen

CEAST 9340 CEAST 9340

CEAST 9340 CEAST 9340

CEAST 9340

Ver. X.XX Ver. X.XX

Ver. X.XX Ver. X.XX

Ver. X.XX

S.N. XXXXX S.N. XXXXX

S.N. XXXXX S.N. XXXXX

S.N. XXXXX

1

2

3

Vid. 00 - CEAST 9340 Startup Screen

press START for press START for

press START for press START for

press START for

CEAST 9340 startup CEAST 9340 startup

CEAST 9340 startup CEAST 9340 startup

CEAST 9340 startup

8.5 PROGRAM START - UP

The program is automatically started when the Main switch is “ON” and it performs the

following operations

:

• Shows, temporarily , on the display the introduction of the program (see Vid. 0) where the

following information are indicated

: (1) name of the instrument, (2) the firmware version

resident in memory and (3) the serial number.

• After few seconds the screen changes from vid. 0 to vid. 00 visualizing the message

“press START for CEAST 9340 startup”.

Note: before pressing the START key check that the POWER ON button is lit.

• When the operator press the START key the program performs the following operations

and at the end it loads the parameters relative to the last test performed (only if it has

been previously stored on the instrument memory) and it visualizes the main menu (see

Vid. 1).

• Check of safety thermostat operation (for instrument equipped with environmental

chamber only);

• Check of temperature sensor operation (Pt100 ohm type) that measure the tempera-

ture in the chamber (for instrument equipped with environmental chamber only);

• Initialization of specimen clamping system;

• Initialization of environmental chamber shutter (optional).

Note: at the start the instrument the “Password” is set to the previous access level (before

switching it off).

Page 48 - CEAST 9340 - Instructions for Use and Maintenance 7510.000MN1r ed. 1 rev . 1

8.5.1 NAVIGATION THROUGH THE PROGRAM MENUS

Below the method of navigation inside the various program menus using the keyoard is

described.

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

XXXXXXXX

XXXXXXXXXXXXXXXX