DC Electronic Load

PEL-3000(H) Series

USER MANUAL

VERSION: 2.00

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................. 3

GETTING STARTED .......................................................... 7

PEL-3000(H) Series Introduction ............................... 9

Accessories.............................................................. 11

Appearance .............................................................. 14

First Time Use Instructions ..................................... 25

OPERATION .................................................................. 51

Basic Operation ....................................................... 54

Basic Configuration ................................................. 66

Advanced Configuration Settings ............................. 73

Step Resolution Configuration ................................. 80

Protection Settings .................................................. 83

System Settings ....................................................... 92

Go-NoGo ................................................................. 97

Save Recall .............................................................100

FUNCTION MENU ........................................................ 113

Function Menu Overview ........................................114

Program .................................................................120

Sequence ................................................................128

OCP Test Automation .............................................147

OPP Test Automation .............................................154

BATT Test Automation ............................................160

MPPT ......................................................................169

EXTERNAL CONTROL ................................................... 182

Analog Control .......................................................183

Parallel Operation ..................................................204

1

PEL-3000(H) User Manual

REMOTE CONTROL ...................................................... 211

Interface Configuration .......................................... 212

FAQ .............................................................................. 234

APPENDIX .................................................................... 236

Replacing the Dust Filter ....................................... 238

Replace the Clock Battery....................................... 239

GPIB Installation ................................................... 240

Ethernet Card Installation ...................................... 241

PEL-3000(H) Default Settings ................................ 242

Frame Control Connector Contacts ........................ 245

Operating Mode Description ................................. 259

Operating Area ...................................................... 264

PEL-3000 Specifications ......................................... 271

PEL-3000H Specifications ...................................... 283

PEL-3000(H) Dimensions ...................................... 295

Declaration of Conformity ...................................... 298

INDEX .......................................................................... 300

2

SAFETY INSTRUCTIONS

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the instrument or to

other properties.

DANGER High Voltage

Attention Refer to the Manual

Earth (ground) Terminal

Frame or Chassis Terminal

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

3

PEL-3000(H) User Manual

General

Guideline

CAUTION

Do not place any heavy object on the

instrument. Note: Only 2 units can be stacked

vertically.

Avoid severe impact or rough handling that

leads to damaging the instrument.

Do not discharge static electricity to the

instrument.

Use only crimped wires, not bare wires, for the

terminals.

Do not block the cooling fan opening.

Do not disassemble the instrument unless you

are qualified.

The equipment is not for measurements

performed for CAT II, III and IV.

(Measurement categories) EN 61010-1:2010 specifies the

measurement categories and their requirements as follows.

Measurement category IV is for measurement

performed at the source of low-voltage

installation.

Measurement category III is for measurement

performed in the building installation.

Measurement category II is for measurement

performed on the circuits directly connected to

the low voltage installation.

0 is for measurements performed on circuits not

directly connected to Mains.

Do NOT position the equipment so that it is

difficult to disconnect the appliance inlet or the

power plug.

If the equipment is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

Safety Guidelines

4

SAFETY INSTRUCTIONS

Power Supply

WARNING

AC Input voltage range: 100-120VAC/200-

240VAC

(90-132VAC/180-250VAC)

Frequency: 47-63Hz

Power:

PEL-3021(H): 90VA Max

PEL-3041(H): 110VA Max

PEL-3111(H): 190VA Max

PEL-3211(H): 230VA Max

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

To avoid electric shock, the power cord

protective grounding conductor must be

connected to ground. No operator serviceable

components inside. Do not remove covers.

Refer servicing to qualified personnel.

Cleaning

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Temperature: 0°C to 40°C

Humidity: 0 to 85% RH

Altitude: <2000m

Overvoltage category II

5

PEL-3000(H) User Manual

(Pollution Degree) EN 61010-1:2010 specifies the pollution degrees

and their requirements as follows. The instrument falls under

degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry,

non-conductive pollution occurs. The pollution

has no influence.

Pollution degree 2: Normally only non-

conductive pollution occurs. Occasionally,

however, a temporary conductivity caused by

condensation must be expected.

Pollution degree 3: Conductive pollution

occurs, or dry, non-conductive pollution occurs

which becomes conductive due to condensation

which is expected. In such conditions,

equipment is normally protected against

exposure to direct sunlight, precipitation, and

full wind pressure, but neither temperature nor

humidity is controlled.

Storage

environment

Location: Indoor

Temperature: -20°C to 70°C

Humidity: <90% RH

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

6

GETTING STARTED

PEL-3000(H) Series Introduction ............................... 9

Model Line Up ................................................................................... 9

Main Features ................................................................................... 10

Accessories.............................................................. 11

Package Contents ............................................................................. 13

Appearance .............................................................. 14

Front Panel ........................................................................................ 14

PEL-3021/ PEL-3041 .............................................................. 14

PEL-3021H/ PEL-3041H ....................................................... 14

PEL-3111 .................................................................................... 15

PEL-3111H ................................................................................ 15

PEL-3211(H) Booster Pack ..................................................... 15

Rear Panel .......................................................................................... 19

PEL-3021/ PEL-3041 .............................................................. 19

PEL-3021H/ PEL-3041H ....................................................... 19

PEL-3111 .................................................................................... 20

PEL-3111H ................................................................................ 20

PEL-3211 Booster Pack ........................................................... 20

GETTING STARTED

This chapter provides a brief overview of the

PEL-3000(H), the package contents, instructions

for first time use and an introduction to the front

panel, rear panel and GUI.

7

PEL-3000(H) User Manual

PEL-3211H Booster Pack ....................................................... 21

Display ............................................................................................... 24

First Time Use Instructions ..................................... 25

Rack Mount Kits .............................................................................. 25

Power Up and Self Test .................................................................. 28

Load Default Settings ...................................................................... 28

Setting the Date and Time .............................................................. 29

Load Wiring ...................................................................................... 29

Load Wire Connections .................................................................. 33

Using the Front Panel Input Terminals ....................................... 34

Using the Rear Panel Input Terminals ......................................... 35

Using the Terminal Cover (PEL-011) .......................................... 36

Using the Terminal Cover (PEL-013) .......................................... 38

Using the Terminal Cover .............................................................. 40

Using the Monitor Out Cover (Only for PEL-3021H,

PEL-3041H, PEL-3111H) .............................................................. 41

Remote Sense .................................................................................... 42

Firmware Update ............................................................................. 43

Conventions ...................................................................................... 45

Help Menu......................................................................................... 50

8

GETTING STARTED

Model

Voltage (DC)

Current

Power

PEL-3021(H)

0V-150V(0V-800V)

35A(8.75A)

175W

PEL-3041(H)

0V-150V(0V-800V)

70A(17.5A)

350W

PEL-3111(H)

0V-150V(0V-800V)

210A(52.5A)

1050W

Booster Model

Voltage (DC)

Current

Power

PEL-3211(H)

0V-150V(0V-800V)

420A(105A)

2100W

PEL-3000(H) Series Introduction

The PEL-3000(H) Series is a family of high performance DC

electronic loads positioned to test a wide range of different power

sources. The DC electronic loads are fully programmable to

simulate anything from basic static loads to complex dynamic loads.

With the ability to operate independently or in parallel, the PEL3000(H) Series is extremely robust and capable of molding to any

test environment.

Please note that throughout this manual the term “PEL-3000(H)”

refers to any one of the models in the series lineup, unless

specifically stated otherwise.

Model Line Up

There are a total of 3 DC electronic load models and 1 booster pack

model.

9

Main Features

Performance

High slew rates of up to 16A/μS(PEL-3111(H))

for a fast response speed

High capacity when used in parallel:

5250W, 1050A(262.5A) (PEL-3111(H) x 5)/

9450W, 1890A(472.5A) (PEL-3111(H) + PEL3211(H) x 4)

High resolution – 16 bit

Features

7 operating modes: CC, CV, CR, CP, CC+CV,

CR+CV, CP+CV

Independent and parallel operation

Fully programmable with normal and fast

sequences

Soft start

Dynamic mode

OCP, OVP and other protection features

Remote sense

Integrated meter

Rack-mountable

Load booster

Interface

USB, RS232, LAN(option) and GPIB(option)

External voltage or resistance control

Front panel trigger out BNC

Front panel voltage/current monitoring BNC

Analog external control

Rear panel voltage/current monitoring

PEL-3000(H) User Manual

10

GETTING STARTED

Standard

Accessories

Part number

Description

Quick Start Guide

User / Programming manual CD

Region dependent

Power cord

PEL-011

Load input terminal Cover

M3

screw

PEL-012

Terminal fittings: 2 sets of

bolts/nuts/springs/washers (type:

M8), Terminal Cover x1 (only for

PEL-3000H series), Monitor Out

Cover x 1(only for PEL-3021H, PEL3041H, PEL-3111H)

M8 x 20

Spring washer

Flat washer

M8 nut

PEL-013

Flexible terminal cover: 2x rubber

sheeting, 4x Velcro fasteners.

(For PEL-3211(H) only)

Velcro

fasteners x4

Rubber

sheeting x2

Accessories

11

PEL-3000(H) User Manual

PEL-014

J1/J2 Protection plug x2 (It is

installed on the device)

61SF-062104N1

Front terminal washers

Spring washer (M6) x2

GTL-255

300mm Frame Link Cable (for

linking units that are stacked).Note

that this accessories is optional for

the PEL-3021(H)/ 3041(H).

Optional

Accessories

Part number

Description

3813-030D0501

CR123A 3V lithium battery for clock.

GRA-413-E

Rack mount bracket for booster PEL3211(H) (EIA)

GRA-413-J

Rack mount bracket for booster PEL3211(H) (JIS)

GRA-414-E

Rack mount frame for PEL-3021(H),

PEL-3041(H), PEL-3111(H)/EIA

GRA-414-J

Rack mount frame for PEL-3021(H),

PEL-3041(H), PEL-3111(H)/JIS

GTL-248

GPIB cable, 2.0m

GTL-246

USB cable, Type A - Type B

PEL-010

Dust Filter

PEL-004

GPIB card

PEL-005

Connect Cu Plate

PEL-006

Connect Cu Plate

PEL-007

Connect Cu Plate

PEL-008

Connect Cu Plate

PEL-009

Connect Cu Plate

PEL-018

LAN card

12

GETTING STARTED

Opening the box

Contents

(single unit)

Main unit

Quick Start manual

User / Programming

manual CD

Terminal fittings

Power cord x1

(region dependent)

Calibration certificate

Package Contents

Check the contents before using the instrument.

13

PEL-3000(H) User Manual

I MON OUT TRIG OUT

1.5 - 150V

175W

0 - 35A

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

Utility

Local

File

0

1

4

7

2

5

8

3

6

9

EnterClear

Shift

Preset

Load

On/

Off

Main

Help

FUNC

Short

Air inlet LCD Display Power key

FUNC/File

Help/Utility

Short

Load On/Off

USB Port, Preset

and Shift keys

Number pad, Clear/

Lock and Enter keys

Main/Local

Scroll wheel

Function keys

Input

terminals

I MON OUT,

TRIG OUT

V

MON OUT

TRIG OUT

5 -800V

350W

0 -8.75A

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

Utility

Local

File

0

1

4

7

2

5

8

3

6

9

EnterClear

Shift

Preset

Load

On/

Off

Main

Help

FUNC

Short

Air inlet LCD Display Power key

FUNC/File

Help/Utility

Short

Load On/Off

USB Port, Preset

and Shift keys

Number pad, Clear/

Lock and Enter keys

Main/Local

Scroll wheel

Function keys

Input

terminals

VMON OUT, I MON

OUT, TRIG OUT

I

MON OUT

A/ B

Appearance

Front Panel

PEL-3021/ PEL-3041

PEL-3021H/ PEL-3041H

14

PEL-3111

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

Utility

Local

File

0

1

4

7

2

5

8

3

6

9

EnterClear

Shift

Preset

Load

On/

Off

Main

Help

FUNC

Short

TRIG

OUT

I MON

OUT

1.5 - 150V

1050W

0 - 70A

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

Utility

Local

File

0

1

4

7

2

5

8

3

6

9

EnterClear

Shift

Preset

Load

On/

Off

Main

Help

FUNC

Short

TRIG OUT

I

MON OUT

5 - 800V

1050W

0 – 52.5A

V

MON OUT

A/B

LINK STBY

Air Inlet

The air inlet has a removable dust filter

LCD display

3.5 inch LCD display

Function keys

The function keys directly correspond to the soft

menu keys at the bottom of the display.

PEL-3111H

GETTING STARTED

PEL-3211(H) Booster Pack

15

PEL-3000(H) User Manual

ON/STBY

Turns the unit on or puts the unit

into standby mode. Use the power

switch on the rear panel to turn

the unit off.

Main/Local

Main

Main: Sets the operating mode:

CC, CV, CR, CP mode.

Local

Main

Shift

Local (Shift + Main): Puts

the instrument back into

local mode from remote

mode.

FUNC/File

FUNC

FUNC: Sets the program function,

sequence function or other special

functions.

File

FUNC

Shift

File (Shift + FUNC):

Accesses the file system.

Help/Utility

Help

Help: Access the help menu.

Utility

Help

Shift

Utility (Shift + Help):

Access the utility menu.

Short

Short

Pressing the Short key will

simulate shorting the input

terminals.

The Short key will be lit when

active.

Load on/off

Load

On/

Off

Turns the load on or off.

The Load On/Off key will be lit

when active.

Scroll wheel

Use the scroll wheel to navigate

the menu system or to edit

parameters. See page 45 for usage

details.

16

GETTING STARTED

Enter

Enter

Press the Enter key to select

highlighted menu items.

Number pad

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

0

1

4

7

2

5

8

3

6

9

Clear

Number pad: Used to enter numerical values.

P0-P9 (Preset + Number keys): Loads one of 10

preset settings.

Clear/Lock

Lock

Clear

Clear: Clears the current

parameter values.

Lock (Shift + Clear): Locks the

front panel keys and selector knob.

Shift

Shift

Shift: Used in conjunction with

other keys to select secondary

functions.

Preset

Preset

Used in conjunction with the

number pad to save or load preset

settings P0 to P9.

USB Port

USB A port. Used for save and

recall functions.

Front panel input

terminals

5-800V

350W

0 - 35A

Negative terminal.

Positive terminal.

17

PEL-3000(H) User Manual

IMON Out

I MON OUT

Current monitor BNC terminal:

Output connector used to monitor

the current by outputting a

voltage. An output voltage of 1V

(10V for PEL-3000H) corresponds

to the full scale current for the H

and L ranges. 0.1V (1V for PEL3000H) corresponds to the full

scale current in the M range.

VMON Out

V MON OUT

Voltage monitor BNC terminal:

Output connector used to monitor

the voltage by outputting a

voltage. An output voltage of 8V

corresponds to the full scale

voltage.

TRIG OUT

TRIG OUT

Trigger out BNC terminal:

Outputs a pulse signal during

sequence or dynamic operation.

The trigger signal has a 5V output

with a pulse width of a least 2us

and an impedance of 500Ω.

LINK/STBY

Indicator

(PEL-3211(H))

LINK STBY

The LINK and STBY indicators

indicate when the booster pack is

properly connected and when the

power has been turned on,

respectively.

18

GETTING STARTED

47 - 63 Hz

90 VA MAX.

AC

100 - 120 VAC

200 - 240 VAC

FRAME CONT

J 1

J 2

SER. NO. LB

RS232C

GPIB

WARNING

TO AVOID ELECTRIC SHOCK THE POWER CORD

DO NOT REMOVE COVERS.

NO OPERATOR SERVICEABLE COMPONENTS INSIDE.

PROTECTIVE GROUNDING CONDUCTOR MUST BE

REFER SERVICING TO QUALIFIED PERSONNEL.

CONNECTED TO GROUND.

Remote sense

inputs

Frame control ports,

J1, J2

RS232C port

USB port

USB device

port

Exhaust fanGPIB(Optinal) Power socket

and switch

Rear panel

inputs

47 - 63 Hz

90 VA MAX.

AC

100 - 120 VAC

200 - 240 VAC

FRAME CONT

J 1

J 2

RS232C

GPIB

Remote sense

inputs

Frame control ports,

J1, J2

RS232C port

USB port

USB device

port

Exhaust fan

GPIB(Optional)

Power socket

and switch

Rear panel

inputs

VR1

VR2 VR3 VR4

V/I MON OUT

1

Monitor Out

ports J3

Variable

Resistor

Rear Panel

PEL-3021/ PEL-3041

PEL-3021H/ PEL-3041H

19

PEL-3111

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

Utility

Local

File

0

1

4

7

2

5

8

3

6

9

EnterClear

Shift

Preset

Load

On/

Off

Main

Help

FUNC

Short

TRIG

OUT

I MON

OUT

1.5 - 150V

1050W

0 - 70A

PEL-3111H

PEL-3000(H) User Manual

PEL-3211 Booster Pack

20

GETTING STARTED

RS232C port

GPIB port

USB B port

The USB B, RS232C and GPIB port are used for

remote control.

USB B port

RS232C 9 pin

DSUB port.

GPIB 24 pin

female.

Frame control

ports, J1, J2

FRAME CONT

J 1

J 2

J1: The J1 connector is assigned to external control.

J2: The J2 connector is used for parallel operation

control.

PEL-3211H Booster Pack

21

PEL-3000(H) User Manual

Monitor Out

ports J3

J3: The J3 connector is assigned to current and

voltage monitor out.

Variable Resistor

The variable resistors are used to adjust the full

scale and offset setting for the input value of the

external control sources such as voltage or

resistance.

Exhaust fan

The exhaust fan is used to expel the heat from the

unit. Please ensure there is at least 20cm distance

between any object and the fan.

Rear Panel Input

terminals

Rear Panel Input Terminals. Electrically connected

to the front panel input terminals. Accepts M8

bolts or M4/M3 sized screws. See page 35 for

connection details.

Remote Sensing

Terminals

Sensing terminals for remote sense. See page 36.

Accepts M3 sized screws.

Power Socket

Power Socket:

100-120V, 200-240V

47-63Hz.

22

GETTING STARTED

Power Switch

Turns the unit on/off.

USB A

USB A Slave port. USB 1.1/2.0

LAN port

LAN

Ethernet port for controlling the

PEL-3000(H) remotely.

23

Display

Date

setting

area

Operation

status

Measurement

area

Mainframe status panel

Soft menus

ModeCCI Range

H 8.75A

V Range

H800V

Function

Static

Configure

0.00

V

0.0000

A

0.00

W

SlewRate 140.00

CC B Value 0.0000

CC A Value 0.0000

LOADRS232

A Value

Fine

01/Oct/2017

mA/us

A

A

panel

Setting area

The setting area is used to display and edit the

settings for the current mode/function.

Measurement

area

Displays the voltage, current and power values.

Date

Displays the date.

Mainframe status

panel

The mainframe status panel displays the status of

the load, remote control and short function.

When an icon is green it indicates that the

function is off. When the icon is orange, the

function is on.

Operation Status

Panel

This status panel is used to display the status of

the current mode.

Soft-keys

The soft-key menus are used to select different

functions or parameters.

PEL-3000(H) User Manual

24

GETTING STARTED

Description

The PEL-3000(H) has a number of rack mount

options for installation. The GRA-413 rack mounts

are suitable for the PEL-3211(H) booster pack. The

GRA-414 rack mounts are capable of holding 1x

PEL-3111(H) or

2x PEL-3021(H)/3041(H) units.

For installation details, please see the GRA-413

and GRA-414 Rack Mount Assembly Manual.

Please see your distributor for which rack mount

is suitable for your application.

GRA-413-E

(EIA standard)

128

532

.

5

482

.

6

First Time Use Instructions

Use the procedures below when first using the PEL-3000(H) to

install the rack mount kit, power up the instrument, set the internal

clock, restore the factory default settings and check the firmware

version. Lastly, the Conventions section will introduce you to the

basic operating conventions used throughout the user manual.

Rack Mount Kits

25

PEL-3000(H) User Manual

GRA-413-J

(JIS standard)

149

532

.

5

482

.

6

GRA-414-E

(EIA standard)

132

382

.

5

477

.

6

26

GETTING STARTED

GRA-414-J

(JIS standard)

149

382

.

5

477

.

6

27

PEL-3000(H) User Manual

Steps

1. Insert the AC power cord into the power

socket.

Turn the external power

switch on.

(O → —)

If the unit doesn’t turn on, press the On/Standby

key.

The ON/STBY key will go from standby (red)

to on (green).

The unit will show the splash screen and then load

the settings from when the unit was last powered

down.

Note

If the PEL-3000(H) fails to start up properly or does

not turn on, please see you local distributor.

Description

When first using the PEL-3000(H), recall the

factory default settings to ensure the unit is in a

known state. See page 241 for a list of the default

settings.

Operation

2. Press

Shift

+

File

FUNC

.

Select Media/Default[F1].

Select Factory Default[F2].

Power Up and Self Test

Load Default Settings

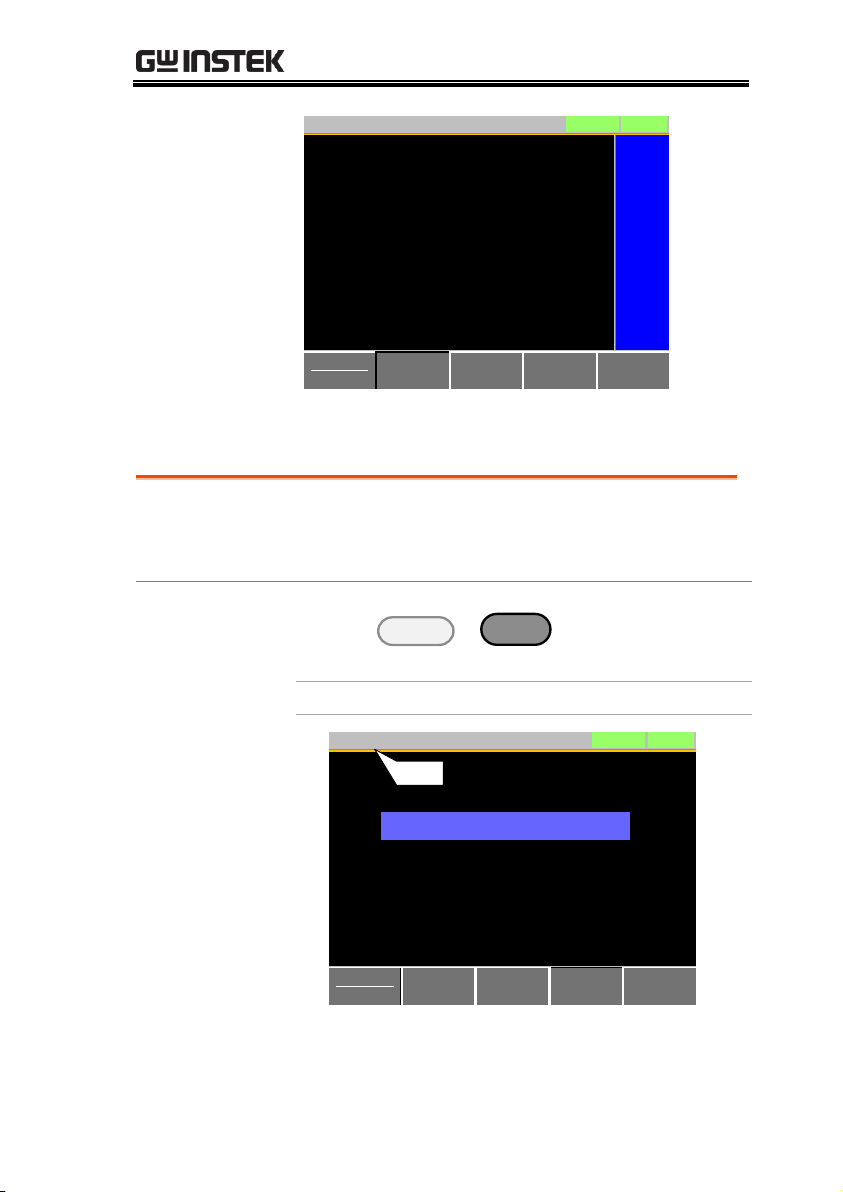

28

GETTING STARTED

Media

Default

Factory

Default

Save Recall

LOADRS232

A Value

03/Oct/2018

Load Default Setup

CC

8.75A

800V

Static

Recall The Default Settings!

Pressing F2 Again will

Warning!!!

Description

The date and time settings are used to time-stamp

files when saving files.

The date is shown on top of the display.

Operation

1. Press

Shift

+

Utility

Help

> Time Set[F4] to set

the date and time.

Settings:

Month, Day, Year, Hour, Minute

System

Info

Load Interface Time Set

LOADRS232

03/Oct/2018

Other

0

Hour 9

Year 2018

Minute

Day

Month

3

10

Date/Time

Date

Setting the Date and Time

Load Wiring

29

PEL-3000(H) User Manual

Wire Gauge

considerations

Before connecting the unit to a power source, the

wire gauge must be taken into account. Load

wires must be large enough to resist overheating

when a short-circuit condition occurs as well as to

maintain a good regulation. The size, polarity and

length of a wire are all factors in determining if a

wire will withstand short circuiting.

Wires that are selected must be large enough to

withstand a short circuit and limit voltage drops

to no more than 2V per wire. Use the table below

to help make a suitable selection.

AWG

Gauge

Conduct or

Diameter

mm

Ohms per

km

Max amps

for chassis

wiring

0000

11.684

0.16072

380 000

10.4038

0.2027

328 00

9.26592

0.25551

283 0

8.25246

0.32242

245 1

7.34822

0.40639

211 2

6.54304

0.51266

181 3

5.82676

0.64616

158 4

5.18922

0.81508

135 5

4.62026

1.02762

118 6

4.1148

1.29593

101 7

3.66522

1.6341

89 8

3.2639

2.0605

73 9

2.90576

2.59809

64 10

2.58826

3.27639

55 11

2.30378

4.1328

47

12

2.05232

5.20864

41 13

1.8288

6.56984

35 14

1.62814

8.282

32

15

1.45034

10.44352

28 16

1.29032

13.17248

22

17

1.15062

17.60992

19 18

1.02362

20.9428

16 19

0.91186

26.40728

14 20

0.8126

33.292

11

30

GETTING STARTED

21

0.7239

41.984

9

Load Line

Inductance

Considerations

When using the PEL-3000(H) load generator,

voltage drop and voltage generated due to load

line inductance and current change must be taken

into account. Extreme changes in voltage may

exceed the minimum or maximum voltage limits.

Exceeding the maximum voltage limit may

damage the PEL-3000(H).

To determine the voltage generated, the following

equation can be used.

E = L x (∆ I / ∆ T)

E= voltage generated

L=load line inductance

∆ I= change of current (A)

∆ T= time (us)

Load line inductance (L) can be approximated as

1uH per 1 meter of wire. (∆ I / ∆ T) is the slew rate

in A/us.

Current

Voltage

time

time

∆I

∆T

E

Min. V

The diagram above shows how changes in current

can affect voltage.

Limiting Load line

inductance

Load line inductance can be reduced in two ways.

1. Ensure load wires are as short as possible and

twist the positive and negative load wires

together.

2. Current change can be limited by limiting the

31

PEL-3000(H) User Manual

slew rate or response speed when switching in

CR and CC mode.

“Twisted pair” will be shown on any connection

diagram where the load wires should be twisted

together.

DUT

-

+

Electronic

Load

+

-

Twisted

pair

DUT

-

+

Electronic

Load

+

-

32

GETTING STARTED

Description

The PEL-3000(H) has input terminals on both the

front and rear panels.

Follow the procedures below for all load

connections. Please adhere to the following

precautions to ensure your safety and to protect

the unit from damage.

Connection

1. When connecting the PEL-3000(H) to the DUT,

make sure that the polarity of the connection

between the DUT and the unit matches.

2. Ensure that the maximum input voltage is not

exceeded. The maximum input voltage is

150(800) volts.

DUT

-

+

Electronic

Load

+

-

Caution

If the polarity to the input terminals is reversed, the

reverse voltage protection function is tripped. The

reverse voltage protection function is tripped when

reverse voltages greater than -0.3V are detected.

Do not touch any of the input terminals when the

voltage is applied to an input terminal.

Connecting the input terminals to the wrong polarity

can damage the DUT or the PEL-3000(H).

The front panel and rear panel input terminals are

physically connected. Any voltage that is input to one

set of terminals will also appear on the other set of

terminals.

Load Wire Connections

33

PEL-3000(H) User Manual

Description

The front panel input terminals feature polaritydistinct caps and accept M6 sized crimped

terminals.

Caution

The front panel input terminals on the PEL-3000(H)

are physically connected to the rear panel terminals.

Steps

1. Turn the power off from the rear panel or put

the unit into standby mode.

2. Turn the power off from the DUT.

3. Connect the load wires to the input terminals:

Connect the positive (+) input terminal on the

load generator to the high potential output of

the DUT.

Connect the negative (-) input terminal to the

low potential output of the DUT.

+ potential

- potential

Negative

terminal

Positive

terminal

Using the Front Panel Input Terminals

34

GETTING STARTED

Description

The rear panel input terminals accept up to M8sized crimped terminals. The rear terminals come

with a load input terminal cover for safety.

Caution

The front panel input terminals on the PEL-3000(H)

are physically connected to the rear panel terminals.

Steps

1. Turn the power off from the rear panel or put

the unit into standby mode.

2. Turn the power off from the DUT.

3. Connect the load wires to the input terminals:

Connect the positive (+) input terminal on the

load generator to the high potential output of

the DUT.

Connect the negative (-) input terminal to the

low potential output of the DUT.

+ potential

- potential

Using the Rear Panel Input Terminals

35

PEL-3000(H) User Manual

Description

The rear panel terminal cover should be used to

prevent electric shock. The rear panel terminal

covers should always be used when connecting a

load to the rear panel terminals. As the front panel

and rear panel terminals are physically connected,

the terminal cover should also be used as a safety

measure when a DUT is connected to the front

terminals

Caution

Ensure the power is off before making any

connections to the PEL-3000(H).

Note

In the following diagrams, the cable wiring is not

shown for clarity.

1. Remove the screw holding the top cover to the

bottom cover.

1

2. Line-up the bottom cover with the notches in

the output terminals.

3. Place the top terminal cover over the bottom

cover.

Using the Terminal Cover (PEL-011)

36

GETTING STARTED

2

Detail

3

4. Use your thumb to slide the terminal covers

shut, as shown in the diagram below.

4

5. When the top and bottom covers are flush,

reinsert the screw that was removed in step 1.

37

PEL-3000(H) User Manual

5

Description

The flexible rear panel terminal cover should be

used when the load wiring becomes too thick to be

used with the PEL-011 terminal cover. This is

especially true when using the load generators in

parallel. Like the PEL-013 terminal cover, the PEL011 is used to prevent electric shock. The rear

panel terminal covers should always be used

when connecting a load to the rear panel

terminals.

Caution

Ensure the power is off before making any

connections to the booster pack.

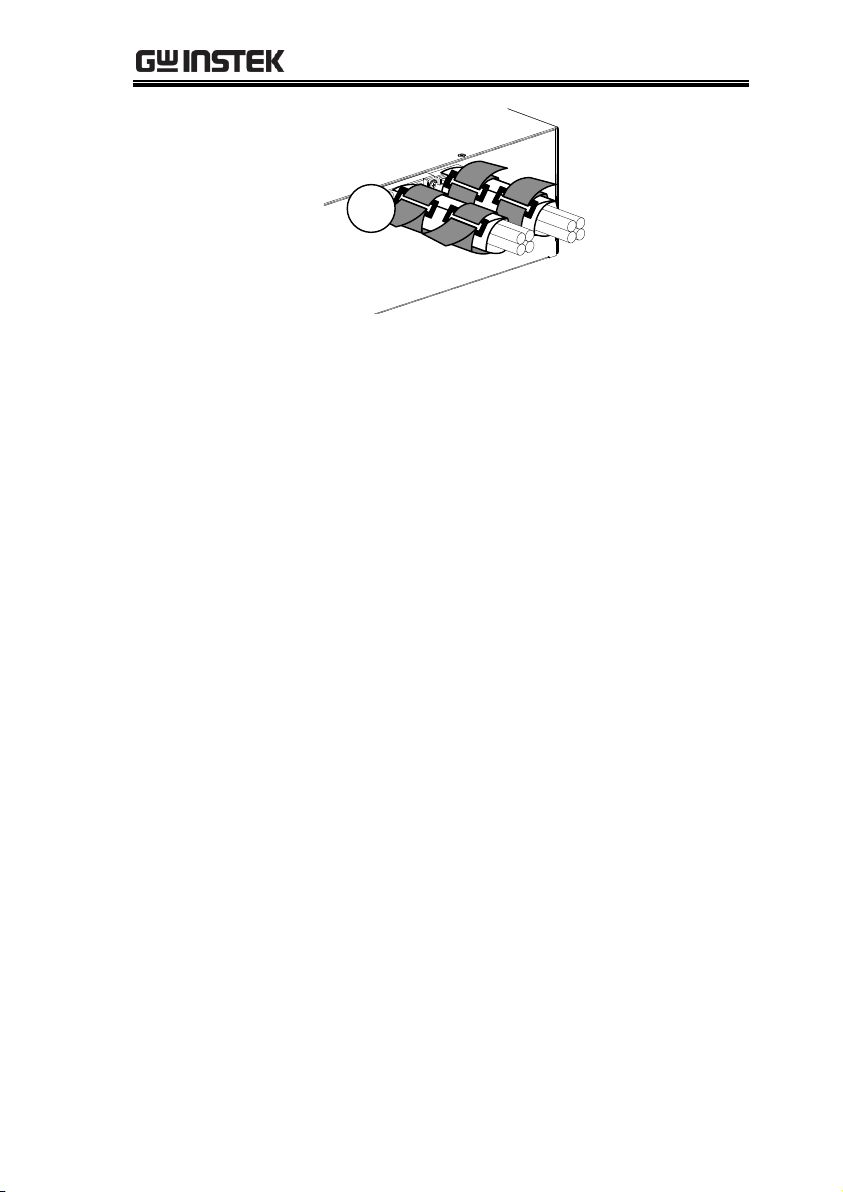

6. Wrap the insulation sheets around the

terminals and load cables, as shown below.

Make sure the terminals and any exposed

wires are covered by the sheets.

Insulation sheet

1

7. Secure the insulation sheets using the supplied

velcro fasteners. 2 fasteners should be used for

each sheet.

Using the Terminal Cover (PEL-013)

38

GETTING STARTED

Fasteners

2

39

PEL-3000(H) User Manual

Description

After connection is finished, please lock terminal

cover to avoid electric shock when using the

frame control terminal for PEL-3000H series.

If connection is needed, please unlock terminal

cover, If connection isn’t needed, please lock

terminal cover to avoid electric shock for PEL3000 series.

Caution

Ensure the power is off before making any

connections to the booster pack.

Install the terminal cover as shown in the picture

below (for PEL-3000H series).

Using the Terminal Cover

40

GETTING STARTED

Install the terminal cover as shown in the picture

below (for PEL-3000 series).

Description

After connection is finished, please lock monitor

out cover to avoid electric shock when using the

monitor out ports.

Caution

Ensure the power is off before making any

connections to the booster pack.

Install the monitor out cover as shown in the

picture below.

Using the Monitor Out Cover (Only for PEL-3021H, PEL3041H, PEL-3111H)

41

Remote Sense

Description

Remote sense can be used to help compensate for

long cable length. The longer the cable, the higher

the potential resistance and inductance, therefore

a short cable is best. Twisting the cable can help

reduce induced inductance and using the Vsense

terminals compensates the voltage drop seen

across the load leads, especially leads with higher

resistance. This is useful when used in CV, CR or

CP mode.

Steps

1. Turn the power off from the rear panel or put

the unit into standby mode.

2. Turn the power off from the DUT.

3. Connect the sense wires to the sense terminals:

Connect the positive sense (+S) terminal to the

high potential output of the DUT.

Connect the negative sense (-S) terminal to the

low potential output of the DUT.

DUT

-

+

Programable

Electronic

Load

+

-

+S

-S

Twisted

pair

PEL-3000(H) User Manual

42

GETTING STARTED

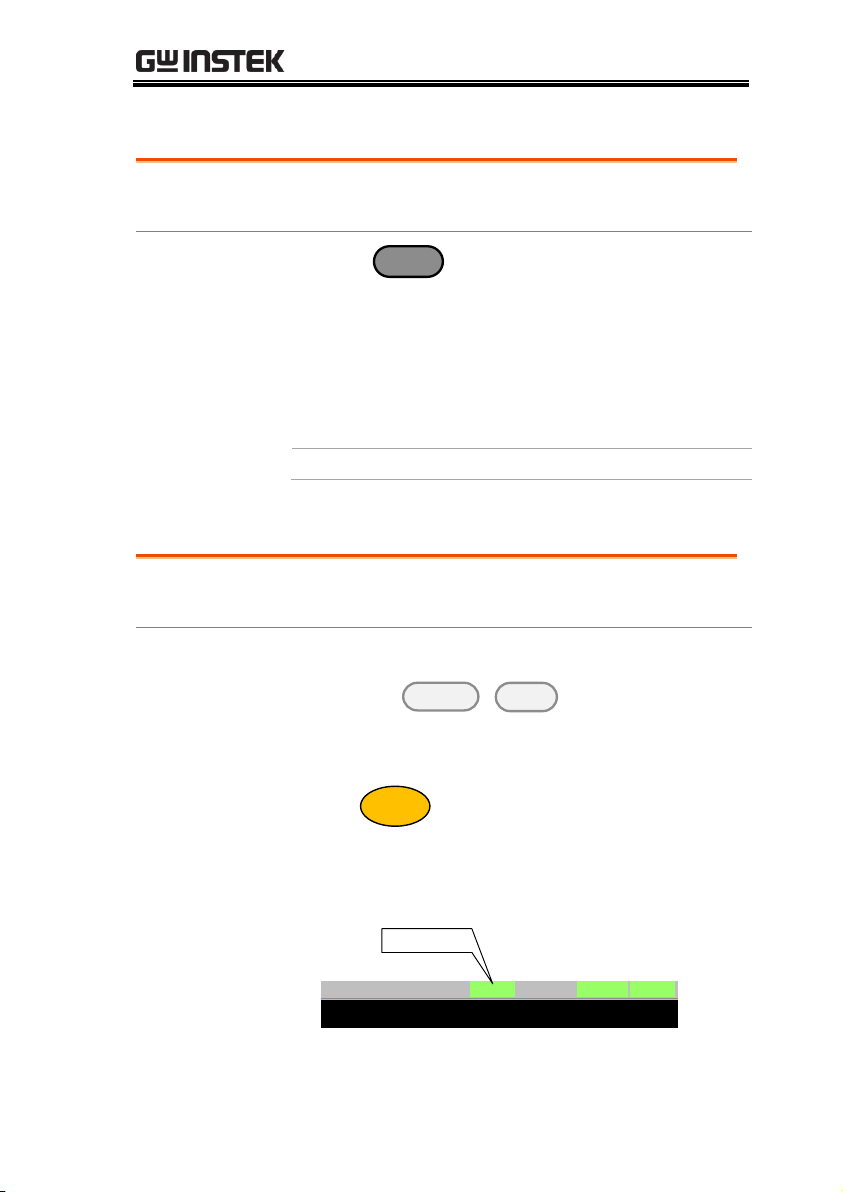

Description

The PEL-3000(H) allows the firmware to be

updated by end-users. Before using the PEL3000(H), please check the GW Instek website or

ask your local distributor for the latest firmware.

System version

Before updating the firmware, please check the

firmware version.

Operation

1. Press

Shift

+

Utility

Help

.

2. Select System/Info[F1].

3. The System information is listed on the

display.

Model: PEL-3000(H) model number.

Serial Number: XXXXXXXX

Firmware Ver.: Firmware version number.

Website address.

4. To view other system information, press

System[F1] and select Memo.

System

Info

Load Interface Time Set

LOADRS232

03/Sep/2018

Model : PEL-3XXX(H)

Firmware Ver. : X.XX

Serial Number : XXXXXXXX

Other

http://www.goodwill.com.tw

Firmware Update

43

PEL-3000(H) User Manual

Update Firmware

1. Insert a USB drive into the USB port. Ensure

the USB drive has the firmware file located in

the root directory.

2. Press

Shift

+

File

FUNC

.

3. Select USB with the Media[F1] soft-key.

4. Press the File Utility[F5] soft-key.

5. Select the *.UPG upgrade file and press

Select[F1] twice. Once to select the file and

once to confirm.

6. Wait for the update to complete and reset the

power when prompted.

Note

Do not turn the load generator off or remove the USB

memory when the firmware is being read or

upgraded.

44

GETTING STARTED

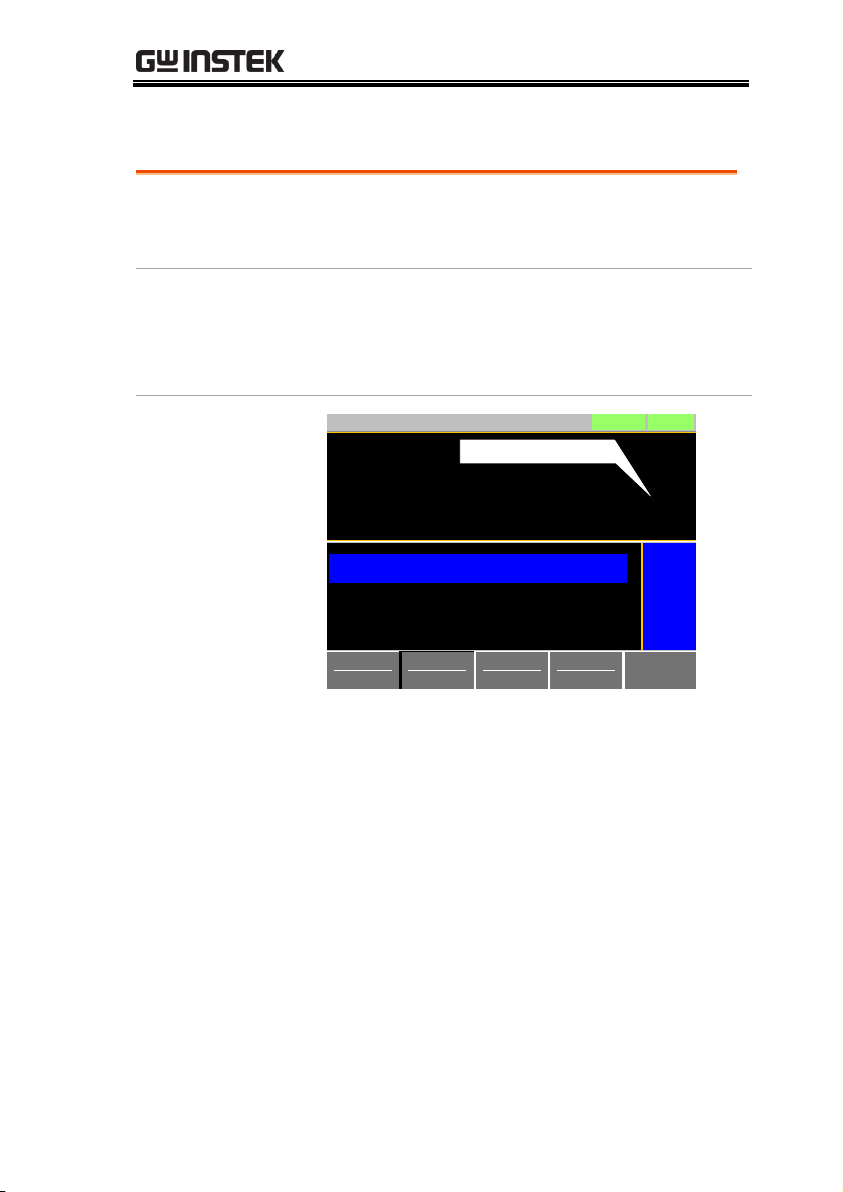

Soft Menu keys

The F1 to F5 function keys at the bottom of the

display correspond directly to the soft-menu keys

on top.

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

Utility

Local

File

0

1

4

7

2

5

8

3

6

9

EnterClear

Shift

Preset

Load

On/

Off

Main

Help

FUNC

Short

F1 ~ F5

Function keys

Soft menus

ModeCCI Range

H 8.75A

V Range

H800 V

Function

Static

Configure

0.00

V

0.0000A

0.00W

SlewRate 140.00

CC B Value 0.0000

CC A Value 0.0000

LOADRS232

A Value

Fine

01/Oct/2017

mA/us

A

A

Select Sub Menu

Configure

Pressing this type of soft-menu key will enter a

submenu.

Conventions

The following conventions are used throughout the user manual.

Read the conventions below for a basic grasp of how to operate the

PEL-3000(H) menu system using the front panel keys.

45

PEL-3000(H) User Manual

Toggle Parameter

or State

Mode

CC

Function/Item

Parameter or State

This type of soft-menu icon has the function/item

on the top of the label and the selected setting or

mode on the bottom of the label.

Repeatedly press the associated function key (F1F5) to cycle through each setting. For example,

repeatedly pressing the Mode soft-menu key will

cycle through the CC, CR, CV and CP modes.

Mode

CR

Mode

CC

Mode

CV

Mode

CP

For some parameters, a popup window will also

appear. Selection of the setting is the same.

Repeatedly pressing the relevant function key (F1F5) will cycle through each setting. The selection

on the popup window will also be reflected on the

label.

ModeCCI Range

H 8.75A

V Range

H800V

Function

Static

Configure

0.00

V

0.0000A

0.00W

SlewRate 140.00

CC B Value 0.0000

CC A Value 0.0000

LOADRS232

A Value

Fine

01/Oct/2017

mA/us

A

A

LOW

Middle

High

87.5mA

0.875A

8.750A

label

Popup window

Prameter selection

Parameter Input

The scroll wheel, Enter key and number pad can

be used to edit parameter values.

46

GETTING STARTED

Number pad

Scroll wheel

Enter key

P0

P1

P4

P7

CAL.

P2

P5

P8

Lock

P3

P6

P9

0

1

4

7

2

5

8

3

6

9

Clear Enter

1. Use the scroll wheel to move the cursor to the

desired parameter.

A scroll bar is shown when there are additional

parameters off-screen.

ModeCPI Range

H 8.75A

V Range

H800V

Function

Dynamic

Configure

0.00

V

0.0000A

0.00W

Timer1 0.025

Level 2 0.00

Level

1

0.00

LOADRS232

Fine

01/Oct/2018

ms

W

W

Scroll bar

Cursor

2. Press the Enter key to select the parameter. The

parameter will become highlighted in white

3. Then use the number pad* or scroll wheel** to

edit the parameter value.

ModeCCI Range

H 8.75A

V Range

H800V

Function

Static

Configure

0.00

V

0.0000A

0.00W

SlewRate 140.00

CC B Value

CC A Value 0.000

LOADRS232

A Value

Fine

01/Oct/2018

mA/us

A

A

1.000

Parameter

4. Press the Enter key again to finish editing the

parameter value.

47

PEL-3000(H) User Manual

Clearing a Value*

*When editing a parameter with the number pad,

pressing the

Clear

key will restore the

parameter to the previous value.

Using the Scroll

Wheel to Edit a

Parameter**

**To edit a parameter using the scroll wheel,

simply turn the scroll wheel. Clockwise increases

the value, counterclockwise decrease the value.

Pressing the scroll wheel when a parameter is

highlighted allows you to change the step

resolution. There are two different step resolution

methods: Step Mode and Cursor Mode. Step

Mode: This is the default step resolution method

and will only be available to use when it is

applicable (Indicated by Fine or Coarse in the

Operation Status panel).

When a parameter is highlighted (step 3 above)

pressing the scroll wheel will toggle the step

resolution between fine and coarse. For details on

how to set the step resolution, see page 81.

ModeCCI Range

H 8.75A

V Range

H800V

Function

Static

Configure

0.00

V

0.0000A

0.00W

SlewRate 140.00

CC B Value

CC A Value 0. 000

LOADRS232

A Value

Fine

01/Oct/2018

mA/us

A

A

1.000

Highlighted

parameter

Coarse/Fine

adjustment

+

Cursor Mode: This method must first be enabled

before it can be used. Pressing the scroll wheel

when a parameter is highlighted allows you to set

the step resolution by a digit value. An orange line

will appear under the currently selected digit

value. Repeatedly pressing the scroll wheel moves

to the next digit. See page 80 for details.

48

GETTING STARTED

ModeCCI Range

H 8.75A

V Range

H800V

Function

Static

Configure

0.00

V

0.0000A

0.00W

SlewRate 140.00

CC B Value

CC A Value 0.0000

LOADRS232

A Value

Cursor

01/Oct/2018

mA/us

A

A

1.0000

+

Cursor

Mode

Indicator

0.00

w

LOADRS232

A

A

Highlighted

parameter

Cursor

position

Entering

Alphanumeric

Characters

When renaming files, creating memos or notes,

you will be required to enter alphanumeric

characters when the character entry screen

appears.

Only alphanumeric characters as well as space

[ ], underscore [_] and minus [-] characters

allowed.

1. Use the scroll wheel to move the cursor to the

desired character.

A B C D E F G H I J K L M

N O P Q R S T U V W X Y Z

1 2 3 4 5 6 7 8 9 0 _ 1

Rename:

Filename

Cursor

2. Press the

Enter

key or Enter Character[F1]

to select a character.

OR

Enter

Character

3. To delete a character, press Back Space[F2].

4. To save the file name or memo, press Save[F3].

49

PEL-3000(H) User Manual

Help Selection

1. Press any function key or soft-menu key.

2. Press

Help

to see the help contents on that

particular function key or menu.

3. Use the scroll to navigate the help contents.

4. Press the Exit[F5] key to exit the help menu.

Help

on Help

LOADRS232

03/Oct/2018

Exit

HELP

Press F5 to exit the Help mode.

Rotate the VARIABLE knob to scroll all

the contents.

-End-

Help Menu

When any function key has been pressed or when a menu has been

opened, the HELP key can be used to display a detailed description.

50

OPERATION

Basic Operation ....................................................... 54

CC Mode ........................................................................................... 54

CR Mode ........................................................................................... 56

CR Units ..................................................................................... 57

CV Mode ........................................................................................... 58

CP Mode ............................................................................................ 59

+CV Mode ........................................................................................ 61

Turning on the Load ....................................................................... 62

Shorting the Load ............................................................................ 62

Safety Short ................................................................................ 63

Short Key Configuration .......................................................... 64

Short Function Enable/Disable ............................................. 65

Locking the Front Panel Controls ................................................ 65

Basic Configuration ................................................. 66

Select the Switching Function ....................................................... 66

Select the Display Units for Dynamic Mode Levels ........... 68

Select the Switching Time Configuration for Dynamic

Mode ............................................................................................ 69

Slew Rate ........................................................................................... 70

CV, +CV Mode Response Speed.................................................. 71

CC, CR and CP Mode Response Speed ....................................... 72

Advanced Configuration Settings ............................. 73

Soft Start ............................................................................................ 73

Von Voltage Settings ....................................................................... 74

Von Voltage ............................................................................... 74

Von Latch ................................................................................... 75

Von Delay ................................................................................... 76

Timer Functions ............................................................................... 76

Count Time ................................................................................ 76

Cut Off Time ............................................................................. 77

Auto Load Configuration ............................................................... 78

Load Off (Mode) and Load Off (Range) ..................................... 79

Step Resolution Configuration ................................. 80

Cursor Mode Configuration ........................................................... 80

OPERATION

51

PEL-3000(H) User Manual

Step Mode Configuration ............................................................... 81

Protection Settings .................................................. 83

OCP .................................................................................................... 83

OPP .................................................................................................... 84

UVP .................................................................................................... 85

UVP Ring Time ................................................................................ 86

OVP .................................................................................................... 88

UnReg ................................................................................................ 89

Para ..................................................................................................... 90

RVP .................................................................................................... 91

System Settings ....................................................... 92

Sound Settings .................................................................................. 92

Speaker Settings ......................................................................... 92

Alarm Tone Settings ................................................................. 93

Display Settings ................................................................................ 93

Contrast and Brightness ........................................................... 93

Control Settings ................................................................................ 94

Language Settings ............................................................................. 94

Input/Output Trigger Settings ...................................................... 94

Trigger In Delay ......................................................................... 94

Trigger Out Width ..................................................................... 95

Measure Average ....................................................................... 95

RVP Load Off ............................................................................ 96

Go-NoGo ................................................................. 97

Setting the Go-NoGo Limits ......................................................... 97

Running a Go-NoGo Test ............................................................. 98

Save Recall ............................................................ 100

File Structure ............................................................................ 100

File Types .................................................................................. 101

Saving Files to Internal Memory ........................................... 102

Saving Files to USB Memory ................................................ 104

Recalling Files from Internal Memory ................................. 106

Recalling Files from USB Memory ....................................... 107

Recall Memory Safety Setting ................................................ 109

File Utility ........................................................................................ 109

Preset ................................................................................................ 111

Quick Preset Save .................................................................... 111

Quick Preset Recall ................................................................. 111

Default Settings .............................................................................. 112

Factory Default Settings ......................................................... 112

User’s Default Setting ............................................................. 112

Function Menu Overview ....................................... 114

Select a Function ............................................................................ 114

52

OPERATION

Turning on the Load with the Selected Function .................... 116

Complete Ring Time ..................................................................... 117

NSEQ Timer .................................................................................. 118

Program .................................................................120

Program Overview ......................................................................... 120

Create a Program ........................................................................... 122

Create a Program Chain ................................................................ 125

Running a Program or Chain ....................................................... 126

Sequence ................................................................128

Normal Sequence Overview ........................................................ 128

Timing Edit Configuration .................................................... 132

Data Edit Configuration ........................................................ 134

Running a Normal Sequence ....................................................... 135

Fast Sequence Overview ............................................................... 138

Timing Edit Configuration .................................................... 142

Data Edit Configuration ........................................................ 143

Running a Fast Sequence .............................................................. 145

OCP Test Automation .............................................147

OPP Test Automation .............................................154

BATT Test Automation ............................................160

MPPT ......................................................................169

Edit Tracking of MPPT function ................................................ 173

Auto Load of MPPT function ..................................................... 174

Data file of test result .................................................................... 179

53

PEL-3000(H) User Manual

Description

In Constant Current Mode the load units will sink

the amount of current programmed. Regardless of

the voltage, the current will stay the same. For

more details on CC mode, please see the Appendix

on page 259.

Warning

If you change the mode or the range when the load is

already on, the load will be turned off automatically.

Operation

1. Make sure the load is off.

2. Press

Main

.

3. Select CC mode with the Mode[F1] soft-key.

4. Select the current range with the I Range[F2]

soft-key.

Range:

High, Middle, Low

5. Select the voltage range with the V Range[F3]

soft-key.

Range:

High, Low

Basic Operation

The PEL-3000(H) supports 7 main operating modes:

CC, CC+CV;

CR, CR+CV;

CV;

CP, CP+CV

CC Mode

54

OPERATION

6. Set the current level parameters using the scroll

wheel and number pad.

For Static mode, set CC A Value and/or CC B

Value.

For Dynamic mode, set Level1 and Level2.

The maximum and minimum current levels

depend on the selected ranges.

7. To add CV mode to CC mode (CC+CV), see

page 61.

8. Set the remaining basic configuration settings

such as the slew rate, and switching function

settings. See page 66 for details.

Display

ModeCCI Range

H 8.75A

VRange

L 80V

Function

Static

Configure

0.000

V

0.0000

A

0.00

W

SlewRate 140.00

CC B Value 0.0000

CC A Value 0.0000

LOADRS232

A Value

Fine

01/Oct/2018

mA/uS

A

A

Mode

Current range

Voltage range

Active setting

Current setting A

Current setting B

Note

Basic CC mode configuration is complete. See page 66

for more configuration options.

The current range and voltage range applies to all the

operating modes.

55

CR Mode

Description

In Constant Resistance Mode, the unit will

maintain a constant resistive load by varying the

current. CR mode uses ohms, Ω (resistance) or

siemens, S (conductance) for the setting units. For

more details on CR mode, see the appendix on

page 260.

Warning

If you change the mode or the range when the load is

already on, the load will be turned off automatically.

Operation

1. Make sure the load is off.

2. Press

Main

.

3. Select CR mode with the Mode[F1] soft-key.

4. Select the current range with the I Range[F2]

soft-key.

Range:

High, Middle, Low

5. Select the voltage range with the V Range[F3]

soft-key.

Range:

High, Low

6. Set the resistance or conductance level

parameters using the scroll wheel and number

pad.

For Static mode, set CR A Value and/or CR B

Value.

For Dynamic mode, set Level1 and Level2.

The maximum and minimum conductance/

resistance levels depend on the selected current

range.

7. To add CV mode to CR mode (CR+CV), see

page 61.

8. Set the remaining basic configuration settings

PEL-3000(H) User Manual

56

such as the slew rate, and switching function

settings. See page 66 for details.

Display

ModeCRI Range

H 8.75A

V Range

L 80V

Function

Static

Configure

0.000

V

0.0000

A

0.00

W

SlewRate 14.000

CR B Value 0.54422

CR A Value 0.54422

LOADRS232

A Value

Fine

01/Oct/2017

mA/uS

Ω

Ω

Mode

Current range

Voltage

range

Active

setting

Conductance/

Resistance

settings

Note

Basic CR mode configuration is complete. See page 66

for more configuration options.

The current range and voltage range applies to all the

operating modes.

CR Units

Description

The CR setting units can be set to ohm (Ω) or

millisiemens (mS).

Operation

1. Make sure the load is off.

2. Press

Main

> Configure[F5] > Other[F2] and

set the CR Unit setting.

Range:

Ω, mS

OPERATION

57

CV Mode

Description

In Constant Voltage Mode, the unit will maintain a

constant voltage. In CV mode you set the constant

voltage level. For more details on CV mode, see the

appendix on page 263.

Warning

If you change the mode or the range when the load is

already on, the load will be turned off automatically.

Operation

1. Make sure the load is off.

2. Press

Main

.

3. Select CV mode with the Mode[F1] soft-key.

4. Select the current range with the I Range[F2]

soft-key.

Range:

High, Middle, Low

5. Select the voltage range with the V Range[F3]

soft-key.

Range:

High, Low

6. Set the voltage level parameters using the scroll

wheel and number pad.

Set CV A Value and/or CV B Value.

The maximum and minimum voltage levels

depend on the selected voltage range.

7. Set the remaining basic configuration settings

such as the response settings. See page 66 for

details.

PEL-3000(H) User Manual

58

Display

ModeCVI Range

H 8.75A

V Range

L 80V

Response

Slow

Configure

0.000

V

0.0000

A

0.00

W

CV B Value 80.000

CV A Value 80.000

LOADRS232

A Value

Fine

01/Oct/2018

V

V

Mode

Current range

Voltage

range

Active

setting

Current setting

Voltage

settings

Note

Basic CV mode configuration is complete. See page 66

for more configuration options.

The current range and voltage range applies to all the

operating modes.

CP Mode

Description

In Constant Power Mode, the unit will maintain a

constant power by varying the current. For more

details on CP mode, see the appendix on page 262.

Warning

If you change the mode or the range when the load is

already on, the load will be turned off automatically.

Operation

1. Make sure the load is off.

2. Press

Main

.

3. Select CP mode with the Mode[F1] soft-key.

4. Select the current range with the I Range[F2]

soft-key.

Range:

High, Middle, Low

5. Select the voltage range with the V Range[F3]

soft-key.

Range:

High, Low

OPERATION

59

PEL-3000(H) User Manual

6. Set the power level parameters using the scroll

wheel and number pad.

For Static mode, set CP A Value and/or CP B

Value.

For Dynamic mode, set Level1 and Level2.

The maximum and minimum power levels

depend on the selected current range.

For static mode, the parameter that is set last

becomes the “active” setting. This will be

shown in the Operation Status Panel.

7. To add CV mode to CP mode (CP+CV), see

page 61.

8. Set the remaining basic configuration settings

such as the slew rate, and timer settings. See

page 66 for details.

Display

ModeCPI Range

H 8.75A

V Range

H 800V

Function

Static

Configure

0.00

V

0.0000

A

0.00

W

CP B Value 0.00

CP A Value 0.00

LOADRS232

A Value

Fine

01/Oct/2017

W

W

Current range

Active

setting

Current setting

Power

settings

+CV OFF

Mode

Voltage

range

Note

Basic CP mode configuration is complete. See page 66

for more configuration options.

The current range and voltage range applies to all the

operating modes.

60

+CV Mode

Description

+CV mode can be added to CC, CR and CP mode.

The +CV settings apply to all applicable modes.

Operation

1. Make sure the load is off.

2. Press

Main

and select to Mode, I Range and

V Range.

3. Set the +CV voltage level. (You may need to

scroll down to the +CV setting)

Range:

OFF - rated voltage+5%

Display

Mode

CP + CV

I Range

H 8.75A

V Range

L 80V

Function

Dynamic

Configure

0.000

V

0.0000

A

0.00

W

+CV 5.500

Timer2 0.025

Timer1 0.025

LOADRS232

01/Oct/2018

V

ms

ms

+CV setting

Note

The +CV settings apply to all the applicable operating

modes.

For example: The +CV settings made in CR mode will

be carried over to the +CV settings in CC and CP

mode.

Note

+CV settings cannot be controlled with external

control. (The external control is not possible only in

+CV settings)

See page 185 for +CV settings with external control

OPERATION

61

PEL-3000(H) User Manual

Description

1. The load can be turned on and off by pressing

the

Load

On/

Off

key.

The

Load

On/

Off

key will turn orange when the load

is “on”.

The LOAD icon in the Main Frame status panel

will turn orange when the load is on.

Note

The load can be set to automatically turn on at

start up. See page 78.

The load can be turned on via remote control.

See the programming manual.

The load can be turned on via external control.

See page 194.

By default the load will automatically turn off if

the range or operating mode (CC, CV, CR, CP)

is changed. To disable this behavior, Set Load

Off (Mode) and Load Off (Range) to the OFF

setting. See page 79 for details.

Display

LOADRS232

03/Oct/2018

LOAD on

Description

The Short key can be used to simulate a short

circuit of the load input terminals. A short circuit is

simulated by:

Setting the current to the maximum value in CC

mode.

Setting the resistance to the minimum value in

CR mode.

Turning on the Load

Shorting the Load

62

OPERATION

Setting the voltage to the minimum value in CV

mode.

Setting the power to the maximum value in CP

mode.

When the load is shorted, the external

controller also sends a short signal. See page

200 for usage details.

Operation

1. The short function can be turned on and off by

pressing the

Short

key.

The

Short

key will turn red when the short

function is active.

The Short icon will appear when the short

function is active.

Display

LOADRS232SHORT

03/Oct/2018

SHORT on

Note

If the load is already off, pressing the Short key will

turn the load on (shorted) at the same time. Pressing

the Short key again will also turn the load off again as

well.

If the load is already on and the Short key is pressed,

then when the Short key is pressed again the load will

remain on (the electronic load will return to its

previous load condition).

Note

The Short key will be disabled if the Short Function

setting is turned off. See page 64 for details.

Description

When activated, the safety short function only

allows the short key to be used when the load is

already on.

Safety Short

63

PEL-3000(H) User Manual

Operation

1. Press

Main

> Configure[F5] > Other[F2] and

set the Short Safety.

When set to OFF, the load can be shorted at

anytime.

When set to ON, the load can only be shorted

when the load is already on.

Short (Safety):

OFF, ON

Note

The Short Safety setting will be grayed out if Short

Function is set to OFF. See page 64 for details.

Description

The Short key can be configured to Toggle or Hold.

By Default the Short key is set to Toggle.

Toggle: Pressing the Short key will toggle the

shorting function on or off.

Hold: Holding the short key will short the load.

Operation

1. Press

Main

> Configure[F5] > Other[F2] and

set the Short Key setting.

Range:

Toggle, Hold

Note

The Short Key setting will be grayed out if Short

Function is set to OFF. See page 64 for details.

Short Key Configuration

64

OPERATION

Description

The short key can be disabled to prevent the

operator accidentally shorting the load.

Operation

1. Press

Main

> Configure[F5] > Other[F2] and

set the Short Function.

When set to OFF, the Short key is disabled and

all short configuration options in the

Main>Configure>Other menu are also

disabled.

When set to ON, the Short key is enabled.

Short Function:

OFF, ON

Description

The keys and scroll wheel on the front panel can be

locked to prevent settings from being changed.

Operation

1. The keys can be locked and unlocked by

pressing

Shift

+

Lock

Clear

.

LOCK will appear in the Mainframe status

panel when the keys are locked.

The

Load

On/

Off

key will not be locked if the load

is on.

Display

LOCK will appear in the Mainframe status panel when

the keys are locked.

LOADRS232

03/Oct/2018

LOCK

LOCK icon

Short Function Enable/Disable

Locking the Front Panel Controls

65

PEL-3000(H) User Manual

Description

The PEL-3000(H) has two switching function, static

and dynamic. The switching function allows the

PEL-3000(H) to switch between two preset levels.

Static mode can only switch between the two levels

manually, while Dynamic mode switches between

each level automatically based on a timer.

Static mode: A Value, B Value

Dynamic mode: Level1, Level2

When the unit is set to static mode, only one value

(A Value or B Value) can be active at a time. The

active value is shown in the Operation Status

Panel.

Configure

W

LOADRS232

A Value

Fine

Active

setting

When the unit is set to dynamic mode, the unit will

switch between Level1 and Level2 based on the

Timer1 and Timer2 parameters, shown below.

Basic Configuration

The basic configuration settings are the common configuration

settings that are used for each operating mode. After selecting a

basic operating mode (CC, CR, CV or CP mode), the slew rate,

switching function, response rate and other common parameters

should be configured.

Select the Switching Function

66

OPERATION

Level

Time

Level 2

Level 1

Timer1 Timer2Timer1

Dynamic Mode

Note

Dynamic mode is not available for CV mode.

Operation

1. Make sure the load is off.

2. Press

Main

.

3. Select Dynamic or Static mode with the

Function[F4] soft-key.

A different switching function can be set for

CC, CR and CP mode.

4. For dynamic mode, set the Timer1 and Timer2

parameters using the scroll wheel and number

pad.

Timer1 sets the Level1 on-time.

Timer2 sets the Level2 on-time.

Take the slew rate settings into consideration

when setting the timers.

The frequency of the dynamic switching is

output via the TRIG OUT BNC.

5. In the static mode, select either value A or value

B as the “active” value for execution followed

by pressing the

Shift

+

Preset

.

The “active” value will be shown in the