Insta 718, 728, 828 Operation And Maintenance Manual

MNL90002 Rev. P 02.16.15

OPERATION AND MAINTENANCE MANUAL

MODEL 718/728/828

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety Summary

International Symbols

the local distributor

Protective Earth

Terminal

During normal operation, the

100

DISENGAGE

switch

WARNING

In case of power cord damage,

do not attempt to repair or

replace the power cord.

Contact the manufacturer or

.

Power Off

Power On

WARNING

For protection against fire and

electric shock, replace with

same type and rating fuse.

Fuse rated max. 1 amp 120V.

WARNING

Hot Surface. Avoid contact.

CAUTION

base of the machine needs to

be installed or placed above

the wall socket.

CAUTION

The recommended input

pressure shall not exceed

psi. The operating pressure is

from 30 – 100 psi.

Hot Surface

Risk of Electrical Shock

Start Action

Disengage

Ground

Caution - Warning

CAUTION

The operation may be

terminated by pressing the

CAUTION

The machine is to be operated

by one person only.

CAUTION

To reduce the risk of electric

shock and injury to persons,

disconnect from power supply

1

before servicing and /or

cleaning.

.

FOR USE BY QUALIFIED PERSONNEL ONLY

Congratulations!

Limited Machine Warranty

o

innovation in the heat

sealing field, insures the

oeocedae

Thi

o cla

oca o a y ds a begeae a ou a

Your selection of the Insta Graphic Systems heat seal

machine is a sound business decision. Insta

equipment is the result of the highest quality

engineering and time-tested design. Your new

machine combined with Insta's reputation of

continuing capability of delivering the best-decorated

substrates possible.

This manual describes installation, operation, and

maintenance procedures for your 700/800 series

machine, as well as easy to use instructions for onthe-spot maintenance.

Your machine will have a long, trouble free life. Read

this manual. Keep it with your machine; it's your key

to proper operation and lasting service.

General Description

The 718, 728 and 828 are Automatic Swing Away

machines generating and distributing evenly

tremendous pressure throughout its upper and lower

platens. These machines are essential in the

application of sublimation transfers. Its cast-in tubular

heating element heats the metal from within, to

produce constant and long lasting heat. The 718

machine has 15” x 15” platens; the 728 has 15” x 20”

platens; the 828 has 20” x 25” platens.

Insta Graphic Systems warrants this heat seal

machine, when operated under normal conditions, to

be free from manufacturing defects in material and

workmanship for a period of one year on parts

(lifetime on the heating element) and 90 days on labor

m the invoice date.

fr

This warranty will be effective only when Insta

authorizes the original purchaser to return the product

to the factory in Cerritos, California, freight prepaid,

and only when the product upon examination has

proven to be defective.

s warranty does not apply to any machine that has

been subjected to misuse, negligence or accident.

Insta shall not be liable for the injury, loss or damage,

direct or consequential, arising out of the use or the

inability to use the product.

N

the sale price of the product or part to which claim is

made.

This is the sole warranty given by the company, it is in

lieu of any other warranties, expressed or implied, in

law or in fact, including the warranties of

merchantability and fitness for a particular use, and is

accepted as such by the purchaser in taking delivery

of this product.

im of any kind shall be greater in amount than

2

FOR USE BY QUALIFIED PERSONNEL ONLY

D

p

effectiveness against the following:

mm) shall be used.

di

Digitsolid object

Digitmoist

2jg

2

when tilted up to

Model 728

1750 Watts

Amps

8

Installation

DOMESTIC – 700 SERIES

Use a separate 15 amp AC circuit.

Only industrial extension cords with

proper wire size should be used:

size 16/3 wire for distances up to 25

feet, and size 14/3 for distances up

to 50 feet.

INTERNATIONAL – 700 SERIES

Use a designated 16 amp AC

circuit. Only industrial extension

cords with proper wire size (2.5 sq.

DOMESTIC – 800 SERIES

Use a separate 230/240 20 amp AC

circuit. Only industrial extension

cords with proper wire size should

be used: size 16/3 wire for distances

up to 25 feet, and size 14/3 for

stances up to 50 feet.

egree of Protection

IP (Ingress Protection) rating according to IEC

60529.

NOTE

IEC 60529 does not specify sealing

mechanical damage of the equipment; the

risk of explosion; certain types of liquid

conditions, e.g. those that are produced by

condensation; corrosive vapours; funus;

vermin

IP54=IP

st

1

Digit5

nd

2

Digit4

st

1

Protection from

s

nd

2

Protection from

ure

INTERNATIONAL – 800 SERIES

Use a designated 20 amp AC

circuit. Only industrial extension

cords with proper wire size (3.3 sq.

mm) shall be used.

Specifications

MODEL 718/728/828

Voltage 120 Volts AC 50/60 Hertz

Model 718 1500 Watts 12.5Amps

14.6

Voltage 240 Volts AC 50/60 Hertz

Model 718 1500 Watts 6.3 Amps

Voltage 230 Volts AC 50/60 Hertz

Model 728 2200 Watts 9.6 Amps

Model 828 3300 Watts 14.4 Amps

Model 718 Machine Weight 128 Pounds (58.1 KG)

Model 728 Machine Weight 143 Pounds (64.9 KG)

Model 828 Machine Weight 218 Pounds (98.9 KG)

0 Non protected 0 Non protected

1

3

4

Objects greater

than 50mm

Objectsgreater

than 12mm

Objects greater

than 2.5mm

Objects greater

than 1mm

1 Dripping water

Dripping water

15 deg.

3 Spraying water

4 Splashing water

5 Dust protected 5 Water jets

6 Dust tight 6 Heavy seas

-- --- 7

-- ---

.15m – 1m

immersion

1m +

submersion

3

O

peration

maintenance. Make sure your hands

g

suitable environmental conditions

3.D

shall

not operate

unless the upper

8.Depress and hold both start buttons

automatically at the end of the selected timing

FOR USE BY QUALIFIED PERSONNEL ONLY

1. Push POWER/MODE button on the controller

to turn ON machine. Hold POWER/MODE for

3 seconds to turn off machine.

2. Set desired temperature and select the

desired timing cycle (see controller operation).

Swing the upper platen arm to its fully open

position, away from lower platen.

3. Allow the machine to warm up until the

selected temperature is reached.

4. Set the desired pressure by adjusting the air

pressure regulator.

5. Place the substrate on lower platen,

smoothing out all wrinkles.

6. Position transfer or lettering on substrate.

7. Swing the upper arm into position directly

over the lower platen.

9. Swing away the upper platen to the opposite

side and remove substrate.

10. The DISENGAGE button may be pushed at

anytime to deactivate the machine.

NOTE

The air filter may be loose a little to

hinder the bowl from breaking

during handling. Do not touch the

polycarbonate bowl with synthetic

grease during operation and

are clean before touching the air

filter bowl.

Environmental Conditions

Only operate Insta heat seal machines under

.

1. Placed on a even, non flammable surface.

SAFETY DELAY FEATURE

For operator safety the machine

platen has fully reached the left

hand position. An additional safety

delay has been incorporated in

machines running software 2.29

(see point 8).

simultaneously until the lower platen contacts

the upper platen. The start buttons must be

held until the upper and lower platens

make contact. At this point the machine

operation is fully automatic. The platens seal

the transfer to the substrate and then release

cycle.

2. Can support a minimum of 300 lbs. if placed

above a platform.

o not restrict access to the main power

switch.

4. Maintain a clearance around any forms of

liquid.

5. Do not over extend the power cord.

6. The operational voltage should not be 10%

max/min of the rated value.

7. Avoid voltage spikes.

8. Sound pressure level at operator station does

not exceed 70dB (A).

4

FOR USE BY QUALIFIED PERSONNEL ONLY

C

gg

y

button until timer is displayed

Program #1 could be set for 325

F and 10

program

Note: there is also a sixth setting

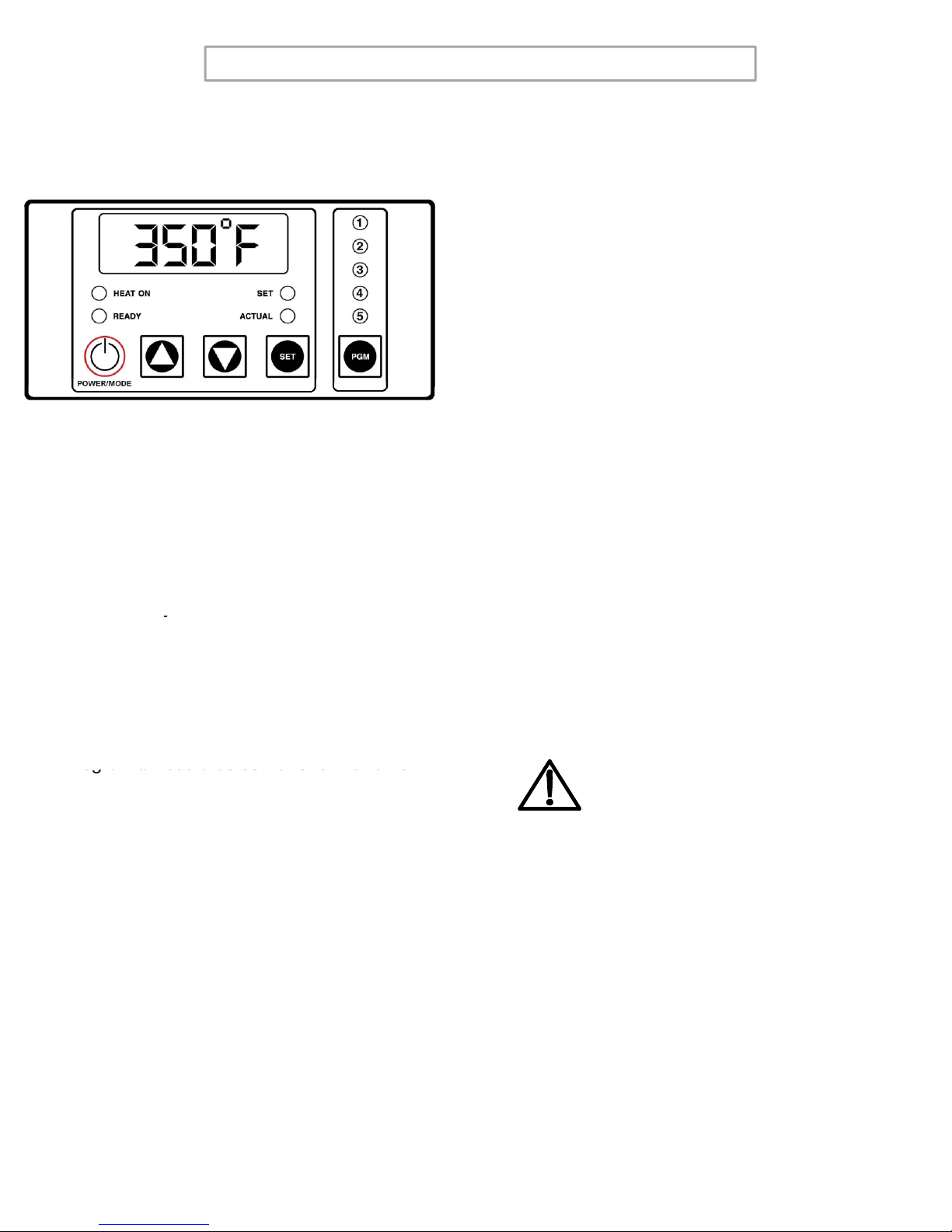

Solid State Controller:

Model 718 shown

This controller has three (4) control features:

1. Temperature - Temperature can be set from

125 - 450°F (52-232°C).

2. Time - Time can be set from 1 second to 10

minutes.

3. Counter –Cycle counter counts the number of

applications from 1 to 9999 (see additional

Notes – Counter).

4. Presets - Five (5) presets that can be

programmed by the user. Each preset will

retain a temperature and time setting, i.e.

°

seconds while Program #2 could be set for

375°F and 15 seconds. Once the five presets

have been programmed, the user need only

press the PGM button repeatedly until the

desired program is selected. The lit LED

above the PGM button indicates the selected

.

that is indicated by no lit LED's.

ontroller Operation

1. Select the desired preset program by pressing

the PGM button until the LED above the PGM

button indicates the desired setting.

2. If a setting other than the programmed

presets are desired, press the PGM button

until none of the LED's above the PGM

button are lit.

3. Changing the Temperature

• Press the POWER/MODE (or MODE)

button until temperature is displayed.

• Press and hold SET button in while

pressing the UP (↑) or DOWN (↓) arrow

buttons to the desired temperature

setting.

4. Changing the Timer

• Press the POWER/MODE (or MODE)

.

• Press and hold SET button in while

pressing the UP (↑) or DOWN (↓) arrow

buttons to the desired timer setting.

NOTE

The DISENGAGE switch (located in

the center of the instrument panel)

may be pushed at any time to

deactivate the machine. The cycle

will stop immediately, and the timer

will reset.

5

FOR USE BY QUALIFIED PERSONNEL ONLY

Setti

NOTE

gp

running

NOTE

button until time is displayed.

g,

(

↑

)

g, p

(

)

ng the Presets

1. Push and hold both the POWER/MODE (or

MODE) and PGM buttons for 3-5 seconds

until one of the programs LED's starts to blink.

This is the programming mode.

2. A blinking LED above the PGM button

indicates which preset is active.

3. Select a program (1,2,3,4,or 5) by pressing

the PGM button.

4. Setting Temperature

• Press the POWER/MODE (or MODE)

button until temperature is displayed.

• Press and hold SET button in while

pressing the UP (↑) or DOWN (↓) arrow

buttons to the desired temperature

setting.

If a Fahrenheit/Celsius change is

desired, see Additional Notes –

Temperature.

5. Setting Time

• Press the POWER/MODE (or MODE)

When the machine is operating with

none of the five program LED's lit,

i.e. no presets, the time and

temperature WILL BE SAVED even

if the power is turned off. The

presets will also be saved when the

power is turned off.

Additional Notes

Timer

• The controller has a count down timer, which

automatically disengages (opens) the machine

at the completion of the application.

• Timer display is minutes:seconds. Range is

00:00 to 10:00, Colons (:) flash while timer is

.

NOTE

The DISENGAGE switch (located in the

center of the instrument panel) may be

pushed at any time to deactivate the

machine. The cycle will stop

immediately, and the timer will reset.

• Press and hold SET button in while

pressing the UP (↑) or DOWN (↓) arrow

buttons to the desired timer setting.

6. Repeat steps 3-5 until all five (5) presets have

the desired preset (temperature/time cycle).

7. Push and hold both the POWER/MODE (or

MODE) and PGM buttons for 3-5 seconds

until a single beep sound is heard to exit the

programming mode.

NOTE

When in the normal mode, none of the

five program LED's will be blinking and

the user cannot change the time and

temperature for any of the five presets.

6

Counter

The controller has a built in cycle counter.

• Press POWER/MODE (or MODE) button until

the counter is displayed.

• Counter display range is 0000 to 9999.

• To reset the cycle counter, display the counter

readin

DOWN (↓) arrow buttons for 3 seconds until

the counter resets to zero (0000) on the

display.

then push and hold UP

and

Loading...

Loading...