Programmable High Precision DC

Power Supply

PPX Series

PROGRAMMING MANUAL

Rev. A

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................. 4

GETTING STARTED .......................................................... 7

PPX Series Overview .............................. 8

Appearance .......................................... 11

Theory of Operation ............................. 19

REMOTE CONTROL ....................................................... 29

Interface Configuration ........................ 31

Socket Server Examples ....................... 64

Command Syntax ................................. 68

Command List ..................................... 72

Status Register Overview ................... 130

Error List ........................................... 142

APPENDIX .................................................................... 151

PPX Series Default Settings ............... 151

INDEX .......................................................................... 154

3

PPX Series Programming Manual

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the PPX or to other

properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

4

SAFETY INSTRUCTIONS

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

General

Guideline

CAUTION

Do not place any heavy object on the PPX.

Avoid severe impact or rough handling that

leads to damaging the PPX.

Do not discharge static electricity to the PPX.

Use only mating connectors, not bare wires, for

the terminals.

Do not disassemble the PPX unless you are

qualified.

Power Supply

CAUTION

WARNING

AC Input Voltage:

100Vac/120Vac/220Vac/240Vac, 50Hz/60Hz,

single phase

Frequency: 47Hz to 63Hz

Before connecting the power plug to an AC line

outlet, make sure the voltage selector switches

of the bottom panel in the correct position.

Disconnect power cord and test leads before

replacing fuse.

The fuse specification is as following:

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Safety Guidelines

5

PPX Series Programming Manual

Cleaning the PPX

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: 20%~ 80% (no condensation)

Altitude: < 2000m

Temperature: 0°C to 40°C

(Pollution Degree) EN61010-1:2010 specifies the pollution degrees

and their requirements as follows. The PPX falls under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

Storage

environment

Location: Indoor

Temperature: -20°C to 70°C

Relative Humidity: 20 to 85%(no condensation)

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

6

GETTING STARTED

PPX Series Overview ............................................... 8

Series lineup ................................................................................................. 8

Main Features .............................................................................................. 8

Accessories .................................................................................................. 9

Appearance ............................................................. 11

Front Panel .................................................................................................. 11

Display Area ................................................................................................ 15

Rear Panel .................................................................................................... 17

Theory of Operation ................................................ 19

Operating Description ............................................................................... 19

CC and CV Mode ....................................................................................... 20

Slew Rate ...................................................................................................... 21

Bleeder Control ........................................................................................... 22

Alarms .......................................................................................................... 23

Considerations ............................................................................................ 24

Grounding ................................................................................................... 27

GETTING STARTED

This chapter describes the power supply in a

nutshell, including its main features and front /

rear panel introduction. After going through the

overview, please read the theory of operation to

become familiar with the operating modes,

protection modes and other safety considerations.

7

PPX Series Programming Manual

Model name

Operation Voltage

Operation Current

Rated Power

PPX-1005

0-10V

0-5A

50W

PPX-2002

0-20V

0-2A

40W

PPX-2005

0-20V

0-5A

100W

PPX-3601

0-36V

0-1A

36W

PPX-3603

0-36V

0-3A

108W

PPX-10H01

0-100V

0-1A

100W

Features

2.4" TFT-LCD Panel.

Preset memory function.

Output ON/OFF delay function.

CV, CC priority start function. (prevents

overshoot with output ON)

Adjustable voltage and current slew rates.

Bleeder circuit ON/OFF setting. (to prevent

over-discharging of batteries)

OVP, OCP, AC Alarm and OTP protection.

Supports test sequence.

Web server monitoring and control. (The

function is activated when connecting to LAN

Interface)

Analog monitor output.

PPX Series Overview

Series lineup

The PPX series consists of 6 models, covering a number of different

current, voltage and power capacities:

Main Features

8

GETTING STARTED

Remote sensing to compensate for voltage drop

in load leads.

Support K type thermocouple temperature

measurement.

With 4 measuring currents and Manual / Auto

shift function.

Interface

Built-in USB, RS-232/485 and LAN interface.

External analog control function.

Optional GPIB interface.

Standard

Accessories

Part number

Description

Qty.

CD-ROM

User manual, Programming manual

1

Power Cord

1

GTL-104A

Test leads for PPX-1005/PPX2005/PPX-3603 (Binding Posts

Terminal), 1m, 10A

1

GTL-105A

Test leads for PPX-2002/PPX-3601,

1m, 3A

1

Short Bar (Binding Posts Terminal)

1

GTL-204A

Test leads for PPX-1005/PPX2005/PPX-3603 (European Type Jack

Terminal), 1m, 10A

1

GTL-203A

Test leads for PPX-2002/PPX3601/PPX-10H01 (European Type Jack

Terminal), 1m, 3A

1

GTL-201A

Ground lead for European Type Jack

Terminal

1

Accessories

Before using the PPX power supply unit, check the package

contents to make sure all the standard accessories are included.

9

PPX Series Programming Manual

Optional

Accessories

Part number

Description

GRA-441-J

Rack for PPX (JIS)

GRA-441-E

Rack for PPX (EIA)

GTL-205A

Temperature probe adaptor with

thermocouple K type

GTL-246

USB Cable (USB 2.0 Type A- Type B Cable,

4P)

GTL-258

GPIB Cable, 2000mm

GTL-259

RS232 cable with DB9 connector to RJ45

GTL-260

RS485 cable with DB9 connector to RJ45

GTL-262

RS485 slave cable

Factory Installed

Options

Part number

Description

Option 1

GPIB interface

10

1

2

3

4

5

6

7

8

9

10

11

12

14

15

13

16

1.

Display

Button

Used to switch among 4 different

display modes.

2.

Knob Key

Used to navigate menu, and to

configure or confirm

voltage/current/time values, among

others. Also, the indicator on the

upper-right corner shows current state

and power mode.

GETTING STARTED

Appearance

Front Panel

11

PPX Series Programming Manual

3.

Left/Right

Arrow Keys

Used to select a parameter number in

the Function settings. Also the left

arrow key can be used as backspace.

4.

Menu Button

Used to enter the Menu page.

M1 Button

(+Shift) Used to recall the M1 setup.

5.

Test Button

Used to run customized test sequence.

M2 Button

(+Shift) Used to recall the M2 setup.

6.

D-Log Button

Used to run data log function.

M3 Button

(+Shift) Used to recall the M3 setup.

7. PROT Button

Used to set OVP, OCP and UVL

protecting functions.

ALM_CLR

Button

+

(+Shift) Used to release protection

functions that have been activated.

The tripped protection alarms include

the following: OVP Alarm, OCP

Alarm, OTP Alarm, AC Alarm, Sense

Alarm, WDOG Alarm, Ah CAP

Alarm, Wh CAP Alarm, TEMP Short

Alarm, TEMP Monitor Alarm.

8.

Shift Button

Used to enable the functions that are

written in blue characters above

certain buttons.

9.

Lock Button

Used to lock all front panel buttons

other than the Output Button.

Unlock/Local

Button

(+Shift) Used to unlock the front panel

buttons or it switches to local mode.

12

GETTING STARTED

10.

Output

Button

Used to turn the output on or off.

11.

USB A Port

USB A port for data transfer, loading

test scripts and firmware update.

12.

TC Input

Terminal to connect the K type

thermocouple cable for temperature

measurement.

13.

Sensing

Terminal

Terminal to connect the sensing

cables, which compensate voltage

drop occurred in load leads.

14.

Power Switch

Used to turn the power on/off.

15.

Output

terminal

DC output terminal for

PPX is European Type

Jack Terminal.

PPX-10H01 the max.

output is 100V/1A/100W

DC output terminal for

PPX is Binding Posts

Terminal or European

Type Jack Terminal.

PPX-1005 the max. output

is 10V/5A/50W

13

PPX Series Programming Manual

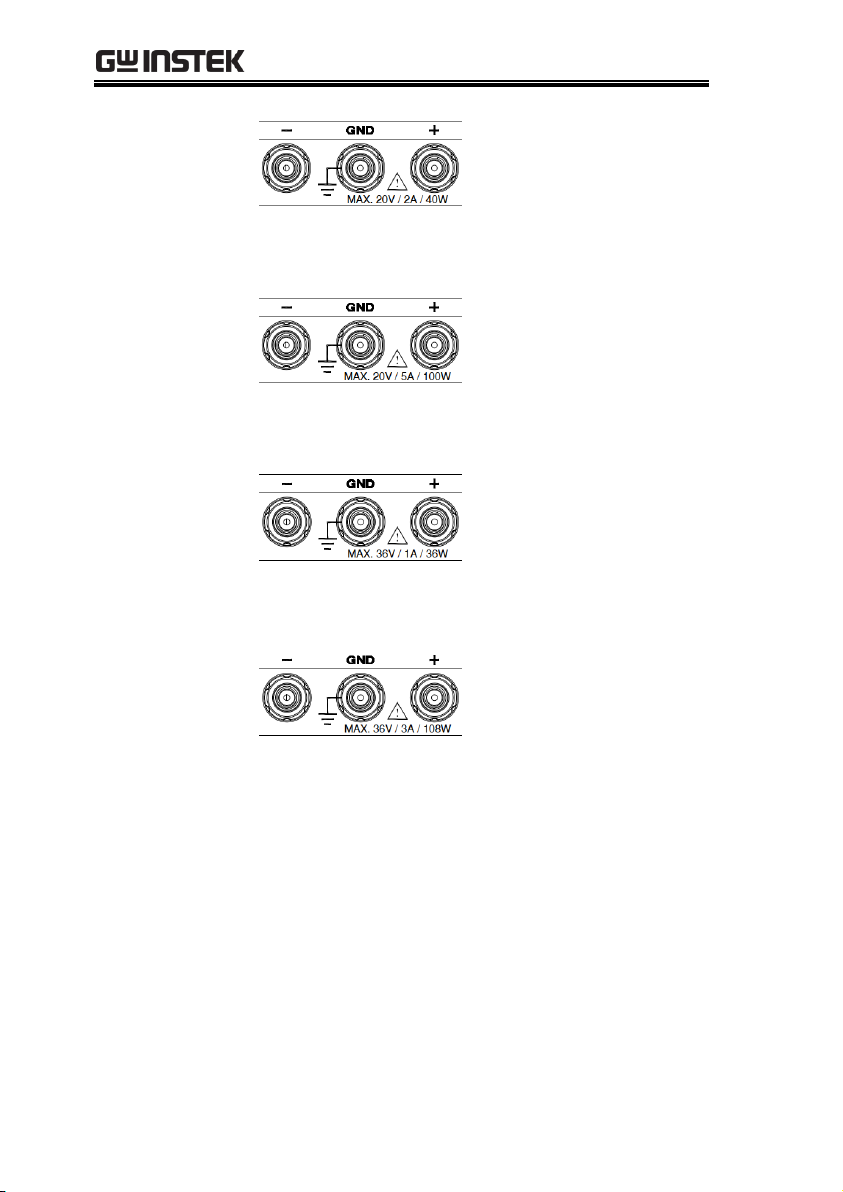

DC output terminal for

PPX is Binding Posts

Terminal or European

Type Jack Terminal.

PPX-2002 the max. output

is 20V/2A/40W

DC output terminal for

PPX is Binding Posts

Terminal or European

Type Jack Terminal.

PPX-2005 the max. output

is 20V/5A/100W

DC output terminal for

PPX is Binding Posts

Terminal or European

Type Jack Terminal.

PPX-3601 the max. output

is 36V/1A/36W

DC output terminal for

PPX is Binding Posts

Terminal or European

Type Jack Terminal.

PPX-3603 the max. output

is 36V/3A/108W

16

Display Area

The display area shows set values, output values

and parameter settings.

14

Display Area

1

2

3

4

5 6

7

8

9

10

17

16

15

14 12

13

11

1

2

3

4

5 6

7

10

17

16

15

14 12

13

11

1.

2Wire/4Wire

2-wire or 4-wire indicator.

2.

Voltage Meter

Displays the voltage.

3.

Current Meter

Displays the current.

4.

V/A Set

Guidance

The scrolling symbol indicates to select

between V and A set via scrolling knob key.

External CC &

CV Control

When the external CC or CV control is

activated, the indicator(s) will be shown.

5.

V Set

Manually sets voltage.

6.

I(A) Set

Manually sets current.

7.

Dlog Icon

When Data Logger is enabled, the icon will be

shown accordingly. Note that when SEQ

appears, the icon will be faded out.

SEQ

When Sequence function is turned On, the icon

will be shown accordingly.

GETTING STARTED

15

PPX Series Programming Manual

8.

DLY Icon

When Output On/Off Dly is enabled, the icon

will be shown accordingly. Note that when

SEQ appears, the icon will be faded out.

9.

VSR/ISR

Icon

When CV/CC Slew Rate Priority (CVLS/CCLS)

is activated, the icon will be shown. Note that

when SEQ appears, the icon will be faded out.

10.

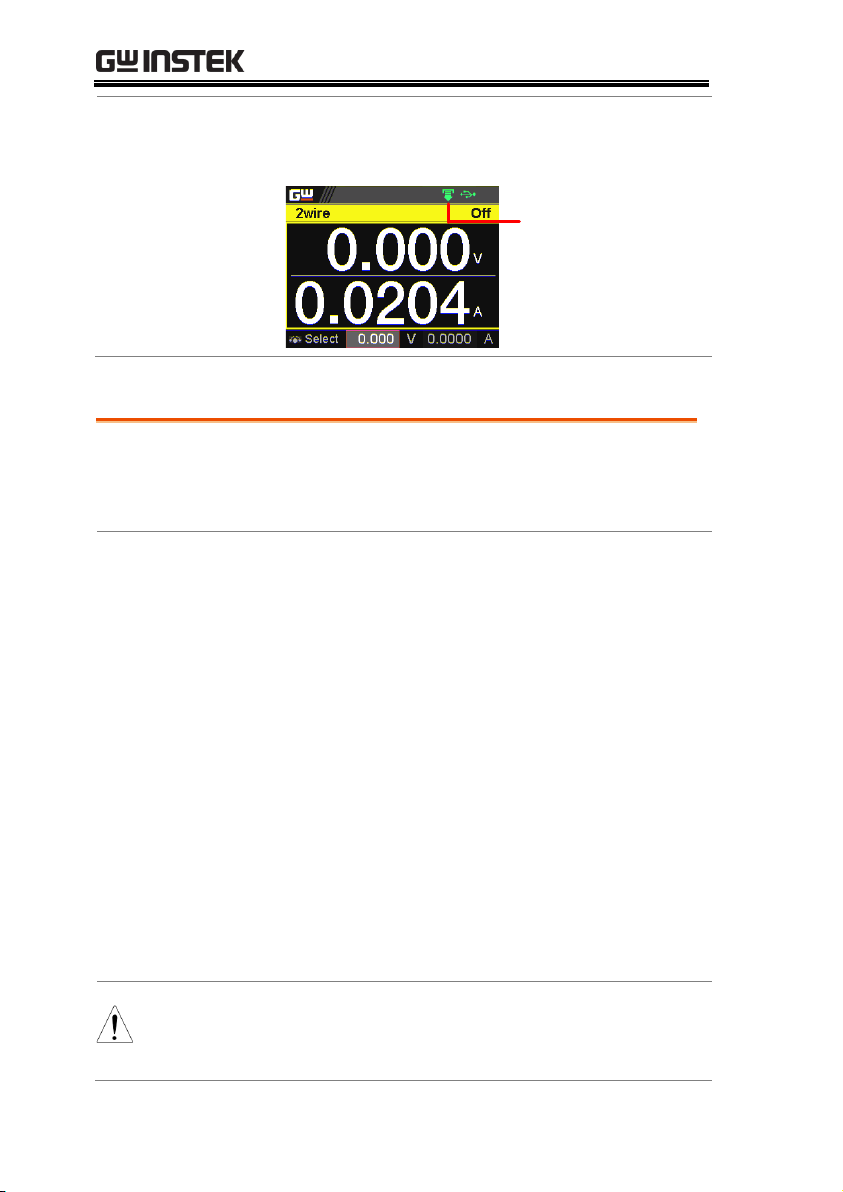

CC/CV/UR

indicator

It shows when constant voltage or constant

current mode is ongoing. However, when output

is unregulated, which means neither in CV mode

nor CC mode, it shows UR instead. If it is not

under power output, it simply shows Off.

11.

LAN Indicator

When PPX series connects to LAN network, the

icon will be shown.

12.

Remote Control

Indicator

When remote control (USB/LAN/GPIB,

UART) is underway, the icon will be shown.

13.

USB Indicator

When USB disk is inserted into the front panel

of PPX series, the icon will be shown.

14.

External Output

Indicator

When external output enable is turned On, the

icon will be shown.

15.

Lock Indicator

When the lock mode is activated, the icon will

be shown.

16.

Communication

Monitor

Indicator

When communication monitor is enabled, the

icon will be shown.

17.

Error Indicator

When error occurs from command of remote

control, the icon will be shown.

16

Rear Panel

5

2

1

3

4

6

7

8

1.

Remote-OUT

RJ-45 connector that is used to daisy chain power

supplies with the Remote-IN port to form a

communication bus.

2.

Remote-IN

Two different types of cables can be used for

RS232 or RS485-based remote control.

PSU-232: RS232 cable with DB9 connector kit.

PSU-485: RS485 cable with DB9 connector kit.

3.

LAN

Ethernet port for controlling the PPX remotely

4.

USB

USB port for controlling the PPX remotely.

GETTING STARTED

17

PPX Series Programming Manual

5.

GPIB

GPIB connector for units equipped with IEEE

programming option. (Factory Installed Options)

6.

EXT I/O

External analog remote control connector.

7.

Line Voltage

Input

AC inlet.

8.

AC Select

Switch

The AC selector is located at the

bottom side of the unit.

Switch Voltage to 100V, 120V,

220V or 240V.

18

GETTING STARTED

Background

The PPX power supplies are regulated DC

power supplies with a stable voltage and

current output. These operate within a switch

automatically between constant voltage and

constant current according to changes in the

load.

Suitable supply cord set for use with the equipment:

Mains plug: shall be national approval

Mains connector: C13 type

Cable:

1. Length of power supply cord: less

than 3m

2. Cross-section of conductors: at least

0.75mm2

3. Cord type: shall meet the

requirements of IEC 60227 or IEC

60245 (e.g.: H05VV-F, H05RN-F)

Caution

If the equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

Theory of Operation

The theory of operation chapter describes the basic principles of

operation, protection modes and important considerations that

must be taken into account before use.

Operating Description

19

PPX Series Programming Manual

CC and CV mode

Description

When the power supply is operating in

constant current mode (CC) a constant current

will be supplied to the load. When in constant

current mode the voltage output can vary,

whilst the current remains constant. When the

load resistance increases to the point where the

set current limit (I

SET

) can no longer be

sustained the power supply switches to CV

mode. The point where the power supply

switches modes is the crossover point.

When the power supply is operating in CV

mode, a constant voltage will be supplied to

the load, whilst the current will vary as the

load varies. At the point that the load

resistance is too low to maintain a constant

voltage, the power supply will switch to CC

mode and maintain the set current limit.

The conditions that determine whether the

power supply operates in CC or CV (V

SET

), the

load resistance (RL) and the critical resistance

(RC). The critical resistance is determined by

V

SET/ISET

. The power supply will operate in CV

mode when the load resistance is greater than

the critical resistance. This means that the

voltage output will be equal to the V

SET

voltage

but the current will be less than I

SET

. If the load

resistance is reduced to the point that the

current output reaches the I

SET

level, the power

supply switches to CC mode.

CC and CV Mode

20

GETTING STARTED

Conversely the power supply will operate in

CC mode when the load resistance is less than

the critical resistance. In CC mode the current

output is equal to I

SET

and the voltage output is

less than V

SET

.

RL=R

C

RL<R

C

VSET

ISET

CV

CC

V

I

RL>R

C

Crossover

point

Theory

The PPX has selectable slew rates for CC and

CV mode. This gives the PPX power supply the

ability to limit the current/voltage draw of the

power supply. Slew rate settings are divided

into High Speed Priority and Slew Rate

Priority. High speed priority mode will use the

fastest slew rate for the instrument. Slew Rate

Priority mode allows for user adjustable slew

rates for CC or CV mode. The rising and falling

slew rate can be set independently.

Slew Rate

21

PPX Series Programming Manual

High Speed

Priority

mode

Slew rate =

Enabled

Background

The PPX DC power supplies employ a bleed

resistor in parallel with the output terminals.

PPX

Load

Bleed

resistor

Bleed resistors are designed to dissipate the

power from the power supply filter capacitors

when power is turned off and the load is

disconnected. Without a bleed resistor, power

may remain charged on the filter capacitors for

some time and be potentially hazardous.

In addition, bleed resistors also allow for

smoother voltage regulation of the power

supply as the bleed resistor acts as a minimum

voltage load.

The bleed resistance can be turned on or off

using the configuration settings.

Bleeder Control

22

GETTING STARTED

Note

By default the bleed resistance is on. For battery

charging applications, be sure to turn the bleed

resistance off as the bleed resistor can discharge

the connected battery when the unit is off.

OVP

Over voltage protection (OVP) prevents a high

voltage from damaging the load. This alarm

can be set by the user.

OCP

Over current protection prevents high current

from damaging the load. This alarm can be set

by the user.

UVL

Under voltage limit. This function sets a

minimum voltage setting level for the output.

It can be set by the user.

OTP

Over temperature protection protect the

instrument from overheating

AC ALARM

When AC input voltage or frequency is

abnormal or beyond the AC power range

under operation, the alarm will be generated.

SENSE ALARM

This alarm function is activated when real

output voltage is larger than sense output

voltage.

Alarm output

Alarms are output via the analog control

connector. The alarm output is an isolated

open-collector photo coupler output.

Alarms

The PPX power supplies have a number of protection features.

When one of the protection alarms is set, the ALM icon on the

display will be lit.

23

PPX Series Programming Manual

Inrush current

When the power supply switch is first turned

on, an inrush current is generated. Ensure there

is enough power available for the power

supply when first turned on, especially if a

number of units are turned on at the same

time.

Caution

Cycling the power on and off quickly can cause the

inrush current limiting circuit to fail as well as

reduce the working life of the input fuse and power

switch.

Pulsed or Peaked

loads

When the load has current peaks or is pulsed, it

is possible for the maximum current to exceed

the mean current value. The PPX power supply

ammeter only indicates mean current values,

which means for pulsed current loads, the

actual current can exceed the indicated value.

For pulsed loads, the current limit must be

increased, or a power supply with a greater

capacity must be chosen. As shown below, a

pulsed load may exceed the current limit and

the indicated current on the power supply

ammeter.

Considerations

The following situations should be taken into consideration when

using the power supply.

24

GETTING STARTED

Current limit

level

Measured

Ammeter

current

Reverse Current:

Regenerative load

When the power supply is connected to a

regenerative load such as a transformer or

inverter, reverse current will feed back to the

power supply. The PPX power supply cannot

absorb reverse current. For loads that create

reverse current, connect a resistor in parallel

(dummy load) to the power supply to bypass

the reverse current. To calculate the resistance

for the dummy resistor, RD, first determine the

maximum reverse current, IR, and determine

what the output voltage, EO, will be.

RD(Ω) ≤ EO(V) ÷ IR(A)

PPX

Load

R

D

I

R

I

R

-

+

E

O

Output

Current

Note

The current output will decrease by the amount of

current absorbed by the resistor.

Ensure the resistor used can withstand the power

capacity of the power supply/load.

25

PPX Series Programming Manual

Reverse Current:

Accumulative

energy.

When the power supply is connected to a load

such as a battery, reverse current may flow

back to the power supply. To prevent damage

to the power supply, use a reverse-currentprotection diode in series between the power

supply and load.

PPX

Load

Diode

CAUTION

Ensure the reverse withstand voltage of the diode

is able to withstand 2 times the rated output

voltage of the power supply and the forward

current capacity can withstand 3 to 10 times the

rated output current of the power supply.

Ensure the diode is able to withstand the heat

generated in the following scenarios.

When the diode is used to limit reverse voltage,

remote sensing cannot be used.

26

GETTING STARTED

Floating

As the output terminals are floating, the load

and all load cables must have an insulation

capacity that is greater than the isolation

voltage of the power supply.

PPX

Load

Ext-V

Ext-R

Analog

connector

( ) Insulation capacity > isolation voltage

of power supply

WARNING

If the insulation capacity of the load and load

cables are not greater than the isolation voltage of

the power supply, electric shock may occur.

Grounding

The output terminals of the PPX power supplies are isolated with

respect to the protective grounding terminal. The insulation

capacity of the load, the load cables and other connected devices

must be taken into consideration when connected to the protective

ground or when floating.

27

PPX Series Programming Manual

Grounded output

terminal

If the positive or negative terminal is connected

to the protective ground terminal, the

insulation capacity needed for the load and

load cables is greatly reduced. The insulation

capacity only needs to be greater than the

maximum output voltage of the power supply

with respect to ground.

PPX

Load

Ext-V

Ext-R

Analog

connector

( ) Insulation capacity > voltage of power

supply with respect to ground

CAUTION

If using external voltage control, do not ground

the external voltage terminal as this will create a

short circuit.

28

REMOTE CONTROL

Interface Configuration ........................................... 31

USB Remote Interface ............................................................................... 31

Configuration ........................................................................................ 31

USB CDC Function Check ................................................................ 32

GPIB Remote Interface ............................................................................ 39

Configuration ........................................................................................ 39

GPIB Function Check ........................................................................ 40

UART Remote Interface ........................................................................... 44

Configure UART .................................................................................. 44

UART Function Check ....................................................................... 46

Multiple Unit Connection ......................................................................... 47

Multi Unit Connection ........................................................................ 47

Multiple units Function Check .......................................................... 48

Error Message ............................................................................................. 50

Command Errors ................................................................................. 50

Execution Errors .................................................................................. 51

Devic Specific Errors .......................................................................... 53

Query Errors ......................................................................................... 53

Other SCPI Defined Error Values.................................................... 54

Configure Ethernet Connection .............................................................. 55

Web Server Configuration .................................................................. 55

Web Server Remote Control Function Check ................................ 56

Sockets Server Configuration ............................................................. 58

Socket Server Function Check ........................................................... 59

Socket Server Examples .......................................... 64

Visual Basic Example ................................................................................. 64

C++ Example ............................................................................................. 65

LabVIEW Example ................................................................................... 67

Command Syntax .................................................... 68

Command List ........................................................ 72

REMOTE CONTROL

This chapter describes basic configuration of

IEEE488.2 based remote control.

29

PPX Series Programming Manual

Status Register Overview ........................................ 130

Introduction to the Status Registers ........................................................130

The Status Registers ...................................................................................131

Questionable Status Register Group .......................................................132

Operation Status Register Group ............................................................135

Standard Event Status Register Group ...................................................138

Status Byte Register & Service Request Enable Register .....................140

Error List ................................................................. 142

Command Errors ........................................................................................142

Execution Errors ........................................................................................146

Device Specific Errors ...............................................................................148

Query Errors ...............................................................................................149

30

REMOTE CONTROL

USB

Configuration

PC side

connector

Type A, host

PPX side

connector

Rear panel Type B, slave

Speed

1.1 (full speed)

USB Class

CDC (communications device

class)

Steps

1. Connect the USB cable to the rear

panel USB B port.

2. Set the USB setting as Auto or Full.

3. The indicator will be shown when a remote

connection has been established.

Remote

Control

indicator

Interface Configuration

USB Remote Interface

Configuration

31

PPX Series Programming Manual

Background

To test the USB CDC functionality, National

Instruments Measurement and Automation

Explorer can be used. This program is available

on the NI website, www.ni.com., via a search

for the VISA Run-time Engine page, or

“downloads” at the following URL,

http://www.ni.com/visa/

Requirements

Operating System: Windows XP, 7, 8,10

Functionality

check

1. In case of Window 7 64 bits, once the USB Cable

was connected to PC correctly for a while

(around 1 min). It may show below message at

the lower right area of display.

2. Open the "Run" dialog box by pressing and

holding the Windows key and then press the R

key ("Run").

3. Type devmgmt.msc and click "OK".

USB CDC Function Check

32

REMOTE CONTROL

4. The Device Manager will show up CDC-

WXXXXXX on “Other Devices”.

5. Select the CDC-WXXXXXX and click the right

button of mouse to "Update Driver Software".

33

PPX Series Programming Manual

6. Select "Locate and install driver software

manually."

7. Indicate the driver folder to the system and

then press "Next".

And this folder should consist of below 2 files.

Note

The USB driver of PPX can be downloaded from

download area of PPX on the GW Instek website

http://www.gwinstek.com/englobal/Support/download

34

REMOTE CONTROL

8. Windows 7 will install the driver for a while.

9. If everything works fine, you may get below

message. And the COM53 is the USB CDC

ACM port of PPX.

35

PPX Series Programming Manual

10. Double check the "Device Manager". The port

should like below.

Steps 1~10 are for the USB CDC Driver

installation.

11. Start the NI Measurement and Automation

Explorer (MAX) program. Using Windows,

press:

Start>All Programs>National

Instruments>Measurement & Automation

36

REMOTE CONTROL

12. From the Configuration panel access;

My System>Devices and Interfaces>Network

Devices

13. Click Open VISA Test Panel.

12

13

14. Click the Configuration icon,

15. Click on I/O Settings.

16. Make sure the Enable Termination Character

check box is checked, and the terminal

character is \n (Value: xA).

17. Click Apply Changes.

14

15

17

16

18. Click the Input/Output icon.

19. Enter *IDN? in the Select or Enter Command

dialog box if it is not already.

20. Click the Query button.

37

PPX Series Programming Manual

21. The *IDN? query will return the Manufacturer,

model name, serial number and firmware

version in the dialog box.

GW-INSTEK,PPX-10H01,TW123456,V0.A4

18

21

19

20

38

REMOTE CONTROL

Configure GPIB

1. Ensure the PPX is off before proceeding.

2. Connect the GPIB cable (GW Instek part

number: GTL-258) from a GPIB controller to the

GPIB port on the PPX.

3. Turn the PPX on.

4. Set the GPIB Address setting per

application.

5. The indicator will be shown when a remote

connection has been established.

Remote

Control

indicator

GPIB constraints

Maximum 15 devices altogether, 20m cable

length, 2m between each device

Unique address assigned to each device

At least 2/3 of the devices turned On

No loop or parallel connection

GPIB Remote Interface

Configuration

To use GPIB, the optional GPIB option (GW Instek part number:

Option 1) must be installed. This is a factory installed option and

cannot be installed by the end-user. Only one GPIB address can be

used at a time.

39

PPX Series Programming Manual

Background

To test the GPIB functionality, National

Instruments Measurement and Automation

Explorer can be used. This program is available

on the NI website, www.ni.com., via a search

for the VISA Run-time Engine page, or

“downloads” at the following URL,

http://www.ni.com/visa/

Requirements

Operating System: Windows XP, 7, 8, 10

Functionality

check

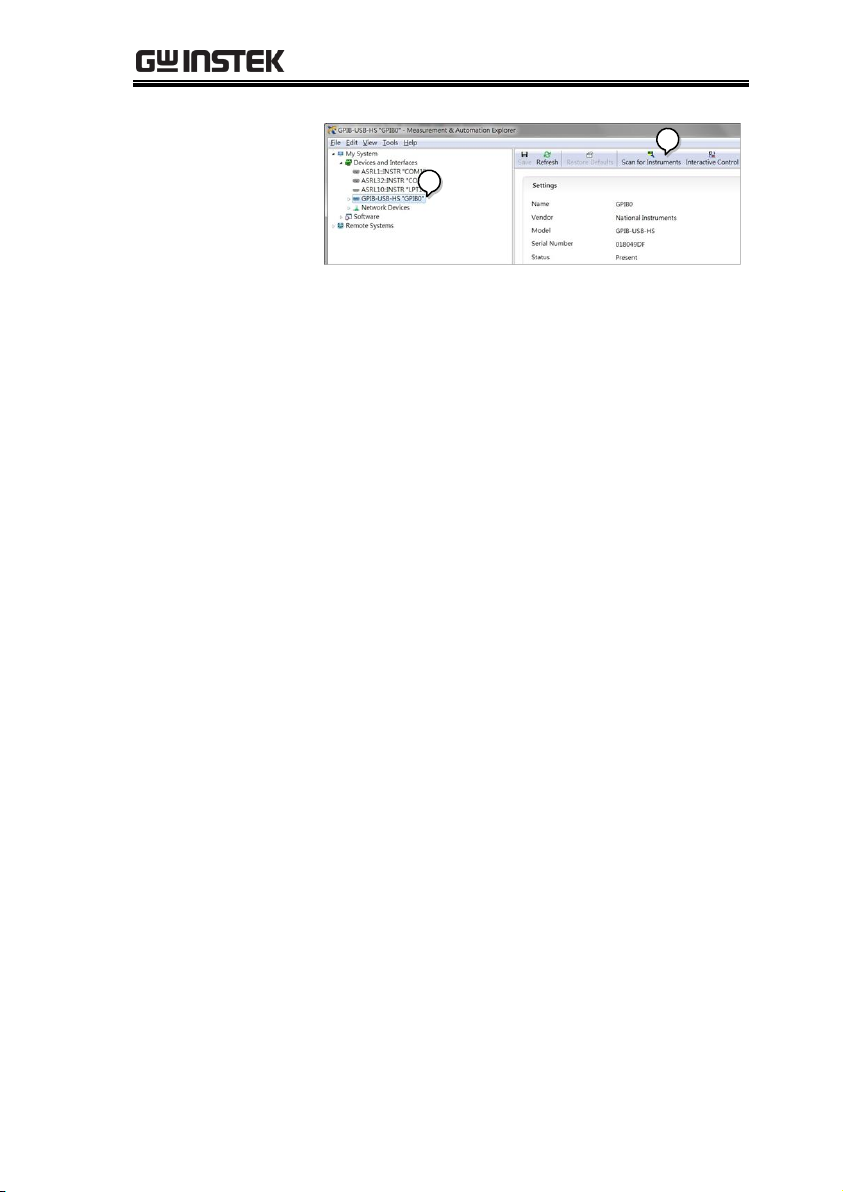

1. Start the NI Measurement and Automation

Explorer (MAX) program. Using Windows,

press:

Start>All Programs>National

Instruments>Measurement & Automation

2. From the Configuration panel access;

My System>Devices and Interfaces>GPIB

3. Press Scan for Instruments.

GPIB Function Check

40

REMOTE CONTROL

2

3

4. Select the device (GPIB address of PPX) that

now appears in the System>Devices and

Interfaces > GPIB-USB-HS “GPIBX” node.

5. Click on the VISA Properties tab on the bottom.

6. Click Open Visa Test Panel.

41

PPX Series Programming Manual

4

5

6

7. Click on Configuration.

8. Click on the GPIB Settings tab and confirm that

the GPIB settings are correct.

7

8

9. Click on the I/O Settings tab.

10. Make sure the Enable Termination Character

check box is checked, and the terminal

character is \n (Value: xA).

11. Click Apply Changes.

42

REMOTE CONTROL

10

9

11

12. Click on Input/Output.

13. Click on the Basic I/O tab.

14. Enter *IDN? in the Select or Enter Command drop

down box.

15. Click Query.

16. The *IDN? query will return the Manufacturer,

model name, serial number and firmware

version in the dialog box.

GW-INSTEK,PPX-10H01,TW123456,V0.A4

43

PPX Series Programming Manual

12

13

15

16

14

Note

For further details, please see the programming

manual, available on the GW Instek web site @

www.gwinstek.com.

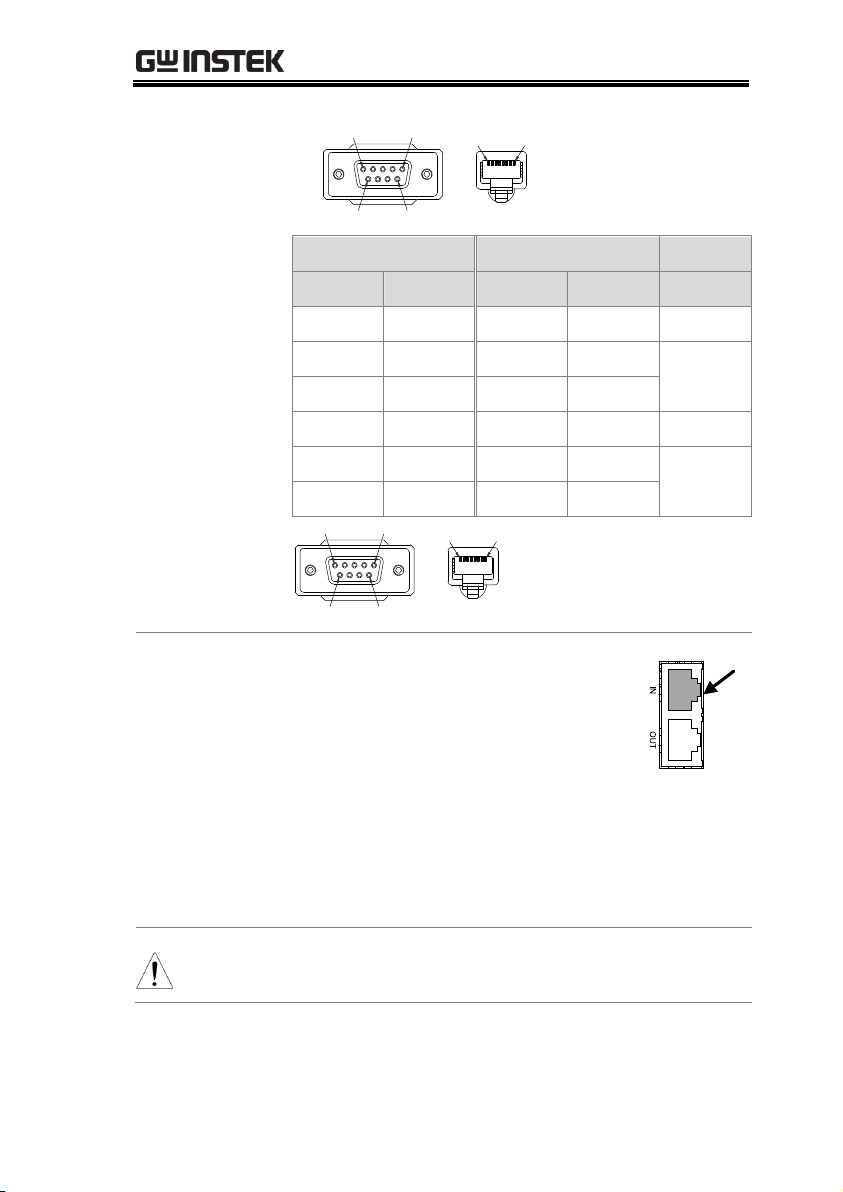

Overview

The PPX uses the IN & OUT ports for UART

communication coupled with RS232 (GW Instek

part number: GTL-259) or RS485 adapters (GW

Instek part number: GTL-260).

The pin outs for the adapters are shown below.

RS232 cable with

DB9 & RJ-45

shielded

connectors from

GTL-259

connection kit

DB-9 Connector

Remote IN Port

Remarks

Pin No.

Name

Pin No.

Name

Housing

Shield

Housing

Shield

2 RX 7 TX

Twisted

pair

3

TX 8 RX

5

SG 1 SG

UART Remote Interface

Configure UART

44

REMOTE CONTROL

5 1

9 6

1 8

RS485 cable with

DB9 & RJ-45

shielded

connectors from

GTL-260

connection kit

DB-9 Connector

Remote IN Port

Remarks

Pin No.

Name

Pin No.

Name

Housing

Shield

Housing

Shield

9 TXD -

6

RXD -

Twisted

pair

8

TXD +

3

RXD +

1

SG 1 SG 5

RXD -

5

TXD -

Twisted

pair

4

RXD +

4

TXD +

5 1

9 6

1 8

Steps

1. Connect the RS232 serial cable or

RS485 serial cable to the Remote IN

port on the real panel. Connect the

other end of the cable to the PC.

RS232

/ RS485

1

2. Select RS485 or RS232 for Mode

setting. Also set UART relevant

settings including Baud Rate, Data

Bits, Parity, Stop Bits and Address.

Note

When RS232 Mode is selected, the Address setting

is not available for assignation.

45

PPX Series Programming Manual

3. The indicator will be shown when a remote

connection has been established.

Remote

Control

indicator

Functionality

check

Invoke a terminal application such as Realterm.

To check the COM port No., see the Device

Manager in the PC

Run this query command via the terminal

application after the instrument has been

configured for UART remote control.

*idn?

This should return the Manufacturer, Model

number, Serial number, and Firmware version

in the following format.

GW-INSTEK,PPX-10H01,TW123456,V0.A4

Manufacturer: GW-INSTEK

Model number : PPX-10H01

Serial number : TW1234567

Firmware version : V0.A4

Note

For further details, please see the programming

manual, available on the GW Instek web site @

www.gwinstek.com.

UART Function Check

46

REMOTE CONTROL

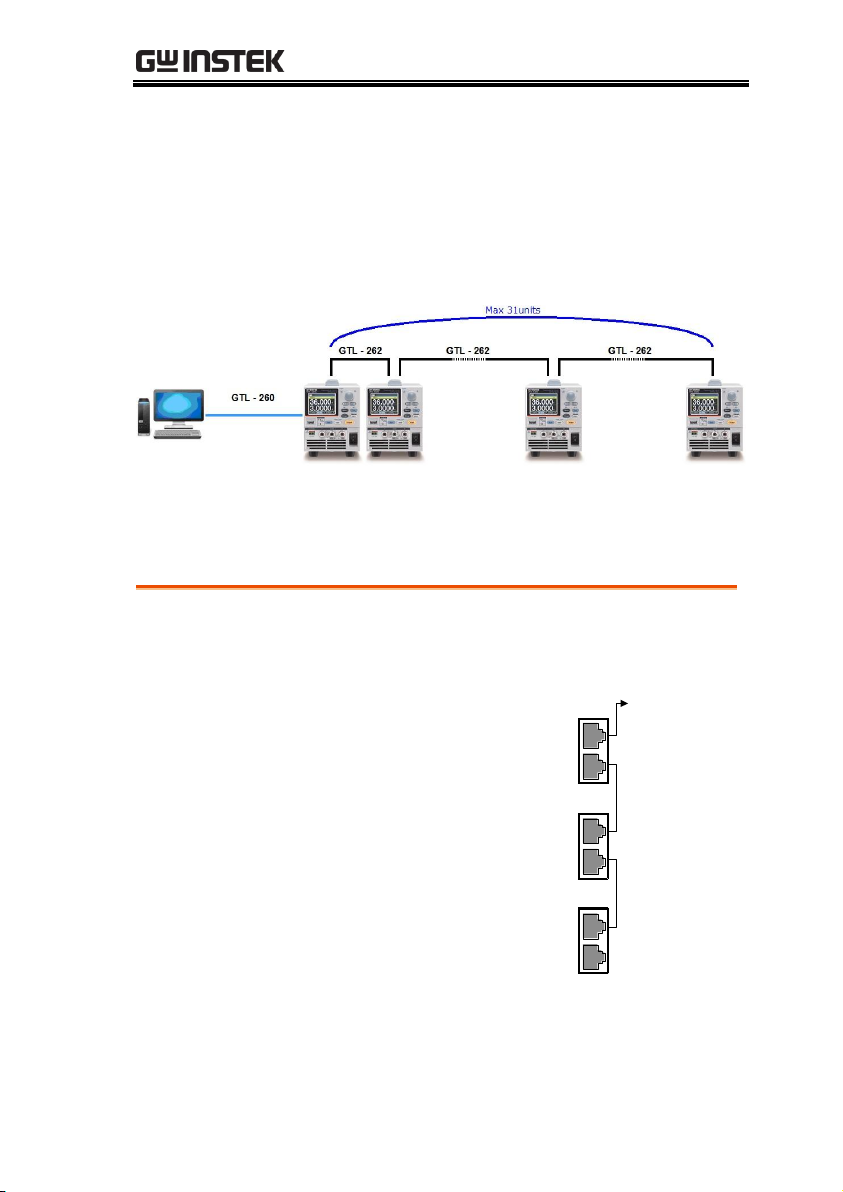

Operation

1. Connect the first unit's IN port to a PC using

RS485 cable with DB9 & RJ-45.

2. Connect the OUT port

on the first unit to the IN

port of the second unit

using the slave serial link

cable (black plug)

supplied in the GTL-262

connection kit.

To PC

IN

IN

serial link cable

(black plug)

Unit #1

OUT

IN

RS 485/232

Unit #2

RS 485/232

Unit #N

RS 485/232

OUT

OUT

PSU-485 cable

with DB9 & RJ-45

serial link cable

(black plug)

3. Power up all units.

Multiple Unit Connection

The PPX power supplies can have up to 31 units daisy-chained

together using the 8 pin connectors (IN OUT ports) on the rear

panel. The first unit in the chain is remotely connected to a PC

using GTL-260 (RS485 cable with DB9 connector).Each subsequent

unit is daisy-chained to the next using a RS485 local bus.

Each unit is assigned a unique address and can then be

individually controlled from the host PC.

Multi Unit Connection

47

PPX Series Programming Manual

4. Set the addresses and mode of all units using

UART menu. It must be a unique address

identifier and mode select is RS485.

5. Multiple units can be operated using SCPI

commands now. See the programming manual

or see the function check below for usage

details.

Functionality

check

Invoke a terminal application such as Realterm.

To check the COM port No, see the Device

Manager in the PC.

For this function check, we will assume that the

one unit is assigned to address 0, while other is

assigned address 5.

ADR 0

OK

*IDN?

GW-INSTEK,PPX-2005,TW123456,V0.A2

VOLT 5

OK

VOLT?

+5.000

Multiple units Function Check

48

REMOTE CONTROL

ADR is followed by address, which can be 0

to 31 and is used to access the power supply.

Selects the unit with address 0 and returns

its identity string. Also, sets its volt as 5 and

returns its volt in 5.

ADR 5

OK

*IDN?

GW-INSTEK,PPX-3601,TW654321,V0.A2

VOLT 10

OK

VOLT?

+10.000

ADR is followed by address, which can be 0

to 31 and is used to access the power supply.

Selects the unit with address 5 and returns

its identity string. Also, sets its volt as 10

and returns its volt in 10.

Note

All setting commands must return an “OK”

response, via a following “Read” action by user,

before any other commands are accepted. The

power supply acknowledges received commands

by returning an “OK” message. If no Read action is

executed after a setting command, and user

proceed to another query command, there will be

something issue occurred within the returned

message where an OK message will be shown

prior to the returned message corresponding to

the query command.

When an error is detected the power supply will

return an error message. For further details, please

see the programming manual, available on the GW

Instek web site @ www.gwinstek.com.

49

PPX Series Programming Manual

Overview

The command error bit in the standard Event

Status Register (ESR) is set to ‘1' when such an

error occurs.

Error Code

Description

E-100

Command error

E-101

Invalid character

E-102

Syntax error

E-103

Invalid separator

E-104

Data type error

E-105

GET not allowed

E-108

Parameter not allowed

E-109

Missing parameter

E-110

Command header error

E-111

Header separator error

E-112

Program mnemonic too long

E-113

Undefined header

E-114

Header suffix out of range

E-115

Unexpected number of parameters

E-120

Numeric data error

E-121

Invalid character in number

E-123

Exponent too large

E-124

Too many digits

E-128

Numeric data not allowed

E-130

Suffix error

E-131

Invalid suffix

E-134

Suffix too long

E-138

Suffix not allowed

E-140

Character data error

E-141

Invalid character data

E-144

Character data too long

Error Message

If an error is detected in command or query, the power supply will

respond with an error message.

Command Errors

50

E-148

Character data not allowed

E-150

String data error

E-151

Invalid string data

E-158

String data not allowed

E-160

Block data error

E-161

Invalid block data

E-168

Block data not allowed

E-170

Expression error

E-171

Invalid expression

E-178

Expression data not allowed

E-180

Macro error

E-181

Invalid outside macro definition

E-183

Invalid inside macro definition

E-184

Macro parameter error

Execution Errors

Overview

The execution error bit in the standard Event

Status Register (ESR) is set to ‘1' when such an

error occurs.

Error Code

Description

E-200

Execution error

E-201

Invalid while in local

E-202

Settings lost due to rtl

E-203

Command protected

E-210

Trigger error

E-211

Trigger ignored

E-212

Arm ignored

E-213

Init ignored

E-214

Trigger deadlock

E-215

Arm deadlock

E-220

Parameter error

E-221

Settings conflict

E-222

Data out of range

E-223

Too much data

E-224

Illegal parameter value

E-225

Out of memory

E-226

Lists not same length

REMOTE CONTROL

51

PPX Series Programming Manual

E-230

Data corrupt or stale

E-231

Data questionable

E-232

Invalid format

E-233

Invalid version

E-240

Hardware error

E-241

Hardware missing

E-250

Mass storage error

E-251

Missing mass storage

E-252

Missing media

E-253

Corrupt media

E-254

Media full

E-255

Directory full

E-256

File name not found

E-257

File name error

E-258

Media protected

E-260

Expression error

E-261

Math error in expression

E-270

Macro error

E-271

Macro syntax error

E-272

Macro execution error

E-273

Illegal macro label

E-274

Macro parameter error

E-275

Macro definition too long

E-276

Macro recursion error

E-277

Macro redefinition not allowed

E-278

Macro header not found

E-280

Program error

E-281

Cannot create program

E-282

Illegal program name

E-283

Illegal variable name

E-284

Program currently running

E-285

Program syntax error

E-286

Program runtime error

E-290

Memory use error

E-291

Out of memory

E-292

Referenced name does not exist

E-293

Referenced name already exists

E-294

Incompatible type

52

REMOTE CONTROL

Overview

The device dependant error bit in the standard

Event Status Register (ESR) is set to '1' when such

an error occurs.

Error Code

Description

E-300

Device-specific error.

E-310

System error.

E-311

Memory error.

E-312

PUD memory lost.

E-313

Calibration memory lost.

E-314

Save/recall memory lost.

E-315

Configuration memory lost.

E-320

Storage fault.

E-321

Out of memory.

E-330

Self-test failed.

E-340

Calibration failed.

E-350

Queue overflow.

E-360

Communication error.

E-361

Parity error in program message.

E-362

Framing error in program message.

E-363

Input buffer overrun.

E-365

Time out error.

Overview

The query error bit in the standard Event Status

Register (ESR) is set to ‘1' when such an error

occurs.

Error Code

Description

E-400

Query error.

E-410

Query INTERRUPTED.

E-420

Query UNTERMINATED.

E-430

Query DEADLOCKED.

E-440

Query UNTERMINATED after indefinite response.

Devic Specific Errors

Query Errors

53

PPX Series Programming Manual

Overview

The corresponding bit in the standard Event Status

Register (ESR) is set to ‘1' when such an event

occurs.

Error Code

Description

E-500

Power on.

E-600

User request.

E-700

Request control.

E-800

Operation complete.

Other SCPI Defined Error Values

54

REMOTE CONTROL

Ethernet

configuration

For details on how to configure the Ethernet

settings, please refer to the User Manual.

Parameters

MAC Address

(display only)

Hostname

(display only)

DHCP On/Off

IP Address

Subnet Mask

Gateway IP

DNS Address

Web Server On/Off

Configuration

This configuration example will configure the

PPX as a web server and use DHCP to

automatically assign an IP address to the PPX.

1. Connect an Ethernet cable from the

network to the rear panel Ethernet

port.

Configure Ethernet Connection

The Ethernet interface can be configured for a number of different

applications. Ethernet can be configured for basic remote control or

monitoring using a web server or it can be configured as a socket

server.

The PPX series supports both DHCP connections so the instrument

can be automatically connected to an existing network or

alternatively, network settings can be manually configured.

Web Server Configuration

55

PPX Series Programming Manual

2. Turn On DHCP and Web Server

settings.

3. The indicator will be shown when a remote

connection has been established.

Remote

Control

indicator

Note

It may be necessary to cycle the power or refresh

the web browser to connect to a network.

Functionality

check

Enter the IP address of the power supply in a

web browser after the instrument has been

configured as a web server.

The web server allows you to monitor the

function settings of the PPX.

Web Server Remote Control Function Check

56

REMOTE CONTROL

The web browser interface appears as follows.

The web browser interface allows you to access the

following:

Network configuration settings

Measurement setting

Normal Function setting

External Control setting

Temperature Control setting

Analog Control

Figure of Dimension

Sequence setting

Datalog setting

57

PPX Series Programming Manual

Configuration

This configuration example will configure the

PPX socket server.

The following configuration settings will

manually assign the PPX an IP address and

enable the socket server. The socket server port

number is fixed at 2268.

1. Connect an Ethernet cable from the

network to the rear panel Ethernet

port.

2. Turn Off DHCP setting followed by

setting the relevant settings

including IP Address, Subnet Mask,

Gateway IP and DNS Address.

3. The indicator will be shown when a remote

connection has been established.

Remote

Control

indicator

Sockets Server Configuration

58

REMOTE CONTROL

Background

To test the socket server functionality, National

Instruments Measurement and Automation

Explorer can be used. This program is available

on the NI website, www.ni.com., via a search

for the VISA Run-time Engine page, or

“downloads” at the following URL,

http://www.ni.com/visa/

Requirements

Operating System: Windows XP, 7, 8, 10

Functionality

check

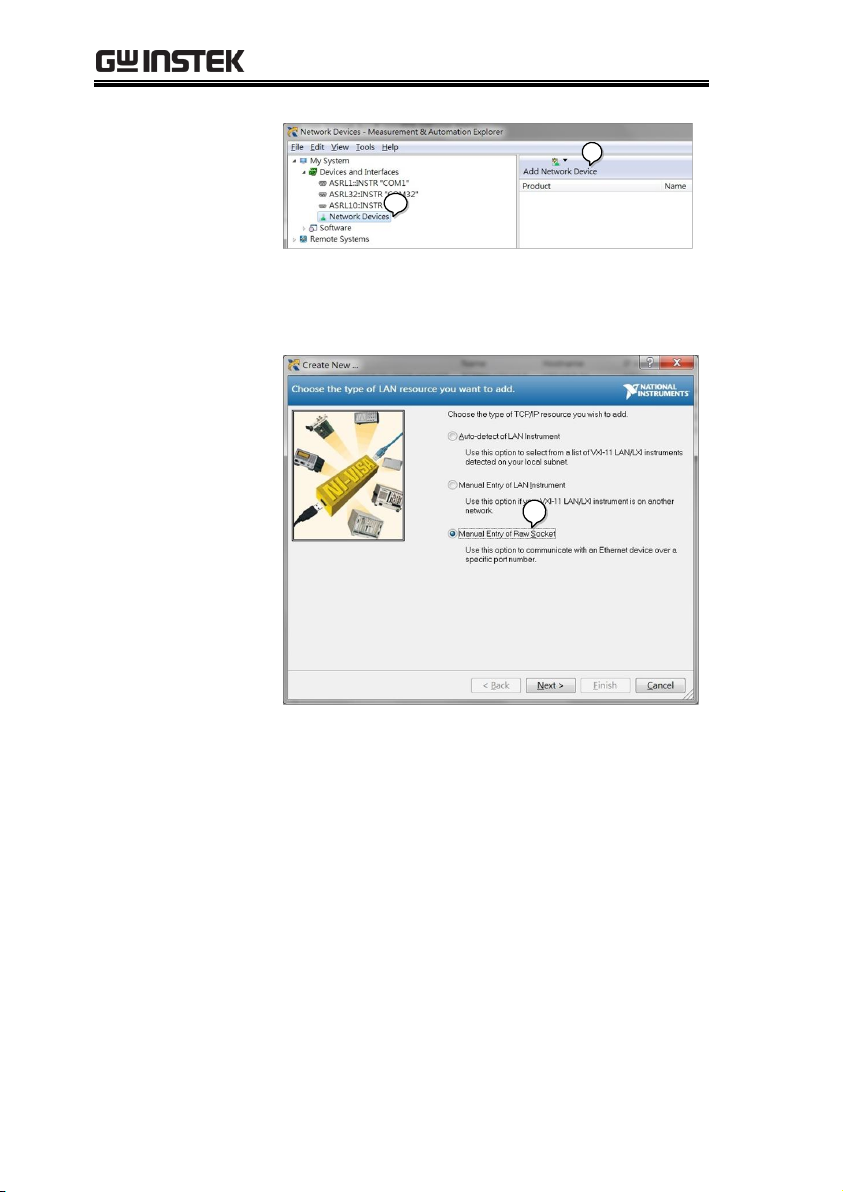

1. Start the NI Measurement and Automation

Explorer (MAX) program. Using Windows,

press:

Start>All Programs>National

Instruments>Measurement & Automation

2. From the Configuration panel access;

My System>Devices and Interfaces>Network

Devices

3. Press Add New Network Device>Visa TCP/IP

Resource…

Socket Server Function Check

59

PPX Series Programming Manual

2

3

4. Select Manual Entry of Raw Socket from the

popup window.

4

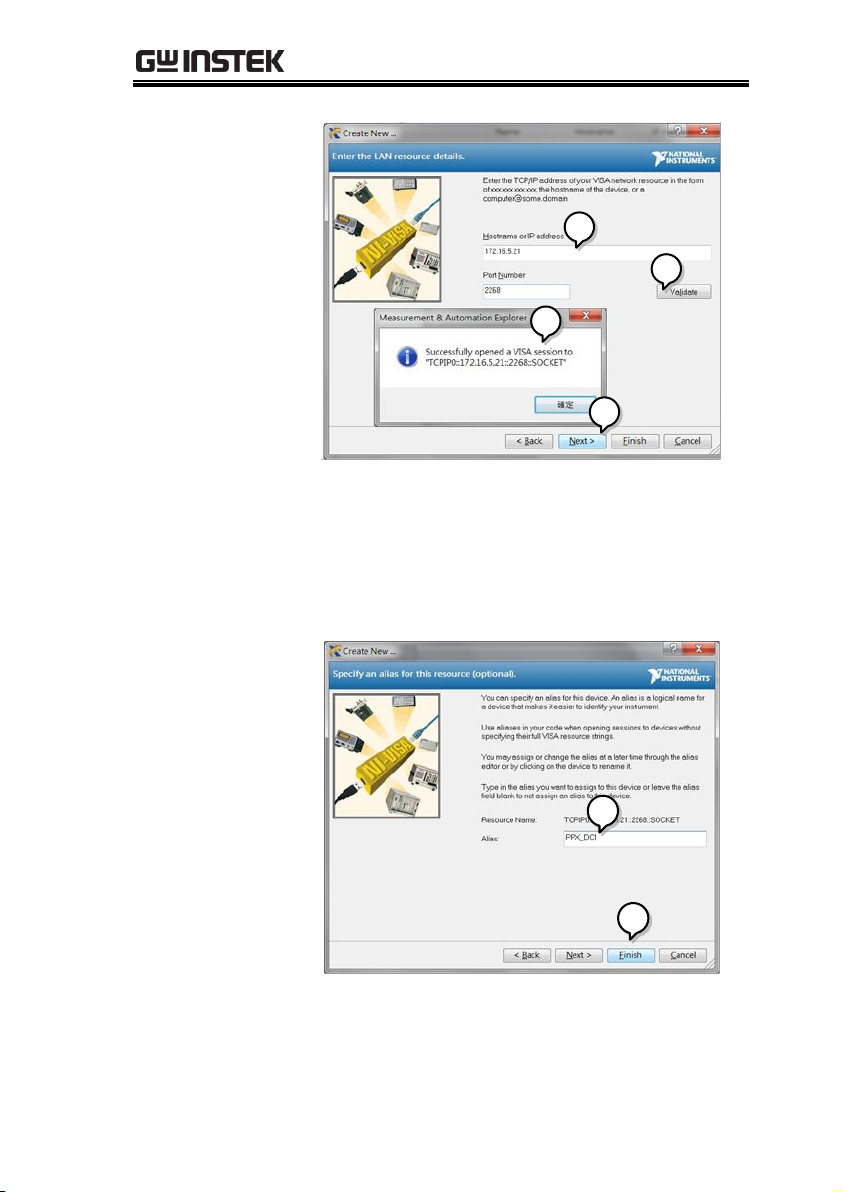

5. Enter the IP address and the port number of the

PPX. The port number is fixed at 2268.

6. Click the Validate button.

7. A popup will appear if a connection is

successfully established.

8. Click Next.

60

REMOTE CONTROL

6

5

7

8

9. Next configure the Alias (name) of the PPX

connection. In this example the Alias is:

PPX_DC1

10. Click finish.

9

10

11. The IP address of the PPX will now appear

under Network Devices in the configuration

panel. Select this icon now.

61

PPX Series Programming Manual

12. Click Open VISA Test Panel.

11

12

13. Click the Configuration icon,

14. Click on I/O Settings.

15. Make sure the Enable Termination Character

check box is checked, and the terminal

character is \n (Value: xA).

16. Click Apply Changes.

14

13

15

16

17. Click the Input/Output icon.

18. Enter *IDN? in the Select or Enter Command

dialog box if it is not already.

19. Click the Query button.

62

REMOTE CONTROL

20. The *IDN? query will return the Manufacturer,

model name, serial number and firmware

version in the dialog box.

GW-INSTEK,PPX-10H01,TW123456,V0.A4

18

17

19

20

Note

For further details, please see the programming

manual, available on the GW Instek web site @

www.gwinstek.com.

63

PPX Series Programming Manual

Visual Basic Example ............................................... 64

C++ Example ........................................................... 65

LabVIEW Example.................................................. 67

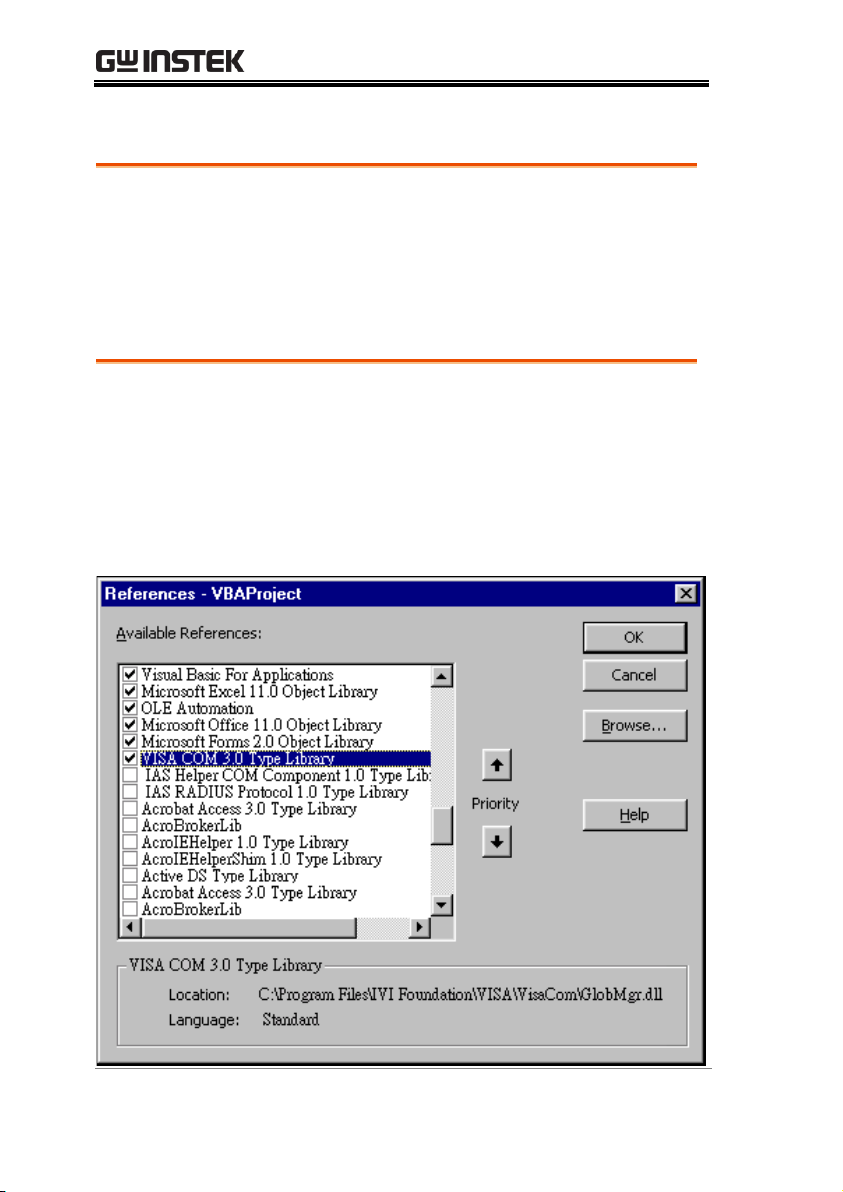

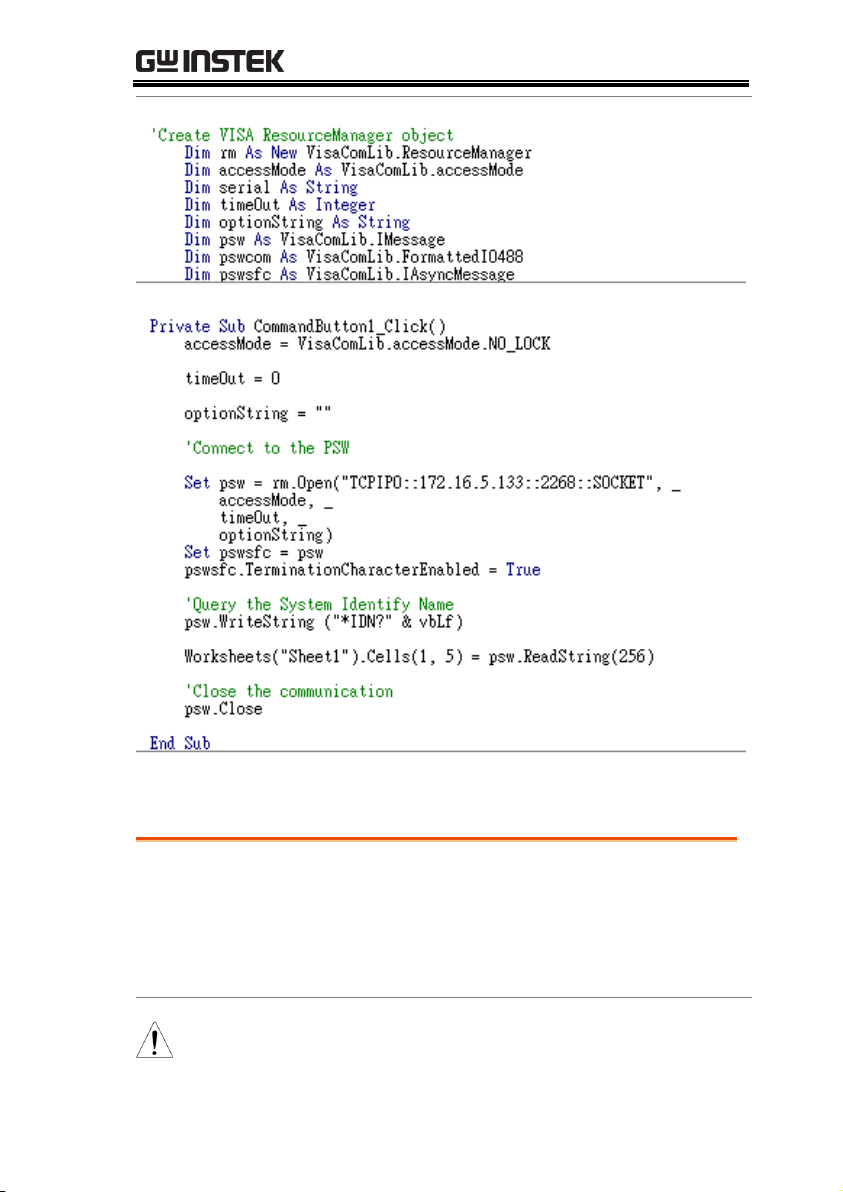

Background

The following visual basic programming

example uses the VISA COM 3.0 Type Library.

The example will connect to the PPX series

using the IP address of 172.15.5.133 over port

2268. The program will send the *IDN? to the

PPX Series, print the return string and then

close the connection.

Socket Server Examples

Visual Basic Example

64

REMOTE CONTROL

Background

The following program creates a connection to

the PPX series and sets the voltage to 3.3 volts

and the current 1.5 amps. The voltage and

current reading is then read back and the

connection is closed.

Note

Add visa32.lib to the project library when

building the following sample program.

C++ Example

65

PPX Series Programming Manual

66

REMOTE CONTROL

Background

The following picture shows a LabView

programming example for the PPX Series.

LabVIEW Example

67

PPX Series Programming Manual

Compatible

Standard

IEEE488.2

Partial compatibility

SCPI, 1999

Partial compatibility

Command

Structure

SCPI commands follow a tree-like structure,

organized into nodes. Each level of the

command tree is a node. Each keyword in a

SCPI command represents each node in the

command tree. Each keyword (node) of a SCPI

command is separated by a colon (:).

For example, the diagram below shows an SCPI

sub-structure and a command example.

DC

MEASure

SCALar

POWer

VOLTage

CURRent

DC

DC

MEASure:SCALar:CURRent:DC?

Command types

There are a number of different instrument

commands and queries. A command sends

instructions or data to the unit and a query

receives data or status information from the

unit.

Command types

Simple

A single command

with/without a parameter

Example

*IDN?

Command Syntax

68

REMOTE CONTROL

Query

A query is a simple or

compound command

followed by a question mark

(?). A parameter (data) is

returned.

Example

meas:curr:dc?

Compound

Two or more commands on

the same command line.

Compound commands are

separated with either a semicolon (;) or a semi-colon and a

colon (;:).

A semi-colon is used to join

two related commands, with

the caveat that the last

command must begin at the

last node of the first

command.

A semi-colon and colon are

used to combine two

commands from different

nodes.

Example

meas:volt:dc?;:meas:curr:dc?

69

PPX Series Programming Manual

Command Forms

Commands and queries have two different

forms, long and short. The command syntax is

written with the short form of the command in

capitals and the remainder (long form) in lower

case.

The commands can be written in capitals or

lower-case, just so long as the short or long

forms are complete. An incomplete command

will not be recognized.

Below are examples of correctly written

commands.

Long

form

STATus:OPERation:NTRansition?

STATUS:OPERATION:NTRANSITION?

status:operation:ntransition?

Short

form

STAT:OPER:NTR?

stat:oper:ntr?

Square Brackets

Commands that contain square brackets

indicate that the contents are optional. The

function of the command is the same with or

without the square bracketed items, as shown

below.

Both “DISPlay:MENU[:NAME]?” and

“DISPlay:MENU?” are both valid forms.

Command

Format

1.5,5.2

1 2 3 4 5

APPLY

1. Command header

2. Space

3. Parameter 1

4. Comma (no space

before/after comma)

5. Parameter 2

Parameters

Type

Description

Example

<Boolean>

Boolean logic

0, 1

70

REMOTE CONTROL

<NR1>

integers

0, 1, 2, 3

<NR2>

decimal

numbers

0.1, 3.14, 8.5

<NR3>

floating point

4.5e-1, 8.25e+1

<NRf>

any of NR1, 2, 3

1, 1.5, 4.5e-1

<block data>

Definitive length arbitrary block

data. A single decimal digit

followed by data. The decimal

digit specifies how many 8-bit

data bytes follow.

Message

Terminator

LF

Line feed code

71

PPX Series Programming Manual

Abort Command

:ABORt ....................................................................... 76

Apply Commands

:APPLy ........................................................................ 76

Address Commands

:ADR ........................................................................... 77

Initiate Commands

:INITiate:CONTinuous[:TRANsient] ................... 77

:INITiate[:IMMediate]:NAME ............................... 78

:INITiate[:IMMediate][:TRANsient] ..................... 78

Memory

Commands

:MEMory:TRIGgered ............................................... 79

Measure

Commands

:MEASure[:SCALar]:ALL[:DC] .............................. 80

:MEASure[:SCALar]:CURRent[:DC] .................... 80

:MEASure[:SCALar]:VOLTage[:DC] .................... 80

:MEASure[:SCALar]:POWer[:DC] ........................ 81

:MEASure[:SCALar]:CURRent:RANGe .............. 81

:MEASure[:SCALar]:VOLTage:RANGe .............. 81

:MEASure:TEMPerature ......................................... 82

Output Commands

:OUTPut:DELay:ON ............................................... 83

:OUTPut:DELay:OFF ............................................. 83

:OUTPut:MODE ...................................................... 84

:OUTPut[:STATe][:IMMediate] ............................. 84

:OUTPut[:STATe]:TRIGgered ............................... 84

:OUTPut:PROTection:CLEar ................................ 85

:OUTPut:PROTection:TRIPped ........................... 85

:OUTPut:PROTection:WDOG[:STATe] ............. 85

:OUTPut:PROTection:WDOG:DELay ............... 85

Command List

72

REMOTE CONTROL

Sense Commands

:SENSe:AVERage:COUNt ..................................... 86

:SENSe:DLOG:SFOL ............................................. 86

:SENSe:DLOG:STATe ........................................... 87

:SENSe:DLOG:PERiod .......................................... 87

:SENSe:AHOur:RESet .............................................. 87

:SENSe:WHOur:RESet ............................................. 87

Status Commands

:STATus:OPERation[:EVENt] .............................. 88

:STATus:OPERation:CONDition ......................... 88

:STATus:OPERation:ENABle ............................... 89

:STATus:OPERation:PTRansition ........................ 89

:STATus:OPERation:NTRansition ....................... 89

:STATus:QUEStionable[:EVENt] ......................... 89

:STATus:QUEStionable:CONDition ................... 90

:STATus:QUEStionable:ENABle .......................... 90

:STATus:QUEStionable:PTRansition ................... 90

:STATus:QUEStionable:NTRansition .................. 91

:STATus:PRESet ....................................................... 91

Source Commands

[:SOURce]:CURRent[:LEVel][:IMMediate]

[:AMPLitude] ............................................................. 92

[:SOURce]:CURRent[:LEVel]:TRIGgered

[:AMPLitude] ............................................................. 93

[:SOURce]:CURRent:LIMit:AUTO ...................... 93

[:SOURce]:CURRent:PROTection:DELay .......... 94

[:SOURce]:CURRent:PROTection[:LEVel] ........ 94

[:SOURce]:CURRent:PROTection:TRIPped ...... 95

[:SOURce]:CURRent:SLEWrate:RISing ............... 95

[:SOURce]:CURRent:SLEWrate:FALLing .......... 96

[:SOURce]:MODE? .................................................. 96

[:SOURce]:VOLTage[:LEVel][:IMMediate]

[:AMPLitude] ............................................................. 97

[:SOURce]:VOLTage[:LEVel]:TRIGgered

[:AMPLitude] ............................................................. 97

[:SOURce]:VOLTage:LIMit:AUTO ...................... 98

[:SOURce]:VOLTage:LIMit:LOW ........................ 98

[:SOURce]:VOLTage:PROTection[:LEVel] ........ 99

[:SOURce]:VOLTage:PROTection:TRIPped ...... 99

[:SOURce]:VOLTage:SLEWrate:RISing .............. 99

[:SOURce]:VOLTage:SLEWrate:FALLing .......... 100

[:SOURce]:VOLTage:SENSe ................................. 100

73

PPX Series Programming Manual

[:SOURce]:POWer[:LEVel][:IMMediate][:AMPLitu

de] ................................................................................ 101

[:SOURce]:POWer:CONTrol ................................. 101

System Commands

:SYSTem:BEEPer[:IMMediate] .............................. 103

:SYSTem:CONFigure:BEEPer[:STATe] .............. 104

:SYSTem:CONFigure:BLEeder[:STATe] ............. 104

:SYSTem:CONFigure:CURRent:CONTrol ......... 105

:SYSTem:CONFigure:VOLTage:CONTrol ........ 105

:SYSTem:CONFigure:OUTPut:PON[:STATe] .. 106

:SYSTem:CONFigure:OUTPut:EXTernal:MODE

...................................................................................... 107

:SYSTem:CONFigure:OUTPut:EXTernal[:STATe]

...................................................................................... 107

:SYSTem:CONFigure:TRIGger:INPut:SOURce 108

:SYSTem:CONFigure:TRIGger:INPut:LEVel .... 108

:SYSTem:CONFigure:TRIGger:OUTPut:SOURce

...................................................................................... 108

:SYSTem:CONFigure:TRIGger:OUTPut:WIDTh

...................................................................................... 109

:SYSTem:CONFigure:TRIGger:OUTPut:LEVel

...................................................................................... 109

:SYSTem:CONFigure:TEMPerature:CONTrol .. 110

:SYSTem:CONFigure:TEMPerature:UNIT ........ 110

:SYSTem:CONFigure:TEMPerature:OUTPut:SAF

E ................................................................................... 111

:SYSTem:CONFigure:TEMPerature:MONitor .. 111

:SYSTem:CONFigure:TEMPerature:ADJust ...... 112

:SYSTem:COMMunicate:ENABle ........................ 112

:SYSTem:COMMunicate:GPIB[:SELF]:ADDRess

...................................................................................... 113

:SYSTem:COMMunicate:LAN:IPADdress .......... 113

:SYSTem:COMMunicate:LAN:GATeway ........... 114

:SYSTem:COMMunicate:LAN:SMASk ................ 114

:SYSTem:COMMunicate:LAN:MAC .................... 114

:SYSTem:COMMunicate:LAN:DHCP ................. 115

:SYSTem:COMMunicate:LAN:DNS .................... 115

:SYSTem:COMMunicate:RLSTate ........................ 115

:SYSTem:COMMunicate:TCPip:CONTrol ......... 116

:SYSTem:COMMunicate:SERial[:RECeive] :TRAN

smit:BAUD ................................................................ 116

:SYSTem:COMMunicate:SERial[:RECeive] :TRAN

smit:BITS .................................................................... 116

74

REMOTE CONTROL

:SYSTem:COMMunicate:SERial[:RECeive] :TRAN

smit:PARity ................................................................ 117

:SYSTem:COMMunicate:SERial[:RECeive] :TRAN

smit:SBITs .................................................................. 117

:SYSTem:COMMunicate:USB:FRONt:STATe .. 118

:SYSTem:COMMunicate:USB:REAR:STATe..... 118

:SYSTem:ERRor ....................................................... 118

:SYSTem:KLOCk ..................................................... 119

:SYSTem:KEYLock:MODE .................................. 119

:SYSTem:ERRor:ENABle ....................................... 119

:SYSTem:PRESet ...................................................... 119

:SYSTem:VERSion ................................................... 119

:SYSTem:KEYBoard:BEEPer .................................. 120

:SYSTem:CAPacity:AHOur ...................................... 120

:SYSTem:CAPacity:WHOur ..................................... 120

:SYSTem:CAPacity:MODE ...................................... 121

:SYSTem:CAPacity:STATe ....................................... 121

Fetch Commands

:FETCh:AHOur? ....................................................... 122

:FETCh:WHOur? ...................................................... 122

Trigger Commands

:TRIGger:OUTPut:SOURce .................................. 123

:TRIGger:OUTPut[:IMMediate] ............................ 123

:TRIGger[:TRANsient]:SOURce ........................... 124

:TRIGger[:TRANsient][:IMMediate]..................... 124

Trigger Command Examples .................................. 125

Common

Commands

*CLS ............................................................................ 126

*ESE ........................................................................... 126

*ESR ............................................................................ 127

*IDN ........................................................................... 127

*OPC ........................................................................... 127

*RCL ........................................................................... 128

*RST ............................................................................ 128

*SAV ........................................................................... 128

*SRE ............................................................................ 128

*STB ............................................................................ 129

*TRG .......................................................................... 129

*TST ............................................................................ 129

*WAI ........................................................................... 129

75

PPX Series Programming Manual

:ABORt ....................................................................... 76

:ABORt

Set

Description

The :ABORt command will cancel any triggered

actions.

Syntax

:ABORt

:APPLy ....................................................................... 76

:APPLy

Set

Query

Description

The apply command sets the voltage and current

at the same time.

Syntax

Query Syntax

:APPLy

{<NRf>(V)|MINimum|MAXimum[,<NRf>(A)|MINimu

m|MAXimum]}

:APPLy?

Parameter/

Return parameter

<NRf>(V)

Voltage setting.

MINimum

Minimum voltage level

MAXimum

Maximum voltage level

<NRf>(A)

Current setting.

MINimum

Minimum voltage level

MAXimum

Maximum voltage level

Example

APPL MIN, MIN

Sets the current and voltage to the minimum settings.

Abort Command

Apply Commands

76

REMOTE CONTROL

:ADR ........................................................................... 77

:ADR

Set

Query

Description

Sets or queries the RS485 interface address.

Syntax

Query Syntax

:ADR <NR1>

:ADR?

Parameter/

Return parameter

<NR1>

0~30

Example

ADR 5

Sets the RS485 address 5.

:INITiate:CONTinuous[:TRANsient] .................. 77

:INITiate[:IMMediate]:NAME .............................. 78

:INITiate[:IMMediate][:TRANsient] ..................... 78

:INITiate:CONTinuous[:TRANsient]

Set

Query

Description

This command continuously initiates software

triggers for the transient or output triggers.

Syntax

Query Syntax

:INITiate:CONTinuous[:TRANsient] {<bool>|OFF|ON}

:INITiate:CONTinuous[:TRANsient]?

Parameter

OFF | 0

OFF

ON | 1

ON

Return parameter

0

OFF

1

ON

Example

INIT:TRAN 1

Turns on the continuous trigger.

Address Commands

Initiate Commands

77

PPX Series Programming Manual

:INITiate[:IMMediate]:NAME

Set

Description

The INITiate command starts the TRANsient or

OUTPut trigger.

Syntax

:INITiate[:IMMediate]:NAME {TRANsient|OUTPut}

Parameter

TRANSient

Starts the TRANsient trigger.

OUTPut

Starts the OUTPut trigger.

Example

INITiate:NAME TRANient

Starts the TRANSient trigger.

:INITiate[:IMMediate][:TRANsient]

Set

Description

This command controls the enabling of output

triggers. When a trigger is enabled, a trigger causes

the specified action to occur. If the trigger system

is not enabled, all triggers are ignored.

Syntax

:INITiate[:IMMediate][:TRANsient]

Example

INIT

78

REMOTE CONTROL

:MEMory:TRIGgered ............................................... 79

:MEMory:TRIGgered

Set

Query

Description

Sets or queries which memory is loaded when a

trigger input is received and the trigger input is

configured to load a memory setting. This is the

equivalent to the TRIG Control menu (Trigin

Memory)settings.

Related

Commands

:SYSTem:CONFigure:TRIGger:INPut:MEMory

{<NR1>|MINimum|MAXimum}

:SYSTem:CONFigure:TRIGger:INPut:MEMory?

[MINimum|MAXimum]

Syntax

Query Syntax

:MEMory:TRIGgered{<NR1>|MINimum|MAXimum}

:MEMory:TRIGgered? [MINimum|MAXimum]

Parameter

<NR1>

MINimum

MAXimum

0(M1)~9(M10).

Return parameter

<NR1>

Returns the memory setting.

Memory Commands

79

PPX Series Programming Manual

:MEASure[:SCALar]:ALL[:DC] ............................. 80

:MEASure[:SCALar]:CURRent[:DC] .................... 80

:MEASure[:SCALar]:VOLTage[:DC] ................... 80

:MEASure[:SCALar]:POWer[:DC] ........................ 81

:MEASure[:SCALar]:CURRent:RANGe .............. 81

:MEASure[:SCALar]:VOLTage:RANGe ............. 81

:MEASure:TEMPerature ......................................... 82

:MEASure[:SCALar]:ALL[:DC]

Query

Description

Takes a measurement and returns the average

output current and voltage

Syntax

:MEASure[:SCALar]:ALL[:DC]?

Return parameter

"+0.0000,+0.00000,+0.000

00"

<voltage>,<current> ,<pow

er>Returns the voltage

(V),current (A),power(W)

respectively.

:MEASure[:SCALar]:CURRent[:DC]

Query

Description

Takes a measurement and returns the average

output current

Syntax

:MEASure[:SCALar]:CURRent[:DC]?

Return parameter

"+0.0000"

Returns the current in amps.

:MEASure[:SCALar]:VOLTage[:DC]

Query

Description

Takes a measurement and returns the average

output voltage.

Syntax

:MEASure[:SCALar]:VOLTage[:DC]?

Return

"+0.0000"

Returns the voltage in volts.

Measure Commands

80

REMOTE CONTROL

:MEASure[:SCALar]:POWer[:DC]

Query

Description

Takes a measurement and returns the average

output power.

Syntax

:MEASure[:SCALar]:POWer[:DC]?

Return

"+0.0000"

Returns the power measured in watts.

:MEASure[:SCALar]:CURRent:RANGe

Set

Query

Description

Sets or queries the current measurement range.

Syntax

Query Syntax

:MEASure[:SCALar]:CURRent:RANGe

{<NR1>|AUTO|IH|IL|ILL}

:MEASure[:SCALar]:CURRent:RANGe?

Parameter

AUTO|0

Current measurement auto range.

IH|1

Current measurement IH range.

IL|2

Current measurement IL range.

ILL|3

Current measurement ILL range.

Return parameter

<NR1>

Returns the current measurement range.