Page 1

www.insize.com

MN- ISH- PHB-E

ISH-PHB

PORTABLE HARDNESS TESTER

OPERATION MANUAL

Page 2

Attention

Description

Don’ t imp act without mea surement and cali bration , oth erwise the

impa ct device may b e damaged .

Plea se r eading the oper ation manual care ful before usin g, m ake

sure the weight, thi ckness, surface rough ness of t he workp iece

are me eting the req uiremen t.

Plea se do calibr ation w hen u se the device first time or int erval for

a long t ime.

Clea n up the rusty, oil on t he surface be fore meas ure.

The distance between any two impact position should be ≥3mm. the

distance between impact position and the edge of the sample should

be ≥3mm.

Make the su pport ri ng stick to and

keep t he impact dir ection pe rpendic ular to

Keep work piece and impact device steady dur ing

ope ra tor,

the sur face of the workpiece

the su rface.

meas urement .

1

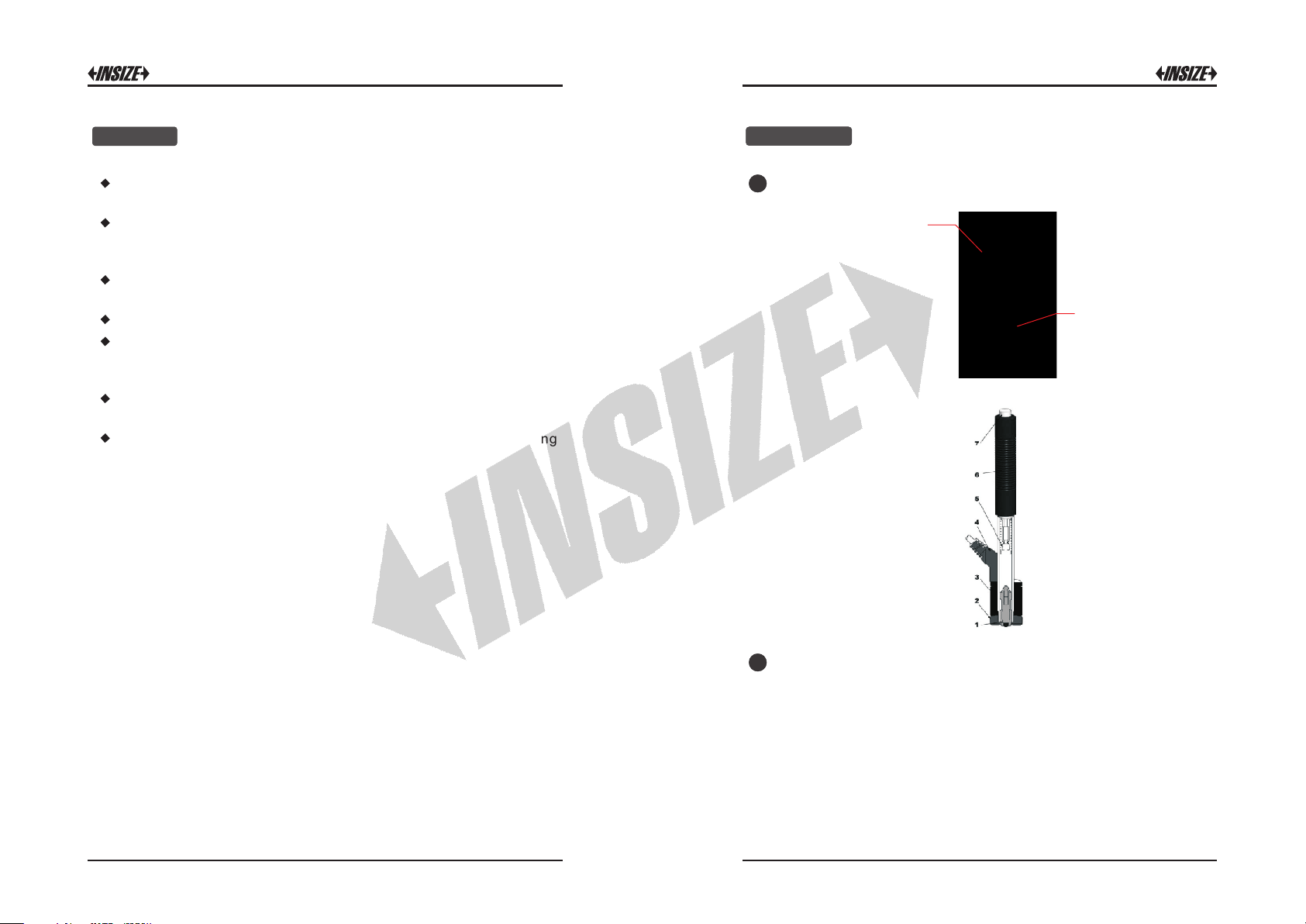

Stru cture:

LCD Display

Butto n

Main unit

1.

Impac t bo dy

2.

Support r in g

3.

Coil

4.

Cable

5.

Catch c hu ck

6.

Loading t ub e

7.

Release b ut ton

Impact device

2

Workin g principle :

Push down the loadi ng tube befo re meas urement, the c atch

chuc k catch u p the i mpact bod y. Make the support r ing sti ck to the

sur face of the work p iece and kee p the imp act dire c tion

perp endicul ar to the s urface. The n press t he releas e button, the

impa ct body wi ll impa ct the surfa ce. The c oil col lect th e veloc ity

sign al and the ca ble transmi t the dada to the m ain unit.

1 2

Page 3

3

Specification:

Disp lay range : 0 999H LD~

Accu racy: ±6HLD (when HLD = 800)

repe atabili ty: 6H LD±

Impa ct directio n: 0 °, °, 180 °, °, °±90 ±45 ±135

Conv ersion sc ales: HV, HB, HRB, HRC, HV, HSD, MPa

4

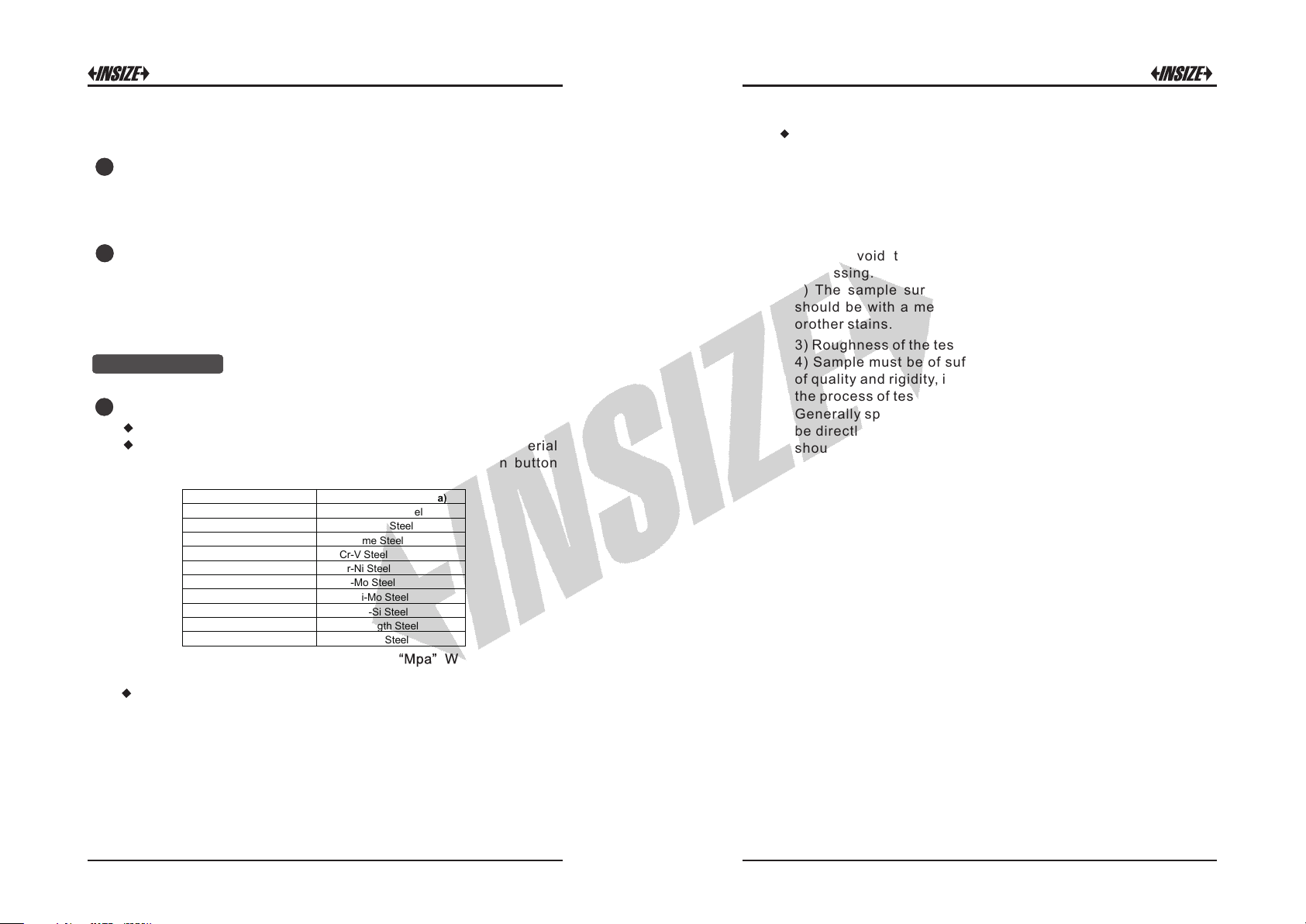

Button function:

5

LCD display:

HLD val ue

Imp ac t and s tat is tic t ime s

Mater ial c ode

Imp ac t dir ect io n

Dat e and tim e

HLD ave ra ged v alue

Conve rsi on val ue

1

3

1. On/Off b utton : Turn it o n/off by press ing and ho lding the

butt on.

2

4

5

2. Up ar row button :

① In me asureme nt m ode, pres s this button t o select

conv ersion sc ale.

② In mea surement m ode, pre ss b utton to delet e curr ent

resu lt and pres s th is button t o confirm.

3. Set up button :

① In measur ement mod e, press this butt on to s elect the items

need to be set like sta tistic tim es, ma terial cod e, date, time,

etc.

② Turn off the mach ine, pres s this bu tton and On/Off button

toge ther to enter c onversi on value cali bration .

4. Ret urn button :

① Back t o measureme nt mode.

② Turn off the mach ine, pres s this bu tton and On/Off button

toge ther to enter L eeb value c alibratio n.

5. Down arrow butto n : In measure ment mode, press this

butt on to enter dat a browsin g mode.

Leeb Value Calibration

Plea se do calibra tion when use t he d evice fir st t ime or interv al for a

long t ime.

Note: Please do calibration with standard test block in packing box.

1

Pres s setup but ton then set me asuring c onditions b y using up an d

down bu ttons, select material code to numb er 01, the i mpact

dire ction is do wn. Turn off the machi ne after do s etup.

2

pres s rut urn b utton and On/Off button toget her ( about 2 seconds)

to e nter Leeb v alue ca libration , the INS IZE logo will blin k on top

left corne r. Meas ure 5 t imes on t he surface of s tandard test

bloc k(you should do en ter c alibrat ion mode again if get any val ue

whic h deviati on is large).

3

Inpu t the actua l HLD value of the t est block by use u p and dow n

butt ons, then pre ss return b utton back to m easurem ent mode.

Note: The distance between any two impact position should be ≥3mm.

the distance between impact position and the edge of the sample

should be ≥3mm.

Conversion Value Calibration

This calib ration is appl ied to some workpiece you don’t know the

Leeb h ardenes s but only conv ersion ha rdness valu e like HB, HV, etc.

Note: Please do calibration with known hardness workpiece.

1

Pres s up arrow button to se lect t he con version scale , then Press

setu p button then s et measur ing conditi ons by usin g up and down

3 4

Page 4

butt ons, sele ct right mate rial code , the impac t directi on is down.

Hardness Tensile strength (MPa)

01.Steel and Cast Steel 11. Low Carbon Steel

02. Alloy Tool Steel 12. Hi Carbon Steel

03. Stainless Steel 13. Chrome Steel

04. Grey Cast Iron 14. Cr-V Steel

05. Ductile Iron 15. Cr-Ni Steel

06. Cast Al Alloys 16. Cr-Mo Steel

07. Cu-Zn Alloys 17. Cr-Ni-Mo Steel

08. Cu-Sn Alloys 18. Cr-Mn-Si Steel

09. Copper 19. Hi Strength Steel

10. Forging Steel 20. Stainless Steel

Tur n off the machine a fter do set up.

2

pres s setup b utton an d On/Off butt on toget her (about 2 second s)

to ent er conver sion value ca librati on, the INSIZ E logo will b link on

top l eft corner. Me asure 5 tim es on the su rface of wo rkpiece (y ou

shou ld do enter calibra tion mode again if get any valu e which

devi ation is la rge).

3

Inpu t the a ctual v alue of wo rkpiece by u se up and down bu ttons

then p ress return b utton bac k to measurem ent mode.

Note: The distance between any two impact position should be ≥3mm.

the distance between impact position and the edge of the sample

should be ≥3mm.

Measurement

1

Prep aration b efore measu ring:

Tur n on the mach ine.

Pres s setup button and set statisti c times, select the mat erial

code accordi ng to the back label, then pre ss retur n button

back t o measureme nt mode.

Note: The value can only convert to “Mpa” When select the

material code 11~20.

Pres s up arrow bu tt on to selec t right conve rsion sca le.

Note

:

1. The conversion value is “---” indicated the conversion is out of

range.

2. Conversion value only supplies the general reference, which

may result in some offset. Precisely conversion generally needs

related comparative tests.

Samp le Prepar ation:

Inap propria te sample will cau se a grea t m easuremen t erro r.

Ther efore, users should make the necessar y hand ling and

prep aration u nder the orig inal cond itions of sam ple.

Prep aration of the sa mple and th e s urface of tes t s hould be

coin cident wi th the follow ing basic r equiremen ts:

1) Dur ing the pro cess of sam ple surfa ce pre paratio n, u sers

shou ld avo id the imp acts of cold p ro cessing and the rmal

proc essing.

2) The sample surface is plane for bett er, the test sur face

shou ld be with a m etallic sh een, and not invol ve oxide laye r

orot her stains.

3) Rou ghness of the t est surfa ce Ra ≤ 1.6

4) Sample must be of su ffic ient quality and rigidi ty. If i t's la ck

of q uality an d rigidit y, it may caus e displac ement or shaking i n

the pr ocess of test ing impac t, which can le ad to large e rrors.

Gene rally spe aking, if the s ample qua lity is more th an 5kg can

be di rectly tes ted; if the sample qua lity is 2~5 kgs, the sample

shou ld b e taken in fixa tion test b y means of appr opriate

clam ping; if t he s ample quality i s 0. 1~2kgs, the sam ple

shou ld be c onducted coup ling bef ore th e te st; if the sampl e

qu a l i t y i s l e s s t h an 0. 1 k g , t h i s h a r dn e s s t e s t e r is

inap propria te to use.

Coup ling meth od: Testing sam ple's back should be p repared

to make a pl ane as a sup porting surf ace wit h a s mo oth

form ation. Fi lling with a li ttle coup ling substa nce (Indu stry

Vaselin e can b e used), users can no w pres s to th e surf ace of

the sup porting obje ct (The weigh t of sup porting ob ject should

be mor e th an 5 kg, and it ca n be rep laced by test block) to

stic k into integr ation.

5) S amples sh ould be t hick enou gh and wi th sufficie nt surfac e

abso rption layered. If users use D-t ype im pact device, the

thic kness of sa mple should n ot be less th an 5mm, and sur face

abso rption layer (or surfac e-hardeni ng laye r) s hould not b e

less t han 0.8mm. To accurat ely measure t he h ardness o f th e

mate rial, the best way is to remove the surfa ce-harden ing

mate rial, the best way is to remove the surfa ce-harden ing

laye r by proces si ng.

6) When test ing s ample surf ace i s not ho rizonta l, th e

curv ature radiu s of testin g and nearby su rface sho uld be

5 6

Page 5

larg er t han 30mm. And approp riate suppo rting ring shou ld b e

elec ted and ins talled.

7) A s ample should not be with magnet ic. The signal of the

impa ct device wou ld be serio usly inter fered in the w or k by the

magn etic, whi ch m ay cause in accurate te st result s.

Meas uring Ste ps:

2

Load ing: S imply load the impact devic e by sliding the loadi ng

tube f orward.

Plac e: Then pla ce and hold the impact device on th e surface

of the test piece at the desir ed test p oint. Impact ind irectio n

shou ld be verti ca l with the te st of surface .

Burs t imp act (Measure ): Trigger the impact by pres sing the

rele ase butt on. The har dness va lue will be insta ntaneousl y

disp layed.

Read o ff t he test resul t from screen .

Note : Gene rally, ea ch measu rement l ocation of sam ple is

cond ucted f or th e five tests . The “ S” (diffe rence o f maxim um

valu e and minimum va lue) value s must be less than 15 HL.

The d istance between any two impa ct posit ion shou ld be ≥3

mm ; the d istance b etween impa ct positi on and the ed ge of the

samp le should b e ≥3 mm.

3

Memo ry:

The data group (suc h as test resul t, conversio n res ult, sample

mate rial an d impac t directi on) aut omatica lly save in memo ry afte r

one i ndividu al measure ment. IS H-PHB ha rdness tes ter can s tore

99 sets of data, when measuring times more th an 99, the las t

grou p of data will store the 99th po sition an d the fir st grou p of

data wil l be erase d. The second grou p of data will be moved into

the 2th position, simult aneously the position of oth er group of

data , will be mov ed into lower p osition .

Pres s down arro w button to enter me mory stor e mode, u se up and

down b uttons to bro wsing the m emory.

4

Prin t (the printe r is option al):

Afte r on e set meas urement press set up butto n an d let the p rint

symb ol blink, n ow press retu rn button to pr int curre nt result.

Maintenance

1

Impa ct Device Mai ntenanc e:

Afte r using 10 00-2000 ti mes, us ers s hould c lean the cat heter of

impa ct dev ice and impact body wit h ny lon brush, and scre w off

the sup porting ri ng before clean the cath eter, and th en ta ke out

the imp act body, rotate the nylon br ush in to the tube in an anticloc kwise dir ection, and p ull out whe n touchin g the bot tom. S o

repe atedly, and then load up the impact b ody and supporti ng ring ;

User s sho uld rel ease the i mpact body a fter use. And the lubri cant

is ban ned.

Norm al Mainte nance Proce dures:

2

In calib ration of the hardn ess tester, if findi ng t hat error is larger

than 6HLD, u sers m ust be r enew t he s teel b all or i mpact body,

beca use the re ason may be that the s teel ba ll or im pact bo dy is

wore o ut to lead to fai lure in ope ration.

7 8

Page 6

Factors Affection Accuracy

Measuring And Conversion Range

Inco rrect opera tion o r improper te sting condi tions would hav e

seri ous impact on testing accur acy. Follow ing is several common

fact ors effect the ac curacy of tes ting for th e use of refere nce:

1) Rou ghness of sam ple surfa ce

When the impact body impact on th e samp le, a small pit would arise

on the sample surfa ce, s o a t the same time , sho uld f inish the surface

of the sample. The more r oughnes s, the less cons umption of impact

ener gy wherea s the less roug hness, the mo re consum ption of impa ct

ener gy. Acc ordingl y, the rough ness of s ample testing points o n the

surf ace Ra≤ 1.6.

2) The sha pe of sample su rface

Leeb testi ng princ iple deman ds the velocit y of rebound and impac t

are on t he same lin e, because th e impact bo dy is moving in a metal

tube . Even if the ve locity o f rebound and imp act are n ot on the same

line , it also can s how h ardness fo r sur e, but the impa ct bo dy wo uld

coll ide wi th t ube wa ll w hen it rebou nds, which will affect t he v elocity

of rebou nd. Ther efore, a g reater error is on t est ac curacy. W hen the

radi us of curvatu re of the t esting sampl e sur face is smaller, th e

solu tion is the use of suitable var iant suppo rting ci rcle. If users

requ ire special sup porting circ le, we can contribut e to design and

proc ess.

3) The wei ght of the samp le

If the sa mple weight must be larg er than or equal to 5kg, and not

easi ly sway. If the samp le weight w ere less, the s ample wou ld need

prop er tr eatment (I t is neces sary to in crease the supp orting or

moun ting th rough coupling comp ress on larger weig ht test ing sta nd),

and the test ing result s can be ac hieved in accur acy. There shou ld be

a certain area at the testi ng po ints (the area require d to meet a set of

test ing points) and no vi bration or shak ing. I f th e we ight i s not

enou gh, users mus t be as much as possib le reduce the ji tter and

slos hing by the method s of i ncreasi ng s upporting , couplin g and

comp ressing . And supporti ng device s hould avoid s hock.

4) The sam ple stabili ty

Any effective test s need to mi nimize possibl e inter ference from

outs ide; it's more impor tant to dynamic me asure such as Leeb

hard ness test. T herefore, meas uring only allowe d in stabl e har dness

test ing system. If it's lik ely to l ead to s ample movem ent in t he t ests,

user s should fi x it b efore tes ting.

HLD

HV

Materials

Steel & cast steel

Tool steel

Stainless steel

Cast iron

Cast aluminum alloy

Brass

Bronze

Copper

300-900

300-840

300-800

360-650

170-570

200-550

300-700

200-960

81-955

80-898

85-802

HB

HRC HRB

-68 38 -100

20

81-654

20-67

85-655

85-655

93-334

93-334

19-164

19-164

40-173

60-290

45-315

47-101

23

13-95

HS

32 -100 375 -2639

-84

Standard Delivery

Main unit

Impact device D

Hardness test block

Small support ring

Cleaning brush

1pc

1pc

1pc

1pc

1pc

Optional Accessory

Support rings

Wireless printer

refer to our catalogue

ISH-DS-PRINTER

Tensile

strength(Mpa)

9 10

Loading...

Loading...