Page 1

FDM 3D Printer

INVENTOR PRO

Yiwu Instone 3D Technology Co.,Ltd

USER’S MANUAL

Page 2

Content

Declaration

............................................................................................................

- 3 -

Legal Statement

.....................................................................................................

- 3 -

Important Security Information

............................................................................

- 3 -

Brief Introduction

..................................................................................................

- 5 -

Overview

................................................................................................................

- 5 -

Get to know your INVENTOR PRO

.........................................................................

- 6 -

Product List

............................................................................................................

- 6 -

Open-package

........................................................................................................

- 7 -

Brief Introduction of User Interface

......................................................................

- 8 -

Machine Installation and Operation Guide

.........................................................

- 11 -

Software Installation and Operation Guide

........................................................

- 13 -

1. Install the Instone 3D

................................................................................

- 13 -

2. Basic settings

............................................................................................

- 14 -

3. Advanced parameters instruction

............................................................

- 15 -

4. Expert Settings

..........................................................................................

- 16 -

5. Load model file

.........................................................................................

- 17 -

6. Rotate

........................................................................................................

- 17 -

7. Scale

..........................................................................................................

- 18 -

8. Mirror

........................................................................................................

- 18 -

9. Right-mouse menu

...................................................................................

- 18 -

Online printing and firmware updates

................................................................

- 19 -

Precautions and FAQ

...........................................................................................

- 20 -

WIFI Module Operating Guide

............................................................................

- 22 -

Page 3

- 3 -

Declaration

All INVENTOR PRO 3D Printer will be tested and calibrated before delivery. With

more than 8-hour continuous printing test, the following phenomena are normal:

particle dust on the shell or the slight traces on the nozzle, etc.. Please read this

manual carefully before using the printer to avoid damaging both the body and

machine.

Legal Statement

We have all the rights to modify the relevant contents of this manual without

notice.

The machine case is flammable and there are heating components inside the

machine. So don’t leave the device unattended after power-on. If any abnormality is

found, please cut off the power supply in time to prevent the fire. Any accidents

caused by misoperation would not be assumed by us.

We are not responsible for any loss without following this manual (including

subsequent loss, misprints and publishing errors). No part of this manual can be

modified, photocopied, or translated without prior written authorization. This manual

is copyrighted and we reserves all the rights of the final explanation.

Important Security Information

Failure to follow the instructions in this manual may result in fire, equipment damage,

property loss or personal injury.

Before using the product, please refer to the Quick Start Guide and User's Manual.

Operation:

1.For INVENTOR PRO and power adapter, please keep the surrounding

temperature range 15~40℃, humidity range 20%~50%. Otherwise it may affect the

quality of the print model and even cause a security risk.

2.INVENTOR PRO 3D Printer can only use the company's standard power

adapter cable. The use of damaged cables, or power in damp environments may

damage the equipment or cause fire.

3.During the printing process, a slight odor is produced. The odor is non-toxic

but might cause slight discomfort to the human body. Therefore, it is recommended to

use in the well-ventilated environment.

4.Try to keep the printer away from strong airflow which might have a certain

impact on print quality.

5.Do not expose the printer to water or other liquids which might cause damage

Page 4

- 4 -

to the machine.

6.If INVENTOR PRO is dropped, burnt, punctured or crushed, it might be

damaged. Do not use the damaged INVENTOR PRO to keep away from personal

injury and property damage.

Maintenance: If INVENTOR PRO is damaged or malfunctioning, please contact our

company or authorized service provider. Do not open the INVENTOR PRO and try to

repair by yourself. Disassemble INVENTOR PRO might cause equipment damage or

personal injury.

Squeeze-Involve-cutting: The INVENTOR PRO has mounts of motion components.

Avoid contact with these moving parts during operation. To prevent the body is

squeezed, involved, cutting and other injuries.

Caution hot scald:

1.During working, the nozzle, floor and other components of machine will

produce high temperature. Please avoid direct skin contact with these parts.

2.Do not touch the high-temperature parts of the model, nozzles, printing

platforms, etc. when models just finish printing. Wait for these components to cool

sufficiently before removing the model and other subsequent operation.

Page 5

- 5 -

YIWU INSTONE 3D TECHNOLOGY CO.,LTD

Website: www.instone3d.com

Contact: Cathy/ Wilona

Support Email: sales01@instone3d.com

Tel: +86-579-89026661

Skype: live:instone01_1

Twitter: Instone_3D

Facebook: Instone 3D

Addr.:

Flr.3, Bld.2, Area B, No.E-21 Xinke Road, Yiwu Economic & Development

Zone, Yiwu, Zhejiang, China

Brief Introduction

1. How to use the manual?

This manual is divided into four sections, including overview, installation,

operation, and common troubleshooting. Please read this manual carefully before use,

and operate according to the manual. If necessary, please print it for reference.

2. How to protect the machine?

Do not turn the power off or unplug

the

SD card while the model is being loaded.

Otherwise, the model data will be lost.

During the printer debugging, the nozzle will squeeze out the material. Make sure

that the distance between the nozzle and the print platform is at least 50 mm, or the

nozzle might be blocked.

Overview

INVENTOR PRO series, with the ownership of several patents ,is the new generation

of 3D printer with independent design, development and manufacturer .After simple

training ,you are able to create whatever model you like even you have never used it

before. The principle of the printer is to melt and extrude the materials at high

temperature and then solidifies after rapid modeling to make it strong and durable .We

continuously improve our systems with implementing of functions such as half-way

reloading ,WIFI, touch screen etc. It will be more convenient to take the model by

adopting the modular design .Users will benefit from better vision ,free from long

bending operation and thus brings more choice and pleasant operating experience

with the touch screen on top of the machine.

Page 6

- 6 -

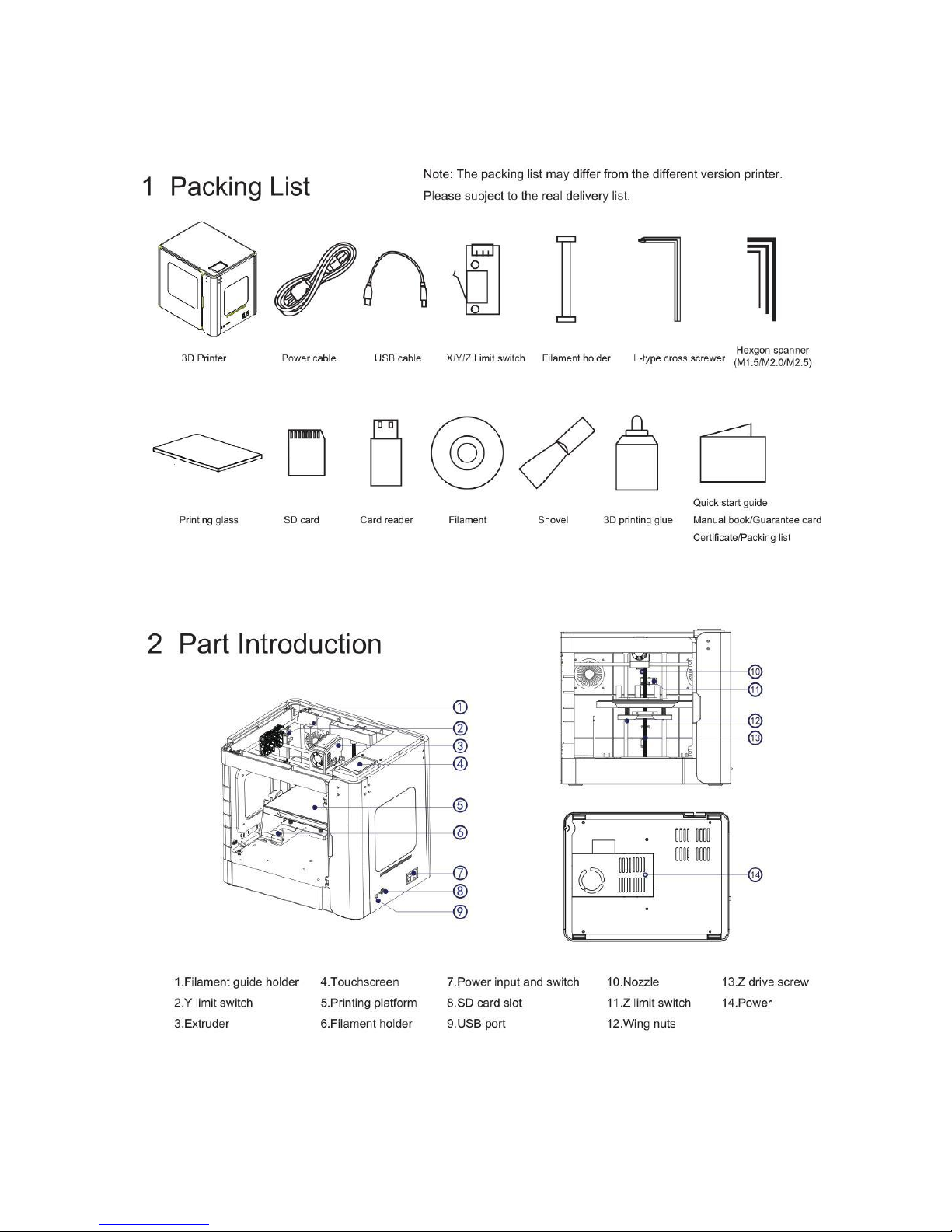

Get to know your INVENTOR PRO

Page 7

- 7 -

Basic parameters:

Product name: FDM 3D Printer Brand: Instone

Model: INVENTOR PRO Input voltage: 110V/220V AC 50/60Hz

Maximum power: 230W Forming principle: FDM

Nozzle temperature: 245℃(Max) Working condition: 10-40℃, Humidity 20-50%

Moulding size: 240x160x160mm Printing speed:40-150mm/s

Positioning accuracy: Axis Z: 0.0025mm, X/Y: 0.011mm

Printing accuracy: ±0.1mm Layer thickness: 0.1-0.3mm

Nozzle diameter: 0.4mm Nozzle number: Single

Changing material midway: Support WIFI: Support

User interface: 3.5 inch touchscreen

Software requirement:

Enclosed software: Inston3D, Cura

Extended software: Slic3r, Repetier-host,Simplify3D

File formats: STL,OBJ,G-Code OS: Windows,Linux,Mac

Consumables specifications:

Printing material: ABS,PLA Diameter: 1.75mm

Color: Colorful

Machine specification:

Size: 441x344x407mm Package size: 525x440x525mm

Machine material: Injection molding/Plastic shell

Product weight: 12KG Gross weight: 18KG

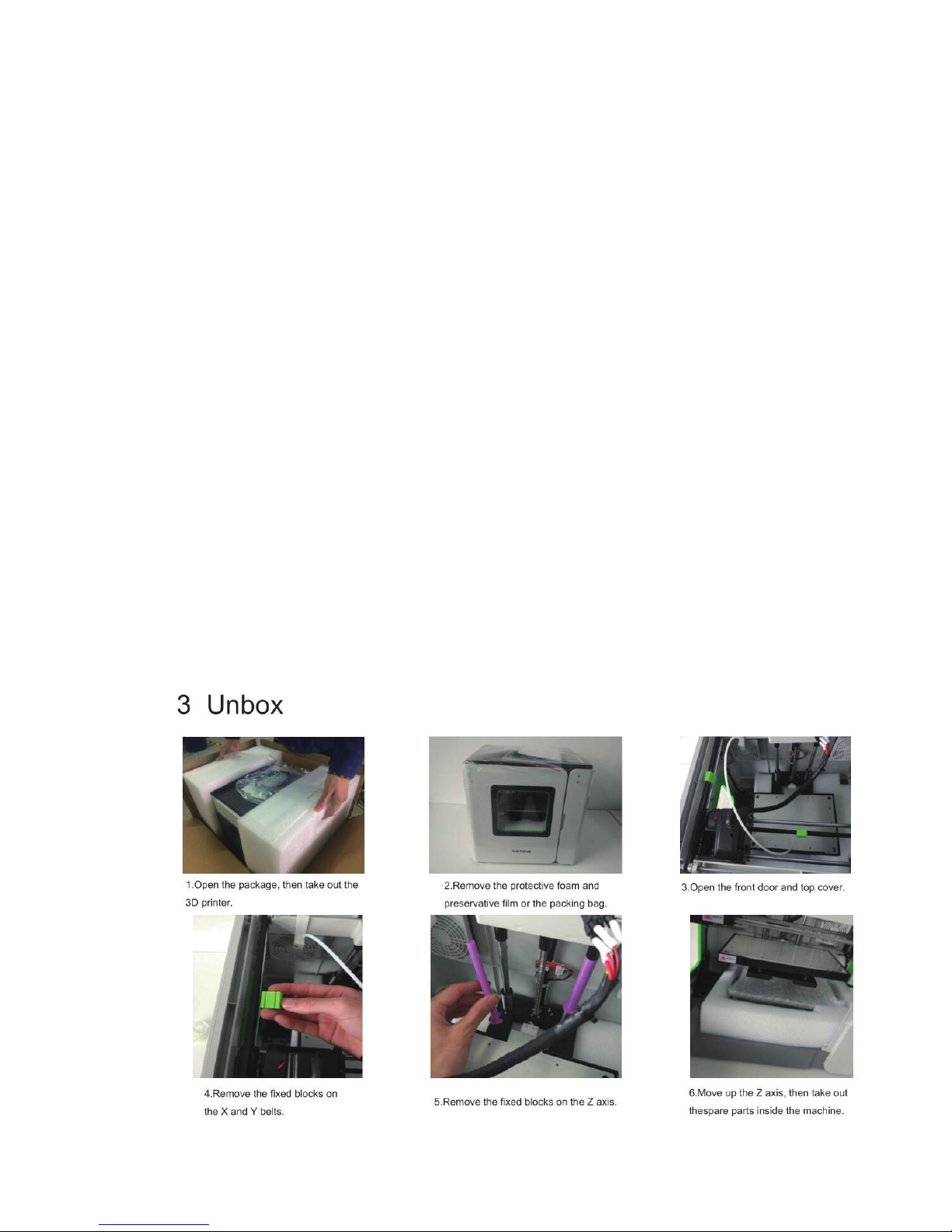

Open-package

Page 8

- 8 -

Brief Introduction of User Interface

Logical Relationship

HOMEPAGE

SYSTEM

Page 9

- 9 -

TOOL

FILE CHOOSE

FILE OPERATION

PRINTING INTERFACE

PRINTING TOOL

NUM KEYBOARD

MANUAL

PREHEAT

Page 10

- 10 -

FILAMENT

LEVEL

FAN

WORKING CONDITION

INFO

WIFI

Page 11

- 11 -

Machine Installation and Operation Guide

1) Remove the platform glass from the packaging carton and

apply a layer of printing glue or heat-resistant adhesive tape to

the upper surface.

In order to ensure the best printing state of model, we have to apply

a layer of 3D printing special glue to the glass platform. The glue can

increase the adhesion of the model and the bottom plate, as much as

possible to reduce the problem of edge lifting. ( After printing 4-5 times or glue invalid need to be

re-applied.)

As shown in the left figure, apply the special glue for 3D printing on the glass plate and level the

glue with the standard model shovel, then level it until it is covered with the bottom plate and glue it

on the Z-axis printing platform.

2) Consumables installation

Remove the accessory "consumables" from the packaging carton and install the filament tray

correctly on the carriage as shown in Figure 1&2, and the consumable material is drawn out from the

inside of the tray (strictly install in the direction shown. Don’t install upside down).

Trim the head of filament, then get it through the thread guide tube to the nozzle case (not really

get through the case). Then open the machine, select the preheat nozzle button, set the nozzle

temperature (PLA material around 200℃, ABS material around 220℃), until the nozzle heated to

the set temperature, and then press the nozzle assembly on the left clamping gear handle. Insert the

material into the throat forcedly, and observe the nozzle, a smooth material out shows that it is

installed successfully.

3) Adjust Printer Optical Flatness

The correct position of printing platform should be in the vertical plane with nozzle. This can

greatly reduce the print failure rate, ensure a more stable printing process, and get the better effect of

the print model. The printing platform is mechanically biased due to transportation or re-installation,

etc. If the following two conditions occur during the printing of the bottom border, the platform needs

to be leveled again.

Consumables not sticking on the platform means the platform is too low. Then it needs for

appropriate increase.

Consumables extruding not smoothly means the platform is too high. Then it needs for a

corresponding reduction.

Figure 1

Figure 3

Figure 2

Figure 4

Page 12

- 12 -

Level adjustment interface on the monitor Figure 1

Leveling method: As shown in Figure 2, the print platform can be raised or lowered by rotating the

bottom of the four knobs to achieve. From the bottom-up perspective, clockwise rotation makes the plat

lower, and counterclockwise rotation makes floor elevation.

Leveling steps:Rotate the four knobs clockwise, so that the printing platform and the nozzle has a

3-5mm gap;

Put an A4 paper on the printing platform, select TOOLS → LEVELING, the

interface displays as shown in Figure 1. Rotate the knob corresponding position of

the nozzle counterclockwise, while swinging A4 paper, when you feel significant

resistance between it and the nozzle, but still easy to swing, stop rotating the

knob, the position is the best leveling position, then click NEXT, repeat the

operation until the main interface says LEVELING SUCCESSFULLY.

4) Model Printing

Copy the already converted GCODE model file to the SD card (the standard

SD card already contains 3 test models). The SD card as shown in the left

Figure. Insert the SD card to the slot with gold finger side up, then select the

Print menu, in the file directory list, select the file you want to print, and wait

for printing to complete.

5) Printing completed

After the model has been printed, wear gloves and use a model blade to

carefully shovel the model down. If the model is braced, remove it

manually or immerse it in special solvent DISSOLUBLE for

approximately 2-5 hours . (The dissolution time is estimated based on the

model structure, and the model with internal cavity supports is longer.)

Warnings for solvent: DISSOLUBLE solvent is flammable; place in where the child can not reach;

do not eat; do not upside down to prevent solvent leakage. Storage of the product in sealed, cool and

dry condition.

Level knob Figure 2

Page 13

- 13 -

Software Installation and Operation Guide

1. Install the Instone 3D (Original ver.15.04.6)

1. Open the folder in the U disk with the machine, then double-click “Instone3D_15.04.6”.

Choose the installation directory in the first interface or default, then click “NEXT”.

2. All the requests during installation, just click “YES”. Then click “NEXT” to finish the

installation.

Page 14

- 14 -

2. Basic settings

Page 15

- 15 -

3. Advanced parameters instruction

Page 16

- 16 -

4. Expert Settings

Page 17

- 17 -

5. Load model file

6. Rotate

Page 18

- 18 -

7. Scale

8. Mirror

9. Right-mouse menu

Page 19

- 19 -

Online printing and firmware updates

Online printing:

Note: There is an offline risk of online printing: If the data cable is disconnected or the

computer shuts down unexpectedly, the machine will stop printing and can not continue from

the last time.

1. Install the driver, open the folder in the standard SD card, select "Driver". Please select the

corresponding file according to the OS used.

Windows: "windows"—"CP210xVCPInstaller_x64/x84.exe"(x64 is 64bit, x84 is

32bit)

Linux:"Linux"—"cp210x.c"

Mac:"Mac"—"SiLabsUSBDriverDisk.dmg"

2. Use the standard USB cable to connect computer and printer.

3. Run the software “Instone3D 15.04.6”, click menu bar “File”—“Machine settings”

—

“Communication settings”—“Serial port”—“COM1” (Please select according to the

allocation of pc ports); “Baudrate”—“115200”, then click “OK”.

4. When “Print with USB” shows above the icon which in the right figure, it means

successful connection.

5. Following the Operation Guide in last chapter, load the model in this program, adjust the

slice parameters, when slicing finished, click “Print with USB”, printer will start heating,

printing, etc. automatically.

Firmware updates:

The factory has installed the latest firmware program before delivery, please do not easily

update the firmware unless there’s a need for maintenance and debugging.

1. As previously described, after the successful connection between computer and printer,

click the “Machine”(on the menu bar)—“Install custom firmware”, then select the file

“INSTONE*.*.*.hex”.

2. Wait for the progress bar of dialog box to complete and display "Done! Installed firmware:

INSTONE *. *. *. hex" to indicate that the update is successful.

3. Turn the printer off and on again. The firmware update is complete.

Page 20

- 20 -

Precautions and FAQ

1. Precautions

A. High-temperature danger. There’s heating board inside the machine. Wait for cooling

down before maintenance.

B. Motor drive can cause crushing and cutting damage. Do not touch any part of the machine

while the machine is working.

C. When operating the equipment, it may cause irritating odor. Keep the environment

ventilated and open when using INVENTOR PRO.

D. Do not leave the INVENTOR PRO unattended while the INVENTOR PRO is operating.

E. When printing is complete, the nozzle and filament are still hot, remove it from the print

platform after cooling down.

2.FAQ

Question 1: Stop suddenly when printing online.

Causes

Solutions

The USB cable is loose or unplugged.

Check the USB port, re-plug cable or use SD card instead.

Program stops or crashes.

Restart the software or computer.

Problems of computer’s port.

Replace the computer, use SD card instead.

Question 2: No filament comes out from the nozzle.

A. If this problem happens with clatters from nozzle when install the new filament, please

check whether the filament head inserted to the tube inside the nozzle, whether it stuck in the

mouth of nozzle, then take out the filament, re-insert after trim.

B. If it is determined that the head has entered the heating head but with clatters, check if the

current temperature of the print head is correct.

C. If the nozzle just extrudes for a while then stops, and with clatters, this might be caused by

the deformation of the filament and stuck of nozzle resulting from too high temperature. Take

out the filament, re-insert after trim, and set the correct temperature.

D. Check if there’s knot and stuck of filament at the material hanger.

E. If the above solutions can’t solve the problems, you can try to open the nozzle cover,

remove the fan and radiator to be repaired. During the repair, it might require nozzle with

temperature, pay special attention not to touch the heating head to prevent burns.

Remove the plastic cover on the right Figure 1

Page 21

- 21 -

Question 3: The material does not stick to the glass board then becomes a mass, or fall off

for a while.

Causes

Solutions

The temperature of glass board is not enough.

High up the temperature or re-paint the

printing glue

The platform is not leveled correctly. Too

large gap between nozzle and platform.

Re-level the platform.

(With large gap, the filament can’t stick on

the board totally; with small gap, the risk of

nozzle stuck will be increased or even

broken the glass board. )

Remove the radiator and fan Figure 2

Clean the stuck material Figure3

Unblock test, if ok, install the right cover Figure4

Page 22

- 22 -

WIFI Module Operating Guide

Page 23

- 23 -

Thanks for choosing Instone!

- The End-

Loading...

Loading...