Issue C April 1995

Instron

Model 4400

Universal Testing System

M10-94400-1

Operator’s Guide

This document and the information that it contains are the property of Instron

Corporation. Rights to duplicate or otherwise copy this document and rights to

disclose the document and the information that it contains to others and the right

to use the information contained therein may be acquired only by written

permissionsigned by a duly authorized officer of Instron Corporation.

Proprietory Rights Notice

© Copyright 1995 Instron Corporation

Amendment

Number

Amendment Incorporation Record

Brief Description of

Content

ECR

Numberr

Preliminary Pages

Person

Incorporating

Amendment

1

Reverse Strain Mode Switch

Settings

B3887 NCW

2

3

4

5

6

7

8

9

10

iii

Preliminary Pages M10-94400-1

Amendment Incorporation Record

Amendment

Number

Brief Description of

Content

ECR

Numberr

Person

Incorporating

Amendment

11

12

13

14

15

Revision Record

Revision ECR No.

iv

Preliminary Pages

Materials testing systems are potentially hazardous.

Materials testing involves inherent hazards from high

forces, rapid motions and stored energy. You must be

aware of all moving and operating components which

are potentially hazardous, particularly the actuator in a

servohydraulic testing system or the moving crosshead

in an electromechanical testing system.

Whenever you consider that safety is compromised,

press the Emergency Stop button to stop the test and isolate the testing system from hydraulic or electrical

power.

Carefully read all relevant manuals and observe all

Warnings and Cautions. The term Warning is used

where a hazard may lead to injury or death. The term

Caution is used where a hazard may lead to damage to

equipmentortolossofdata.

Ensure that the test set-up and the actual test you will

be using on materials, assemblies or structures constitutes no hazard to yourself or others. Make full use of

all mechanical and electronic limits features. These are

supplied for your safety to enable you to prevent movement of the actuator piston or the moving crosshead beyond desired regions of operation.

The following pages detail various general warnings

that you must heed at all times while using materials

testing equipment. You will find more specific warnings and cautions in the t ext whenever a potential hazard exists.

Your best safety precautions are to gain a thorough understanding of the equipment by reading your instruction manuals and to always use good judgement.

v

Preliminary Pages M10-94400-1

Warning

Disconnect the electrical power supply before removing the covers to electrical equipment.

Disconnect the equipment from the electrical power supply before removing any electrical safety covers or replacing fuses. Do not reconnect the power source while

the covers are removed. Refit covers as soon as possible.

Disconnect power supplies before removing the covers to rotating machinery.

Disconnect the equipment from all power supplies before removing any cover which gives access to rotating

machinery. Do not reconnect any power supply while

the covers are removed unless you are specifically instructed to do so in the manual. If the equipment needs

to be operated to perform maintenance tasks with the

covers removed, ensure that all loose clothing, long hair,

etc. is tied back. Refit covers as soon as possible.

Shut down the hydraulic power supply and

discharge hydraulic pressure before disconnecting any hydraulic fluid coupling.

Do not disconnect any hydraulic coupling without first

shutting down the hydraulic power supply and discharging stored pressure to zero. Tie down or otherwise secure all pressurized hoses to prevent movement during

system operation and to prevent the hose from whipping

about in the event of a rupture.

vi

Warning

Do not release gas connections without first disconnecting the gas supply and discharging any residual pressure

to zero.

Use protective shields whenever a risk of injury to operators and observers exists from the failure of a test specimen, assembly or structure, particularly where explosive

disintegration may occur.Due to the wide range of specimen materials, assemblies or structures that may be tested,

any hazard resulting from the failure of a test specimen, assembly or structure is entirely the responsibility of the

owner and the user of the equipment.

Preliminary Pages

Shut off the supply of compressed gas and

discharge residual gas pressure before disconnecting any compressed gas coupling

Use protective shields or screens if any possibility exists of a hazard from the failure of

a specimen, assembly or structure under

test.

Protect electrical cables from damage and

inadvertent disconnection.

The sudden loss of controlling and feedback signals

which can result from a disconnected or damaged cable

causes an open loop condition which may drive the actuator or crosshead rapidly to its extremes of motion.

Protect all electrical cables, particularly transducer cables, from damage. Never route cables across the floor

without protection, nor suspend cables overhead under

excessive strain. Use padding to avoid chafing where cables are routed around corners or through wall openings.

vii

Preliminary Pages M10-94400-1

Warning

Wear protective clothing when handling

equipment at extremes of temperature.

Materials testing is often carried out at non-ambient temperatures using ovens, furnaces or cryogenic chambers.

Extreme temperature means an operating temperature exceeding 60 °C (140 °F) or below 0 °C (32 °F). You must

use protective clothing, such as gloves, when handling

equipment at these temperatures. Display a warning notice concerning low or high temperature operation whenever temperature control equipment is in use. You

should note that the hazard from extreme temperature

can extend beyond the immediate area of the test.

Take care when installing or removing a

specimen, assembly or structure.

Installation or removal of a specimen, assembly or structure involves working inside the hazard area between the

grips or fixtures. Keep clear of the jaws of a grip or fixture at all times. Keep clear of the hazard area between

the grips or fixtures during actuator or crosshead movement. Ensure that all actuator or crosshead movements

necessary for installation or removal are slow and,

where possible, at a low force setting.

viii

Warning

The actuator or crosshead will immediately respond to

manual control settings when the system is placed offline from computer control. Before transferring to manual control, make sure that the control settings are such

that unexpected actuator or crosshead movement cannot

occur.

The robot in an automated testing system presents a hazard because its movements are hard to predict. The robot

can go instantly from a waiting state to high speed operation in several axes of motion. During system operation ,

keep away from the operating envelope of the robot. Deactivate the robot before entering the envelope for any

purpose, such as reloading the specimen magazine.

Preliminary Pages

Do not place a testing system offline from

computer control without first ensuring that

no actuator or crosshead movement will occur upon transfer to manual control.

Keep clear of the operating envelope of a

robotic device unless the device is de-activated.

ix

Preliminary Pages M10-94400-1

Table of Contents

Chapter Page

1 Introduction

Outline .........................................................................1-1

Introduction..................................................................1-2

About this Manual...............................................1-3

Product Support..................................................1-3

General Characteristics...............................................1-4

Console Components..................................................1-7

Front Panel..................................................................1-8

Main Panel Section.............................................1-8

Display Panel Section.........................................1-10

Limits Panel Section ...........................................1-10

Crosshead Control Section.................................1-11

Internal Status Indicators ....................................1-12

Recorders ...........................................................1-12

Console Internal Functions..........................................1-14

Central Processing Unit (CPU) ...........................1-14

Crosshead Control Function ...............................1-14

Load Sensor Conditioner....................................1-14

Strain Sensor Conditioner...................................1-15

IEEE-488 Interface .............................................1-15

2 Specifications

Introduction..................................................................2-2

Specifications...............................................................2-3

3 Installation

Outline .........................................................................3-1

General Considerations...............................................3-2

x

Preliminary Pages

Table of Contents (continued)

Chapter Page

3 Installation

(continued)

Console Connections...................................................3-3

Mounting the Console.........................................3-3

Attaching the Console...................................3-3

Mounting the Console Bracket......................3-4

Connector Panel.................................................3-5

Installing Cables .................................................3-7

Cabling for Optional Equipment..........................3-9

Cables...........................................................3-9

Analog Output Connector .............................3-9

Opening the Console...................................................3-11

4 Function Of Controls

Outline .........................................................................4-1

Preliminary Considerations..........................................4-2

Function Of Controls....................................................4-3

Main Panel..........................................................4-3

Display Section...................................................4-12

Limits Section .....................................................4-14

Data Storage ...............................................................4-16

Nonvolatile Memory............................................4-16

System Reset .....................................................4-16

Volatile Memory ..................................................4-16

Resident Test Program Overview................................4-20

Self Test Routine .........................................................4-23

Self Test - Part 1 .................................................4-23

Self Test - Part 2 .................................................4-24

Self Test Result - No Failures .............................4-24

xi

Preliminary Pages M10-94400-1

Table of Contents (continued)

Chapter Page

4 Function Of Controls

(continued)

Self Test Result - Failures...................................4-25

Self Test Result Display......................................4-25

Version Number...........................................................4-31

Selecting Operating Units............................................4-32

Switching Units ...................................................4-32

Operating Units for Self Identified Load Cells

and Load Frames................................................4-33

Operating Units for Non-Self Identified Load

Cells and Load Frames.......................................4-34

Area...................................................................4-35

Energy Units .......................................................4-35

5 System Operation

Outline .........................................................................5-1

Operating Considerations............................................5-2

Pretest Procedures......................................................5-3

Turn Instrument On: Warm-up.....................................5-4

Self Test Routine At Power Up ....................................5-5

System Reset At Initial Power Up................................5-7

Load Calibration ..........................................................5-8

Overview ............................................................5-8

Electrical Calibration of Self Identifying

Load Cells ..........................................................5-9

Manual Calibration of Self Identifying

Load Cells ..........................................................5-10

Electrical Calibration of Non-Self Identifying

Load Cells...........................................................5-12

xii

Preliminary Pages

Table of Contents (continued)

Chapter Page

5 System Operation

(continued)

Manual Calibration of Non-Self Identifying

Load Cells..........................................................5-13

Load Weighing System Balance ........................5-15

Calibration And Balance Errors...........................5-16

Strain Calibration.........................................................5-18

Overview.............................................................5-18

Strain Operating Mode........................................5-18

Strain Gauge Extensometers..............................5-20

Electrical Calibration of Self Identifying Strain

Gauge Extensometers ......................................5-22

Manual Calibration of Strain Gauge

Extensometers...................................................5-22

Extensometers - Operating Notes.......................5-25

Display Panel...............................................................5-26

Description..........................................................5-26

Operation............................................................5-26

Establish Gauge Length ..............................................5-28

Electronic Limits...........................................................5-30

Operating Notes - Limits Panel...........................5-30

Operation............................................................5-31

Set Crosshead Travel Limit Stops...............................5-34

Set Crosshead Speed .................................................5-35

Crosshead Jog Control................................................5-37

Area Compensation.....................................................5-38

Install Specimen ..........................................................5-42

Set Testing Area ..........................................................5-43

Run a Test ...................................................................5-45

xiii

Preliminary Pages M10-94400-1

Table of Contents (continued)

Chapter Page

6 System Options

Overview......................................................................6-1

Introduction..................................................................6-2

Strip Chart Recorder....................................................6-3

Description..........................................................6-3

Specifications......................................................6-4

Power Requirements ....................................6-6

Installation...........................................................6-7

Operation............................................................6-8

Pen Scaling...................................................6-8

Pen Calibration .............................................6-9

X-Y Recorder...............................................................6-12

Description.........................................................6-12

Specifications......................................................6-13

Installation...........................................................6-15

Power Requirements ....................................6-15

Signal Input Connection................................6-15

Operation............................................................6-16

Initial Setup...................................................6-16

Calibration.....................................................6-19

Time Base Operation....................................6-22

Normal Operation..........................................6-23

Printer..........................................................................6-24

Description..........................................................6-24

Installation...........................................................6-24

Operation............................................................6-25

Printout Format...................................................6-25

Printer Units........................................................6-26

xiv

Preliminary Pages

Table of Contents (continued)

Chapter Page

6 System Options

(continued)

AC/DC Strain Conditioner............................................6-30

Specifications......................................................6-31

Installation...........................................................6-31

Operation............................................................6-32

Preset Points ...............................................................6-34

Description..........................................................6-34

Operation............................................................6-35

Energy .........................................................................6-37

Description..........................................................6-37

Operation............................................................6-37

Cycle Counter..............................................................6-39

Pip Control...................................................................6-41

Air Kit Option ...............................................................6-44

Overview.............................................................6-44

Description..........................................................6-44

Operation............................................................6-45

Manual Operation .........................................6-46

Grip Control Function Operation ...................6-47

Pretension and Excess Tension Operation...6-47

Automatic Start Operation.............................6-48

Automatic Release Operation .......................6-49

Set pretension Level .....................................6-49

Set Excess Tension Level .............................6-50

Time Delays ..................................................6-50

Continuous Pretension Testing.....................6-50

xv

Preliminary Pages M10-94400-1

Table of Contents (continued)

Chapter Page

7 Test Check List

8 Maintenance

Overview......................................................................8-1

Introduction..................................................................8-2

General...............................................................8-2

Special Maintenance Considerations..................8-2

Preventive Maintenance ..............................................8-3

Cleaning - Control Console.................................8-3

Error Messages ...........................................................8-4

Overview.............................................................8-4

Displaying Error Messages.................................8-4

Rear Panel Indicators ..................................................8-10

Rear Panel Indicators .........................................8-10

General.........................................................8-10

Power Supply Condition Indicators...............8-11

Green Test LEDs...........................................8-11

Red Activity LEDs .........................................8-12

Red Latch Indicator LEDs.............................8-13

IEEE-488 Interface Indicators.......................8-14

Summary of Operating Sequence for

Rear Panel Indicators ..................................8-15

Fault Indications ..........................................................8-16

Appendix A Test Planning

Applications .................................................................A-2

Load Requirements .....................................................A-4

Selection Of Grips........................................................A-5

xvi

Preliminary Pages

Table of Contents (continued)

Chapter Page

Appendix A Test Planning (continued)

Establishing Gauge Length..........................................A-7

Selection Of Testing Speed .........................................A-8

Strain Rate...................................................................A-9

Area Compensation.....................................................A-10

Description..........................................................A-10

Determining Stress Range..................................A-11

Limitations Due To Load Cell Capacity ...............A-12

Chart Magnification......................................................A-14

Appendix B Glossary

xvii

Preliminary Pages M10-94400-1

List of Illustrations

Figure Page

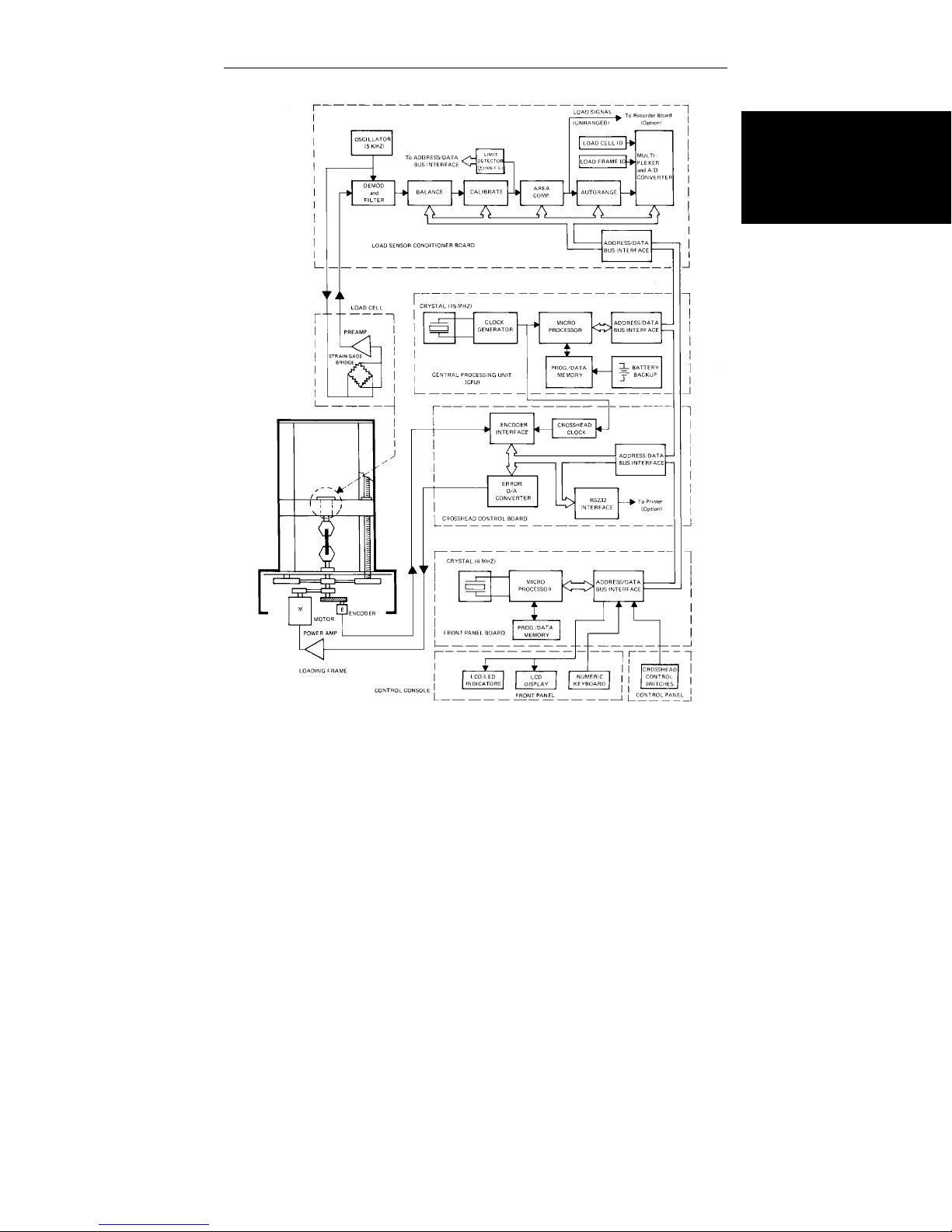

1-1. Functional Block Diagram............................................1-5

1-2. Control Console Front Panel ......................................1-9

3-1. Console Rear Panel Connectors .................................3-6

3-2. Rear Panel Cable Arrangement...................................3-8

3-3. Access to Interior of Console.......................................3-12

4-1. Main Panel...................................................................4-3

4-2. Display Section............................................................4-12

4-3. Limits Section ..............................................................4-14

4-4. Console Section Numbers Assigned to

Main Panel Display for Self Test Result......................4-26

4-5. Coding of Display Results for Self Test Result ............4-27

4-6. Characters Displayed in Self Test Result....................4-27

6-1 Model 4400 X-Y Recorder Panel.................................6-17

6-2. Typical Test Curve with Preset Points..........................6-34

8-1. Rear Panel Indicators .................................................8-12

8-2. Closeup Detail of Console Status and

Fault Indicators............................................................8-13

xviii

Preliminary Pages

List of Tables

TablePage

3-1. Series 4400 Console Option Cables............................3-9

3-2 Analog Output Connector Pin Assignments ................3-10

4-1. Main Panel Functions..................................................4-3

4-2. Display Section Functions ...........................................4-12

4-3. Limits Section Functions..............................................4-14

4-4. Variables and Functions in Nonvolatile

Memory........................................................................4-17

4-5. Control Console Sections ............................................4-26

4-6. Characters Possible in Self Test Result for

Each Digit of Main Panel Display.................................4-29

4-7. Operating Units for Self-Identified Load

Cells 4-33

5-1. Low Capacity Load Cells Calibration Data ..................5-13

5-2. Transducer Calibration/Balance Errors........................5-17

6-1. Strip Chart Recorder Supplies.....................................6-6

6-2. Recorder Line Voltage Selection .................................6-7

6-3. Calibration Signal for Load Cells .................................6-10

6-4. Recorder Supplies.......................................................6-14

6-5. Chart Speed Conversions............................................6-22

6-6. Strain Units Printout.....................................................6-26

6-7. Energy Units Printout...................................................6-27

6-8. Printout with Strain as Independent

Variable........................................................................6-28

6-9. Printout with Extension as Independent

Variable........................................................................6-28

xix

Preliminary Pages M10-94400-1

List of Tables (continued)

Table Page

6-10. Example Pip Delay Values vs Test Speeds.................6-43

6-11. Air Kit Functions ..........................................................6-46

8-1. Sections of the Control Console..................................8-5

8-2. Error Messages ...........................................................8-7

8-3. LED Error Codes for IEEE-488 Section Tests .............8-14

8-4. Fault Indications ..........................................................8-16

A-1. Gripping Techniques....................................................A-6

A-2. Typical Testing Speed Ranges for Various

Materials......................................................................A-8

xx

Preliminary Pages

xxi

Preliminary Pages M10-94400-1

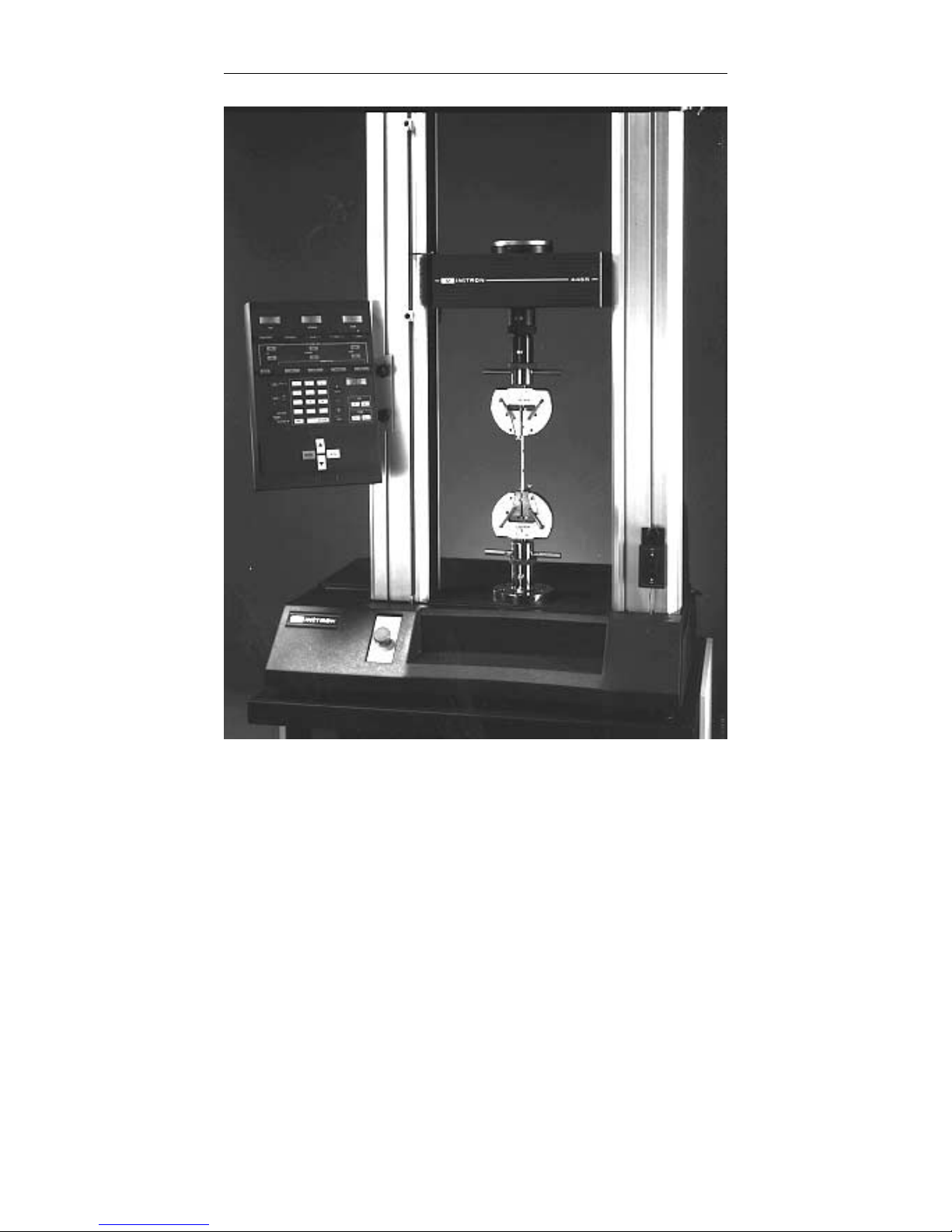

Frontispiece.Series 4400 Universal Testing System

xxii

Outline

Chapter 1

Introduction

Introduction

• Introduction ........................Page 1-2

• General Characteristics ...............Page 1-4

• Console Components .................Page 1-7

• Front Panel.........................Page 1-8

• Console Internal Functions ............Page 1-14

The Instron Series 4400 Universal Testing Instruments are

electromechanical systems employing the latest printed circuit board technology to provide a small, light and efficient

testing system. This manual describes the functions and operation of the Control Console. Other manuals include

Load Frame operating instructions for each of the Series

4400 systems and an IEEE Interface User’s Guide.

This chapter describes:

• The features and functions of the Series 4400

Systems

• The physical layout of the system

• Some of the optional accessories available for the

system

1-1

Introduction M10-94400-1

Introduction

The Instron Series 4400 Universal Testing Instrument is

a materials testing instrument designed to test the

strength of a wide variety of materials. The system is

made up of a load frame, in which a specimen of the

test material is mounted, that applies a tension or compression load to the specimen, and a control console that

provides the calibration, test setup, and test operating

controls. The control console is compact enough to

mount directly on the load frame, eliminating the need

for a separate support table or workbench.

The Series 4400 Control Console includes an operator’s

front panel with controls that offer complete communications with the system through a numeric keypad, pushbutton selection switches and Liquid Crystal Displays

(LCDs).

The Console front panel is divided into sections according

to functional groupings of controls. For example, a Main

section contains a numeric keypad and digital display for

data input, a Limits section sets up the electronic limits,

and a Display section contains LCD displays of real-time

values of test parameters. These panel sections are described more fully later in this chapter.

1-2

Optional interfacing is available for an X-Y or a strip chart

recorder, a printer, and a programmable computer. These

options may be specified with your initial order or added

later to expand the capabilities of your testing system.

About this Manual

The purpose of this manual is to provide a basic understanding of the Control Console and its principles of operation. It contains specifications, cable installation,

component and control descriptions, operating details

for both basic and optional features, and maintenance.

Appendices contain an introduction to materials testing

and a glossary of terms related to materials testing.

In addition to this manual, there is also a manual covering the installation, maintenance, and parts list for the

load frame. Accessories, such as the strip chart and X-Y

recorders, printer, and most grips and extensometers,

come with their own separate instruction manuals.

Product Support

If you encounter any problems with using or maintaining your testing instrument, or if you want to order accessories or parts, you can obtain answers to your

questions or place orders by calling Instron Service, using the list below:

Introduction

Introduction

In the United States: 1-800-473-7838

In Canada: 1-800-461-9123

In all other regions of the world: Nearest Instron

Service Office

A listing of international Instron Sales and Service offices, including addresses and telephone numbers, can

be found on the back cover of this manual.

1-3

General Characteristics M10-94400-1

General Characteristics

The Series 4400 control system is made up of two major

subsystems: a crosshead drive and control system, that

applies tensile or compressive loading to a specimen;

and a highly sensitive load weighing system, that measures the loading of a specimen. Figure 1-1 is a functional

block diagram showing the interfacing of these two systems, and the signal flow within the overall instrument.

During a test, results occur as tracked (instantaneous)

values of load, extension and strain or, after a test, as

stored break and peak values of these parameters. Total

energy and load and energy values at preset points are

also available as stored parameters. Several choices of

analog and digital output devices are available as options for viewing and recording test results.

The control console provides control, data acquisition

and data readout functions for the load frame. All operations are directed by a microprocessor-based central

processing unit (CPU). The crosshead control network

allows programmable crosshead speeds and provides

digital control of the crosshead position. The operating

mode of the console data entry and readout functions

can be in English, metric or SI units, as selected by a

switch. A status indicator on the main panel shows the

system of units selected.

1-4

The action of the moving crosshead during a test - stop,

return, or cycle - can be controlled manually by pushbutton switches, or automatically by the functions provided

by the Limits feature. These functions may be based on

the applied load, extension or strain, or to a detected

specimen break.

General Characteristics

Introduction

Figure 1-1. Functional Block Diagram

1-5

General Characteristics M10-94400-1

A CPU-controlled sensor conditioner in the load weighing system allows calibration and balance procedures to

be performed automatically, after you initiate them at

the front panel. The sensor conditioner provides both an

unranged analog and an automatically ranged digital

load signal output suitable for several types of optional

readout devices.

Optional readouts for test results include interfacing for

an X-Y recorder, a strip chart recorder, and an 80 character-width printer.

The console also has provisions for an IEEE-488 interface. This is a General Purpose Instrument Bus (GPIB)

which allows remote supervisory control of test procedures through a programmable computer.

1-6

Console Components

The Series 4400 Control Console contains a single

printed circuit board on which are mounted all of the

electrical components, including the front panel

switches and displays, and rear panel connectors.

The console printed circuit board is the interface for all

connections to the console. The interconnecting cables

from the load frame and load cell, and cabling from optional recorders, printers, and strain measuring devices

plug into connector locations on the rear of the board.

Since the console receives its electrical power from a

d.c. power supply in the load frame, there is no need for

bulky power supplies and cooling fans, and thus a compact size has been achieved.

The Console itself is mounted on the load frame by

means of a special bracket. A friction locking device on

the bracket rides in grooves in the crosshead column covers on the load frame, allowing the console to be moved

to any convenient working height. The bracket is symmetrical, allowing the console to be mounted on either

the right-hand or left-hand column on the frame.

Console Components

Introduction

The main components of the control console are shown

in Figure 1-2. Access to the interior of the console is described in Chapter 4.

1-7

Front Panel M10-94400-1

Front Panel

The Front Panel (Figure 1-2) is divided into four major

sections. The Main section contains a numeric keypad

for data entry of system setup parameters, an LCD display for the numeric input, pushbuttons for such functions as crosshead speed selection, and gauge length

setting, among others. The Display section contains

LCD displays of real-time values of Load, Extension,

and Strain, while the Limits section sets electronic limits

for the system. The last section is the Crosshead Control

section, in which manual controls for crosshead positioning are located.

Main Panel Section

The Main Panel section consists of test function entry

keys, a numeric keypad and a 4-digit LCD display.

Status indicators on the left-hand side of the panel, when

lit, signify that a fault has occurred. The current units

(S.I., English, metric) in use by the testing system are

also shown in this area. The panel provides the following functions:

• Load cell calibration

• Crosshead speed selection

• Gauge length

1-8

• Area compensation

• Testing area definition

• Strain transducer calibration

• Printer operation

• IEEE bus enable/disable

• Special Software - Diagnostics

Front Panel

Introduction

Figure 1-2. Control Console Front Panel

1-9

Front Panel M10-94400-1

Display Panel Section

The Display Panel section contains three 4-digit LCD

displays and control keys to allow load, extension, and

strain to be tracked during a test, and the peak and break

values of these parameters to be observed. All values are

computed and saved at the end of each test and may be

viewed as needed during and after the test. An indicator

lamp shows the active selection key.

Limits Panel Section

The Limits Panel section allows you to specify what action

the system takes whenmaximumand minimum values of

load, extension or strain occur during a test. The electronic

Limits function acts to protect valuable specimens, grips,

and test fixtures from the effects of crosshead overtravel

and possible collision.

You should always set limits and assign a crosshead action before starting a test. Enter limits values using the

keypad and view them on the Main Panel Display.

1-10

Descriptions of the Limits Panel control functions are

found in Table 4-3.

The Limits Panel section allows a crosshead action to be

specified that is independently based on the following

limit conditions during a test:

LOAD - minimum, maximum

EXTENSION - minimum, maximum

STRAIN - minimum, maximum

BREAK - detection

The action assigned to a limit can be:

STOP - stop crosshead at current position.

RETURN - return crosshead to gauge length.

CYCLE - change direction of crosshead motion at

the limit.

OFF - no action

An indicator lamp lights at the active limit and at the related crosshead action key. A STATUS indicator lamp is lit

whenever a limit is set to control a crosshead action. Whenever a STOP or RETURN action occurs as the result of a

limit, the related STATUS lamp flashes.

Crosshead Control Section

The crosshead control keys, located at the bottom of the

Front Panel are used for manually controlling crosshead

functions. The STOP, UP, DOWN and RETURN keys

each have an associated indicator lamp which is lit when

the function of the key, as described below, is controlling the crosshead.

Front Panel

Introduction

STOP - crosshead stops.

UP - crosshead moves up at programmed speed.

DOWN - crosshead moves down at programmed

speed.

RETURN - crosshead returns at a speed which increases exponentially to maximum and then decreases exponentially to stop crosshead at gauge

length.

1-11

Front Panel M10-94400-1

Internal Status Indicators

A series of Light Emitting Diode (LED) indicators are

mounted on the circuit board inside the console, but are

visible through a window cutout in the rear panel. These

indicators report the condition of power supply voltages,

the pass/fail condition of some CPU functions during the

Self-Diagnostic Test, and onthe activity of CPU circuits

during normal operation. Refer to Chapter 8, Maintenance, for a detailed description of the Status LEDs.

Recorders

You have a choice of using an X-Y recorder or a strip

chart recorder as a readout device. The X-Y recorder allows two test parameters, often Load versus Strain, to be

plotted against each other. A strip chart recorder, on the

other hand, plots one parameter versus time. Since crosshead speed can be converted directly into time, the

speed of the strip chart can be correlated with crosshead

speed and a plot of a test parameter, such as Load or

Strain, versus crosshead speed can be obtained.

1-12

Load and strain ranging are performed at the front panel

of the recorder itself. This allows you to select an operating range for each parameter from a predefined list of

gain factors. The operating range of the recorder is defined as the percentage of the maximum capacity of the

installed load cell that causes a full scale reading on the

recorder.

The specific recorders available for the Series 4400 Testing System are:

XY/YT Plotter Cat. No. 2310-901

Front Panel

Single Pen Strip Chart Recorder Cat. No. 2310-904

Double Pen Strip Chart Recorder Cat. No. 2310-905

Introduction

1-13

Console Internal Functions M10-94400-1

Console Internal Functions

In addition to the operator interface and cabling interface functions described previously, the console circuit

board provides a number of internal functions to complete the testing system. These functions include a Central Processing Unit (CPU), a Crosshead Control

function, a Load Sensor Conditioner, a Strain Sensor

Conditioner, and an IEEE-488 Interface function. These

functions are described in the following sections.

Central Processing Unit (CPU)

The CPU is a computer chip that provides the main processing functions for the console. A digital bus originating in this section allows communication with and

control of all other operations, including optional interfacing for peripheral devices. Battery backup in this section allows nonvolatile parameter storage.

Crosshead Control Function

This function provides the interfacing between the load

frame and console for the crosshead control signals. The

encoder output signal provides crosshead position (extension) information that is conditioned and the

crosshead position (extension) determined by the functions in this section. An error signal is developed when

the extension is compared with the commanded

crosshead speed and fed back to the crosshead drive system.

Load Sensor Conditioner

1-14

This function provides interfacing between the load

transducer (load cell) and the console. Functions that

this section supplies are excitation to a load cell, processing of its output signal, and providing calibrated analog

and digital load weighing information to the console and

readout devices.

Strain Sensor Conditioner

This function is located on an optional plug-in board and

is similar to the Load Sensor Conditioner. It provides interfacing between strain measuring extensometers and

the console, and is available as an AC Strain Conditioner (Catalog No. 2210-863). This conditioner is used

with strain gauge extensometers, rationalized long-travel

extensometers, and linear variable displacement

transducers (LVDTs). An AC/DC version (Catalog No.

2210-865) is used with video extensometers and high

resolution digital (HRD) automatic extensometers.

Console Internal Functions

Introduction

IEEE-488 Interface

This function allows a Series 4400 testing system to be

remotely controlled by an external personal computer

through a General Purpose Instrument Bus (GPIB). This

microprocessor-based pc board interacts directly with

the CPU, thus enabling a supervisory program to control

console and load frame functions. The external computer must be able to transfer program messages to and

receive measurement messages and status from the test

instrument. Complete programming information is supplied with the IEEE-488 interface option kit.

1-15

Console Internal Functions M10-94400-1

1-16

Chapter 2

Specifications

• Introduction ........................Page 2-2

• Specifications.......................Page 2-3

This chapter lists physical and electrical specifications

for the Series 4400 Control Console. Load Frame specifications and specifications for the system as a whole are

given in the load frame manual.

Specifications

2-1

Specifications M10-94400-1

Introduction

The following table lists physical and electrical specifications for the Series 4400 Control Console. Specifications for the Load Frame and its components are given

in the load frame manual.

Since system specifications depend, to a large extent, on

the system transducers (load cell, extensometers, etc.) in

use, and the load capacity of the load frame, it is not possible to list system specifications for all possible combinations of load frames and transducers.

The generalized specifications in this chapter will help

you to determine whether your system will meet your individual testing requirements. If you have any questions

about specifications, your regional Instron Sales Engineer will be happy to assist you.

2-2

Specifications

Components

Standard:

Options:

Power Requirements

+5 Vd.c.

+15 Vd.c.

-15 Vd.c.

(All voltages supplied from Load Frame, must be free of

spikes, surges, or sags exceeding 10% of the average

voltage)

Specifications

Main Panel

Display Panel

Limits Panel

Load Sensor Conditioner

RS-232 Interface

Strain Sensor Conditioner

IEEE-488 Interface

Strip Chart Recorder

X-Y Recorder

Printer

Specifications

Operating Performance

Load Weighing Accuracy

±0.01% of full scale or ±0.5% of reading (whichever is

greater) ±1 count on the load display.

Load weighing system meets or surpasses the following

standards: ASTM E4, BS1610, DIN 51221, ISO 7500/1,

EN10002-2, AFNOR AO3-501

2-3

Specifications M10-94400-1

Strain Measurement Accuracy

±0.05% of full scale or ±0.5% of reading (whichever is

greater) ±1 count on the strain display

Strain measurement system meets or surpasses the

following standards: ASTM E83, BS3846, ISO 9513,

EN1002-4

Environmental Requirements

Operating temperature:

+10 to +38 °C (+50 to +100°F)

(other ranges available on request)

Storage temperature:

-40 to +60 °C (-40 to +140°F)

Relative Humidity:

10% to 90% non-condensing

Atmosphere:

Use in normal laboratory conditions.

2-4

Note:

Protective measures may be required if excessive dust, corrosive fumes, electromagnetic

fields or hazardous conditions are present.

Materials

Enclosure: Structural foam

Keyboard: Cleanable mylar surface

with silicon rubber switches.

Dimensions

Height: 406.4 mm (16 in.)

Width: 280 mm (11 in.)

Depth: 58.2 mm (2.3 in.)

Weight 2.7 kg (6 lb) approx.

Specifications

Specifications

2-5

Specifications M10-94400-1

2-6

Outline

Chapter 3

Installation

• General Considerations ...............Page 3-2

• Console Connections .................Page 3-3

• Opening the Console .................Page 3-11

This chapter contains instructions for installing the Series 4400 Console on the load frame and for cabling optional accessories. Installation instructions for the load

frame itself are contained in the load frame instruction

manual.

You will use this chapter to find out how to:

• Connect system cables

• Mount the Console

• Open the console for servicing

Installation

3-1

General Considerations M10-94400-1

General Considerations

Installation of a basic Series 4400 testing instrument is

described in the load frame manual for the system. This

chapter describes how to access the interior of the console and install cabling for optional devices. The basic

cables, Load and Frame, are installed at the factory.

As part of the preparation for a testing routine, you

should connect any cabling required for peripheral readout and control accessories before powering up the system. These accessories include strain measuring devices,

a recorder, printer and a computer. Any panels or circuit

boards required to use these accessories have usually

been installed previously at the factory.

3-2

Console Connections

Mounting the Console

The Series 4400 Console is attached to a console mounting

bracket that is, in turn, mounted on one of the load frame

columns, either directly in grooves in the column cover (table models) or on an extension of the column cover (floor

models). On floor model load frames, the column cover extension can be mounted on either the right-hand or lefthand load frame column, specified at the time of purchase,

but this can be changed later, if necessary. The console is

attached to the mounting bracket with screws, and the

bracket can rotate around a vertical axis to provide a comfortable viewing angle for the console.

Console Connections

Attaching the Console

The console mounting bracket is in two parts; a sliding

bracket that attaches to the load frame, and a pivot

bracket that attaches to the Control Console. A 15° tilt

bracket is also provided so that the console can be tilted

back from vertical for more comfortable operation.

Attach the console to the pivot bracket first, then attach

the pivot bracket to the sliding bracket. The whole assembly is then mounted on the load frame. Use the following procedure to assemble all parts:

(a) Place the console against the pivot bracket, and align

the mounting holes. (If you wish to use the 15° tilt

bracket, attach it to the console before attaching the

console to the pivot bracket).

Installation

3-3

Console Connections M10-94400-1

(b) Insert a socket head cap screw in each of the four

mounting holes and hand tighten.

(c) With all screws in place, tighten the screws evenly

until all are secure.

(d) Attach the sliding bracket to the pivot bracket using

the pins provided.

(e) Lightly tighten the thumbscrews (these will be tight-

ened firmly when the console is mounted on the load

frame and a comfortable viewing position has been

selected).

Mounting the Console Bracket

To mount the console on the load frame column:

(a) Place the console bracket against the side of the col-

umn (or column extension) so that the T-nuts of the

friction devices are in the grooves of the load frame

column cover.

3-4

(b) Slide the bracket up or down in the groove to a con-

venient height for comfortable operation. Tighten

both friction knobs by hand, but avoid over-tightening.

(c) Loosen the rotational securing screws and rotate the

bracket to one of four positions for a comfortable

viewing angle. Tighten the thumbscrews firmly, but

do not over-tighten.

(d) Go to the next section to install cables.

Connector Panel

The connector panel for the Series 4400 Control Console (Figure 3-1) is located on the rear of the console

unit. The components on this panel are described below.

The load frame, load cell, strain channel and recorder cables connect directly to the console at connectors provided for the purpose. All of the connectors are standard

D-shell connectors.

Console Connections

TEST - Connector used by Instron Service personnel for testing the IEEE-488 interface. An IEEE-488

Service Test printed circuit board, which is available

only to service personnel, is required to run this test.

IEEE 488 - the connector for cabling from the IEEE

compatible digital interface to a programmable computer.

RS-232 OUT - a connector used mainly for output

to a printer with an RS-232 interface capability. Can

also be used for other RS-232 devices.

Installation

FRAME - a connector for cabling between the load

frame and the control console.

STRAIN - a connector for cabling from a strain

measuring extensometer.

ANALOG OUT - the parallel outputs of the signals

used for recorder operation, made available for signal monitoring purposes on devices such as a recorder.

LOAD - a connector for cabling from the load cell

transducer.

3-5

Console Connections M10-94400-1

3-6

Figure 3-1. Console Rear Panel Connectors

Installing Cables

For Series 4400 systems, cabling to the console includes

cables for load frame interface, a load cell, an extensometer, and a d.c. power cable. In addition, options

such as a recorder, a printer and a computer also connect

to the rear panel of the console, using the cables provided with these options.

To install cables:

(a) Match the individual cables with their proper connec-

tors on the rear panel of the console (see Figure 3-1).

Console Connections

POWER - the d.c. connector for control console

main power. The input voltage to the console is supplied from the load frame, where a d.c. power supply is located that provides d.c. power for the entire

system.

mm/IN/SI switch - a 3-position rocker switch for

setting the operating units (S.I., English, or metric)

of parameters in the load and extension channels.

Installation

(b) Press the cable connector into its mating connector

Caution

on the rear panel. Use a small screwdriver to insert

and tighten the cable connector screws. If you do not

do this, cables may fall off during a test.

Do not allow the cables to droop in

a haphazard manner from the rear

of the console.

3-7

Console Connections M10-94400-1

(c) When all cables have been connected, dress the cables

into the cable clips provided on the console mounting

bracket, as shown in Figure 3-2. This will ensure that

the cables will not catch on the load frame, grips, or

testing fixtures while the crosshead is moving.

Figure 3-2. Rear Panel Cable Arrangement

3-8

Cabling for Optional Equipment

Cables

For Series 4400 systems, a recorder, printer and computer connect directly to the rear panel of the console, using the cables provided with these options (see Table

3-1). The cables for load and strain measuring devices

plug into connectors on the devices themselves, as described in the system load frame manual. Thus, you usually will not have to open the console as part of the

installation procedure.

Table 3-1. Series 4400 Console Option Cables

Console Connections

OPTIONAL

ACCESSORY

CABLE ASSEMBLY

CONSOLE

CONNECTOR

X-Y Recorder A570-26 ANALOG OUT

Strip Chart

Recorder

Extensometers

(all types)

A570-26 ANALOG OUT

(Supplied with

Extensometer)

STRAIN

Printer (Supplied with Printer) RS-232

Computer 144-1-35 IEEE

Analog Output Connector

The Analog Output connector on the rear panel of the

console is used to connect to a chart recorder, a strip

chart recorder, or other data acquisition device. This connector is a 9-pin, miniature, female “D” connector, that

has the pin assignments shown in Table 3-2.

Installation

3-9

Console Connections M10-94400-1

Table 3-2. Analog Output Connector Pin Assignments

Pin Number Signal

Metal Shell Chassis Ground

1 Load

2 Strain

3 No Connection

4 Pip

5 Run

6 Analog Ground

7 Analog Ground

8 Digital Ground

9 No Connection

The pinout appears as follows, looking at the connector:

3-10

54321

9876

The Load and Strain output pin signals are ±10 volts,

relative to Analog Ground. +10 volts corresponds to tension full scale.

The PIP pin connection is an active low TTL signal relative to Digital Ground. The signal is driven by a contact

closure fed into the Pip Jack on the console.

The Run pin connection is an active high TTL signal

relative to Digital Ground. The signal goes high when a

test is running.

Opening the Console

Under normal conditions, it should not be necessary to

open the console. There are no user-serviceable components or adjustments inside the console case, but if it

should become necessary to check for loose internal connections or wiring, or to install an option board, you can

open the console as follows (also see Figure 3-3):

Warning

Do not remove covers from the console without first shutting off main

power and disconnecting the a.c.

power cable at the load frame.

(a) Disconnect all cables to the rear of the console. Label all

cables before removing them for identification, if necessary .

Opening the Console

Installation

(b) Remove the console from its mounting bracket by remov-

ing the three screws in the rear cover of the console.

(c) To open the console, remove six screws located on

the rear panel of the console.

(d) Place the console face down on a work surface. Lift

the rear cover off of the console.

(e) The main printed circuit board is attached to the back

of the front panel with six screws. The keys and pushbuttons are part of three rubber stampings sandwiched

between the printed circuit board and the front panel. If

you are replacing a key or pushbutton, you must replace the entire rubber sheet containing that key.

3-11

Opening the Console M10-94400-1

3-12

Figure 3-3. Access to Interior of Console

(f) Reassemble the console in reverse order of the steps

to disassemble. Be sure to replace all screws.

(g) Remount the console on its mounting bracket.

(h) Reinstall cabling removed in step (a). Be sure to

tighten all connector screws to prevent connectors

from falling loose during operation.

Outline

Chapter 4

Function Of Controls

• Preliminary Considerations ............Page 4-2

• Function of Controls .................Page 4-3

• Data Storage........................Page 4-16

• Resident Test Program Overview .......Page 4-20

• Self-Test Routine ....................Page 4-23

• Version Number.....................Page 4-31

• Selecting Operating Units .............Page 4-32

This chapter describes the function of front panel controls and how data resulting from a test is saved. It then

describes the Self-Test routine and how you can use it to

make sure your system is operating properly. The chapter then describes how to select and change system operating units.

Function of

Controls

4-1

Preliminary Considerations M10-94400-1

Preliminary Considerations

The purpose of this chapter is to provide details of the

operational features of the Series 4400 Control Console,

so the application of each device and its purpose in the

calibration and operation of the system will be understood.

The operational capabilities of a Series 4400 testing instrument depend upon the installed options and the peripheral readout and control devices that have been

selected to be used with the system. Complete installation instructions are supplied with any option ordered

later to expand a system.

This chapter contains the function of all controls and indicators on the main panel that supply the operator interface to the instrument. Also included are descriptions of

the system data storage capability and self-test feature.

4-2

Function Of Controls

Main Panel

Function Of Controls

Figure 4-1. Main Panel

Table 4-1. Main Panel Functions

CONTROL or

INDICATOR

Numeric Keypad (a)Numeric Keys, 0 through 9, allow entry of:

1. Value of calibration signal for manually calibra-

transducers.

2. Desired crosshead speed.

3. Area compensation value.

4. Maximum and minimum electronic limits for

load,extension, and strain.

5. Preset points.

FUNCTION

Function of

4-3

Controls

Function Of Controls M10-94400-1

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

Numeric Keypad

(continued)

Display A 4-digit display used to view system variables in the

AT G.L. Gauge length indicator LED is lit whenever crosshead is at

G.L. RESET Gaugelength resetkey, whenpressed, causes current

(b) +/- key defines the values of load, extension,

and strain as + for tension testing and - for compression testing. This key is also used when entering the electronic limits.

(c)REJect key allows the rejection of an incorrect

input on keypad before pressing ENTER key.

(d)ENTER key must be pressed to change any

system variable entered on keypad or to complete a transducer calibration or balance.

range from .0001 to .9999. “EEEE” is shown if an

overflow of the display register occurs. A “——” is shown

when the system is uncalibrated and no valid data can

be read. “LOSS” is shown if the non-volatile memory is

reset to a default state. All keypad entries (0-9, +/-) are

read on this display.

gauge length. Lamp flashes when power is initially turned

on, or a momentary power loss occurs to indicate a loss of

gauge length information. Pressing G.L..RESET key or

moving crosshead by pressing UP, DOWN, RETURN or

JOG stops the flashing.

crosshead position to be entered as the gauge length. Also,

any EXTENSION readout will be set to zero. Pressing this

key causes the AT G.L. LED to stop flashing.

FUNCTION

4-4

Function Of Controls

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

AREA

SET

≠ 1

TESTING AREA

BELOW XHEAD

ABOVE XHEAD

SPEED Allows a desired crosshead speed to be entered on the

LOAD CAL Initiates a load cell calibration procedure. The LOAD

Enables an area compensation circuit which divides both

displayed load value and output voltage to a recorder by

a set value between 1.000 and 9.999. When this key is

pressed, the SET LED lights and an area value can be

entered on the keypad.

After the ENTER key is pressed, if the value of area

compensation is other than 1.000, the ≠1 LED lights and

the SET LED stays on. Area compensation is

temporarily set to 1.000 during a load cell calibration

procedure. The default value of area compensation is

1.000.

Defines the location in the load frame (above/below

crosshead) to be used for specimen testing. This

function is necessary for the proper operation of cycling

limits and pneumatic grips. To change this function, the

S1 key must be enabled and “SL” must be on the Main

Panel Display (refer to SI KEY description). The BELOW

XHEAD or ABOVE XHEAD LED lights to indicate the

selection.

numeric keypad. If the load frame has not been

identified, the display will show “——” when this key is

pressed.

CAL key LED is lit during calibration or when a load

calibration relay is closed. A flashing LED indicates a

calibration error. A test cannot be started during a

calibration procedure, and calibration is locked out

during a test.

FUNCTION

Function of

Controls

4-5

Function Of Controls M10-94400-1

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

LOAD BAL Sets a load cell balance, or zero, during a calibration

procedure or when balancing out the tare of grips and

fixtures before starting a test. The LOAD BAL key LED is

lit during a balance operation or if a load calibration relay

is closed. A flashing LED indicates a calibration or

balance error. A test cannot be started during a balance

operation, and the balance function is locked out during

a test.

STRAIN CAL Initiates an extensometer calibration procedure. The

STRAIN CAL key LED is lit during calibration or when an

extensometer calibration relay is closed. A flashing LED

indicates a calibration error. A test cannot be started

during a calibration procedure, and calibration is locked

out during a test.

STRAIN BAL Sets an extensometer balance, or zero, during a

calibration procedure or when balancing out the tare of

grips and fixtures before starting a test. The STRAIN

BAL key LED is lit during a balance operation or if a load

calibration relay is closed. A flashing LED indicates a

calibration or balance error. A test cannot be started

during a balance operation, and the balance function is

locked out during a test.

METRIC

ENGLISH

SI

Status indicators that show the operating units for the

load and strain channels. The indicator that is lit shows

the current status of the units, as determined by the

positioning of a switch mounted on the rear connector

panel of the console. The selection of units determines

the scaling of displays and the input to a recorder. After

switching units, the Main Panel display will show

“LOSS”, indicating that nonvolatile memory is reset to

the default state and stored test data is lost. Load and

strain channels must be recalibrated and all electronic

limits reset.

FUNCTION

4-6

Function Of Controls

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

LOAD Fault indicator that lights when a load overrange (102%

or greater of load cell maximum capacity) occurs. The

crosshead stops and the indicator flashes until the

overload is cleared by pressing the UP or DOWN key or

a JOG key on the load frame, whichever direction

decreases the measured load.

TRAVEL Fault indicator that lights when the overtravel limits for

the moving crosshead are actuated. The crosshead is

stopped when this indicator is lit.

MOTOR Fault indicator that functions as described below. This

indicator is lit steadily for the following conditions:

1. Motor drive enabling sequence (5 sec. duration).

2. Motor drive cannot be enabled.

3. Load frame cannot be identified.

4. Load frame power supply failure.

5. Crosshead second level travel limit tripped.

6. Emergency stop switch tripped.

This indicator flashes for the following conditions:

1. Drive motor overheats.

2. Drive loop failure (stall, etc.)

The MOTOR status indicator will remain on (steady or

flashing) after the condition/fault is cleared, except after the

5-sec motor drive enable sequence. Perform the key

sequence [S1] [1] [ENTER] to restore the indicator to

standby (off) condition.

TIMER Fault indicator thatlights when the CPUmalfunctionsanda

special circuit shuts off the crosshead drive motor. Usually,

momentarily shutting down the system power clears this

condition. This LED also lights if the +/- 15 Vd.c. console

power supply fails.

FUNCTION

Function of

Controls

4-7

Function Of Controls M10-94400-1

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

POWER Faultindicator that lights if a momentary power failure

occurs. Momentarily shutting down system power clears

this condition.

PRINT Obtain a printout of the current test at any time, or a

printout of the last test when no test is running.

IEEE Status indicator that is lit when an IEEE-488 option is set

to receive keyboard commands from an external

computer.The indicator does not light if the IEEE option

is not installed.

S1 Enables or disables system options, as follows:

(a)System reset option - clearing of nonvolatile

memory. Press S1, then 0 and ENTER on keypad.

This sequence clears the nonvolatile memory,

setting all variables to a default state, and thereby resetting the system to a known condition.

Also, any previously stored data will be lost. The

Main Panel Display will show “LOSS” after this type

of reset key sequence is entered.

(b)System reset option - no clearing of nonvolatile

memory. Press S1, then 1 and ENTER on the keypad. This sequence is a“warm restart” of the

system which is used to to reset certain fault

conditions, without resetting nonvolatile memory to

the default state; that is, all previously entered

parameters will remain in storage. An exception is

when this sequence is used to enable a change in

system operating units.

FUNCTION

4-8

Function Of Controls

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

S1 (c) Diagnostic Monitor - Press S1, then 2 and ENTER

on keypad. This sequence initiates the diagnostic

troubleshooting routine which is part of the Resident Test Program for the Series 4400 console

(refer to Resident Test Program for details and

exiting procedure).

Note

The Diagnostic Monitor feature should be used by

qualified maintenance personnel only.

(d) Energy option - press S1, then 3 and + /- on the

keypad. With an optional printer installed, this sequence provides an energy printout after a test.

The Main Panel Display must show “SL 3" for this

option to be enabled, and”SL-3" to be disabled,

which is the default condition. The key sequence

[S1] [3] [ +/- ]...[ +/- ] toggles between these two

conditions. (See Item (g) below for the selection

of the Energy Integration Variable.)

(e)Preset Point option - press S1, then 4 and +/-. This

sequence provides a printout of load and energy

at three preset points (PPT1, PPT2, PPT3) versus an

independent variable after a test. These values

can be used to determine modulus of elasticity.

(See Item (f) below for the selection of independent variable.) The Main Panel Display must show

“SL 4" for this option to be enabled and ”SL-4" to be

disabled, which is the default condition. The key

sequence [S1] [4] [ / ]...[ / ] toggles between

these two states.

FUNCTION

Function of

Controls

4-9

Function Of Controls M10-94400-1

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

S1

(continued)

FUNCTION

(f) Set Preset Point Values - if the values of the Preset

Points (PPT1, PPT2) are to be other than the default values as shown in Table 4-5, then the following key sequences are used to enter new values

(where PPT1 and PPT2 are indicated, enter the

actual numerical value on the keypad of the

independent variable: Extension in inches or millimeters, or strain in percent):

[S1] [41] PPT1 [ENTER]

[S1] [42] PPT2 [ENTER]

[S1} [43] PPT3 [ENTER]

(g)Select Energy Integration Variable and Preset

Points Independent Variable - the key sequence

[S1] [5] [ / ]...[ / ] toggles the selection of energy

and preset points variable between Extension

and Strain (that is, the active strain channel). The

Main Panel Display will show “SL 5" for Extension

and ”SL-5" for Strain. The default variable is Strain,

if this option is installed. If Strain is not installed,

then Extension is the default variable.

(h)Autoprint option - press S1, then 6 and + /- on

keypad. With an optional printer installed, this

sequence provides an automatic printout each

time a test ends. The Main Panel Display must

show “SL 6" for this option to be enabled, and

”SL-6" to be disabled (continued) which is the

default condition. The key sequence [S1] [6]

[+/- ]...[+/-] toggles between these two conditions.

4-10

(i) TESTING AREA enable - press S1, “SL” will show on

the Main Panel Display and the TESTING AREA

function can be changed.

Function Of Controls

Table 4-1. Main Panel Functions (continued)

CONTROL or

INDICATOR

S1

(continued)

UP

DOWN

STOP

RETURN

FUNCTION

(j) Air Kit Option – provides automatic grip control

for pneumatic grips. The key sequence [S1][7][+/–]

enables or diables grip control, and the Main Panel

Display shows “SL 7 when enabled and ”SL–7"

when disabled. The key sequence [S1][7][n][+/–],

where “n” is a number between 1 and 4, or

[S1][7][v], where “v” is a value entered at the keypad, enables or disables various options under

automatic grip control and sets values for Pretension or Excess Tension Levels (see Chapter 6 for

details).

(k) Miscellaneous

[S1] [8] [+/–] Cycle Counter Printout

[S1] [8] [1] Cycle Limit

[S1] [8] [2] Enter Pip Delay Value

[S1] [8] [3] Display Cycles/Pip

(l) Firmware Date - [S1] [9] [ENTER] displays the date of

the firmware installed on this system.

(m) Cycle Count Display - [S1] [+/–] displays the cy-

cle or pip count in the setup display.

The pushbutton switches (keys) used for manually

controlling the crosshead. Each key has an LED that is

lit when the function of the key is active.

STOP - crosshead stops.

UP - crosshead moves up at programmed speed.

DOWN - crosshead moves down at programmed

speed.

RETURN - crosshead returns at a speed that

increases exponentially to maximum and then

decreases exponentially to stop the crosshead at

gauge length.

Function of

Controls

4-11

Function Of Controls M10-94400-1

Display Section

Figure 4-2. Display Section

Table 4-2. Display Section Functions

4-12

CONTROL or

INDICATOR

LOAD

DISPLAY

EXTENSION

DISPLAY

STRAIN

DISPLAY

TRACK Sets the displays to show instantaneous values of load,

A 4-digit display which indicates + and - values of load

between .0001 and 9999. The display shows “——” when

the load cell is uncalibrated; is blank without data; and

shows “EEEE” when overranged.

A 4-digit display which indicates + and - extension values

between .0001 and 9999 from gauge length. The display

shows “——” if the load frame has not been identified,

and is blank if no data is available.

A 4-digit display which indicates strain values between

.0001 and 9999. The display shows “——” if the strain

channel is not calibrated, “EEEE” if it is overranged, and

is blank if strain is not installed or no data is available.

extension and strain. The displays are updated every 300

msec during a test. The TRACK LED is lit when this key

is active. (Peak and break values are recorded even

though tracking is active.)

FUNCTION

Function Of Controls

Table 4-2. Display Section Functions (continued)

PEAK Sets the displays to show load, extension and strain

values that occur at the peak load during a test. These

values are held on the display at the end of a test. When

a test begins, the displays show current tracking values

until a “peak” load is reached. The PEAK LED is lit when

this key is active.

BREAK Sets the displays to show load, extension and strain at

specimen break, where break is defined as just prior to

break detection. When a test begins, the displays are

blank and remain blank until the break criteria is met. The

BREAK LED is lit when this key is active.

PEAK

BREAK

RESET PEAKS This key is used during a test to reset the stored peak

Sets the LOAD display to show the peak load value for a

test and the EXTENSION and STRAIN displays to show

values that occur at specimen break. The LED at this key

is lit when the key is active.

values of load, extension, and strain to the values at the

current load. The peak storage is then continuously

updated to the values at the next peak load that occurs

during the remainder of the test. This key does not

change which values are selected to be displayed

(Break, Peak, or Track) and it is functional only when a

test is in progress.

Function of

Controls

4-13

Function Of Controls M10-94400-1

Limits Section

Figure 4-3. Limits Section

Table 4-3. Limits Section Functions

4-14

CONTROL or

INDICATOR

LOAD MAX/MIN

EXTENSION MAX/

MIN

STRAIN MAX/MIN

BREAK

OFF

STOP

RETURN

CYCLE

FUNCTION

Electronic limits which permit an action to be

independently assigned to the maximum and minimum

values of load, extension or strain, or to detect break. An

LED to the left of each key lights when the key is

pressed. This shows that the key has enabled the

numeric keypad and a limit value can be entered and

viewed on the display (except BREAK, as this has an

unknown numeric value). If the Recorder is installed, the

STRAIN limits are functional only if STRAIN is selected

for the X-axis of the X-Y recorder.

Crosshead actions that can be selected to occur at the

electronic limits. The actions are:

OFF - no action

STOP - stop crosshead when limit occurs

RETURN - return crosshead to gauge length

CYCLE - change crosshead travel direction

Whenever a limit key LED is lit, a CROSSHEAD ACTION

key LED is lit also. To change the action, press a different

key.

Function Of Controls

Table 4-3. Limits Section Functions (continued)

STATUS

LEDs

A rectangular STATUS LED is located to the right of the

BREAK key and one each between the LOAD,

EXTENSION, and STRAIN MAX/MIN limit keys. When a