Multi-Range DC Power Supply

PSB-1000 Series

QUICK START GUIDE

GW INSTEK PART NO. 82SB-18000M01

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is

protected by copyright. All rights are reserved. No part

of this manual may be photocopied, reproduced or

translated to another language without prior written

consent of Good Will Corporation.

The information in this manual was correct at the time

of printing. However, Good Will continues to improve

its products and therefore reserves the right to change

the specifications, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd. No. 7-1, Jhongsing Rd., Tucheng

Dist., New Taipei City 236, Taiwan.

1

Warning

Warning: Identifies conditions or

practices that could result in injury or

loss of life.

Caution

Caution: Identifies conditions or

practices that could result in damage

to the PSB-1000 or to other properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

Do not dispose electronic equipment

as unsorted municipal waste. Please

use a separate collection facility or

contact the supplier from which this

instrument was purchased.

SAFETY INSTRUCTIONS

This section contains the basic safety symbols that may

appear on the accompanying User Manual CD or on the

instrument. For detailed safety instructions and

precautions, please see the Safety Instructions chapter

in the user manual CD.

Safety Symbols

These safety symbols may appear in the user manual or

on the instrument.

2

Green/ Yellow:

Earth Blue:

Neutral

Brown:

Live (Phase)

Power Cord for the United Kingdom

When using the instrument in the United Kingdom,

make sure the power cord meets the following safety

instructions.

NOTE: This lead/appliance must only be wired by

competent persons.

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in

accordance with the following code:

As the colours of the wires in main leads may not correspond with

the coloured marking identified in your plug/appliance, proceed as

follows:

The wire which is coloured Green & Yellow must be connected to

the Earth terminal marked with either the letter E, the earth symbol

or coloured Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal

marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or

contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, a cable of

0.75mm2 should be protected by a 3A or 5A fuse. Larger conductors

would normally require 13A types, depending on the connection

method used.

Any exposed wiring from a cable, plug or connection that is engaged

in a live socket is extremely hazardous. If a cable or plug is deemed

hazardous, turn off the mains power and remove the cable, any

fuses and fuse assemblies. All hazardous wiring must be

immediately destroyed and replaced in accordance to the above

standard.

3

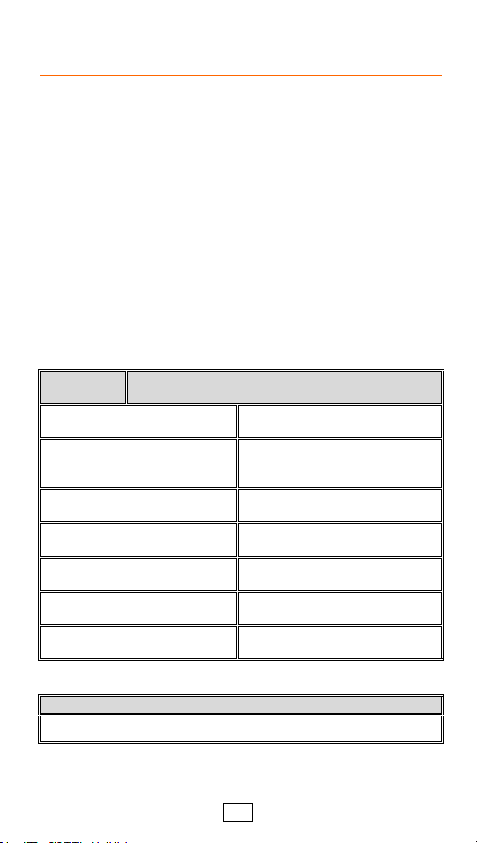

Model name

Output

Voltage

Output

Current

Output Power

PSB-1400L

40

40

400

PSB-1400M

160

10

400

PSB-1800L

40

80

800

PSB-1800M

160

20

800

Performance

• Maximum output voltage of 160V

• Maximum output current of 80A

GETTING STARTED

The Getting Started chapter describes the power source

in a nutshell, including its main features and front/rear

panel introduction.

Overview

The PSB-1000 Series consists of 4 models: PSB-1400L,

PSB-1400M, PSB-1800L, and PSB-1800M. Note that

throughout the user manual, the term “PSB-1000” refers

to all the models in the PSB-1000 Series lineup, unless

stated otherwise.

Model Line Up

Main Features

4

Features

• OVP, OCP and OTP protection

• Low AC input protection

• Sequence function

• Large 3.5 inch LCD panel

• 100V - 240V power inlet

• Multi-range output power

• Bleeder circuit ON/OFF setting

• CV, CC priority start function

• Internal resistance setting

function

• Parallel master/slave operation

with active current sharing

• Remote sensing to compensate for

voltage drop in load leads

• Analog output programming and

monitoring

Interface

• Ethernet port

• USB host

• USB CDC

• GPIB (optional)

• External Control I/O

Standard Accessories

Item

Part Number

User manual, programming manual

CD ROM

Power cord

Output terminal cover

PSW-009

Type A - B USB Cable

GTL-240

Accessories

Continued on the next page...

5

Basic Accessory Kit:

M4 terminal screws and washers x2,

M8 terminal bolts, nuts and washers

x2, Analog control protection dummy

x1, analog control lock level x2, short

bar x1.

PSB-106

Optional Accessories

Item

Part Number

Analog remote control connector kit:

Socket x 1pc

Pins x 10pcs

Protection cover x 1 set

Chassis connection wire x 1

PSW-001

Simple IDC tool

PSW-002

Contact removal tool

PSW-003

Cable for 2 units of PSB-1000 units in

parallel mode connection

PSB-101

Cable for 3 units of PSB-1000 units in

parallel mode connection

PSB-102

Cable for 4 units of PSB-1000 units in

parallel mode connection

PSB-103

Cable for 2 units of PSB-1000 units in

series mode connection

PSB-104

GPIB card

PSB-105

Rack-mount adapter(JIS)

GRA-418-J

Rack-mount adapter(EIA)

GRA-418-E

Test leads: 1x red, 1x black

GTL-123

Download

Item

Description

gw_psb1k.inf

USB driver

6

0 - 160V , 10A

S S

F 1 F 2 F 3 F 4 F 5

PSB-1400M

0 - 160V / 0 - 10A , 400W

Multi-Range DC Power Supply

Main

FUNC

FileUtility

0

1

4

7

2

5

8

3

6

9

Voltage

Clear

Enter Lock

Output

Current

OVP

OCP

Local

CLR PROT. Unlock

: Long Push

17

2

4

6

15

7

9

8

10

1

16 14

13 12

11

5

3

Description

1. F1~F5 soft-keys

2. LCD display

3. Voltage, Current,

OVP/CLR PROT,

OCP keys

4. Menu keys:

Main/Local, FUNC,

Utility, File

5. Number pad

6. Scroll wheel

7. Arrow keys

8. Lock/unlock key

9. Enter key

10. Output key

11. Sense+ terminal

12. +Terminal

13. Ground terminal

14. -Terminal

15. Sense- terminal

16. USB A port

17. Power switch

Front Panel

7

TRIG IN

TRIG OUT

LAN

100 240V

1100VA MAX.

AC

47 63Hz

GPIB

SER. NO. LB

VOLT TRIG

910

1

2

7 6

543

8

TRIG IN

TRIG OUT

LAN

100 240V

550VA MAX.

AC

47 63Hz

GPIB

SER. NO. LB

VOLT TRIG

PSB-1800M/L

PSB-1400M/L

Description

1. TRIG OUT

2. TRIG IN

3. Rear panel terminals

4. J1connector

5. USB B port

6. GPIB option

7. Line input

8. Fan

x1: PSB-1800M/L

x2: PSB-1400M/L

9. LAN port

10. VOLT TRIG

Rear Panel

8

Status bar

Description

Output OFF

OVP tripped

CV mode active

OCP tripped

CC mode active

OTP tripped

Output operating

at 105% rated

power (CP mode)

Remote sense fail

Power fail

Speaker enabled

GPIB installed

Speaker disabled

GPIB installed &

disabled

Panel lock on

Connected to PC

via USB

Panel lock off

Connected to LAN

Remote control

mode

USB flash drive

recognized

Note: Only the most common status bar icons are

shown here. Please see the user manual for more

information.

Status Bar Icons

9

Use the following procedures when first using the

PSB-1000 to power up the instrument, reset to the

factory settings, view the system information and

install the USB driver. Lastly, the How to Use the

Instrument section will introduce you to the basic

operating conventions used throughout the user

manual. Please see the user manual for a more

comprehensive first-time-use and safety information.

1. Connect the power cord to the rear panel socket.

2. Press the POWER key. The splash

screen will appear momentarily

before the continuous mode

screen appears with the settings

loaded.

CAUTION

The power supply takes around 10

seconds to fully turn on and around

half that time to shutdown.

Do not turn the power on and off

quickly.

First Time Use Instructions

Power Up

10

The factory default settings can be restored from the

Utility menu. See the user manual for a list of factory

settings.

1. Press the

Utility

key. The utility menu will

appear on the display.

2. Go to Factory Setting and press Enter.

3. Press Restore[F4] to restore the factory settings.

4. Press OK [F4] to confirm.

The Utility>System Information setting displays the

serial number and software version number.

1. Press the

Utility

key. The utility menu will

appear on the display.

2. Use the scroll wheel to go to System Information

and press Enter.

3. The system information should now be listed on

the display.

System Information

Reset to Factory Settings

View System Information

11

If the USB Type B interface is to be used for remote

control, the USB driver needs to be installed.

Note

The USB driver, GW_PSB1k, is located

on the CD-ROM that accompanied this

user manual. Alternatively the driver

can be downloaded from the GW

Instek website.

1. Connect the rear panel USB-B port on the PSB-

1000 to the PC using a USB Type A to B cable.

2. Go the Windows Device Manager

3. For Windows 7:

Start > Control Panel > Hardware and Sound >

Device Manager.

The PSB-1000 will be located under Other Devices

in the hardware tree. Right-click PSB-1XXX and

choose Update Driver Software.

4. From the hardware wizard choose Browse my

computer driver software.

5. Set the file path to the location of the USB driver,

click Next and finish the driver installation.

6. The PSB-1000 will now be located in the Ports

node of the hardware tree in the Windows Device

Manager if the driver installation was successful.

USB Driver Installation

12

The PSB-1000 power supplies generally use the scroll

wheel, arrow keys, Enter keys and soft-menu function

keys to edit numerical values or to select menu

options.

The following section will explain some of these

concepts in detail.

Soft menu keys

The F1 ~ F5 function keys at the bottom of the

display correspond directly to soft-menu keys

above. The soft-menu keys have a number of

different functions, depending on the use-case.

They can be used as quick-action keys, option keys

or as submenus.

0 - 160V , 10A

S S

F 1 F 2 F 3 F 4 F 5

PSB-1400M

0 - 160V / 0 - 10A , 400W

Multi-Range DC Power Supply

Main

FUNC

FileUtility

0

1

4

7

2

5

8

3

6

9

Voltage

Clear

Enter Lock

Output

Current

OVP

OCP

Local

CLR PROT. Unlock

: Long Push

F1 ~ F5

function keys

Soft-menu

keys

Menu Keys

Pressing a Menu key will enter the corresponding

menu for that key.

How to Use the Instrument

13

Selecting Menu Items

1. Turn the scroll wheel to select

parameters in menus and lists.

The selected parameter will be

highlighted in orange. The scroll

wheel is also used to

increment/decrement setting

values.

2. Press the Enter key to edit the

parameter or to enter the selected

menu.

Enter

Example: The following is an example of the

Function menu that appears when the FUNC

key is pressed.

Selected menu item

Navigating Menus one page at a time

1. For menus with more than 1 page

of items, pressing the directional

keys will allow you to jump to

the next menu page.

14

Using the Keypad to edit parameter values

When editing a value the keypad can be used to

directly enter the desired value.

1. Type the value of the

parameter using the

keypad.

7

4

1

0

8

5

2

Clear

3

6

9

2. Press the Enter key to confirm the

edit.

Enter

Example

Parameter

Using the Arrow Keys and Scroll wheel to edit

parameter values

1. Use the arrow keys to move to

the digit of the desired power

(shown in blue).

2. Turn the scroll wheel to edit the

value by the resolution of the

selected digit.

15

Cursor

3. Repeat the steps above for all the relevant

digits.

4. Press the Enter key to confirm the

edit.

Enter

Using the onscreen keyboard

The onscreen keyboard is used for creating

filenames, renaming files, and so on. The

screenshot below is an example of the onscreen

keyboard.

Entered characters

On-screen keyboard

1. Use the scroll wheel to move the

cursor to the desired character on

the keyboard.

2. Press Enter character [F2] or the

right arrow key to enter the

desired character into the text

entry area.

OR

16

3. Use the A ↔ a 1 ↔ ![ F1] key to

toggle the keyboard to lower case

characters and other nonalphanumeric characters.

4. Use the left arrow key to delete

the character to the left of the

cursor.

5. Press Enter to finish using the

keyboard.

Enter

Model

PSB-1400L

PSB-1400M

Rated output

voltage*

40V

160V

Rated output

current*

40A

10A

Rated output power

400W

400W

Power Ratio

4

4

Model

PSB-1400L

PSB-1400M

Line regulation*

23mV

83mV

Load regulation*

25mV

85mV

Ripple and noise*

60mVp-p *

60mVp-p *

SPECIFICATIONS

The following are the basic specifications for the PSB-

1000. For detailed specifications, please see the user

manual.

Output (400W models)

Constant Voltage Mode (400W models)

17

Model

PSB-1400L

PSB-1400M

Line regulation*

45mA

15mA

Load regulation*

45mA

15mA

Ripple and noise*

80mA

20mA

Model

PSB-1800L

PSB-1800M

Rated output

voltage*

40V

160V

Rated output

current*

80A

20A

Rated output power

800W

800W

Power Ratio

4

4

Model

PSB-1800L

PSB-1800M

Line regulation*

23mV

83mV

Load regulation*

25mV

85mV

Ripple and noise*

80mVp-p*

80mVp-p*

Model

PSB-1800L

PSB-1800M

Line regulation*

85mA

25mA

Load regulation*

85mA

25mA

Ripple and noise*

160mA

40mA

*Subject to limitations/conditions. Please see the user

manual specifications for more details.

Constant Current Mode (400W models)

Output (800W models)

Constant Voltage Mode (800W models)

Constant Current Mode (800W models)

18

We

GOOD WILL INSTRUMENT CO., LTD.

No.7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236,

Taiwan

GOOD WILL INSTRUMENT (SUZHOU) CO., LTD.

No. 69, Lushan Road, Suzhou New District Jiangsu, China

declare that the below mentioned products

PSB-1400L, PSB-1400M, PSB-1800L, PSB-1800M

are herewith confirmed to comply with the requirements set

out in the Council Directive on the Approximation of the Laws

of the Member States relating to the Low Voltage Directive

(2004/108/EC & 2014/30/EU) and Electromagnetic

Compatibility (2006/95/EC & 2014/35/EU). For the evaluation

regarding the Electromagnetic Compatibility and Low Voltage

Equipment Directive, the following standards were applied:

◎ EMC

EN 61326-1:

EN 61326-2-1:

Electrical equipment for measurement, control and

laboratory use –– EMC requirements (2013)

Conducted & Radiated Emission

EN 55011: 2009+A1:2010

Electrostatic Discharge

EN 61000-4-2: 2009

Current Harmonics

EN 61000-3-2: 2014

Radiated Immunity

EN 61000-4-3: 2006 +A1:2008

+A2:2010

Voltage Fluctuations

EN 61000-3-3: 2013

Electrical Fast Transients

EN 61000-4-4: 2012

-------------------------

Surge Immunity

EN 61000-4-5: 2006

-------------------------

Conducted Susceptibility

EN 61000-4-6: 2014

-------------------------

Power Frequency Magnetic Field

EN 61000-4-8: 2010

-------------------------

Voltage Dip/ Interruption

EN 61000-4-11: 2004

◎ Safety

Low Voltage Equipment Directive 2006/95/EC and 2014/35/EU

Safety Requirements: EN 61010-1: 2010; EN 61010-2-030: 2010

Declaration of Conformity

Loading...

Loading...