Page 1

5940 Series Single Column Table Frames

Operator’s guide M10-16245-EN Revision E

The difference is measurable

®

Page 2

Electromagnetic Compatibility

Where applicable, this equipment is designed to comply with International Electromagnetic Compatibility (EMC) standards.

To ensure reproduction of this EMC performance, connect this equipment to a low impedance

ground connection. Typical suitable connections are a ground spike or the steel frame of a building.

Proprietary Rights Notice

This document and the information that it contains are the property of Illinois Tool Works Inc.

(ITW). Rights to duplicate or otherwise copy this document and rights to disclose the document and

the information that it contains to others and the right to use the information contained therein may

be acquired only by written permission signed by a duly authorized officer of ITW.

Trademarks

Instron® is a registered trademark of Illinois Tool Wo rks Inc. (ITW). Other names, logos, icons and

marks identifying Instron products and services referenced herein are trademarks of ITW and may

not be used without the prior written permission of ITW.

Other product and company names used herein are trademarks or trade names of their respective

companies.

Original Instructions

© Copyright 2009 Illinois Tool Works Inc. All rights reserved. All of the specifications

shown in this document are subject to change without notice.

Worldwide Headquarters

Instron

825 University Avenue

Norwood, MA 02062-2643

United States of America

European Headquarters

Instron

Coronation Road

High Wycombe, Bucks HP12 3SY

United Kingdom

Industrial Products Group

Instron

900 Liberty Street

Grove City, PA 16127

United States of America

Page 3

General Safety Precautions

Materials testing systems are potentially hazardous.

Materials testing involves inherent hazards from high forces, rapid motions, and stored

energy . You must be aware of all moving and operating components in the testing system

that are potentially hazardous, particularly force actuators or a moving crosshead.

Carefully read all relevant manuals and observe all Warnings and Cautions. The term

Warning is used where a haza rd may lead to injury or death. The term Caution is used

where a hazard may lead to damage to equipment or to loss of data.

Instron products, to the best of its knowledge, comply with various national and

international safety standards, in as much as they apply to materials and structural

testing. We certify that our products comply with all relevant EU directives (CE mark).

Because of the wide range of applications with which our instruments are used, and over

which we have no control, additional protection devices and operating procedures may

be necessary due to specific accident prevention regulations, safety regulations, further

EEA directives or locally valid regulations. The extent of our delivery regarding

protective devices is defined in your initial sales quotation. We are thus free of liability

in this respect.

Preliminary Pages

At your request, we will gladly provide advice and quotations for additional safety

devices such as protective shielding, warning signs or methods of restricting access to

the equipment.

The following pages detail various general warnings that you must heed at all times

while using materials testing equipment. You will find more specific Warnings and

Cautions in the text whenever a potential hazard exists.

Your best safety precautions are to gain a thorough understanding of the equipment by

reading your instruction manuals and to always use good judgement.

It is our strong recommendation that you should carry out your own safety risk

assessment on the use of the test system, test methods employed, specimen loading and

specimen behavior at failure.

Product Support: www.instron.com

iii

Page 4

Preliminary Pages

Warnings

Crush Hazard - Allow only one person to handle or operate the system at all times.

Operator injury may result if more than one person operates the system. Before working

inside the hazard area between the grips or fixtures, ensure that no other personnel can

operate the computer or any of the system controls.

Crush Hazard - Take care when installing or removing a specimen, assembly,

structure, or load string component.

Installation or removal of a specimen, assembly, structure, or load string component

involves working inside the hazard area between the grips or fixtures. Keep clear of the

jaws of a grip or fixture at all times. Keep clear of the hazard area between the grips or

fixtures during actuator or crosshead movement. Ensure that all actuator or crosshead

movements necessary for installation or removal are slow and, where possible, at a low

force setting.

Hazard - Press the Emergency Stop button whenever you consider that an unsafe

condition exists.

The Emergency Stop button removes hydrau lic power or electrical dri ve from the testing

system and brings the hazardous elements of the system to a stop as quickly as possible.

It does not isolate the system from electrical power, other means are provided to

disconnect the electrical supply. Whenever you consider that safety may be

compromised, stop the test using the Emergency Stop button. Investigate and resolve the

situation that caused the use of the Emergency Stop button before you reset it.

Flying Debris Hazard - Make sure that test specimens are installed correctly in

grips or fixtures in order to eliminate stre sses that can cause breakage of grip

jaws or fixture components.

Incorrect installation of test specimens creates stresses in grip jaws or fixture components

that can result in breakage of these components. The high energies involved can cause

the broken parts to be projected forcefully some distance from the test area. Install

specimens in the center of the grip jaws in line with the load path. Insert specimens into

the jaws by at least the amount recommended in your g r ip documentation. This amount

can vary between 66% to 100% insertion depth; refer to supplied instructions for your

specific grips. Use any centering and alignment devices provided.

Hazard - Protect electrical cables from damage and inadvertent disconnection.

The loss of controlling and feedback signals that can result from a disconnected or

damaged cable causes an open loop condition that may drive the actuator or crosshead

rapidly to its extremes of motion. Protect all electrical cables, particularly transducer

cables, from damage. Never route cables across the floor without protection, nor suspend

cables overhead under excessive strain. Use padding to avoid chafing where cables are

routed around corners or through wall openings.

iv M10-16245-EN

Page 5

Preliminary Pages

Warnings

High/Low Temperature Hazard - Wear protective clothing when handling

equipment at extremes of temperature.

Materials testing is often carried out at non-ambient temperatures using ovens, furnaces

or cryogenic chambers. Extreme temperature means an operating temperature exceeding

60 °C (140 °F) or below 0 °C (32 °F). You must use protective clothing, such as gloves,

when handling equipment at these temperatures. Display a warning notice concerning

low or high temperature operation whenever temperature control equipment is in use.

You should note that the hazard from extreme temperature can extend beyond the

immediate area of the test.

Hazard - Do not place a testing system off-line from computer control withou t first

ensuring that no actuator or crosshead movement will occur upon transfer to

manual control.

The actuator or crosshead will immediately respond to manual control settings when the

system is placed off-line from computer control. Before transferring to manual control,

make sure that the control settings are such that unexpected actuator or crosshead

movement cannot occur.

Robotic Motion Hazard - Keep clear of the operating envelope of a robotic device

unless the device is de-activated.

The robot in an automated testing system presents a hazard because its movements are

hard to predict. The robot can go instantly from a waiting state to high speed operation in

several axes of motion. During system operation, keep away from the operating envelope

of the robot. De-activate the robot before entering the envelope for any purpose, such as

reloading the specimen magazine.

Hazard - Set the appropriate limits before performing loop tuning or running

waveforms or tests.

Operational limits are included within your testing system to suspend motion or shut off

the system when upper and/or lower bounds of actuator or crosshead travel, or force or

strain, are reached during testing. Correct setting of operational limits by the operator,

prior to testing, will reduce the risk of damage to test article and system and associated

hazard to the operator.

Electrical Hazard - Disconnect the electrical power supply before r emoving the

covers to electrical equipment.

Disconnect equipment from the electrical power supply before removing any electrical

safety covers or replacing fuses. Do not reconnect the power source while the covers are

removed. Refit covers as soon as possible.

Product Support: www.instron.com

v

Page 6

Preliminary Pages

Warnings

Rotating Machinery Hazard - Disc onnect power supplies before removing the

covers to rotating machinery.

Disconnect equipment from all power supplies before removing any cover which gives

access to rotating machinery. Do not reconnect any power supply while the covers are

removed unless you are specifically instructed to do so in the manual. If the equipment

needs to be operated to perform maintenance tasks with the covers removed, ensure that

all loose clothing, long hair, etc. is tied back. Refit covers as soon as possible.

Hazard - Shut down the hydraulic power supply and discharge hydraulic pres sur e

before disconnection of any hydraulic fluid coupling.

Do not disconnect any hydraulic coupling without first shutting down the hydraulic

power supply and discharging stored pressure to zero. Tie down or otherwise secure all

pressurized hoses to prevent movement during system operation and to prevent the hose

from whipping about in the event of a rupture.

Hazard - Shut off the supply of compressed gas and discharge residual gas

pressure before you disconnect any compressed gas coupling.

Do not release gas connections without first disconnecting the gas supply and

discharging any residual pressure to zero.

Explosion Hazard - Wear eye protection and use protective shields or screens

whenever any possibility exists of a hazard from the failure of a specimen,

assembly or structure under test.

Wear eye protection and use protective shields or screens whenever a risk of injury to

operators and observers exists from the failure of a test specimen, assembly or structure,

particularly where explosive disintegration may occur. Due to the wide range of

specimen materials, assemblies or structures that may be tested, any hazard resulting

from the failure of a test specimen, assembly or structure is entirely the responsibility of

the owner and the user of the equipment.

Hazard - Ensure components of the load string are correctly pre-loaded to

minimize the risk of fatigue failure.

Dynamic systems, especially where load reversals through zero are occurring, are at risk

of fatigue cracks developing if components of the load string are not correctly pre-loaded

to one another. Apply the specified torque to all load string fasteners and the correct

setting to wedge washers or spiral washers. Visually inspect highly stressed components

such as grips and threaded adapters prior to every fatigue test for signs of wear or fatigue

damage.

vi M10-16245-EN

Page 7

Preliminary Pages

Table of Contents

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Description and Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Principle of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Hardware Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Components and Interconnections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

System Safety and Information Labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Product Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Product Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Chapter 2 Preparing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Before you Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power Input Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Emergency Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Start the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bluehill Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Home Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Status Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Assemble the Load String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Select a Load Cell. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Install the Load Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Select Grips and Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Insert Jaw Faces into Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Install Grips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Preload the Load String. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

To preload the load string: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

To unload the load string: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Product Support: www.instron.com

vii

Page 8

Preliminary Pages

Chapter 3 Testing Specimens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Testing a Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Create a sample in Bluehill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Create a new sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Name the new sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Calibrate a transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Automatic calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Manual calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Set the zero extension point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

From Bluehill software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

From the Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Set the crosshead limit stops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Set the crosshead limit stops:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Move Off a Crosshead Limit Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Set the limits for a transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Balance a transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Stop a test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Control Panel Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Emergency Stop Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Crosshead Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Software Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Shut down the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

A Software Transducer Limit Trips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

A Crosshead Travel Limit Trips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

You press the Emergency Stop button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

The System Shuts down Unexpectedly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Appendix A Conformance Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Certificate of Conformance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

viii M10-16245-EN

Page 9

Chapter 1

Introduction

• System Description and Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

• System Components and Interconnections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

• System Safety and Information Labeling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

• Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

• Product Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

These instructions describe the following table model single column load frames, Model

5942 500 N capacity, Model 5943 1 kN capacity, Model 5944 2kN capacity. They are

intended to get you started working with your testing system.

These instructions assume the following:

• You are an operator familiar with the operation of materials testing systems in general.

• Your system consists of a load frame with integral controller and a control panel fitted to

®

the column, a load cell, a set of manually-operated grips and Instron Bluehill

control software.

test

• The system has been installed in its final location by an Instron service engineer.

• Bluehill software test methods that are appropriate for your testing requirements are

available.

Using these instructions you will be able to:

• Check the interconnections between all the individual elements of the basic system.

• Select and install a load cell, if the one that you want to use is not already installed.

• Install the grips and preload the loadstring.

• Prepare a set of specimens (sample) for testing.

• Test the sample.

• View the test results and print a test report.

These instructions do not include the development of Bluehill test methods. This is covered

in more advanced training that can be provided by Instron Service and Training

departments.

1-1

Page 10

Chapter: Introduction

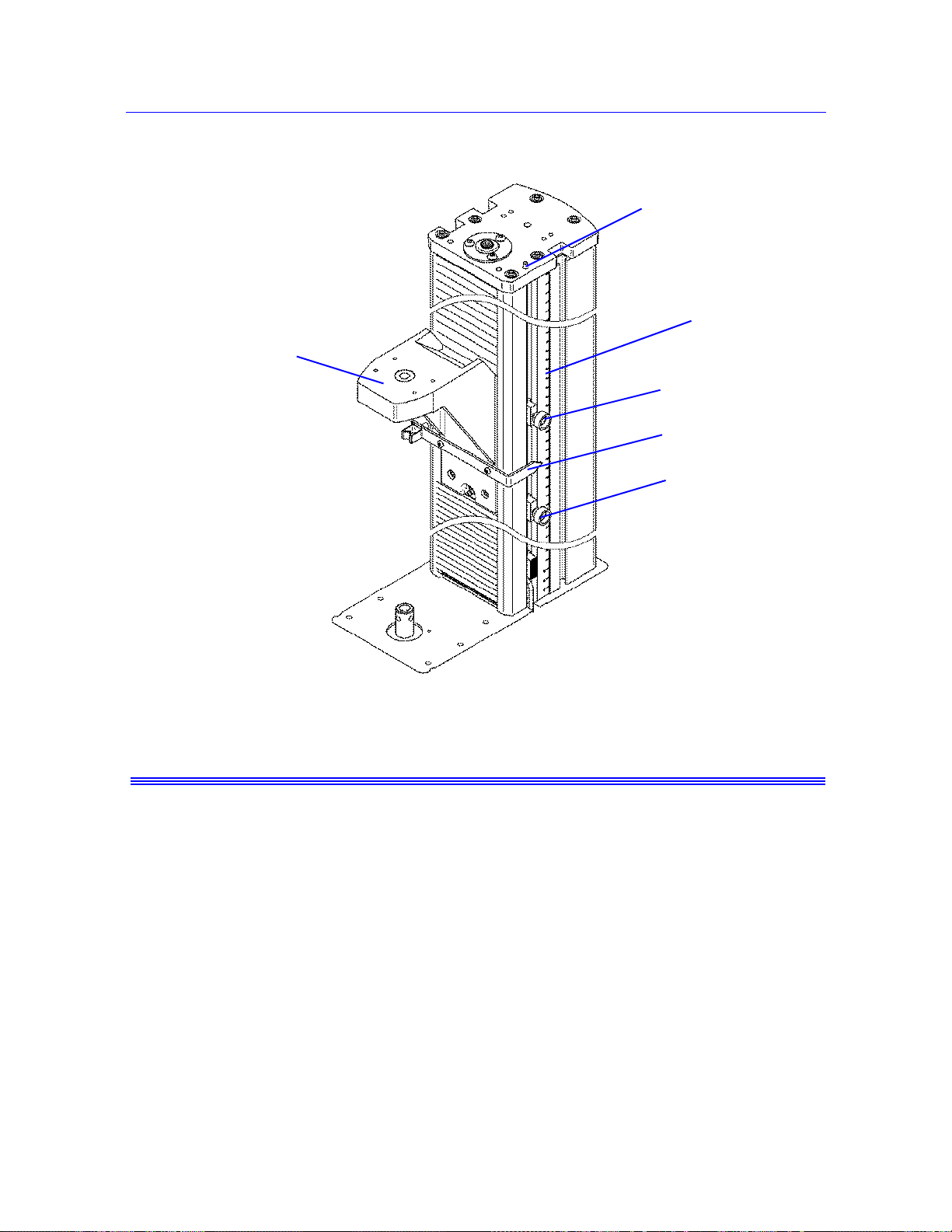

Frame base

Base

Base adapter

Controller

Motor cover

Ground stud

Not shown: Computer

T-slots

Crosshead

Lifting eye

Emergency stop

button

Power input

connector

Control

panel

beam

System ID label

Options

panel

Upper limit stop

Lower limit stop

Ballscrew cover

Column

cover

System Description and Terminology

Components

The major components of an Instron electromechanical testing system include:

Figure 1-1. 5940 Single Column Table Frame

• Load frame with integral controller

• Load cell mounted to the crosshead

1-2 M10-16245-EN

Page 11

System Description and Terminology

• Grips for tension testing or table-mounted anvils on a platen for compression testing.

• Instron approved computer system with Instron Bluehill

Special fixtures are available for applications such as flexure and peel testing. For strain

measurement, an optional strain gauge extensometer attaches to the specimen. You can use

non-contacting extensometers with specimens that are unable to support a contacting

extensometer. Contact your regional Instron office or check our web site at

www.instron.com

The following table defines the components of the testing system:

Component Description

Load Frame The load frame comprises a base, one or two columns, a moving

for assistance with Instron’s grips and fixtures.

Table 1-1. Testing System Components

crosshead, and a top plate. It is a high stiffness support structure

against which the test forces react.

Each column comprises a guide column and a ballscrew. The

crosshead is mounted on both the guide column and the ballscrew.

Rotation of the ballscrew drives the crosshead up or down while the

guide column provides stability.

®

software.

Controller The hardware that controls the frame and any ancillary equipment

connected to the testing system. The controller panel contains all the

connectors for load cells, extensometers and any other sensors that

are required for testing.

Control Panel The hardware panel, mounted on the side of the load frame, that lets

you perform some of the software functions directly at the frame.

Load String Comprises all of the components that you install between the moving

crosshead and the load frame base (or fixed crosshead). Typically

this involves a load cell, a set of grips, any adapters that are required

to connect the components, and the specimen to be tested.

Typically, you mount a load cell on the crosshead, then a pair of grips

or fixtures on the load cell and frame base. The grips or fixtures

secure the specimen and when you start a test the crosshead moves

up or down applying a tensile or compressive load to the specimen.

The load cell converts this load into an electrical signal that the

software measures and displays.

Bluehill Software Instron testing software that controls the testing system, running tests

and analyzing test data to produce test results.

Specimen A single piece of material to be tested.

Product Support: www.instron.com

1-3

Page 12

Chapter: Introduction

Principle of Operation

The system communicates primarily through the controller. The controller contains sensor

conditioning cards for the system transducers and transfers data between the transducers and

the computer. The controller also communicates with the load frame via a frame interface

board (FIB) inside the load frame. The FIB links all the electrical components of the frame

together.

Hardware Controls

The hardware controls consist of:

• Emergency stop button - to be used whenever you need to stop the crosshead

immediately because an unsafe condition exists.

• Limit stops - these must be set before each test session to protect the operator against

unexpected crosshead movement.

• Control panel - lets you perform certain functions at the frame instead of at the

computer. These include starting and stopping a test and using the jog controls to

position the crosshead prior to installing a specimen.

Software

Control of the testing system is carried out via Instron Bluehill software. Setting test

parameters, operating the system, and collecting test data is done through the software

program.

Table 1-2. Software Terminology

Term Description

Test Method In Bluehill software, a test method is a file that contains a set of

defined parameters that the system uses to run tests, analyze the test

data, and produce calculated results.

Sample A group of material specimens, whose properties are studied and

compared to gain statistical or quality assurance information. For

example, you could take a specimen from different parts of a single

manufacturing run of a material to form a sample of the material. The

sample is then representative of the complete run and you can test it

to ensure that the material quality has remained stable over the

complete run. You perform the same test on each specimen in a

sample.

1-4 M10-16245-EN

Page 13

System Components and Interconne ctions

Load cell

Load cell

cable

Mains power cable

Ground stud

Computer interface

Ethernet crossover

cable

connection

Computer interface

connection

Controller cover

Load cell connector

Controller

Supplemental ground cable

GRN/YEL - Earth

BRN - Live

BLU - Neutral

System ID label

Options panel

System Components and Interconnections

Figure 1-2 on page 1-5 shows you how each hardware component is connected to make up

the complete testing system.

Figure 1-2. 5940 System Connections

Product Support: www.instron.com

1-5

Page 14

Chapter: Introduction

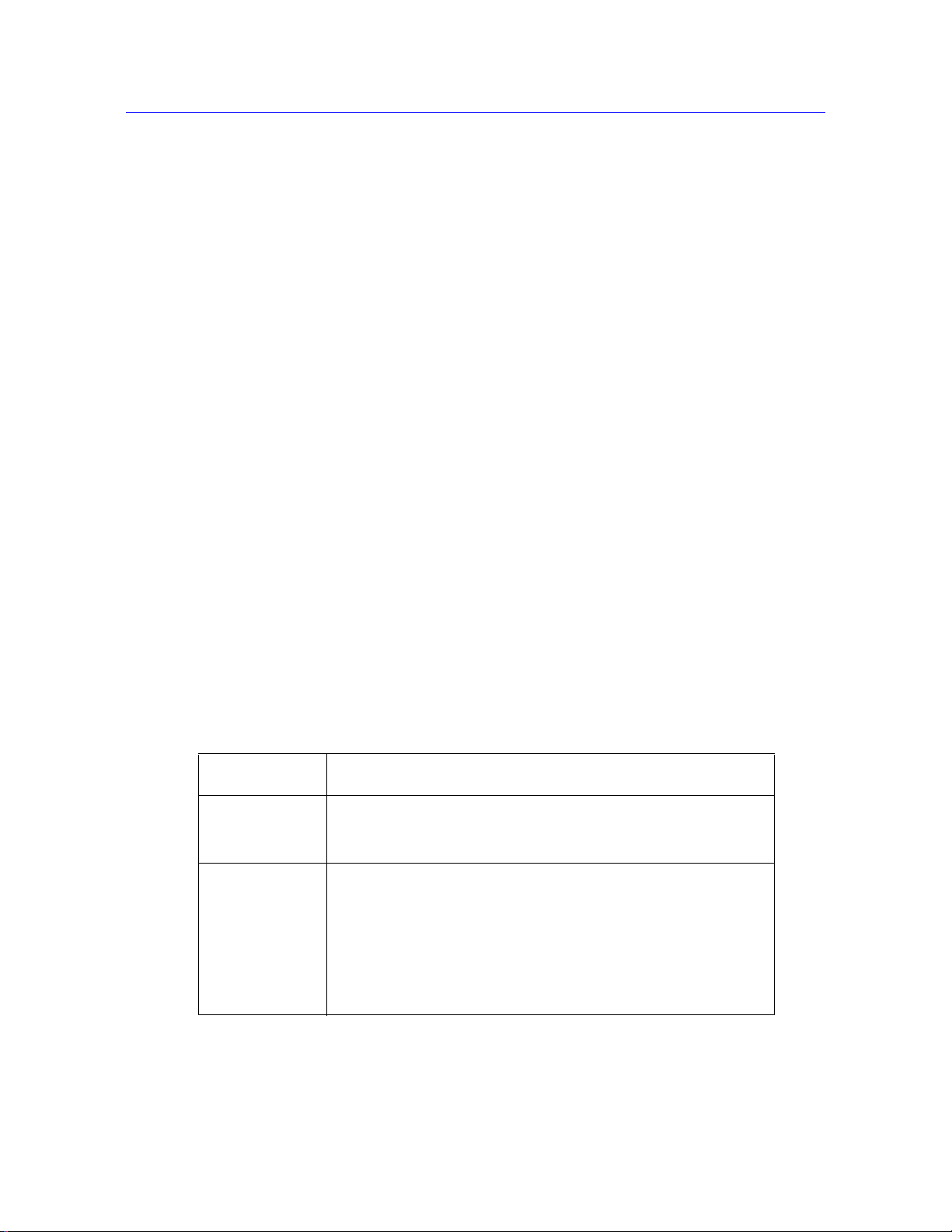

System Safety and Information Labeling

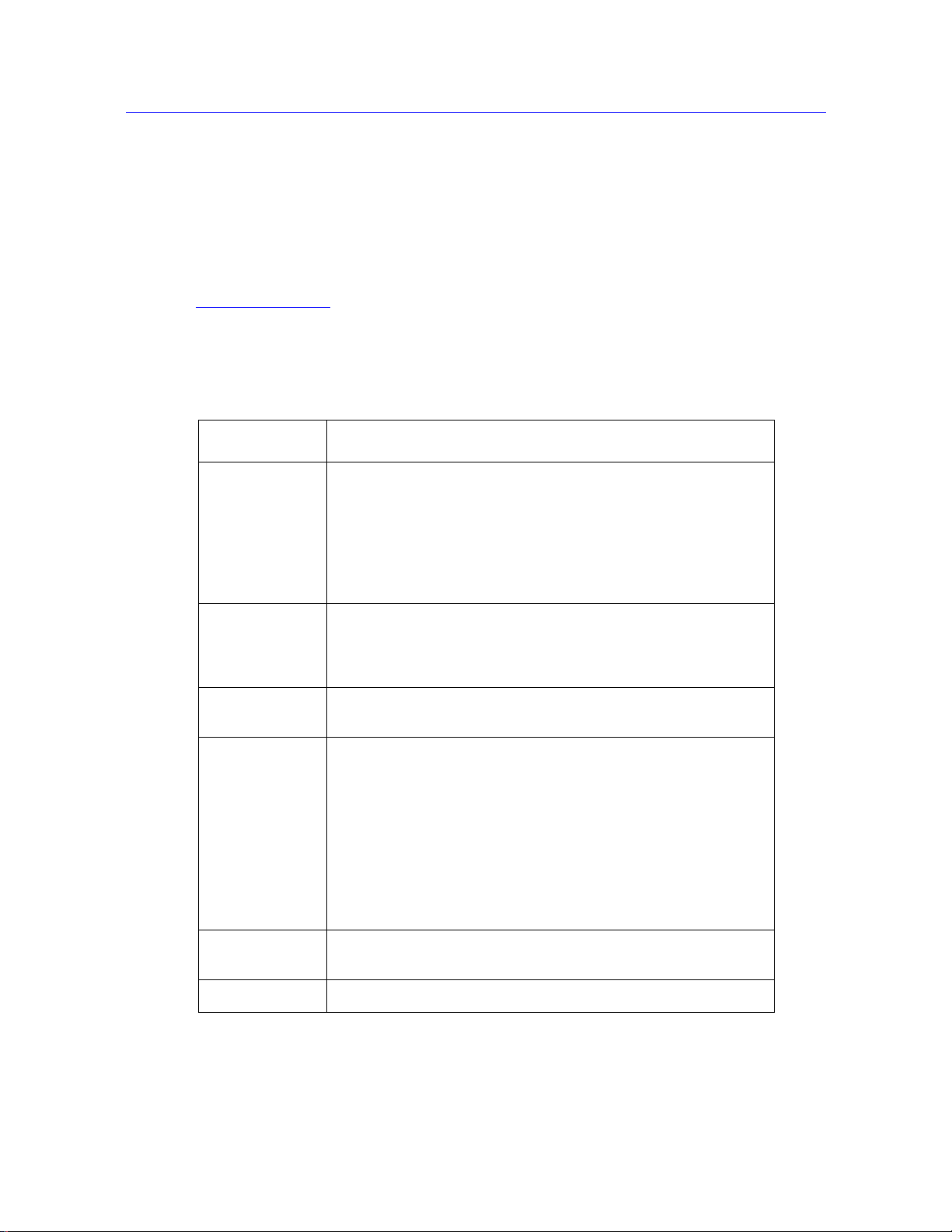

Table 1-3 on page 1-6 explains the meanings of any safety and information labels that may

be attached to any part of the testing system.

Table 1-3. Safety and Information Labeling Descriptions

Label Meaning Purpose

Electrical

hazard

Disconnect power

supply

Electrical - fuse

warning Indicates an electrical hazard exists.

Belt

entanglement hazard

Indicates that an electrical hazard exists

from high voltage or electrical current.

Disconnect the power supply before

servicing machine.

Advises about disconnecting power mains

before changing fuses and using only

specified fuses.

Indicates that a hazard exists from the

drive belt and pulley system.

High

temperature hazard

Rotating machinery

hazard

Indicates that a heat hazard exists. Stay

clear of area when operating the machine.

Indicates that a rotating hazard exists.

Keep clear of these areas (and tie back

long hair).

1-6 M10-16245-EN

Page 15

System Safety and Information Labeling

Crush hazard.

Keep clear of test

area when machine

is in motion.

Read and understand

operator's manual

before using this

machine.

!

WARNING

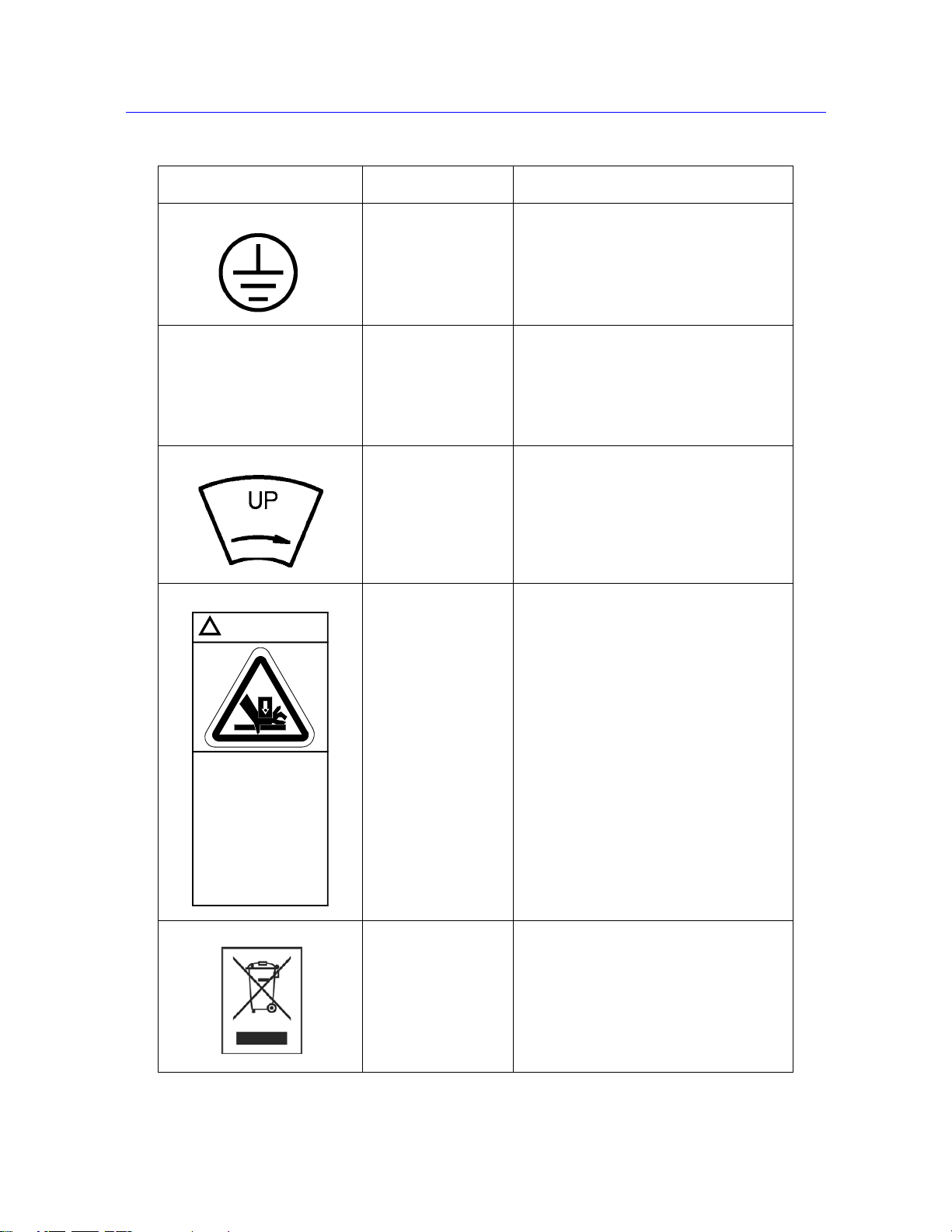

Table 1-3. Safety and Information Labeling Descriptions (Continued)

Label Meaning Purpose

Ground stud Indicates a ground stud.

Read the manual Read and understand the operator’s

manual before using the machine.

Crosshead direction Indicates the direction to turn the pulley to

manually move the crosshead upward.

Pulleys can be turned by hand when

power is disabled.

Crush hazard Indicates the crush hazard of the moving

crosshead and instructs the user to read

and understand the operator’s manual

before using the machine.

Waste Electrical and

Electronic Equipment

(WEEE)

In accordance with the European Union’s

WEEE directive, the crossed out wheeled

bin symbol indicates that the equipment

must be disposed of separately from other

waste at the end of its usable life. For

advice on the disposal of electrical and

electronic equipment in your country,

contact your local Instron representative.

Product Support: www.instron.com

1-7

Page 16

Chapter: Introduction

Product Support

Instron provides documentation, including manuals and online help, that can answer many

of the questions you may have. It is recommended that you review the documentation sent

with the system you purchased for possible solutions to your questions.

If you cannot find answers in these sources, contact Instron’s Service department directly . A

list of Instron offices is available on our website at www.instron.com. In the US and

Canada, you can call directly at 1-800-473-7838.

Product Documentation

Instron offers a comprehensive range of documentation to help you get the most out of your

Instron products. Depending on what you have purchased, your documentation may include

some or all of the following:

Operator’s Guide How to use your system components and controls,

procedures for setting limits, calibration and other

frequently performed operating tasks.

System Support Information about system installation, set up and

configuration, transducer connection and calibration.

Online Help Software products come complete with context

sensitive help, which provides detailed information on

how to use all software features.

Accessory

Equipment Reference

We welcome your feedback on any aspect of the product documentation. Please email

info_dev@instron.com with your comments.

How to set up and use any accessories you have

purchased, for example grips, fixtures, extensometers,

transducers, and environmental chambers.

1-8 M10-16245-EN

Page 17

• Before you Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

• Start the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

• Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

• Bluehill Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

• Assemble the Load String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

• Preload the Load String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Before you Begin

Before you start the system, make sure you familiarize yourself with the following controls:

Chapter 2

Preparing the System

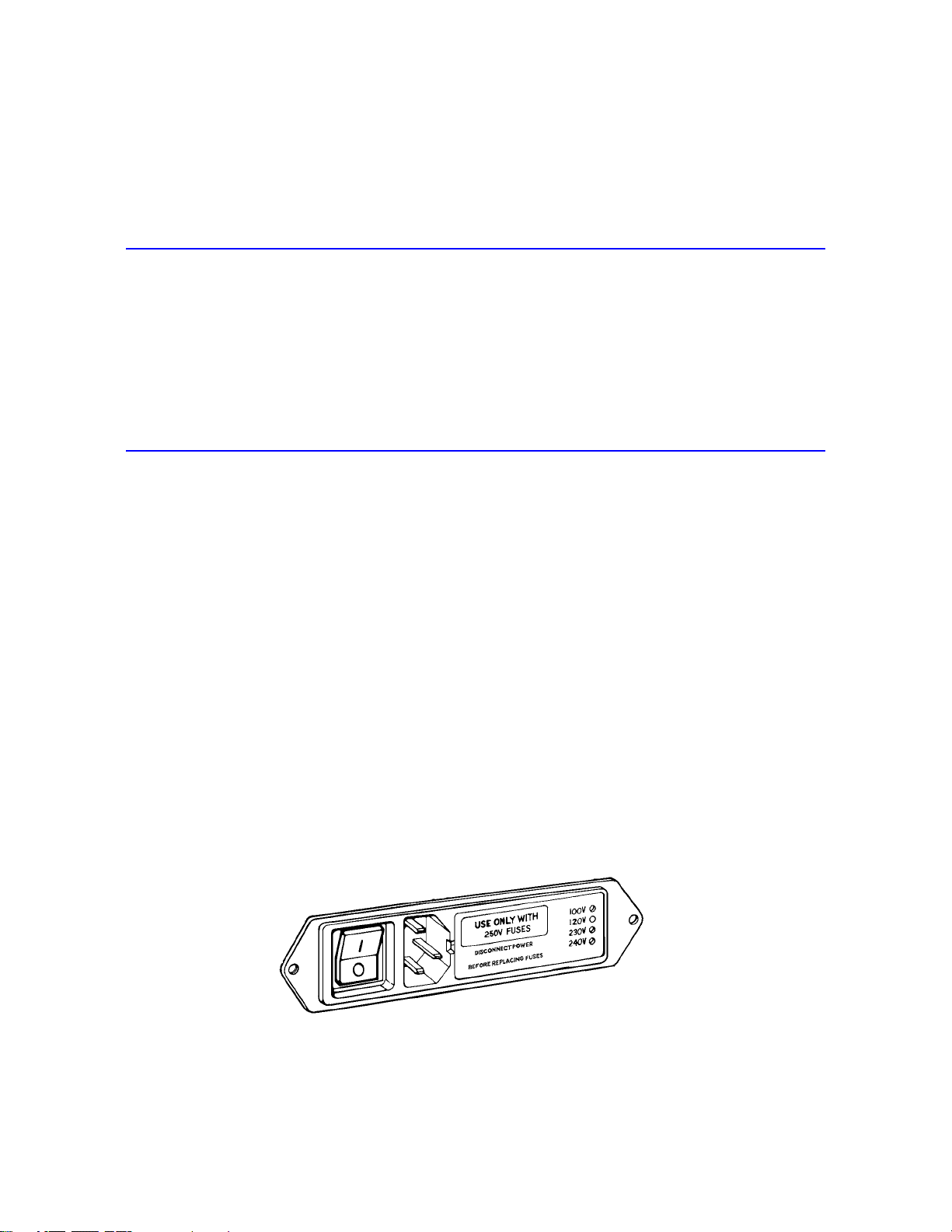

Power Input Connector

The power input connector, shown in Figure 2-1, performs the following functions:

• Connects the load frame to the electrical power supply.

• Contains the power ON/OFF switch.

• Holds the power fuse.

• Controls the voltage setting. The voltage setting can be changed if necessary , refer to the

System Support manual for details.

Figure 2-1. Power Input Connector

2-1

Page 18

Chapter: Preparing the System

Refer to Figure 1-1 on page 1-2 to see the location of the power input connector on the

load frame.

Emergency Stop Button

Figure 2-2. Emergency Stop Button

The Emergency Stop button is a large, round, red button on the testing system. Press this

button to stop the test as soon as possible when a condition develops that:

• Could affect the safety of persons operating the system.

• Could damage the specimen, load frame, or test fixtures.

Start the System

Before operating the system each day, ensure:

• All cables are properly installed and securely connected.

• All cables are free of wear and chafing. Re-route the cables if necessary, and replace any

damaged cables.

• Signal and power cables have adequate slack to prevent excessive strain on connectors.

• All grips, fixtures and accessories are free of dirt, damage and deformation.

• The load frame is level. If an adjustment is necessary, refer to the System Support

manual.

Correct any problems before you operate the testing system. If you require assistance,

contact your local Instron Service department.

2-2 M10-16245-EN

Page 19

Control Panel

Warning

1. Turn the power switch for the frame to the On (I) position. Ensure that the POWER

indicator light illuminates.

2. Power on all other system components (e.g. computer and any other accessories).

3. Observe the display on the control panel; an hourglass displays while the system

performs its self-test procedure. The procedure is complete when the hourglass

disappears and only the Instron logo displays.

If the hourglass persists or if it is replaced with a warning icon, then the self-test has not

been successful. Contact Instron Service.

4. When the system self-test has completed successfully, start the Instron Bluehill

software.

5. Wait for the software to fully initialize the machine before using the jog controls on the

machine. The machine relay makes a clicking sound before the machine is ready.

6. Ensure that the

Refer to “Control Panel” on page 2-3 and “Bluehill Software” on page 2-6. for details

of the controls available in each.

Control Panel

The control panel attaches to one of the column covers on the load frame and works in

conjunction with the software to operate the frame. The control panel lets you perform many

of the software functions directly at the frame, so you can perform these functions either at

the computer or at the load frame.

Crush Hazard - Do not place your hands between the moving grips or fixtures

while operating any controls on the control panel.

FRAME READY indicator on the control panel illuminates.

The display and its associated numbered buttons operate together with Bluehill software.

Any soft key functions that you have assigned in Bluehill are shown in the display next to

the appropriate button. Pressing a button performs the action displayed next to it.

Use the toggle button on the left of the display key to toggle the display between soft key

functions and up to 4 live displays. The live displays are copies of any live displays that you

If the display is showing live displays you must toggle back to show the softkey functions if

you want to use a soft key button on the control panel.

Product Support: www.instron.com

2-3

Page 20

Chapter: Preparing the System

Figure 2-3. Control Panel

2-4 M10-16245-EN

Page 21

Control Panel

Table 2-1. Control Panel Functions

Control Function

JOG UP Press the JOG UP arrow button to move the crosshead in tension (away from the

base beam). Pressing the button increases the speed linearly, up to a maximum speed,

until you release the button.

JOG DOWN Press the JOG DOWN arrow button to move the crosshead in compression

(toward the base beam). Pressing the button increases the speed linearly, up to a

maximum speed, until you release the button.

FINE JOG Turn this thumbwheel to slowly position the crosshead. This control lets you set an

accurate zero extension point, or set a precise grip position for loading specimens.

Note: on some control panels, this control is labeled

FINE POSITION.

ZERO

EXTENSION

Press this button to set the current position of the crosshead as the zero extension point

(or gauge length) position. After setting the zero extension point, the crosshead returns

to this position when:

• You press the RETURN button

• The crosshead encounters a pre-set limit or event that instructs the crossh ead to

return to the zero extension point

Note’: on some control panels, this button is labeled

RESET GL (reset gauge length).

AT Z E RO This indicator illuminates when the crosshead is at the zero extension point.

Note’: on some control panels, this indicator is labeled

AT GL (at gauge length).

POWER This indicator illuminates when the system power is in either STANDBY or FRAME

SPECIMEN

PROTECT

READY

its conditioner board but not to the frame. In FRAME READY mode, the system

supplies power to all load frame and transducer components. This indicates that the test

system is ready for operation.

Press this button to toggle on or off the SPECIMEN PROTECT function. This

function protects the test specimen and load string components from overloads.

The

mode. In STANDBY mode, the system supplies power to the load cell and

ON indicator flashes when SPECIMEN PROTE CT is functioning.

START TEST After you set the test parameters, press this button to begin the test. When the

crosshead starts to move, the appropriate

illuminates showing the direction of crosshead movement.

TEST IN PROGRESS indicator

STOP TEST Press this button to stop crosshead motion during or at the end of a test. The TEST

STOPPED

crosshead has not returned to the gauge length position.

indicator illuminates to show that the test has stopped, but that the

RETURN Press this button to move the crosshead back to the gauge length position after a test.

RETURN IN PROGRESS indicator illuminates to show that the crosshead is

The

returning to the gauge length position.

Figure 2-3 on page 2-4 illustrates the control panel. Table 2-1 on page 2-5 describes the

control panel’s functions.

Product Support: www.instron.com

2-5

Page 22

Chapter: Preparing the System

Bluehill Software

Setting test parameters, operating the system, and collecting test data is done through the

software program.

Home Screen

Bluehill software opens at the Home screen. The console section of the software is at the

top of the screen and provides important information about the system. The console is

always visible and always available from any screen within the software.

Buttons on the Home screen take you to other parts of the software, as follows:

Button Function

Test Click this button to perform tests on specimens. The software displays a

sequence of screens where you:

1. choose a test method from which to load test parameters.

2. name the sample and select a location to store the test data.

3. perform tests.

Table 2-2. Buttons on the Home screen

Console

Method Click this button to edit and save test method files.

Refer to the software online help.

Analysis Click this button to either modify an existing sample or replay a sample with

parameters from a different test method.

Refer to the software online help.

Admin Click this button to change the configuration of the testing system.

Refer to the software online help.

User This button is grayed if Security is not enabled.

Click this button to log out the current user and let a new user log in to the

software. When you log out you do not exit the program.

Help Click this button to open the online help.

Exit Click this button to exit the program.

The console area of the software provides important information during testing and is also

where you can edit system wide settings.

2-6 M10-16245-EN

Page 23

Table 2-3. Console Controls

Control Function

Bluehill Software

Frame status

indicator

System settings This area contains a number of buttons, one for each component that makes

Soft keys You can assign up to four functions that you use frequently to these keys. Each

Live display You can set up a number of live displays that display values of parameters that

During test setup, the image of the frame changes according to the status of

the testing system.

• image grayed when frame is disabled

• green arrow superimposed on image indicates direction that crosshead

will move when test starts

When a test is running, the image changes to display the icon of the transducer

that is controlling the test. A large green arrow flashes to indicate the direction

of the test and that the test is running.

up the testing system, as follows:

• Frame - enables and disables the frame and set the jog speed

• Extension - lets you set limits for extension and reset the gauge length

• Load - lets you set limits for load, calibrate and balance the load cell

• Strain - lets you set limits for strain, calibrate and balance the

extensometer connected to this channel

Other buttons will display for other more specialized equipment, for example a

video extensometer or automatic extensometer.

key can display on the control panel so that you can perform that function from

the software console or from the control panel. Examples of common functions

assigned to soft keys are Balance Load and Reset Gauge Length.

you choose throughout the test.

System event log The event log provides information and warnings regarding various aspects of

the system. These include frame status messages, indications that certain test

method parameters are preventing the start of a test, or indications that the

system cannot open a sample file or method file.

Status Bar

The status bar appears at the bottom of every screen and provides status information for:

• Security - is security enabled and, if it is, the name of the current user.

• Machine - is the software connected to a testing machine or running in demo mode.

• Sample - the name of the current sample.

• Method - the name of the current method file that is open, if any.

• Report - the name of the current report template that is open.

Product Support: www.instron.com

2-7

Page 24

Chapter: Preparing the System

• Progress messages - various messages indicating progress, for example “Opening”,

“Closing” and “Generating”.

Assemble the Load String

The load string consists of all the hardware components between the crosshead and the base

of the testing machine. It includes the load cell, the grips, the specimen and any adapters that

allow you to connect all of these components together.

The service engineer will set up the testing machine during the installation, but you may

need to change one or more of these components for different types of testing.

When creating a load string, keep in mind the maximum capacity for all the components

making up the load string. The expected test load should not exceed the maximum cap a city

of any load string component including, but not limited to:

• load frame

• load cell

• adapters

• grips or fixtures

Select a Load Cell

If you know the approximate tensile or compressive strength of the material that you are

testing, use these guidelines to choose a load cell:

• The minimum test load must be greater than the smallest load cell capacity range shown

in the specifications for your machine.

• If there is a choice between two different load cells because of overlapping ranges:

• select a higher capacity load cell when you require minimum deflection

• select a lower capacity load cell when you require maximum long term balance or

stability

If you don’t know the tensile strength of the material, refer to a Properties of Materials

handbook to obtain an approximate strength. To calculate the tensile strength in force units

for a specimen, use the following equation:

tensile strength x cross-sectional area

2-8 M10-16245-EN

Page 25

Assemble the Load String

For example, for a standard ASTM tensile specimen (0.502 in wide, 0.125 in thick) made

with a material of tensile strength 5200 psi (from Materials Handbook) perform the

following calculation:

5200 x 0.502 x 0.125 = 328 lbf

This produces a recommendation of the 5 kN (1000 lb, 500kg) capacity load cell.

If you cannot determine an approximate value of tensile strength, use the highest capacity

load cell rated for the frame. Perform a preliminary test at a very slow speed to obtain the

load range required. You can then determine if a lower capacity load cell can provide

improved resolution.

Table 2-4 on page 2-9 lists the load cells that are recommended for use with 5940 Series

frames. If you have a load cell that is not listed, contact Instron for advice on compatibility

and adapters that may be available for your load cell.

Table 2-4. Compatible Load Cells for 5940 Frames

Torque - load cell to machine - Nm (ft-lb) 19 (14)

Install the Load Cell

Check the following before installing a load cell:

The load cell installation drawings are available and you have all the parts that are

required for the installation.

Capacity

Load Cell

Catalog no. 2580-105 2580-106 2580-107

Weight - kg (lb) 0.6 (1.3)

Effective Length - mm (in) 100 (3.9)

Machine Interface M10 x 40 long x 1.5 pitch

Accessory Interface Integral type O (female)

500 N 1 kN 2 kN

RH central thread

12 mm clevis with 6 mm clevis pin

Mounting screws are lubricated.

A torque wrench is available.

All threads, bores and mating surfaces are clean and free of damage.

Product Support: www.instron.com

2-9

Page 26

Chapter: Preparing the System

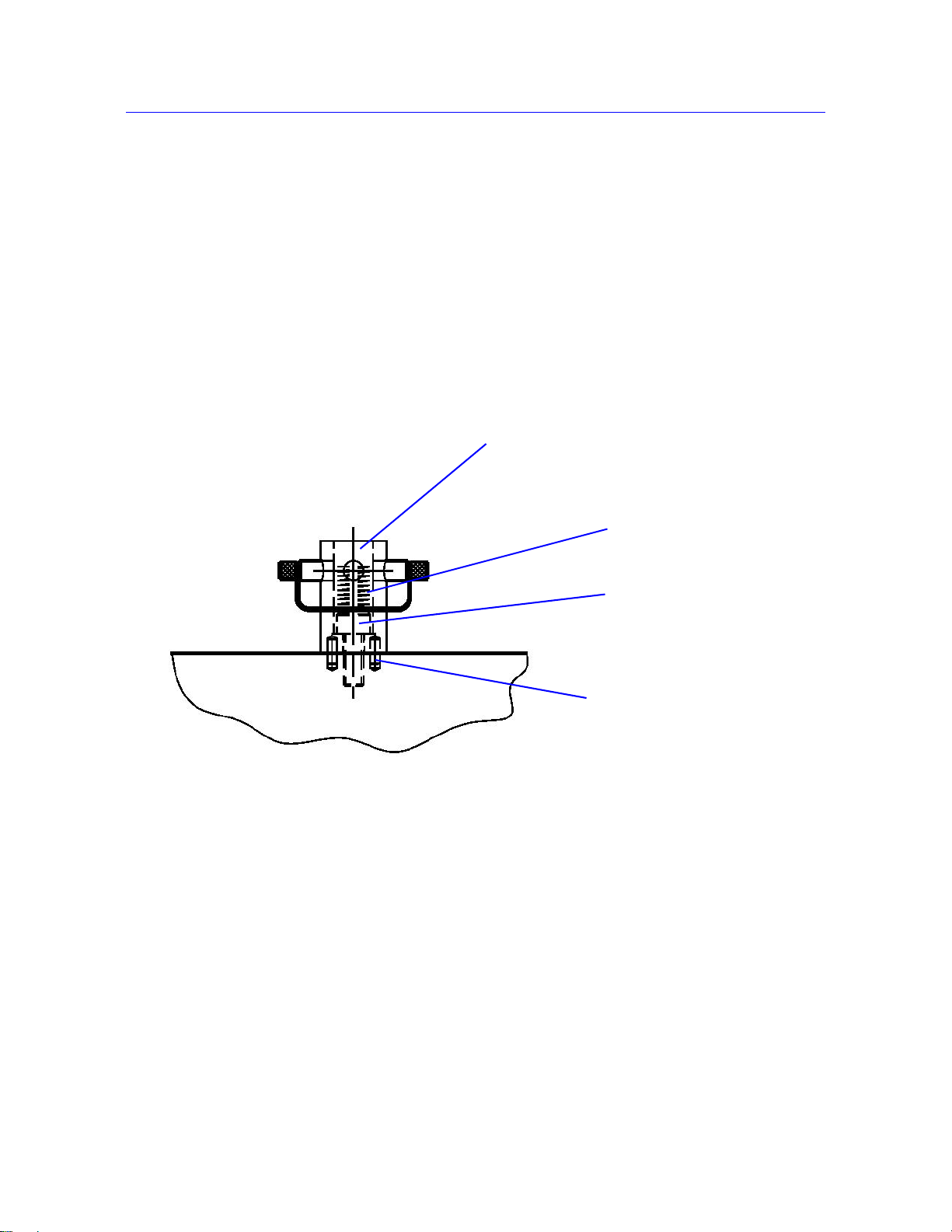

A

B

C

D

Load cell

Crosshead

The crosshead is positioned below its travel midpoint so that you can easily and safely

access the crosshead.

The crosshead is stationary and the TEST IN PROGRESS indicator light is not

illuminated.

Refer to Figure 2-4 on page 2-10 and perform the following procedure.

Figure 2-4. Installing the Load Cell

Load cell installation procedure:

1. Refer to the load cell installation drawing and collect together the correct mounting

screw , washer, anti-rotation pin and locating ring for your combination of load frame

and load cell.

2-10 M10-16245-EN

Page 27

Assemble the Load String

Caution

2. Assemble the mounting screw (A) and washer (B), as shown in the figure.

3. Place the mounting screw and washer assembly into the top of the central bore of the

crosshead.

4. Insert the anti-rotation pin (C) into one of the holes on the bottom of the crosshead.

There are four pin holes on the bottom of the crosshead that let you position the load cell

either straight on or at a 45° angle.

5. Place the locating ring (D) into the top of the load cell that connects to the crosshead.

6. Place the load cell against the bottom of the crosshead, ensuring that the anti-rotation

pin and locating ring fit securely in place against both the crosshead and load cell. Place

the cable to the left side of the column.

7. Tighten the mounting screw by hand so that it secures to the load cell underneath the

crosshead.

When applying torque to the mounting screw, prevent the load frame from sliding by

holding the crosshead with one hand while applying torque with the other.

8. Set the torque wrench to the value specified in the load cell installation drawing (and in

“Compatible Load Cells for 5940 Frames” on page 2-9) and tighten the mounting

screw .

9. Connect the load cell cable to the

connector is fully engaged in the socket.

10. Press the load cell cable into the clips on the rear of the column cover to prevent it from

interfering with your test.

11. Calibrate the load cell (refer to “Calibrate a transducer” on page 3-6).

12. Leave the system on for at least 15 minutes to allow the load cell circuitry to stabilize.

After this warm-up period, calibrate the load cell again.

Adapters

Adapters let you connect grips or fixtures to the frame when the interfaces have different

connection sizes. There are two types of adapters: base adapters and coupling adapters.

Base Adapters

LOAD connector on the controller. Ensure that the

Base adapters let you connect grips and fixtures to the base of the load frame. All 5940

Series load frames are supplied with a Type O base adapter installed. A T ype D base adapter

Product Support: www.instron.com

2-11

Page 28

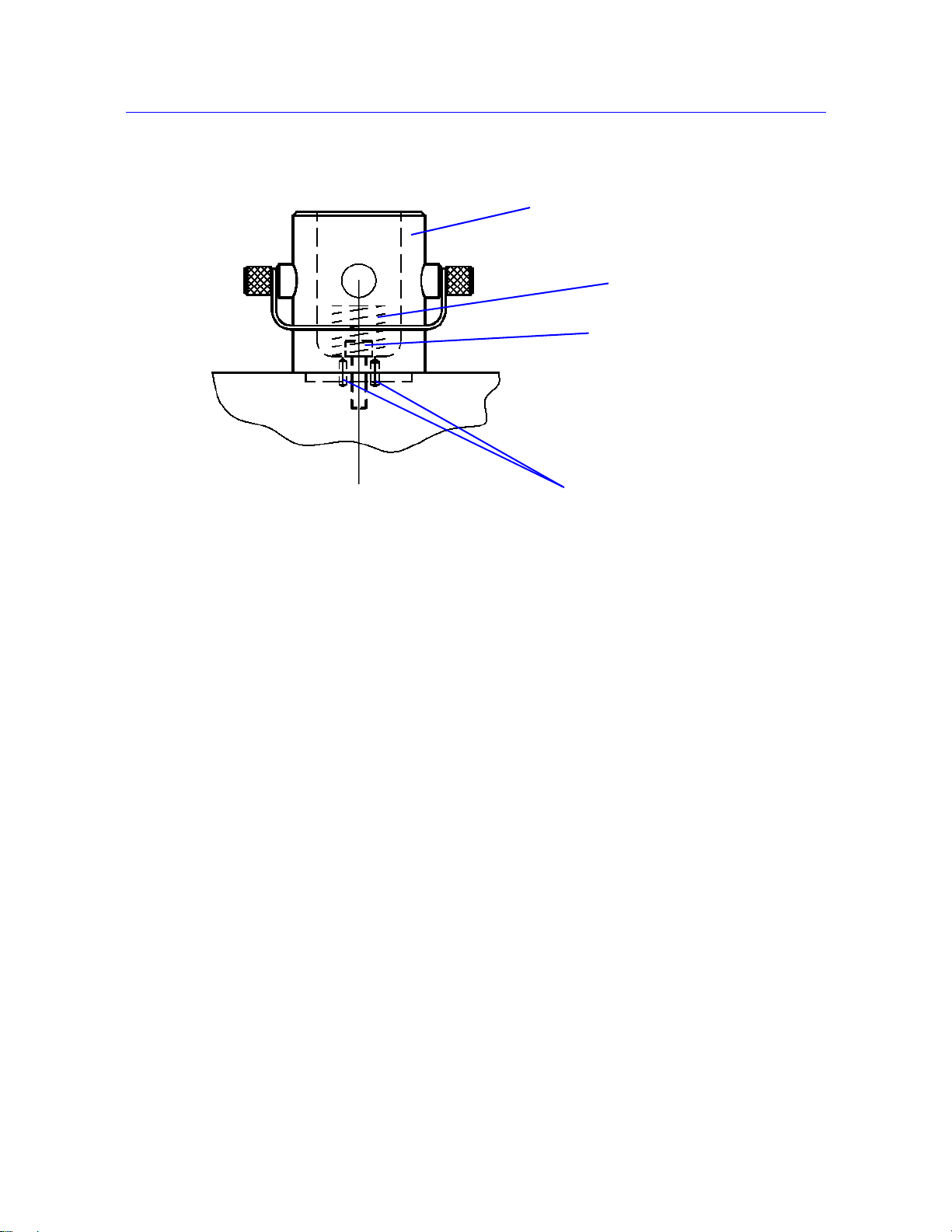

Chapter: Preparing the System

Locating pins

Base adapter

M6 bolt

Compression spring

is also supplied in the ancillary parts kit. If you need to remove and re-install the base

adapter, for example to change the orientation, use one of the following procedures.

To remove the base adapter:

1. Remove the compression spring located inside the adapter.

2. Insert a 5mm hex key into the base adapter, ensuring that it fits into the screw at the base

of the adapter.

3. Using a torque wrench, loosen and remove the screw inside the adapter.

4. Lift the base adapter away from the base beam.

Figure 2-5. Type O Base Adapter

To re-install the base adapter:

1. Insert the adapter into the base beam, noting the orientation of the locating pin on the

bottom of the adapter . The locating pin fits into any of the three locating pin holes on the

base beam.

2. Insert a 5mm hex key into the base adapter, ensuring that it fits into the screw at the base

of the adapter.

3. Using a torque wrench, tighten the screw to 7 Nm (5.2 ftlb)

4. Remove the hex key and insert the compression spring.

2-12 M10-16245-EN

Page 29

Figure 2-6. Type D Base Adapter

Base adapter

Compression

spring

M6 bolt

Locating pins

Assemble the Load String

Product Support: www.instron.com

2-13

Page 30

Chapter: Preparing the System

Coupling Adapters

Coupling adapters let you attach grips and fixtures of different sizes to the load cell and base

adapter, providing more options for testing. There are two primary types:

• For tension testing only:

Tension coupling adapters, also known as self-aligning coupling adapters, which

provide a swivel connection and connect between clevis pin type interfaces. The swivel

action allows the grip or fixture to self-align in the direction of the test load, thus

minimizing any bending load on the specimen.

• For tension or compression testing:

Rigid coupling adapters which also connect between clevis pin type interfaces but use

checknuts to provide fixed connections. This type can also have a threaded interface.

These couplings are not self-aligning and the load string alignment is dependent on the

accuracy of load cell alignment during installation.

When assembling the load string, you may need to use adapters if the load cell interface, or

base adapter interface, differs from your grip interface. A coupling adapter creates a secure

connection between these two different interfaces.

If your grip or fixture interface is the same size as your load cell interface, then you can

connect these directly and you do not need an adapter. If, however, you need the selfaligning feature that the adapter offers, you should use the appropriate self-aligning coupling

adapter.

Coupling types are listed from the load cell towards the accessory or from the frame base

towards the accessory. For example, if you need to connect a load cell with a Type D

(female) connector to a grip with a Type O (male) connector you require a Type Dm to Of

adapter.

Select Grips and Fixtures

A set of grips are installed on the system during installation by a service engineer. If your

testing requires it, you may need to install a different set to obtain optimum test results.

The selection of grips depends on the material, geometry and strength of the test specimen.

In compression testing, the diameter or area of the anvil is important, in addition to the

maximum loading capacity .

For tensile testing:

Make sure the tensile strength of the specimen does not exceed the maximum loading

capacity of the grips.

Minimize the risk of slippage by:

2-14 M10-16245-EN

Page 31

selecting jaw faces with a surface area large enough to cover the tab (for dumbbell-

•

shaped specimens) or as much surface area as possible for parallel-sided specimens.

• ensuring that the specimen is gripped by at least 75% of the available jaw face

length.

• using serrated jaw faces

Breaks at the jaw face may be caused by:

• Screw action grips - you may be using too much force when tightening the grips.

Use a torque wrench or switch to pneumatic grips for a consistent force.

• Pneumatic grips - the pressure may be too high. Drop the pressure, but not to the

point where you get slippage.

• Serrated faces - the serrations are damaging the specimen. Change to faces that have

more serrations per inch (less bite) or cover with masking tape or similar material to

soften the bite and prevent damage to the specimen.

Insert Jaw Faces into Grips

Install Grips

Different grips use different mechanisms for attaching jaw faces. Refer to the documentation

supplied with the grips for more information.

Install Grips

Figure 2-7 on page 2-16 shows a typical grip with clevis pin coupling.

Before you begin, check the following:

There is sufficient space between the load cell and the load frame base to install the

grips.

The crosshead is stationary and the TEST IN PROGRESS indicator light is not

illuminated.

The crosshead limit stops on the load frame are set to prevent the upper and lower grips

from colliding with each other (refer to “Set the crosshead limit stops” on page 3-10).

The mating surfaces of the grips, load cell and the base adapter are free of dirt or debris.

To install the grips:

1. For the lower grip, insert the adapter on the grip into the female clevis socket on the load

frame base adapter, as shown in Figure 2-7 on page 2-16.

2. Align the clevis holes and insert the clevis pin through the holes.

Product Support: www.instron.com

2-15

Page 32

Chapter: Preparing the System

Grip

Clevis

socket

Clevis

pin

Lock nut

Clevis pin

clip

Grip

shank

3. Secure the clevis pin in position with the clevis pin clip.

4. Repeat steps 1 through 3 to install the upper grip onto the load cell.

5. When both grips are installed, follow the procedure to preload the load string (refer to

“Preload the Load String” on page 2-17).

Figure 2-7. Grip with Clevis Pin Coupling

2-16 M10-16245-EN

Page 33

Preload the Load String

This procedure eliminates back lash and de flections within the load string which can degrade

the integrity of test results, especially when testing at high loads. The procedure involves

preloading the entire load string and then hand-tightening all the locknuts on all the grips

and couplings. Even when using self-aligning couplings on the upper grip, it is good practice

to preload the lower grip.

You will need a rigid specimen that is strong enough to sustain the preload value without

breaking. This means a specimen that can sustain a load that is:

• 10% above the expected test load, or

• the maximum load rating of the weakest component of the load string (grips or load cell)

whichever is less. For example, if your grips are rated at 1kN, the load cell at 2kN and your

expected test load is 500N then you should preload to at least 550N but not more than 1kN.

Before inserting the specimen ensure that:

Preload the Load String

The grips and couplings are installed but the locknuts are not tightened.

Crosshead travel limits are set (refer to “Set the crosshead limit stops” on page 3-

10).

The value of load in the live display is near zero. If it is not, balance the load (refer to

“Balance a transducer” on page 3-12).

The load limits are set in the software to a value that matches the maximum load

capacity of the weakest component in the load string.

To preload the load string:

1. Install the strong specimen.

2. Increase the load on the load string to the chosen preload value.

3. Hand tighten all the locknuts on the grips and any intermediate couplings.

4. Reduce the load to zero.

5. Remove the specimen.

The load string is now preloaded and all the locknuts are tight and should not move during

subsequent testing. The system is now ready to test.

Product Support: www.instron.com

2-17

Page 34

Chapter: Preparing the System

When you next need to change grips or any other part of the load string, the locknuts will be

too tight to loosen by hand. Follow the unload procedure (“To unload the load string:” on

page 2-18).

To unload the load string:

1. Install the strong specimen.

2. Increase the load on the load string to the chosen preload value.

3. Loosen all the locknuts on the grips and any intermediate couplings.

4. Reduce the load to zero.

5. Remove the specimen.

The load string is now unloaded and all the locknuts are loose so that you can change any

component.

2-18 M10-16245-EN

Page 35

Chapter 3

Warnings

Testing Specimens

• Testing a Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

• Create a sample in Bluehill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

• Calibrate a transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -6

• Set the zero extension point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

• Set the crosshead limit stops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

• Set the limits for a transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

• Balance a transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

• Stop a test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

• Shut down the system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

• Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Materials testing systems are inherently hazardous. The following two statements warn of

behavior that offers the highest probability of personal injury from using the system.

Hazard - do not allow more than one person to operate a testing machine.

Operator injury may result if more than one person operates the testing machine. For

example, injury can occur if one person moves the crosshead or actuator while the other is

working inside the hazard area between the grips or fixtures.

Crush hazard - take care when insta lling or removing a specimen, assembly, structure

or load string component.

Installation or removal of a specimen, assembly, structure or load string component involves

working inside the hazard area between the grips or fixtures. When working in this area,

ensure that other personnel cannot operate any of the system controls. Keep clear of the jaws

of a grip or fixture at all times. Keep clear of the hazard area between the grips or fixtures

during actuator or crosshead movement. Ensure that all actuator or crosshead movements

necessary for installation or removal are slow and, where possible, at a low force setting.

3-1

Page 36

Chapter: Testing Specimens

Testing a Sample

The following are guidelines for the steps that you would typically go through when testing

a group of specimens on a 5900 system. Some steps include references to more detail in

separate sections.

These guidelines assume that a test method has already been created that satisfies your

testing requirements and provides the required test parameters (e.g. specimen dimensions,

testing notes) on the test workspace.

1. Collect all specimens together that will make up your testing sample.

2. Identify each specimen, e.g. by marking. Y ou need to identify each specimen so that you

can match it to the appropriate specimen number in the completed sample test report.

3. In Bluehill, create a new sample, refer to “Create a sample in Bluehill” on page 3-4.

4. Verify the test area and test direction is correct on the Frame Status indicator in the

console area.

5. Verify these settings on the control panel:

• FRAME READY indicator illuminates

• TEST STOPPED indicator illuminates

• START TEST arrow indicator illuminates the correct direction of the test

• AT ZERO (or AT GL) indicator illuminates green if you are starting the test from

zero extension

6. If necessary , calibrate the transducer configurations required by the test method, refer to

“Calibrate a transducer” on page 3-6.

If the load frame was previously switched off, allow the load cell to warm up for at least

20 minutes after calibration to ensure stable readings.

7. If the test method includes a specimen protect threshold value, enable specimen protect

by pressing the

SPECIMEN PROTECT button on the control panel.

8. Take measurements of the required specimen dimensions for each specimen and enter

the values into the appropriate fields in the operator’s input component of the test

workspace.

9. Complete any additional fields that the test method requires, e.g. specimen notes,

sample notes.

10. Use the jog controls to move the crosshead to its starting position for the test and set the

zero extension point (refer to “Set the zero extension point” on page 3-9).

11. Ensure that the crosshead travel limits are set (refer to “Set the crosshead limit

stops” on page 3-10).

3-2 M10-16245-EN

Page 37

Testing a Sample

Warnings

12. Ensure that limits are set for each transducer (extension, load, strain and user-defined)

required by the test method. Refer to “Set the limits for a transducer” on page 3-12).

13. Balance each transducer configuration required by the test method. Refer to “Balance a

transducer” on page 3-12. If the method has this function assigned to a soft key, click

the Balance soft key or the Balance all soft key.

Hazard - do not allow more than one person to operate a testing machine.

Operator injury may result if more than one person operates the testing machine. For

example, injury can occur if one person moves the crosshead or actuator while the other is

working inside the hazard area between the grips or fixtures.

Crush hazard - take care when insta lling or removing a specimen, assembly, structure

or load string component.

Installation or removal of a specimen, assembly, structure or load string component involves

working inside the hazard area between the grips or fixtures. When working in this area,

ensure that other personnel cannot operate any of the system controls. Keep clear of the jaws

of a grip or fixture at all times. Keep clear of the hazard area between the grips or fixtures

during actuator or crosshead movement. Ensure that all actuator or crosshead movements

necessary for installation or removal are slow and, where possible, at a low force setting.

Flying Debris Hazard - Make sure that test specimens are installed correctly in grips

or fixtures in order to eliminate stresses that can cause breakage of grip jaws or

fixture components.

Incorrect installation of test specimens creates stresses in grip jaws or fixture components

that can result in breakage of these components. The high energies involved can cause the

broken parts to be projected forcefully some distance from the test area. Install specimens in

the center of the grip jaws in line with the load path. Insert specimens into the jaws by at

least the amount recommended in your grip documentation. This amount can vary between

66% to 100% insertion depth; refer to supplied instructions for your specific grips. Use any

centering and alignment devices provided.

14. Install the specimen into the grips. Refer to the documentation provided with the grips

for details.

15. Check that the specimen is aligned properly in the grips.

16. Start the test by pressing the

START button on the control panel or by clicking the Start

button in the Bluehill test workspace.

The test method may also include a start test paramete r that may automatically start a

test when specified criteria are satisfied. Review the T est Control > S t art Test screen

to verify how the test should start.

Product Support: www.instron.com

3-3

Page 38

Chapter: Testing Specimens

A test method includes the layout of the test workspace, which typically includes a

graph, a results table, and an area where you can enter parameter values before or after

the test. As the test proceeds you can view the graph and when the test is complete,

results for that specimen display in the results table.

17. If you need to stop the test before it completes, press the

panel or click the Stop button in the Bluehill test workspace (refer to “Stop a test” on

page 3-13).

If during the test a condition develops that could affect the safety of an operator or could

damage the specimen or test equipment, press the Emer gency Stop bu tton on the front of

the frame.

18. When the test is complete, remove the specimen by first releasing the upper grip

followed by the lower grip.

19. Bring the crosshead back to gauge length by pressing the

control panel or by clicking the Return button in the Bluehill test workspace. The

system is ready for the next specimen.

20. After all specimens are tested, click the Finish button in the Bluehill test workspace.

Create a sample in Bluehill

Create a new sample

STOP button on the control

RETURN button on the

The first step to create a sample is to select an existing test method that contains the settings

and parameters for the test.

1. Click Test on the Home screen.

2. Click New Sample > Select Method in the navigation bar.

3. Select a test method. You can either:

• browse to select an existing method. Refer to “Select a test method file” on

page 3-5.

• select a method shown on the Most Recently Used list. Refer to “Select from the

Most Recently Used list” on page 3-5

If the test method has the Automatically name the sample feature enabled, the system

automatically names the sample according to the default name and the default location

identified in the test method. The system appends a number to the sample name every time

this method is used for a new sample. The system skips the second step and advances

directly to the test workspace on the Test tab.

3-4 M10-16245-EN

Page 39

Select a test method file

1. Click Browse… to open a standard Open File dialog box.

2. Find the method file and click Open.

When you open the selected method file, the software advances to the next step in which

you name the new sample.

If the file does not open, the system displays an open file error messag e. Refer to the online

help for further assistance.

Select from the Most Recently Used list

1. Click on the name in the Most recently used list. The file name and its location

appear in the associated fields and a preview of the file displays in the Preview

window.

2. Click Next to open the file.

The software advances to the next step in which you name the new sample.

Create a sample in Bluehill

Double-click a file name in the list to open it.

Name the new sample

The second step in creating a new sample is to name the sample and identify where to save

the sample file.

If the test method has the Automatically name the sample feature enabled, the system

automatically names the sample according to the default name and the default location

identified in the test method. The system appends a number to the sample name every time

this method is used for a new sample. The system skips the second step and advances

directly to the test workspace on the Test tab.

To name a sample file:

1. In the Sample name field, enter a name for the sample file or accept the name

generated by the system.

The system produces a suggested name for the sample file, based on the most recently

used sample file name. If there are no sample files created, the system uses

“TestSample” as the default name. The system appends a number to the file name to

ensure a unique name.

Product Support: www.instron.com

3-5

Page 40

Chapter: Testing Specimens

2. In the Location field, verify the location to save the sample file. To change the

location, refer to “Change the location for the sample files” below.

3. Click Next to advance to the Test tab.

To return to the previous screen, click Back.

Change the location for the sample files

1. Click Browse… on the right side of the screen.

The Save Sample File As dialog displays.

2. Browse to find the directory to save the output files and, if desired, enter a different file

name.

3. Click Save.

The system creates the sample file and advances to the Test tab.

Calibrate a transducer

Automatic calibration

1. Click on the icon for the transducer in the system settings area of the console.

2. In the first tab, select the transducer configuration in the Transducer configuration

field.

3. Ensure that Calibration type is set to Automatic.

Automatic calibration uses the following basis for the calibration point value:

Load 50% of the full-scale load transducer

Strain 100% of the full-scale strain transducer

4. Set the transducer to its zero point. For load, zero point means no load on the system.

For strain, zero point means returning to the gauge length position.

5. Click Calibrate.

The system performs the calibration and displays a dialog with the calibration status.

6. Click Done to complete the calibration.

3-6 M10-16245-EN

Page 41

Manual calibration

During a manual calibration, you apply a measured physical force to the transducer and the

system calibrates on the signal that is output as a result of that force. For strain calibration,

you can install the extensometer on a specially designed calibration jig to apply a precise

deflection to the extensometer. For load calibration, you can hang a measured weight from

the load cell.

The system only saves the values entered for a manual calibration after there is a successful

calibration. If you select a different transducer configuration or close the dialog before

calibrating a transducer configuration, the calibration fields revert to the default values for

that configuration.

Rationalized transducers

1. Click on the icon for the transducer in the system settings area of the console.

2. In the first tab, select the transducer configuration in the Transducer configuration

field.

3. Set Calibration type to Manual.

Calibrate a transducer

4. Enter a value for the calibration point. This value is the load (for a load cell) or

deflection (for an extensometer) that you apply to the transducer during calibration.

For example, to calibrate a 100 kN load cell using a 50 kN weight, the full scale value is

100 kN and the calibration point is 50 kN.

The range for a valid calibration point value is between:

Load

(% full scale)

Minimum 2 2

Maximum 105 110

If you change the units for a field, the softwar e converts the corresponding value to its

equivalent value in the new units. Verify that the value is correct for the specified units.

Strain

(% full scale)

5. Click Calibrate. Follow the directions in the message window sequence, as follows:

a. Set the transducer to its zero or gauge length point.

b. Click OK.

c. Deflect the transducer to its calibration point using a weight (load cell) or a

calibration jig (extensometer). For load, if you have a load cell with an associated

Product Support: www.instron.com

3-7

Page 42

Chapter: Testing Specimens

electrical calibration circuit, you can use this to apply an electrical signal instead of

applying a physical force to the load cell.

d. Click OK.

e. Reset the transducer to its zero or gauge length point.

f. Click OK.

Non- rationalized transducers

1. Click on the icon for the transducer in the system settings area of the console.

2. In the first tab, select the transducer configuration in the Transducer configuration

field.

3. Set Calibration type to Manual.

4. Enter the full scale value of the transducer.

5. For strain transducers, enter the gauge length of the extensometer.

The system must know the gauge length of the installed extensometer in order to

calculate strain values for display and for further calculations.

6. Enter a value for the calibration point. This value is the load (for a load cell) or

deflection (for an extensometer) that you apply to the transducer during calibration.

For example, to calibrate a 100 kN load cell using a 50 kN weight, enter 100 kN as the

full scale value and 50 kN as the calibration point.

The range for a valid calibration point value is between:

Load

(% full scale)

Minimum 2 2

Maximum 105 110

If you change the units for a field, the software converts the corresponding value to its

equivalent value in the new units. Verify that the value is correct for the specified units.

Strain

(% full scale)

7. Click Calibrate. Follow the directions in the message window sequence, as follows:

a. Set the transducer to its zero or gauge length point.

b. Click OK.

3-8 M10-16245-EN

Page 43

c. Deflect the transducer to its calibration point using a weight (load cell) or a

calibration jig (extensometer). For load, if you have a load cell with an associated

electrical calibration circuit, you can use this to apply an electrical signal instead of

applying a physical force to the load cell.

d. Click OK.

e. Reset the transducer to its zero or gauge length point.

f. Click OK.

Set the zero extension point

From Bluehill software

1. Use the jog controls to move the crosshead to its starting position for the test.

2. Click in the console area to open the Transducer Settings dialog for Extension.

3. Click the Extension tab.

Set the zero extension point