Inspur NF5166M4 User Manual

© Copyright Inspur 2016. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any

means without prior written consent of Inspur.

The information in this manual is subject to change without notice.

Inspur is the registered trademark of Inspur. All the other trademarks or registered

trademarks mentioned in this manual are the property of their respective holders.

Edition: 1

June 2016

Abstract

This manual contains technical information such as specications, hardware

operations, software conguration, fault diagnosis, etc. that are relevant to the

maintenance and operation of this server.

It is recommended that server installation, conguration, and maintenance to be

performed by experienced technicians only.

Target Audience

This manual mainly adapts to the following personnel:

● Technical support engineers

● Product maintenance engineers

It is suggested that server maintenance operation shall be carried out by professional

engineers with related server knowledge via referring to this manual.

Warnings:

TThis manual introduces the server’s technical features, system installation and

setup, which will help the user to understand how best to utilize the server and all its

functionalities.

1.For your safety, please do not disassemble the server’s components arbitrarily.

Please do not extend conguration or connect other peripheral devices arbitrarily. If

needed, please contact Inspur for our support and guidance.

2.Before disassembling the server’s components, please be sure to disconnect all

the power cords connected to the server.

3.BIOS and BMC setup is a signicant factor in correctly conguring your server. If

there are no special requirements, it is suggested to use the default values and not

alter the parameter settings arbitrarily.

4.Please use the driver shipped with the server or provided in Inspur ofcial website , if

you use non-Inspur driver, it may cause compatibility issues and affect the normal use of

the product, Inspur will not assume any responsibility or liability.

The manufacturer is not responsible for any damages, including loss of prots, loss of

information, interruption of business, personal injury, and/or any damage or consequential

damage without limitation, incurred before, during, or after the use of our products.

Table of Contents

1 Safety Instructions ........................................................................................... 1

2 Product Specications ..................................................................................... 6

2.1 Introduction ............................................................................................... 6

2.2 Features and Specications ...................................................................... 6

2.3 Front Panel ............................................................................................... 7

2.4 Rear Panel ................................................................................................ 8

2.5 Motherboard Layout .................................................................................. 9

2.6 CLR_CMOS Jumper Introductions............................................................ 10

3 BIOS Setup ...................................................................................................... 11

3.1 System BIOS Setup Methods ................................................................... 11

3.2 BIOS Settings ........................................................................................... 12

3.3 BIOS Update ............................................................................................. 62

4 BMC Settings ................................................................................................... 67

4.1 Introduction ............................................................................................... 67

4.2 Functional Modules ................................................................................... 68

4.3 Web Interface Introduction ........................................................................ 69

4.4 Command Line Introduction ...................................................................... 97

4.5 Time Zone Table ....................................................................................... 111

4.6 Key Features ............................................................................................. 113

5 Hardware Maintenance .................................................................................... 115

5.1 Tool Preparation ....................................................................................... 115

5.2 Parts Replacement ................................................................................... 115

6 Common Faults, Diagnosis and Troubleshooting ............................................ 126

6.1 Common Faults ......................................................................................... 126

6.2 Diagnosis and Troubleshooting Instructions ............................................. 127

7 Certications & Standards ............................................................................... 130

7.1 USA FCC Declaration ............................................................................... 130

7.2 CE Declaration of EU ................................................................................ 130

7.3 China CCC ................................................................................................ 131

7.4 China Environmental Labeling .................................................................. 131

Global Limited Warranty and Technical Support ................................................ 133

Hardware limited warranty .............................................................................. 133

How to obtain warranty service ...................................................................... 139

Types of warranty service ............................................................................... 140

Contacting Inspur ............................................................................................ 141

1 Safety Introduction

Warning: the following warnings show that there are potential dangers that may

cause property loss, personal injury or death:

1. The power supply equipment in the system may generate high voltage and

dangerous electrical energy and thus cause personal injury. Please do not

dismount the cover of the host or to dismount and replace any component in

the system by yourself, unless otherwise informed by Inspur; only maintenance

technicians trained by Inspur have the right to disassemble the cover of the

host, dismount and replace the internal components.

2. Please connect the equipment to appropriate power supply, and the power

should be supplied by external power supply which is indicated on the rated

input label. To prevent your equipment from damages caused by momentary

Safety Introduction

spike or plunge of the voltage, please use relevant voltage stabilizing equipment

or uninterruptible power supply equipment.

3. If extended cables are needed, please use the three-core cables matched with

correct earthed plug, and check the ratings of the extended cables to make sure

that the sum of rated current of all products inserted into the extended cables do

not exceed 80% of the limits of the rated currents of the extended cables.

4. Please be sure to use the supplied power supply component, such as power

lines, power socket (if supplied with the equipment) etc. For the safety of

equipment and the user, do not replace randomly power cables or plugs.

5. To prevent electric shock dangers caused by leakage in the system, please

make sure that the power cables of the system and peripheral equipment are

correctly connected to the earthed power socket. Please connect the three-

core power line plug to the three-core AC power socket that is well earthed and

easy to access, be sure to use the earthing pin of power lines and do not use

the patch plug or the earthing pin unplugged with cables. In case of the earthing

conductors not installed and it is uncertain whether there are appropriate

earthing protections, please do not operate or use the equipment. Contact and

consult with the electrician.

1

6. To avoid short circuit of internal components and re or electric shock hazards,

please do not ll any object into the open pores of the system.

7. Please place the system far away from the cooling plate and at the place with

heat sources, and be sure not to block the air vents.

8. Be sure not to scatter food or liquid in the system or on other components, and

do not use the product in humid and dusty environment.

9. The replacement of batteries with those of another model may cause explosion.

When replacement of batteries is required, please consult rst the manufacturer

and choose batteries of the same or a similar model recommended by the

manufacturer. Do not dismount, extrude and pink the batteries or make

the external connection point short circuit, and do not expose them in the

environment over 60°C. Never throw them into re or water. Please do not

try to open or repair the batteries, and be sure to reasonably deal with the at

batteries and do not put the at batteries, the circuit boards that may include

the batteries and other components with other wastes. For relevant battery

recovery, please contact the local waste recovery and treatment mechanism.

10. Before installing equipment in the chassis, please install front and side

supporting feet on the independent chassis; for cabinet connecting with

other chassis, it shall install the front supporting foot rst. If you fail to install

correspondingly the supporting foot before installing equipment in the chassis, it

may cause the cabinet to turn over in some cases, and thus may cause personal

injury. Therefore, it is necessary to install supporting feet before installing

equipment in the chassis. After installing the equipment and other components

in the chassis, it can only pull out one component from the cabinet through its

sliding component at one time. Pulling out several components at the same time

may lead the cabinet to turn over and cause serious personal injury.

11. Please do not move the chassis independently. Considering the height and

weight of the chassis, at least two people are needed to complete its movement.

12. Please do not carry out direct contact operation on power copper busbar when

the cabinet is powered on, and it is prohibited to carry out direct short circuit of

power copper busbar.

13. The product is Grade A product, and in the living environment, it may cause radio

interference. In such case, it may need the user to take feasible measures for the

2

Safety Introduction

interference.

Note: In order to help you use the equipment, the following considerations can help

avoid the occurrence of problems that may damage the components or cause data

loss etc.

1. In case of the following cases, please unplug the power line plug of products

from the power socket and contact customer service department of Inspur:

1) The power cables, extended cables or power plugs are damaged.

2) The products get wet by water.

3) The products have fallen off or been damaged.

4) Objects fall into the products.

5) When operating according to the operation instructions, the products cannot

function normally.

2. If the system becomes damp, please dispose according to the following steps:

1) Switch off the power supplies of the system and the equipment, disconnect

them with the power socket, wait for 10 to 20 minutes, and then open the

cover of the host.

2) Move the equipment to the ventilation place to dry the system at least for 24

hours and make sure that the system is fully dried.

3) Close the cover of the host, re-connect the system to the power socket, and

then start the equipment.

4) In case of operation failure or abnormal situation, please contact Inspur and

get technical support.

3. Pay attention to the position of the system cables and power cables, wire them

in places not to be stepped on or knocked down and ensure not to place other

objectives on the cables.

4. Before dismounting the cover of host or contacting the internal components, you

shall cool down the equipment rst; to avoid damaging the main-board, please

power off the system and wait for 5 seconds, and then dismount the components

from the main-board or disconnect the connection of peripheral equipment of

the system.

5. If there are modulator-demodulator, telecommunication or local area network

options in the equipment, please pay attention to the following matters:

3

1) In case of thunder and lightning weather, please do not connect or use the

modulator-demodulator. Otherwise, it may be subject to lightning strike.

2) Never connect or use modulator-demodulator in moist environment.

3) Never insert the modulator-demodulator or telephone cables to the socket of

network interface controller (NIC).

4) Before unpacking the product package, contacting or installing internal

components or contacting un-insulated cables or jacks of the modulator-

demodulator, please disconnect the modulator-demodulator cables.

6. In order to prevent the electrostatic discharge from damaging the electronic

components in the equipment, please pay attention to the following matters:

1) You shall conduct off the static electricity on the body before dismounting

or contacting any electronic component in the equipment. You can conduct

off the static electricity on the body by contacting the metal earthing objects

(such as the unpainted metal surface on the chassis) to prevent the static

electricity on the body from conducting itself to the sensitive components.

2) For electrostatic sensitive components not ready to be installed for

application, please do not take them out from the antistatic package

materials.

3) During the work, please touch the earthing conductor or the unpainted metal

surface on the cabinet regularly to conduct off the static electricity on the

body that may damage the internal components.

7. When dismounting the internal components with the approval of Inspur, please

pay attention to the following matters:

1) Switch off the system power supply and disconnect the cables, including

disconnecting any connection of the system. When disconnecting the

cables, please grab the connector of cables and plug it out, and never pull

the cables.

2) Before dismounting the cover of cabinet or touching the internal

components, the products need to be cooled down.

3) Before dismounting and touching any electronic component in the

equipment, you shall conduct off the static electricity on the body by

touching the metal earthingobjectives.

4) During the dismounting process, the operation shall not be too big, so as to

4

Safety Introduction

prevent damage to the components or scratching of the arms.

5) Carefully deal with the components and plug-in cards, and please never

touch, the components or connection points on the plug-in cards. When

taking the plug-in cards or components, you should grab the edges of the

plug-in cards or components or their metal xed supports.

8. During the process of cabinet installation and application, please pay attention

to the following matters:

1) After the installation of cabinet is nished, please ensure that the supporting

feet have been xed to the rack and supported to the ground, and all weight

of the rack have been fell onto the ground.

2) It shall install into the cabinet according to the sequences from the bottom to

the top, and rst install the heaviest component.

3) When pulling out the components from the cabinet, it shall apply force

slightly to ensure the cabinet to keep balance and stabilization.

4) When pressing down the release latch of the sliding rail of components and

sliding in or out, please be careful, as the sliding rail may hurt your gures.

5) Never make the AC power branch circuit in the cabinet overload. The sum

of cabinet load shall not exceed 80% of the ratings of branch circuits.

6) Ensure that components in the cabinet have good ventilation.

7) When repairing components in the cabinet, never step on any other

components.

5

2 Product Specications

2.1 Introduction

NF5166M4 is a 1U high-density storage server, supporting up to 2 Intel XEON E526**V4 processors, 16 DDR4 DIMMs, 12 3.5-inch hot-plug SAS/SATA hard disks,

4 2.5-inch hot-plug SSDs, and 2 M.2 SSDs of 2280 specication; there are 2 1GbE

network ports on the motherboard; supporting OCP NIC slot; the system uses 700W

1+1 redundant power supply.

2.2 Features and Specications

Processor

Processor type Intel 2-socket XEON E5-2600V4 series (up to 2 135w processors)

Processor interface Socket-R3 (2)

Chipset

Chipset type PCH C612 (Wellsburg)

Memory

Memory type DDR4 ECC RDIMM/LRDIMM

Memory slot Qty. 16

Total memory capacity Support up to 512GB (32G per DIMM)

I/O interface

USB interface 2 rear USB 2.0 interfaces, 1 front USB 2.0 interface

Display interface 1 rear VGA interface

Serial Interface 1 rear serial interface

ID LED interface 1 ID LED (blue) and button

Display controller

Controller type Integrated in Aspeed2400 chip, support up to 1280*1024 resolution

SAS backplane

SAS backplane

Management chip

Management chip

NIC

NIC controller

6

The internal SAS backplane supports hot-plug SAS/SATA HDDs.

The front SAS backplane supports hot-plug SSD HDDs.

Integrate 1 independent 1000Mbps network interface, special for

IPMI remote management.

1 onboard Intel I350 dual-port Gigabit NIC, provide 2 1000M

adaptive RJ45 network interfaces; support 1 external network

daughter card.

PCI expansion slot

Product Specications

PCI expansion slot

HDD

HDD type

External memory driver

USB drive Optional USB drive

Power supply

Specications

Power input Please refer to the nameplate label on the host

Physical specications

Package size W(width)721mm; H(height)279mm; D(depth)1168mm

Host size W(width)447mm; H(height)43mm; D(depth)900mm

Weight

2 onboard PCI Express 3.0 x8 slots (non-standard interfaces,

used for supporting network daughter card and SAS card)

Support up to 4 front 2.5-inch SSD HDDs, 12 internal 3.5-inch

SAS/SATA HDDs or 2.5-inch SAS HDDs, and 2 M.2 SSD HDDs.

700W and above output power; 1+1 redundancy; 2 power

modules; support PMBus power supply, realize Node Manager

3.0 function

Full conguration

Host weight: 30kg

Gross weight:41kg (it includes: Host + Packing box + Rail +

Parts box)

Environment parameter

Operating environment

temperature

Storage and transport

temperature

Operating humidity 35%-80% relative humidity

Storage and transport

humidity

10℃-35

-40℃-55

20%-93% (40℃) relative humidity

℃

℃

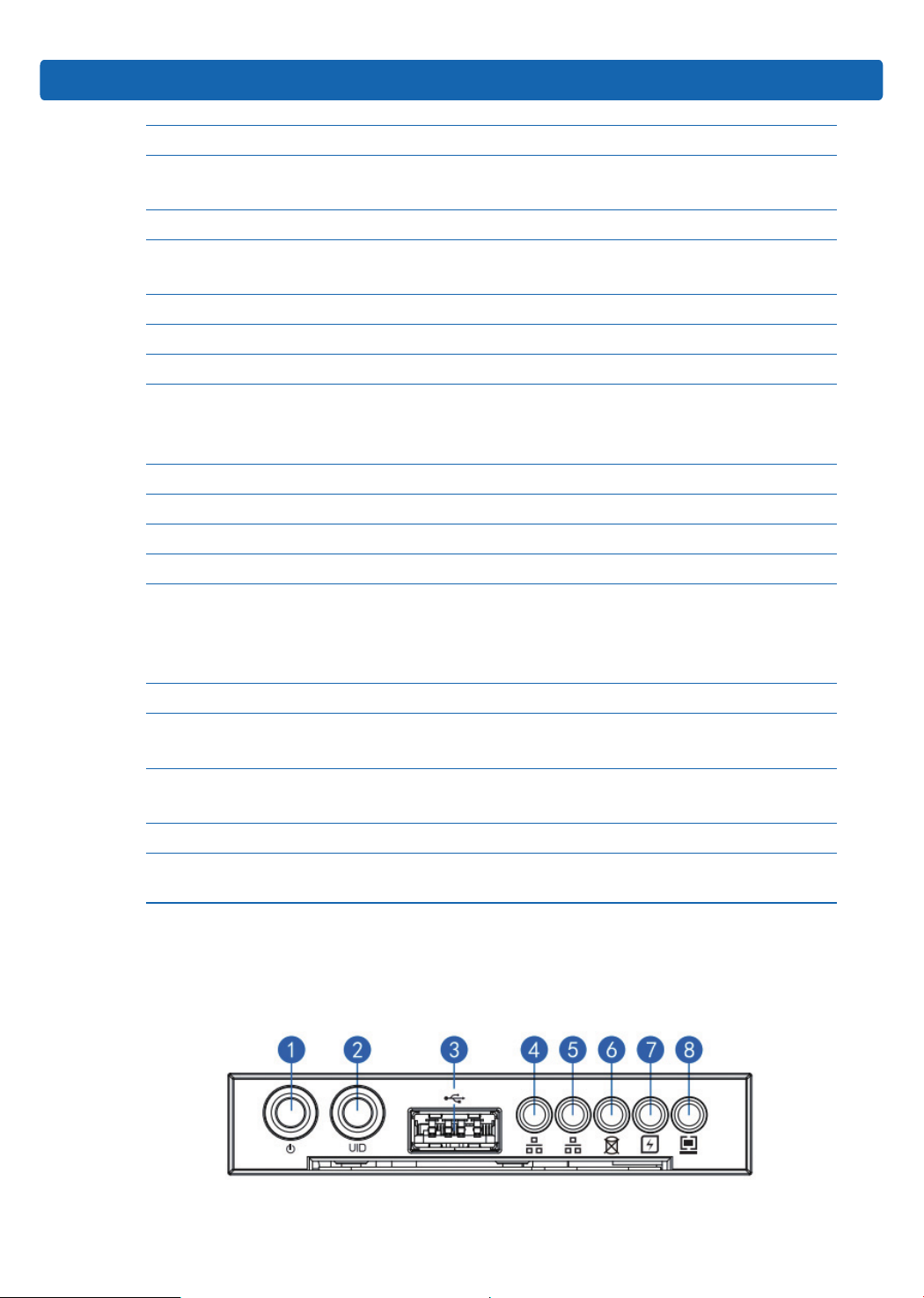

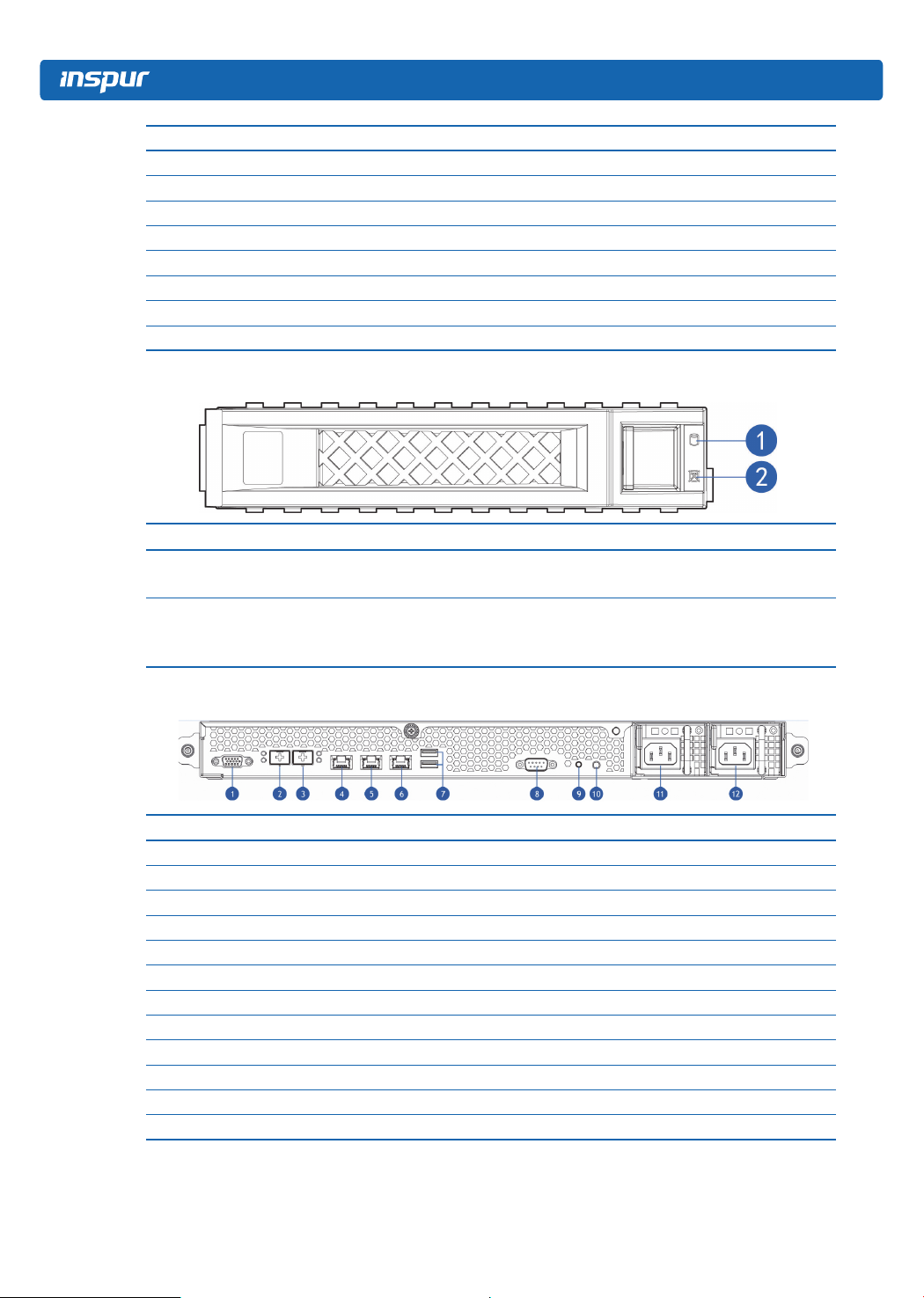

2.3 Front Panel

2.3.1 Buttons and LEDs on the Front Panel

7

No. Name

1 Server switch button

2 ID light and button

3 USB interface

4 NI0 status LED

5 NI1 status LED

6 HDD fault LED

7 Power fault LED

8 System fault LED

2.3.2 LEDs on the HDD Bracket

No. Name Description

1 HDD activity status LED

2 HDD fault alarm LED

Steady green: normal

Blinking green: HDD is going on read-write activity

Steady red: HDD fails

Steady blue: HDD locating

Steady blue: RAID Rebuilding

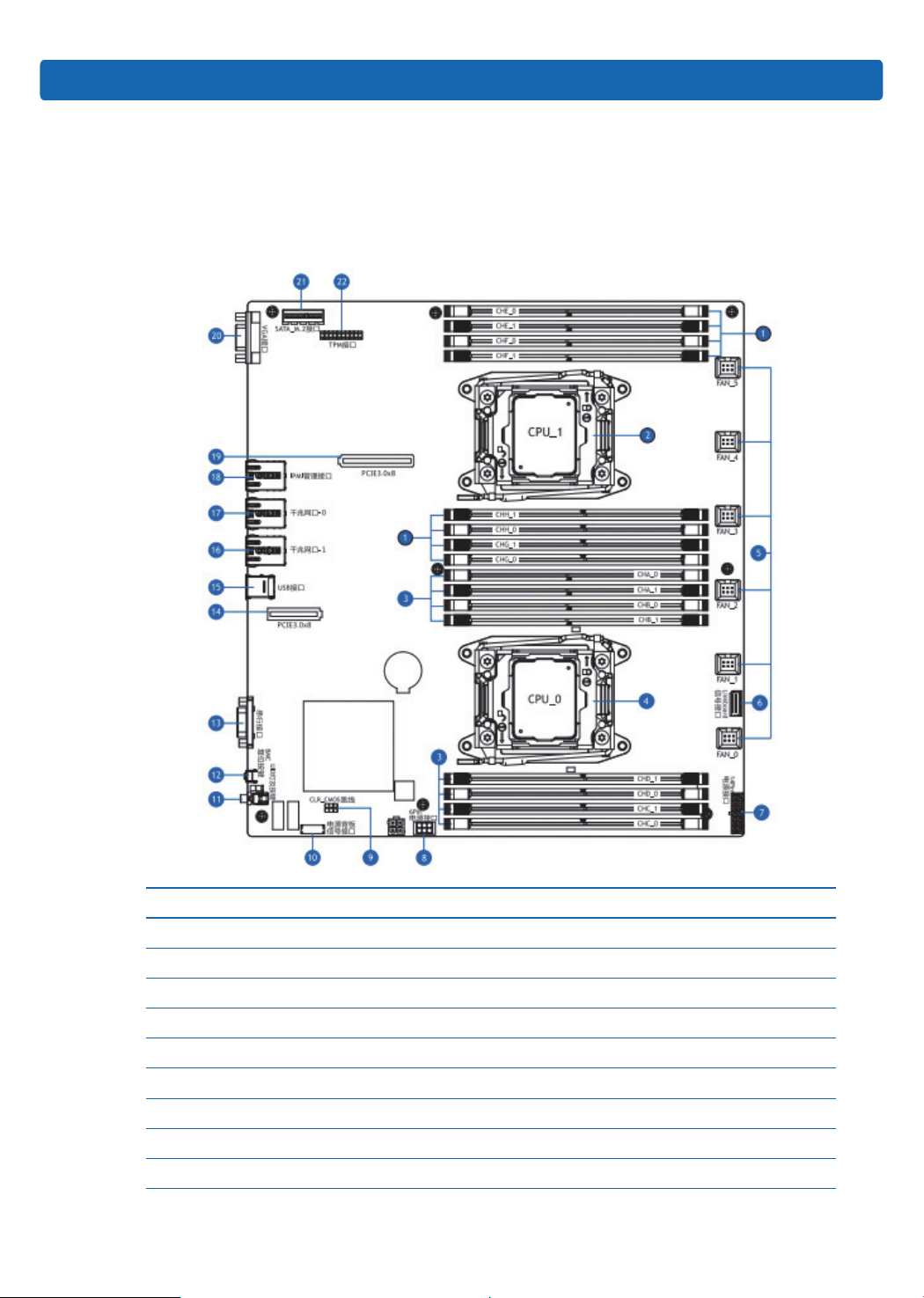

2.4 Rear Panel

No. Name

1 VGA interface

2 10 GbE port 1

3 10 GbE port 0

4 IPMI management interface

5 GbE port 0

6 GbE port 1

7 USB port

8 Serial interface

9 BMC reset button

10 UID LED and button

11 PSU1

12 PSU0

Note: according to system settings, the external 10 Gigabit NIC has a higher priority

than Gigabit NIC.

8

For example: if the server is congured with an external dual-port 10 Gigabit NIC,

the priority is 10 GbE port0> 10 GbE port1> GbE port0> GbE port1.

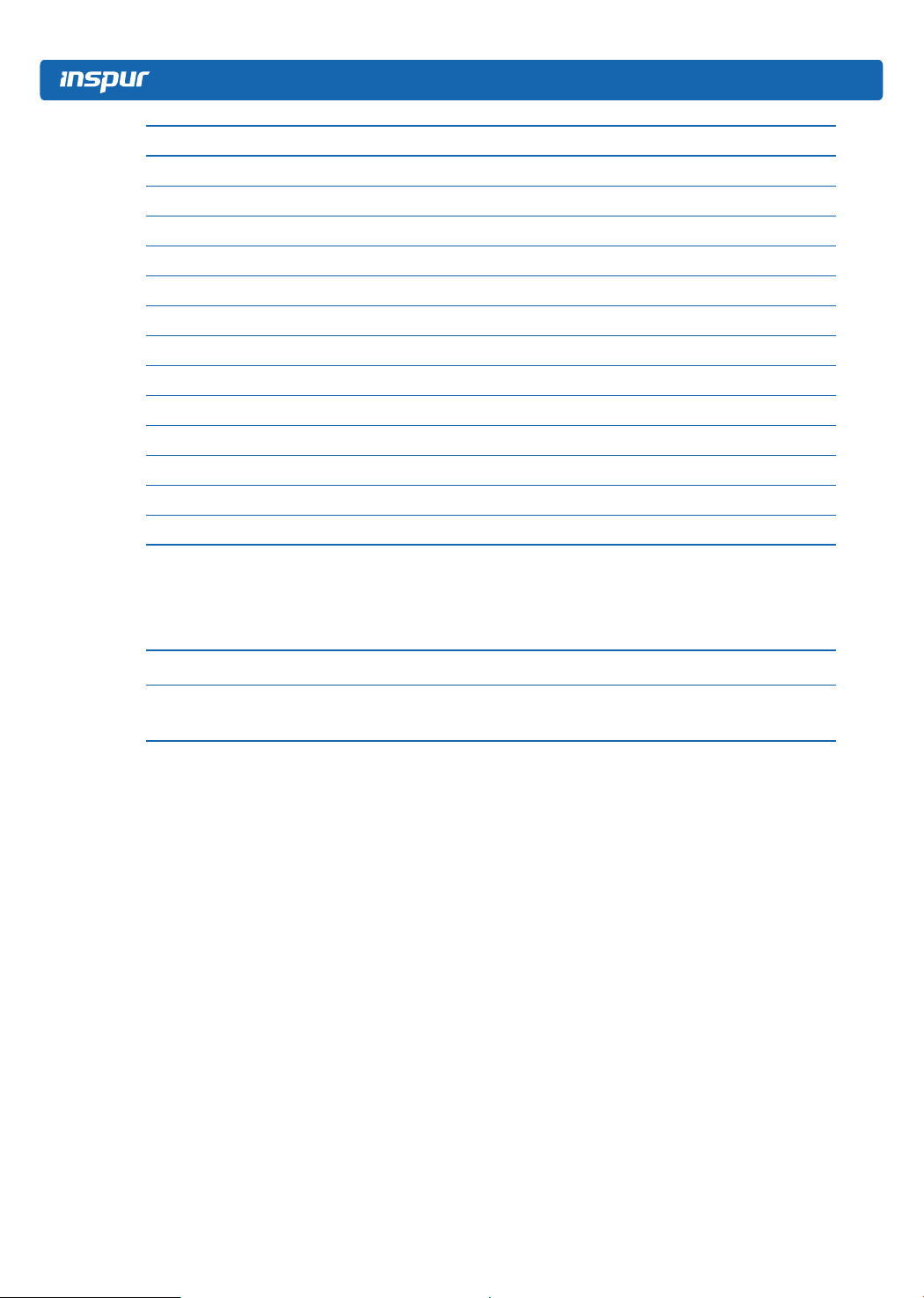

2.5 Motherboard Layout

Product Specications

No. Name

1 DIMMs (corresponding to CPU1)

2 CPU1

3 DIMMs (corresponding to CPU0)

4 CPU0

5 System fan interface (6)

6 Linkboard signal interface

7 14pin power interface

8 6pin power interface

9 CLR_CMOS jumper

9

No. Name

10 Power backplane signal interface

11 UID LED and button

12 BMC Reset button

13 Serial interface

14 PCIE3.0 X8 slots

15 USB port (2)

16 GbE port 1

17 GbE port 0

18 IPMI management port

19 PCIE3.0 X8 slots

20 VGA interface

21 SATA_M.2 interface

22 TPM interface

2.6 CLR_CMOS Jumper Introductions

See [2. 5 Motherboard Layout] for jumper positions.

Jumper No. Name Jumper Functions

CLR_CMOS CMOS clear jumper

Short-circuit pin1-2, normal status; short-circuit

pin 2-3, clear CMOS.

Note:

It is required to shut down the system, as well as disconnect power supply during

CMOS clearing, keep for 5 seconds after short-circuiting Pin2-3; then short-circuit

Pin1 and Pin2 of CLR_CMOS jumper (the default status) with a jumper cap, to

restore to its original status.

10

3 BIOS Setup

This chapter introduces how to congure BIOS. All operations described in this

section are only limited to operators or administrators with system maintenance

qualication.

BIOS is a basic input and output system. The system parameters and hardware

parameters can be adjusted through special setup procedure. BIOS has a great

impact on the system booting and running, setting parameters improperly may cause

conicts among hardware resources, or degrade the system running performance.

Hence understanding the BIOS setup is signicant to the conguration of your

server. If no especial requirement, you are suggested to use the default value and

not alter the parameters arbitrarily.

1. Before changing the BIOS setup, please record the corresponding original setup.

BIOS Setup

Hence when there are operating problems in the system due to the option altered,

the setup can revert to the previous state.

2. Ordinarily the factory default settings are the optimal settings. Don’t try to alter the

parameters before you understand their denotations.

3. The common settings are introduced in detail in this chapter. The less referred

options during using are simply explained or not.

4. The BIOS content varies according to different congurations of the products;

hence the detailed introduction is elided.

3.1 System BIOS Setup Methods

Power on the server, system starts to boot, when the following content appears

below Inspur logo on the screen:

“Press <DEL> to SETUP or <TAB> to POST or <F12> to PXE Boot.”, press [DEL]

button; when “Entering Setup...” appears in the lower right corner, it will enter system

BIOS conguration later, and you could select options in BIOS main menu using

arrow buttons to enter sub-menu.

Note: Options in grey are not available. Options with symbol “ ” have a sub-menu.

11

Control key instruction table

Press Key Function

<Esc> Exit or return from sub-menu to main menu

<←> or <←> Select a menu

<←> or <←> Move the cursor up or down

<Home> or <End> Move the cursor to the top or bottom of the screen

<+> or <->

<F1> Help

<F2> Restore to the last conguration

<F9> Restore to default conguration

<F10> Save and exit

<Enter> Execute commands or select a sub-menu

3.2 BIOS Settings

3.2.1 Main Menu

Select the previous or next numerical value or setting of the

current one

12

Main Interface Instruction Table

Interface Parameters Function Des cription

BIOS Information BIOS information

BIOS Version BIOS version information

Build Date and Time BIOS build date and time

Customer ID Customer ID

Processor Information Processor information

Socket 0 CPU0 model information

Socket 1 CPU1 model information

Current Speed CPU current speed

Memory Information Memory information

Total Memory Memory total memory

Current Speed Memory current speed

Display and set system date

Use <Tab> or <Enter> to switch between options of the

System Date

system date and time, directly input the number or use +/keys to change the value (press + key once, the value will

increase by 1, press - key once, the value will decrease by 1)

BIOS Setup

System Time

3.2.2 Advanced Menu

Display and set system time

Use <Tab> or <Enter> to switch between options of the

system date and time, directly input the number or use +/keys to change the value (press + key once, the value will

increase by 1, press - key once, the value will decrease by 1)

13

Advanced Interface Instruction Table

Interface Parameters Function Description

Trusted Computing Trusted computing conguration

ACPI Settings

AST2400 Super IO Conguration AST2400 I/O chip parameter conguration

Serial Port Console Redirection Serial port console redirection settings

PCI Subsystem Settings PCI subsystem settings

Network Stack Conguration Network stack conguration

CSM Conguration CMS conguration

NVMe Conguration NVMe conguration

USB Conguration USB conguration

Onboard LAN Conguration Onboard network card conguration

iSCSI Conguration iSCSI conguration

Intel® I350 Gigabit Network

Connection

Advanced conguration and power interface

settings

Intel® I350 GbE NIC connection settings

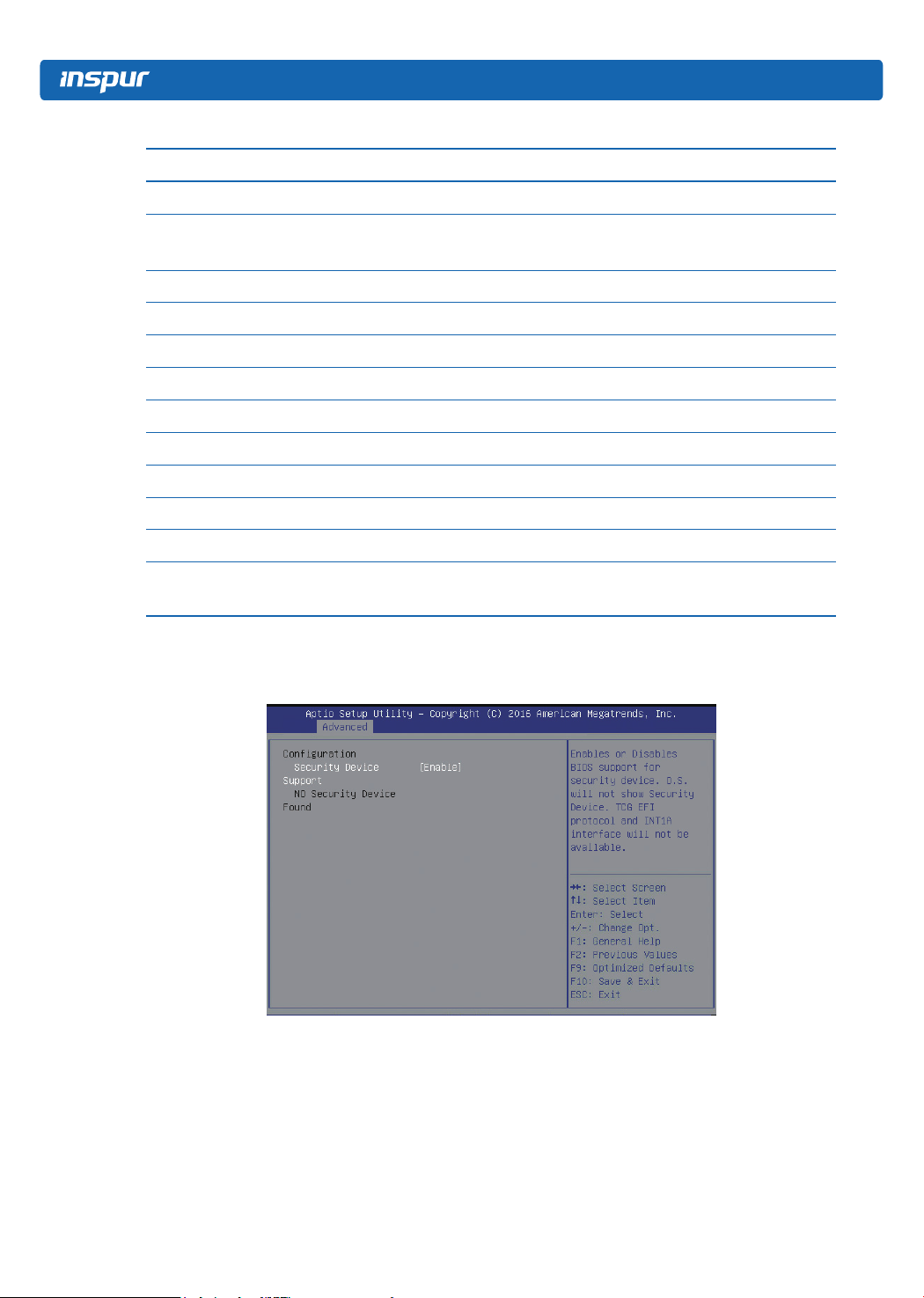

3.2.2.1 Trusted Computing

14

Trusted Computing Interface Instruction Table

Interface Parameters Function Description

Security device support on/off settings,

option parameters:

Enabled

Disabled

Security Device Support

BIOS supports TPM TCG version 1.2/2.0.

BIOS supports TPM module through TPM

software binding, if the software binding

validation fails, BIOS will record the error to

the SEL.

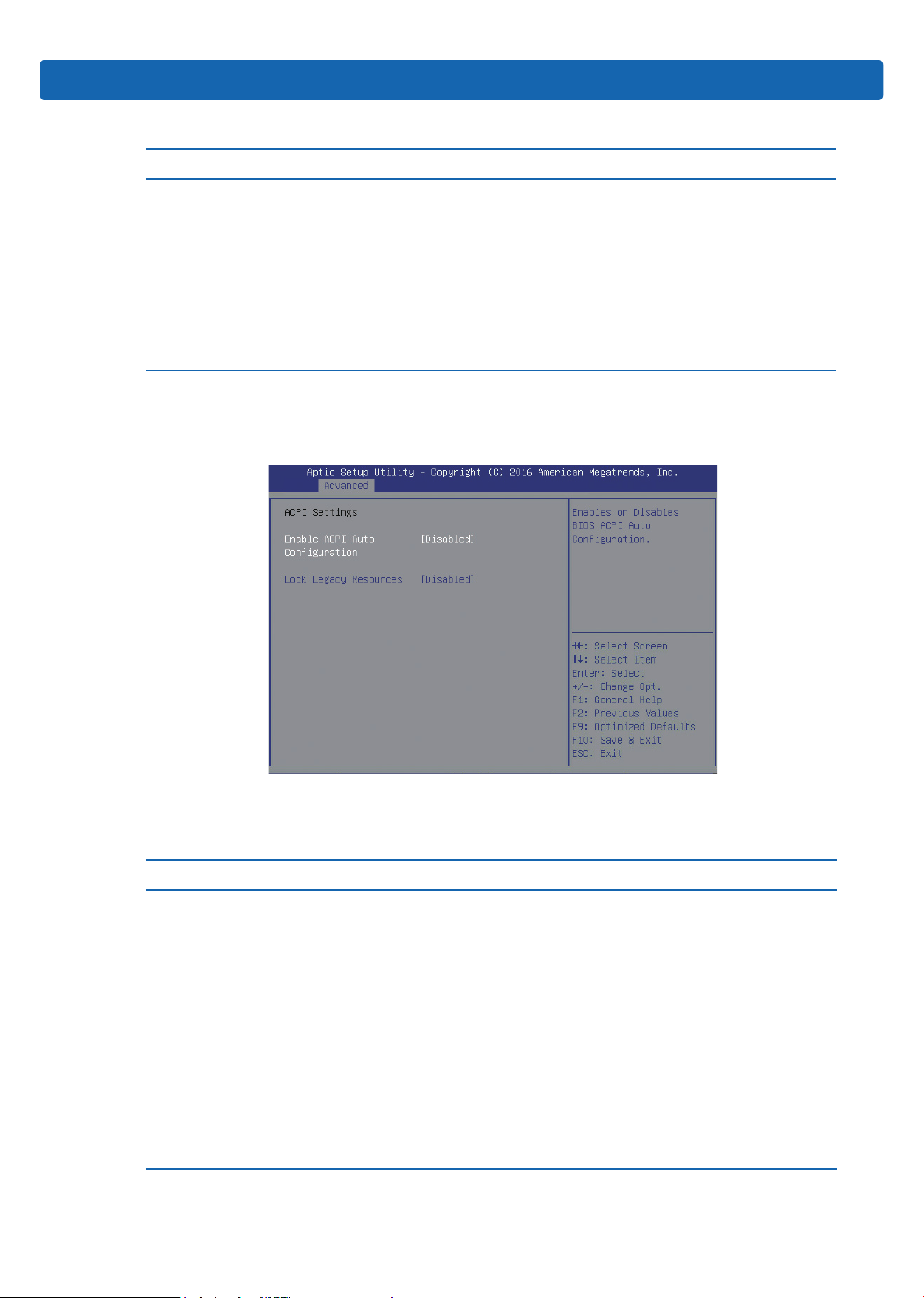

3.2.2.2 ACPI Settings

BIOS Setup

Default

Enabled

Advanced Interface Instruction Table

Interface Parameters Function Description

ACPI auto conguration on/off settings, option

parameters:

Enable ACPI

Auto Conguration

Lock Legacy Resources

Enabled

Disabled

If enabled, the Lock Legacy Resources will be

hidden, and manual modication is not allowed.

Lock legacy resources on/off settings, option

parameters:

Enabled

Disabled

If enabled, OS will lock the device’s legacy

resources.

Default

Disabled

Disabled

15

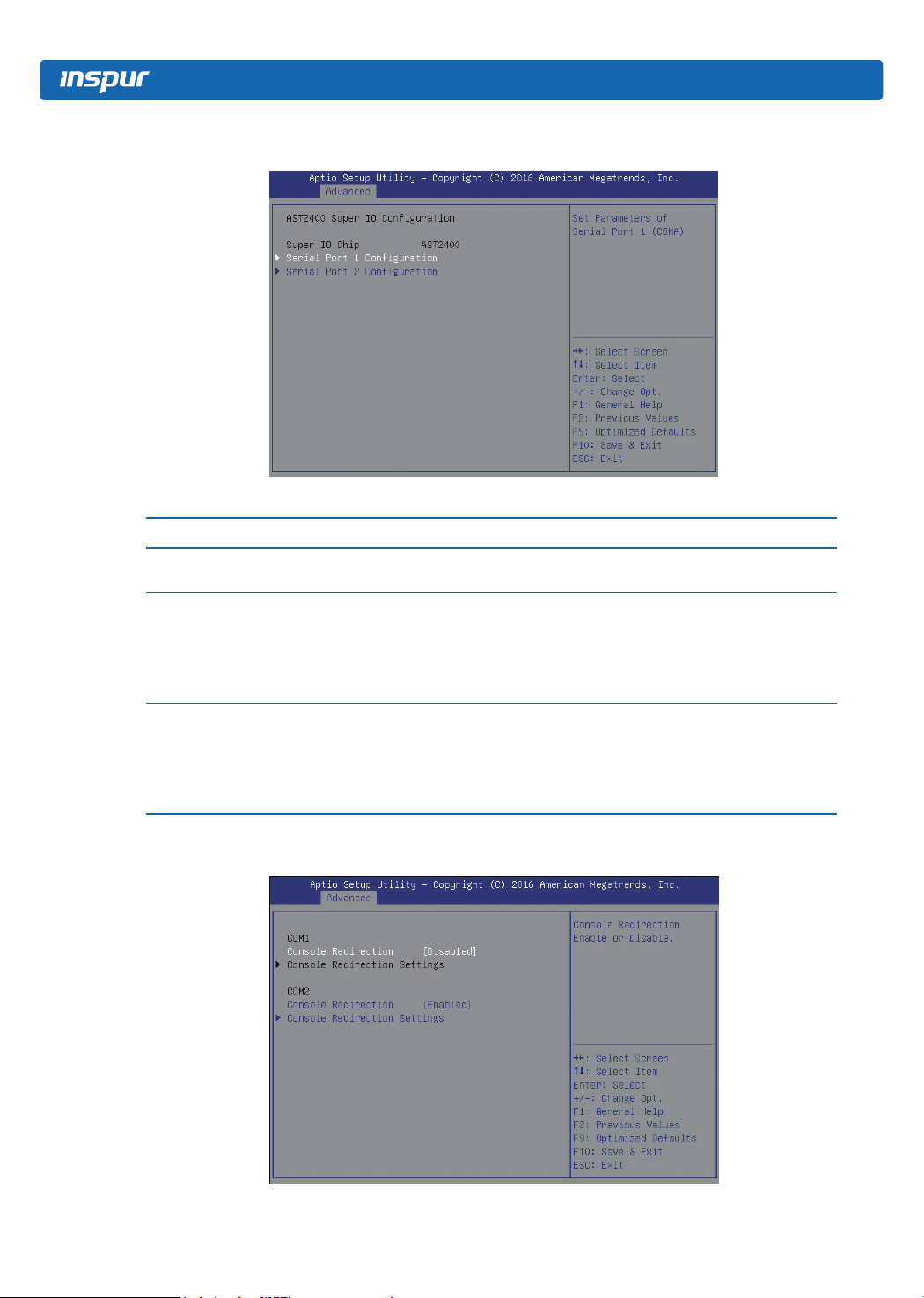

3.2.2.3 AST2400 Super IO Configuration

AST2400 Super IO Conguration Interface Instruction Table

Interface Parameters Function Description

Super IO Chip

Serial Port 1 Conguration

Serial Port 2 Conguration

Display the super I/O chip that the motherboard uses

currently

Serial port 1 conguration, the conguration interface

provides this serial port on/off control and resource

adjustment functions. The resource adjustment function

can manually adjust the IO PORT and IRQ number that

COM PORT uses.

Serial port 2 conguration, the conguration interface

provides this serial port on/off control and resource

adjustment functions. The resource adjustment function

can manually adjust the IO PORT and IRQ number that

COM PORT uses.

3.2.2.4 Serial Port Console Redirection

16

Serial Port Console Redirection Interface Instruction Table

Interface Parameters Function Description

Console redirection on/off settings, option

Console Redirection

Console Redirection Settings Console redirection parameter settings

parameters : Enabled

Disabled

3.2.2.4.1 Console Redirection Settings

BIOS Setup

Default

Disabled

--

When the Console Redirection option is set to [Enabled], the Console Redirection

Settings menu will appear.

Console Redirection Settings Interface Introduction

Interface Parameters Function Description Default

Terminal type settings, option parameters:

VT100

Terminal Type

Bits per second

VT100+

VT-UTF8

ANSI

Bits per second settings, option parameters:

9600

19200

38400

57600

115200

ANSI

115200

17

Data Bits

Parity

Stop Bits

Flow Control

Data bits width settings, option parameters:

7

8

Parity settings, option parameters:

None (no parity)

Even (even parity)

Odd (odd parity)

Mark (odd-even check)

Space (memory parity check)

Stop bits settings, option parameters:

1

2

Flow control settings, option parameters:

None

Hardware RTS/CTS

8

None

1

None

VT-UTF8 Combo Key

Support

VT-UTF8 combo key support settings Enabled

Recorder Mode Recorder mode on/off settings Disabled

Resolution 100×31

Extension terminal resolution 100×31 on/off

settings

Disabled

Legacy OS redirection resolution settings,

Legacy OS Redirection

Resolution

option parameters:

80×24

80×24

80×25

Putty function keys and keyboard settings,

option parameters:

VT100

Putty KeyPad

LINUX

XTERMR6

VT100

SCO

ESCN

VT400

Redirection settings after BIOS post, option

Redirection After BIOS

POST

parameters:

Always Enabled

Always

Enabled

BootLoader

18

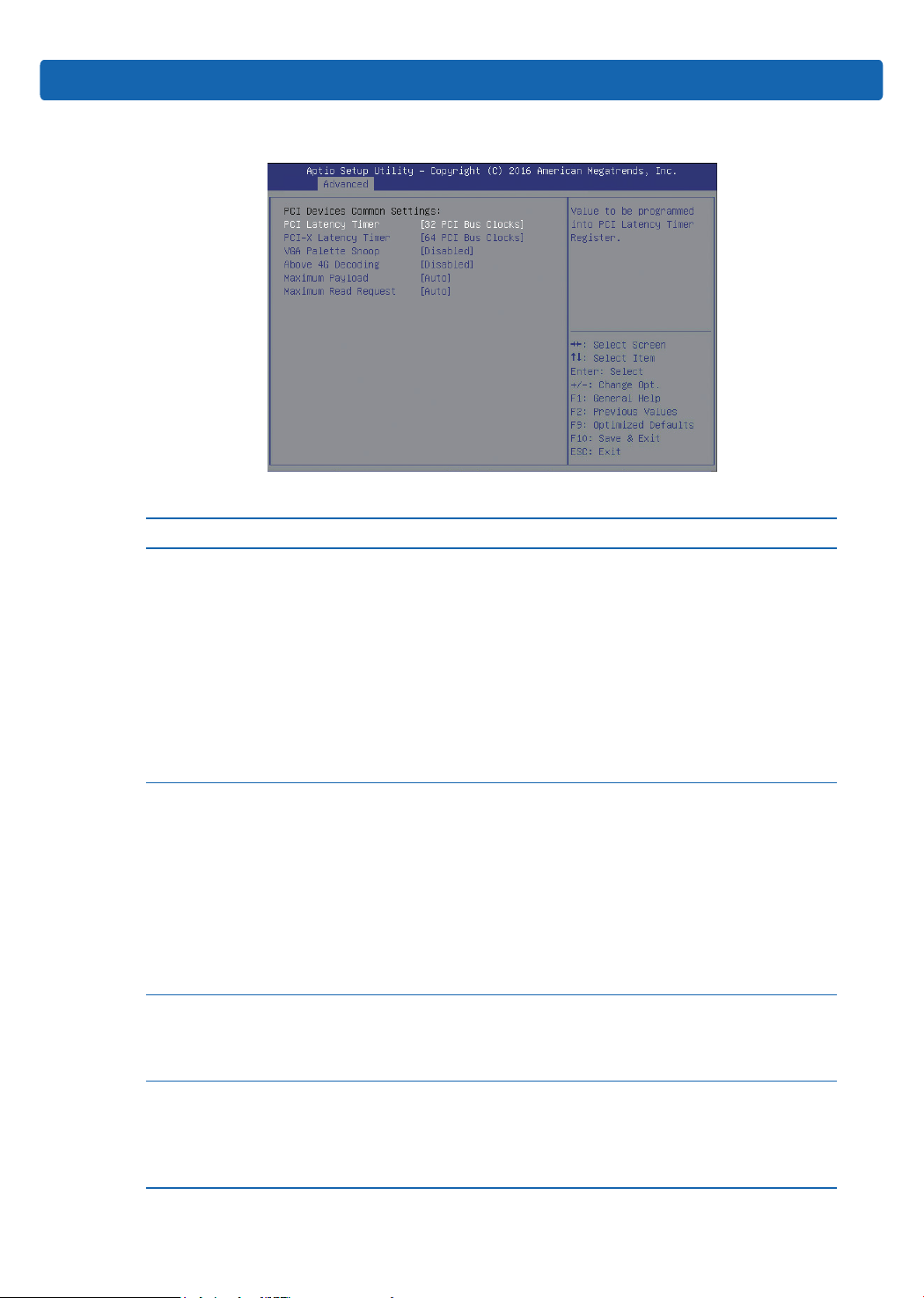

3.2.2.5 PCI Subsystem Settings

PCI Subsystem Settings Interface Instruction Table

Interface Parameters Function Description

PCI device latency timer settings, this is used

to set the time that each PCI device can

occupy the bus, option parameters:

32 PCI Bus Clocks

64 PCI Bus Clocks

PCI Latency Timer

PCI-X Latency Timer

VGA Palette Snoop

Above 4G Decoding

96 PCI Bus Clocks

128 PCI Bus Clocks

160 PCI Bus Clocks

192 PCI Bus Clocks

224 PCI Bus Clocks

248 PCI Bus Clocks

PCI-X device latency timer settings, option

parameters:

32 PCI Bus Clocks

64 PCI Bus Clocks

96 PCI Bus Clocks

128 PCI Bus Clocks

160 PCI Bus Clocks

192 PCI Bus Clocks

224 PCI Bus Clocks

248 PCI Bus Clocks

VGA palette snoop on/off settings, option

parameters:

Enabled

Disabled

4G above memory access control on/off

settings, option parameters:

Enabled

Disabled

Enable or disable above 4G decoding function

BIOS Setup

Default

32 PCI Bus

Clocks

64 PCI Bus

Clocks

Disabled

Disabled

19

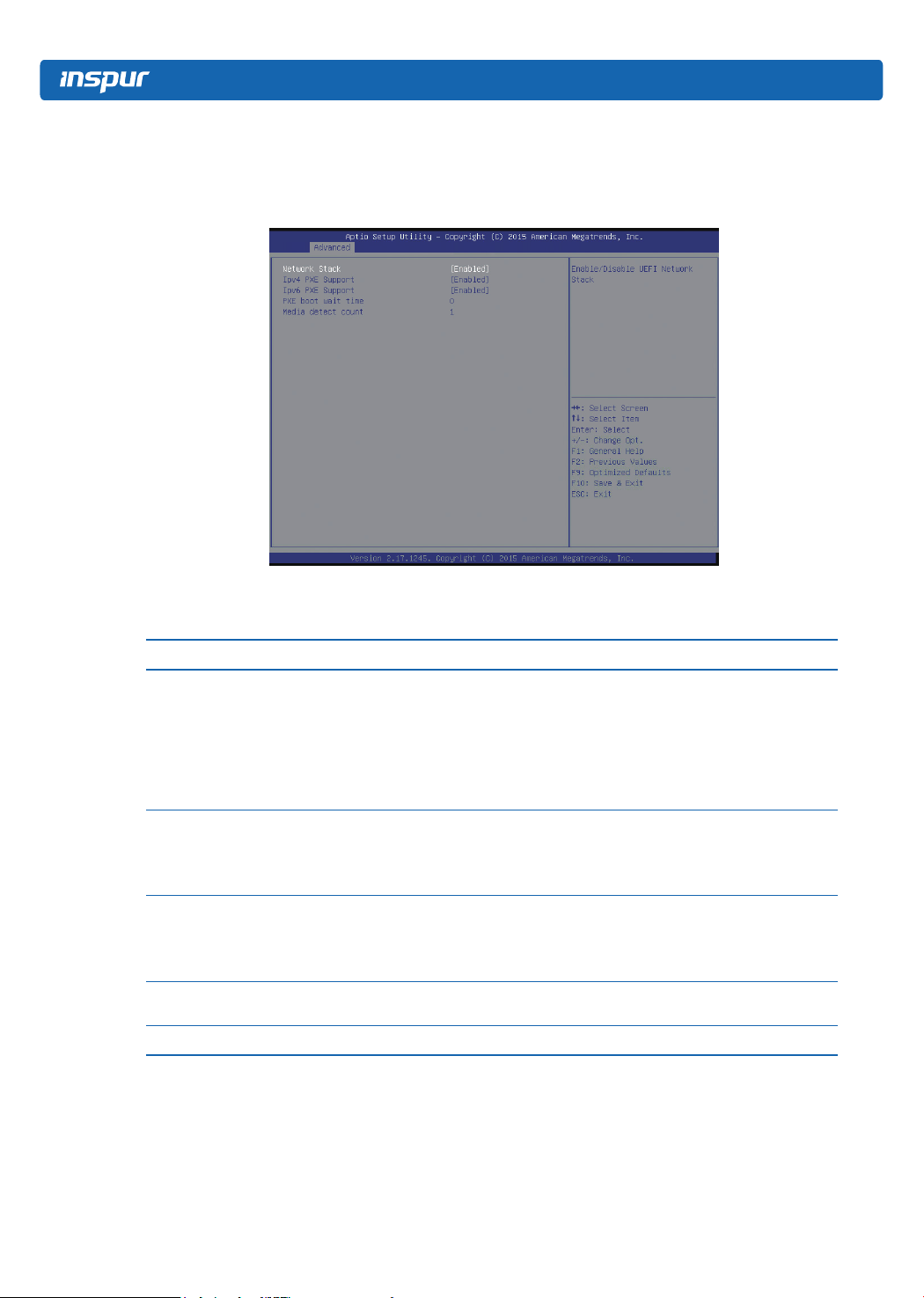

3.2.2.6 Network Stack Configuration

Network Stack Conguration interface is used to set the related options of UEFI pre-

boot network.

Network Stack Conguration Interface Instruction Table

Interface Parameters Function Description

Network stack on/off settings, option parameters:

Enabled

Network Stack

IPv4 PXE Support

IPv6 PXE Support

PXE boot wait time

Media detect count Set PXE media detect count

Disabled

The following options are controlled by this option,

only this option is enabled, the following options will

be displayed and settable.

IPv4 PXE support on/off settings, option

parameters:

Enabled

Disabled

IPv6 PXE support on/off settings, option

parameters:

Enabled

Disabled

Set wait time, pressing ESC key can suspend PXE

boot.

Default

Disabled

Enabled

Enabled

0

1

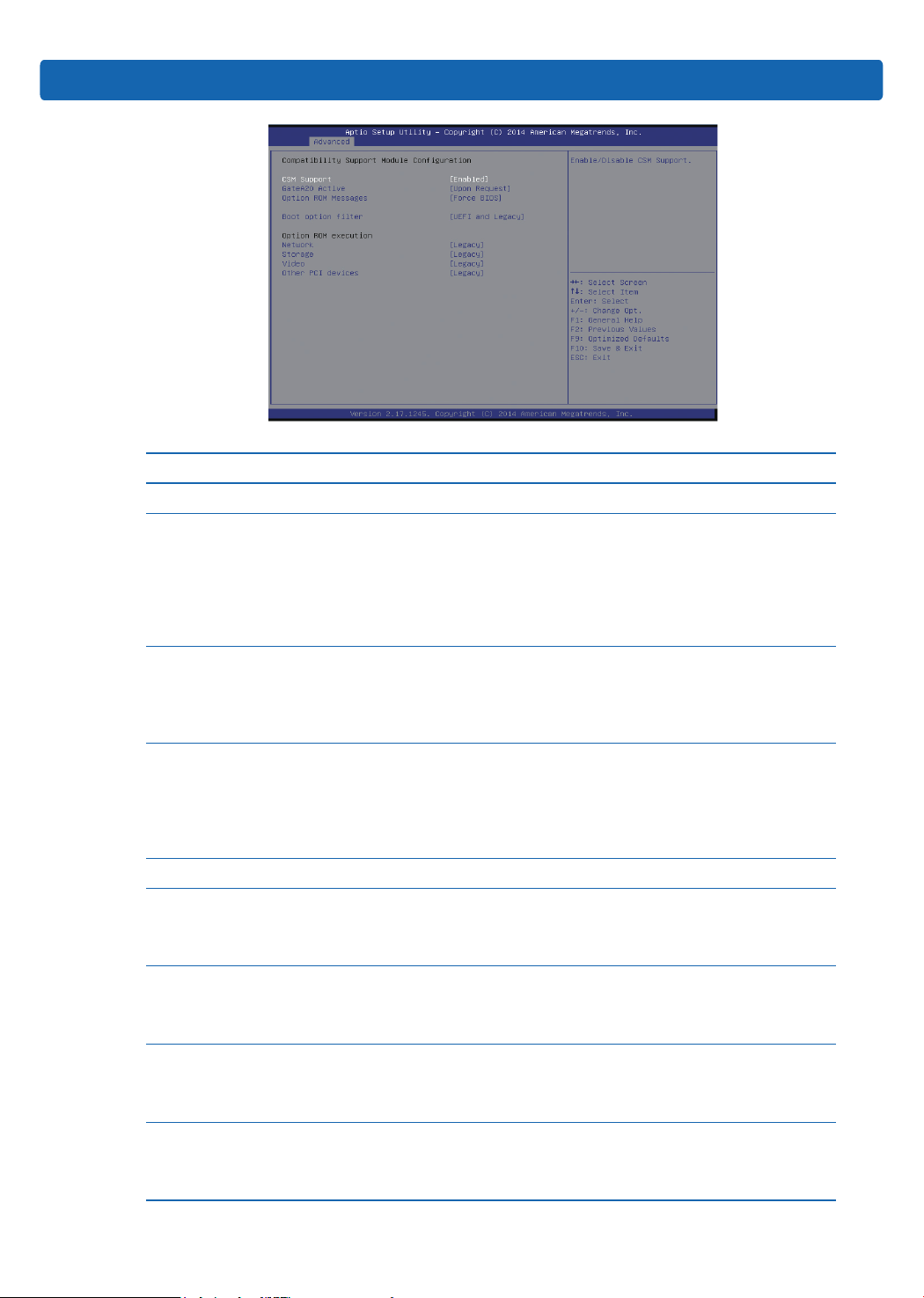

3.2.2.7 CSM Configuration

CSM Conguration interface is used to set the related options of compatible module.

20

CSM Conguration Interface Instruction Table

Interface Parameters Function Description

CSM Support CSM support on/off settings

A20 address wire control mode settings,

option parameters:

Upon Request

GateA20 Active

Option Rom Messages

Boot option lter

Option ROM execution Option Rom execution mode

Network

Storage

Video

Other PCI devices

Always

A20 is an address wire, which can control the

system how to access memory spaces that

are more than 1MB.

Option Rom messages display mode settings,

option parameters:

Force BIOS: forced display BIOS information

Keep Current: keep current state

Option Rom: no information displayed

Boot option lter settings, to control Legal

and UEFI Option Rom’s boot strategy, option

parameters:

UEFI and Legacy

UEFI only

Legacy only

NIC Option Rom execution mode settings,

option parameters:

Legacy

UEFI

Storage device Option Rom execution mode

settings, option parameters:

Legacy

UEFI

Video device Option Rom execution mode

settings, option parameters:

Legacy

UEFI

Other PCI devices Option Rom execution

mode settings, option parameters:

Legacy

UEFI

BIOS Setup

Default

Enabled

Upon Request

Force BIOS

UEFI and

Legacy

---

Legacy

Legacy

Legacy

Legacy

21

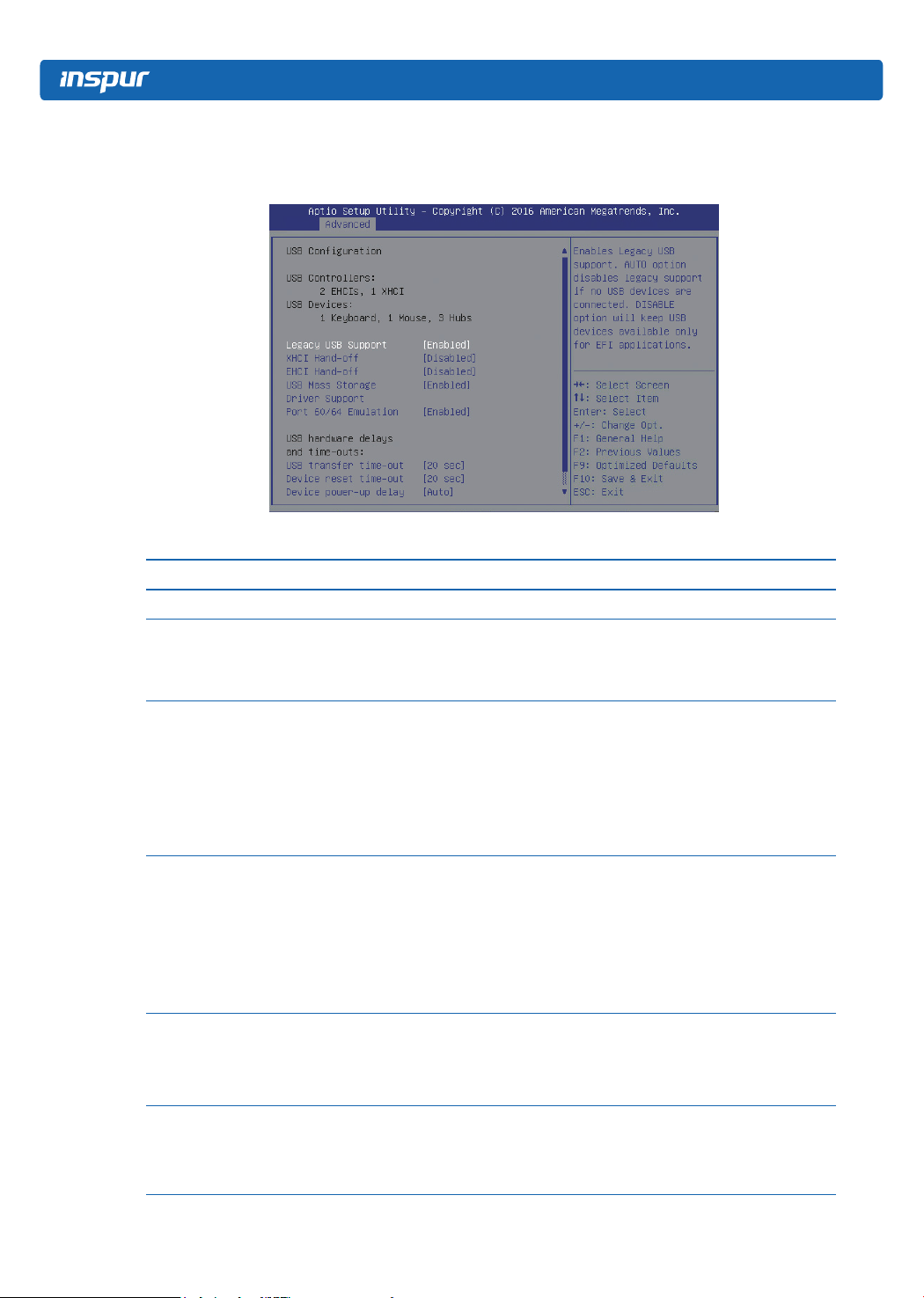

3.2.2.8 USB Configuration

USB Conguration interface is used to set USB related options.

USB Interface Instruction Table

Interface Parameters Function Description

USB Devices Current USB devices information

Legacy USB support on/off settings, option

Legacy USB Support

XHCI Hand-off

EHCI Hand-off

USB Mass Storage

Driver Support

Port 60/64 Emulation

parameters:

Enabled

Disabled

Enable or disable XHCI hand-off function, option

parameters:

Enabled

Disabled

For the operating systems that do not support

XHCI (USB3.0) function, enabling XHCI hand-off

function can realize the support for XHCI.

Enable or disable EHCI hand-off function, option

parameters:

Enabled

Disabled

For the operating systems that do not support

EHCI (USB2.0) function, enabling EHCI hand-off

function can realize the support for EHCI.

USB mass storage driver support on/off settings,

option parameters:

Enabled

Disabled

USB port 60/64 emulation on/off settings, option

parameters:

Enabled

Disabled

Default

--

Enabled

Enabled

Disabled

Enabled

Enabled

22

BIOS Setup

USB Hardware Delay

and Time-outs

USB Transfer Timeout

Device Reset Time-

out

Device Power-up

Delay

Device Power-up

Delay in Seconds

USB hardware delay and time-outs settings --

USB transfer time-out settings, option parameters:

1 sec

5 sec

10 sec

20 sec

USB high-capacity devices reset time-out settings,

option parameters:

10 sec

20 sec

30 sec

40 sec

Device power-up delay settings, option

parameters:

Auto

Manual

Only when the Device power-up delay option is

set to Manual, this option will be displayed and

it is used to set device power-up delay time, set

range is 1-40s.

20 sec

20 sec

Auto

5

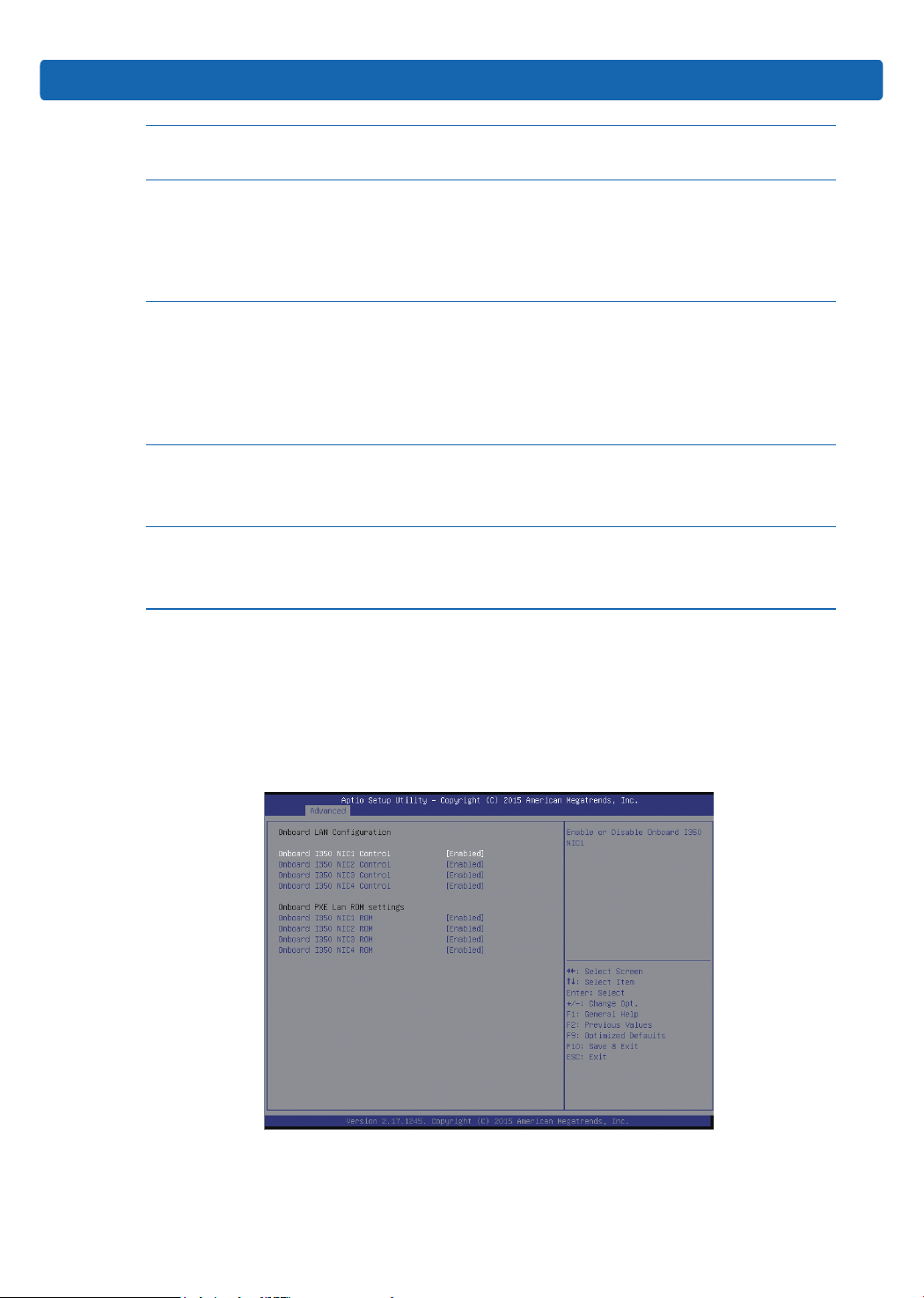

3.2.2.9 Onboard LAN Configuration

Onboard LAN Conguration is used to set the related options of onboard NIC. The

options on this interface vary with different onboard NICs, the specic model will

prevail.

23

Onboard LAN Conguration Interface Instruction Table

Interface Parameters Function Description

Onboard NIC1 on/off settings, option parameters:

Onboard NIC1 Control

Onboard NIC2 Control

Onboard NIC3 Control

Onboard NIC4 Control

Onboard NIC1 ROM

Onboard NIC2 ROM

Onboard NIC3 ROM

Onboard NIC4 ROM

Enabled

Disabled

Onboard NIC2 on/off settings, option parameters:

Enabled

Disabled

Onboard NIC3 on/off settings, option parameters:

Enabled

Disabled

Onboard NIC4 on/off settings, option parameters:

Enabled

Disabled

Onboard NIC1 PXE Oprom on/off settings, option

parameters:

Enabled

Disabled

Onboard NIC2 PXE Oprom on/off settings, option

parameters:

Enabled

Disabled

Onboard NIC3 PXE Oprom on/off settings, option

parameters:

Enabled

Disabled

Onboard NIC4 PXE Oprom on/off settings, option

parameters:

Enabled

Disabled

3.2.3 Chipset

Default

Enabled

Enabled

Enabled

Enabled

Enabled

Enabled

Enabled

Enabled

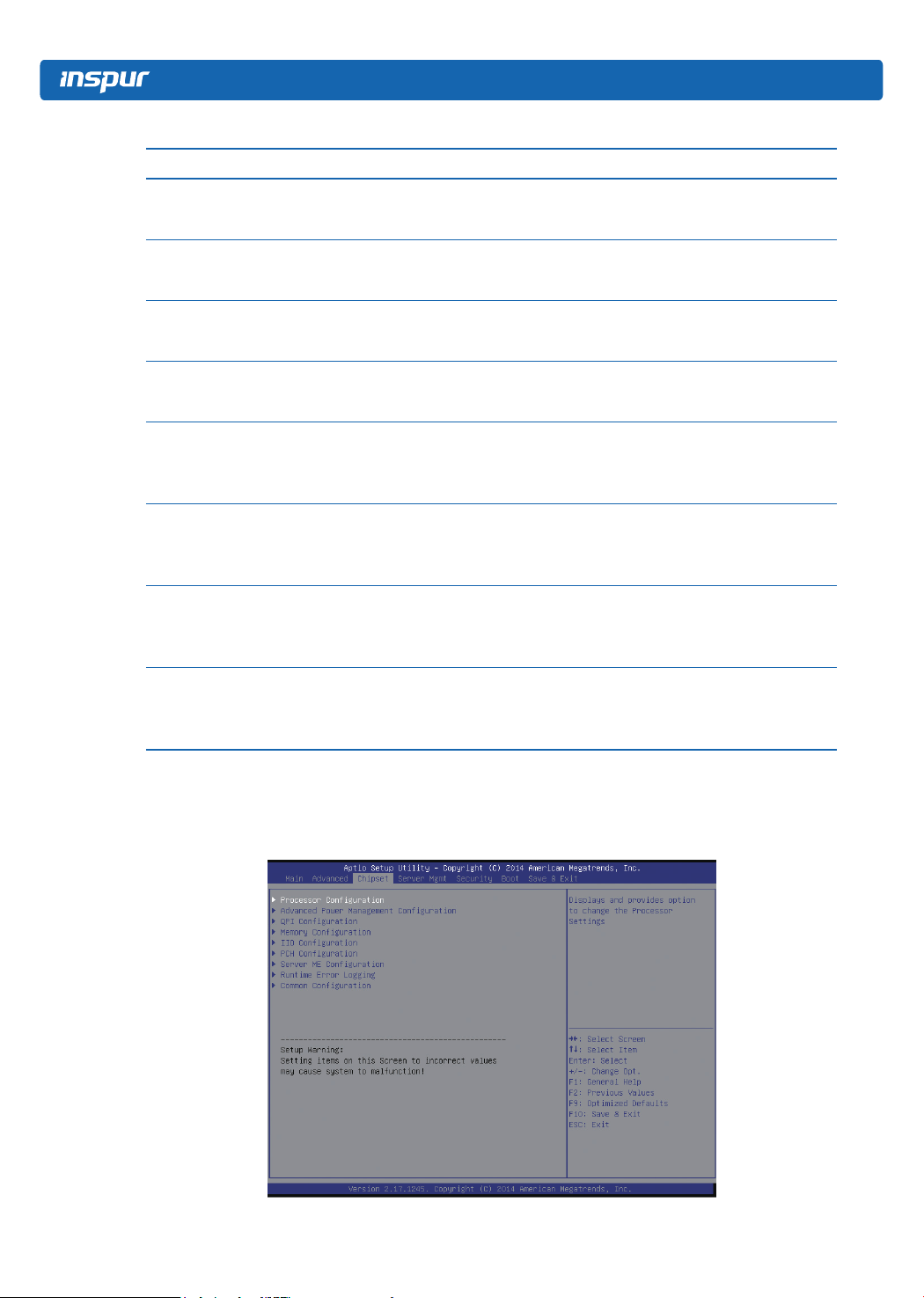

Chipset interface includes the information of CPU, QPI, memory, PCH, ME and other

devices. Users can manage these devices through this interface.

24

Chipset Interface Instruction Table

Interface Parameters Function Description

Processor Conguration Processor conguration

Advanced Power Management Conguration

QPI Conguration QPI conguration

Memory Conguration Memory conguration

IIO Conguration IIO conguration

PCH Conguration PCH conguration

Server ME Conguration Server ME conguration

Runtime Error Logging Runtime error logging conguration

Common Conguration Common options conguration

Advanced power management

conguration

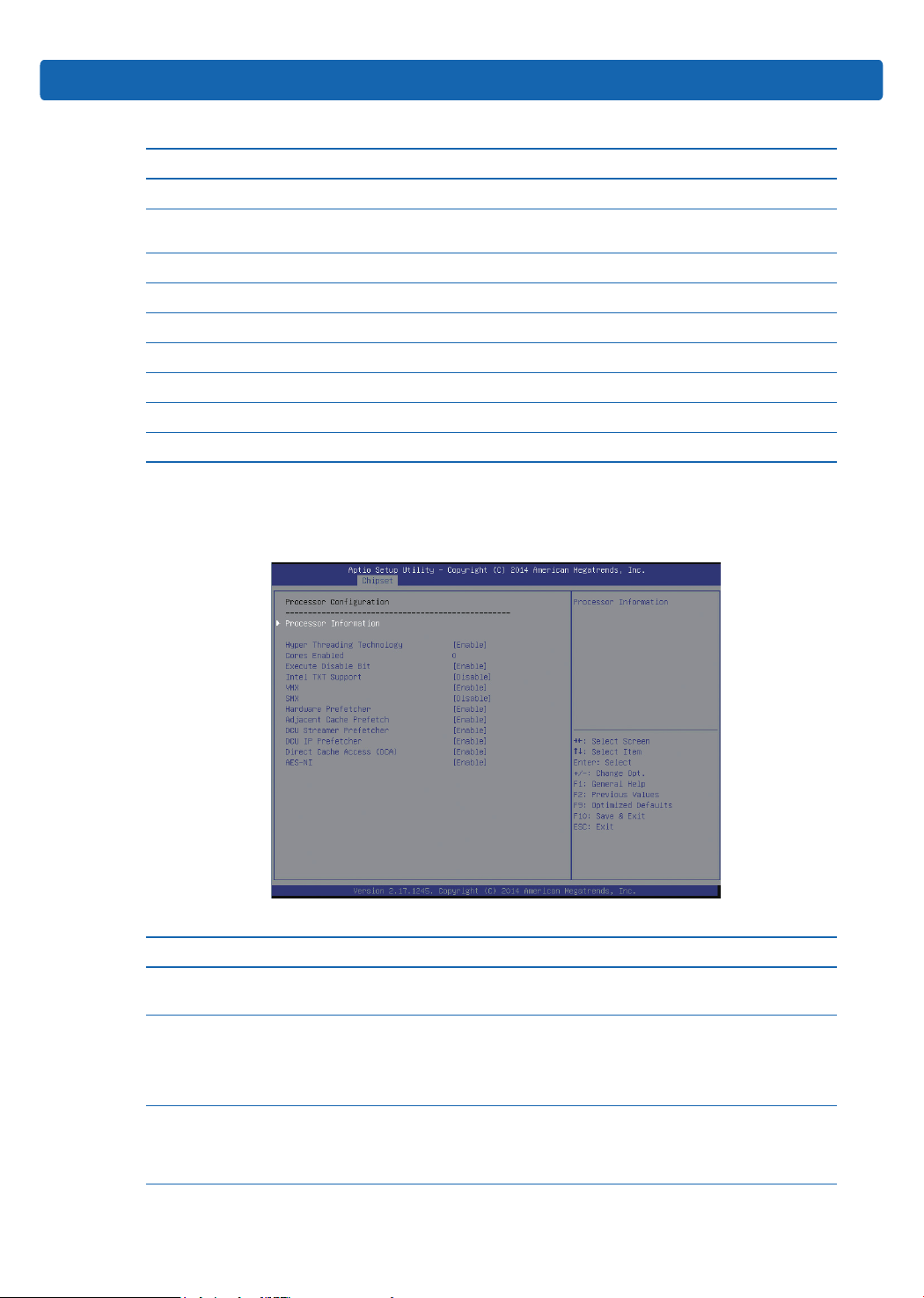

3.2.3.1 Processor Configuration

Processor Conguration is used to set the related options of processor.

BIOS Setup

Processor Conguration Interface Instruction Table

Interface Parameters Function Description Default

Processor

Information

Hyper Threading

Technology

Core Enabled

Processor information submenu, display processor

detailed information.

Hyper threading technology settings, option parameters:

Enabled

Disabled

Number of CPU cores settings, input the number of

CPU cores to be enabled. The default valued is 0,

which means enabling all CPU cores.

--

Enabled

0

25

Execute Disable Bit

Intel TXT Support

VMX

SMX

Hardware Prefetcher

Adjacent Cache

Prefetch

DCU Streamer

Prefetcher

DCU IP Prefectcher

Direct Cache Access

(DCA)

AES-NI

Execute Disable Bit on/off settings, option parameters:

Enabled

Disabled

Intel TXT support on/off settings, option parameters:

Enabled

Disabled

Intel VMX on/off settings, option parameters: Enabled

Disabled

SMX on/off settings, option parameters: Enabled

Disabled

Hardware prefetcher on/off settings, option parameters:

Enabled

Disabled

Before CPU processing instructions or data, it will

prefetch these instructions or data from memory to L2

cache, to shorten the amount of time reading memory

takes, to help eliminate potential bottlenecks, to

improve system performance.

Adjacent cache prefetch on/off settings, option

parameters:

Enabled

Disabled

If this function is enabled, when computer reading

data, it will intelligently consider the adjacent data is

needed as well, and it will prefetch these data during

processing, to speed up the reading process.

DCU streamer prefetcher on/off settings, option

parameters:

Enabled

Disabled

This function can prefetch CPU data to shorten the data

reading time.

DCU IP prefectcher on/off settings, option parameters:

Enabled

Disabled

This function can judge from the history whether there

is data to prefetch, to shorten the data reading time.

Direct cache access on/off settings, option parameters:

Enabled

Disabled

DCA is a system-level driver, it can directly put the data

from IO device into CPU cache to improve the network

IO performance.

AES instruction on/off settings, option parameters:

Enabled

Disabled

This menu is mainly used to control whether CPU

supports AES instructions, which are used to support

fast and secure encryption and decryption.

Enabled

Disabled

Enabled

Disabled

Enabled

Enabled

Enabled

Enabled

Enabled

Enabled

26

Loading...

Loading...