PUMA

SUBSOILER

INSTRUCTIONS MANUAL

PUMA H

01

01 - Introduction

- Warranty certifi cate

02 - Parts:

- Subsoiler Puma

- Subsoiler Puma H

03 - Safety Rules

- Transport over truck

04 - Technical features:

05 - Assembly

- Assembly of ground wheel on the frame

- Wheel Assembly

- Rear roller Assembly

- Coulter Blade assembly

- Hydraulic system assembly

- Drawbar assembly

- Shanks assembly

06 - Hitch:

- Hitching the Subsoiler in the tractor

- Puma H Hitch Procedure

- Puma H Alignment Procedure

- Puma H Leveling Procedure

07 - Adjustment and operations:

- Depth Adjustment for Subsoiler Puma

- Depth Adjustment for Subsoiler Puma H

- Pressure Adjustment in auto-return Device

- Spacing between shanks Puma H

- Coulter Blade adjustment

- Rear Roller Subsoiler Puma

- Operations

08 - Maintenance:

- Lubrication

- Operations maintenance - Problems During the Subsoilers Works

- Operations maintenance - Problems With Hydráulics System

- Lubrication point

- Tyres infl ations

- Subsoiler transport

10 - Clear procedure

11 - Spare parts

12 - Identifi cation

TABLE OF CONTENT

2

3

4

5

6 - 7

8

9

10

10

10

11

11

12

12

13 - 14

15

15

16

16

17

17

18

18

19

19

20

21

21

22

23

24

25

25

26

26

26

02

INTRODUCTION

This manual is an important part of your machine provided by INRODA

Indústria de Roçadeiras Desbravador Avaré Ltda and should remain with

the machine when you sell it.

Reading your operator’s manual will help you and others avoid personal

injury or damage to the machine. Information given in this manual will provide the operator with the safest and most effective use of the machine.

Knowing how to operate this machine safely and correctly will allow you to

train others who may operate this machine.

The dealer will delivery the equipments and explain about safe working,

maintenance technical support and provide further details about the terms

and conditions of the warranty.

To obtain performance of the warranty, the original purchaser must request warranty service from a distributor authorized to sell the product to

be serviced .

Following the instructions of this manual and correct maintenance it will

provide a long years of trouble-free from your implement.

03

WARRANTY CERTIFICATE

INRODA Indústria de Roçadeiras Desbravador Avaré Ltda., as manufacturer warrants all parts, (except those referred to below), of the product

described in this manual to be free from defects in materials and workmanship during the period of 6 (six) month from the invoice date to the first

purchaser following the rules bellow :

WARRANTY COVER

The warranty will cover defective parts not subject to normal wear and tear will be repaired or replaced at our option during the warranty period

when the use follow the content of this manual.

To requesting the warranty is necessary show the warranty certificate and invoice with all fields filled in observance of the warranty rules.

WARRANTY VOID CONDITIONS

This warranty does not apply to equipment or parts that have been subjected to improper or unauthorized installation or alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper maintenance, repair or storage so as, in our judgment, to adversely affect its

performance and reliability;

Failure to follow recommended operating and maintenance procedures, including maintenance in dealer unauthorized by the manufacturer, also

voids warranty

Maintenance and replacement of parts by not genuine INRODA parts;

Project changes also void the warranty;

Incomplete or incorrect filling of the warranty certificate.

THE WARRANTY DOES NOT COVER:

Damages caused by accidents;

Part damaged by the normal wear unless problems from defects in materials and workmanship.

Fluids and lubricate oil;

Transportation charges on product submitted for repair or replacement under this warranty must be borne by purchaser.

GENERAL CONDITIONS

All equipment and parts replaced under this warranty will become the property of the manufacturer, INRODA;

The warranty of parts replaced are limited of the equipment warranty period above described.

Delay in warranty services does not provide right to reimbursement, indemnification or extending the warranty

04

01 - Complete auto-return shank

02 - Complete Wheel

03 - Complete wheel articulation support

04 - Frame

05 - Hydraulic hose support

06 - Hydraulic hoses

07 - Rear roller bearing

08 - Drawbar adjuster

09 - Drawbar hitch device

10 - Rear roller

11 - Complete coulter blade

12 - Attachment rear roller support

13 - Hydraulic cylinder

14 - Rear roller oscillation bar

02 - PARTS

13

14

07

05

12

08

DRAWING 01

09

06

09

04

14

01

02

03

11

10

SUBSOILER PUMA

05

01 - Frame

02 - Complete Shank

03 - Depth control wheels

02 - PARTS

02

01

03

SUBSOILER PUMA H

DRAWING 02

06

03 - SAFETY RULES

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL PERSONAL INJURY HAZARDS.

OBEY ALL SAFETY MESSAGES THAT FOLLOW THIS SYMBOL TO AVOID POSSIBLE INJURY OR DEATH.

1 - Do not keep bystanders, child near of the working area during the operations or over the implement.

2 - Do not turn on the tractor engine in closed place without appropriate ventilation because the gas is bad for health.

3 - Before coupling or uncoupling the hydraulic hoses relief the pressure

4 - Inspect periodically the hydraulic hoses and replace when fi nd any wear or damage, the oil work in high pressure and any damages may result in

serious injuries or death.

5 - Do not any adjustment when tractor is turned on

6 - During the tractor moving by roads pay attention in brake controls and use the safety devices

7 - Before performing any services in the discs gangs wear gloves.

8 - While maneuvering the tractor to hitch the implement be sure that there is enough space and nobody is too close, maneuver always in slow gear

and be ready to brake in case of emergency.

9 - Do not use large clothes because they can get caught on the implement.

10 - Drive the tractor always at safe speeds, especially when working in irregular or inclined lands, keep the tractor always geared.

11 - When working over hilly land try to keep the necessary stability. In case of instability reduce the acceleration, turn the wheels to the inclined side of

the land and never lift the implement.

07

12 - When you start the tractor engine, be correctly placed at the operators seat and be aware of the correct and safe handling of both tractor and implement. Always place the gearshift crank at the neutral position, turn off the gear of the power command and place the hydraulic commands at the neutral

position.

13 - Do not work with the tractor front’s too light in order to avoiding this problem use the extra-weights

14 - When you leave the tractor set the gear in neutral position and use the parking break. Never leaves the tractor with the hydraulic system raised.

WARNING: The incorrect handing of this implement may result in serious injuries or death. Before using the implement read carefully the instruction manual. Be sure that the person responsible for the operation is instructed about the correct handing and safety and has understood

the instruction manual concerning this machine.

08

TRANSPORT OVER TRUCK

The transport in long distances must be done by a truck or another vehicle able to doing it, following the instructions

below:

- For loading and unload the hoist use proper ramps Do not use hilly places it may result in serious injuries

or death.

- For unloading the hoist use proper anchor points .

- Lock the hoist on the vehicle during the transport.

- Use the proper devices (rope, chain, wire) to attaching the hoist during the transport procedures

- Inspect the hoist after 8km then check ropes and attachment devices every 100km traveled

- Pay attention about the transport height because electrical power lines overhead or in bridges may result

in serious injuries or death..

- Inform about local laws height and width requirements when necessary follow the regulations for lighting

requirements be sure turn signal lights and tail lights are clean and visible.

09

TABLE 01

Model Number

of shank

Working

Width

Spacing between

shanks (mm)

Weight Working depth

(mm)

Tractor

required (CV)

Work

speed

PUMA 3000 H 3 930

310

456

450

45 - 65

4 a 8 km/h

PUMA 5000 H 5 1550 642 60 - 80

PUMA 7000 H 7 2170 860 80 - 105

PUMA 9000 H 9 2790 1039 100 - 130

04 - TECHNICAL FEATURES

TABLE 02

Model Number

of shank

Working

Width

Disc

Diameter

Spacing between

shanks (mm)

Spacing betw

shanks

Working depth

(mm)

Tractor

required (CV)

Work

speed

PUMA 5000 5 1875

18” 375

1552

450

100 - 125

4 a 8 km/h

PUMA 7000 7 2625 2186 140 - 175

PUMA 9000 9 3357 2569 180 - 225

PUMA 11000 11 4125 3098 220 - 275

PUMA 13000 13 4875 3538 260 - 325

10

To inspecting the parts in the packet wear gloves and to moving the parts

from the packet use proper procedures.

05 - ASSEMBLY

ASSEMBLE OF GROUND WHEEL ON THE FRAME

WHEEL ASSEMBLY

To assemble the ground wheel on the frame follow the instructios below:

Install the bearing (1) in the wheel (2) using the bolts (3) then use the bolt

in the frame (4) locking with the washer (5) and nuts (6).

Install the hydraulic cylinder (7) between the frame (4) and wheel (2) using

the pins and cotter pins (8) follow the right position illustrated in the drawing

03.

DRAWING 03

Install the complete ground wheel (1) in the implement housing (2), then

attach using the nuts (3).

03

06

05

01

02

04

08

07

08

DRAWING 04

01

02

03

11

COULTER BLADE ASSEMBLY

Couple the coulter blade bearing (1) in the frame (2) using the bracket (3),

install the bolt (4) by the items (1) and (3) locking with the washer and nuts

(5) then install the coulter blade support (06) in the bearing, reaching the

best position for the working lock using the bolt and nut (7).

DRAWING 06

REAR ROLLER ASSEMBLY

To assembling the rear roller follow the instructions below:

When you fi nish the procedure to assemble the shank in the frame, couple

the support (1) on the frame (2) using the brackets (3) then put the bolt (1)

in the items (1) and (3) locking with the nuts and washers (5) as illustrated

in the drawing 5.

Then install the spring rod (6) in supports (1) locking with the cotter pin

(7), install the bar (8) in the support (1) coupling the spring rod (6) in the

bar (8) locking with the pin (9) and cotter-pin (10). Moreover install in the

spring rod the bushing (11), the spring (12) lock with the nuts (13), install in

DRAWING 05

the rear roller (14) the metal sheet (15) and couple the bar (08) using the

washer and nuts (16).

13

11

13

12

11

08

16

15

04

07

01

09

03

05

02

14

06

10

04

05

07

03

02

01

06

12

DRAWBAR ASSEMBLY

DRAWING 08

Joint the drawbar (1) in the frame (2) lock with the pin and lynch pin (3)

install the three point device (4) in the items (1) and (2) lock with the lynch

pin (5) then install the adjustment nut (6) and the hoses supports (7) as

illustrated in the drawing 8.

07

03

01

06

04

05

02

05

Attach the connector support (1) in the frame couple the hoses (2) from

the connectors support (1) to the hydraulic cylinder (3), the hoses from

the connectors support to hydraulic cylinder (5) and the hoses to (6) the

remote control. Then attach the hoses (4) using the supports (7) washer

and bolts (8).

DRAWING 07

08

08

07

02

04

01

05

03

06

07

HYDRAULIC SYSTEM ASSEMBLY (11 AND 13 SHANKS)

13

o facilitating the implement transport from the factory to the dealer it leaves

the factory almost assembled to fi nish the assembly procedures you will

need install the shanks. The drawings bellow has been illustrated to show

the right shank position on each models.

Couple in the frame (1) the shank support (2) and the spring support (3)

locking with the bolts (4) washers and nuts (5) install the spring adjustment

rod (6) in the shank auto-return system (7), in the spring support (3) attaching the bushing (8) springs (9) and locking with the nuts (10).

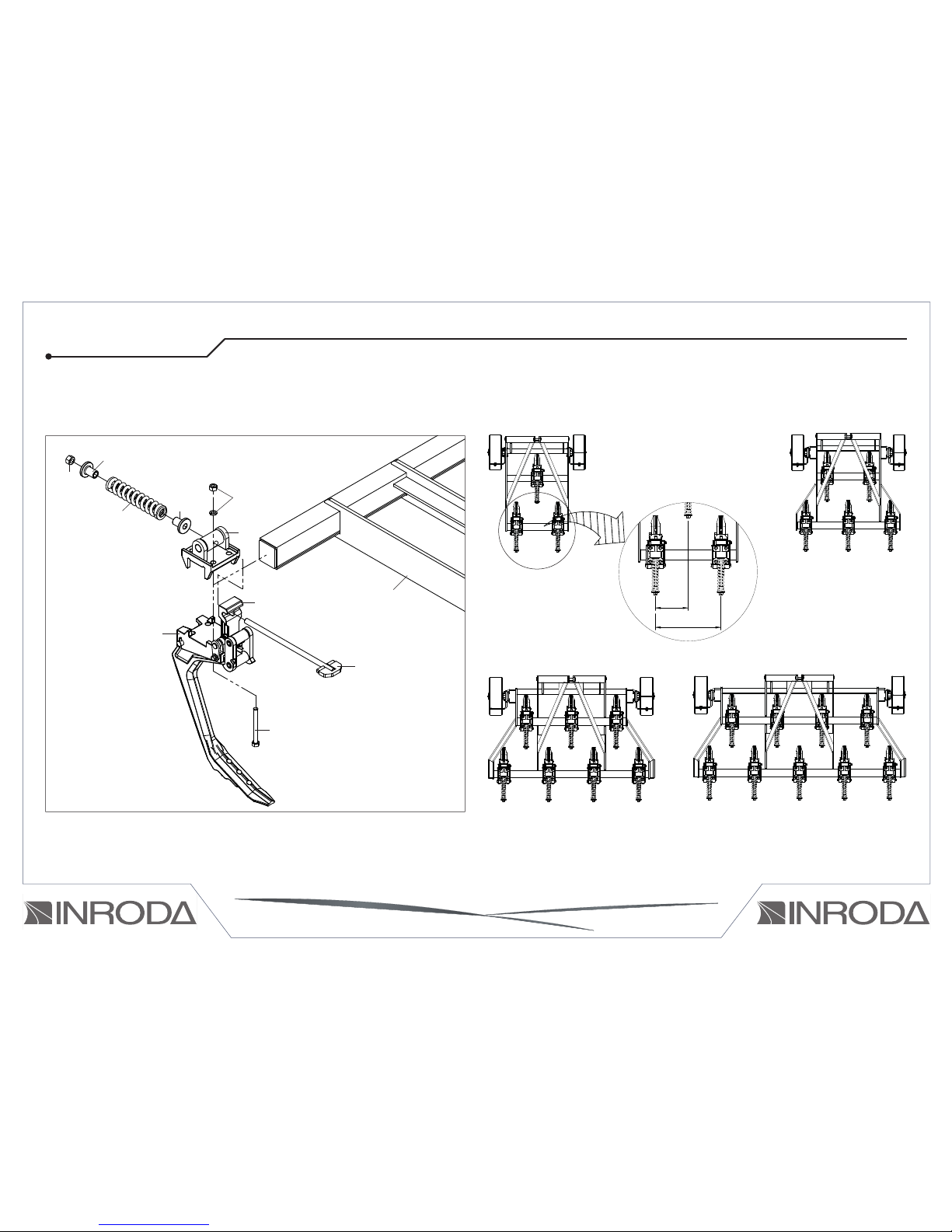

SHANKS ASSEMBLY

10

05

01

09

08

06

04

02

07

03

08

DRAWING 09

Puma 7000 H

Puma 3000 H

Puma 5000 H

Pum 9000 H

DRAWING 10

310

620

14

The drawings bellow has been illustrated the shank right position for each subsoiler model. Pay attention because the shanks are assembly in odd amount

in order to right assemble you need start by the central shank then reaching the ideal spacing for the working and assembly the lateral shanks.

Puma 5000

Puma 9000

Puma 7000

Puma 11000 Puma 13000

375750

750

DRAWING 11

15

PUMA H HITCH PROCEDURE

HITCHING THE SUBSOILER IN THE TRACTOR

To hitching the subsoiler in the tractor couple the implement drawbar (1) on

the tractor drawbar (02), couple the hydraulic hoses from the cylinders in

the quick-coupler.

Before coupling the implement in the tractor, be sure they are ready for this

procedure following the instructions below:

- Remove the drawbar

- When necessary use the tractor extra-weight

- The hitch procedure must be done in plane surface using daylight or good

artifi cial light

- Couple the three point left low arm using the pin (1) on the support “A”

- Couple the three point upper arm on the support “B” and lock with the pin

Then using the tractor height lever hitch the right low arm in the support “C”,

suing the lock as illustrated in drawing 13.

DRAWING 12

DRAWING 13

To coupling the hydraulic system clear the quick-coupler push the

female tip fi rmly into the coupler with another hand install the connector and loosen the quick-coupler. If you have any diffi cult push

the male quick-coupler against a clean and hard surface for relief the

pressure in the tip.

ATTENTION

B

01

A

C

06 - HITCH PROCEDURE

01

02

03

16

D

D

PUMA H ALIGNMENT PROCEDURE

The implement alignment procedure is done following steps below:

Align the upper three point bar in order to the length “D” is same in the both

sides of the tractor using as reference the tractor tyres. The lower tractor

three point arms must be aligned in the same position.

DRAWING 14

PUMA H LEVELING PROCEDURE

DRAWING 15

For leveling the implement follow the instructions below:

Choose a leveled surface, for leveling the implement in the transversal di-

rection (width) use the level from the lower right arm, inspect if the confi gu-

rations is in according to the drawing 15

The leveling longitudinal (length) is done by the three-point upper arm, it

must be done parallel in relation to the terrain.

Manivela de Regulagem

Braço do 3º ponto

Nivelamento longitudinal

(Comprimento)

H

H

Nivelamento Transversal

(Largura)

17

DEPTH ADJUSTMENT FOR SUBSOILER PUMA

07 - ADJUSTMENT AND OPERATIONS

DEPTH ADJUSTMENT FOR SUBSOILER PUMA H

The depth working of subsoiler PUMA H is done by the wheel (1) that keeps

all shanks in same position.

In order to adjusting it loosen the nut (2) move the wheel to the ideal position retighten the nuts.

Adjust the scrapers (3) loosening the nuts (4) moving the scrapers until

the right position, the manufacturer recommends keep the scrapers from 10

com to 20 cm far of the wheel.

The working depth is done by the depth wheel that is controlled by the

hydraulic system (1).

Defi ne the shank depth working raise the wheels until the depth reached

then install the lock device (2) in the hydraulic cylinder rods.

After this adjustment the depth working will be in according to the depth

defi ned because the lock devices not allow that the wheels move for

another position.

DRAWING

16

DRAWING 17

01

02

03

04

01

02

10 a 20 cm

18

PRESSURE ADJUSTMENT IN AUTO-RETURN DEVICE

The subsoiler leaves the factory with the spring adjusted in 30cm (length),

it is indicated for working in normal soil conditions. The increase the spring

pressure adjust is done by the nut “A” to decrease loosen it. The pressure

range is from 27,5cm to 30cm based on the spring length.

ATTENTION

The subsoiler not requires any additional

adjustment in the shanks, if the shank is

working out of the confi gurations, ins-

pect the soil conditions it has been hard

or compressed.

ATTENTION

For the best performance of subsoiler work with less pressure as

possible, but pay attention for de auto-return device not working out

of desired confi gurations.

DRAWING 18 DRAWING 19

30cm

SPACING BETWEEN SHANKS PUMA H

The shank’s spacing must be adjusted when you remove any shank, eg.

the subsoiler used to working with 9 shank right now will working with 7

shanks in according to the soil conditions.

To adjusting the shank’s spacing loosen the nuts (1) and move the shank

(3) to the desired position and retighten the nuts.

DRAWING 20

A

B

01

02

19

COULTER BLADE ADJUSTMENT

REAR ROLLER SUBSOILER PUMA

Conditions as subsoiling depth, amount of straws and moisture requires

adjusts in the height and down-pressure in the coulter blade.

To adjusting the coulter blade’s height (1) loosen the bolts (2) move the

shaft (3) for desired position then retighten the bolts (2).

The coulter blade down-pressure is done by the adjustment of the nuts and

cotter-nuts.

03

01

02

ATTENTION

Pay attention the coulter blade must be aligned with the shanks. All

counter blade should have the same adjustment.

DRAWING

21

The rear roller is proper to maintain the soil in the right position after the

subsoiling procedures, in order to level the terrain allocate the straws and

other debris provide a good conditions for no-till.

The rear roller pressure must be adjusted in according to the soil conditions, and provide a good completion of the job. In order to adjusting the

rear roller down-pressure

user the nuts (1).

To adjusting the right down-

-pressure follow the instructions below:

Adjust the depth working loosen the down-pressure nuts

(1);

Set the subsoiler in work position tighten the nuts until

lock the spring.

Turn twice time each nut to

provide the right pressure for

the springs.

ATTENTION

The device must be adjusted to providing the same down-pressure

in the rear roller, the down-pressure should be adjusted until not to

raise the subsoiler, it will provide a not regular subsoiling procedure.

Do not tighten too the nuts it may result in damages for some parts.

DRAWING 22

01

20

- Before set up the implement adjustment inspect the terrain’s

compaction dimension using proper methods.

- The subsoiler shanks was developed to auto-returning system when touch some debris, in order to unlock the system

just raise the implement after touch the debris.

OPERATIONS

- Retighten the nuts and bolts when you fi nish the fi rst working

day, inspect the pins, cotters pins and others device that may loosen, then inspect every 24 working hours.

- The subsoiling procedure should be done in terrain dry, to remove compaction lays and low areas to improve water drainage.

- The compaction layer is located below the fi rst terrain layer its

from 10 to 15 cm from terrain surface the layer compaction dimension is from 5 cm to 15cm.

- In some terrain conditions the hardest implement adjustment

could be not enough to subsoiling procedure, in these situations

the manufacturer recommends use other implements.

- Pay special attention in the discs gangs retighten daily in the

fi rst working week then repeat this procedure periodically.

- Set a right tractor gear in order it provide extra-power in any

unexpected event.

- The working speed is defi ned in according to the terrain con-

ditions, the manufacturer recommends a working speed from

4,5km/h to 5km/h the high working speed is able to decrease the

implement’s performance.

- Follow the lubrications schedule

- The tractor drawbar usually have a oscillation during the work.

21

TABELA 03

08 - MAINTENANCE

The correct lubrication is very important for providing a high durability and

a good working of the rotating parts of the engine that result in years of

trouble-free from the PUMA.

Before running the subsoiler, lubricate all-grease nipples in accordance

with the schedule on the next pages. Use lubes of high quality recommended by the manufacturer.

Existing lubricante or grease of other brands consult their technical

publication

The Puma subsoiler was developed for a long-term of trouble free in order

to reach this conditions you should realize a right maintenance procedure

as the described below:

- When you store the implement for a long term re-paint, protect the discs

with oil, lubricate all points avoiding the soil touch.

- The discs should be replaced when it decrease the performance, pay

attention in the discs diameter and other damages.

- Inspect all rotating parts replace when it show any worn.

- Re-tighten the bolts daily.

- Inspect daily the shanks tines and replace when it is worn.

- Inspect for leaks in hydraulic system (see more in table 03).

- Use the quick-coupler’s lids to protecting this device.

LUBRICATION

ATTENTION

MANUFACTURER RECOMMENDED GREASE TYPE

PETROBRÁS LUBRAX GMA 2

PETRONAS KP2K

IPIRANGA SUPER GRAXA IPIRANGA

IPIRANGA SUPER GRAXA 2

IPIFLEX 2

CASTROL LM 2

MOBIL MOBILGREASE MP 77

TEXACO MARFAK 2

AGROTEX 2

SHELL GRADUS S1 V150

MOBIL MULTIPURPOSE GREASE H

LITHOLINE MP 2

BARDAHL MAXLUB APG 2 EP

TUTELA KP2K

22

OPERATIONS MAINTENANCE - PROBLEMS DURING THE SUBSOILERS WORKS

The auto-return system not

unlock

The shanks are locked. Lubricate or replace.

The springs are too tighten Adjust the down-pressure as indicated in the label maximum 27.5cm

The frame is cracked

or warped

You working in curves too closed with the subsoiler into

the terrain.

When you maneuvering the implement remove the arms using the tractor remote control.

The auto-return system not unlock Adjust the down-pressure as indicated in the label maximum 27.5cm

Excessive tightening of the Springs Adjust the down-pressure as indicated in the label maximum 27.5cm

The springs are too tighten Low quality bolt Replace for spare parts the manufacturer recommends steel bolts 8.8

Subsoiler enter into the soil.

Implement working position is out of horizontal position Set the implement in horizontal position using the drawbar.

The shanks tines are worn Inverse the shank or replace it.

The adjustment bolt is short Turn the two bolts in counterclockwise direction until reach the right position. Do

the same confi guration in booth bolts.

The auto-returning system

unlock unexpected way.

The terrain there are many debris eg. stones stumps

roots.

Decrease the working speed or avoiding this areas.

Soil too compacted Replace the shanks tine from the 3” to 2”.

The tractor has high-power for this implement or high

speed.

Use the power and speed s recommended by the manufacturer.

Springs down pressure are not enough. Adjust the down-pressure as indicated in the label maximum 27.5cm.

The shanks devices are worn. Replace the worn parts.

PROBLEM POSSIBLE CAUSE SOLUTION

TABLE 04

23

OPERATIONS MAINTENANCE - PROBLEMS WITH HYDRÁULICS SYSTEM

Hydraulic cylinder leaks

Dirty oil High working pressure Replace oil and fi lters Adjust the pressure using a manometer,

the manufacturer recommends

Damaged seal rings Shank damaged. 180kg/cm2. Replace the seal rings. Replace the shanks

Reparos danifi cados. Substituir os reparos.

Haste danifi cada.* Substituir a haste.

Leaks in the hoses

with the connector

SAE JIC 37.

The conical device damaged. Cut of the hoses and install again.

Tighten not enough. Re-tighten carefully.

The implement is not moving or

moving too slow

Problem in tractor hydraulic system. Inspect and use a right tractor.

The oil level is low. Fill the oil.

Hoses reversed. Inspect the system and install the hoses in right position.

The hydraulic cylinder is damaged. Replace the hydraulic cylinder.

The hydraulic command pressure not enough Replace oil and fi lters Adjust the pressure using a manometer, the manufacturer

recommends 180kg/cm2.

The connectors pressure is not the same. Adjust and replace when necessary.

Hydraulic hoses clogged or damaged. Inspect and replace when necessary.

The equipment is moving

without use the hydraulic

controls

Seals rings are damaged. Replace the seal rings.

Hydraulic cylinder seal rings damaged. Inspect the hydraulic cylinder and replace seal device.

The nuts are loosen Tighten the hydraulic cylinder bolts carefully.

There is not enough seal tape. Use enough seal tape.

The quick-coupler not

connect.

The quick-coupler has different models. Use the same kind of quick-coupler.

Leaks in the hoses or

connector.

Not enough seal tape. Use enough seal tape.

The connector is not tighteen. Re-tighten carefully.

PROBLEM POSSIBLE CAUSE SOLUTION

TABLE 05

24

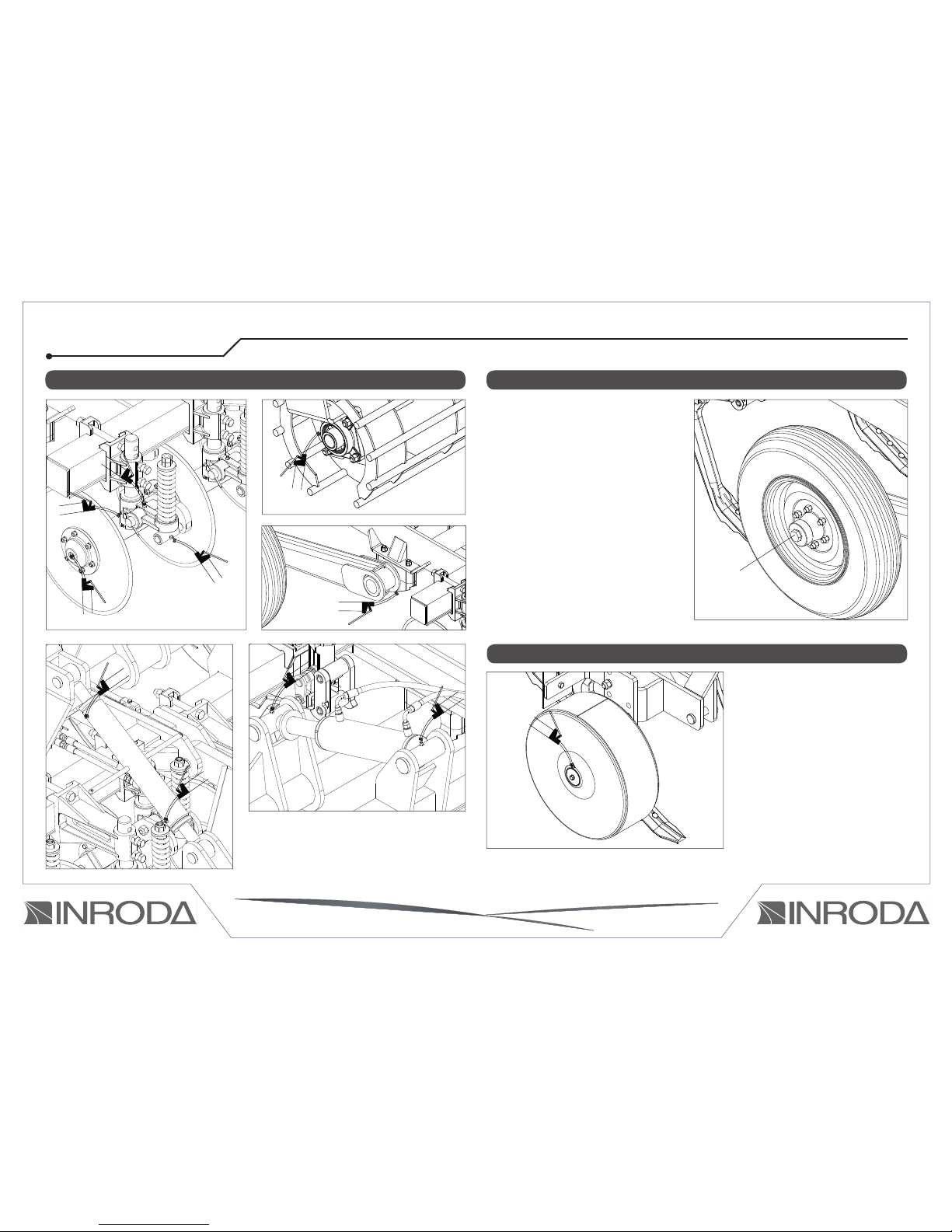

LUBRICATION POINTS

LUBRICATE EVERY 60 WORKING HOURSLUBRICATE EVERY 10 WORKING HOURS

Lubricate periodically the wheel

housing of you subsoiler PUMA,

the manufacturer recommends lubricate every 60 working hours and

when you fi nish the season, follow

the instructions below:

Remove the dust cap (1) from the

wheel housing, Clear the worn grease Inspect the bearing, adjust the

loosen when necessary.

Insert the new grease on the dust

cap and wheel housing.

Reinstall the dust cap (1) in the

wheel as illustrated on the drawing

24.

DRAWING

23

DRAWING 24

01

LUBRICATE EVERY 100 WORKING HOURS

DRAWING 25

25

TYRES INFLATION

Properly infl ating of grader tyres to improve the life and performance of the

tyres and implement, avoiding premature wear the manufacturer recom-

mends that right infl ation rate is 60lb/pol for tyres model 7-50/x 16.

HIGHT

PRESSURE

LOW PRESSURE RECOMMENDED

PRESSURE

DRAWING 26

SUBSOILER TRANSPORT

To transport the subsoiler follow the instructions bellow:

Remove the springs rod (1) that lock the oscillation bar, including nuts,

bushing and springs.

Then move the rear roller (02) in the raise position in order to it be positioned over the implement, keeping the spring rod free as illustrated in the

view “A”.

01

DRAWING 27

DETALHE “A”

01

02

26

The drawing shown in this manual and catalogue parts are merely

illustrative

ATTENTION

If you have any doubt Do not use this implement contact the Inroda Techinical support

Assistência@inroda.com.br

09 - CLEAN PRODUCERE

- Inspect all rotation parts, when they are loosen adjust and replace parts

damaged or worn it will keep the hoist able to working in the next season.

Use only INRODA spare parts.

-Before storing the hoist clear it using neutral detergent, check the paint

when it is damaged repaint then use paint protector oil.

-Lubricate all parts

- Store the hoist in dry place, correctly positioned, avoiding that the imple-

ment touch directly the fl oor.

10 - SPARE PARTS

Use only Genuine Inroda Parts to yield the best results from your work

without compromising your Equipment.

11 - IDENTIFICATION

When consulting the parts catalog or soliciting INRODA technical

assistance, always indicate the serial number (1), model (2), and the date

of manufacture (3), that can be found on the equipment identifi cation tag

(Drawing 28).

1

2 3

DRAWING 28

Fill out the data below to always have a record of the correct information about your equipment.

Owner:___________________________________________________________________________________________________________________

Retailer:__________________________________________________________________________________________________________________

Farm:___________________________________________________________________________________________________________________

City:__________________________________________________________________________ State:_____________________________________

Warrenty Number:________________________________________________________________________________________________________

Model:___________________________________________________________________________________________________________________

Serial Number:____________________________________________________________________________________________________________

Date purchased:_______/ _______/ ________ Receipt Number:____________________________________________________________________

________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________

Notes:

Prepared by: João Paulo

Ilustrations: Hermida

Diagram: Wellington Caio

Code: 210259

Rua Piauí, 810 - Cx. Postal 293 CEP 18700-030 - Avaré - SP - Brasil

Website: http://www.inroda.com.br - E-mail: inroda@inroda.com.br

Phone (14) 3711-3000 - Fax (14) 3711-3002

Loading...

Loading...