Page 1

M20-52630-1

Issue C January 1997

Instron

2630-100 Series Clip-On

Extensometers

Operator’s Guide

Page 2

PROPRIETARY RIGHTS NOTICE

This document and the information that it contains are

the property of Instron Corporation. Rights to

duplicate or otherwise copy this document and rights

to disclose the document and the information that it

contains to others and the right to use the information

contained therein may be acquired only by written

permission signed by a duly authorised officer of

Instron Corporation.

© Copyright 1997 Instron Corporation

Page 3

Preliminary Pages

Amendment Incorporation Record

AMENDMENT

NUMBER

1

2

3

4

5

6

7

8

BRIEF DESCRIPTION OF

CONTENT

Additional information

covering Phase 2 and

Phase 3 extensometers

Wire clip information

amended. Issue raised to

C, ECR35152

NAME OF

PERSON

INCORPORATING

AMENDMENT

Siân Oakes

Siân Oakes

9

10

iii M20-52630-1

Page 4

Preliminary Pages

Amendment Incorporation Record

AMENDMENT

NUMBER

11

12

13

14

15

16

17

18

BRIEF DESCRIPTION OF

CONTENT

NAME OF

PERSON

INCORPORATING

AMENDMENT

19

20

iv

Page 5

Preliminary Pages

GENERAL SAFETY PRECAUTIONS

Materials testing systems are potentially

hazardous!

Materials testing involves inherent hazards

from high forces, rapid motions and stored

energy. Youmust be aware of all moving and

operating components which are potentially

hazardous, particularly the actuator in a

servohydraulic testing system or the moving

crosshead in an electromechanical testing

system.

Always be aware of the possible hazards

involvedwhen operating and maintaining these

systems. You must not operate any materials

testing equipment unless you are thoroughly

familiar with its functions and operation.

Unfamiliarity with a materials testing system

can lead to unexpected actuator or crosshead

motion with the consequent risk of injury and

damage.

Carefully read all relevant manuals and observe

all WARNINGS and CAUTIONS. The term

WARNING is used where a hazard may lead to

injury or death. The term CAUTION is used

where a hazard may lead to damage to

equipment or to loss of data.

Ensure that the test set-up to be followed and

the actual test to be performed on materials,

assemblies or structures constitutes no hazard

to operating personnel.

Make full use of all mechanical and electronic

limits features. These are supplied for your

v M20-52630-1

Page 6

Preliminary Pages

safety to enable you to prevent movement of

the actuator piston / moving crosshead beyond

the desired regions of operation.

The following pages detail various general

warnings that you must heed at all times while

using materials testing equipment. More

specific warnings and cautions will be found in

the text whenever your attention needs to be

drawn to a potential hazard.

Your best safety precautions are to gain a

thorough understanding of the equipment by

reading your instruction manuals and to always

use good judgement.

WARNING

DISCONNECT THE ELECTRICAL

POWER SUPPLY BEFORE

REMOVING THE COVERS OF

ELECTRICAL EQUIPMENT

You must disconnect the equipment from the

electrical power supply before removing any

electrical safety covers or replacing fuses. Do

not reconnect the main power source while the

covers are removed unless you are specifically

instructed to do so in the manual. Refit covers

as soon as possible.

DISCONNECT POWER SUPPLIES

BEFORE REMOVING THE COVERS

OF ROTATING MACHINERY.

You must disconnect the equipment from all

power supplies before removing any cover

vi

Page 7

Preliminary Pages

which gives access to rotating machinery, e.g.

belts, screws or shafts. Do not reconnect any

power supply while the covers are removed

unless you are specifically instructed to do so

in the manual. If the equipment needs to be

operated to perform maintenance tasks with the

covers removed, ensure that all loose clothing,

long hair, etc. is tied back. Refit covers as soon

as possible.

WARNING

SHUT DOWN THE HYDRAULIC

POWER SUPPLY AND DISCHARGE

HYDRAULIC PRESSURE BEFORE

DISCONNECTION OF ANY

HYDRAULIC FLUID COUPLING.

Do not disconnect any hydraulic coupling

without first shutting down the hydraulic power

supply and discharging stored pressure to zero.

Tie down or otherwise secure all pressurised

hoses to prevent movement during system

operation and to prevent the hose from

whipping about in the event of a rupture.

SHUT OFF THE SUPPLY OF

COMPRESSED GAS AND

DISCHARGE RESIDUAL GAS

PRESSURE BEFORE

DISCONNECTION OF ANY

COMPRESSED GAS COUPLING.

vii M20-52630-1

Page 8

Preliminary Pages

Do not release gas connections without first

disconnecting the gas supply and discharging

any residual pressure to zero.

WARNING

USE PROTECTIVE SHIELDS OR

SCREENS IF ANY POSSIBILITY OF

A HAZARD EXISTS FROM THE

FAILURE OF A SPECIMEN,

ASSEMBLY OR STRUCTURE UNDER

TEST.

Protective shields should be used whenever a

risk of injury to operators and observers exists

from the failure of a test specimen, assembly or

structure, particularly where explosive

disintegration may occur. Due tothe wide

range of specimen materials, assemblies or

structures that may be tested using materials

testing equipment, any hazard resulting from

the failure of a test specimen, assembly or

structure is entirely the responsibility of the

owner and user of the equipment.

PROTECT ELECTRICAL CABLES

FROM DAMAGE AND

INADVERTENT DISCONNECTION.

The sudden loss of controlling and feedback

signals which can result from a disconnected or

damaged cable causes an open loop condition

which may drive the actuator of crosshead

rapidly to its extremes of motion. All electrical

cables, particularly transducer cables, must be

viii

Page 9

Preliminary Pages

protected from damage. Never route cables

across the floor without protection, nor suspend

cables overhead under excessive strain. Use

paddings to avoid chafing where cables are

routed around corners or through wall openings.

WARNING

WEAR PROTECTIVE CLOTHING

WHEN HANDLING EQUIPMENT AT

EXTREMES OF TEMPERATURE.

Materials testing is often carried out at

non-ambient temperatures using ovens,

furnaces or cryogenic chambers. Extreme

temperature means an operating temperature

exceeding +60 °C (140 °F) or below 0 °C

(32 °F). Youmust use protectiveclothing, such

as gloves, when handling equipment at these

temperatures. A warning notice concerning low

or high temperature operation must be

displayed whenever temperature control

equipment is in use. You should note that the

hazard from extreme temperature can extend

beyond the immediate area of the test.

TAKE CARE WHEN INSTALLING OR

REMOVING A SPECIMEN,

ASSEMBLY OR STRUCTURE.

Installation or removal of a specimen, assembly

of structure involves working inside the hazard

area between the grips or fixtures. Keep clear

of the jaws of a grip or fixture at all times.

Keep clear of the hazard area between the grips

or fixtures during actuator or crosshead

ix M20-52630-1

Page 10

Preliminary Pages

movement. Ensure that all actuator or

crosshead movements necessary for installation

or removal are slow and, where possible, at a

low force setting.

WARNING

BEFORE THE EXTENSOMETER IS

USED IN STRAIN CONTROL,

CHECK THE FOLLOWING:

1. Ensure that the extensometer

is securely attached to the

specimen.

2. Ensure that the extensometer

is calibrated.

3. Set the Load, Position and

Strain limits.

4. Ensure that the testing

machine loop-shaping

parameters are set correctly.

BEFORE REMOVING THE

EXTENSOMETER FROM THE

SPECIMEN AT ANY TIME, ENSURE

THAT THE MACHINE IS NOT IN

STRAIN CONTROL!

x

Page 11

Preliminary Pages

xi M20-52630-1

Page 12

Preliminary Pages

Table Of Contents

Chapter Page

INTRODUCTION 1-1

GENERAL 1-1

BASIC FEATURES 1-2

EQUIPMENT SUPPLIED 1-4

OPTIONAL ACCESSORIES& SPARES 1-4

SPECIFICATION 2-1

ENVIRONMENTAL 2-1

OPERATION 3-1

GAUGE LENGTH SETTING 3-1

SPECIMEN ATTACHMENT 3-3

Wire Clip 3-3

Variable Pressure Specimen

Clamp 3-5

Elastic Bands or O-Rings 3-7

Fitting to the Specimen using

Both Hands 3-8

Fitting to the Specimen using

One Hand 3-9

CABLE CLEAT AND EXTENSOMETER

HOLDER 3-10

xi M20-52630-1

Page 13

Preliminary Pages

KNIFE EDGE CHANGING 3-12

Specimen Centering Stops 3-13

IMPORTANT SAFETY NOTE 3-14

CALIBRATION 3-15

Automatic Electrical

Calibration 3-15

Manual Electrical

Calibration 3-16

Manual Mechanical

Calibration 3-18

VERIFICATION 3-19

APPENDIX A

CLIP SIZES A-1

CLIPS FOR ROUND SPECIMENS A-2

CLIPS FOR RECTANGULAR

SPECIMENS A-4

Notes A-6

xii

Page 14

Preliminary Pages

LIST OF ILLUSTRATIONS

Figure Page

1-1. Case Layout 1-5

3-1. Gauge Length Setting with the

cone-latch released 3-1

3-2. Gauge Length Setting with the

cone-latch engaged

(gauge length set) 3-2

3-3. Insertion of Clips 3-4

3-4. Wire clips in use 3-4

3-5. Specimen attachment using the

optional Specimen Clamps

and Pivot Knife Edges 3-6

3-6. Specimen attachment using

elastic bands 3-7

3-7. Two-handed Installation 3-8

3-8. Single-handed Installation 3-9

3-9. Extensometer suspended from

cleat post — T-slot machines 3-10

3-10. Extensometer suspended from

cleat post — steel covered

machines 3-11

3-11. Knife Edge Replacement 3-12

xiii M20-52630-1

Page 15

Preliminary Pages

3-12. Specimen Stops 3-13

3-13. Extensometer mounted on an

optional calibration fixture

(Cat. No. 2602-017) 3-17

List of Tables

Table Page

1. Extensometer Gauge Lengths

and Travel 2-1

2. General Specification 2-3

3. Machine Compatibility 2-5

4. Extensometer Physical

Compatibility with 3119 Series

Temperature Chambers 2-8

xiv

Page 16

GENERAL

The 2630-100 series extensometers convert

the mechanical displacement of a strained

test specimen into an electrical signal. When

used with the current range of Instron

testing machines, each extensometer is

automatically recognised, and is able to be

calibrated at the touch of a button.

The displacement is transmitted by a light

rigid frame to strain gauges bonded to a

flexural element. The gauges are arranged in

a fully active four-arm Wheatstone Bridge

circuit.

The 2630-100 series of extensometers

includes different gauge lengths/strain range

options to suit a wide range of specimen

characteristics.

Robust construction provides accuracy and

reliability.As with all measuring

instruments, rough handling, contamination

with dirt and moisture effect calibration and

shorten the life of the instrument.

INTRODUCTION

INTRODUCTION

The extensometer is supplied in a

foam-lined presentation case, dimensions

350 mm (13.8 in.) long, 260 mm (10.2 in.)

wide and 85 mm (3.3 in.) deep. The

shipping weight is 0.9 kg (2 lbs).

When not in use, the extensometer should

be stored in the presentation case.

1-1 M20-52630-1

Page 17

INTRODUCTION

BASIC FEATURES

• Ergonomic, lightweight,

cross-braced design with overload

protection.

• Easy attachment and release from

the specimen facilitate

single-handed operation.

• Simple, cone latch gauge-length

setting method with automatic

disengagement.

• Precise, fixed gauge-lengths with

automatic recognition and

calibration capability.

• Available in metric and U.S.

Customary versions to meet

ISO 9513 and ASTM E83

standards of accuracy.

• Low operating-force arms with

single-bevel, interchangeable knife

edges.

• Suitable for a wide range of

specimen materials, geometry and

size with a choice of attachment

methods.

• Combined cable cleat and

extensometer holder with

provision for retaining cord

attachment to the extensometer.

• High impact plastic storage case

with a contour moulded insert,

securely retains the extensometer

1-2

Page 18

INTRODUCTION

and accessory parts together with

its Calibration Certificate and

comprehensive operating manual.

1-3 M20-52630-1

Page 19

INTRODUCTION

EQUIPMENT SUPPLIED

Refer to Figure 1-1.

1 Extensometer

2 Cable cleat and extensometer holder

3 Allen key

4 11 pairs of wire clips

5 Specimen centering stops

6 Operator’s guide

7 Calibration certificate

8 Foam lined presentation case

OPTIONAL ACCESSORIES &

SPARES

1 Variable pressure specimen clamps: see page 3-5.

2 Replacement knife edges, one pair, straight

profile. All purpose use on round and rectangular

cross section specimens. Cat No. 2601-077.

3 Replacement knife edges, one pair. Three point

contact for flat specimens that are not truly flat.

Cat No. 2601-078.

4 Replacement knife edges one pair. Radiused edge

for flat specimens that are not truly flat.

Cat No. 2601-079.

5 Digital Readout Extensometer Calibrator for manual

span setting. Cat No. 2602-017.

7 Wire clips (see Appendix A).

8 O-Rings, internal diameter 11 mm unstretched.

(Instron Part No. T1351-1034).

1-4

Page 20

INTRODUCTION

CASE

EXTENSOMETER

OPERATOR’S GUIDE

CABLE CLEAT AND

EXTENSOMETER HOLDER

ALLEN

KEY

SPECIMEN

STOPS

CLIPS FOR ROUND

CLIPS FOR RECTANGULAR

SPECIMENS

SPECIMENS

Figure 1-1. Case Layout

1-5 M20-52630-1

Page 21

SPECIFICATION

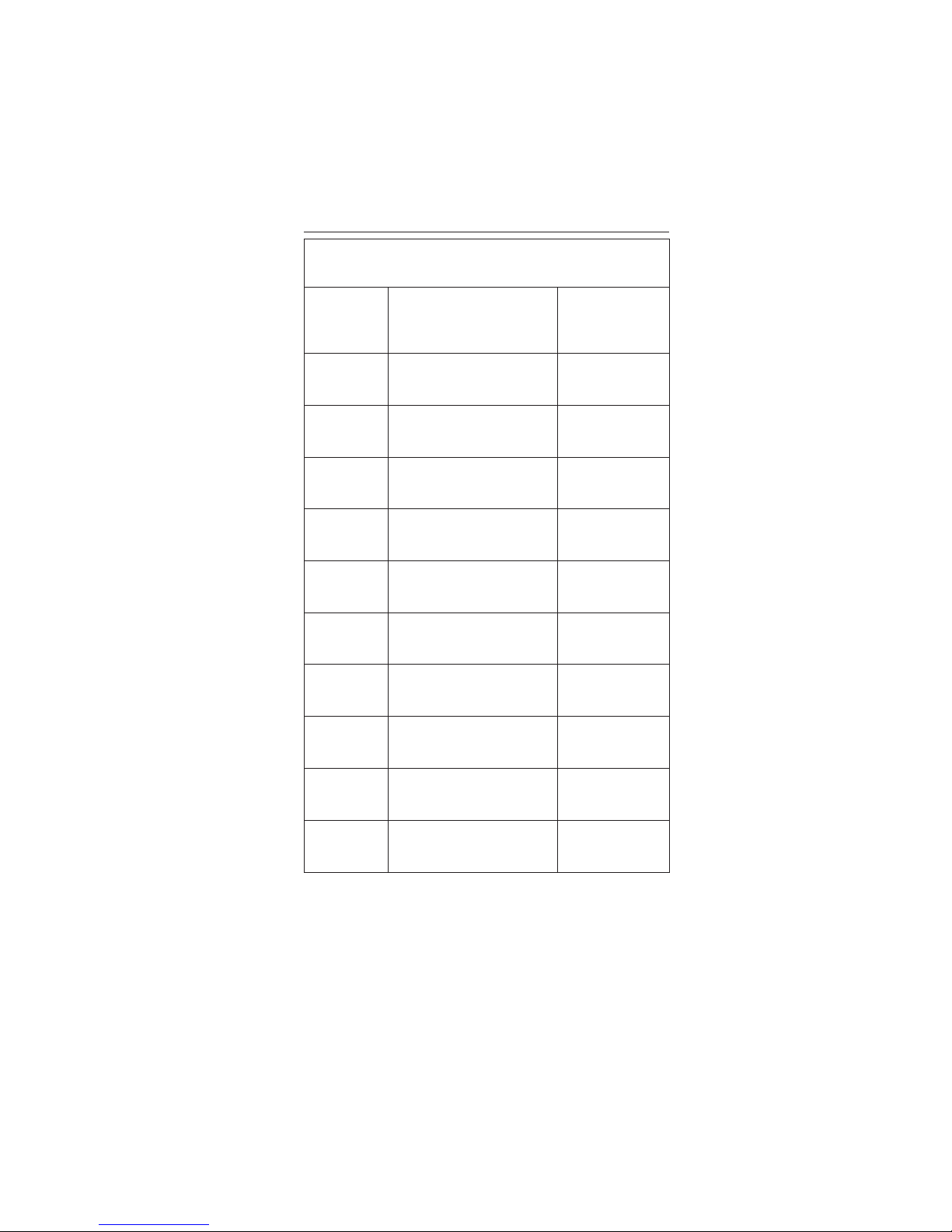

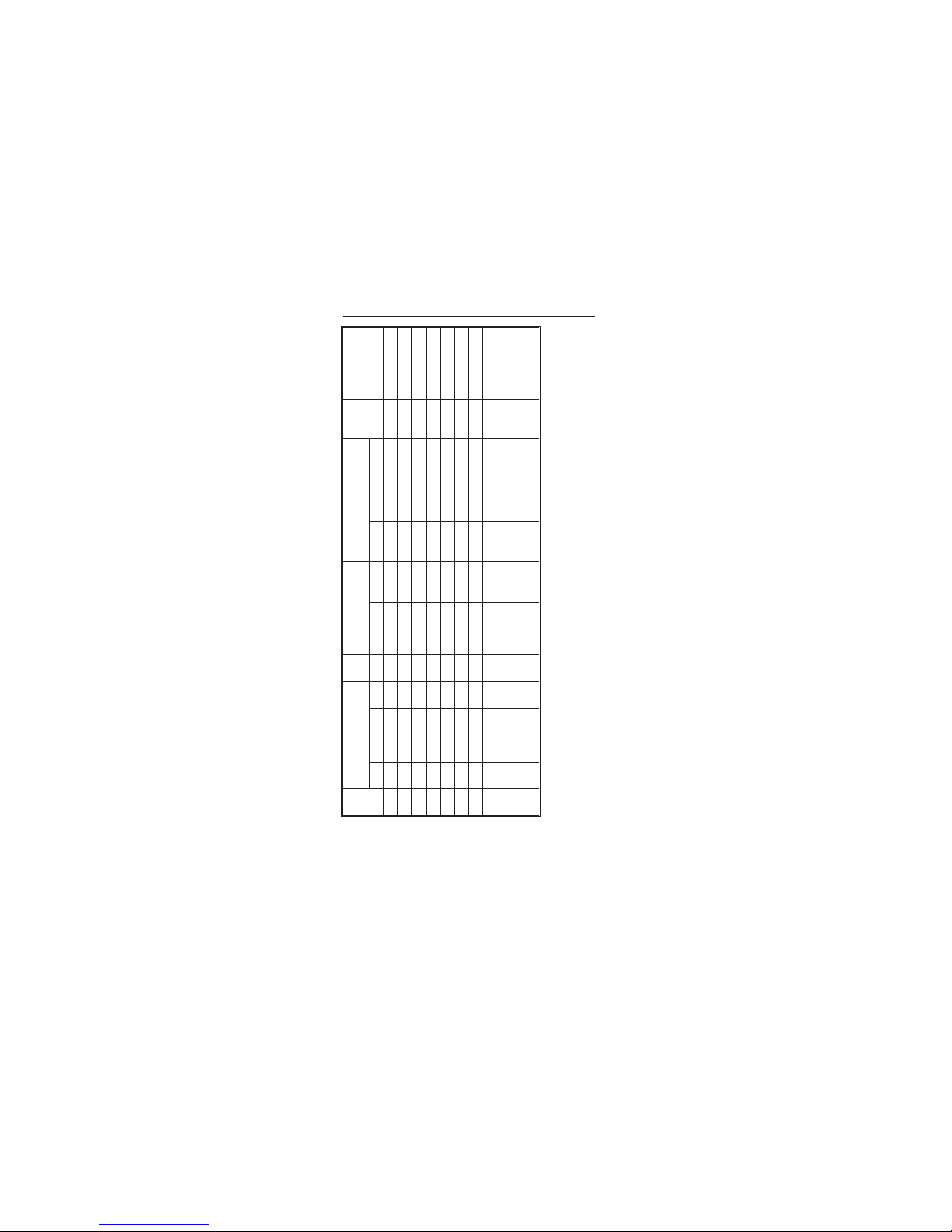

Table 1. Extensometer Gauge Lengths and Travel

SPECIFICATION

G.L

Strain % Travel mm (in.)

mm

(in.)

+ve -ve +ve -ve 2630- Class 0.5(B-2) Class 1 (C) Length Width Height

8 50 50 4 4 120 0, +50 30, +50 67 (2.64) 39 (1.5) 25 (1) 20(0.04) 27 (0.06) Dual

2-1

(0.3) 50 50 (0.15) (0.15) 121 0, +50 30, +50 67 (2.64) 39 (1.5) 25 (1) 20 (0.04) 27 (0.06) Dual

10 10 10 1 1 101 -10,+10 67 (2.6) 39 (1.5) 25 (1) 160 (0.35) 27 (0.06) Single

10 50 50 5 5 102 0, +50 30, +50 67 (2.64) 39 (1.5) 25 (1) 20 (0.04) 27 (0.06) Single

(0.5) 10 10 (0.05) (0.05) 103 -10, +10 67 (2.64) 39 (1.5) 25 (1) 170 (0.37) 27 (0.06) Single

(0.5) 50 50 (0.25) (0.25) 104 0, +50 30, +50 67 (2.64) 39 (1.5) 25 (1) 20 (0.4) 27 (0.06) Single

25 10 10 2.5 2.5 105 -10, +10 100 (4) 39 (1.5) 52 (2) 55 (0.12) 56 (0.12) Single

25 50 10 12.5 2.5 106 0, +50 115(4.5) 39 (1.5) 58 (2.3) 75 (0.17) 58 (0.13) Single

25 100 10 25 2.5 107 0, +70 0, +100 132 (5.2) 39 (1.5) 69 (2.7) 45(0.1) 60 (0.13) Single

(1) 10 10 (0.1) (0.1) 108 -10, +10 100 (4) 39 (1.5) 52 (2) 56 (0.12) 56 (0.12) Single

Cat.

*Class I SO9513 (ASTME83)

No.

Strain%

Overall Dimensions

mm (in.)

Operating

Force

g (lbs)

+Weight

g (lbs)

Code

Type

Page 22

G.L

mm

(in.)

Strain % Travel mm (in.)

Cat.

No.

*Class ISO 9513 (ASTM E83)

Strain%

Overall Dimensions

mm (in.)

Operating

Force

g (lbs)

+Weight

g (lbs)

Code

Type

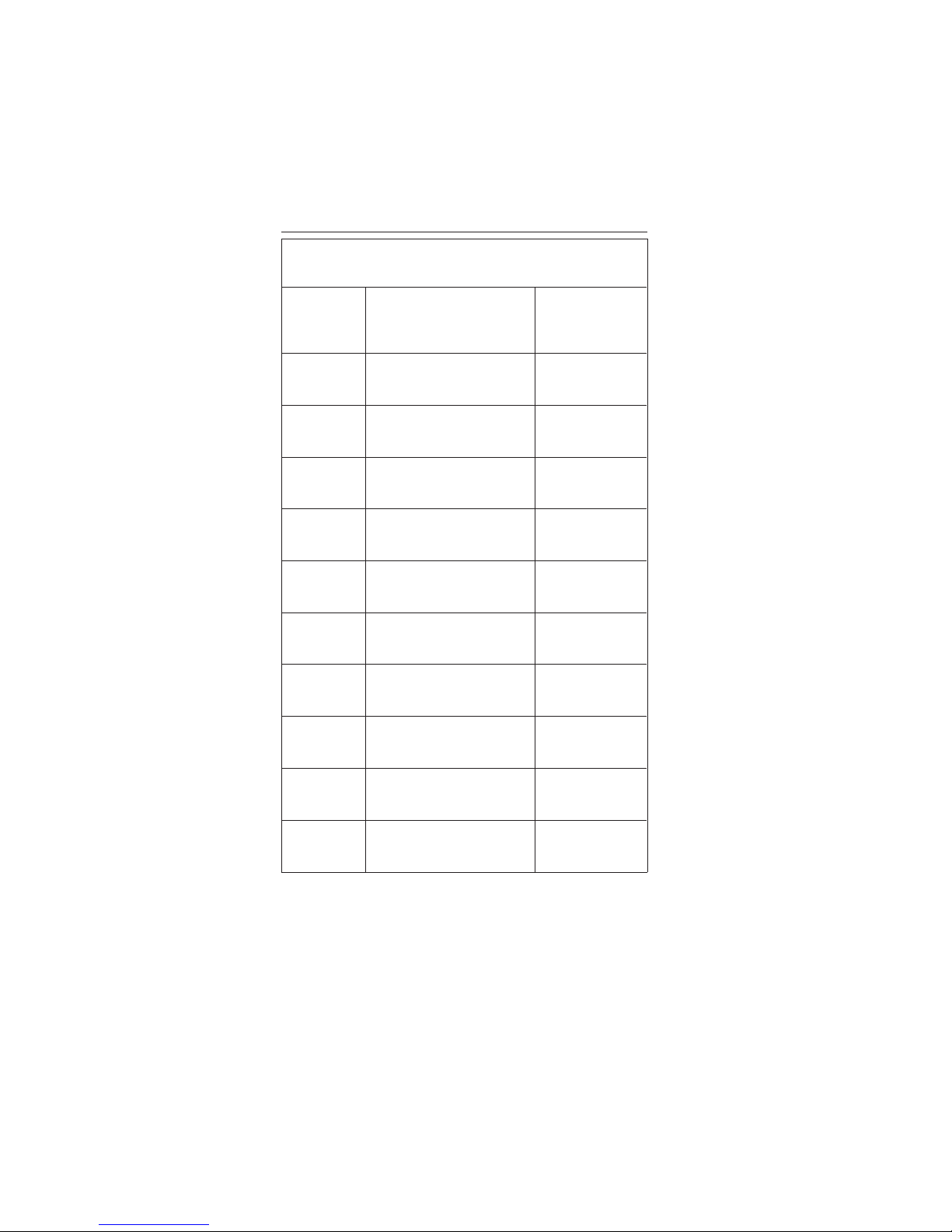

+ve -ve +ve -ve 2630- Class 0.5 (B-2) Class 1 (C) Length Width Height

(1) 50 10 (0.5) (0.1) 109 0, +50 115 (4.5) 39 (1.5) 58 (2.3) 75 (0.17) 58 (0.13) Single

(1) 100 10 (1) (0.1) 110 0, +70 0, +100 132 (5.2) 39 (1.5) 69 (2.7) 45 (0.1) 60 (0.13) Single

50 10 10 5 5 111 -10, +10 100 (4) 39(1.5) 72 (2.8) 45 (0.1) 60 (0.13) Single

50 50 5 25 2.5 112 0, +35 0, +50 132 (3.2) 39 (1.5) 72 (2.8) 45 (0.1) 60 (0.13) Single

50 100 10 50 5 113 0, +70 0, +100 181 (7.1) 39 (1.5) 72 (2.8) 37(0.08) 70 (0.15) Dual

(2) 10 10 (0.2) (0.2) 114 -10, +10 100 (4) 39 (1.5) 72 (2.8) 45 (0.1) 60 (0.13) Single

(2) 50 5 (1) (0.1) 115 0, +35 0,+50 132 (5.2) 39 (1.5) 72 (2.8) 45 (0.1) 60 (0.13) Single

(2) 100 10 (2) (0.2) 116 0, +70 0, +100 181 (7.1) 39 (1.5) 72 (2.8) 37 (0.08) 70 (0.15) Dual

80 10 1 8 0.8 117 0, +10 116 (4.6) 39 (1.5) 101(4) 60 (0.13) 60 (0.13) Dual

80 50 5 40 4 118 0, +35 0, +50 181 (7.1) 39 (1.5) 101(4) 45(0.1) 70 (0.15) Dual

100 50 5 50 5 119 0, +35 0, +50 181 (7.1) 39 (1.5) 121 (4.8) 37 (0.08) 70 (0.15) Dual

*:

+

:

When calibrated using appropriate calibration apparatus these extensometers are guaran-

teed to meet the stated classification. Outside these stated ranges the extensometers in

compressive mode generally perform to ISO 1.0 or ASTM C classification.

Weightexcludes cable and connector.

2-2 M20-52630-1

SPECIFICATION

Page 23

Table 2. General Specification

SPECIFICATION

Creep (3 mins - 5 secs)

Repeatability <0.1 % of FS

Hysteresis <0.3 % of FS

Balance

Excitation 1 to 5 Vrms, d.c. to 5 kHz

2-3

Sensitivity (full scale) 2.5 +1 % -3 % mV/V

Overtravel limit Mechanical stops

Electrical calibration accuracy

Bridge resistance (nominal) 350

Gauge length accuracy

Temperature range -100 to +200 °C

Temperature effect on zero

<± 0.15

<± 2.5

± 0.06

± 0.5

± 0.01

% of FS

% of FS

% of FS

Ω

% of GL

% /°C

Page 24

Effect of Temperature on

sensitivity

-0.006, 20 to 100 °C (typical)

-0.008, 100 to 150 °C (typical)

-0.01, 150 to 200 °C (typical)

% /°C

Method of attachment to

Specimen

11 types of wire clips.

Elastic bands (not supplied).

Optional specimen clamps (refer to page 3-5).

Immersibility

Non-conductive / non-corrosive fluids, i.e.

acetone, mineral and silicone oils, alcohol, etc.

Gauge length setting Cone latch with automatic release

Round specimen sizes <15, (0.6 in.) and 20 (0.8 in.) mm

Rectangular specimen sizes

Width <40 (1.6 in.)

Thickness <15, (0.6 in.)

mm

Knife edge gripping force

300 to 600 (0.66 to 1.32 lbs), subject to the correct

selection of clips

grams

Maximum width of specimen

with specimen stops fitted

18 mm (0.71 in.)

NOTE FS — Full Scale. All values relate to a temperature of 22 °C unless otherwise stated.

2-4 M20-52630-1

SPECIFICATION

Page 25

Table 3. Machine Compatibility

The extensometer connector plugs contain codes which are used by the testing machine to define gauge length, travel

and calibration points. The extensometers are fitted with either a single code or dual codes, as shown in Tabl e1.

SPECIFICATION

Machine Series

Automatic

Electrical Calibration

Manual Electrical

Calibration

Manual

Mechanical

Calibration

Comments

Via user-defined

2-5

8000 All Not available All

transducer setup

using first code

only.

8500 prior to V21 Single code only Single code only Single code only

8500 V21

8500 Plus All All All

All except 2630-119,

120, 121

All except 2630-119,

120, 121

All except 2630-119,

120, 121

Versions may be

identified via the

front panel or

MDC board label.

Page 26

Machine Series

Automatic

Electrical Calibration

Manual Electrical

Calibration

Manual

Mechanical

Calibration

Comments

6000 All Not available All

Via user-defined

transducer setup

using first code

only.

4500 prior to

V2.25MS04

Single code only All All

Versionmay be

identified via the

Master board

label.

4500 post V2.25MS04

All except 2630-120,

121

All All

4500 Post V2.25MS05

or later

All All All

4200/4300 CPU card

with PROMs prior to

A474-717, 718, 719, 720

Single code only

All All

Check CPU card.

4200/4300 CPU card

with PROMs

A474-717, 718, 719, 720

All except 2630-120,

121

All All

2-6 M20-52630-1

SPECIFICATION

Page 27

Machine Series

Automatic

Electrical Calibration

Manual Electrical

Calibration

Manual

Mechanical

Calibration

Comments

4200/4300 CPU card

with PROMS A474-736,

737, 738, 739 or later

All All All

Check CPU card.

2180/2160 Not available All All

1100 No All All

4400

All except

2630-120,121

All All

4400 PROM A474-740

or later

All All All

5500 Pre-Dec 93

All except 2630-120,

121

All All

5500 Post-Dec 93 All All All

2-7

SPECIFICATION

Page 28

SPECIFICATION

ENVIRONMENTAL

The extensometer’s simple and easy

attachment method make it ideal for use

in a temperature chamber.

The extensometer’s temperature

capability is stated in Table 2.

High relative humidity may alter

calibration and it is advisable to confirm

the calibration using a suitable

calibration fixture at the test condition.

CAUTION:

Contamination by

condensation, electrically

conducting fluids, dirt or

corrosive substances may

damage the extensometer.

Table 4.

Extensometer Physical Compatibility with

3119 Series TemperatureChambers

Chamber

Cat. No.

3119-005 All except 2630-113, 116, 118 and 119

3119-006 All except 2630-113, 116, 118 and 119

3119-007 All

3119-008 All

3119-009 All except 2630-113, 116, 118 and 119

Suitable Extensometers

2-8 M20-52630-1

Page 29

OPERATION

OPERATION

GAUGE LENGTH SETTING

Before strain can be accurately measured

the extensometer arms must be spaced to

set the knife edges at gauge length. The

extensometer features an integral cone

latch arm locating system.

To set gauge length press the two round

buttons with index finger and thumb of

either left or right hand. Ensure the cone

locates in the cone-seat. The extensometer

knife edges are now held at the correct

gauge length. The extensometer is ready

for attaching to a test specimen (refer to

Figures 3-1 and 3-2).

CONE PIN

CONE SEAT

Figure 3-1. Gauge Length Setting

with the cone-latch released

3-1

Page 30

OPERATION

Verification of gauge length may be

confirmed by engaging the gauge length

cone latch and checking the distance

between the knife edges using either

callipers or a slip gauge.

Figure 3-2. Gauge Length Setting

with the cone-latch engaged

(gauge length set)

3-2 M20-52630-1

Page 31

OPERATION

SPECIMEN ATTACHMENT

For accurate results, effective attachment

of the extensometer to the specimen is

essential. Test results may be altered if the

knife edges press too firmly into the

specimen. A sign of excessive knife edge

pressure is breaking of the specimen at the

knife edge point of contact. At the other

extreme, with low knife edge pressure,

slippage may occur. This can be identified

from a stress v strain graph by a rapid

change in strain for a small change in

stress. If a test is to involve strains greater

than 10%, a higher clamping force may be

required.

A number of different attachment

methods are available offering the

flexibility to suit a wide range of testing

conditions. Care during attachment should

avoid any difficulties and permit the

optimum knife edge pressure to be

achieved.

Knife edges should be replaced if blunt,

as described on page 3-12.

Wire Clip

Clips are available in two profiles to

accommodate round and rectangular

specimens. It is important for good results

to select the clip that best suits the

specimen. Appendix A gives full size

scale diagrams of the available clips with

information on the optimum working

range for each clip. The clips mount into

the extensometer arms from either side,

3-3

Page 32

OPERATION

using the technique shown in Figure

3-3. Figure 3-4 shows the wire clip in

operation holding the extensometer to a

typical specimen.

Once the wire clip is selected and a test

specimen is correctly installed in the

testing machine grips the extensometer

can be attached.

Figure 3-3. Insertion of Clips

Figure 3-4. Wire clips in use

3-4 M20-52630-1

Page 33

OPERATION

Variable Pressure Specimen Clamp

If preferred, the instrument may be

changed to use variable pressure specimen

clamps as supplied on earlier 2630 series

instruments. This requires optional notch

pivot knife edges to permit the use of

specimen clamps.

Specimen clamps are an optional extra

and can be ordered from Instron using the

following Catalogue Numbers:

Cat No. 2601-081, specimen clamp and

knife edges — Small, minimum gauge

length 10 mm. Accommodates round

specimens 1 to 9 mm in diameter or flat

specimens to 9 mm wide and 1 to 10 mm

thick.

Cat No. 2601-082, specimen clamp and

knife edges — Medium, minimum gauge

length 25 mm. Accommodates round

specimens 1 to 15 mm in diameter in diameter or flat specimens to 14 mm wide

and 1 to 18 mm thick.

Cat No. 2601-083, specimen clamp and

knife edges — Large, minimum gauge

length 25 mm. Accommodates round

specimens 1 to 10 mm in diameter or flat

specimens to 25 mm wide and 1 to 10 mm

thick.

To fit the Extensometer to the Specimen

Hold the extensometer with the Gauge

Length cone-latch engaged and position

the knife edges against the test specimen.

Holding a specimen clamp, straddle the

3-5

Page 34

OPERATION

specimen above the knife edges of the

extensometer. Press the clamp against

the specimen to compress the spring

loaded plunger and hook the specimen

clamp on the knife edges. Ensure that

the knife edge seats properly in the

specimen clamp notch pivot. Repeat the

same operation on the lower specimen

clamp.

When testing round specimens, align the

“V” groove of the spring-loaded plunger

before straddling the specimen.

Note that the notch pivot slots in the

specimen clamp should always point

away from the gauge length, as shown

below.

NOTCH PIVOT

NOTCH PIVOT SLOTS

POINTING OUTWARDS FROM

THE GAUGE LENGTH

VARIABLE PRESSURE

SPECIMEN CLAMP

PRESSURE ADJUSTER RING

Figure 3-5. Specimen attachment

using the optional Specimen Clamps

and Pivot Knife Edges

3-6 M20-52630-1

Page 35

OPERATION

Elastic Bands or O-Rings

Hooks for elastic bands or O-rings are an

integral part of the knife edges, although

elastic bands and O-rings are not supplied

with the extensometer. Refer to page 1-4

for O-ring details.

Hold the extensometer with the gauge

length cone latch engaged and position

the knife edges on the test specimen.

Stretch good quality elastic bands or

O-rings around the specimen and loop the

ends over the two knife edge hooks, as

shown in Figure 3-6.

Figure 3-6. Specimen attachment

using elastic bands

3-7

Page 36

OPERATION

Fitting to the Specimen using Both

Hands

When testing soft or delicate materials,

two-handed installation reduces the

possibility of marking the specimen.

Hold the extensometer with either hand

and engage the gauge length cone-latch.

Using the other hand open the wire clips

to clear the specimen, as shown in

Figure 3-7. Position the extensometer in

line with the specimen and gradually

release the clips. Once the extensometer

is attached to the specimen the gauge

length cone-latch can be released. If the

extensometer is not held firmly onto the

specimen select a smaller clip.

PRESS TO SET

GAUGE LENGTH

CLIP PRONG

Figure 3-7. Two-handed Installation

3-8 M20-52630-1

Page 37

OPERATION

Fitting to the Specimen using One Hand

Single handed installation is useful for

working in temperature cabinets where

access is limited.

Hold the extensometer with either hand

and engage the gauge length cone-latch.

Hook the wire clip prongs behind the

specimen as shown in Figure 3-8. Pull the

extensometer to open the wire clips to

clear the specimen. Slide the clip against

the specimen bringing the extensometer in

line with the specimen and gradually

release the clips so the knife edges gently

touch the specimen. Do not slide the knife

edge against the specimen as the

specimen may be marked or the knife

edge blunted. Once the extensometer is

attached to the specimen, release the

gauge length cone-latch. If the

extensometer is not held firmly onto the

specimen select a smaller clip.

PRESS TO SET

GAUGE LENGTH

Figure 3-8. Single-handed Installation

CLIP PRONG

3-9

Page 38

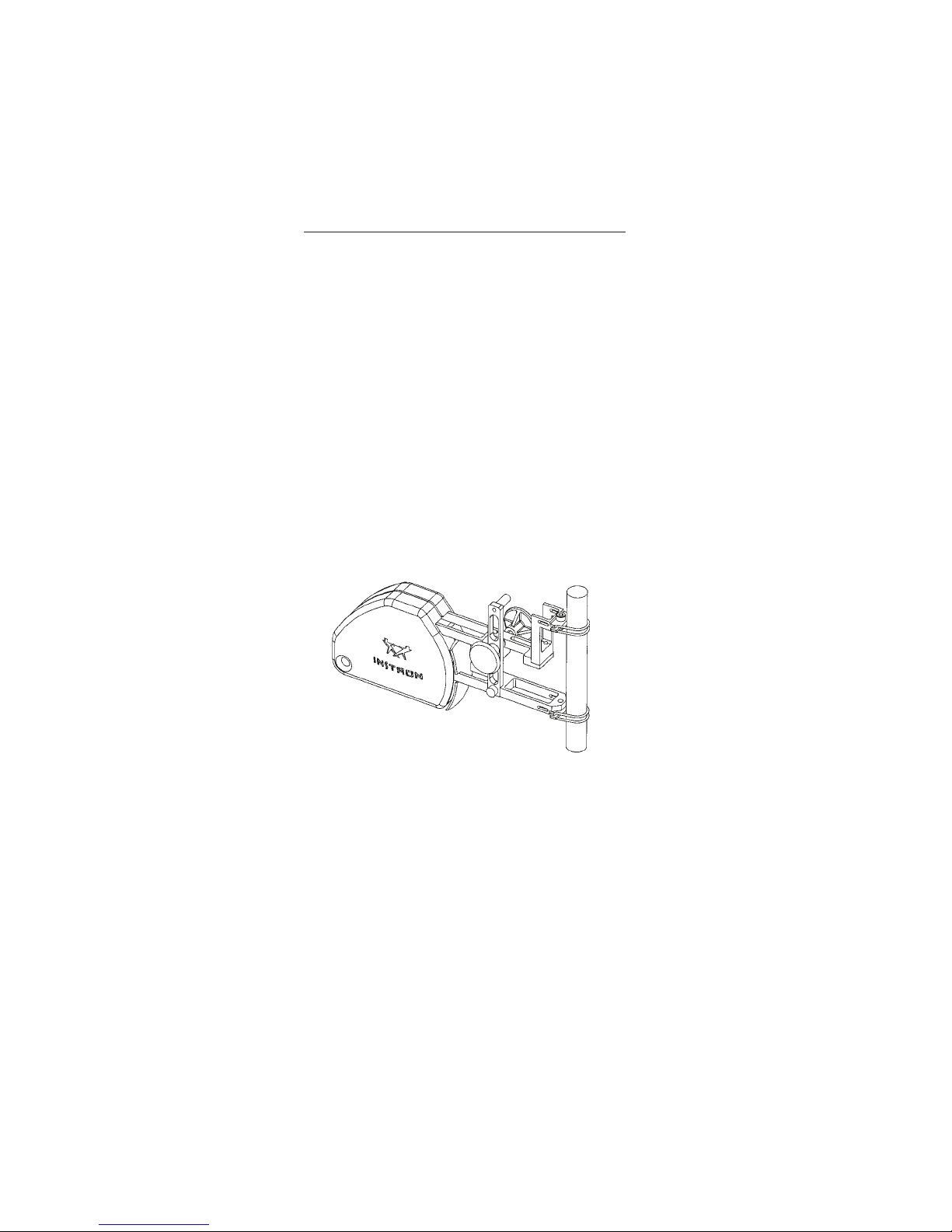

CABLE CLEAT AND

EXTENSOMETER HOLDER

A combined cable cleat and

extensometer holder is provided, and is

shown in Figures 3-9 and 3-10.

The magnetic base of the cleat can be

attached to steel parts of the testing

machine e.g. the column covers. For “T”

slot machines with aluminium column

covers the special keeper assembly will

slide into the “T” slot and then the cleat

will attach to the keeper.

The slot in the base of the cleat is used

to support the extensometer cable. The

cleat should be positioned to reduce the

effects of cable tension on the

extensometer.

OPERATION

KEEPER NUT

SLIDE INTO

T-SLOT

Figure 3-9. Extensometer suspended

from cleat post — T-slot machines

3-10 M20-52630-1

Page 39

OPERATION

ATTACH TO

STEEL

SURFACE

SLOT FOR

CABLE

Figure 3-10. Extensometer suspended

from cleat post — steel covered

machines

When the extensometer is not in use but is

still required to be connected to the testing

machine, it may be secured to a cleat post

using the hole provided in the

extensometer cover.

Ensure the cleat is returned to the

presentation case, with the magnet

attached to the keeper plate when not in

use.

3-11

Page 40

KNIFE EDGE CHANGING

Refer to Figure 3-11 below. Loosen the

socket head cap screw using the

supplied allen key.

Position replacement knife edge with

the bevel side of the knife edge furthest

from the cut-out in the extensometer

arms. Secure with socket head cap

screw ensuring alignment faces of the

knife edge and extensometer touch.

SOCKET HEAD CAP

SCREW

ALIGNMENT FACES

OPERATION

KNIFE EDGE

BEVELLED

EDGE

Figure 3-11. Knife Edge Replacement

3-12 M20-52630-1

Page 41

OPERATION

SPECIMEN CENTERING STOPS

Precise alignment of the extensometer is

necessary to ensure the correct

measurement of strain in a specimen and

to enable rapid, precise attachment to the

specimen. To achieve this a pair of

optional stops are supplied to assist with

aligning the extensometer relative to the

specimen. Graduations are marked on the

surface of the stops to allow equal setting.

The installation of a specimen stop is

shown below in Figure 3-12.

SOCKET HEAD

CAP SCREW

EXTENSOMETER

ARM

SPECIMEN STOP

Figure 3-12. Specimen Stops

3-13

Page 42

OPERATION

IMPORTANT SAFETY NOTE

WARNING

BEFORE THE EXTENSOMETER

IS USED IN STRAIN

CONTROL, CHECK THE

FOLLOWING:

1. Ensure that the

extensometer is securely

attached to the specimen.

2. Ensure that the

extensometer is calibrated.

3. Set the Load, Position

and Strain limits.

4. Ensure that the testing

machine loop-shaping

parameters are set

correctly.

BEFORE REMOVING THE

EXTENSOMETER FROM THE

SPECIMEN AT ANY TIME,

ENSURE THAT THE MACHINE

IS NOT IN STRAIN CONTROL.

3-14 M20-52630-1

Page 43

OPERATION

CALIBRATION

The extensometer and machine

conditioning electronics must be

calibrated before use. Three parameters

must be defined: full scale, calibration

point and gauge length.

Three methods of calibration are possible:

Automatic Electrical Calibration

This is the normal method of calibration

for current Instron testing machines. The

extensometer is self-identifying via its

code resistors. These are interrogated by

the testing machine which has the

calibration parameters stored within its

memory. If the extensometer is to be used

on an older Instron machine check

compatibility with automatic calibration,

refer to page 2-5.

To operate the automatic electrical

calibration, refer to the operating

instructions or user’s guide supplied with

the testing machine.

Note: Ensure that the

extensometer is set at

gauge length, and is

correctly attached to the

test specimen. Refer to

pages 3-1 to 3-8.

3-15

Page 44

OPERATION

Manual Electrical Calibration

This method can be used if your testing

machine is unable to use the

self-identifying feature or if you wish to

modify the calibration parameters.

To operate manual electrical calibration

refer to the operating instructions or

user’s guide supplied with the testing

machine.

Note: Ensure that the exten-

someter is set at gauge

length, and is correctly attached to the test specimen. Refer to pages 3-1

to 3-8.

3-16 M20-52630-1

Page 45

OPERATION

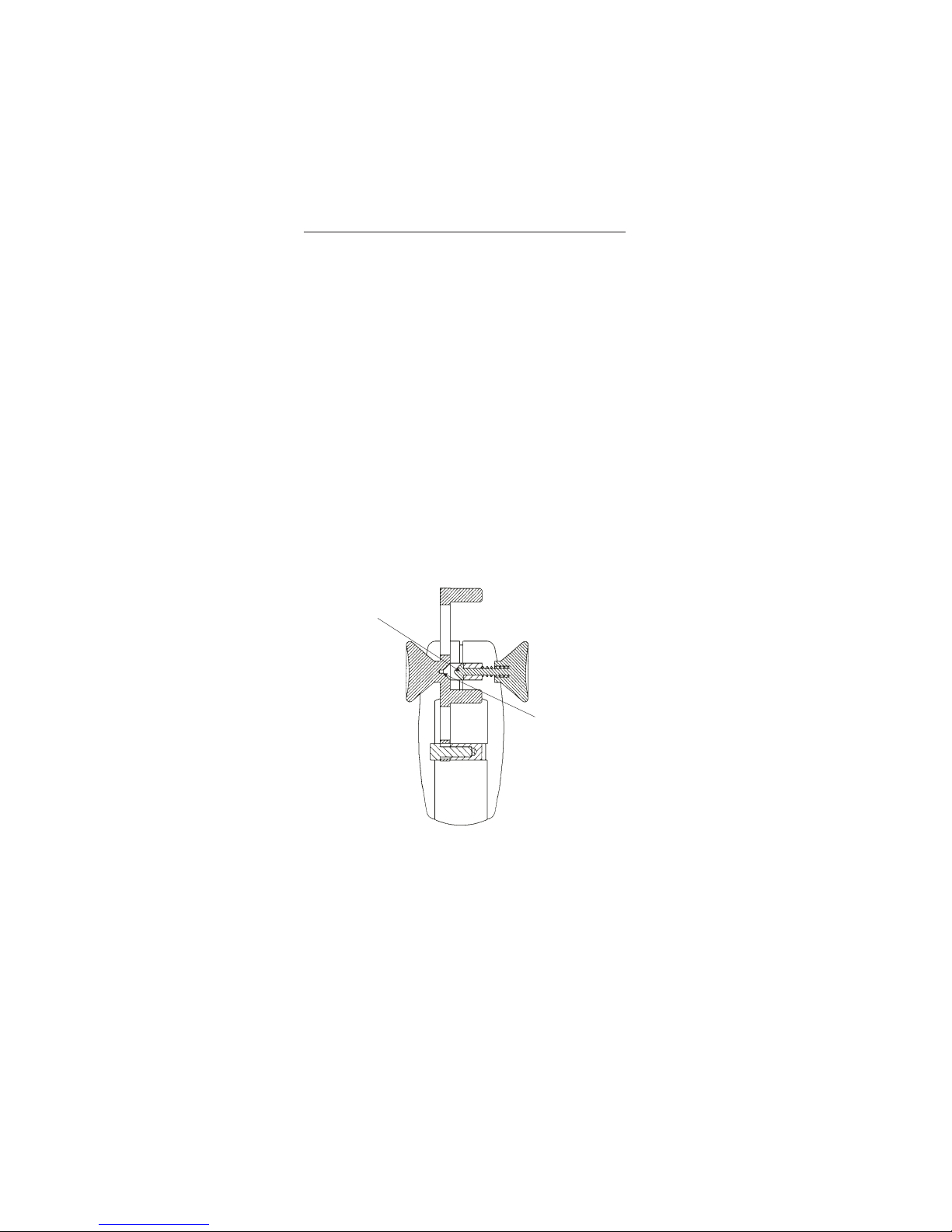

Figure 3-13. Extensometer mounted on

an optional calibration fixture

(Cat. No. 2602-017)

3-17

Page 46

OPERATION

Manual Mechanical Calibration

This method must be used on older

testing machines that are unable to

perform any other type of calibration. It

is also a way of confirming the electrical

calibration.

A calibration fixture is required for

manual mechanical calibration (refer to

page 1-4 — Optional Accessories and

Spares). The fixture consists of a digital

micrometer head, mounted on a stand

frame, with two knurled collets for

holding various calibrator spindles

corresponding to types and sizes of

specimens to be tested. It enables the

extensometer to be exercised over its

mechanical displacement range and the

span to be checked or set.

Note: Ensure that the exten-

someter is set at gauge

length, and is correctly attached to the Calibrator.

Refer to pages 3-1 to 3-8.

3-18 M20-52630-1

Page 47

OPERATION

VERIFICATION

The achievable ISO or ASTM

classification is given in Table 1 on pages

2-1 and 2-2. Certification of the strain

measurement system which includes the

extensometer, conditioning electronics

and readout to the international standards

should be arranged through accredited

calibration services. Your local Instron

area office will be able to arrange

verification.

NOTE It is advisable to check the

accuracy of the

automatic/manual

electrical calibration at

least once per year.

3-19

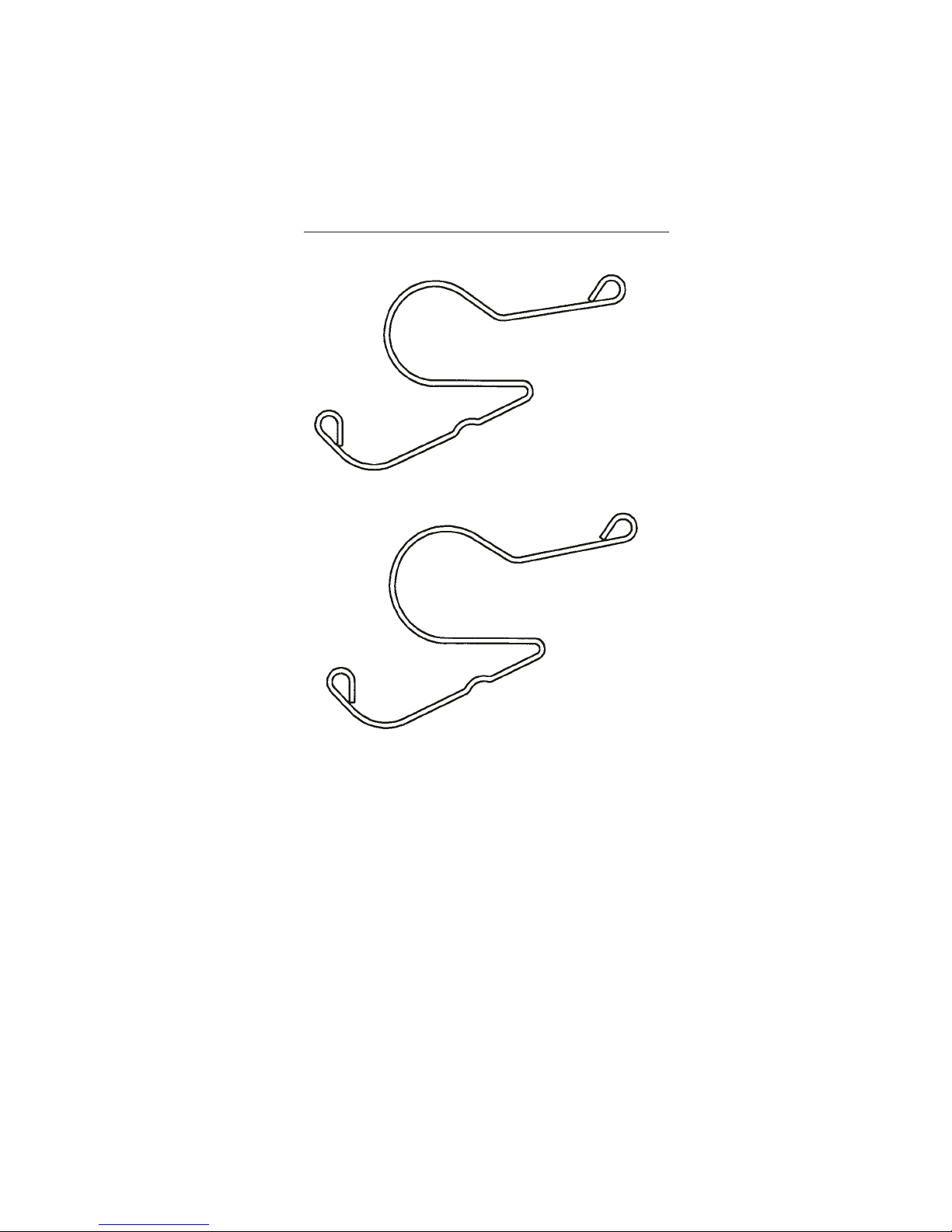

Page 48

CLIP SIZES

APPENDIX A

CLIP SIZES

Use the full-scale diagrams on the following

pages to identify the various clips supplied

with the extensometer.

Appendix A A-1 M20-52630-1

Page 49

CLIP SIZES

CLIPS FOR ROUND SPECIMENS

(Supplied in pairs)

T1696-1390

Ø0 to 3 mm

Ø 0 to 0.12 in.

T1696-1391

Ø3 to 6 mm

Ø 0.12 to 0.24 in.

Appendix A A-2

T1696-1392

Ø6 to 9 mm

Ø 0.24 to 0.35 in.

Page 50

CLIP SIZES

T1696-1393

Ø9 to 12 mm

Ø0.35 to 0.47 in.

T1696-1394

Ø12 to 15 mm

Ø0.47 to 0.59 in.

Appendix A A-3 M20-52630-1

T1696-1388

Ø20 mm

Ø0.79 in.

Page 51

CLIP SIZES

CLIPS FOR RECTANGULAR

SPECIMENS

(Supplied in pairs)

T1696-1395

SQR 0 to 3 mm

SQR 0 to 0.12 in.

T1696-1396

SQR 3 to 6 mm

SQR 0.12 to 0.24 in.

Appendix A A-4

T1696-1397

SQR 6 to 9 mm

SQR 0.24 to 0.35 in.

Page 52

CLIP SIZES

T1696-1398

SQR 9 to 12 mm

SQR 0.35 to 0.47 in.

T1696-1399

SQR 12 to 15 mm

SQR 0.47 to 0.59 in.

Appendix A A-5 M20-52630-1

Page 53

CLIP SIZES

NOTES

Appendix A A-6

Loading...

Loading...