Page 1

www.insigniarange.com Last Modied: 26/01/2017

INSTALLATION MANUAL

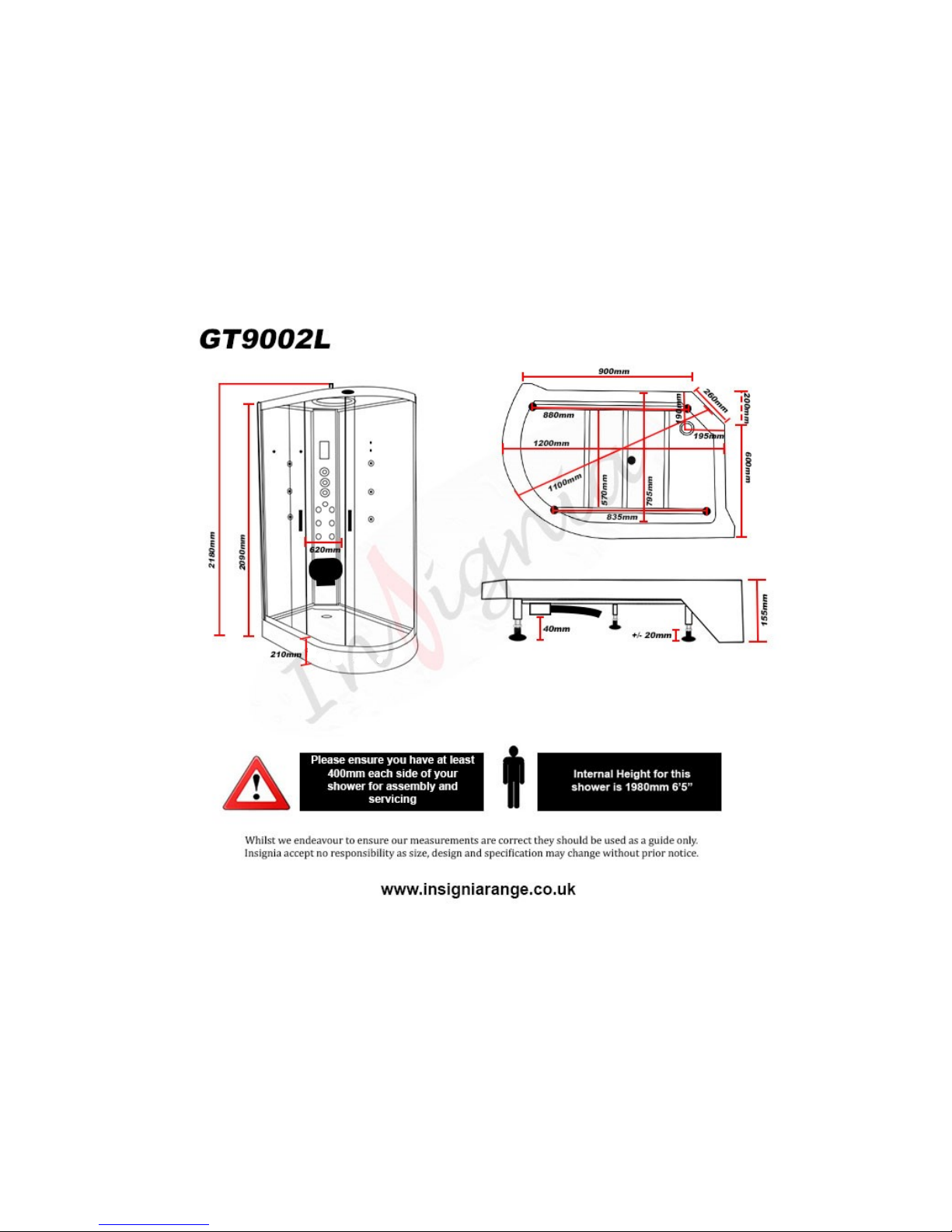

GT9002L

ATTENTION INSTALLERS:

These instrucons must be

le with the customer

30 Day Technical Support: 01908 226545

(NOTE: This service is only available to customers from the day of deli very,

please have your supplier’s details and your postcode to hand be fore calling)

Replacements Parts: inside of your warranty contact:

www.insigniarange.co.uk/customerService.aspx

Spares/Replacements Parts: outside of your warranty

contact 0844 800 3069

www.insigniarange.co.uk

WARRANTY REG NO: __________________________

To claim your full 5 year warranty, register your shower within 90 days of delivery at: www.insigniarange.co.uk/

warrantyreg.aspx. Standard 12 month warranty applies if outside this me period.

CHECK ALL CONTENTS BEFORE BUILD COMMENCES. NO RETURNS CAN BE MADE

ONCE THE BUILD HAS STARTED AS IT IS DEEMED ACCEPTANCE OF PRODUCT!

Page 2

www.insigniarange.com Last Modied: 26/01/2017

02

Contents

Introduction

Electrical Requirements

What’s In The Boxes?

Screw Pack Contents

Plumbing Requirements

Schematics

Starting The Installation

Electric Box Connections

Sealing and Water Testing

MK117L Control Panel Instructions

Help Book Information

Parts list

3

5

6

8

9

10

11

20

21

22

23

24

Page 3

www.insigniarange.com Last Modied: 26/01/2017

03

Thank you for your recent purchase of an Insignia shower. Please read this booklet with great care to ensure you get the best out of your build and have a shower that

will last for many years to come!

Like everything, in order to obtain a first class product that will serve you well for many years, the effort and correctness put into the assembly will reflect in the quality of

your finish.

OUR BADGE RATING IN TERMS OF DIFFICULTY OF ASSEMBLY IS BASED ON CLIENT FEEDBACK

1 Badge = Very easy

2 Badges = Easy

3 Badges = Moderate

4 Badges = Harder than average

5 Badges = Professional skills required

This shower is rated 3 Badges

Page 4

www.insigniarange.com Last Modied: 26/01/2017

04

ASSEMBLY AND PLUMBING

THIS PRODUCT BUILD IS RATED SUITABLE FOR DIY PURPOSES PROVIDING THE CUSTOMER IS OF ABOVE AVERAGE SKILL AND FEELS CONFIDENT IN

THEIR ABILITY. ONLY YOU THE CUSTOMER WILL KNOW THIS SO BEFORE ANY ATTEMPT IS MADE TO ASSEMBLE, READ THROUGH THE FOLLOWING

PAGES IN DETAIL THEN DECIDE. IF YOU HAVE ANY DOUBT USE THE SERVICES OF A PROFESSIONAL. IN PICKING SUCH, ALLOW THEM TO DECIDE IF

THEY ARE CAPABLE OF BUILD BY FIRST SHOWING THESE INSTRUCTIONS TO THEM. ALWAYS GET THREE QUOTES.

REMEMBER THE BEST IS NOT ALWAYS THE CHEAPEST!

REMEMBER PLUMBERS PLUMB! 90% OF THIS JOB IS NOT PLUMBING!

DUE TO THE NATURE OF THIS PRODUCT WE HIGHLY ADVISE THE PURCHASE AND FITTING OF A WATER SOFTENER

(PLEASE NOTE LIMESCALE BUILD UP MAY CAUSE DAMAGE TO YOUR SHOWER AND WILL NOT BE COVERED UNDER WARRANTY)

ELECTRICAL CONNECTION TO HOUSE MAINS

WHEN YOUR ITEM IS ASSEMBLED ALWAYS USE THE SERVICES OF A FULLY QUALIFIED ELECTRICAN COMPANY TO COMPLETE THE CONNECTION FROM

SHOWER TO THE HOUSE SUPPLY. LAWS DEMAND IN MANY CASES YOU DO THIS AND YOUR WARRANTY IS VOID IN REGARDS TO THE ELECTRICAL

ITEMS IF THIS IS NOT UNDERTAKEN.

YOURS AND OTHERS SAFETY IS PARAMOUNT. NEVER ATTEMPT THIS YOURSELF!

REMEMBER:

These showers are designed to be free standing and movable from their location should you have the need to replace anything. ALWAYS USE Flexible braided water

inlet pipes (not supplied) at least a metre long (not central heating plastic type!)

Always use a flexible waste pipe from your house supply to the shower .

NEVER FIX with rigid pipes, NEVER FIX the unit to the wall.

DURING BUILD, LIKE ALL SHOWERS CORRECT SEALING IS IMPERATIVE.

If you are using Insignia’s RubberGum, please ensure the product does not come in contact with your silicone as this will cause the RubberGum to fail and

will not adhere as intended.

ATTENTION

ALWAYS FIT EASY TO GET TO ISOLATION TAPS ON BOTH THE HOT AND COLD WATER SUPPLY (NOT SUPPLIED). JUST LIKE A

DISHWASHER OR WASHING MACHINE, THIS PRODUCT MUST BE ISOLATED WHEN NOT IN USE.

FLEXIBLE SUPPLY HOSES (NOT SUPPLIED) COUPLE HERE AS ORIGIN OF SUPPLY

Page 5

www.insigniarange.com Last Modied: 26/01/2017

05

TOTAL ELECTRICAL REQUIREMENTS

Voltage Rating 220 -240AC

Frequency Rating 50HZ

Power Rating 2.8KW

Your electrical contractor should understand ALL legal requirements of connection before undertaking any work or installation.

UNDER NO CIRCUMSTANCES UNDERTAKE THIS YOURSELF!!!

Note for electrician. This product comes with 13 amp plug(s) fitted with an RCD unit. We leave it this way for you to connect this your own way

due to continued additions to current regulations. As at October 2010 we offered two methods.

1) Connect within current laws and IP directives using plug and RCD provided with steam version or supply one for non steam version

2) (Preferred) Wire into isolated fused feed connecting directly to the house consumer/service box. Remove the fitted plug and ensure the

Consumer unit has capabilities to replace RCD feature if RCD is removed.

Always use protection against electrical surge. Your shower should be treated the same as a home computer. A surge protector should

eradicate the possibility of either the transformer or computer control being burnt out. Please note earth is required and found on chassis of

shower tray. A further earth is required from Steam Generator unit. Each earth must ground through power supply line.

Page 6

www.insigniarange.com Last Modied: 26/01/2017

06

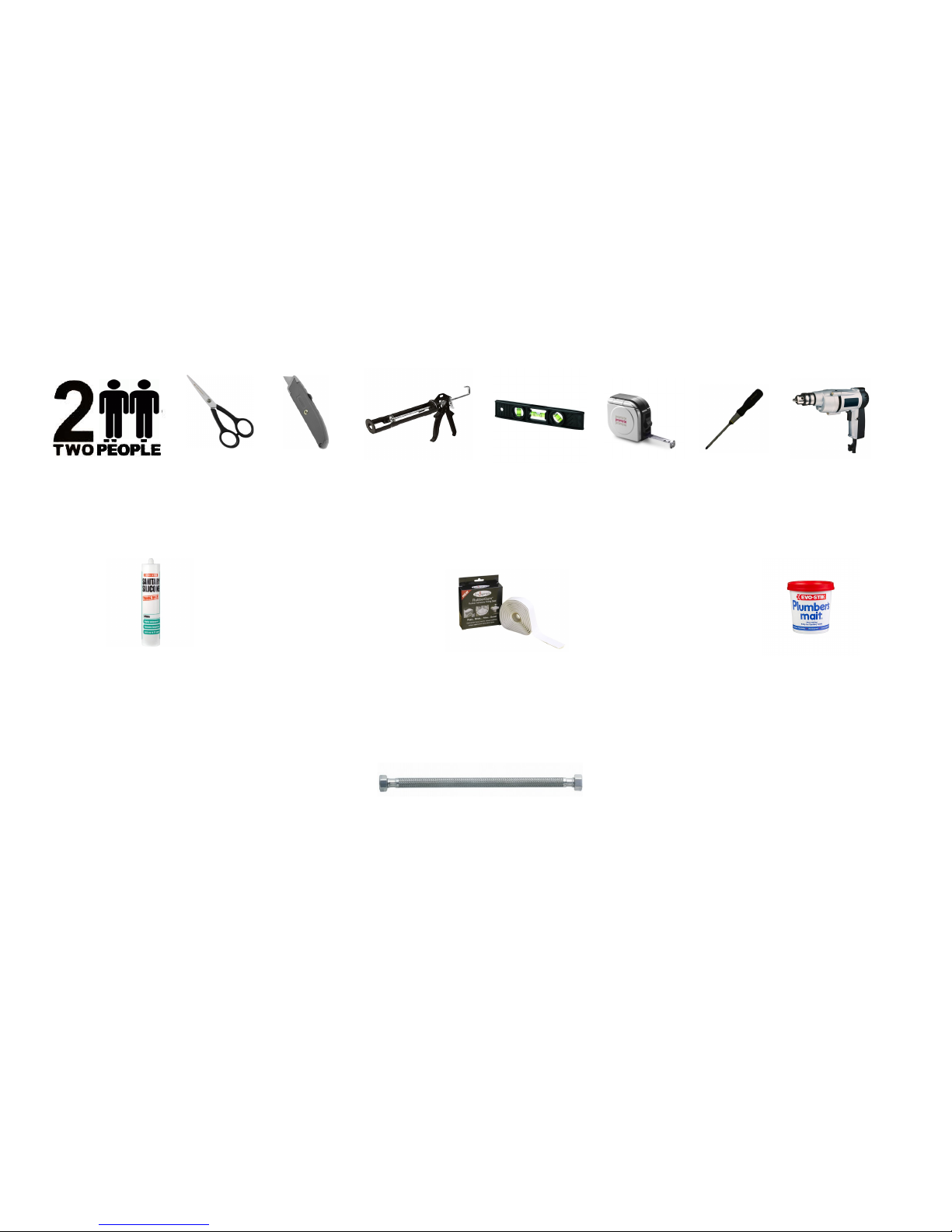

Tool Requirements

None Supplied

Scissors Stanley Blade Silicone Gun Spirit Level Tape Measure Philips Screwdriver Electric Drill

Adhesive Requirements

Hardware Requirements

Bacteria Resistant Sanitary Silicone - (for vertical joints) RubberGum Plumbers Mait (for waste joints)

A Hydro-Massage Shower requires 2 x 1 Metre Braided Hose

Not Supplied

Not Supplied

Not Supplied

Supplied

Page 7

www.insigniarange.com Last Modied: 26/01/2017

07

Whilst the next steps show you how to assemble your shower we want to make sure you have a correct build to ensure you get a trouble free shower. Therefore our advice

is to follow the instructions and perform a dry run to ensure you are confident with the build and you understand fully how t he unit is assembled. When we use the word

“DRY RUN” this means you do not silicone anything, just simply construct the shower, align, drill and screw everything together. Once y ou are happy with the build take the

unit apart and carry out the final fix.

What’s In The Boxes?

Tray Box

1x Tray

1x Roof

2x Curved Rails

1 x AC-DC 12V Adapter

Glass Room

2x Door seals

2x Glass doors

2x fixed glass

Column

1x Complete Column

Backwalls

1x Left Panel Backwall

1x Right Panel Backwall

In addition to above you will have all the required internal accessories to complete the shower

Page 8

www.insigniarange.com Last Modied: 26/01/2017

08

Insignia Screw Pack

VERY IMPORTANT

Have you got everything? If not please contact the Insignia Support Line on 01908 226545. Remember NEVER book your tradesman until everything has arrived, been

checked and is present. No replacement/missing parts can be obtained free of charge during or after the build. Any claims can only be within the timescale permitted (48

hours after delivery) and always BEFORE build.

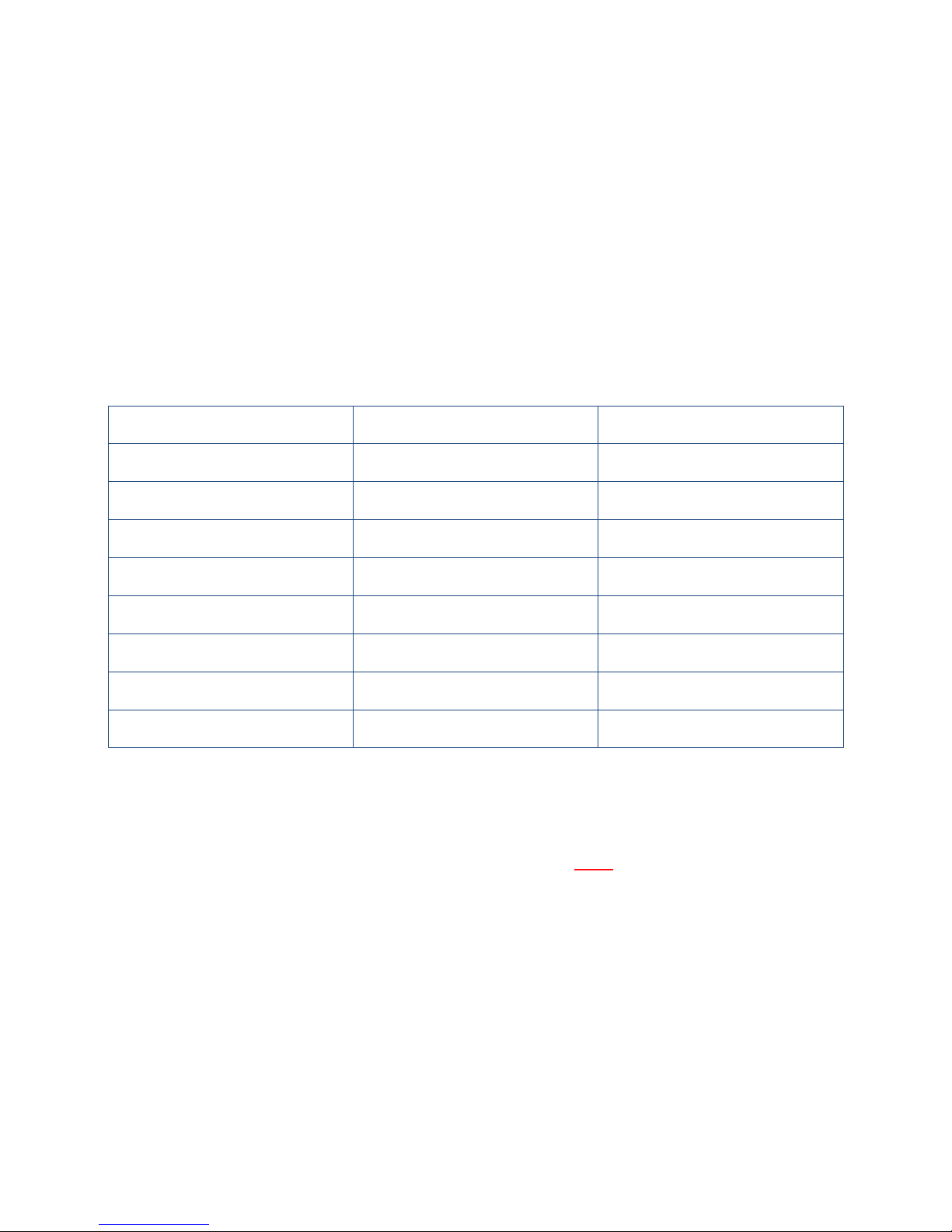

Product Code Descripon Quanty

SP097 Door Handles 2

SP008 Door Wheels 8

ST20 20mm Screws 20

ST35 35mm Screws 10

ST14 14mm Screws 6

ST25 25mm Screws 10

SW9 Small Washers 20

DB9 Drill Piece 1

Note: In some cases you may have more screws than needed, this is done so you have spares!

Page 9

www.insigniarange.com Last Modied: 26/01/2017

09

Pressure Requirements from your house supply

We recommend a bar pressure between 2.5 and 3.4 BAR. If you have a combi boiler system no problem should be experienced. If you have a gravity feed older type

installation (hot water tank type usually less than 1 bar) you will almost certainly need a pump. We cannot advise on which t ype of pump is used, location or design because

all house plumbing layouts vary. This is a job for your installer/plumber. The end delivery however must fall within the scop e above.

Important Note Do n ot exceed 3.4 BAR pressu re u nder any ci rcumstan ces. War ran ty is voi d i f s o as d amag e will o cc ur. If you h ave a c ombi s up ply, pl ease u se a

pressure reducing valve if required to lower the BAR pressure to the shower.

Please Remember that this product is free standing and is designed to be pulled away from the wall.

The waste hose must be of a flexible type (1m flexible waste supplied).

The water supply pipes need to be at least 1 metre in length and must be that of a flexible braided type (not supplied).

DO NOT OVERTIGHTEN THE BRAIDED HOSES AS IT CAN CAUSE THE CONNECTION TO POP AFTER A FEW WEEKS OF USE

Page 10

www.insigniarange.com Last Modied: 26/01/2017

10

Page 11

www.insigniarange.com Last Modied: 26/01/2017

11

TO START

Make sure you have a clear space, remember when finished and in place you need access to check your

build and able to pull the shower out for servicing or should you have the need to replace anything!

Take the shower tub and remove all the protective wrapping and fit the waste. In the side of the waste

supplied in the optional fitting kit you will notice a spigot not seen on an ordinary waste. In most cases this

is blanked yet should you have a steam version you need to gently drill this out as this item is for the

steam generator drainage and will be connected in the instructions later.

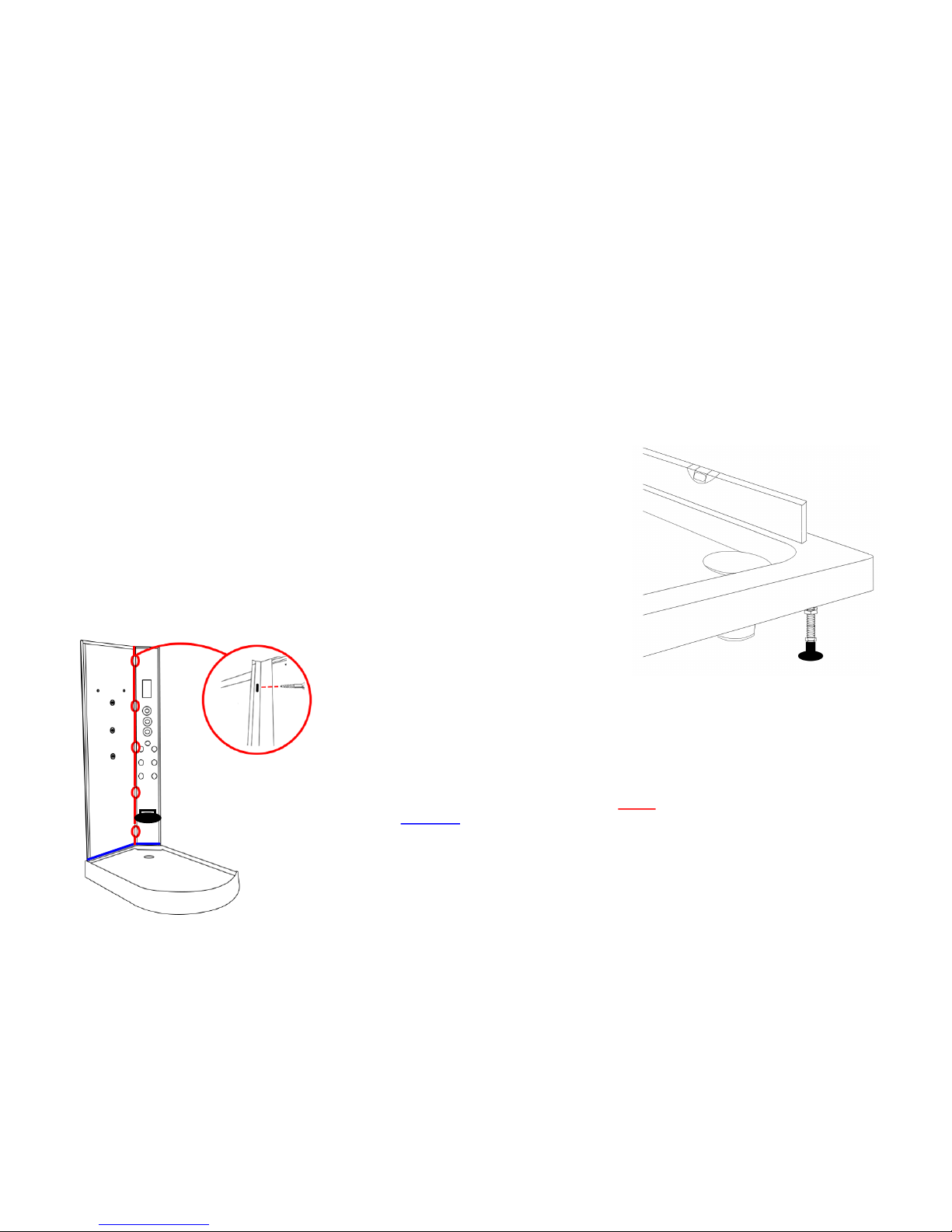

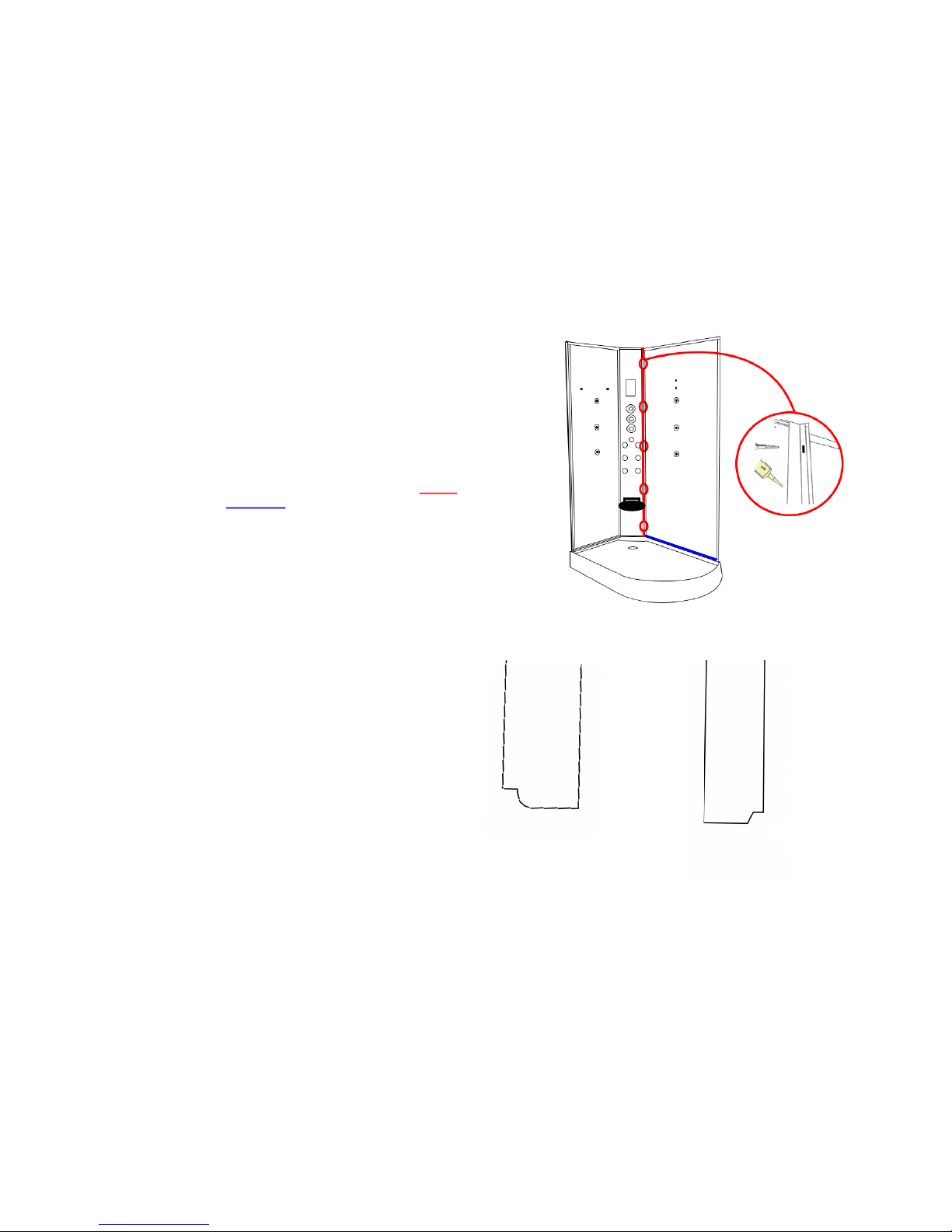

Step 1

Attach the small hand back panel to the back column.

Once you are happy with the alignment, run a bead of silicone up the

edge and Rubbergum along the bottom of the panels and screw to-

gether using the ST20

(please note, if your column has a rubber seal at the bottom , take the rubber

off and apply silicone inside the rubber and replace)

Whilst the next steps show you how to assemble your shower we want to make sure you have a correct build to ensure you get a

trouble free shower. Therefore our advice is to follow the instructions and perform a dry run to ensure you are confident with the

build and you understand fully how the unit is assembled. When we use the word “DRY RUN” this means you do not silicone

anything, just simply construct the shower, align, drill and screw everything together. Once you are happy with the build take the unit

apart and carry out the final fix.

Page 12

www.insigniarange.com Last Modied: 26/01/2017

12

Step 2

Now attach the large back panel to the column.

Once you are happy with the alignment, run a bead of silicone up

the edge and Rubbergum along the bottom of the panels and

screw together using the ST20

Step 3

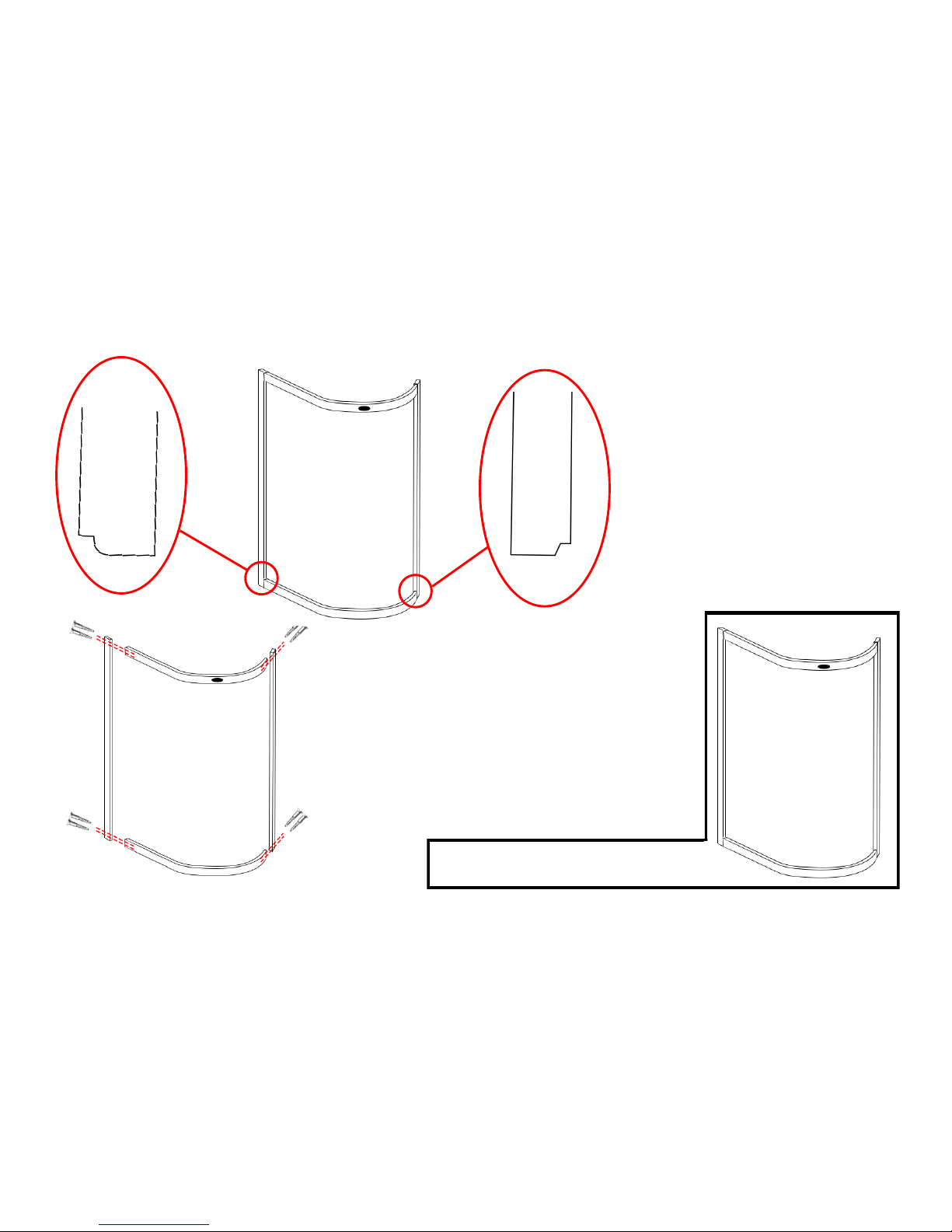

Front Fixed Uprights.

PLEASE NOTE:

The uprights have small grooves cut out, please see diagram. These

are designed to go at the bottom, connecting to the tray.

Please see next page for positioning on the tray!

Page 13

www.insigniarange.com Last Modied: 26/01/2017

13

Step 3 (Continued)

The next step is to attach both front uprights to the curved rails using

the ST35 screws as shown in the picture to the left

PLEASE NOTE

The screw head needs to bypass the OUTER hole. If this does not

occur please bore out the outer hole only by about 2-4mm

Your front metal work should now look like this

Step 3 (Continued)

Please Note:

With the groove sitting on the tray, you need to

have the “U” shaped channel facing inwards to

allow the glass to be inserted correctly.

Page 14

www.insigniarange.com Last Modied: 26/01/2017

14

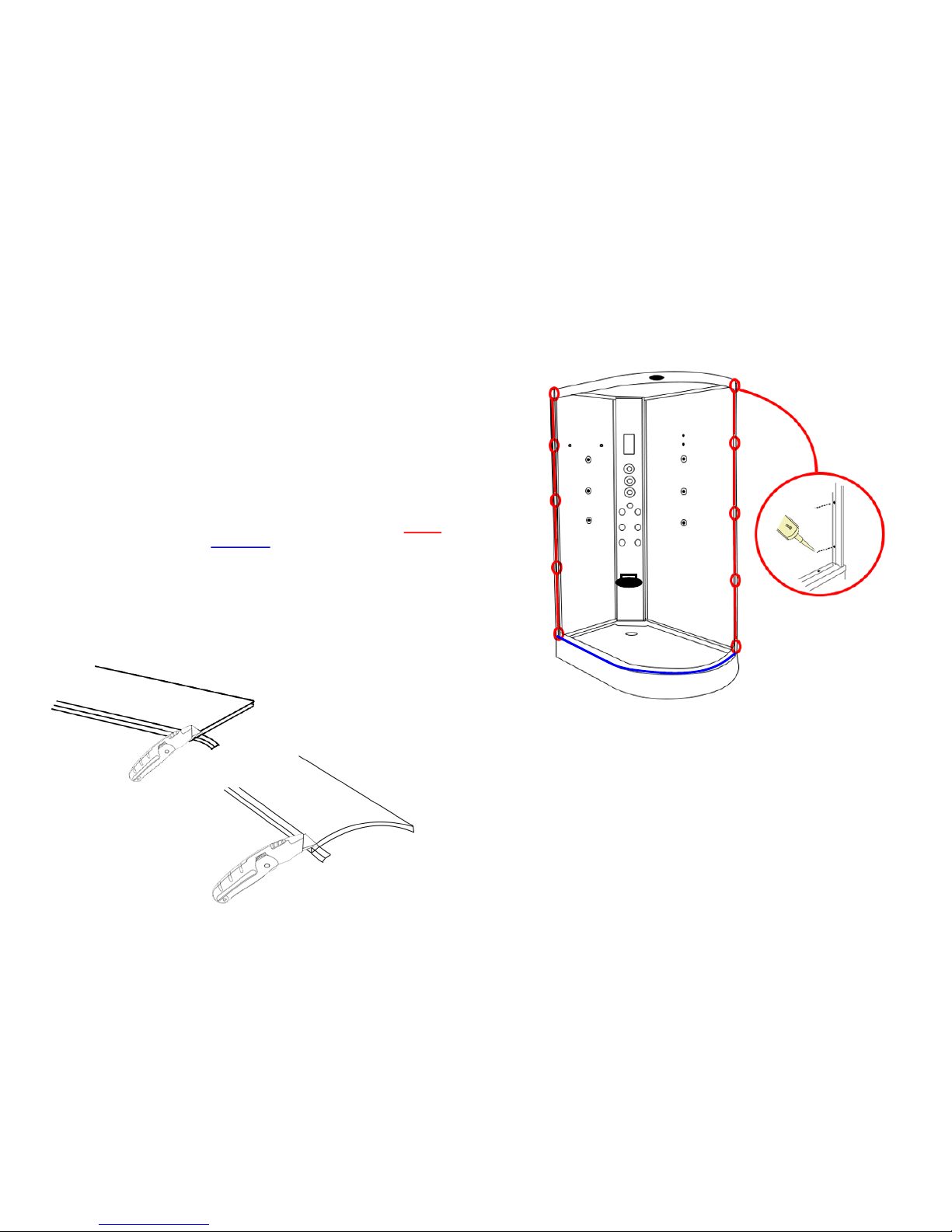

Step 5

Next attach the “U shape” rubber glass seal to the outer edge of the

curved and the straight fixed glass panels and cut any excess of if

required.

Step 4

Now attach your front metal work to the fitted back panels.

Once you are happy with the alignment, run a bead of silicone up

the edge and Rubbergum along the bottom of the panels and

frame and screw together using the ST20

Page 15

www.insigniarange.com Last Modied: 26/01/2017

15

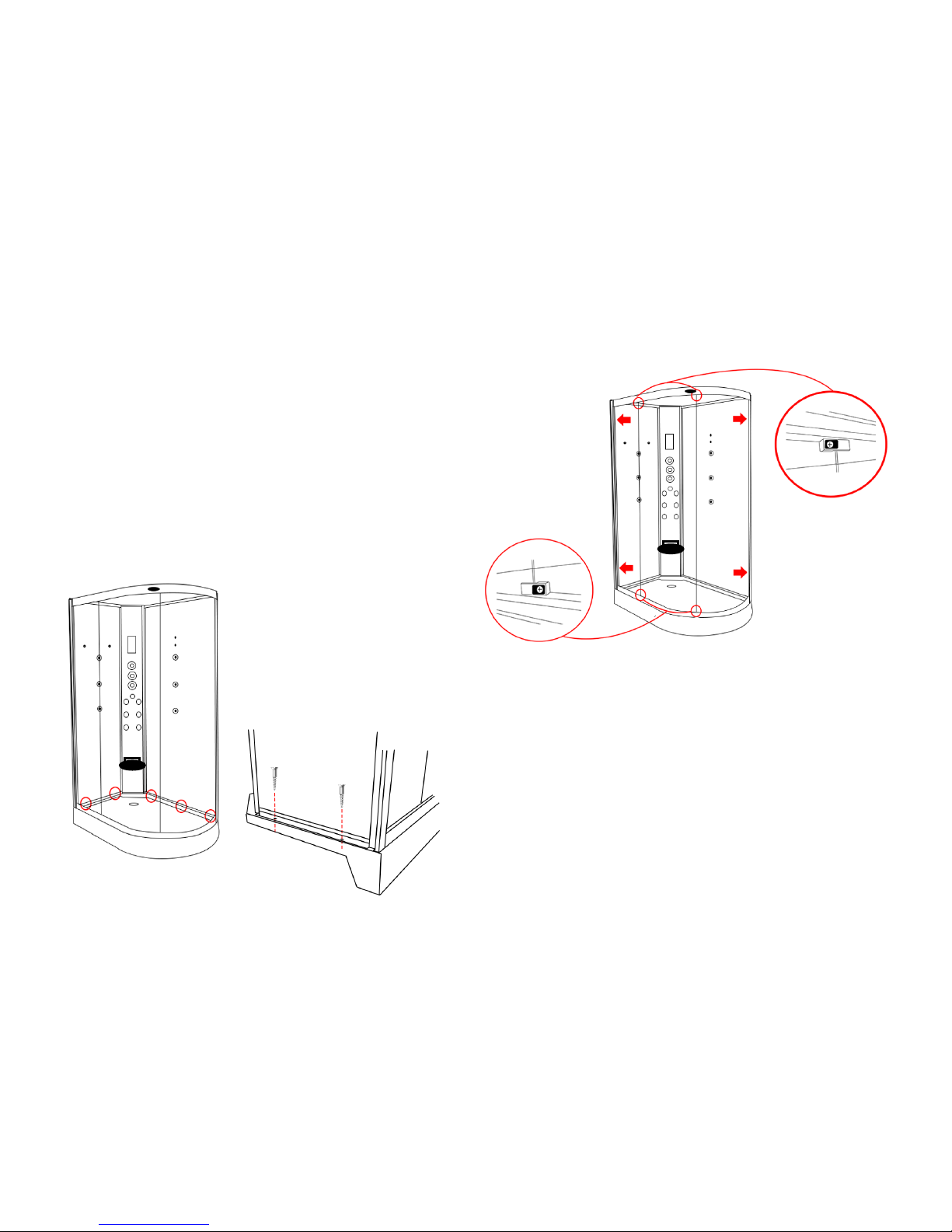

Step 7

Using the ST25 screws, ensure the back panels are square and you are happy with the

position of the panels then screw into place

Step 6

With the frame now attached to the back panels, locate and fix the glass panels into

place by pushing them as per the arrows in the adjacent image Making sure the

edge of the glass with the rubber seal fits into the grove tightly. Now screw the glass

retaining clips into place using the ST14 screws making sure the glass has a tight fit

Page 16

www.insigniarange.com Last Modied: 26/01/2017

16

Step 8

Next locate the roof into position. Once you are happy with the positioning of

this, screw into place using the ST25 screws,

Step 9

Fit the adjustable wheels to the top and bottom of the glass doors and ensure the

wheels are at their lowest position and hang on the inner curved rails with the wheels

facing the outside of the glass.

Once all wheels are fitted and on the rails you can adjust the wheels by turning the

plastic bolt clockwise in which in turn will pull the wheels towards the track ensuring a

secure a tight fit.

Now grease the track to ensure a smooth and long lasting operation

(not supplied)

Page 17

www.insigniarange.com Last Modied: 26/01/2017

17

Shelf

Fix the chrome floating shelf brackets to your glass back panel by using the provided screws. Now attach the chrome tubed bar s to your glass shelf as illustrated in the

below image. Next slide the shelf into your shelf brackets and secure by tightening the grub screw situated on the bottom of the bracket.

Accessory Installation

Please Note

Ensure all grey backing film on the rear of the glass panels are pierced through the existing glass holes

with a knife to provide an efficient smooth fitting and location of the accessories. We recommend using

a screwdriver on the smaller holes.

Hand Shower

1. Attach the chrome holder to the

back wall via the 2 screws provided

in the pack.

2. Attach the chrome water outlet to

the back of the centre column, fixing

it from the rear with the plastic hex

nut.

3. Attach the chrome flexible hose to

the water outlet with via small cou-

pling end

4. Attach the other end (sleeved) to

the hand shower and place in to the

holder.

NOTE: If you attach the wrong end of the

hose to the hand shower it will not sit in

the holder.

Page 18

www.insigniarange.com Last Modied: 26/01/2017

18

Door Seals

Magnetic Seal: Push the magnetic door seal on the handle side of the glass door ensuring

this is tightly fitted.

Rear Door Seal: Place the rear door seal on the opposite side to the magnetic strip ensuring

the flap is facing the fixed glass panel

Handle

Ensuring that the inner thread is protruding out from the handle far enough, place the handle

on the outside of the door and secure by tightening the inner chrome knob to the protruding

inner thread.

Monsoon Head

Attach the grey hose from your valve to the inner black tube using PTFE tape

(please note this only needs to be hand tight. Over tightening will snap/damage

the inner black tube)

Page 19

www.insigniarange.com Last Modied: 26/01/2017

19

Hot Water Inlet Cold Water Inlet

Hand Shower

Body Jets

Side Body Jets Monsoon Shower

Shower Valve

Connect the corresponding hoses to the rear of the valve as shown.

Device output may differ from the image. Please refer to your outer chrome faceplate in-

side your Insignia shower as a reference point.

IF YOUR DIAL DOES NOT CORRESPOND TO THE APPROPRIATE DEVICE:

Turn on your water to the shower and note which output the water exits from then turn off

the water and swap over the relevant hose.

Alternatively remove the outer chrome knob by removing the chrome cap and loosening

the grub screw (please ensure not to unscrew fully as this will drop within the chrome

knob) this is found on the opposite side to the chrome pillar. Once you have succeeded in

loosening this you can now slide your faceplate to correspond to the device.

This should be capped with a

brass cap.

Page 20

www.insigniarange.com Last Modied: 26/01/2017

20

Electric Box Connections

Roof Light

Fan

Speaker

Antenna

Back Lights

RJ11 Phone Connection

12V power Supply

Connect the cables below to the corresponding devices on the shower

Page 21

www.insigniarange.com Last Modied: 26/01/2017

21

Silicone Seal (vertical joints) - RubberGum (horizontal joints)

TESTING FOR WATER LEAKS

LEAVE THE SHOWER 24 HOURS AFTER BUILD TO ALLOW SEALENT TO

CURE AND ENSURE THE SHOWER IS AWAY FROM ITS FINAL POSITION

TO ALLOW REAR VIEWING

Ensure all connections are tight and sealed including the waste, body jets and

steam outlet (model dependent) on your shower.

Switch on the overhead shower NOT the massage jets, remember these will fire

water out at you and are not suitable for checking leaks as they would normally

only operate when a person is in front of them. DO NOT AIM THE HAND

SHOWER AT THE JOINTS OF YOUR SHOWER AS THIS DOES NOT FALL

UNDER “NORMAL EVERYDAY USE”. Adjust the feet to ensure the direction of

the water flows towards to the waste to prevent puddling.

Just use COLD water setting as hot will make cabin misty and condensate thus

the inspection becomes very difficult. Now on the OUTSIDE of the shower

inspect each joint, factory seal, hose, clip and jet by walking from one side and

going around to the back and then to the other side finishing at the front. If you

have a small leak (normally caused through insufficient sealer or air bubble on

assembly, dry the area thoroughly and reseal.

Please remember the location of the water may not be exactly where the leak is

as it could have run around to a low point. Never seal your inner fittings unless

necessary, remember you will see this for the life of the shower! Again leave to

cure and check. Once you are happy check the shower functions i.e. jets for

back massage, foot massage and finally hand shower (model dependent) check

your joints to these functions at the rear again. Never use the shower until all

checks have been made and the installer is 100% happy in the knowledge no

leaks are present.

All good?

Now push your shower FROM THE BASE and NEVER THE GLASS OR FRAME

into its final resting position.

Happy Showering!

Page 22

www.insigniarange.com Last Modied: 26/01/2017

22

MK117L Control Panel Instructions

Buon 1 (Light Bulb)

Press 1x For Top Light

Press 2x For Column Light

Press 3x For All Lights

Press 4x To Switch O Lights

Buon 2 (Radio)

On/O

Buon 3 (Fan)

On/O

Buon 4 (Speaker)

Volume Down

Buon 5 (Radio)

Press once to acvate manual tune

Press and hold to acvate auto scan

Buon 6 (Speaker)

Volume Up

Buon 7 (Down Arrow)

Channel select down/manual search down

Buon 8 (M)

Access saved channels

Buon 9 (Up Arrow)

Channel select up/manual search up

Buon 10 (Alarm)

Acvate Alarm

Buon 11 (Telephone)

Answer telephone

Buon 12 (Lock)

The control panel will automacally lock when not in use for a

short me, hold this buon down for 3 seconds unl a beep is

heard and this will unlock and reacvate the control panel for

use

PLEASE NOTE:

(when in lock mode the display will have 2 ashing lines on the

display and the only buon that will work is the alarm)

Page 23

www.insigniarange.com Last Modied: 26/01/2017

23

Need Help?

Then simply download the following "Help" advice booklet found at this link below. This contains many useful items such as is your parts warranty registered, advice on

cleaning / servicing your shower cabin, fault finding and many more items. This is a MUST to read and not just "HELP". It saves time in nearly all cases, avoiding contact

with ourselves as most answers are there for a ready fix!

Simply visit: www.insigniarange.co.uk/help.aspx

Page 24

www.insigniarange.com Last Modied: 26/01/2017

24

Internal Items

External Items

Parts List

Part Code Part Descripon

GT9002L-15 Le Upright (straight)

GT9002L-16 Right Upright (Angled)

GT9002L-9 Blank column

GT9002L-17 Top rail

GT9002L-18 Boom rail

GT9002L-3 Blank roof

GT9002L-19 Tray

Framework (Le hand)

Part Code Part Descripon

GT9002L-6 Curved front door

GT9002L-7 Flat front glass door

GT9002L-14

GT9002L-11

Large Black Backwall

Small Black Backwall

GT9002L-12

GT9002L-4

Large Mirrored Backwall

Small Mirrored Backwall

GT9002L-13

GT9002L-10

Large White Backwall

Small White Backwall

GT9002L-5 Curved front xed glass

GT9002L-8 Flat front xed glass

Glass (Le Hand)

Part Code Part Descripon

SP063 Monsoon Shower head

SP243 Fold down seat

SP048 Massage jet—2 open ends

SP048A Massage jet—1 open, 1 closed

SP123 Shower head holder

SP159 Shower waste

SP097 Chrome rectangular door han-

dles

SP240 Glass Shelf

SP072 Door stoppers

SP008 Door Wheels

SP060 Electrical extension cable

SP003 Ring light

SP038 Speaker

SP007 Fan

SP037 Fan & speaker cover

SP177 MK117L Control panel

SP152 Standard shower head

Sp166 Approximately 4 meters of

“U Style” seals

Part Code Part Descripon

SP300 Waste hose

SP187 Drain Hose

SP024 Transformer

SP308 Magnec door seals

SP310 Rear door seals

SP153

SP126

SP045

SP182

SP043

3 port—3 feed thermostac valve

4 Port Selector Cartridge

On/O Water Mixer

Valve

Vernet Screw Fit Thermostac Cartridge

Plasc Thermostac

Page 25

www.insigniarange.com Last Modied: 26/01/2017

25

All images are subject to copyright. Images may not be used in any way shape or form with out written permission from Maclean International Ltd. Images are NOT permitted

to be saved, printed or uploaded. Violation of copyright laws are punishable by law.

All images are registered with

ImageTraker

Insignia™ is a registered trademark of Maclean International Ltd

Page 26

www.insigniarange.com Last Modied: 26/01/2017

INSTALLATION MANUAL

GT9002R

ATTENTION INSTALLERS:

These instrucons must be

le with the customer

30 Day Technical Support: 01908 226545

(NOTE: This service is only available to customers from the day of deli very,

please have your supplier’s details and your postcode to hand be fore calling)

Replacements Parts: inside of your warranty contact:

www.insigniarange.co.uk/customerService.aspx

Spares/Replacements Parts: outside of your warranty

contact 0844 800 3069

www.insigniarange.co.uk

WARRANTY REG NO: __________________________

To claim your full 5 year warranty, register your shower within 90 days of delivery at: www.insigniarange.co.uk/

warrantyreg.aspx. Standard 12 month warranty applies if outside this me period.

CHECK ALL CONTENTS BEFORE BUILD COMMENCES. NO RETURNS CAN BE MADE

ONCE THE BUILD HAS STARTED AS IT IS DEEMED ACCEPTANCE OF PRODUCT!

Page 27

www.insigniarange.com Last Modied: 26/01/2017

02

Contents

Introduction

Electrical Requirements

What’s In The Boxes?

Screw Pack Contents

Plumbing Requirements

Schematics

Starting The Installation

Electric Box Connections

Sealing and Water Testing

MK117L Control Panel Instructions

Help Book Information

Parts list

3

5

7

8

9

10

11

20

21

22

23

24

Page 28

www.insigniarange.com Last Modied: 26/01/2017

03

Thank you for your recent purchase of an Insignia shower. Please read this booklet with great care to ensure you get the best out of your build and have a shower that

will last for many years to come!

Like everything, in order to obtain a first class product that will serve you well for many years, the effort and correctness put into the assembly will reflect in the quality of

your finish.

OUR BADGE RATING IN TERMS OF DIFFICULTY OF ASSEMBLY IS BASED ON CLIENT FEEDBACK

1 Badge = Very easy

2 Badges = Easy

3 Badges = Moderate

4 Badges = Harder than average

5 Badges = Professional skills required

This shower is rated 3 Badges

Page 29

www.insigniarange.com Last Modied: 26/01/2017

04

ASSEMBLY AND PLUMBING

THIS PRODUCT BUILD IS RATED SUITABLE FOR DIY PURPOSES PROVIDING THE CUSTOMER IS OF ABOVE AVERAGE SKILL AND FEELS CONFIDENT IN

THEIR ABILITY. ONLY YOU THE CUSTOMER WILL KNOW THIS SO BEFORE ANY ATTEMPT IS MADE TO ASSEMBLE, READ THROUGH THE FOLLOWING

PAGES IN DETAIL THEN DECIDE. IF YOU HAVE ANY DOUBT USE THE SERVICES OF A PROFESSIONAL. IN PICKING SUCH, ALLOW THEM TO DECIDE IF

THEY ARE CAPABLE OF BUILD BY FIRST SHOWING THESE INSTRUCTIONS TO THEM. ALWAYS GET THREE QUOTES.

REMEMBER THE BEST IS NOT ALWAYS THE CHEAPEST!

REMEMBER PLUMBERS PLUMB! 90% OF THIS JOB IS NOT PLUMBING!

DUE TO THE NATURE OF THIS PRODUCT WE HIGHLY ADVISE THE PURCHASE AND FITTING OF A WATER SOFTENER

(PLEASE NOTE LIMESCALE BUILD UP MAY CAUSE DAMAGE TO YOUR SHOWER AND WILL NOT BE COVERED UNDER WARRANTY)

ELECTRICAL CONNECTION TO HOUSE MAINS

WHEN YOUR ITEM IS ASSEMBLED ALWAYS USE THE SERVICES OF A FULLY QUALIFIED ELECTRICAN COMPANY TO COMPLETE THE CONNECTION FROM

SHOWER TO THE HOUSE SUPPLY. LAWS DEMAND IN MANY CASES YOU DO THIS AND YOUR WARRANTY IS VOID IN REGARDS TO THE ELECTRICAL

ITEMS IF THIS IS NOT UNDERTAKEN.

YOURS AND OTHERS SAFETY IS PARAMOUNT. NEVER ATTEMPT THIS YOURSELF!

REMEMBER:

These showers are designed to be free standing and movable from their location should you have the need to replace anything. ALWAYS USE Flexible braided water

inlet pipes (not supplied) at least a metre long (not central heating plastic type!)

Always use a flexible waste pipe from your house supply to the shower .

NEVER FIX with rigid pipes, NEVER FIX the unit to the wall.

DURING BUILD, LIKE ALL SHOWERS CORRECT SEALING IS IMPERATIVE.

If you are using Insignia’s RubberGum, please ensure the product does not come in contact with your silicone as this will cause the RubberGum to fail and

will not adhere as intended.

ATTENTION

ALWAYS FIT EASY TO GET TO ISOLATION TAPS ON BOTH THE HOT AND COLD WATER SUPPLY (NOT SUPPLIED). JUST LIKE A

DISHWASHER OR WASHING MACHINE, THIS PRODUCT MUST BE ISOLATED WHEN NOT IN USE.

FLEXIBLE SUPPLY HOSES (NOT SUPPLIED) COUPLE HERE AS ORIGIN OF SUPPLY

Page 30

www.insigniarange.com Last Modied: 26/01/2017

05

TOTAL ELECTRICAL REQUIREMENTS

Voltage Rating 220 -240AC

Frequency Rating 50HZ

Power Rating 2.8KW

Your electrical contractor should understand ALL legal requirements of connection before undertaking any work or installation.

UNDER NO CIRCUMSTANCES UNDERTAKE THIS YOURSELF!!!

Note for electrician. This product comes with 13 amp plug(s) fitted with an RCD unit. We leave it this way for you to connect this your own way

due to continued additions to current regulations. As at October 2010 we offered two methods.

1) Connect within current laws and IP directives using plug and RCD provided with steam version or supply one for non steam version

2) (Preferred) Wire into isolated fused feed connecting directly to the house consumer/service box. Remove the fitted plug and ensure the

Consumer unit has capabilities to replace RCD feature if RCD is removed.

Always use protection against electrical surge. Your shower should be treated the same as a home computer. A surge protector should

eradicate the possibility of either the transformer or computer control being burnt out. Please note earth is required and found on chassis of

shower tray. A further earth is required from Steam Generator unit. Each earth must ground through power supply line.

Page 31

www.insigniarange.com Last Modied: 26/01/2017

06

Tool Requirements

None Supplied

Scissors Stanley Blade Silicone Gun Spirit Level Tape Measure Philips Screwdriver Electric Drill

Adhesive Requirements

Hardware Requirements

Bacteria Resistant Sanitary Silicone - (for vertical joints) RubberGum Plumbers Mait (for waste joints)

A Hydro-Massage Shower requires 2 x 1 Metre Braided Hose

Not Supplied

Not Supplied

Not Supplied

Supplied

Page 32

www.insigniarange.com Last Modied: 26/01/2017

07

Whilst the next steps show you how to assemble your shower we want to make sure you have a correct build to ensure you get a trouble free shower. Therefore our advice

is to follow the instructions and perform a dry run to ensure you are confident with the build and you understand fully how t he unit is assembled. When we use the word

“DRY RUN” this means you do not silicone anything, just simply construct the shower, align, drill and screw everything together. Once y ou are happy with the build take the

unit apart and carry out the final fix.

What’s In The Boxes?

Tray Box

1x Tray

1x Roof

2x Curved Rails

1 x AC-DC 12V Adapter

Glass Room

2x Door seals

2x Glass doors

2x fixed glass

Column

1x Complete Column

Backwalls

1x Left Panel Backwall

1x Right Panel Backwall

In addition to above you will have all the required internal accessories to complete the shower

Page 33

www.insigniarange.com Last Modied: 26/01/2017

08

Insignia Screw Pack

VERY IMPORTANT

Have you got everything? If not please contact the Insignia Support Line on 01908 226545. Remember NEVER book your tradesman until everything has arrived, been

checked and is present. No replacement/missing parts can be obtained free of charge during or after the build. Any claims can only be within the timescale permitted (48

hours after delivery) and always BEFORE build.

Product Code Descripon Quanty

SP097 Door Handles 2

SP008 Door Wheels 8

ST20 20mm Screws 20

ST35 35mm Screws 10

ST14 14mm Screws 6

ST25 25mm Screws 10

SW9 Small Washers 20

DB9 Drill Piece 1

Note: In some cases you may have more screws than needed, this is done so you have spares!

Page 34

www.insigniarange.com Last Modied: 26/01/2017

09

Pressure Requirements from your house supply

We recommend a bar pressure between 2.5 and 3.4 BAR. If you have a combi boiler system no problem should be experienced. If you have a gravity feed older type

installation (hot water tank type usually less than 1 bar) you will almost certainly need a pump. We cannot advise on which t ype of pump is used, location or design because

all house plumbing layouts vary. This is a job for your installer/plumber. The end delivery however must fall within the scop e above.

Important Note Do n ot exceed 3.4 BAR pressu re u nder any ci rcumstan ces. War ran ty is voi d i f s o as d amag e will o cc ur. If you h ave a c ombi s up ply, pl ease u se a

pressure reducing valve if required to lower the BAR pressure to the shower.

Please Remember that this product is free standing and is designed to be pulled away from the wall.

The waste hose must be of a flexible type (1m flexible waste supplied).

The water supply pipes need to be at least 1 metre in length and must be that of a flexible braided type (not supplied).

DO NOT OVERTIGHTEN THE BRAIDED HOSES AS IT CAN CAUSE THE CONNECTION TO POP AFTER A FEW WEEKS OF USE

Page 35

www.insigniarange.com Last Modied: 26/01/2017

10

Page 36

www.insigniarange.com Last Modied: 26/01/2017

11

Step 1

Attach the small hand back panel to the back column.

Once you are happy with the alignment, run a bead of silicone up the

edge and Rubbergum along the bottom of the panels and screw

together using the ST20

(please note, if your column has a rubber seal at the bottom , take the rubber

off and apply silicone inside the rubber and replace)

Whilst the next steps show you how to assemble your shower we want to make sure you have a correct build to ensure you get a

trouble free shower. Therefore our advice is to follow the instructions and perform a dry run to ensure you are confident with the

build and you understand fully how the unit is assembled. When we use the word “DRY RUN” this means you do not silicone

anything, just simply construct the shower, align, drill and screw everything together. Once you are happy with the build take the unit

apart and carry out the final fix.

TO START

Make sure you have a clear space, remember when finished and in place you need access to check your

build and able to pull the shower out for servicing or should you have the need to replace anything!

Take the shower tub and remove all the protective wrapping and fit the waste. In the side of the waste

supplied in the optional fitting kit you will notice a spigot not seen on an ordinary waste. In most cases this

is blanked yet should you have a steam version you need to gently drill this out as this item is for the

steam generator drainage and will be connected in the instructions later.

Now please level the tray by firstly placing the tray in its final location and then using a spirit level, adjust

the tray feet accordingly. Once you are happy with the levelling of the tray, you can pull it out to begin the

main construction.

Page 37

www.insigniarange.com Last Modied: 26/01/2017

12

Step 2

Now attach the large back panel to the column.

Once you are happy with the alignment, run a bead of silicone up

the edge and Rubbergum along the bottom of the panels and

screw together using the ST20

Step 3

Front Fixed Uprights.

PLEASE NOTE:

The uprights have small grooves cut out, please see diagram. These

are designed to go at the bottom, connecting to the tray.

Please see next page for positioning on the tray!

Page 38

www.insigniarange.com Last Modied: 26/01/2017

13

Step 3

The next step is to attach both front uprights to the curved rails using

the ST35 screws as shown in the picture to the left

PLEASE NOTE

The screw head needs to bypass the OUTER hole. If this does not

occur please bore out the outer hole only by about 2-4mm

Your front metal work should now look like this

Step 3 (Continued)

Please Note:

With the groove sitting on the tray, you need to

have the “U” shaped channel facing inwards to

allow the glass to be inserted correctly.

Page 39

www.insigniarange.com Last Modied: 26/01/2017

14

Step 5

Next attach the “U shape” rubber glass seal to the outer edge of the

curved and the straight fixed glass panels and cut any excess of if

required.

Step 4

Now attach your front metal work to the fitted back panels.

Once you are happy with the alignment, run a bead of silicone up

the edge and Rubbergum along the bottom of the panels and

frame and screw together using the ST20

Page 40

www.insigniarange.com Last Modied: 26/01/2017

15

Step 7

Using the ST25 screws, ensure the back panels are square and you are happy with the

position of the panels then screw into place

Step 6

With the frame now attached to the back panels, locate and fix the glass panels into

place by pushing them as per the arrows in the adjacent image Making sure the

edge of the glass with the rubber seal fits into the grove tightly. Now screw the glass

retaining clips into place using the ST14 screws making sure the glass has a tight fit

Page 41

www.insigniarange.com Last Modied: 26/01/2017

16

Step 8

Next locate the roof into position. Once you are happy with the positioning of

this, screw into place using the ST25 screws,

Step 9

Fit the adjustable wheels to the top and bottom of the glass doors and ensure the

wheels are at their lowest position and hang on the inner curved rails with the wheels

facing the outside of the glass.

Once all wheels are fitted and on the rails you can adjust the wheels by turning the

plastic bolt clockwise in which in turn will pull the wheels towards the track ensuring a

secure a tight fit.

Now grease the track to ensure a smooth and long lasting operation

(not supplied)

Page 42

www.insigniarange.com Last Modied: 26/01/2017

17

Shelf

Fix the chrome floating shelf brackets to your glass back panel by using the provided screws. Now attach the chrome tubed bar s to your glass shelf as illustrated in the

below image. Next slide the shelf into your shelf brackets and secure by tightening the grub screw situated on the bottom of the bracket.

Accessory Installation

Please Note

Ensure all grey backing film on the rear of the glass panels are pierced through the existing glass holes

with a knife to provide an efficient smooth fitting and location of the accessories. We recommend using

a screwdriver on the smaller holes.

Hand Shower

1. Attach the chrome holder to the

back wall via the 2 screws provided

in the pack.

2. Attach the chrome water outlet to

the back of the centre column, fixing

it from the rear with the plastic hex

nut.

3. Attach the chrome flexible hose to

the water outlet with via small cou-

pling end

4. Attach the other end (sleeved) to

the hand shower and place in to the

holder.

NOTE: If you attach the wrong end of the

hose to the hand shower it will not sit in

the holder.

Page 43

www.insigniarange.com Last Modied: 26/01/2017

18

Door Seals

Magnetic Seal: Push the magnetic door seal on the handle side of the glass door ensuring

this is tightly fitted.

Rear Door Seal: Place the rear door seal on the opposite side to the magnetic strip ensuring

the flap is facing the fixed glass panel

Handle

Ensuring that the inner thread is protruding out from the handle far enough, place the handle

on the outside of the door and secure by tightening the inner chrome knob to the protruding

inner thread.

Monsoon Head

Attach the grey hose from your valve to the inner black tube using PTFE tape

(please note this only needs to be hand tight. Over tightening will snap/damage

the inner black tube)

Page 44

www.insigniarange.com Last Modied: 26/01/2017

19

Hot Water Inlet Cold Water Inlet

Hand Shower

Body Jets

Side Body Jets Monsoon Shower

Shower Valve

Connect the corresponding hoses to the rear of the valve as shown.

Device output may differ from the image. Please refer to your outer chrome faceplate in-

side your Insignia shower as a reference point.

IF YOUR DIAL DOES NOT CORRESPOND TO THE APPROPRIATE DEVICE:

Turn on your water to the shower and note which output the water exits from then turn off

the water and swap over the relevant hose.

Alternatively remove the outer chrome knob by removing the chrome cap and loosening

the grub screw (please ensure not to unscrew fully as this will drop within the chrome

knob) this is found on the opposite side to the chrome pillar. Once you have succeeded in

loosening this you can now slide your faceplate to correspond to the device.

This should be capped with a

brass cap.

Page 45

www.insigniarange.com Last Modied: 26/01/2017

20

Electric Box Connections

Roof Light

Fan

Speaker

Antenna

Back Lights

RJ11 Phone Connection

12V power Supply

Connect the cables below to the corresponding devices on the shower

Page 46

www.insigniarange.com Last Modied: 26/01/2017

21

Silicone Seal (vertical joints) - RubberGum (horizontal joints)

TESTING FOR WATER LEAKS

LEAVE THE SHOWER 24 HOURS AFTER BUILD TO ALLOW SEALENT TO

CURE AND ENSURE THE SHOWER IS AWAY FROM ITS FINAL POSITION

TO ALLOW REAR VIEWING

Ensure all connections are tight and sealed including the waste, body jets and

steam outlet (model dependent) on your shower.

Switch on the overhead shower NOT the massage jets, remember these will fire

water out at you and are not suitable for checking leaks as they would normally

only operate when a person is in front of them. DO NOT AIM THE HAND

SHOWER AT THE JOINTS OF YOUR SHOWER AS THIS DOES NOT FALL

UNDER “NORMAL EVERYDAY USE”. Adjust the feet to ensure the direction of

the water flows towards to the waste to prevent puddling.

Just use COLD water setting as hot will make cabin misty and condensate thus

the inspection becomes very difficult. Now on the OUTSIDE of the shower

inspect each joint, factory seal, hose, clip and jet by walking from one side and

going around to the back and then to the other side finishing at the front. If you

have a small leak (normally caused through insufficient sealer or air bubble on

assembly, dry the area thoroughly and reseal.

Please remember the location of the water may not be exactly where the leak is

as it could have run around to a low point. Never seal your inner fittings unless

necessary, remember you will see this for the life of the shower! Again leave to

cure and check. Once you are happy check the shower functions i.e. jets for

back massage, foot massage and finally hand shower (model dependent) check

your joints to these functions at the rear again. Never use the shower until all

checks have been made and the installer is 100% happy in the knowledge no

leaks are present.

All good?

Now push your shower FROM THE BASE and NEVER THE GLASS OR FRAME

into its final resting position.

Happy Showering!

Page 47

www.insigniarange.com Last Modied: 26/01/2017

22

MK117L Control Panel Instructions

Buon 1 (Light Bulb)

Press 1x For Top Light

Press 2x For Column Light

Press 3x For All Lights

Press 4x To Switch O Lights

Buon 2 (Radio)

On/O

Buon 3 (Fan)

On/O

Buon 4 (Speaker)

Volume Down

Buon 5 (Radio)

Press once to acvate manual tune

Press and hold to acvate auto scan

Buon 6 (Speaker)

Volume Up

Buon 7 (Down Arrow)

Channel select down/manual search down

Buon 8 (M)

Access saved channels

Buon 9 (Up Arrow)

Channel select up/manual search up

Buon 10 (Alarm)

Acvate Alarm

Buon 11 (Telephone)

Answer telephone

Buon 12 (Lock)

The control panel will automacally lock when not in use for a

short me, hold this buon down for 3 seconds unl a beep is

heard and this will unlock and reacvate the control panel for

use

PLEASE NOTE:

(when in lock mode the display will have 2 ashing lines on the

display and the only buon that will work is the alarm)

Page 48

www.insigniarange.com Last Modied: 26/01/2017

23

Need Help?

Then simply download the following "Help" advice booklet found at this link below. This contains many useful items such as is your parts warranty registered, advice on

cleaning / servicing your shower cabin, fault finding and many more items. This is a MUST to read and not just "HELP". It saves time in nearly all cases, avoiding contact

with ourselves as most answers are there for a ready fix!

Simply visit: www.insigniarange.co.uk/help.aspx

Page 49

www.insigniarange.com Last Modied: 26/01/2017

24

Parts List

Part Code Part Descripon

GT9002R-10 Le Upright (Angled)

GT9002R-11 Right Upright (straight)

GT9002R-19 Blank column

GT9002R-12 Top rail

GT9002R-13 Boom rail

GT9002R-4 Blank roof

GT9002R-2 Tray

Framework (Right hand)

Part Code Part Descripon

GT9002R-6 Curved front door

GT9002R-8 Flat front glass door

GT9002R-17

GT9002R-15

Large Black Backwall

Small Black Backwall

GT9002R-1

GT9002R-9

Large Mirrored Backwall

Small Mirrored Backwall

GT9002R-16

GT9002R-14

Large White Backwall

Small White Backwall

GT9002R-5 Curved front xed glass

GT9002R-7 Flat front xed glass

Glass (Right hand)

Internal Items

External Items

Part Code Part Descripon

SP063 Monsoon Shower head

SP243 Fold down seat

SP048 Massage jet—2 open ends

SP048A Massage jet—1 open, 1 closed

SP123 Shower head holder

SP159 Shower waste

SP097 Chrome rectangular door han-

dles

SP240 Glass Shelf

SP072 Door stoppers

SP008 Door Wheels

SP060 Electrical extension cable

SP003 Ring light

SP038 Speaker

SP007 Fan

SP037 Fan & speaker cover

SP177 MK117L Control panel

SP152 Standard shower head

Sp166 Approximately 4 meters of

“U Style” seals

Part Code Part Descripon

SP300 Waste hose

SP187 Drain Hose

SP024 Transformer

SP308 Magnec door seals

SP310 Rear door seals

SP153

SP126

SP045

SP182

SP043

3 port—3 feed thermostac valve

4 Port Selector Cartridge

On/O Water Mixer

Valve

Vernet Screw Fit Thermostac Cartridge

Plasc Thermostac

Page 50

www.insigniarange.com Last Modied: 26/01/2017

25

All images are subject to copyright. Images may not be used in any way shape or form with out written permission from Maclean International Ltd. Images are NOT permitted

to be saved, printed or uploaded. Violation of copyright laws are punishable by law.

All images are registered with

ImageTraker

Insignia™ is a registered trademark of Maclean International Ltd

Loading...

Loading...