Page 1

Mixed-Domain Oscilloscope

MDO-2000EG & MDO-2000EX

USER MANUAL

ISO-9001 CERTIFIED MANUFACTURER

Page 2

May 2017

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan

Page 3

TABLE OF CONTENTS

Table of Contents

SAFETY INSTRUCTIONS .................................................. 4

GETTING STARTED .......................................................... 9

MDO-2000EG/2000EX Series Overview 10

Appearance .......................................... 14

Set Up .................................................. 27

Built-in Help ........................................ 37

MEASUREMENT ............................................................ 38

Basic Measurement ............................. 39

Automatic Measurement ...................... 46

Cursor Measurement ........................... 60

Math Operation ................................... 67

ADVANCED CONFIGURATION ....................................... 77

Acquisition .......................................... 80

Segmented Memory Acquisition .......... 85

Display................................................. 97

Horizontal View ................................. 102

Vertical View (Channel) ...................... 110

Bus Key Configuration........................ 118

Trigger ............................................... 140

Search ................................................ 172

System Settings and Miscellaneous

Settings ............................................. 181

ARBITRARY WAVE GENERATOR .................................... 186

Arbitrary Wave Generator Operation .. 187

SPECTRUM ANALYZER .................................................. 220

Spectrum Analyzer operation ............. 221

1

Page 4

MDO-2000EG & 2000EX User Manual

DMM ............................................................................ 239

DMM function ................................... 240

POWER SUPPLY ............................................................ 249

Power supply function ........................ 250

APPLICATIONS ............................................................. 253

Introduction ....................................... 254

Go-NoGo application ......................... 256

DVM application ................................ 261

Data Log application .......................... 263

Digital Filter application .................... 265

Mask application................................ 267

SAVE/RECALL ............................................................... 277

File Format/Utility ............................. 278

Create/Edit Labels .............................. 284

Save ................................................... 287

Recall ................................................. 295

Reference Waveforms ......................... 301

FILE UTILITIES ............................................................. 303

File Navigation .................................. 304

Create Folder...................................... 306

Rename File ....................................... 307

Delete File or Folder .......................... 308

Copy File to USB ................................ 309

HARDCOPY KEY ........................................................... 310

REMOTE CONTROL CONFIG ........................................ 314

Interface Configuration ...................... 315

MAINTENANCE ............................................................ 325

2

Page 5

TABLE OF CONTENTS

FAQ .............................................................................. 331

APPENDIX .................................................................... 333

Updating the Firmware ...................... 334

MDO-2000EG/2000EX Specifications . 336

Probe Specifications .......................... 342

Dimensions ....................................... 344

Declaration of Conformity .................. 345

INDEX .......................................................................... 346

3

Page 6

MDO-2000EG & 2000EX User Manual

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the equipment or to

other properties.

DANGER High Voltage

(Note)

Attention required

Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the Product

name.

4

Page 7

SAFETY INSTRUCTIONS

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

General Guideline

WARNING

CAUTION

Make sure the BNC input voltage does not

exceed 300Vrms.

Never connect a hazardous live voltage to the

ground side of the BNC connectors. It might

lead to fire and electric shock.

Do not place any heavy object on the MDO-

2000EG/2000EX.

Avoid severe impact or rough handling that

leads to damaging the MDO-2000EG/2000EX.

Do not discharge static electricity to the MDO-

2000EG/2000EX.

Use only mating connectors, not bare wires, for

the terminals.

Do not block the cooling fan opening.

Do not perform measurement at a power source

or building installation (Note below).

Do not disassemble the MDO-2000EG/2000EX

unless you are qualified.

Note

(Measurement categories) EN 61010-1:2010 specifies the

measurement categories and their requirements as follows. The

MDO-2000EG/2000EX falls under category I.

Measurement category IV is for measurements performed at the

source of low-voltage installation.

Measurement category III is for measurements performed in the

building installation.

Measurement category II is for measurements performed on

circuits directly connected to the low voltage installation.

Measurement category I is for measurement performed on

circuits not directly connected to Mains.

Safety Guidelines

5

Page 8

MDO-2000EG & 2000EX User Manual

Power Supply

WARNING

AC Input voltage: 100 - 240V AC, 50 - 60Hz,

auto selection. Power consumption: 40W for

MDO-2000EG; 50W for MDO-2000EX.

Connect the protective grounding conductor of

the AC power cord to an earth ground, to avoid

electrical shock.

Cleaning the

MDO2000EG/2000EX

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh materials

such as benzene, toluene, xylene and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: ≤80%, 40°C or below; ≤45%,

41°C ~ 50°C

Altitude: < 2000m

Temperature: 0°C to 50°C

Note

(Pollution Degree) EN 61010-1:2010 specifies the pollution degrees

and their requirements as follows. The MDO-2000EG/2000EX falls

under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

6

Page 9

SAFETY INSTRUCTIONS

Storage

environment

Location: Indoor

Temperature: -10°C to 60°C

Humidity: Up to 93% RH (non-condensing) /

≤40ºC, up to 65% RH (non-condensing) / 41ºC

~ 60 ºC

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

7

Page 10

MDO-2000EG & 2000EX User Manual

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

Power cord for the United Kingdom

When using the oscilloscope in the United Kingdom, make sure the

power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

As the colours of the wires in main leads may not correspond with

the coloured marking identified in your plug/appliance, proceed

as follows:

The wire which is coloured Green & Yellow must be connected to

the Earth terminal marked with either the letter E, the earth symbol

or coloured Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the

terminal marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment

or contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, a cable

of 0.75mm2 should be protected by a 3A or 5A fuse. Larger

conductors would normally require 13A types, depending on the

connection method used.

Any exposed wiring from a cable, plug or connection that is

engaged in a live socket is extremely hazardous. If a cable or plug is

deemed hazardous, turn off the mains power and remove the cable,

any fuses and fuse assemblies. All hazardous wiring must be

immediately destroyed and replaced in accordance to the above

standard.

8

Page 11

GETTING STARTED

MDO-2000EG/2000EX Series Overview .................... 10

Integrated instruments and series lineup ..................................... 10

Main Features ................................................................................... 11

Accessories ........................................................................................ 12

Appearance .............................................................. 14

MDO-2000EG/2000EX 4-channel models Front Panel ......... 14

MDO-2000EG Rear Panel ............................................................. 22

MDO-2000EX Rear Panel ............................................................. 22

Display ............................................................................................... 24

Set Up ..................................................................... 27

Tilt Stand ........................................................................................... 27

Power Up .......................................................................................... 28

First Time Use .................................................................................. 29

How to Use This Manual ............................................................... 32

Built-in Help ............................................................ 37

GETTING STARTED

This chapter describes the MDO-2000EG/2000EX

in a nutshell, including its main features and

front / rear panel. After going through the

overview, follow the Set Up section to properly

set up the device for first time use. The Set Up

section also includes an introduction on how to

use this manual effectively.

9

Page 12

MDO-2000EG & 2000EX User Manual

Model name

AWG

(1)

DMM

(2)

SA

(3)

Power

(4)

MDO-2000EG

✓

✗ ✓ ✗

MDO-2000EX

✓ ✓ ✓

✓

Model name

Frequency

bandwidth

Input channels

Max. Real-time

Sampling Rate

MDO-2072EG / 2072EX

70MHz

2

1GSa/s

MDO-2074EG / 2074EX

70MHz

4

1GSa/s

MDO-2102EG / 2102EX

100MHz

2

1GSa/s

MDO-2104EG / 2104EX

100MHz

4

1GSa/s

MDO-2202EG / 2202EX

200MHz

2

1GSa/s

MDO-2204EG / 2204EX

200MHz

4

1GSa/s

MDO-2000EG/2000EX Series Overview

Integrated instruments and series lineup

The MDO-2000EG and MDO-2000EX have different hardware

implemented instruments:

(1) Arbitrary Wave Generator

(2) Digital Multi-Meter

(3) Spectrum Analyzer

(4) Power Supply

The MDO-2000EG/2000EX series consists of 12 models, divided

into 2-channel and 4-channel versions. Note that throughout the

user manual, the term “MDO-2000EG/2000EX” refers to all models

of the series, unless stated otherwise.

10

Page 13

GETTING STARTED

Features

8 inch, 800 x 480, WVGA TFT display.

Available from 70MHz to 200MHz.

Real-time sampling rate of 1GSa/s (2 channel

models), 1GSa/s max. (4 channel models).

Deep memory: 10M points record length.

Waveform capture rate of 120,000 waveforms

per second.

Vertical sensitivity: 1mV/div~10V/div.

Segmented Memory: Optimizes the acquisition

memory to selectively capture only the

important signal details. Up to 29,000 successive

waveform segments can be captured with a

time-tag resolution of 4ns.

Waveform Search: Allows the scope to search

for a number of different signal events.

Arbitrary Wave generator: Full-function dual

channel arbitrary waveform generator.

Spectrum Analyzer: A handy tool to perform

signal analysis in the frequency domain.

DMM: Up to 5000 counts and DCV, DCA, ACV,

ACA, R, Diode, Continuity and temperature

measurement were supported (MDO-2000EX

only)

Power Supply: Dual channel output, 1V to 5V

continuously adjustable (0.1V step) (MDO2000EX only)

Powerful embedded applications such as: Data

Logging, Digital Voltmeter, Go-No Go, Mask,

Digital filter, etc..

On-screen Help.

32 MB internal flash disk.

Main Features

11

Page 14

Interface

USB host port: front panel, for storage devices.

USB device port: rear panel, for remote control

or printing.

Ethernet port as standard.

Probe compensation output with selectable

output frequency (1kHz ~ 200kHz).

Calibration output.

Accessories

Standard

Accessories

Part number

Description

N/A region dependent

Power cord

GTP-70B-4, for

MDO-2072EG/2072EX

MDO-2074EG/2074EX

Passive probe; 70 MHz

GTP-100B-4, for

MDO-2102EG/2102EX

MDO-2104EG/2104EX

Passive probe; 100 MHz

GTP-200B-4, for

MDO-2202EG/2202EX

MDO-2204EG/2204EX

Passive probe; 200 MHz

GTL-105A

Test lead for power supply

(for MDO-2000EX only).

GTL-110

Test lead for AGW.

GTL-207

Test lead for DMM (for MDO2000EX only).

Standard Apps

Name

Description

Go-NoGo

Go-NoGo testing app.

DataLog

Waveform or image data logging

app.

DVM

Digital Voltmeter app.

MDO-2000EG & 2000EX User Manual

12

Page 15

GETTING STARTED

Digital Filter

High ,low or band pass digital filter

for analog inputs.

Mask

Creates shape templates for signal

comparison.

Remote Disk

Allows the scope to mount a network

share drive.

Demo mode

Demonstration mode that is used

with the GDB-03 demo board.

Optional

Accessories

Part number

Description

GDB-03

Demo board.

Drivers, others

USB driver

LabVIEW driver

13

Page 16

MDO-2000EG & 2000EX User Manual

Side

menu keys

LCD

Variable knob

and Select key

Autoset, Run/Stop,

Single and Default

settings

Trigger

controls

Function keys

USB Host port, Probe

Compensation terminals

Power

button

Hardcopy key

Math, Reference

and Bus keys

Bottom

menu keys

Horizontal

controls

Vertical

controls

Option key

Menu key

DMM ports

CH1~CH4

LCD

Variable knob

and Select key

Autoset, Run/Stop,

Single and Default

settings

CH1~CH2,

EXT TRIG

Trigger

controls

Function

keys

USB Host port, Probe

Compensation terminals

Hardcopy key

Math, Reference

and Bus keys

Bottom

menu keys

Vertical

controls

Option key

Menu key

Side

menu keys

DMM ports

Power

button

Horizontal

controls

EXT TRIG

Appearance

MDO-2000EG/2000EX 4-channel models Front Panel

MDO-2000EG/2000EX 2-channel models Front Panel

14

Page 17

GETTING STARTED

LCD Display

8” WVGA TFT color LCD. 800 x 480 resolution,

wide angle view display.

Menu Off Key

Use the Menu Off key to hide the

onscreen menu system.

Option Key

The Option key is used to access

installed options.

Menu Keys

The side menu and bottom menu keys are used to

make selections from the soft-menus on the LCD

user interface.

To choose menu items, use the 7 Bottom menu

keys located on the bottom of the display panel.

To select a variable or option from a menu, use the

side menu keys on the side of the panel. See page

32 for details.

VARIABLE

POSITION

HORIZONTAL

TRIGGER

LEVEL

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

Measure

Display

Cursor

Help

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Select

Search

Set/Clear

Zoom

Menu

50 %

Force-Trig

POSITION

POSITION

VERTICAL

MATH

REF

BUS

SCALESCALE

PUSH TO

ZERO

PUSH TO

ZERO

M

R

B

Digital Storage Oscilloscope

GDS-2202E

200 MHz 1 GS/s

Visual Persistence Oscilloscope

Side menu keys

Bottom menu keys

Hardcopy Key

The Hardcopy key is a quick-save

or quick-print key, depending on

its configuration. For more

information see pages 312 (save)

or 311 (print).

15

Page 18

MDO-2000EG & 2000EX User Manual

Variable Knob

and Select Key

Select

VARIABLE

The Variable knob is used to

increase/decrease values or to

move between parameters.

The Select key, when lit up, is

used to make selections.

Function Keys

The Function keys are used to enter and configure

different functions on the MDO-2000EG/2000EX.

Measure

Measure

Configures and runs automatic

measurements.

Cursor

Cursor

Configures and runs cursor

measurements.

APP

APP

Configures and runs GW Instek

applications.

Acquire

Acquire

Configures the acquisition mode,

including Segmented Memory

acquisition.

Display

Display

Configures the display settings.

Help

Help

Shows the Help menu.

Save/Recall

Save/Recall

Used to save and recall

waveforms, images, panel settings.

16

Page 19

GETTING STARTED

Utility

Utility

Configures the Hardcopy key,

display time, language, probe

compensation and calibration. It

also accesses the file utilities

menu.

Autoset

Autoset

Press the Autoset key to

automatically set the trigger,

horizontal scale and vertical scale.

Run/Stop Key

Run/Stop

Press to Freeze (Stop) or continue

(Run) signal acquisition (page 42).

The run stop key is also used to

run or stop Segmented Memory

acquisition (page 88).

Single

Single

Sets the acquisition mode to single

triggering mode.

Default Setup

Default

Resets the oscilloscope to the

default settings.

Horizontal

Controls

The horizontal controls are used to change the

position of the cursor, set the time base settings,

zoom into the waveforms/traces and search for

events.

Horizontal

Position

POSITION

PUSH TO

ZERO

The Position knob is used to

position the waveforms/traces

horizontally on the display screen.

Pressing the knob will reset the

position to zero.

SCALE

SCALE

The Scale knob is used to change

the horizontal scale (TIME/DIV).

17

Page 20

MDO-2000EG & 2000EX User Manual

Zoom

Zoom

Press Zoom in combination with

the horizontal Position knob.

Play/Pause

The Play/Pause key allows you to

view each search event in

succession – to effectively “play”

through each search event. It is

also used to play through a

waveform/trace in zoom mode.

Search

Search

The Search key accesses the search

function menu to set the search

type, source and threshold.

Search Arrows

Use the arrow keys to navigate the

search events.

Set/Clear

Set/Clear

Use the Set/Clear key to set or

clear points of interest when using

the search function.

Trigger Controls

The trigger controls are used to control the trigger

level and options.

Level Knob

LEVEL

Used to set the trigger level.

Pressing the knob will reset the

level to zero.

Trigger Menu Key

Menu

Used to bring up the trigger menu.

50% Key

50 %

Sets the trigger level to the half

way point (50%).

Force - Trig

Force-Trig

Press to force an immediate trigger

of the waveform.

18

Page 21

GETTING STARTED

Vertical

POSITION

POSITION

PUSH TO

ZERO

Sets the vertical position of the

waveform/trace. Push the knob to

reset the vertical position to zero.

Channel Menu

Key

CH1

Press the CH1~4 key to set and

configure the corresponding

channel.

(Vertical)SCALE

Knob

SCALE

Sets the vertical scale of the

channel (TIME/DIV).

External Trigger

Input

EXT TRIG

Accepts external trigger signals

(page 140). Only on 2 channel

models.

Input impedance: 1MΩ

Voltage input: ±15V (peak), EXT

trigger capacitance: 16pF.

Math Key

MATH

M

Use the Math key to set and

configure math functions.

Reference Key

REF

R

Press the Reference key to set or

remove reference waveforms.

BUS Key

BUS

B

The Bus key is used for serial bus

(UART, I2C, SPI, CAN, LIN)

configuration.

19

Page 22

MDO-2000EG & 2000EX User Manual

Channel Inputs

CH1

Accepts input signals.

Input impedance: 1MΩ.

Capacitance: 16pF

CAT I

USB Host Port

2V

Type A, 1.1/2.0 compatible. Used

for data transfer.

Ground Terminal

2V

Accepts the DUT ground lead for

common ground.

Probe

Compensation

Output

2V

The probe compensation output is

used for probe compensation. It

also has an adjustable output

frequency.

By default this port outputs a

2Vpp, square wave signal at 1kHz

for probe compensation.

Please see page 184 for details.

Power Switch

Used to turn the power on/off.

: ON

: OFF

DMM Ports

(For MDO2000EX only)

10A MAX

FUSED

V

W

COMA mA

CAT II 600V

CAT III 300VFUSED

600mA MAX

20

Page 23

GETTING STARTED

mA

Accepts up to 600mA.

Fuse protection: 1A.

A

Accepts up to 10A.

Fuse protection: 10A

COM

Com port

V

W

Voltage, Resistance and Diode

port.

Max voltage: 600V

21

Page 24

MDO-2000EG & 2000EX User Manual

Calibration

output

Key lock Power input socket

Fan

Go/No Go

output

LAN portUSB Device port

AWG channels

output

Calibration

output

Key lock Power input socket

Fan

Go/No Go

output

LAN portUSB Device port

AWG channels

output

Power supply

output

Calibration

Output

Outputs the signal for vertical scale

accuracy calibration (page 327).

MDO-2000EG Rear Panel

MDO-2000EX Rear Panel

22

Page 25

GETTING STARTED

USB Device Port

The USB Device port is used for

remote control.

LAN (Ethernet)

Port

The LAN port is used for remote

control over a network or when

combined with the Remote Disk

app, allows the scope to be

mounted to a share disk.

Power Input

Socket

Power cord socket accepts AC

mains, 100 ~ 240V, 50/60Hz.

For power up sequence, see page

28.

Security Slot

Kensington security slot

compatible.

Go-No Go

Output

Outputs Go-No Go test results

(page 256) as a 500us pulse signal.

AWG Output

GEN 1

Output the GEN1 or GEN2 signal

from the Arbitrary Wave Generator

function. (see page 188).

Power Supply

outputs

5V/1A Dual power supply outputs,

(For MDO-2000EX only, see page

249).

23

Page 26

MDO-2000EG & 2000EX User Manual

Memory

bar

Reference

waveform

Analog

Waveform

Channel status Horizontal status

Trigger

configuration

Waveform

frequency

Date and time

Trigger

position

Trigger status

Acquisition

mode

Trigger level

Channel

Indicators

Memory length

and sample rate

Analog

Waveforms

Shows the analog input signal waveforms.

Channel 1: Yellow

Channel 2: Blue

Channel 3: Pink

Channel 4: Green

Bus decoding

Shows serial bus data decoding. The values are

displayed in hex or binary.

Reference

waveform

Reference waveform(s) can be displayed for

reference, comparison or other operations.

Channel

Indicators

The channel indicators for each activated channels

are located at the zero volt level of each signals.

Any active channel is shown with a solid color.

Example:

Analog channel indicator

Reference waveform indicator

Math indicator

Display

Below is a general description of the main display. As the display

changes while activating the different functions of the MDO2000EG/2000EX, please refer to each function sub-chapters of this

user manual for more details.

24

Page 27

GETTING STARTED

Trigger Position

Shows the position of the trigger.

Horizontal Status

Shows the horizontal scale and position.

Date and Time

Current date and time (page 183).

Trigger Level

Shows the trigger level on the graticule.

Memory Bar

The ratio and the position of the displayed

waveform compared to the internal memory (page

102).

Trigger Status

Trig’d

Triggered.

PrTrig

Pre-trigger.

Trig?

Not triggered, display not updated.

Stop

Trigger stopped. Also appears in

Run/Stop (page 42).

Roll

Roll mode.

Auto

Auto trigger mode.

For trigger details, see page 140.

Acquisition Mode

Normal mode

Peak detect mode

Average mode

For acquisition details, see page 80.

Signal Frequency

Shows the trigger source

frequency.

Indicates the frequency is

less than 2Hz (lower

frequency limit).

Trigger

Configuration

Trigger source, slope,

voltage and coupling.

Horizontal Status

Horizontal scale,

horizontal position.

25

Page 28

MDO-2000EG & 2000EX User Manual

For trigger details, see page 140.

Channel Status

Channel 1, DC coupling,

2V/Div.

For channel details, see page 110.

26

Page 29

Set Up

Tilt

To tilt, pull the legs forward, as shown below.

Stand

To stand the scope upright, push the legs back

under the casing as shown below.

Tilt Stand

GETTING STARTED

27

Page 30

Power Up

Requirements

The MDO-2000EG/2000EX accepts line voltages of

100 ~ 240V at 50 or 60Hz.

Step

1. Connect the power cord to

the rear panel socket.

2. Press the POWER key. The

display becomes active in

~ 30 seconds.

: ON

: OFF

Note

The MDO-2000EG/2000EX recovers the state right

before the power is turned OFF. The default settings

can be recovered by pressing the Default key on the

front panel. For details, see page 296.

MDO-2000EG & 2000EX User Manual

28

Page 31

First Time Use

Background

This section describes how to connect, adjust the

scale and compensate the probe. Before operating

the MDO-2000EG/2000EX in a new environment,

run these steps to make sure the instrument

performs at its full potential.

1. Power On

Follow the procedures on the previous page.

2. Firmware

Update to the latest firmware.

Page 334

3. Set the Date

and Time

Set the date and time.

Page 183.

4. Reset System

Reset the system by recalling the

factory settings. Press the Default key

on the front panel. For details, see

page 296.

Default

5. Connect the

probe

Connect the probe that you will use for

measurements to the Channel 1 input and to the

probe compensation output. This output provides

by default a 2V peak to peak, 1kHz square wave

for signal compensation.

Set the probe attenuation to x10 if the probe has

adjustable attenuation.

GETTING STARTED

29

Page 32

MDO-2000EG & 2000EX User Manual

x1

x10

X

10

X

1

CH1

2V

6. Capture Signal

(Autoset)

Press the Autoset key. A square

waveform appears on the center of

the screen. For Autoset details, see

page 40.

Autoset

7. Select Vector

Waveform

Press the Display key, and set the

display to Vector on the bottom menu.

Display

30

Page 33

GETTING STARTED

8. Compensate

the probe

Turn the adjustment point on the probe to make

the square waveform as flat as possible.

9. Start operations

Continue with the other operations.

Measurement: page 38

Configuration: page 77

Using the Spectrum

Analyzer: page 220.

Using the Power Supply:

page 249.

Using the DMM: page

239.

Applications: page 220

Save/Recall: page 277

File Utilities: page 303

Hardcopy key: page 310

Remote Control: page

314

Maintenance: page 325

Under

Compensation

Normal

Over

Compensation

31

Page 34

MDO-2000EG & 2000EX User Manual

Background

This section describes the conventions used in this

manual to operate the MDO-2000EG/2000EX.

Throughout the manual any reference to pressing

a menu key refers to the keys directly below or

beside any menu icons or parameters.

When the user manual says to “toggle” a value or

parameter, press the corresponding menu item.

Pressing the item will toggle the value or

parameter.

Active parameters are highlighted for each menu

item. For example in the example below, Coupling

is currently set to DC.

If a menu item can be toggled from one value or

parameter to another, the available options will be

visible, with the current option highlighted. In the

example below the slope can be toggled from a

rising slope to a falling slope or either slope.

Menu item

Parameter

Menu item

Active

parameter

Optional

parameters

Menu item

Selecting a Menu

Item, Parameter

or Variable

When the user manual says to “select” a value

from one of the side menu parameters, first press

the corresponding menu key and use the Variable

knob to either scroll through a parameter list or to

increase or decrease a variable.

How to Use This Manual

32

Page 35

GETTING STARTED

Example 1

1

2

3

3. Press a bottom menu key to access

the side menu.

4. Press a side menu key to either set

a parameter or to access a sub

menu.

5. If accessing a sub menu or setting

a variable parameter, use the

Variable knob to scroll through

menu items or variables. Use the

Select key to confirm and exit. The

Select key is lit-up when such

selection can be made.

Select

VARIABLE

6. Press the same bottom menu key

again to reduce the side menu.

Example 2

For some variables, a circular arrow icon indicates

that the variable for that menu key can be edited

with the Variable knob.

33

Page 36

MDO-2000EG & 2000EX User Manual

1

7. Press the desired menu key to select it. The

circular arrow will become highlighted.

8. Use the Variable knob to edit the value.

Toggling a Menu

Parameter

1

9. Press the bottom menu key

to toggle the parameter.

Reduce Side

Menu

1

34

Page 37

GETTING STARTED

10. To reduce the side menu, press the

corresponding bottom menu that brought up

the side menu.

For example: Press the Source soft-key to

reduce the Source menu.

Reduce Lower

Menu

11. Press the relevant function

key again to reduce the

bottom menu. For example:

press the Trigger Menu key

to reduce the trigger menu.

POSITION

SCALE

TRIGGER

LEVEL

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Zoom

Menu

50 %

Force-Trig

1

Remove All

Menus

35

Page 38

MDO-2000EG & 2000EX User Manual

12. Press the Menu Off key to

reduce the side menu, press

again to reduce the bottom

menu.

VARIABLE

POSITION

HORIZONTAL

POSITION

POSITION

POSITION

POSITION

VERTICAL

MATH

REF

BUS

SCALE

TRIGGER

LEVEL

PUSH TO

ZERO

SCALESCALESCALE

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

CH1 CH2 CH3 CH4

2V

Measure

Display

Cursor

Help

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Select

Search

Set/Clear

Zoom

CH1 CH2 CH3 CH4

M

R

B

Menu

50 %

Force-Trig

1

Remove OnScreen Messages

13. The Menu Off key can also be

used to remove any on

screen messages.

VARIABLE

POSITION

HORIZONTAL

POSITION

POSITION

POSITION

POSITION

VERTICAL

MATH

REF

BUS

SCALE

TRIGGER

LEVEL

PUSH TO

ZERO

SCALESCALESCALE

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

PUSH TO

ZERO

SCALE

CH1 CH2 CH3 CH4

2V

Measure

Display

Cursor

Help

Test

Save/Recall

Acquire

Utility

Autoset

Run/Stop

Single

Default

Select

Search

Set/Clear

Zoom

CH1 CH2 CH3 CH4

M

R

B

Menu

50 %

Force-Trig

1

36

Page 39

GETTING STARTED

The Help key accesses a context sensitive help menu. The help menu

contains information on how to use the front panel keys.

Panel Operation

1. Press the Help key. The

display changes to Help

mode.

Help

2. Use the Variable knob to scroll up and down

through the Help contents. Press Select to view

the help on the selected item.

Example: Help on

the Display key

Home Key

Press the Home key to return to

the main help screen.

Go Back

Press the Back key to go to the

previous menu page.

Exit

Press the Help key again or press

the Exit key to exit the Help

mode.

Help

Built-in Help

37

Page 40

MDO-2000EG & 2000EX User Manual

Basic Measurement ................................................. 39

Channel Activation .......................................................................... 39

Autoset ............................................................................................... 40

Run/Stop ........................................................................................... 42

Horizontal Position/Scale .............................................................. 43

Vertical Position/Scale .................................................................... 45

Automatic Measurement .......................................... 46

Measurement Items ......................................................................... 46

Add Measurement ............................................................................ 50

Remove Measurement ..................................................................... 52

Gated mode ....................................................................................... 53

Display All mode .............................................................................. 54

High Low Function ......................................................................... 55

Statistics ............................................................................................. 56

Reference Levels .............................................................................. 58

Cursor Measurement ............................................... 60

Use Horizontal Cursors .................................................................. 60

Use Vertical Cursors ........................................................................ 63

Math Operation ....................................................... 67

Basic Math Overview & Operators .............................................. 67

Addition/Subtraction/Multiplication/Division ......................... 67

FFT Overview & Window Functions .......................................... 69

FFT Operation ................................................................................. 70

Advanced Math Overview .............................................................. 72

Advanced Math Operation ............................................................. 73

MEASUREMENT

38

Page 41

MEASUREMENT

Activate Channel

To activate an input channel,

press a channel key.

When activated, the channel

key will light up. The

corresponding channel menu

will also appear.

CH1 CH1

Each channel is associated with the color shown

beside each channel’s vertical SCALE dial: CH1:

yellow, CH2: blue, CH3: pink and CH4: green.

When a channel is activated, it is shown above the

bottom menu system.

CH1 CH3CH2 CH4

Basic Measurement

This section describes the basic operations required in capturing,

viewing and measuring the input signal. For more detailed or more

specific operations, see the following chapters.

Advanced Configuration → from page 77

Arbitrary Wave Generator → from page 186

Spectrum Analyzer→ from page 220

Digital Multi-meter (MDO-2000EX only)→ from page 239

Power Supply (MDO-2000EX only)→ from page 249

Applications→ from page 253

Before operating the oscilloscope, please see the Getting Started

chapter, page 9.

Channel Activation

39

Page 42

De-activate

Channel

To de-activate a channel, press

the corresponding channel key

again. If the channel menu is

not open, press the channel key

twice (the first press shows the

Channel menu).

CH1 CH1

Default Setup

To activate the default state,

press Default (this will reset the

system and recall the factory

defaults, see page 296).

Default

Autoset

Background

The Autoset function automatically configures the

panel settings to position the input signal(s) to the

best viewing condition. The MDO-2000EG/2000EX

automatically configures the following parameters:

Horizontal scale

Vertical scale

Trigger source channel

There are two operating modes for the Autoset

function: Fit Screen Mode and AC Priority Mode.

Fit Screen Mode will fit the waveform to the best

scale, including any DC components (offset). AC

priority mode will scale the waveform to the

screen by removing any DC component.

Panel Operation

1. Connect the input signal to the

MDO-2000EG/2000EX and press

the Autoset key.

Autoset

2. The waveform appears in the center of the

display.

MDO-2000EG & 2000EX User Manual

40

Page 43

MEASUREMENT

Before

After

3. To undo Autoset, press Undo

Autoset from the bottom menu.

Change modes

4. Choose between Fit Screen Mode

and AC Priority Mode from the

bottom menu.

5. Press the Autoset key again to use

Autoset in the new mode.

Autoset

Fit Screen Mode

AC Priority

Limitation

Autoset does not work in the following situations:

Input signal frequency is less than 20Hz

Input signal amplitude is less than 10mV

Note

The Autoset key does NOT automatically activate the

channels to which input signals are connected.

41

Page 44

Run/Stop

Background

By default, the waveform on the display is

constantly updated (Run mode). Freezing the

waveform by stopping signal acquisition (Stop

mode) allows flexible observation and analysis. To

enter Stop mode, two methods are available:

pressing the Run/Stop key or using the Single

Trigger mode.

Stop mode icon

When in Stop mode, the

Stop icon appears at the

top of the display.

Triggered icon

Freeze Waveform

using the

Run/Stop Key

Press the Run/Stop key once.

The Run/Stop key turns red.

The waveform and signal

acquisition freezes.

Stop:

Run/Stop Run/Stop

To unfreeze, press the Run/Stop

key again. The Run/Stop key

turns green again.

Run:

Run/Stop Run/Stop

Freeze Waveform

by Single Trigger

Mode

Press the Single key to go into

the Single Trigger mode. The

Single key turns bright white.

In the Single Trigger mode, the

scope will be put into the pretrigger mode until the scope

encounters the next trigger

point. After the scope has

triggered, it will remain in Stop

mode, until the Single key is

pressed again or the Run/Stop

key is pressed.

SingleSingle

Waveform

Operation

The waveform can be moved or scaled in both Run

and Stop mode, but in different manners. For

details, see page 102 (Horizontal position/scale)

and page 110 (Vertical position/scale).

MDO-2000EG & 2000EX User Manual

42

Page 45

MEASUREMENT

Set Horizontal

Position

The horizontal position knob

moves the waveform left and

right.

POSITION

PUSH TO

ZERO

Set Horizontal

Position to 0

Pressing the horizontal position

knob will reset the horizontal

position to 0.

POSITION

PUSH TO

ZERO

Alternatively, pressing the Acquire

key and then pressing Reset H

Position to 0s from the bottom menu

will also reset the horizontal position.

Acquire

As the waveform moves, the display bar on the top

of the display indicates the portion of the

waveform currently shown on the display and the

position of the horizontal marker on the

waveform.

Position Indicator

The horizontal position is shown at the bottom of

the display grid to the right of the H icon.

Horizontal Position/Scale

For more detailed configuration, see page 102.

43

Page 46

MDO-2000EG & 2000EX User Manual

Select Horizontal

Scale

To select the timebase, turn the

horizontal SCALE knob; left (slow) or

right (fast).

SCALE

Range

1ns/div ~ 100s/div, 1-2-5 increments

The scale is displayed to the left of the H icon at

the bottom of the screen.

Display bar

The display bar indicates how much

of the waveform is displayed on the

screen at any given time. Changes to

timebase will be reflected on the

display bar.

Fast

Medium

Slow

Stop mode

In the Stop mode, the waveform size

changes according to the scale.

Note

The Sample rate changes according to the timebase

and record length. See page 84.

44

Page 47

MEASUREMENT

Set Vertical

Position

To move the waveform up or down, turn

the vertical position knob for each channel.

POSITION

PUSH TO

ZERO

Push the vertical position knob to

reset the position to 0.

As the waveform moves, the

vertical position of the channel

indicator appears on the display.

POSITION

PUSH TO

ZERO

Run/Stop

mode

The waveform can be moved

vertically in both Run and Stop

mode.

Select Vertical

Scale

To change the vertical scale, turn

the vertical SCALE knob; left

(down) or right (up).

SCALE

Range

1mV/div ~ 10V/div

1-2-5 increments

The vertical scale indicator for

each channel on the bottom of

the display changes

accordingly.

Vertical Position/Scale

For more detailed configuration, see page 110.

45

Page 48

MDO-2000EG & 2000EX User Manual

V/I Measurements

Time Meas.

Delay Meas.

Overview

FPREShoot

RPREShoot

FOVShoot

ROVShoot

Cycle Area

Area

Cycle RMS

RMS

Cycle Mean

Mean

Low

High

Amplitude

Min

Max

Pk-Pk

Frequency

Dutycycle

-Width

+Width

FallTime

RiseTime

Period

-Edges

+Edges

-Pulses

+Pulses

% Flicker

Flicker Idx

A

B

(A-B)

(A+B)

A1

A1

A1+A2

A2

Voltage/Current

Measurement

Pk-Pk

(peak to

peak)

Difference between positive

and negative peak.

(=max − min)

Max

Positive peak.

Min

Negative peak.

FRR

FRF

FFR

Phase

LFF

LFR

LRF

LRR

FFF

Automatic Measurement

The automatic measurement function measures and updates major

items for Voltage/Current, Time, and Delay type measurements.

Measurement Items

46

Page 49

MEASUREMENT

Amplitude

Difference between the

global high value and the

global low value, measured

over the entire waveform or

gated region. (=high − low)

High

Global high voltage. See

page 55 for details.

Low

Global low voltage. See page

55 for details.

Mean

The arithmetic mean value is

calculated for all data

samples as specified by the

Gating option.

Cycle Mean

The arithmetic mean value is

calculated for all data

samples within the first cycle

found in the gated region.

RMS

The root mean square of all

data samples specified by the

Gating option.

Cycle RMS

The root mean square value

is calculated for all data

samples within the first cycle

found in the gated region.

Area

Measures the positive area of

the waveform and subtracts

it from the negative area. The

ground level determines the

division between positive

and negative areas.

Cycle Area

The Summation based on all

data samples within the first

cycle found in the gated

region.

ROVShoot

Rise overshoot

47

Page 50

MDO-2000EG & 2000EX User Manual

FOVShoot

Fall overshoot

RPREShoot

Rise preshoot

FPREShoot

Fall preshoot

Time

Measurement

Frequency

Frequency of the waveform.

Period

Waveform cycle time.

(=1/Freq)

RiseTime

The time required for the

leading edge of the first

pulse to rise from the low

reference value to the high

reference value.

FallTime

The time required for the

falling edge of the first pulse

to fall from the high

reference value to the low

reference value.

+Width

Positive pulse width.

–Width

Negative pulse width.

Duty Cycle

Ratio of signal pulse

compared with whole cycle.

=100x (Pulse Width/Cycle)

+Pulses

Measures the number of

positive pulses.

-Pulses

Measures the number of

negative pulses.

+Edges

Measures the number of

positive edges.

48

Page 51

MEASUREMENT

-Edges

Measures the number of

negative edges.

% Flicker

A

B

(A-B)

(A+B)

Ratio in percentage of the

peak-to-peak value to the

sum of peak values.

Flicker Idx

A1

A1

A1+A2

A2

Ratio of the area above the

average to the total area

during one cycle.

Delay

Measurement

FRR

Time between:

Source 1 first rising edge and

Source 2 first rising edge.

FRF

Time between:

Source 1 first rising edge and

Source 2 first falling edge.

FFR

Time between:

Source 1 first falling edge

and Source 2 first rising

edge.

FFF

Time between:

Source 1 first falling edge

and Source 2 first falling

edge.

LRR

Time between:

Source 1 first rising edge and

Source 2 last rising edge.

LFR

Time between:

Source 1 first rising edge and

Source 2 last falling edge.

LRF

Time between:

Source 1 first falling edge

and Source 2 last rising edge.

LFF

Time between:

Source 1 first falling edge

and Source 2 last falling

edge.

49

Page 52

MDO-2000EG & 2000EX User Manual

Phase

The phase difference of two

signals, calculated in

degrees.

360x

t2

t1

Note

The in-built help system can be used to see detailed

automatic measurement definitions.

Add

Measurement

Item

1. Press the Measure key.

Measure

2. Press Add Measurement from the

bottom menu.

3. Choose either a V/I, Time or Delay

measurement from the side menu

and choose the type of

measurement you wish to add.

V/I

(Voltage/

Current)

Pk-Pk, Max, Min, Amplitude, High,

Low, Mean, Cycle Mean, RMS,

Cycle RMS, Area, Cycle Area,

ROVShoot, FOVShoot, RPREShoot,

FPREShoot

Time

Frequency, Period, RiseTime,

FallTime, +Width, –Width, Duty

Cycle, +Pulses, -Pulses, +Edges, Edges, %Flicker, FlickerIndex

Add Measurement

The Add Measurement function allows you to add up to eight

automatic measurement items on the bottom of the screen from any

channel source.

50

Page 53

MEASUREMENT

Delay

FRR, FRF, FFR, FFF, LRR, LRF, LFR,

LFF, Phase

4. All of the chosen automatic measurements will

be displayed in a window on the bottom of the

screen. The channel number and channel color

indicate the measurement source.

For the analog inputs: yellow = CH1,

blue = CH2, pink = CH3, green = CH4.

Choose a Source

The channel source for measurement items can be

set either before or when selecting a measurement

item.

5. To set the source, press either the

Source1 or Source2 key from the

side menu and choose the source.

Range

Source1: CH1~CH4, Math

Source2: CH1~CH4, Math

(Note)

Source 2 is only applicable to Delay

measurements.

Only selected Time Frequency measurements

can be applied to Frequency, Period, +Width, Width and Dutycycle.

51

Page 54

MDO-2000EG & 2000EX User Manual

Remove

Measurement

Item

1. Press the Measure key.

Measure

2. Press Remove Measurement from the

bottom menu.

3. Press Select Measurement and select

the item that you want to remove

from the measurement list.

Remove All Items

Press Remove All to remove all the

measurement items.

Remove Measurement

Individual measurements can be removed at any time using the

Remove Measurement function.

52

Page 55

MEASUREMENT

Set Gating Mode

1. Press the Measure key.

Measure

2. Press Gating from the bottom

menu.

3. Choose one of the gating modes

from the side menu: Off (full

record), Screen, Between Cursors.

Cursors On

Screen

If Between Cursors is selected, the

cursor positions can be edited by

using the cursor menu.

Page 60

Gated mode

Some automatic measurements can be limited to a “gated” area

between cursors. Gating is useful for measuring a magnified

waveform or when using a fast time base. The Gated mode has

three possible configurations: Off (Full Record), Screen and

Between Cursors.

53

Page 56

MDO-2000EG & 2000EX User Manual

View

Measurement

Results

1. Press the Measure key.

Measure

2. Press Display All from the bottom

menu.

3. Press Source from the side menu

and choose a measurement source.

Range

CH1~CH4, Math

4. The results of Voltage and Time type

measurements appear on the display.

Remove

Measurements

To remove the measurement results,

press OFF.

Delay

Measurements

Delay type measurements are not available in this

mode as only one channel is used as the source.

Use the individual measurement mode (page 50)

instead.

Display All mode

Display All mode shows and updates all items from Voltage and

Time type measurements.

54

Page 57

MEASUREMENT

Background

The High-Low function is used to select the

method for determining the value of the High-Low

measurement values.

Auto

Automatically chooses the best

high-low setting for each

waveform when measuring.

Histogram

Uses histograms to determine the

high-low values. This mode

ignores any pre-shoot or

overshoot values. This mode is

particularly useful for pulse-type

waveforms

low

high

Min-max

Sets the high-low values as the

minimum or maximum measured

values.

low

high

Set High-Low

1. Press the Measure key.

Measure

2. Press High-Low from the bottom

menu.

High Low Function

55

Page 58

3. Select the type of High-Low settings from the

side menu.

High-Low Settings:

Histogram, Min-Max,

Auto

Restore Default

High-Low

Settings

To return to the default High-Low

settings, press Set to Defaults.

Statistics

Background

The Statistics function can be used to view a

number of statistics for the selected automatic

measurements. The following information is

displayed with the Statistics function:

Value

Currently measured value

Mean

The mean value is calculated from

a number of automatic

measurement results. The number

of samples used to determine the

mean can be user-defined.

Min

The minimum value observed

from a series of measured results

for the selected automatic

measurement items.

MDO-2000EG & 2000EX User Manual

56

Page 59

MEASUREMENT

Max

The maximum value observed

from a series of measured results

for the selected automatic

measurement items.

Standard

Deviation

The variance of the currently

measured value from the mean.

The standard deviation equals the

squared root of the variance value.

Measuring the standard deviation

can, for example, determine the

severity of jitter in a signal.

The number of samples used to

determine the standard deviation

can be user-defined.

Panel Operation

1. Press the Measure key.

Measure

2. Select at least one automatic

measurement.

Page 50

3. Press Statistics from the bottom

menu.

4. Set the number of samples to be

used in the mean and standard

deviation calculations.

Samples:

2~1000

5. Press Statistics and turn Statistics

on.

6. The statistics for each automatic measurement

will appear at the bottom of the display in a

table.

57

Page 60

MDO-2000EG & 2000EX User Manual

Reset Statistics

To reset the standard deviation

calculations, press Reset Statistics.

Background

The reference level settings determine the

measurement threshold levels for some

measurements like the Rise Time measurement.

High Ref: Sets the high reference

level.

Mid Ref: Sets the middle reference

for the first and second

waveforms.

Low Ref: Sets the low reference

level.

Panel Operation

1. Press the Measure key.

Measure

2. Press Reference Levels from the

bottom menu.

Reference Levels

58

Page 61

MEASUREMENT

3. Set the reference levels from the side menu.

Ensure the reference levels do not cross over.

High Ref

0.0% ~ 100%

Mid Ref

0.0% ~ 100%

0.0% ~ 100%

Low Ref

0.0% ~ 100%

Default Settings

4. Press Set to Defaults to set the

reference levels back to the default

settings.

59

Page 62

MDO-2000EG & 2000EX User Manual

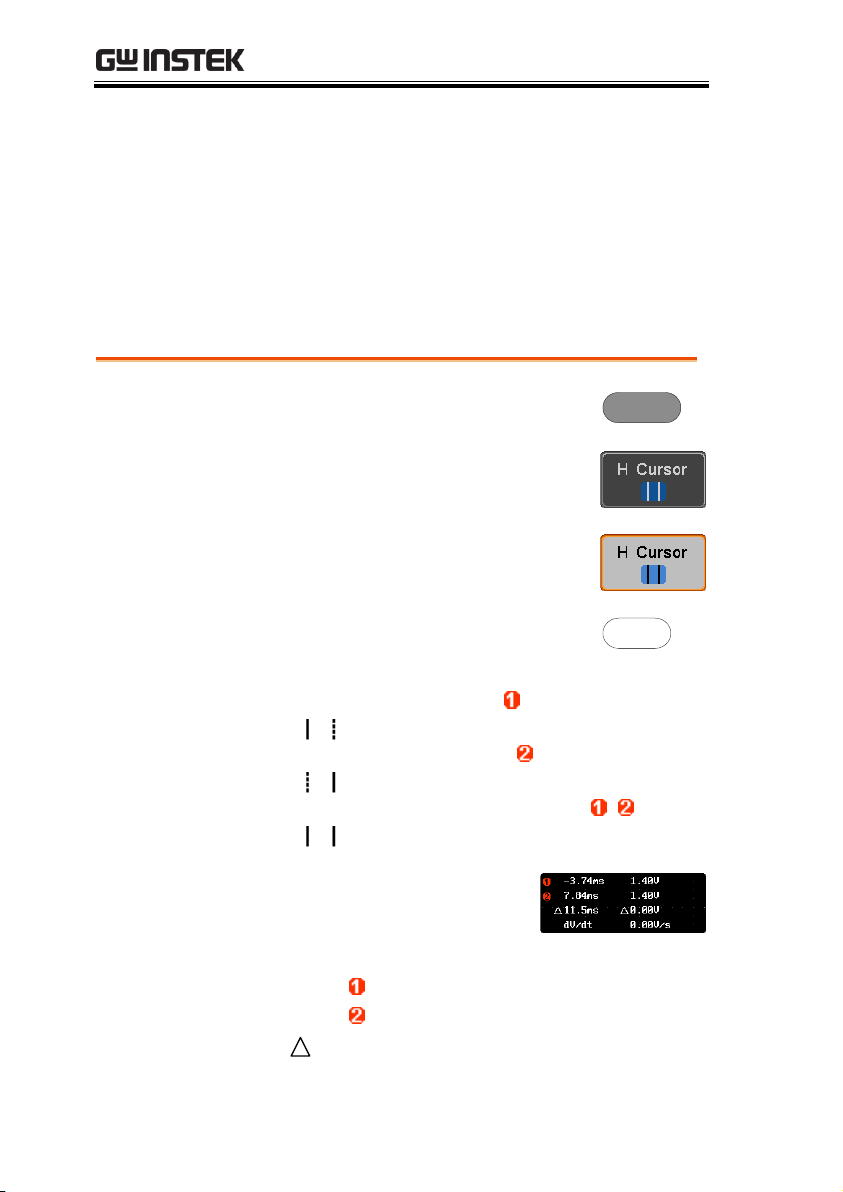

Panel Operation

1. Press the Cursor key once.

Cursor

2. Press H Cursor from the bottom

menu if it is not already selected.

3. When the H Cursor is selected,

repeatedly pressing the H Cursor

key or the Select key will toggle

which cursor is selected.

OR

Select

Range

Description

Left cursor ( ) movable, right

cursor position fixed

Right cursor ( ) movable, left

cursor position fixed

Left and right cursor ( + )

movable together

4. The cursor position

information appears on the

top left hand side of the

screen

Cursor

Hor. position, Voltage/Current

Cursor

Hor. position, Voltage/Current

Delta (difference between cursors)

dV/dt or dI/dt

Cursor Measurement

Horizontal or vertical cursors are used to show the position and

values of waveform measurements and math operation results.

These results cover voltage, time, frequency and other math

operations. When the cursors (horizontal, vertical or both) are

activated, they will be shown on the main display unless turned off.

Use Horizontal Cursors

60

Page 63

MEASUREMENT

5. Use the Variable knob to move the

movable cursor(s) left or right.

VARIABLE

(Note)

The selected cursor(s) will move

along the active waveform. To

move along another waveform,

select its corresponding channel

and press the cursor key again to

re-enter the cursor menu.

Select Units

6. To change the units of the

horizontal position, press H Unit.

Units

S, Hz, % (ratio), ˚(phase)

Phase or Ratio

Reference

7. To set the 0% and 100% ratio or the

0˚ and 360˚ phase references for the

current cursor positions, press Set

Cursor Positions As 100%.

Example

Horizontal

cursors

61

Page 64

MDO-2000EG & 2000EX User Manual

FFT

FFT cursors can use different

units. For FFT details, see page

69.

Cursor

Hor. position, dB/Voltage

Cursor

Hor. Position, dB/Voltage

Delta (difference between cursors)

dV/dt or d/dt

Example

Horizontal

cursors

XY Mode

XY mode cursors measure a number of X by Y

measurements. See page 82.

Cursor

Time, rectangular, polar coordinates, product, ratio.

Cursor

Time, rectangular, polar coordinates, product, ratio.

Delta (difference between cursors)

62

Page 65

MEASUREMENT

Example

Horizontal

cursors

Panel Operation/

Range

1. Press the Cursor key twice.

Cursor

x2

2. Press V Cursor from the bottom

menu if it is not already selected.

3. When the V Cursor is selected,

repeatedly pressing the V Cursor

key or the Select key will toggle

which vertical cursor is selected.

OR

Select

Range

Upper cursor movable, lower

cursor position fixed

Lower cursor movable, upper

cursor position fixed

Upper and lower cursor movable

together

Use Vertical Cursors

63

Page 66

MDO-2000EG & 2000EX User Manual

4. The cursor position

information appears on the

top left hand side of the

screen.

,

Time: cursor 1, cursor 2

,

Voltage/Current: cursor1, cursor2

Delta (difference between cursors)

dV/dt or dI/dt

5. Use the Variable knob to move the

cursor(s) up or down.

VARIABLE

Select Units

6. To change the units of the vertical

position, press V Unit.

Units

Base (source wave units), % (ratio)

Base or Ratio

Reference

7. To set the 0% and 100% ratio

references for the current cursor

position, press Set Cursor Positions

As 100%.

Example

Horizontal

cursors

Vertical

cursors

64

Page 67

MEASUREMENT

FFT

FFT has different content. For

FFT details, see page 69.

,

Frequency/Time: cursor1, cursor2

,

dB/V: cursor1, cursor2

Delta (difference between cursors)

d/dt

Example

Horizontal

cursors

Vertical

cursors

XY Mode

XY mode cursors measure a number of X by Y

measurements. See page 82.

Cursor

Rectangular, polar co-ordinates,

product, ratio.

Cursor

Rectangular, polar co-ordinates,

product, ratio.

Delta (difference between cursors)

65

Page 68

MDO-2000EG & 2000EX User Manual

Example

Horizontal

cursors

Vertical

cursors

66

Page 69

MEASUREMENT

Background

The Math function performs basic math functions

(addition, subtraction, multiplication, division) on

the input signals or the reference waveforms. The

resultant waveform will be shown on the screen in

real-time.

Addition (+)

Adds the amplitude of two signals.

Source

CH1~4, Ref1~4

Subtraction (–)

Extracts the amplitude difference between two

signals.

Source

CH1~4, Ref1~4

Multiplication (×)

Multiplies the amplitude of two signals.

Source

CH1~4, Ref1~4

Division (÷)

Divides the amplitude of two signals.

Source

CH1~4, Ref1~4

Panel Operation

1. Press the Math key.

MATH

M

2. Press the Math key on the lower

bezel.

3. Select Source 1 from the side menu

Range

CH1~4, Ref1~4

Math Operation

Basic Math Overview & Operators

Addition/Subtraction/Multiplication/Division

67

Page 70

MDO-2000EG & 2000EX User Manual

4. Press Operator to choose the math

operation.

Range

+, -, ×, ÷

5. Select Source 2 from the side menu.

Range

CH1~4, Ref1~4

6. The math measurement result appears on the

display. The vertical scale of the math

waveform appears at the bottom of the screen.

From left: Math function, source1, operator,

source2, Unit/div

Example

Math

Source 2

Source 1

Position and Unit

To move the math waveform

vertically, press the Position key from

the side menu and use the Variable

knob to set the position.

Range

–12.00 Div ~ +12.00 Div

68

Page 71

MEASUREMENT

To change the unit/div settings, press

Unit/div, then use the Variable knob to

change the unit/div.

The units that are displayed depend

on which operator has been selected,

and whether the probe for the selected

channel has been set to voltage or

current.

Operator:

Unit/div:

Multiplication

Division

Addition/Subtraction

VV, AA or W

V/V, A/A

V or A

Turn Off Math

To turn off the Math result from the

display, press the Math key again.

MATH

M

Background

The FFT function performs a Fast Fourier

Transform on one of the input signals or the

reference waveforms. The resultant spectrum will

be shown on the screen in real-time. Four types of

window function are available: Hanning,

Hamming, Rectangular, and Blackman, as

described below.

Hanning

Frequency resolution

Good

Amplitude resolution

Not good

Suitable for....

Frequency measurement on

periodic waveforms

FFT Overview & Window Functions

69

Page 72

MDO-2000EG & 2000EX User Manual

Hamming

Frequency resolution

Good

Amplitude resolution

Not good

Suitable for....

Frequency measurement on

periodic waveforms

Rectangular

Frequency resolution

Very good

Amplitude resolution

Bad

Suitable for....

Single-shot phenomenon

(this mode is the same as

having no window at all)

Blackman

Frequency resolution

Bad

Amplitude resolution

Very good

Suitable for....

Amplitude measurement on

periodic waveforms

(Note)

For more complete measures and functions in the

frequency domain of a signal, please also refer to

the Spectrum Analyzer option of the MDO-2000EG

on page 220.

Panel Operation

1. Press the Math key.

MATH

M

2. Press FFT from the bottom menu.

3. Select the Source from the side

menu.

Range

CH1~4, Ref~4

FFT Operation

70

Page 73

MEASUREMENT

4. Press the Vertical Units key from

the side menu to select the vertical

units used.

Range

Linear RMS, dBV RMS

5. Press the Window key from the side

menu and select the window type.

Range

Hanning, Hamming, Rectangular,

and Blackman.

6. The FFT result represents the frequency-

domain representation of a signal. Hence, the

horizontal scale changes from time to

frequency, and the vertical scale from

voltage/current to dB/RMS.

Math

Source

Position and

Scale

To move the FFT waveform vertically,

press Vertical until the Div parameter

is highlighted and then use the

Variable knob.

Range

–12.00 Div ~ +12.00 Div

To select the vertical scale of the FFT

waveform, press Vertical until the dB

or voltage parameters are highlighted

and then use the Variable knob.

71

Page 74

MDO-2000EG & 2000EX User Manual

Range

2mV~1kV RMS (Linear RMS),

1~20 dB (dB VRMS)

Horizontal

Position and

Scale

To move the FFT waveform

horizontally, press Horizontal until the

Frequency parameter is highlighted

and then use the Variable knob.

Range

0Hz ~ half of the sampling

frequency

To select the horizontal scale of the

FFT waveform, press Horizontal

repeatedly until the Hz/div parameter

is highlighted and then use the

Variable knob.

Background

The advanced math function allows complex math

expressions to be created based on the input

sources, reference waveforms or even the

automatic measurements available from the

Measure menu (see page 46).

An overview of each of the major parameters that

can be used in the advanced math function are

shown below:

Expression

Displays the function expression as it is created.

Source

Selects the source signal.

Source

CH1~4, Ref1~4

Function

Adds a mathematical function to the expression.

Function

Intg, Diff, log, Ln, Exp, Sqrt, Abs,

Rad, Deg, Sin, Cos, Tan, Asin,

Acos, Atan

Advanced Math Overview

72

Page 75

MEASUREMENT

Variable

Adds a user-specified variable to the expression.

Source

CH1~4, Ref1~4

Operator

Adds an operator or parenthesis to the function

expression.

Operator

+, -, *, /, (, ), !(, <, >, <=, >=, ==, !=,

||, &&

Figure

Adds a value to the expression.

Figure

Integers, floating point, or floating

point with exponent values.

Measurement

Adds automatic measurements to the expression.

Not all automatic measurements are supported.

Measurement

Pk-Pk, Max, Min, Amp, High,

Low, Mean, CycleMean, RMS,

CycleRMS, Area, CycleArea,

ROVShoot, FOVShoot, Freq,

Period, Rise, Fall, PosWidth,

NegWidth, Dutycycle, FRR, FRF,

FFR, FFF, LRR, LRF, LFR, LFF,

Phase, RPRFShoot, FPREShoot,

+Pulses, -Pulses, +Edges, -Edges

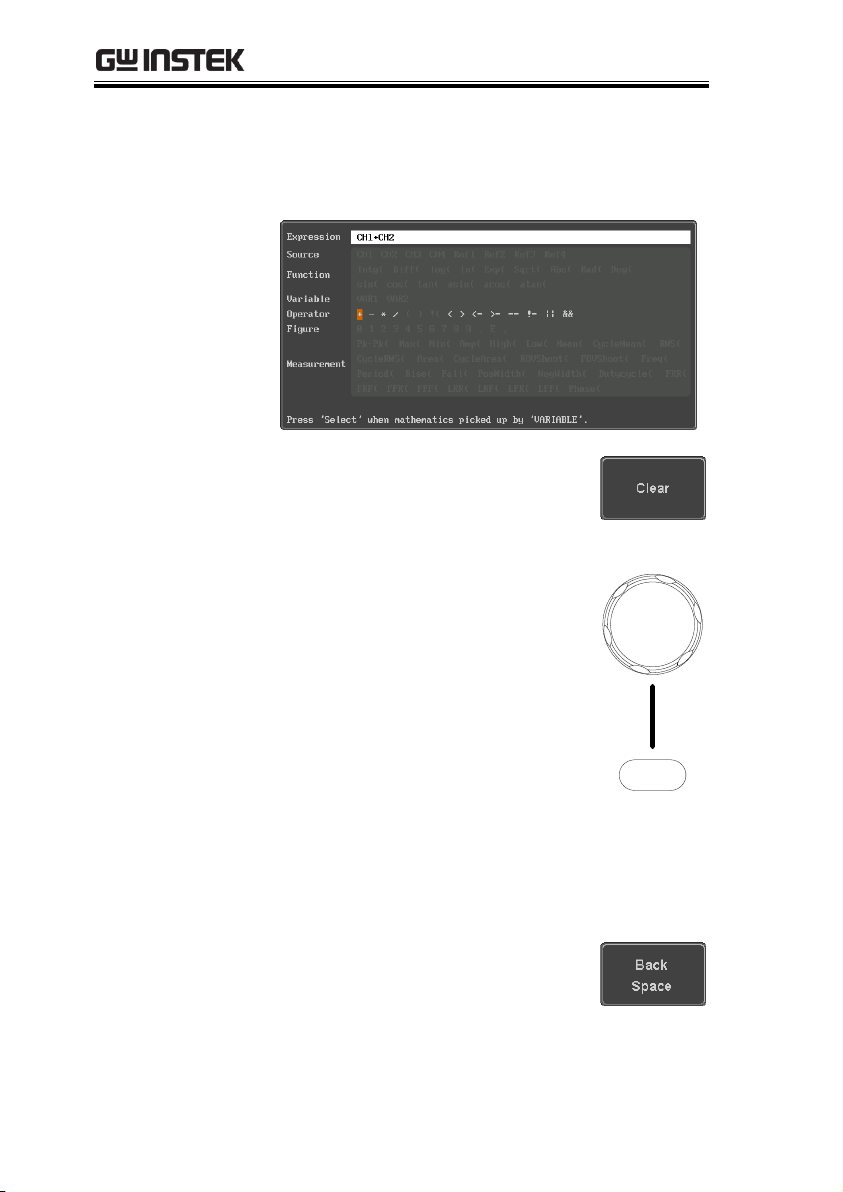

Panel Operation

1. Press the Math key.

M

MATH

2. Press Advanced Math from the

bottom menu.

3. Press Edit Expression.

Advanced Math Operation

73

Page 76

MDO-2000EG & 2000EX User Manual

4. The Edit f(x) screen appears. CH1 + CH2 is

shown in the expression box as an example at

startup.

5. Press Clear to clear the expression

entry area.

6. Use the Variable knob and the Select

key to create an expression.

Use the Variable knob to highlight a

source, function, variable,

operator, figure or measurement in

orange.

Press the Select key to make the

selection.

If a particular parameter is grayed

out, it indicates that the particular

parameter is not available at that

time.

Select

VARIABLE

Back Space

7. To delete the last parameter press

Back Space.

74

Page 77

MEASUREMENT

8. When the expression is complete,

press OK Accept.

Example:

CH1 + CH2

Advanced Math

Source1

Source2

Set the VAR1 &

VAR2

9. Press VAR1 or VAR2 to set

VAR1/VAR2 if they were used in

the expression created previously.

10. Press Mantissa.

Use the Left and Right arrow keys

to select a digit and use the

variable knob to set the value of

the selected digit.

11. Press Exponent.

Use the Variable knob to set the

exponent of the variable.

12. Press Go Back to finish editing

VAR1 or VAR2.

Vertical Position

and Scale

13. Press Unit/div and use the Variable

knob to set the vertical scale of the

math waveform.

75

Page 78

MDO-2000EG & 2000EX User Manual

14. Press Position and use the Variable

knob to set the vertical position of

the math waveform on the display.

Clear Advanced

Math

To clear the advanced math result

from the display, press the Math key

again.

MATH

M

76

Page 79

ADVANCED CONFIGURATION

Acquisition .............................................................. 80

Select Acquisition Mode ................................................................. 80

Show Waveform in XY Mode ....................................................... 82

Set the Record Length .................................................................... 84

Segmented Memory Acquisition .............................. 85

Segments Display ............................................................................. 87

Set the Number of Segments ......................................................... 87

Run Segmented Memory ................................................................ 88

Navigate Segmented Memory ........................................................ 90

Play Through Each Segment ......................................................... 91

Measurement on Segments ............................................................ 91

Segment Info .................................................................................... 96

Display .................................................................... 97

Display Waveform as Dots or Vectors ........................................ 97

Set the Level of Persistence ........................................................... 97

Set the Intensity Level ..................................................................... 98