Instek PEL-5006C-150-600, PEL-5008C-1200-320, PEL-5024C-600-1680, PEL-5008-150-800, PEL-5010C-150-1000 User Manual

...

High Power Electronic Load

PEL-5000C Series

USER MANUAL

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................. 4

GETTING STARTED .......................................................... 8

PEL-5000C Series Introduction .............................. 10

Accessories............................................................ 13

Operating Mode Description ................................. 14

Operating Area ...................................................... 20

Appearance ............................................................ 27

FUNCTION DESCRIPTION ............................................. 38

Function keys description ...................................... 39

Test keys description ............................................. 53

System keys description ........................................ 68

Test keys description ............................................. 77

CONNECTION ............................................................... 79

Rear Panel ............................................................. 80

Connecting the I-monitor to an oscilloscope ......... 84

Master/Slave Instructions ..................................... 85

INSTALLATION .............................................................. 88

Check line voltage .................................................. 89

Grounding requirements ....................................... 89

Power up ............................................................... 90

Connection to the load Input Terminal .................. 90

GPIB & RS232 interface option .............................. 91

RS232 interface option .......................................... 92

GPIB interface option ............................................ 92

USB interface option ............................................. 92

LAN interface option ............................................. 93

I/O connection ...................................................... 93

1

PEL-5000C User Manual

Load current slew rate setting ............................... 94

Load wire inductance ............................................ 96

REMOTE CONTROL ...................................................... 100

Interface Configuration ........................................ 101

Communication Interface programming command

list ....................................................................... 103

Command Syntax ................................................. 115

Command List ..................................................... 117

PRESET Commands ............................................. 119

Limit Commands ................................................. 132

STAGE commands ............................................... 135

System Commands .............................................. 141

Measure Commands ............................................ 143

APPLICATION ............................................................... 144

Local sense connections ...................................... 145

Remote sense connections .................................. 146

Constant Current mode application ..................... 148

Constant Voltage mode application ..................... 151

Constant Resistance mode application ................ 153

Constant Power mode application ....................... 155

CC + CV mode of operation application ............... 157

CP + CV mode of operation application ............... 159

Constant current source operating ....................... 161

Zero-Volt loading application ............................... 162

Parallel operation ................................................ 163

Power Supply OCP testing ................................... 164

Power Supply OPP testing ................................... 166

SHORT testing ..................................................... 168

Battery discharge test .......................................... 171

APPENDIX .................................................................... 175

PEL-5000C Default Settings ................................. 176

PEL-5000C Dimensions ........................................ 183

2

Table of Contents

PEL-5000C series Specifications .......................... 187

Certificate Of Compliance .................................... 208

GPIB programming Example ................................ 209

PEL-5000C series USB Instruction ....................... 213

PEL-5000C series Auto, Sequence function provide

EDIT, ENTER, EXIT, TEST and STORE 5 keys

operation ............................................................. 215

PEL-5000C series LAN Instruction ....................... 219

3

PEL-5000C User Manual

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the instrument or to

other properties.

DANGER High Voltage

Attention Refer to the Manual

Earth (ground) Terminal

Frame or Chassis Terminal

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

SAFETY INSTRUCTIONS

This chapter contains important safety instructions that you must

follow during operation and storage. Read the following before any

operation to insure your safety and to keep the instrument in the

best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

4

SAFETY INSTRUCTIONS

General

Guideline

CAUTION

Do not place any heavy object on the

instrument. Note: Only 2 units can be stacked

vertically.

Avoid severe impact or rough handling that

leads to damaging the instrument.

Do not discharge static electricity to the

instrument.

Use only crimped wires, not bare wires, for the

terminals.

Do not block the cooling fan opening.

Do not disassemble the instrument unless you

are qualified.

The equipment is not for measurements

performed for CAT II, III and IV.

(Measurement categories) EN 61010-1:2010 specifies the

measurement categories and their requirements as follows.

Measurement category IV is for measurement performed at the

source of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

0 is for measurements performed on circuits not directly

connected to Mains.

Do NOT position the equipment so that it is

difficult to disconnect the appliance inlet or the

power plug.

If the equipment is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

Safety Guidelines

5

PEL-5000C User Manual

Power Supply

WARNING

AC Input voltage range: 100-240VAC, Single

phase

90-250VAC

Frequency: 47-63Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

To avoid electric shock, the power cord

protective grounding conductor must be

connected to ground. No operator serviceable

components inside. Do not remove covers.

Refer servicing to qualified personnel.

Cleaning

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Temperature: 0°C to 40°C

Humidity: 0 to 85% RH

Altitude: <2000m

Overvoltage category II

6

SAFETY INSTRUCTIONS

(Pollution Degree) EN 61010-1:2010 specifies the pollution degrees

and their requirements as follows. The instrument falls under

degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

Storage

environment

Location: Indoor

Temperature: -20°C to 70°C

Humidity: <90% RH

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

7

PEL-5000C User Manual

PEL-5000C Series Introduction ............................. 10

Main Features ............................................................................... 10

Protection features ....................................................................... 11

Accessories ........................................................... 13

Operating Mode Description ................................ 14

CC Mode ....................................................................................... 14

CR mode ........................................................................................ 14

CV mode ........................................................................................ 14

CP mode ........................................................................................ 15

GETTING STARTED

The PEL-5000C series Electronic Load is designed to test,

evaluation and burn-in of DC power supplies and batteries.

The PEL-5000C series high power electronic Load can be controlled

locally at the front panel or remotely via computer over the

GPIB/RS232/USB/LAN. Constant Current (CC) mode, Constant

Resistance (CR) mode, and Constant Voltage (CV) mode. And

Constant Power (CP) mode. The wide range dynamic load with

independent rise and fall current slew rate and analog

programming input with arbitrary wave-form input is available in

Constant Current mode.

8

GETTING STARTED

Slew Rate ....................................................................................... 15

Dynamic Waveform Definition................................................. 17

Operating Area ...................................................... 20

Appearance ............................................................ 27

Front Panel .................................................................................... 27

LCD Display ................................................................................. 28

9

PEL-5000C User Manual

Features

CC, CR, CV, CP, Dynamic, and Short Operating

Mode.

Remote control via a choice of computer

interfaces.

High accuracy & resolution with 16 bit voltage

and current meter.

Built in pulse generators for dynamic loading.

Independently adjustable current rise and fall

times.

Short circuit test with current measurement

Dedicated over current and overpower

protection test functions

Programmable voltage sense capability.

Full protection from overpower, over-

temperature, overvoltage, and reverse polarity.

Analogue programming input for tracking an

external signal

Current Monitor with BNC (non-isolated)

socket.

Digital Calibration

Advance Fan speed control

Ability to save load setup via the mainframe

memory (150 store/recall locations)

Auto sequence function allowing test routines

to be set from the mainframe

PEL-5000C Series Introduction

Main Features

10

GETTING STARTED

Overvoltage

protection

The Electronic Load will turn OFF Load OFF if the

overvoltage circuit is tripped. The message OVP

will be displayed on the LCD. When the OVP fault

has been removed the load can be set to sink

power again. While the unit will attempt to

protect itself given an OVP state it is strongly

advised to guard against any potential OVP fault

state by using external protection and the correctly

rated electronic load.

The Overvoltage protection circuit is set at a

predetermined voltage and cannot be adjusted.

The OVP level is 105% of the PEL-5000C series

nominal voltage rating.

Caution

Never apply an AC voltage to the input of the PEL5000C series Load. Do not apply a DC voltage that is

higher than PEL-5000C series Load rating. If this

advice is ignored it is likely that damage will be caused

to the electronic load module. This damage will not be

covered by the warranty.

Over current

protection (OCP)

The PEL-5000C series Electronic Load monitors the

current level. The input to the load is automatically

switched to LOAD OFF if the current is greater

than 104% of the rated current input. If an over

current condition occurs the display will show

OCP.

Over power

protection (OPP)

The PEL-5000C series Electronic Load monitors the

power dissipation level. The input to the load is

automatically switched to LOAD OFF if the power

dissipation is greater than 105% of the rated power

input. If an over power condition occurs the

display will show OPP.

Protection features

The protection features of the PEL-5000C series Electronic load

modules are as follows:

11

PEL-5000C User Manual

Over temperature

protection

The load internal temperature at the heat sink is

monitored. If the temperature reaches

approximately 90°C the OTP message will be

displayed and the unit will automatically switch to

the LOAD OFF state. If an OTP error occurs please

check the ambient temperature is between 0 to

40°C. Also ensure that the front and rear air vents

of the mainframe are not obstructed. The air flow

is taken from the front of the mainframe and

exhausted from the rear. Therefore a suitable gap

needs to be left at the rear of the mainframe. A

minimum of 15cm is recommended. After a

suitable cooling period the load can be switched.

Reverse Polarity

The PEL-5000C series load module will tolerate a

reverse current up to the maximum current rating

of the load module. The ‘-‘symbol will be shown

on the voltage and current displays.

Caution

If a reverse polarity situation occurs the load will sink

power even if the LOAD button is OFF. No current will

be displayed on the PEL-5000C series load module.

Current up to the load’s maximum current rating will

be tolerated in reverse polarity. However there is no

OVP OCP and OPP protection. It is strongly

recommended that the load lines be fused if it is likely

that the load could be subject to reverse polarity.

These fuses should be fast acting and rated at the

maximum current of the load module +5%.

12

GETTING STARTED

Standard Accessories

Description

PCs

PEL-5000C series operation manual

It can be downloaded

from GW Instek website.

BANANA PLUGS

1

BNC – BNC CABLE

1

HD-DSUB 15PIN Parallel wire

1 Optional Accessories

Description

PCs

GPIB+RS232 interface

PEL-030

1

RS232 interface

PEL-023

1

GPIB interface

PEL-022

1

USB interface + USB driver (The

driver can be downloaded from GW

Instek website)

PEL-025

LAN interface + LAN driver (The

driver can be downloaded from GW

Instek website)

PEL-024

GPIB cable

GTL-250 GPIB Cable, 0.6m

1

GPIB cable

GTL-248 GPIB Cable, 2m

1

USB cable

GTL-246 USB Cable, 1.2m

1

PEL-5000C, AEL-5006, AEL-5008,

AEL-5012 and AEL-5015 handle

PEL-028

1

PEL-5000C Hook Ring

PEL-026

Rack Mount Kit For PEL-5006C

PEL-027-1

Rack Mount Kit For PEL-5008C,

PEL-5010C, PEL-5012C

PEL-027-2

Rack Mount Kit For PEL-5015C,

PEL-5018C

PEL-027-3

Rack Mount Kit For PEL-5020C,

PEL-5024C

PEL-027-4

Accessories

13

PEL-5000C User Manual

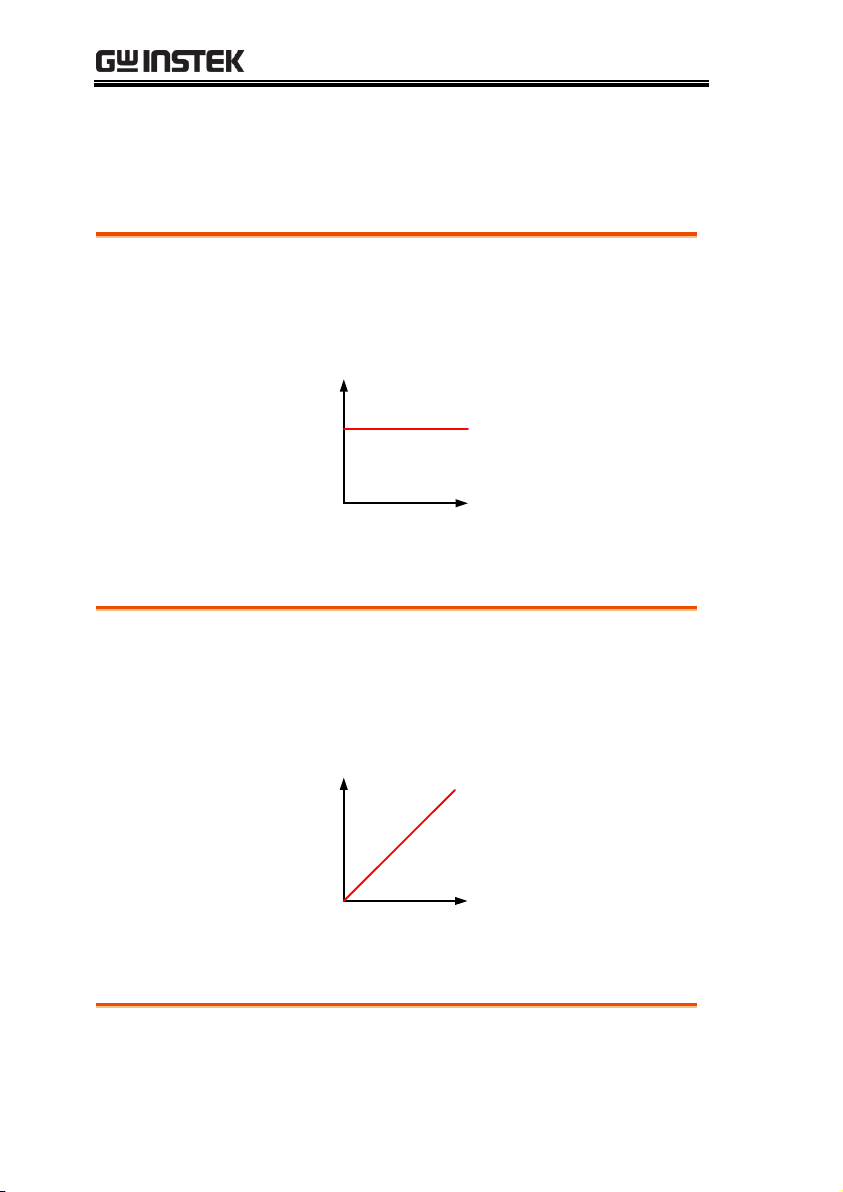

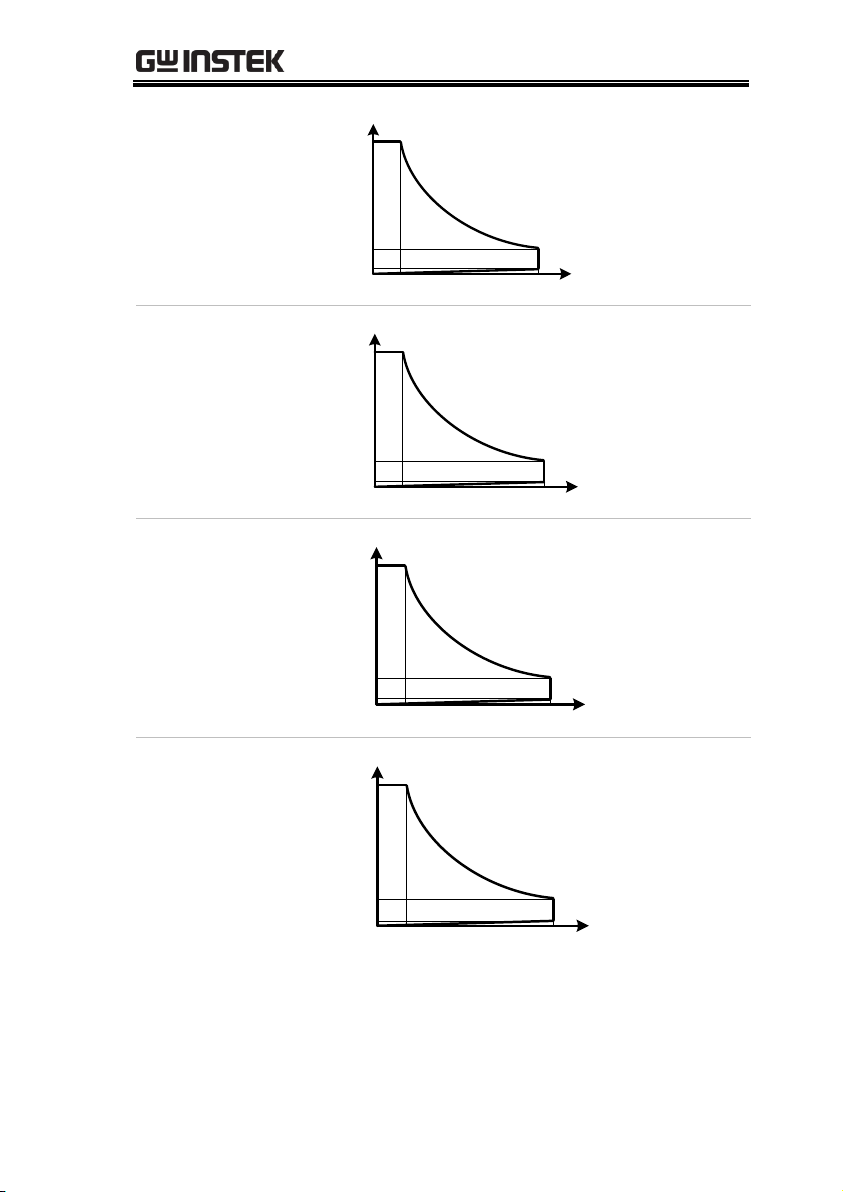

Background

With the operating mode of Constant Current, the

PEL-5000C Series electronic load will sink a

current in accordance with the programmed value

regardless of the input voltage

CURRENT SETTING

LOAD

CURRENT

INPUT VOLTAGE

V

CC

Background

At Constant Resistance mode, the PEL-5000C

series electronic load will sink a current linearly

proportional to the load input voltage in

accordance with the programmed resistance

setting

RESISTANCE

SETTING

LOAD

CURRENT

INPUT VOLTAGE

V

I

Background

At Constant Voltage mode, the PEL-5000C series

electronic load will attempt to sink enough current

Operating Mode Description

CC Mode

CR mode

CV mode

14

until the load input voltage reaches the

programmed value

VOLTAGE

SETTING

LOAD

CURRENT

INPUT VOLTAGE

V

I

CP mode

Background

At Constant Power mode, the PEL-5000C series

electronic load will attempt to sink load power

(load voltage * load current) in accordance with

the programmed power.

POWER

SETTING

LOAD

CURRENT

INPUT VOLTAGE

V

I

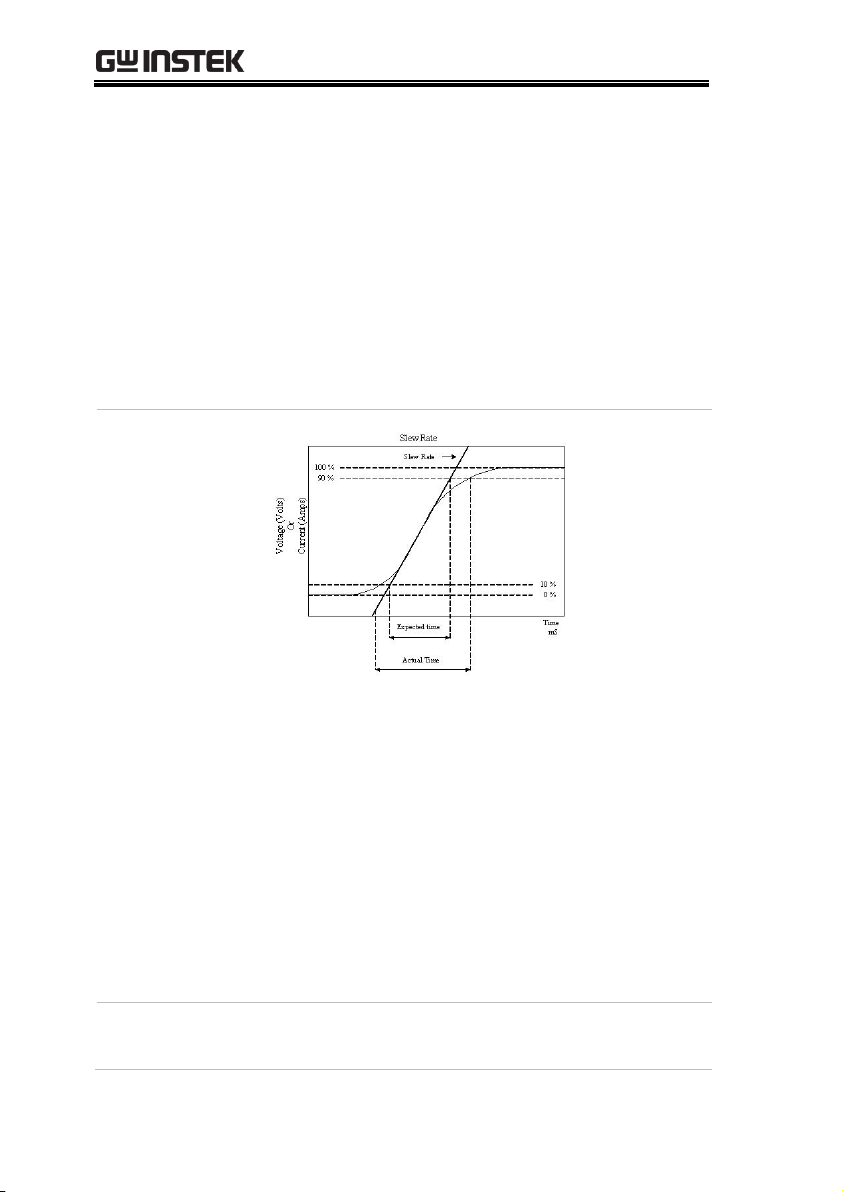

Background

Slew rate is defined as the change in current or

voltage over time. A programmable slew rate

allows for a controlled transition from one load

setting to another. It can be used to minimize

induced voltage drops on inductive power wiring,

or to control induced transients on a test device

(such as would occur during power supply

transient response testing).

In cases where the transition from one setting to

GETTING STARTED

Slew Rate

15

PEL-5000C User Manual

another is large, the actual transition time can be

calculated by dividing the voltage or current

transition by the slew rate. The actual transition

time is defined as the time required for the input to

change from 10% to 90% or from 90% to 10% of the

programmed excursion.

In cases where the transition from one setting to

another is small, the small signal bandwidth (of the

load) limits the minimum transition time for all

programmable slew rates. Because of this

limitation, the actual transition time is longer than

the expected time based on the slew rate.

Rise Time

Transition

Limitation

Therefore, both minimum transition time and slew

rate must be considered when determining the

actual transition time. Following detail description

is excluding in specification sheet.

The minimum transition time for a given slew rate

as about a 30% or greater load change, the slew

rate increases from the minimum transition time to

the Maximum transition time at a 100% load

change. The actual transition time will be either the

minimum transition time, or the total slew time

(transition divided by slew rate), whichever is

longer.

Example

PEL-5012C-600-840 600V/840A/12000W (CCH CCL >840Ax 30%)

16

GETTING STARTED

Use the following formula to calculate the

minimum transition time for a given slew rate min

transition time=252A/slew rate (in amps/second).

10.5uS (252A/24) x 0.8(10%~90%) =8.4uS

Use the following formula to calculate the

maximum transition time for a given slew rate max

transition time=840/slew rate (in amps/second).

35uS (840A/24) x 0.8(10~90%) = 28uS

EX. CCH=168A, CCL=0A Slew Rate =24A, the

expected time is 5.6uS but the actual Transition

Time Will be limited to 4.8Us.

7uS (168/24 x 0.8(10%~90%) = 5.6uS

Note

When CC mode rang1 slew rate, CCL setting at least

0.1% larger than the specification.

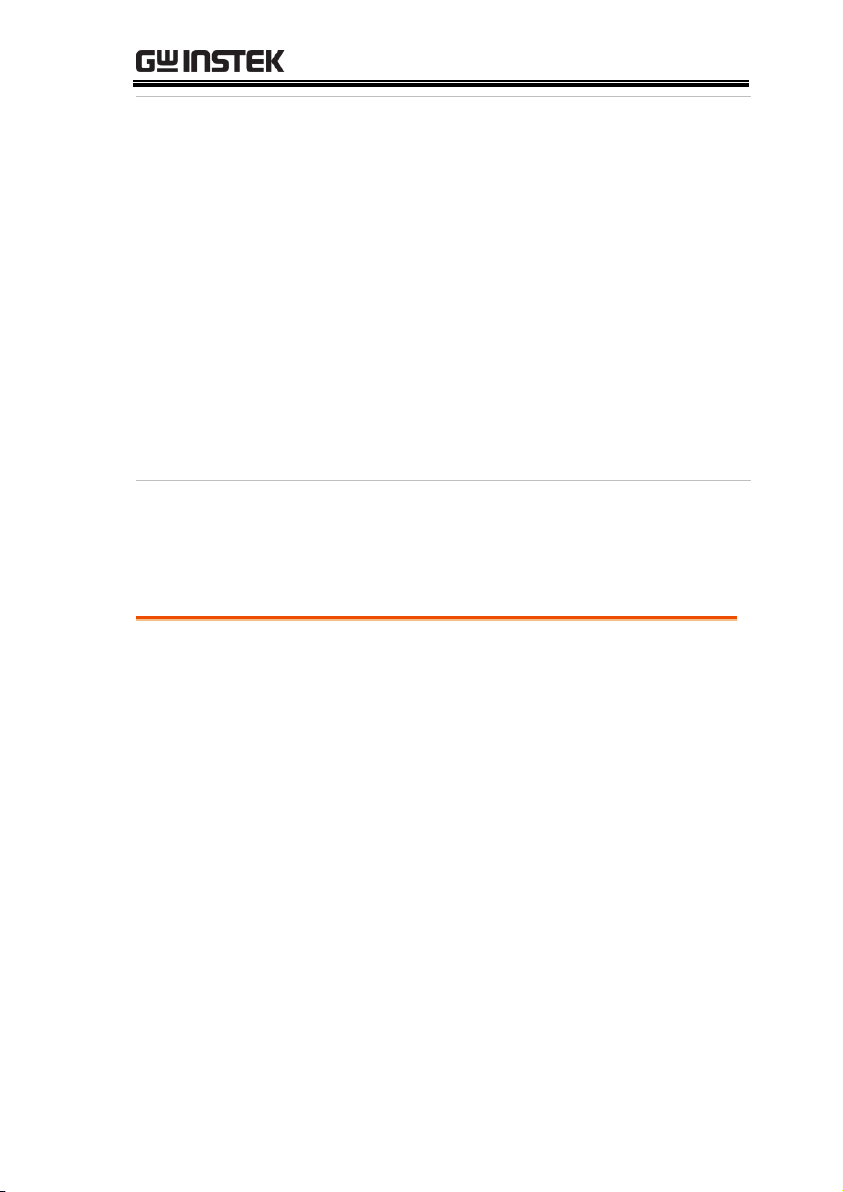

Background

Along with static operation the PEL-5000C series

electronic load are built with a dynamic mode for

operation in Constant Current (CC), Constant

Resistance (CR) or Constant Power (CP). This

allows the test engineer to simulate real world

pulsing loads or implement a load profile that

varies with time.

A dynamic waveform can be programmed from

the front panel of the PEL-5000C electronic load.

The user would first set a High and low value of

load current using the Level button. The Dynamic

Setting then allows for the rise and fall time

between these 2 current values to be adjusted. The

time period that the waveform is high (Thigh)

along with the time period that the waveform is

low (Tlow) can also be set.

Dynamic Waveform Definition

17

PEL-5000C User Manual

Dynamic Wave

form

I

V

LOAD

CURRENT

RISE

SLEW RATE

HIGH LOAD

LOAD

LOW LOAD

LEVEL

T

HIGHTLOW

FALL SLEW RATE

The dynamic waveform can also be set up via the

optional computer interface. Dynamic waveform

settings made from the front panel of the load

module can also be saved in the memory of the

PEL-5000C series Electronic Load. For the

store/recall procedure and the computer

command set please refer to the relevant operating

manual for the PEL-5000C series Electronic Load.

Further dynamic waveform definitions are:

The period of dynamic waveform is Thigh +

Tlow

The dynamic frequency = 1 /( Thigh + Tlow )

The duty cycle = Thigh / ( Thigh + Tlow )

Example 1

PEL-5000C series, Dynamic up to 50 KHz

frequency

Dynamic highest frequency 50 KHz = 0.02ms=20us

Setting THIGH=10 uS, TLOW=10uS,

THIGH+TLOW=20uS

CCH-CCL/SR≦10uS

Setting CCH=30A, CCL=10A

(30-10)/2.5A/uS≦10 uS

8 uS≦10 uS ,Compliance with frequency 50KHz

Example 2

Setting THIGH=10 uS, TLOW=10uS,

THIGH+TLOW=20uS

CCH-CCL/SR≦10uS

18

GETTING STARTED

Setting CCH=50A, CCL=0A

(50-0)/2.5A/uS=20uS, 20uS>10uS, It's not

compliance the frequency 50 KHz

The analogue programming input also provides a

convenient method of implementing a dynamic

waveform.

19

PEL-5000C User Manual

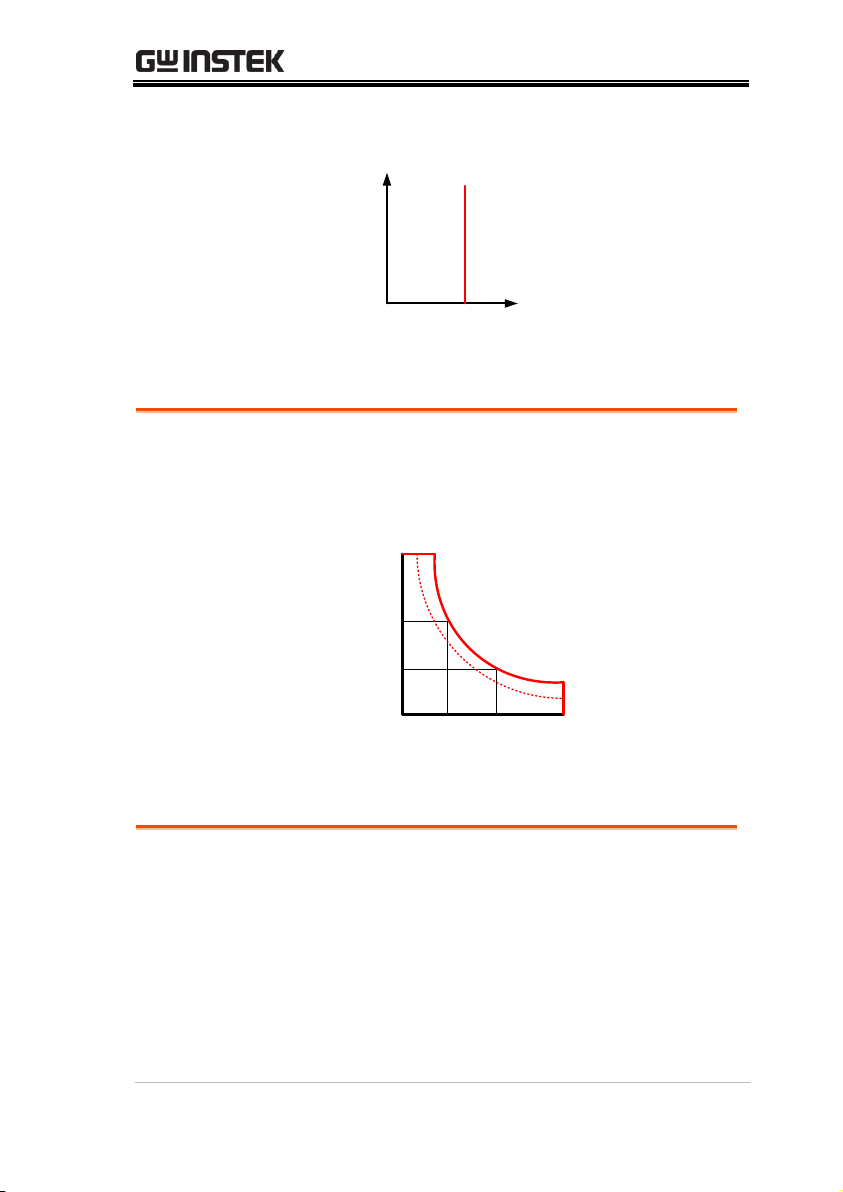

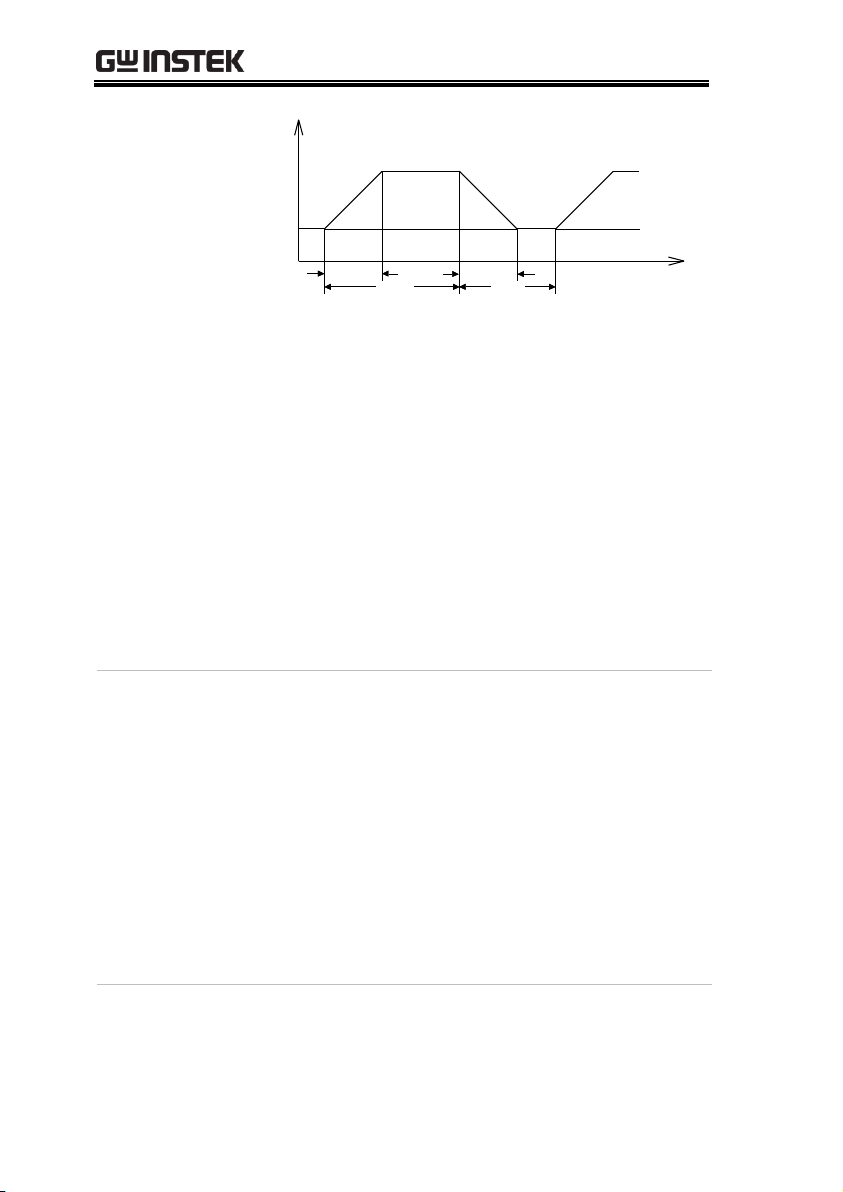

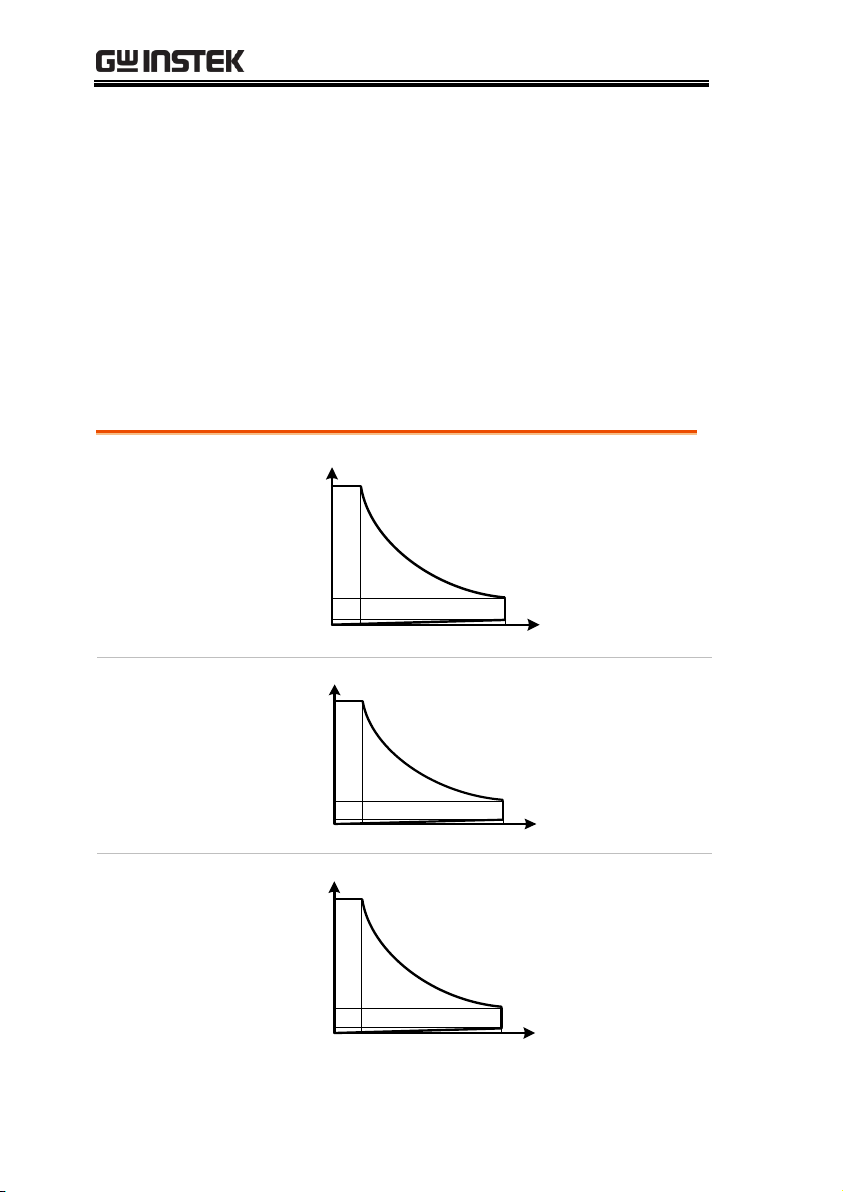

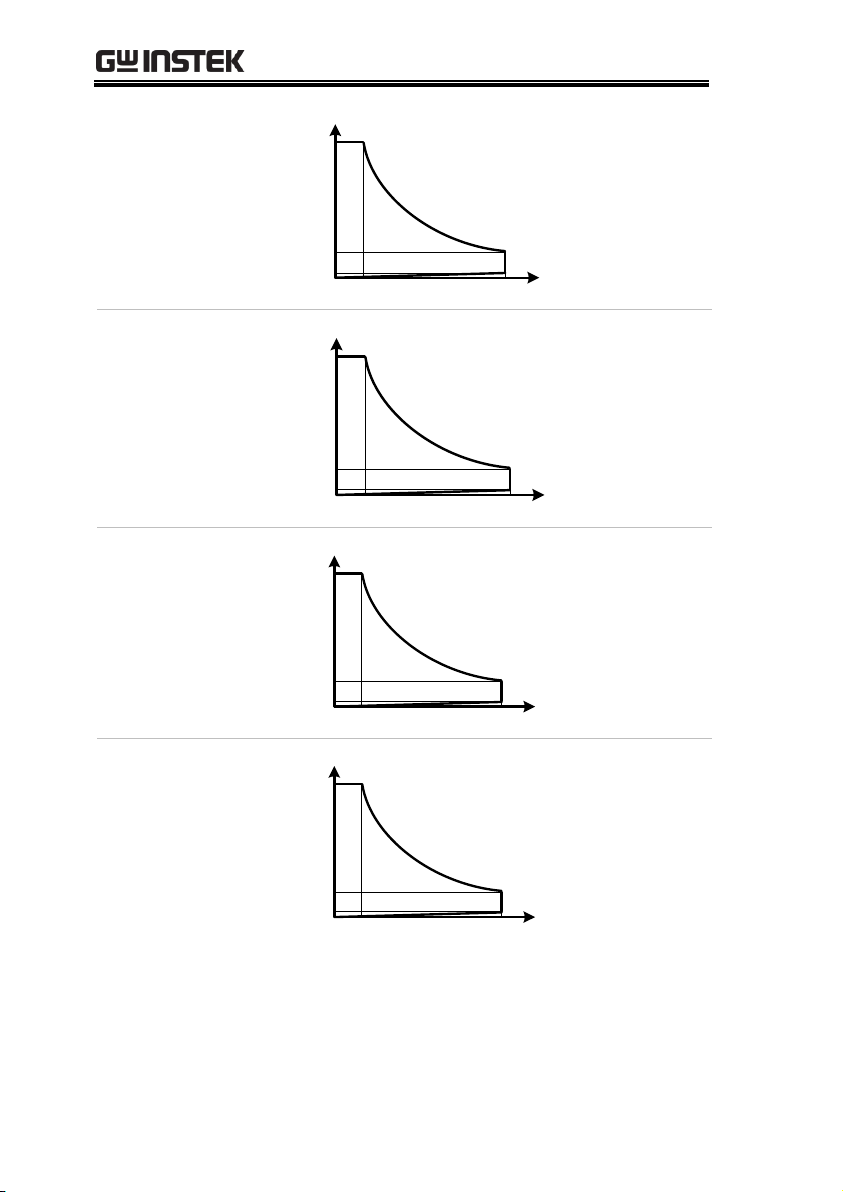

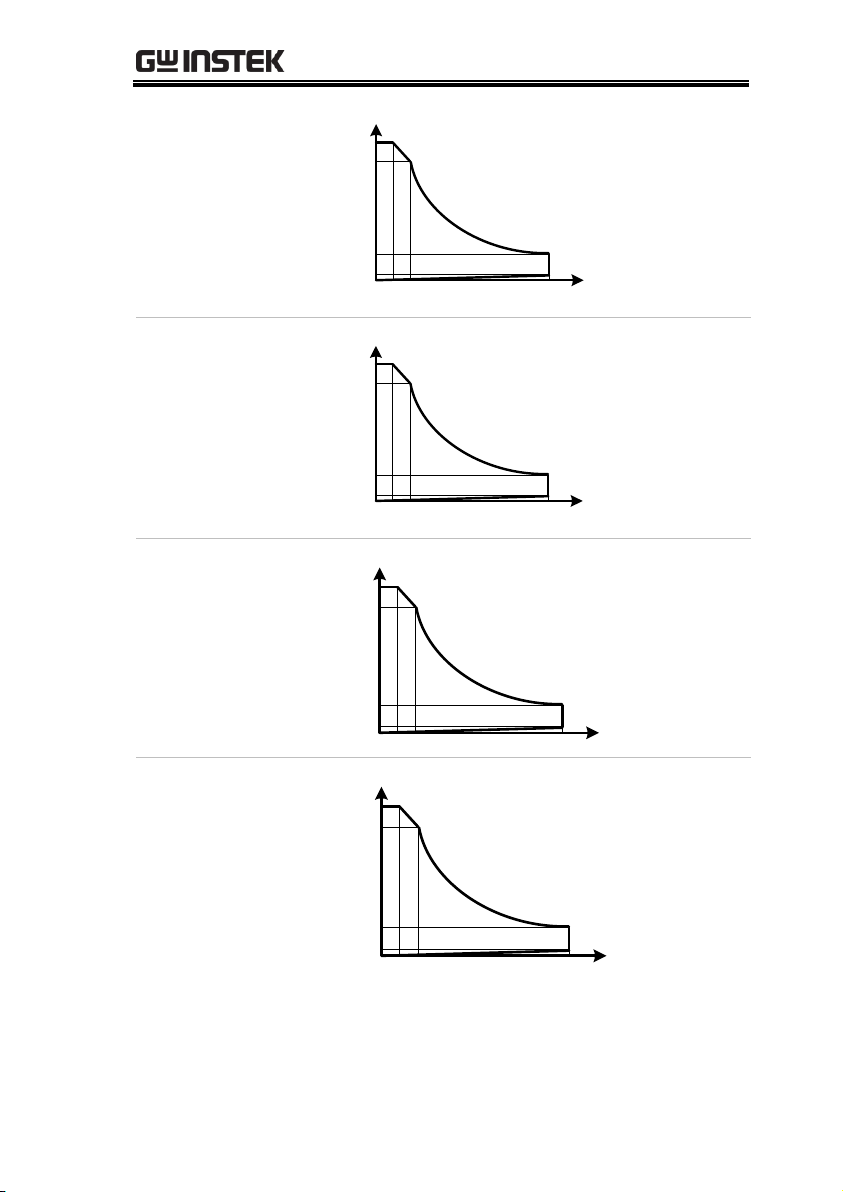

PEL-5006C-150-600

power contour

150V

10V

600A

40A

6KW

Power Curve

Current

0.7V

Voltage

PEL-5008C-150-800

power contour

150V

10V

800A

53.3A

8KW

Power Curve

Current

Voltage

0.7V

PEL-5010C-150-1000

power contour

150V

10V

1000A

66.6A

10KW

Power Curve

Current

Voltage

0.7V

Operating Area

The PEL-5000C series electronic load can be operated for manual

and GPIB operation.

The PEL-5000C series high power electronic Load can be controlled

locally at the front panel or remotely via computer over the

GPIB/RS232/USB/LAN. Constant current (CC) mode, constant

resistance (CR) mode, and constant voltage (CV) mode and

constant power (CP) mode. The wide range dynamic load with

independent rise and fall current slew rate and analog

programming input with arbitrary wave-form input is available in

Constant Current mode.

20

GETTING STARTED

PEL-5012C-150-1200

power contour

150V

10V

1200A

80A

12KW

Power Curve

Current

Voltage

0.7V

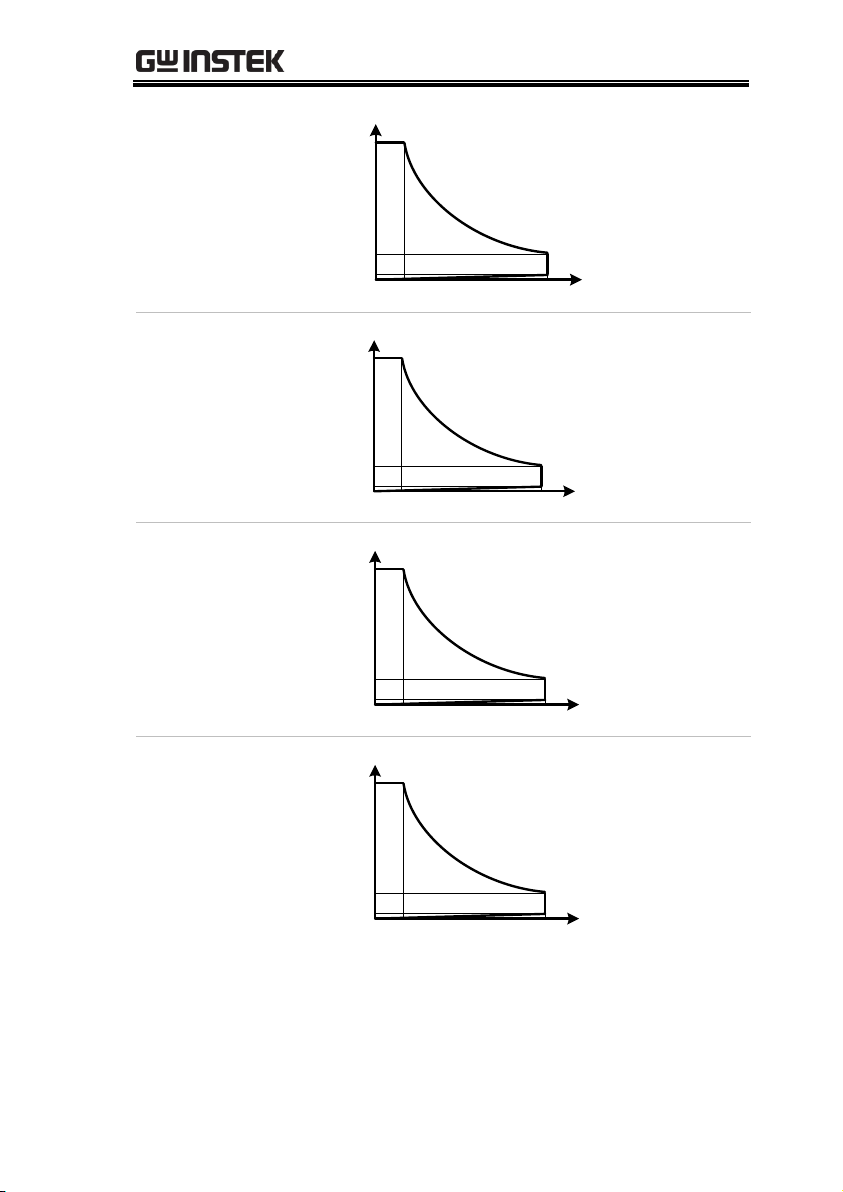

PEL-5015C-150-1500

power contour

150V

10V

1500A

100A

15KW

Power Curve

Current

Voltage

0.7V

PEL-5018C-150-1800

power contour

150V

10V

1800A

120A

18KW

Power Curve

Current

Voltage

0.7V

PEL-5020C-150-2000

power contour

150V

10V

2000A

133.3A

20KW

Power Curve

Current

Voltage

0.7V

21

PEL-5000C User Manual

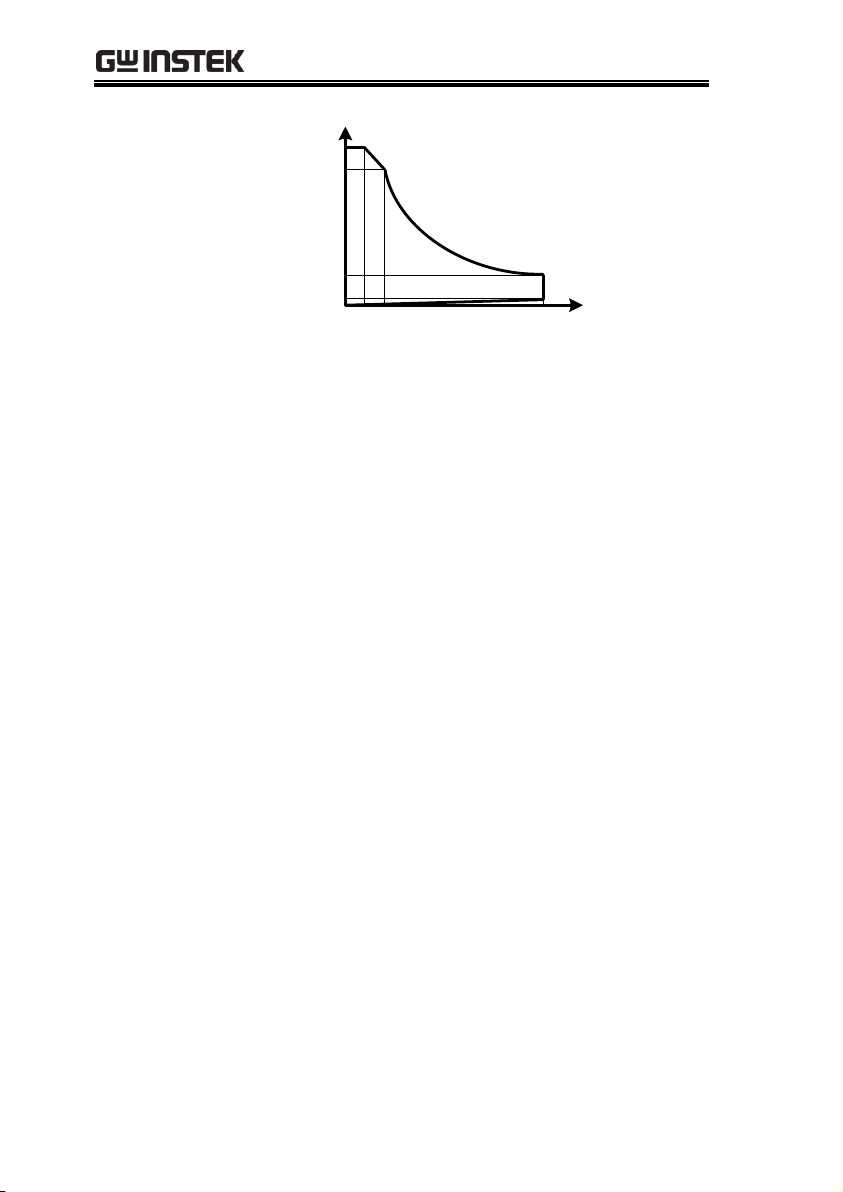

PEL-5024C-150-2000

power contour

150V

12V

2000A

160A

24KW

Power Curve

Current

Voltage

0.7V

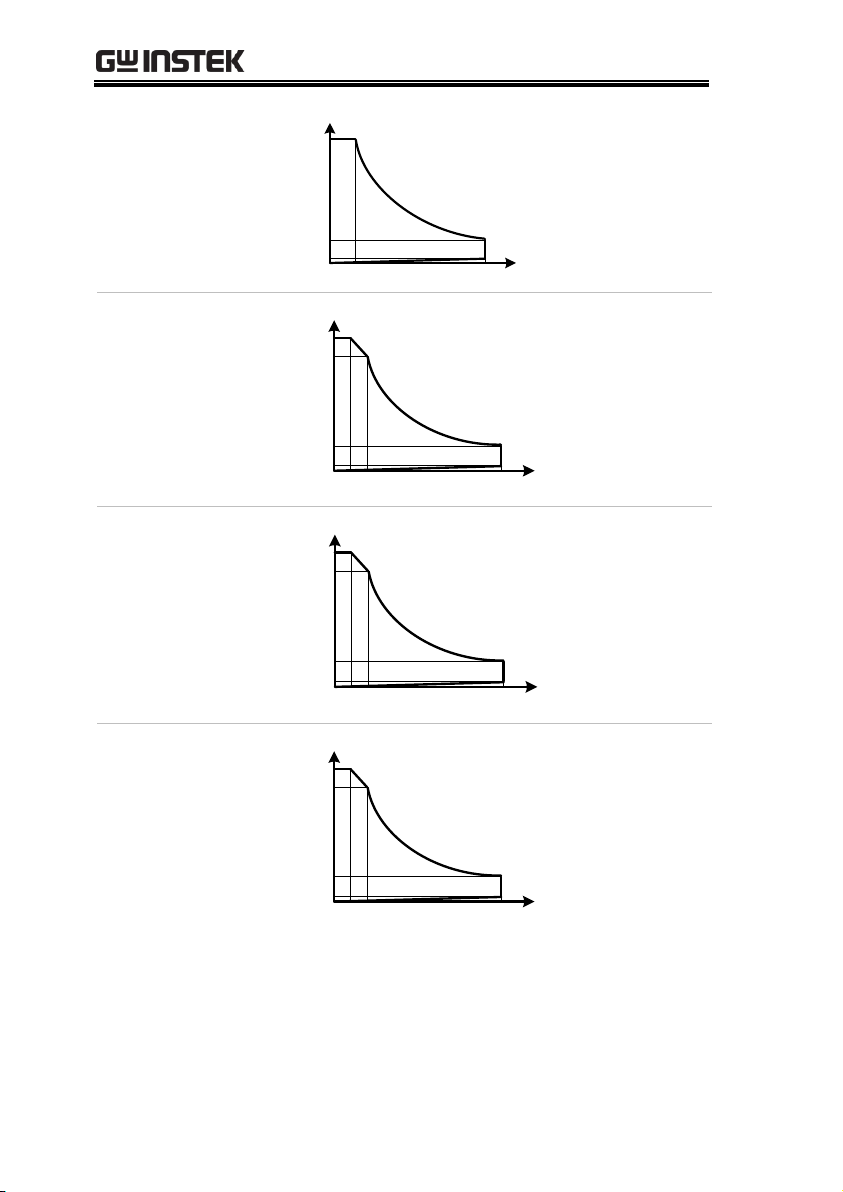

PEL-5006C-600-420

power contour

600V

14.29V

420A

10A

6KW

Power Curve

Current

Voltage

10V

PEL-5008C-600-560

power contour

600V

14.29V

560A

13.33A

8KW

Power Curve

Current

Voltage

10V

PEL-5010C-600-700

power contour

600V

14.29V

700A

16.66A

10KW

Power Curve

Current

Voltage

10V

22

GETTING STARTED

PEL-5012C-600-840

power contour

600V

14.29V

840A

20A

12KW

Power Curve

Current

Voltage

10V

PEL-5015C-600-1050

power contour

600V

14.29V

1050A

25A

15KW

Power Curve

Current

Voltage

10V

PEL-5018C-600-1260

power contour

600V

14.29V

1260A

4.16A

18KW

Power Curve

Current

Voltage

10V

PEL-5020C-600-1400

power contour

600V

14.29V

1400A

33.33A

20KW

Power Curve

Current

Voltage

10V

23

PEL-5000C User Manual

PEL-5024C-600-1680

power contour

600V

14.29V

1680A

40A

24KW

Power Curve

Current

Voltage

10V

PEL-5006C-1200-240

power contour

1200V

25V

240A6A

6KW

Power Curve

Current

Voltage

15V

1000V

3A

PEL-5008C-1200-320

power contour

1200V

25V

320A8A

8KW

Power Curve

Current

Voltage

15V

1000V

4A

PEL-5010C-1200-400

power contour

1200V

25V

400A

10A

10KW

Power Curve

Current

Voltage

15V

1000V

5A

24

GETTING STARTED

PEL-5012C-1200-480

power contour

1200V

25V

480A12A

12KW

Power Curve

Current

Voltage

15V

1000V

6A

PEL-5015C-1200-600

power contour

1200V

25V

600A15A

15KW

Power Curve

Current

Voltage

15V

1000V

7.5A

PEL-5018C-1200-720

power contour

1200V

25V

720A

18A

18KW

Power Curve

Voltage

15V

1000V

9A

PEL-5020C-1200-800

power contour

Current

1200V

25V

800A20A

20KW

Power Curve

Voltage

15V

1000V

10A

25

PEL-5000C User Manual

PEL-5024C-1200-960

power contour

1200V

25V

960A24A

24KW

Power Curve

Current

Voltage

15V

1000V

12A

26

GETTING STARTED

3 4

5

6 721

1

Power switch

2

LCD Multi-function display

3

System keys

4

Function keys

5

Test function keys

6

Number keypad

7 Knob setting

Appearance

Front Panel

27

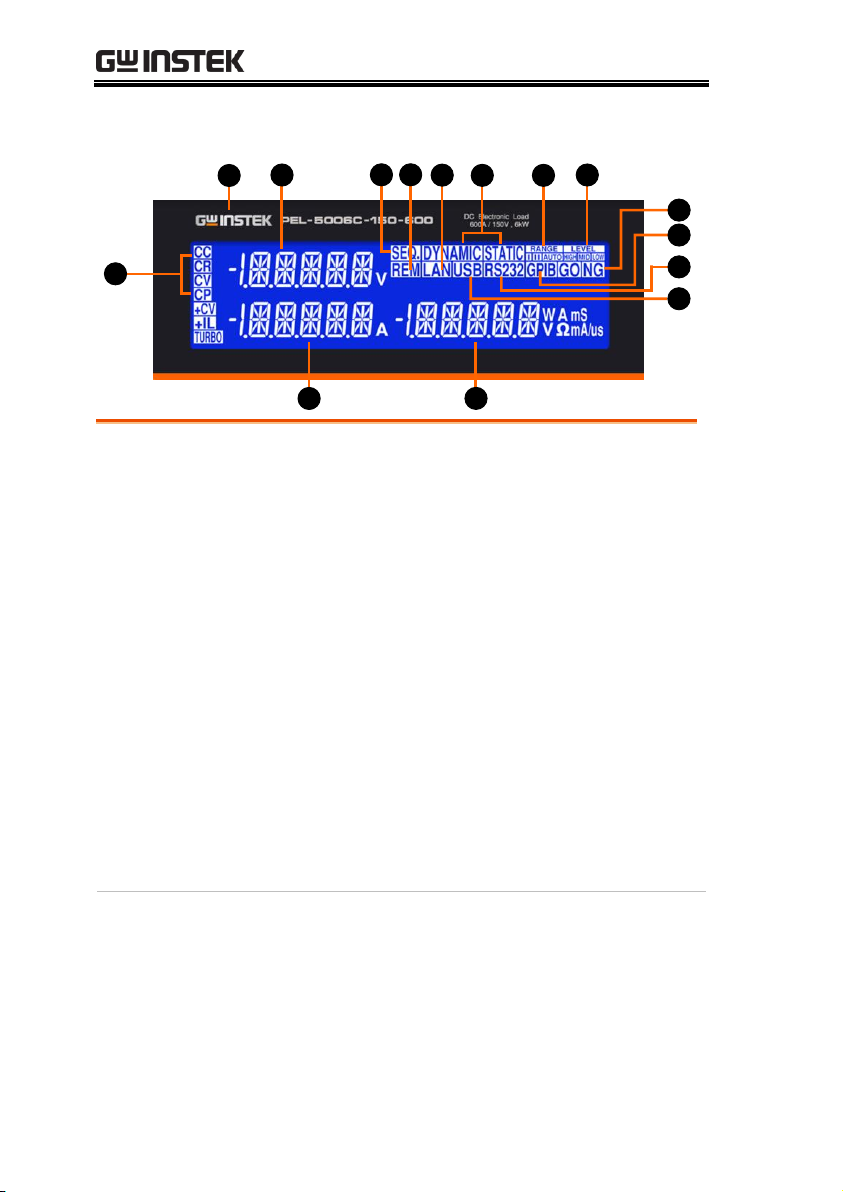

LCD Display

1

3

6 7

9

13

2

15

8

14

4

5

12

9

10

11

1

Model number

and sink ranges

The model number along with maximum

voltage, current and power values are detailed

in this position at the top of the load front

panel.

2

Left 5 digit LCD

display

The 5 digit LCD display is a multi-function

display. The function of the display changes

depending whether the user is in NORMAL

mode or in a SHORT, OPP or OCP modes:

Status display:

When enter System Setting or AUTO

SEQUENCE, the display setting item.

Normal mode

The left 5 digit display displays the voltage

present at the load’s input terminals. The

value displayed will include the automatic

voltage compensation if the sense terminals

are also connected to the device under test

(DUT).

Note

If V-sense is set to “AUTO” and the sense leads

are connected to the DUT the losses need to be

approx. 700mV (PEL-5006C-150-600) before the

display compensates for the voltage loss.

If V-sense is set to “ON” and the sense terminals

are connected to the DUT the load will check and

compensate for all voltage drops.

PEL-5000C User Manual

28

GETTING STARTED

Test mode

If the SHORT, OPP or OCP buttons are

pressed the left display will show a text

Message that correlates with the selected test

function.

SHORT test selected: left display will show

“Short”.

OPP test selected: left display will show

“OPP”.

OCP test selected: left display will show

“OCP”.

During the test the left display will show the

load Input voltage.

3

SEQ. indicator

When entering AUTO SEQUENCE mode,

LCD indicator will light up.

4

REM LCD

Indicator

If the REMOTE LCD Indicator is illuminated

this means that the unit is operating remotely

via one of the optional interfaces. While

REMOTE is lit it is not possible to make

settings manually at the front panel. The

LOCAL button on the mainframe can be used

to revert back to front panel control. When the

unit is operating from the front panel the

REMOTE LCD will not be illuminated.

5

LAN mode Lit

It is LAN interface inside.

6

DYN/STA LED

Indicator

The DYN button allows the user to switch

between DYNAMIC operation and STATIC

operation. Dynamic operation is only possible

in constant current (CC) or Constant power

(CP) mode only. The LED next to the DYN

button will become lit When DYNAMIC

operation is selected. If you are in constant

resistance (CR) or Constant voltage (CV) mode

pressing the DYN button will have no effect.

7

Rang LED

Indicator

The PEL-5000C series Load Module features 2

setting ranges for CC, CR, CV & CP operation.

This allows improved resolution for setting

29

PEL-5000C User Manual

low values. When left in the default AUTO

mode the changeover between ranges is

automatic depending on the setting value

entered.

If desired the RANGE button can be pressed

to force the unit to operate only in ANGE II.

This is signaled by the accompanying LED

becoming lit.

Note

That it is only possible to force RANGE II in CC

mode.

8

Level LED

Indicator

or Low load value. The setting value changes

between current, resistance, voltage or power

depending whether CC, CR, CV or CP mode

has been selected. If the LED is lit then the

High level value setting has been enabled. If

the LED is not lit then the low load level can

be set using the rotary switch in combination

with the arrow keys.

High and low load levels during operation.

only) the preset high and low levels are used

to define the dynamic waveform.

Note

The converse is also true in that the High level

cannot be set below the low level.

9

NG LCD

Indicator

The user can adjust upper and lower limits for

voltage, current and power within the

CONFIG menu and turn the NG Indicator

ON. If a voltmeter, ammeter or wattmeter

measurement is outside these set limits then

the NG indicator will illuminate.

10

GPIB mode Lit

It is GPIB inside. The LCD will be lit GPIB

when Power ON. If PEL-5000C series is

controlled by GPIB through PC, the GPIB will

30

GETTING STARTED

be lit.

11

RS232 mode Lit

It is RS232 inside. The LCD will be lit RS232

when Power ON. If PEL-5000C series is

controlled by RS232 through PC, the RS232

will be lit.

12

USB mode Lit

It is USB interface inside.

13

The right 5 digit

displays

The right 5 digit displays also changes

function depending if the unit is in normal

mode or one of the setting menus has been

activated.

Display System Setting state or AUTO

SEQUENCE setting value.

Normal mode

In normal mode the right 5 digit displays

shows the power consumption in Watts (W).

Setting mode

The right display together with the rotary

adjustment knob is used to set values.

The value changes according to the setting

function that is active. The middle LCD

provides a text message to tell the user which

part of the setting menu is active.

14

Middle 5 digit

LCD display

function depending if the user is in normal

mode or has entered a setting menu

Status display:

When enter System Setting or AUTO

SEQUENCE, the display setting item.

Normal mode

In normal mode the middle LCD display

functions as a 5 digit ammeter. The 5 digit

DAM shows the load current flowing into the

DC load when the Load is ON.

Setting mode

If CONFIG, LIMIT, DYN, SHORT, OPP or

OCP buttons are pressed the middle LCD

show a text message according to the setting

function it is in. Each subsequent press of the

31

PEL-5000C User Manual

button moves the display to the next available

function.

The sequence of each setting menu is detailed

below

CONFIG:

Sequence is “SENSE” ”LDon” “LDoff”

”POLAR” “MPPT” ”CPRSP”

”AVG”

LIMIT:

Sequence is “Add.CV” “V_Hi”

”V_Lo” ”I_Hi” “I_Lo” ”W_Hi”

”W_Lo” “NG”

DYN setting:

Sequence is “T-Hi” “T-Lo” “RISE”

“FALL”

SHORT:

Sequence is “PRESS” “TIME” “V_Hi”

“V_Lo”

OPP:

Sequence is “PSTAR” “PSTEP”

“PSTOP“ “Vth”

OCP:

Sequence is “ISTAR” “ISTEP”

“ISTOP" “Vth”

PRESET mode

The value of the setting entered on the right

display changes depending on the operating

MODE that has been selected

If CC mode is selected the right display

provides setting in amps "A".

If CR mode is selected the right display

provides setting in ohms “Ω”

If CP mode is selected the right display

provides setting in watts “W”.

If CV mode is selected the right display

provides setting in volts “V”.

LIMIT

Each press of the LIMIT button changes the

32

GETTING STARTED

middle LCD text. The sequence and the

corresponding setting value shown on the

bottom display is as follows:

Set CC + CV or CP + CV upper limit voltage,

the middle of the display show “Add.CV”,

right display set value, the unit is V.

V_Hi (left limit voltage) displays the set

value in volts “V”

V_Lo (right limit voltage) displays the set

value in volts “V”

I_Hi (left limit current) displays the set

value in amps “A”

I_Lo (right limit current) displays the set

value in amps “A”

W_Hi (left limit power) displays the set

value in watts “W”

W_Lo (right limit power) displays the set

value in watts “W”

NG displays whether the NG flag is set to

“ON” or “OFF”.

DYN Setting

Each press of the DYN setting button changes

the text on the middle LCD. The sequence and

the corresponding setting value shown on the

bottom display are as follows:

T-Hi (time high) displays the set value in

milliseconds “ms”

T-Lo (time low) displays the set value in

milliseconds “ms”

Rise (current rise time/slew rate) displays

the set value in “A/us” or “A/ms”

Fall (current fall time/slew rate) displays the

set value in “A/us” or “A/ms”

CONFIG

Each press of the CONFIG button changes the

right upper LCD Text.

The sequence and the corresponding setting

33

PEL-5000C User Manual

value shown on the bottom displays are as

follows:

SENSE can be set to “AUTO” or “ON”

LDon (load ON voltage) displays the set

value in volts “V”

LDoff (load OFF voltage) displays the set

value in volts “V”

POLAR (load polarity) can be set

to ”+LOAD” or “-LOAD”

MPPT (Maximum power point tracking)

BATT1 (Battery Discharge)

BATT2 (Battery Discharge)

BATT3 (Battery Discharge)

CPRSP (CP RESPONSE)

AVG

SHORT test

This allows the parameters of the short test to

be set up.

Each press of the SHORT button moves the

setting function. The sequence of the short test

along with the setting value is as follows:

Short Press Start (pressing the

START/STOP button starts the test).

TIME shows the duration of the SHORT

test. “CONTI”, on the bottom display

indicates continuous. Time can be adjusted

in “ms”.

V-Hi (voltage high threshold) displays the

set value in volts “V”

V-Lo (voltage low threshold) displays the

set value in volts “V”

When the test is started the right display will

show RUN. When the test has finished the

right display will show END.

OPP test

This allows the parameters of the over power

protection test to be set up. Each press of the

34

GETTING STARTED

OPP button moves the setting function. The

sequence of the OPP test along with the

setting value is as follows:

OPP Press Start (pressing the red

START/STOP button starts the test)

PSTAR (power start point) right display

provides setting in watts “W”

PSTEP (power steps) right display

provides setting in watts “W”

PSTOP (power stop point) right display

provides setting in watts “W”

VTH (voltage threshold) right display

provides setting in volts “V”

When the test is started the right display will

show the power value being taken by the load.

If the Device Under Test is able to supply the

load according to the values set then the right

display will show PASS and the right display

will show the maximum power taken during

the OPP test. If during the test, OTP is

displayed the over temperature protection has

been engaged. Similarly if OPP is shown on

the display the over power protection has

been activated.

OCP test

This allows the parameters of the over current

protection test to be set up. Each press of the

OCP button moves the setting function.

The sequence of the OCP test along with the

setting value is as follows:

OCP Press Start (pressing the red

START/STOP button starts the test)

ISTAR (current start point) right display

provides setting in amps “A”

ISTEP (current steps) right display

provides setting in amps “A”

ISTOP (current stop point) right display

35

PEL-5000C User Manual

provides setting in amps “A”

VTH (voltage threshold) right display

provides setting in volts “V”

When the test is started the right display will

show the current value being taken by the

load. If the Device under Test is able to supply

the load according to the values set then the

middle display will show PASS and the right

display will show the maximum current taken

during the OCP test. If during the test, OTP is

displayed the over temperature protection has

been engaged. Similarly if OPP is shown on

the display the over power protection has

been activated.

10

Mode and

Indicators

There are four operating modes that can be

selected by pressing the “MODE” key on the

PEL-5000C series Electronic Load module. The

sequence is Constant Current (CC), Constant

Resistance (CR), Constant Voltage (CV), and

Constant Power (CP). Each time the "MODE"

key is pressed the operating mode is changed.

The actual operating mode selected is

indicated on the left hand side of the LCD.

OPP test

This allows the parameters of the over power

protection test to be set up. Each press of the

OPP button moves the setting function. The

sequence of the OPP test along with the

setting value is as follows:

OPP Press Start (pressing the red

START/STOP button starts the test)

PSTAR (power start point) right display

provides setting in watts “W”

PSTEP (power steps) right display

provides setting in watts “W”

PSTOP (power stop point) right display

provides setting in watts “W”

VTH (voltage threshold) right display

36

GETTING STARTED

provides setting in volts “V”

When the test is started the right display will

show the power value being taken by the load.

If the Device Under Test is able to supply the

load according to the values set then the right

display will show PASS and the right display

will show the maximum power taken during

the OPP test. If during the test, OTP is

displayed the over temperature protection has

been engaged. Similarly if OPP is shown on

the display the over power protection has

been activated.

37

PEL-5000C User Manual

Function keys description ..................................... 39

Test keys description ............................................ 53

System keys description ........................................ 68

Test keys description ............................................ 77

FUNCTION DESCRIPTION

38

FUNCTION DESCRIPTION

Mode and CC,

CR, CP, CV

Indicator

Mode

SEQ

There are four operating modes. These can

be selected in turn by pressing the

“MODE” key on the PEL-5000C series

Electronic Load module. The sequence is:

(CC) Constant Current

(CR) Constant Resistance

(CP) Constant Power

(CV) Constant Voltage

The appropriate LCD will illuminate

according to the operating mode is

selected.

Load key and

LED

indicators

Load

On/Off

The input to the PEL-5000C Series

electronic load can be switched ON/OFF

by using the “LOAD” button. Indication of

the ON/OFF state is provided by

illumination of the button.

LOAD button lit = LOAD ON (load sinks

according to the preset values)

LOAD button unlit = LOAD OFF (the load

does not sink current)

Turning the LOAD OFF does not affect the

preset values. When the LOAD ON state is

enabled the unit will revert to sinking

according to the preset values.

When the Load ON/OFF key is operated

Function keys description

39

PEL-5000C User Manual

the current taken by load will follow the

RISE or FALL with time according to the

preset rate. The current RISE and FALL

times can be adjusted in the DYN Setting

button of the front panel.

In addition to the LOAD ON/OFF

function the user can also adjust the

voltage level at which the unit will

automatically start or stop sinking energy.

The adjustable LDon and LDoff voltage

levels are found within the CONFIG

menu.

Please note that the LDoff level cannot be set

higher than the LDon level.

Preset key and

LED

indicators

Preset

If the PRESET key is pressed the button

will become lit indicating that the PRESET

mode has been accessed. The lowest 5 digit

display will change from showing the

power consumption in watts to displaying

the value to be preset. The value that can

be programmed changes according to the

operating mode that has been selected.

Constant Current (CC) mode:

The A and B levels of load current can

be preset at right lower 5 digit LCD.

The “A” LED will be lit indicating the

setting value is amps.

Constant Resistance (CR) mode:

The A and B levels of load resistance

can be preset on the right lower 5 digit

LCD. The “Ω” LED will be lit indicating

the setting value is ohms.

Constant Voltage (CV) mode:

The A and B levels of load voltage can

be preset on the right lower 5 digit

LCD. The “V” LED will be lit indicating

the setting value is volts.

Constant Power (CP) mode:

40

FUNCTION DESCRIPTION

The A and B levels of load power can

be preset on the right lower 5 digit

LCD. The “W” LED will be lit

indicating the setting value is watts.

Dynamic mode (CC, CR or CP modes

only):

Preset key

DYN

STA

Each press of the DYN button cycles

through the dynamic load settings. The

DYN settings are used in conjunction with

the High and Low levels of load current to

define the dynamic waveform. Each press

of the DYN button switches from T_Hi

(time high), to T_Lo (time low), to Rise

time and then to fall time. The middle LCD

shows the section of the dynamic

waveform which is programmed with the

rotary knob and read from the right

display. The “ms” LED shows that the

settings are programmed in milliseconds.

Range key

Range

The PEL-5000C series Load Module

features 2 setting ranges for CC, CR, CV &

CP operation. This allows improved

resolution for setting low values. When left

in the default AUTO mode the changeover

between ranges is automatic depending on

the setting value entered.

If desired the RANGE button can be

pressed to force the unit to operate only in

RANGE II. This is signaled by the

accompanying LED becoming lit.

Note

It is only possible to force RANGE II in CC

mode.

41

PEL-5000C User Manual

Level key

Level

The LEVEL button is used to program a

High or Low load value. The setting value

changes between current, resistance,

voltage or power depending whether CC,

CR, CV or CP mode has been selected. If

the LED is lit then the High level value

setting has been enabled. If the LED is not

lit then the low load level can be set using

the rotary switch in combination with the

arrow keys.

In STATIC mode the user can switch

between High and low load levels during

operation.

In DYNAMIC operation (CC & CP modes

only) the preset high and low levels are

used to define the dynamic waveform.

Note

The low level setting cannot exceed the high

level. The converse is also true in that the

High level cannot be set below the low level.

Limit key

Limit

The LIMIT button allows the user to set

left and right thresholds for voltage,

current or power. These threshold settings

are used in conjunction with the NG

function to flag when the load is operating

outside the desired limit.

Each press of the LIMIT key enables a

different value to be entered. On first press

of the LIMIT key the button will illuminate

Add.CV will be displayed on the middle

LCD. The setting is made with the rotary

knob and can be read from the right LCD

during setting.

The setting sequence is shown below:

Add.CV (CC+CV or CP+CV upper

limit)

V_Hi (DVM upper limit)

42

FUNCTION DESCRIPTION

V_Lo (DVM lower limit)

I_Hi (DAM upper limit)

I_Lo (DAM lower limit)

W_Hi (DWM upper limit)

W_Lo (DWM lower limit)

NG OFF/ON (No Good Flag)

LIMIT setting function OFF

The engineering unit is “V”, “A” or “W”

depending on the threshold LIMIT being

set.

Setting CC+CV or CP+CV upper limit

voltage, Middle 5 digit LCD

display ”Add.CV”, right 5 digit LCD

display the unit is “V” ,The Add.CV set

range from 0.00 V to 600.00V step 0.01V by

rotating the Setting knob.

43

PEL-5000C User Manual

Setting upper limit voltage VH , Middle 5

digit LCD display “V-Hi”, right 5 digit

LCD display the unit is “V” ,The V-Hi set

range from 0.00 V to 600.00V step 0.01V by

rotating the Setting knob.

Setting lower limit voltage VL, the right

upper 5 digit monitor display ”V-Lo” and

right lower monitor display lower limit of

the voltmeter with the unit as “V” ,The VLo set range from 0.00 V to 600.00V step

0.01V by rotating the Setting knob.

Setting upper limit current IH , the right

upper 5 digit monitor display ”I-Hi” and

right lower monitor display upper limit of

the voltmeter with the unit as “A”, the I-Hi

set range from 0.000 A to 840.00A step

0.0001A by rotating the Setting knob.

Setting lower limit current IL , the right

upper 5 digit monitor display ”I-Lo” and

right lower monitor display lower limit of

the voltmeter with the unit as “A”, the I-Lo

set range from 0.000 A to 840.00A step

0.01A by rotating the Setting knob.

44

FUNCTION DESCRIPTION

Setting upper limit power WH, the right

upper 5 digit monitor display ”W-Hi” and

right lower monitor display upper limit of

the voltmeter with the unit as “W”, the WHi set range from 0 W to 12000W step 1W

by rotating the Setting knob.

Setting lower limit power WL, the right

upper 5 digit monitor display ”W-Lo” and

right lower monitor display lower limit of

the voltmeter with the unit as “W”, the WLo set range from 0 W to 12000W step 1W

by rotating the Setting knob.

Setting NG ON/OFF, When exceed VH,

VL, IH, IL, WH, WL One of these whether

NG on LCD display.

Limit

CC mode, press limits key to set the V-Hi

and V-Lo voltage upper and lower limits

of the GO / NG.

Go

NG

NG

Current

Voltage

Load Current

Low

High

Limit

CC Dynamic Mode, press key to set the

Level Hi and Level Low voltage upper and

lower limits of the GO / NG.

45

PEL-5000C User Manual

Go

NG

NG

Current

Voltage

Level Low

Low

High

Level Hi

Limit

CR mode, press limits key to set the V-Hi

and V-Lo voltage upper and lower limits

of the GO / NG.

Go

NG

NG

Load Current

Low

High

Load input Voltage

Resistance

Limit

CV mode, press limits key to set the I-Hi

and I-Lo Current upper and lower limits of

the GO / NG.

Load lnput Voltage

Go

NG

NG

Load Current

Low

High

Voltage

Limit

CP mode, press limits key to set the W-Hi

and W-Lo power upper and lower limits of

the GO / NG.

46

FUNCTION DESCRIPTION

DYN setting

key

DYN

Setting

The DYN button allows the user to define

the timings of the dynamic load

Waveform. Firstly the high and low levels

of load current will need to be set via the

LEVEL switch. The RISE and FALL times

between the low load current and the high

load current along with the TIME the

waveform is HIGH and the TIME LOW

can is set via the DYN menu.

Each press of the DYN key enables a

section of the DYNAMIC waveform to be

set.

On first press of the DYN key the button

will illuminate and T-Hi will be displayed

on the middle LCD. The value is adjusted

with the rotary knob and can be read from

the right LCD during setting.

The setting sequence is shown below:

T_Hi (time the waveform is high)

T_Lo (time the waveform is low)

RISE (rise time)

FALL (fall time )

DYN setting function OFF

The time that the waveform is high

includes the rise time and is set in “ms”.

The time that the waveform is low

includes the fall time and is set in “ms”.

The RISE and FALL time is set in “A/μs”.

47

PEL-5000C User Manual

The actual engineering unit is shown on

the right of the Right 5 digit display

Press DYN setting key, LED will ON

setting level High Period, Middle 5 digit

LCD display will show “T-Hi” Right 5

digit LCD display will show setting value,

the unit is “ms”, The T-Hi set range from

0.010 ms to 9999 ms step 0.001ms by

rotating the setting knob.

There are four ranges from 0.010 ms to

9999 ms, the ranges are below:

Range 1:0.010ms~9.999ms

Range 2:10.00ms~99.99ms

Range 3:100.0ms~999.9ms

Range 4:10000ms~9999ms

48

FUNCTION DESCRIPTION

Setting level Low period, Middle 5 digit

LCD display will show “T-Lo”, right 5

digit LCD display will show setting value,

the unit is “ms” , the T-Lo set range from

0.010 ms to 9999 ms step 0.001ms by

rotating the Setting knob.

Setting rise time, Middle 5 digit LCD

display will show “RISE”, right 5 digit

LCD display will show setting value, the

unit is “A/μs”, the RISE time set range

from 0.672A/us to 42.840 A/us step

0.168A/us by rotating the Setting knob.

Setting fall time, Middle 5 digit LCD

display will show “FALL”, right 5 digit

LCD display will show setting value, the

unit is “A/μs” , the FALL time set range

from 0.672A/us to 42.840A/us step

0.168A/us by rotating the Setting knob.

Config key

Config

The CONFIG key allows the sense function

to engage automatically or switched ON.

The CONFIG key also enables the LOAD

to automatically turn ON/OFF when a

voltage level is reached. The polarity

symbol can also be switched via the

CONFIG menu.

Each press of the CONFIG key moves the

menu on one step. On first press of the

CONFIG key the button will illuminate

and EXTIN will be displayed on the Right

49

PEL-5000C User Manual

upper LCD. The value is adjusted with the

rotary knob and can be read from the right

LCD during setting. The setting sequence

is shown below:

SENSE (AUTO or ON)

LDon (Voltage at which LOAD turns

ON)

LDoff (Voltage at which LOAD turns

OFF)

POLAR (change polarity symbol)

MPPT

CPRSP

Exit CONFIG options

Note

The adjustable LDon (LOAD ON) voltage is valid for

CC, CR & CP operating modes. The adjusted LDon

voltage will not operate in CV mode.

The LDon (LOAD ON) voltage setting cannot be lower

than the LDoff (LOAD OFF) voltage. If 0V is required

for both LOAD ON and LOAD OFF make the LOAD

OFF adjustment first.

Set vsense and load input switching

methods, the middle of the 5 digit LCD

display will show “SENSE”, Right 5 digit

LCD display will show “AUTO” or “ON”.

50

FUNCTION DESCRIPTION

Set Load ON voltage, the middle of the 5

digit LCD display will show “LDon”,

Right 5 digit LCD display will show

setting value, the units is V, The Load ON

Voltage set range from 0.8V to 100.0V step

0.4V by rotating the setting knob. If the

load is greater than the input voltage Load

ON voltage setting, the Electronic load

current begin to load on.

Note

CC/CR/CP MODE is controlled by Load ON voltage, CV

MODE is not controlled by Load ON voltage.

Set Load OFF voltage, the middle of the 5

digit LCD display will show “LDoFF”,

Right the 5 digit LCD display will show

settings value, the units is V, The Load

OFF Voltage set range from 0.0V to 99.00V

step 0.01V by rotating The Setting knob.

If the load input voltage is less than Load

OFF setting voltage, the electronic load to

load off.

Set Load polarity, the middle of the 5 digit

LCD display will show “POLAR”, Right

the 5 digit LCD display will show “+

LOAD” or “-LOAD”, use the knobs and

key settings “+ LOAD” or “-LOAD”.

51

PEL-5000C User Manual

Set MPPT (Maximum power point

tracking) testing, the middle of the 5 digit

LCD display will show “MPPT”, Right the

5 digit LCD display “1000”, the MPPT

setting range from 1000mS to 60000mS.

Set CPRSP, the middle of the 5 digit LCD

display will show “CPRSP”, Right the 5

digit LCD display “0”, the CPRSP set

range from 0 to 4 steps 1 by rotating the

setting knob. Setting CP Mode reaction

speed, 0: Fast, 4: Slow.

Set AVG, the middle of the 5 digit LCD

display will show “AVG”, Right the 5 digit

LCD display “1”, the AVG setting range

from 1 to 64 steps 1 by rotating the setting

knob.

52

FUNCTION DESCRIPTION

Item, Setting

and Exit keys

Item

Setting

Exit

Item, Setting and Exit key for Test. There

are eight operating modes. These can be

selected in turn by pressing the “Item

“key. Press ITEM key enter setting mode,

ITEM LED light ON, the setting sequence

is shown below:

OCP

OPP

DISch

SURGE

Exit ITEM options

Test keys description

53

PEL-5000C User Manual

Setting Short

mode

The Setting key allows the parameters of a

SHORT circuit test to be entered. The

SHORT test will attempt to sink high

current up to the PEL-5000C series load

maximum current in order to check the

power source’s protection and behavior.

The test time can be adjusted and

threshold values for the High and low

voltage limits set.

Setting

Pressing the Setting key once will cause

the button to illuminate. The Message

“SHORT PRESS START” will be shown

across the 3 displays.

Setting

Each press of the SHORT key moves the

menu on one step. The left and Middle

LCDs show the currently selected test

parameter as text. The value is adjusted by

the rotary knob and can be read from the

right display during Setting.

The setting sequence is shown below:

SHORT PRESS START (pressing the

start/stop key starts test)

SHORT Time (CONTI = Continuous or

100ms to 10,000ms possible)

SHORT V_Hi (High voltage threshold

setting)

SHORT V_Lo (Low voltage threshold

setting

Exit SHORT test set-up

54

FUNCTION DESCRIPTION

Set the short test time, the LCD display

show “SHORT” on left 5 Digits LCD

display, shows “TIME” on middle 5 digits

LCD display, right 5 digit LCD

display ”CONTI”, the unit is “ms”.

TIME: Set the short test time, The LCD

display show “SHORT” on left 5 digits

LCD display, shows “TIME” on middle 5

digits LCD display the unit is “ms”, and

shows “CONTI” on right 5 digits LCD

display, the setting range is “CONTI”

means continue, 100mS to 10000mS step

100mS by clockwise rotate the setting

knob. The short test will be no time

limitation when setting to CONTI until

press “START/STOP” key to stop the

short test.

55

PEL-5000C User Manual

V-Hi : Short test voltage check upper

limitation setting, the LCD display shows

“SHORT” on left 5 digit LCD display,

Middle 5 digit LCD display ”V-Hi”, right 5

digit LCD display setting value, the unit is

“V”, The V-Hi setting range from 0.00V to

600.00V step 0.01V by rotating the setting

knob.

V-Lo : Short test voltage check lower

limitation setting, the Left 5 digit monitor

display the “SHORT” ,the middle 5 digit

monitor display the “V-Lo” and right

lower monitor display setting value, the

unit is “V”. The range is 0.01V to 600.00V.

Start

Stop

Once the test parameters have been

entered the test is started by pressing the

START/STOP button while the SHORT

PRESS START text is displayed. During

the test the bottom LCD will show run and

the actual short current will be displayed

on the right upper LCD.

Note

The message PASS END will be displayed if the

measured voltage levels stay within the V_Hi and

V_Lo threshold levels during the test.

The message FAIL END will be displayed if the

measured voltage levels fall outside the V_Hi and

V_Lo threshold levels during the test. The NG flag will

also illuminate.

If continuous short time is selected the test is ended

by pressing the red START/STOP button.

56

FUNCTION DESCRIPTION

OCP

parameters

setting

The OCP key allows the parameters of an

Over Current Protection test to be entered.

The OCP test will ramp up the load

current in steps to validate the Device

Under test’s (DUT) protection and

behavior. A voltage threshold level can be

set. If the voltage measured during the test

is lower than the set Threshold voltage

then the test will fail and the display will

signal OCP ERROR. Similarly a current

Threshold (I STOP) can be set. If the

measured Current reaches the I STOP

Threshold the test will be discontinued

and the OCP ERROR message will be

displayed.

Setting

Press the Setting key once will cause the

button to illuminate. The message “OCP

PRESS START” will be shown across the 3

displays.

Each press of the OCP button moves the

menu on one step. The Left and Middle

LCDs show the currently selected test

parameter as text. The value is adjusted by

the rotary knob and can be read from the

Right display during setting.

The setting sequence is shown below:

OCP VTH OCP PRESS START

(pressing the red start/stop key starts

test)

OCP I STAR (current starting point of

the OCP test)

OCP I STEP (value of incremental

current steps from I START)

OCP I STOP (the OCP test’s upper

current threshold

OCP Vth (the voltage threshold setting)

Exit OCP test set-up

57

PEL-5000C User Manual

ISTAR: setting the start current point, the

Left 5 digit monitor display the “OCP”, the

right upper 5 digit monitor display the

“ISTAR”, and right lower monitor display

setting value, the unit is “A”. The range is

0.001A to the full scale of the CC mode

specification. The setting is by rotating the

setting knob.

ISTEP: setting the increment step current

point, The LCD display shows ”OCP” on

Left 5 digit LCD display, Middle 5 digit

LCD display ”ISTEP”, right 5 digit LCD

display setting value, the unit is “A”. The

setting range is 0.01A to the full scale of

the CC mode specification. The setting is

by rotating the setting knob.

58

FUNCTION DESCRIPTION

ISTOP: setting the stop current point, The

LCD display shows “OCP” on Left 5 digit

LCD display, Middle 5 digit LCD display

“ISTOP”, right 5 digit LCD display setting

value, the unit is “A”, the setting range is

0.000A to the full scale of the CC mode

specification. The setting is by rotating the

setting knob.

Vth: Setting threshold voltage; The LCD

display shows “OCP” on left 5 Digit LCD

display, middle 5 digit LCD display “Vth”,

right 5 digit LCD Display setting value, the

unit is “V”, the setting range is 0.00V to the

full scale of the voltage specification. The

setting is by rotating the setting knob.

Start

Stop

Once the test parameters have been

entered the test is started by pressing the

red START/STOP button while the OCP

PRESS START text is displayed. During the

Test the middle LCD will show run and the

actual current being Taken will be

displayed on the Right LCD

Note

The message OCP ERROR will be displayed if the DUT

fails the test. The reasons for failure are due to one of the

following conditions:

(a) the voltage level of the DUT falls below the set

voltage threshold (OCP Vth)during the test

(b) The current taken from the DUT reaches the OCP I

STOP setting.

The message PASS will be displayed if the DUTs voltage

stays above the set threshold. Also to PASS the OCP test

the current taken from the DUT cannot equal the I STOP

59

PEL-5000C User Manual

setting.

If the DUT passes the OCP test the maximum current

taken during the test is displayed on the right LCD.

Upon PASS or OCP ERROR the test will automatically

stop. The red START/STOP button can be used during the

test to immediately cease operation.

OPP

parameters

setting

The OPP allows the parameters of an Over

Power Protection test to be entered. The

OPP test will ramp up the load power in

steps to validate the Device under test’s

(DUT) protection and behavior. A voltage

threshold level can be set. If the voltage

measured during the test is lower than the

set Threshold voltage then the test will fail

and the display will signal OPP ERROR.

Similarly a power threshold (P STOP) can

be set. If the measured power reaches the P

STOP threshold the test will be

discontinued and the OPP ERROR

message will be displayed.

Setting

Press the Setting key once will cause the

button to illuminate. The message “OPP

PRESS START” will be shown across the

displays.

60

FUNCTION DESCRIPTION

Each press of the OPP button moves the

menu on one step. The Left and Middle

LCDs show the currently selected test

parameter as text. The value is adjusted by

the rotary knob and can be read from the

Right display during Setting.

The setting sequence is shown below:

OPP PRESS START (pressing the red

start/stop key starts test)

OPP P STAR (power starting point of

the OPP test)

OPP P STEP (value of incremental

current steps from P START)

OPP P STOP (the OPP test’s upper

threshold power limit)

OPP Vth (the voltage threshold setting)

Exit OPP test set-up

PSTAR: setting the start power, the LCD

display shows “OPP” on left 5 digit LCD

display, middle 5 digit LCD

display ”PSTAR”, right 5 digit LCD

display setting value, the unit is “W”, the

setting range is 0.00W to the full scale of

the CP mode specification. The setting is

by rotating the setting knob.

61

PEL-5000C User Manual

PSTEP: setting the increment step power,

the LCD display shows “OPP” on left 5

digit LCD display, middle 5 digit LCD

display ”PSTEP”, right 5 digit LCD display

setting value, the unit is “W”, the setting

range is 0.00W to the full scale of the CP

mode specification. The setting is by

rotating the setting knob.

PSTOP: setting the stop power, the Left 5

digit monitor display the “OPP” ,the right

upper 5 digit monitor display the

“PSTOP”, and right lower monitor display

setting value, the unit is “W”. The range is

0.1W to the full scale of the CP mode

specification.

Vth : Setting threshold voltage; the Left 5

digit monitor display the “OPP” ,the right

upper 5 digit monitor display the “Vth”,

and right lower monitor display setting

value, the unit is “V”. The range is 0.00V to

the full scale of the voltage specification.

The setting is by rotating the setting knob.

Start

Stop

Once the test parameters have been

entered the test is started by pressing the

red START/STOP button while the OPP

RESS START text is displayed. During the

Test the middle LCD will show run and the

actual current being Taken will be

displayed on the Right LCD

62

FUNCTION DESCRIPTION

Note

The message OPP ERROR will be displayed if the DUT

fails the test. The reasons for failure are due to one of the

following conditions:

(c) the voltage level of the DUT falls below the set

voltage threshold (OPP Vth)during the test

(d) The current taken from the DUT reaches the OPP P

STOP setting.

The message PASS will be displayed if the DUTs voltage

stays above the set threshold. Also to PASS the OPP test

the current taken from the DUT cannot equal the I STOP

setting.

If the DUT passes the OPP test the maximum current

taken during the test is displayed on the right LCD.

Upon PASS or OCP ERROR the test will automatically

stop. The red START/STOP button can be used during the

test to immediately cease operation.

Battery

discharge

setting

Disch

Mode CC

Disch

Mode CP

DIsch the test function has 5 parameters,

“CC”, “VOLT.V”, “TIME.S”, “CAP.AH”

and CAP.WH parameters.

Press the Setting key to set stop discharge

voltage “VOLT.V”, Press again Setting key

to set stop discharge time “TIMES.S”.

Press Setting key again to stop discharge

capacity “CAP.AH” / “CAP.WH”.

63

PEL-5000C User Manual

Setting battery discharge CC mode, DISCH

CC, LCD show “DISch”, middle 5 digit

LCD display “CC”, setting range 0.00A to

full scale.

Setting stop discharge voltage STOP

“VOLT.V”, middle 5 digit LCD display

“VOLT.V”, right 5 digit LCD display

setting value, unit is V, STOP “VOLT.V”

setting range 0.00V to full scale.

Setting stop discharge time, setting STOP

“TIME.S”, middle 5 digit LCD display

“TIME.S”, right 5 digit LCD display setting

value, STOP “TIME.S” setting OFF to

99999, each setting knob and button

adjustment interval is 1.

64

FUNCTION DESCRIPTION

Setting stop discharge capacity, setting

STOP “CAP.AH”, middle 5 digit LCD

display “CAP.AH”,right 5 digit LCD

display setting value, STOP “CAP.AH”

setting range OFF to 19999.9, each setting

knob and button adjustment interval is 0.1.

Setting stop discharge capacity, setting

STOP “CAP.WH”, middle 5 digit LCD

“CAP.WH”, right 5 digit LCD display

setting value, STOP “CAP.WH” setting

range OFF to 19999.9, each setting knob

and button adjustment interval is 0.1.

Surge current

testing setting

SURGE sequence is shown below:

SURGE the test function has 4 parameters,

“SUR.I”, “NOR.I’, “TIME” and “STEP”

parameters.

Press the Setting key to set surge

current testing loading current value

“SUR.I”.

Press again Setting key to set normal

current testing loading current value

“NOR.I”.

Press Setting key again to set surge

current testing time “TIME”.

Press the Setting key again to set surge

current testing diminishing step current

setting value “STEP”.

65

PEL-5000C User Manual

Set SURGE testing surge current, unit is A,

setting range 0.00A to full scale.

Set SURGE testing normal current, unit is

A, setting range 0.00A to full scale.

Set SURGE time, unit is mS, setting range

10mS to 1000mS.

Set SURGE step, setting range 1 to 5.

Setting fig

explanation.

66

FUNCTION DESCRIPTION

Exit Key

Exit

Setting OCP / OPP / DISch / SURGE

during the setting process press Exit key to

exit setting item.

Start/Stop key

Start

Stop

The START/STOP key is used in

conjunction with the SHORT, OCP or OPP

test functions. It is used to START a test

according to the set parameters or to STOP

a test before PASS or FAIL is signaled.

Please refer to the preceding sections for

more information on the SHORT, OCP &

OPP tests.

67

PEL-5000C User Manual

Shift key

Shift

Shift key is used to switch the key to the

second function key.

System key

System

Press SYSTEM to set the argument, GPIB

address, RS232 BAUD- RATE, WAKE UP

and buzzer Alarm power ON/OFF and

Master/Slave control.

Local key

Local

Press Local key to exit REMOTE mode

System keys description

68

FUNCTION DESCRIPTION

Setting system

parameters

Set GPIB address, RS232 BAUD RATE,

WAKE UP, Buzzer ON/OFF

Set GPIB

address

System

First press SYSTEM key, the LCD display

shows GPIB on left 5 digit LCD display,

Middle 5 digit LCD display Addr, right 5

digit LCD display setting GPIB address of

the representative, Press UP, DOWN

buttons to adjust the GPIB address 1~30,

Key and then press ENTER, PEL-5000C

series GPIB Address value is saved, Press

system key four times to leave the GPIB

address configuration State.

Set RS232

BAUD RATE

System

X2

SYSTEM key first by the second, the LCD

display shows RS232 on left 5 digit LCD

display, Middle 5 digit LCD display baud,

right 5 digit LCD display setting BAUDRATE, Press UP, DOWN buttons to adjust

the value of BAUD RATE, Key and then

press ENTER, PEL-5000C series is saved

setting BAUD RATE, press system key

three times to leave the BAUD-RATE

setting state.

69

PEL-5000C User Manual

WAKE-UP

function

System

X3

This function is designed for auto setting

the load status and load level in turning on

the PEL-5000C series every time. SYSTEM

key first by the three, The LCD display

shows WAKE on left 5 digit LCD display,

Middle 5 digit LCD display UP, right 5

digit LCD display setting, Press UP,

DOWN buttons to adjust the 0~150.

Press ENTER key to be stored, press

system key two times to leave the WAKEUP setting state, If set to “0” means do not

call.

70

FUNCTION DESCRIPTION

Buzzer ON/

OFF

This is the test set automatically (AUTO

SEQUENCE) at the end, if it increases

buzzer function, if set to ON, Then when

the test result is PASS automatically when

the buzzer will call out, if the test result is

FAIL when the buzzer will call the second

tone.

System

X4

Setting method:

first by 4 Times SYSTEM key and the LCD

display shows SEQ on left 5 digit LCD

display, Middle 5 digit LCD display bEEP,

right 5 digit LCD display setting ON or

OFF, press UP DOWN key to adjust.

Note

Setting system parameters, if the input is required to use