Instanta WM3, WM3SS, WM7, WM7SS, WM15-3SS Installation And User Instructions Manual

...

WM SERIES Models:

WM3, WM3SS, WM7, WM7SS,

WM15-3SS, WM15-6SS & WM25SS

Auto-Fill, Wall-mount Catering

Water Boilers

Installation and User Instructions

INSTANTA LIMITED

Canning Road, Southport, Merseyside, PR9 7SN

Tel: (01704) 501114 Fax: (01704) 501115

IB21 – ISS: 03

The Professional’s Choice

2 3

CONTENTS & INTRODUCTION 2

SAFETY INFORMATION 2

ENVIRONMENTAL INFORMATION & DELIVERY CHECKLIST 3

TECHNICAL SPECIFICATION 3

INSTALLATION 4 - 5

OPERATION 5 - 6

REGULAR DAILY USE 6

ECO MODE 6

LCD & PROGRAM MODE 6 - 7

CLEANING 7

MAINTENANCE, SPARES & SERVICE INFORMATION 8

SERVICE WARNINGS & FAULT DIAGNOSTICS 8 - 9

FULL PROGRAM MENU 10

SERVICE/TECHNICAL SUPPORT/GUARANTEE 11

Introduction

Dear Customer,

Congratulations on the purchase of your

Instanta machine.

Your new boiler is designed to give years

of trouble-free service, provided that the

instructions contained in this manual are

followed.

All new series Instanta products are energy

ef cient, simple to operate and easy to service.

Find out more about Instanta products at

www.instanta.com

Safety Information

Please read the following carefully

before switching on this appliance:

A competent installation engineer should install

this appliance in accordance with the installation

instructions for this appliance and all relevant

local and national standards including the

following:

• Health and Safety at Work Act

• IEE regulations

• Local and national building regulations

• BS Codes of practice

• Water supply regulations

Your new water boiler is designed to provide

a constant source of near-boiling water for the

preparation of hot drinks.

Caution Safety: All personnel must be

provided with suf cient and appropriate

training in the safe use of this appliance.

• In line with Health and Safety requirements

we recommend that a risk assessment be

carried out after the boiler has been

installed.

• A warning notice, displayed next to the

machine, is often helpful in notifying users

that the appliance contains and dispenses

near-boiling water.

• Inform users that certain surfaces will

become hot (especially the draw off tap).

Care should be taken to avoid potential

injury from burns and scalding whilst

operating this appliance.

• The unit must be earthed.

• Always disconnect the unit from the power

supply before servicing

Environmental

(Information on Disposal for Users of Waste

Electrical & Electronic Equipment)

The “crossed out wheelie bin” symbol on

this product means that discarded electrical

and electronic products should not be mixed

with general waste. Disposing of the product

correctly will help to save valuable resources

and prevent any potential negative effects

on human health and the environment which

could otherwise arise from inappropriate waste

handling. For proper treatment, recovery and

recycling of end-of-life products, please contact

your dealer or supplier for further information,

or local authority for details of your nearest

designated collection point.

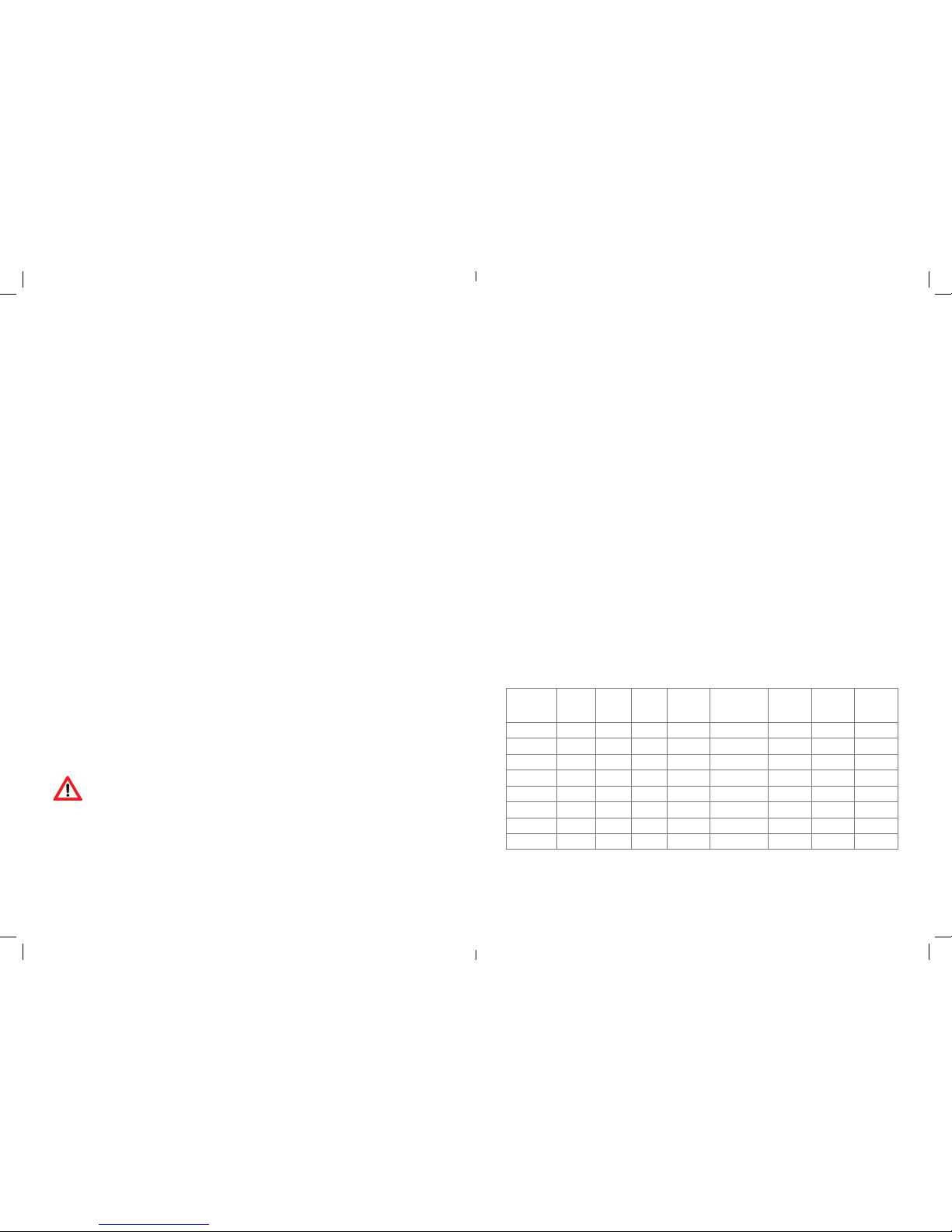

Model Width Depth Height Power

Rating

Rapid

Draw-off

Weight

(empty)

Weight

(full)

Water

Inlet

Pressure

mm mm mm kW Litres KG KG Bar

WM3 332 210 452 3 3 7.3 12.5 2 to 7

WM3SS 314 215 414 3 3 9.4 14.5 2 to 7

WM7 350 220 498 3 7 8.4 18.6 2 to 7

WM7SS 320 225 456 3 7 9.5 19.7 2 to 7

WM15-3SS 350 250 545 3 15 10.7 29 2 to 7

WM15-6SS 350 250 545 6 15 10.9 29.2 2 to 7

WM25SS 410 304 596 3 or 6 25 17.1 48 2 to 7

Technical Specifi cation

Outer casing is constructed from either impact

resistant plastic or Type-304 stainless steel.

The tank is made from Type-304 stainless steel

and the internal baf e-plates [for condensing

steam within the tank, are made from Type-316

stainless steel. The tank is fully insulated with

high-temperature polystyrene.

The appliance has electronic control of the main

functions. This means that the heating, lling

and temperature are controlled precisely within

given parameters.

Checklist

Before starting installation check that you have

the following parts:

1. Main Boiler Unit

2. Boiler Case

3. Paper Mounting Template

4. Fitting Kit (screws & wall-plugs etc.)

5. Instruction Booklet

54

Installation [All Models]

a) Positioning the unit

The boiler should be positioned in a convenient

place, on a wall that is capable of supporting it

safely (refer to section “Technical Specication”

for weight of boiler). Use the mounting template

and tting kit provided.

Position the boiler so that the tap is

approximately 400mm above a draining board.

Leave sufcient space around the unit to enable

access for servicing, paying particular attention

to the position of the top-centre xing screw that

holds the case in place.

When mounting on wall, screw in the top two

screws leaving about 6mm protruding and hang

the machine using the keyhole slots provided.

Once the machine is positioned, tighten the top

screws and insert the bottom screw.

b) Electrical Connection

3.0kW Units: (WM3, WM3SS, WM7, WM7SS,

WM15-3SS)

Supply: 230V, 50/60Hz (3.0kW).

The circuit should be protected by its own

13amp double pole connection unit with ex

outlet to BS5733, alternatively the circuit should

have means of disconnection incorporated in

xed wiring, having a contact separation of a

least 3mm in all poles. Minimum cable size is

1.5mm2. The use of an ELCB is recommended.

Base Entry of Cable: Use the cable gland.

Loosen cable-gripping nut and pass cable

through gland, leaving enough free cable to

connect to terminal block. Tighten cable gland

grip nut.

Alternative Rear Entry Installation (Electrical):

The xed or exible cable is connected direct

to the terminal block – the cable gland is not

utilised.

DO NOT SWITCH ON UNTIL THE

INSTALLATION IS COMPLETE AND THE

CASE AND TAP ARE IN PLACE

6.0kW Unit: (WM15-6SS)

Supply: 230V, 50/60Hz (6.0kW).

This unit is 6KW so must be connected to a

30amp isolator tted with a suitable ELCB.

Electrical installation should conform to current

I.E.E. wiring regulations.

3.0 or 6.0kW Unit: (WM25SS) - Optional on

installation

The 25 litre unit can be congured to either

3KW or 6KW.

As it leaves the factory it is congured to 3KW.

This can be changed to 6KW by tting the link

wire (supplied) to the second heating element.

NOTE:

If the unit is congured to 6KW then the unit

must be connected to a 30amp isolator tted

with a suitable ELCB. Electrical installation

should conform to current I.E.E. wiring

regulations.

In addition, the “Heater Rating” must be

changed in the Program Mode, from 3KW to

6KW (select “Set Heater Rating”). To access

Program Mode, follow instructions as on page 6

- WARNING: This appliance must be earthed.

- Electrical installation should conform to

current I.E.E. wiring regulations.

ONLY A QUALIFIED ELECTRICIAN SHOULD

CARRY OUT THIS WORK

c) Water Connection

The water supply must have a pressure not

exceeding 7bar and no lower than 2bar.

If the mains water pressure is below 2bar, a fault

situation could arise.

If the water pressure exceeds 7bar a suitable

water pressure reducing valve will need to be

tted to the water supply to bring it to a level

that the machine can cope with. Failure to do so

could result in the boiler overlling.

THE MANUFACTURERS CANNOT BE

HELD RESPONSIBLE FOR ANY MACHINE

MALFUNCTION IF THE WATER PRESSURE

IS NOT WITHIN THE RANGE STATED. IF IN

DOUBT, CONSULT YOUR WATER SUPPLY

COMPANY.

- Connect to a suitable cold water drinking

supply using 15mm copper pipe and using

“T” piece supplied.

- Push the “T” piece rmly onto the water

inlet solenoid pipe with the brass plug

facing forward (Note: the “T” has been

blanked off using a brass plug – leave the

plug in-place).

- Push the 15mm cold water supply rmly

into the bottom of the tting.

Alternative Rear Entry Installation (Water

Connection):

Remove the brass plug from “T” piece and

re-t into the bottom of the “T” piece instead.

Push rmly onto the inlet solenoid pipe with the

“T” facing the wall. Push the 15mm cold water

supply rmly into the “T” tting.

NOTE: To avoid damage to the appliance, do

not use any solder connections whilst pipes

are connected to the boiler.

- A 15mm stop valve must be tted between

the water supply and the boiler so that it

can be isolated.

- Water purication lters are available from

Instanta to ensure fresh tasting water.

In hard water areas, scale can cause

problems. Fitting a scale reducer will help

minimise scale but will not eliminate scale

completely.

d) Overow/Drain

The tting kit includes a 15mm, straight push-t

coupling with a small piece of 15mm copper

pipe pushed into it. NOTE: This connector

must be pushed onto the corresponding

brass overow connection on the services-

bracket (along side the solenoid).

If the overow is to be extended, remove the

copper pipe (supplied) and replace with 15mm

pipe of your chosen length. The pipe must have

a continuous fall and should not be longer than

300mm (if a longer run is required, use 22mm

pipe to avoid airlocks). The overow pipe should

have no more than four right angle bends and

should discharge to a safe, visible position.

Alternative Rear Entry Installation

(Overow/Drain):

If rear entry has been chosen, the straight

push-on coupling must be replaced with a

15mm push-t elbow (available from plumber’s

merchants). Push the elbow onto the brass

overow connection on the services bracket

(alongside the solenoid). As described above,

the pipe must have a continuous fall etc.

Under certain conditions the overow

pipe could vent steam, hot water or cold

water. The manufacturers cannot be held

responsible should damage occur from

such discharge, if the overow pipe has not

been directed to a suitable position where

overowing water can run away safely.

VENT PIPE:

A small silicone rubber tube connects the tanklid to the back panel. Ensure this is connected

(and hasn’t come off in transit) and that the

outlet tting in the back-panel is not obstructed.

e) Fitting Case:

- Stainless Steel Case Units Only: Attach

the Earth wire connection to the bottom of

the boiler-case (screw & washer supplied).

- Position the boiler-case close to the

wall-mounted boiler assembly and plug-in

the communications lead (located on inside

of boiler-case) into the circuit board.

- With the communications lead connected,

offer up the case to the wall-mounted boiler

assembly, aligning the tap and plastic

spring-mounted tap moulding with the

cut-out in the boiler-case.

- Secure case in position using M4 screws

(supplied) at top and bottom of the case.

- Slide the grey tap collar along the chromed

tap assembly so that it ts snugly against

the plastic tap moulding.

Operation

First use (once water and electrical connections

have been made):

NOTE: If the “7-day Timer” or “Filter Monitor”

features are not required, the boiler can be

used without any program set-up.

Simply switch the machine on by pressing the

small button at the top of the LCD window.

Loading...

Loading...