900MHz

Frequency Agile

®

Technology

Installation

Installation

InstallationInstallation

Instructions

Instructions

InstructionsInstructions

FA202

Scope of Manual:

lation manual:

ming and servicing the detector in response to trouble in dications at the control panel.

This Inovonics manual contains additional installation and servicing information that is not available in the accompanying primary instal-

ESL 560 Series Wireless Smok e Detector Installatio n Instru ction s

. This secondary manual is chiefly concerned with transmitter program-

FA202 Current Draw Specifications

(Supersedes Sentrol ESL 560 specifications)

Typical average standby current......................................................38.5µA

Typical peak alarm current..............................................................91.1mA

The FA202 Wireless Smoke Detector, built upon photoelectric Sentrol/ESL

technology, continually monitors its own sensitivity and operational status.

If it detects a Low Battery condition or is in need of cleaning, it transmits a

Low Battery signal that should be interpreted as a “Maintenance Needed”

trouble condition at the control panel. If the unit is in need of cleaning, it can

be serviced on-s ite by rep la c ing its Sm o ke C ha mbe r. Two 3 vo lt lit hiu m ba tteries, supplied with the product, provide at least one year of operation.

(National Fire Protection A ssociation, Batterymarch Park, Quincy, MA 02269)

Programming Procedure

1. Locate the transmitter programming pins by disassemblin g the dete c tor

as follows (refer to Figures 4 through 7 in the ESL 560 instructions):

a. Remove the red dust cover containing the batteries from the smoke

detector.

b. With the smoke detector facing you, remove the detector from its

Mounting Base by twisting the detector about 15 degr ees counterclockwise with respect to the Mounting Base.

c. Remove the Detector Cap by first sliding a flatblade screwdriver

part way into the slot on the side of the Detector Cap. Now, gently

push the handle down while twisting the Detector Cap counterclockwise with respect to the Detector Lid.

d. Remove the Detector Lid from the Body by pushing down on the

Smoke Chamber while p ull ing u p on th e bo tto m of t he Li d (se e Fi gure A).

2. Using an appropriate Inovonics programming device, set the program-

Note: These also are the factory default programming options. Some programming devices like the FA422 Receiver can place an Identification Number into a transmitter without changing the default settings.

FA202 Wireless Smoke Detector

FA202 Wireless Smoke Detector

with CleanMe™ Signaling

with CleanMe™ Signaling

HIS EQUIPMENT SHOULD BE INSTALLED IN ACCORDANCE WITH

T

THE NATIONAL FIRE PROTECTION ASSOCIATION’S STANDARD

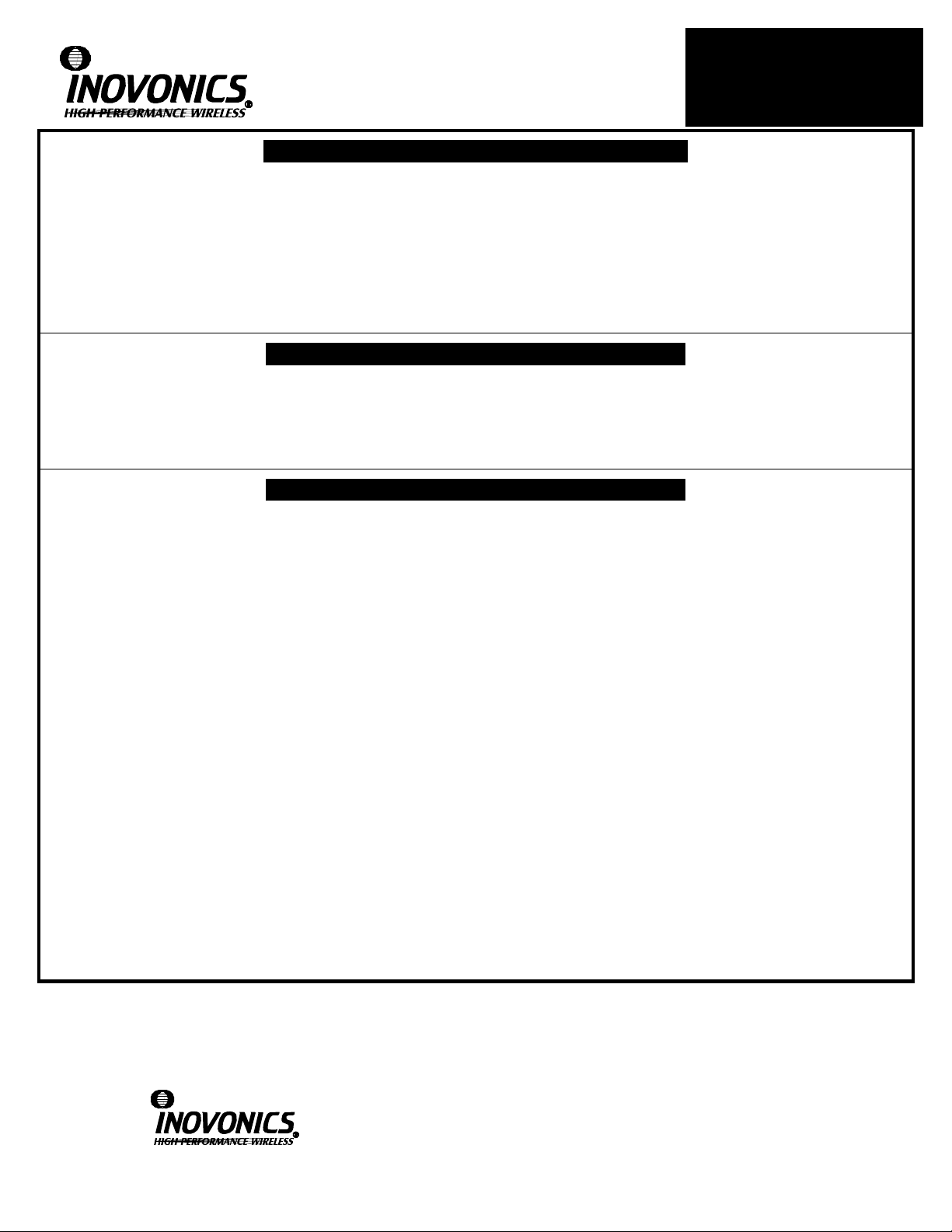

3-pin programm ing header

Reset button

CleanM e

enab led position

Figure B: Transmitter Board Features

ming options as follows:

• External Switch Type: Normally Closed

• EOL Resistor: No

• Use Internal Contact: No

• Check-in Time: 60 seconds

CleanM e

disabled position

72.

Figure A: Removing the Detector Lid

e. Remove the Battery Cover that encloses the Battery Compartment

by pushing on the area marked

f. Take the batteries out of the red dust cover holder and load them

into the Battery Compartment. Make sure to observe battery polarity and that the battery removal ribbon rests unde r the batterie s.

g. Refer to Figure B to locate the program ming pin s on the transmit ter

board.

OPEN

.

3. When prompted by the programming device to plug in t he transmitter,

connect the programming cable to the 3-pin header. (Orientation of the

cable with respect to the 3-pin h eader is not im portant; bot h outside pins

on the 3-pin header are at ground potential.)

4. Press the Reset button on the transmitter.

When programming is complete, disconnect the cable, test the detector per

the Wireless Sensitivity Test Procedure (on the back of this sheet), and reassemble the smoke detector.

© 1999 Inovonics support@inovonics.com phone: 800.782.2709 www.inovonics.com

Page 1

F202_V1.FM re v 1.10 1/27/00

FA202

Wireless Sensitivity Test Procedure

The FA202 should be tested upon initial programming and each time the Smoke Chamber is changed or the batteries are replaced. To make wireless signals from the detector cause an al arm or trouble indication at the control panel, receiver and panel pr ogramming must be completed prior to this test. If

this has not been done, do so now.

To t est the detector, fo llow th e pro ced ure described under the Testing the Detector Sensitivity section in th e ES L 5 60 in stru ctions. When the test button is

pressed, the LED will flash the number of times that corresponds to its sensitivity. During this test, the control panel should receive an alarm, followed a

few seconds later by a restoral.

If the panel fails to respond properly, i t is po ssible th at the tra nsmitter failed to reset properly when the batteries wer e insta lled. To force a transmitter reset, remove the batteries from the FA202 for a least 30 seconds, reinstall them, and then retest as described above.

Disabling Wireless CleanMe Reporting

As the factory default condition, the FA202 combines the CleanMe signal described in the ESL 560 instructions with its Low Battery signal. If the control panel indicates a Low Battery trouble conditi on, this shou ld be interprete d as a Maintenan ce Needed trouble indication . (The battery may be fin e, but

the detector needs cleaning.) If this multiple-condition panel indication is not desired, wireless reporting of the CleanMe status can be disabled by moving the jumper on the CleanMe 3-pin header to the inactive position (see Figure B). When this is done, only a Low Battery signal will be sent from the

detector, and only a Low Battery trouble condition reported at the panel.

Servicing Panel Trouble Indications

In the event that a Low Battery trouble in di cation appears on the control pane l, service the FA202 as described in the following procedure:

1. Remove the FA202 from its Mounting Base and disassemble the unit as described in the above Programming Procedure. (The Detector Lid needs to

be removed from the De te ct or B od y.)

2. Perform a wireless sensitivity test on the unit as described in the previous Wireless Sensitivity Test Procedure. Depending on the results of this test

do the following:

a. If the results of this test show that the detector

detector’s latest operation a l status.

If the panel trouble indication returns, the batteries need changing. Change the batteries as described in the Replacing the Batteries section of the

ESL 560 instructions and repeat this step.

As indicated in the

batteries

If the panel trouble indication now remains off, servicing has been completed.

b. If the results of this test shows that the unit

tion of the ESL 560 instru ctio ns. No w, press the Reset button on the transmitter to update the panel with th e dete ctor’s latest operational status.

If the panel trouble indicatio n remai ns of f, the uni t is performing normally, the batteries do not need changing, and servicing has been completed.

If, however, the panel trouble indication returns, the detector probably has a secondary Low Battery conditi on that requires that the batteries be

replaced. Change the batteri es as describ ed in th e Replacin g th e Batteries sectio n of the ESL 560 instruct ion s, wai t abou t nin e seconds until the

detector LED begins to flash, and press the transmitter Reset button.

As indicated in the

batteries

If the panel trouble indication now remains off, servicing has been completed.

As discussed before, if the wireless CleanMe signal reporting were disabled, some of this complication could be avoided . A Low Battery indica-

Note:

tion at the panel would always mean that the batteries needed changing; there would be no CleanMe signal piggybacked onto the Low Battery indication.

However, it is recomme nd ed th a t the wirele ss Clea nMe sign al rep orting rema in e nab led (fa c tor y de fa ult co n diti on ) in or der to let t he pa ne l k no w tha t th e

detector is operating within normal limits, and to avoid potential false alarms due to detector over-sensitivity.

. This is necessary to force an immediate test of the new batteries.

. This is necessary to force an immediate test of the new batteries.

WARNING

WARNING

label on the Battery Compartment,

label on the Battery Compartment,

does not

does

need cleaning, press the Reset button on the transmitter to update the panel with the

wait at least 30 seconds after removing batteries before inserting new

need cleaning, replace the Smoke Chamber and retest the unit per the Cleaning the Detector sec-

wait at least 30 seconds after removing batteries before inserting new

If an FA202 fails to operate properly, phone Inovonics Technical Support (800.782.2709) to request a

Return Material Authorization (“RMA”) number, then ship the unit to the address shown below.

(Please include the RMA number on the package to expedite handling.)

Inovonics Corporation

Inovonics Corporation

Inovonics CorporationInovonics Corporation

RMA # ________

RMA # ________

RMA # ________RMA # ________

2100 Central Ave

2100 Central Ave

2100 Central Ave2100 Central Ave

Boulder CO 80301

Boulder CO 80301

Boulder CO 80301Boulder CO 80301

© 1999 Inovonics support@inovonics.com phone: 800.782.2709 www.inovonics.com

Page 2

F202_V1.FM re v 1.10 1/27/00

Warranty & Disclaimer

Inovonics Corporation ("Inovonics") warrants its products ("Product" or "Products") to conform to its

own specifications and to be free of defects in materials and workmanship under normal use for a

period of twenty-four (24) months from the date of manufacture. Within the warranty period Inovonics Corporation will repair or replace, at its option, all or any part of the warrantied product. Inovonics

will not be responsible for dismantling and/or reinstallation charges. To exercise the warranty, the

User ("User", "Installer" or "Consumer") must be given a Return Material Authorization ("RMA")

Number by Inovonics. Details of shipment will be arranged at that time.

This warranty does not apply in cases of improper installation, misuse, failure to follow installation

and operating instructions, alteration, abuse, accident or tampering, and repair by anyone other than

Inovonics.

This warranty is exclusive and expressly in lieu of all other warranties, obligations or liabilities,

whether written, oral, express, or implied, including any warranty of merchantability or fitness for a

particular purpose. Inovonics will not be liable to anyone for any consequential or incidental damages

for breach of this warranty or any other warranties.

This warranty will not be modified, varied or extended. Inovonics does not authorize any person to

act on its behalf to modify, vary or extend this warranty. This warranty will apply to Inovonics Products only. All other products, accessories or attachments used in conjunction with Inovonics equipment, including batteries, will be covered solely by their own warranty, if any. Inovonics will not be

liable for any direct, incidental or consequential damage or loss whatsoever, caused by the malfunction of Product due to products, accessories, or attachments of other manufacturers, including batteries, used in conjunction with Inovonics Products.

This warranty does not warrant the replacement of batteries that are used to power Inovonics Products.

The User recognizes that a properly installed and maintained security system may only reduce the

risk of events such as burglary, robbery, personal injury and fire. It does not insure or guarantee that

there will be no death, personal damage and/or damage to property as a result.

claim that the Product may not be compromised and/or circumvented, or that the Product will

prevent any death, personal and/or bodily injury and/or damage to property resulting from

burglary , r o bbery, fire or otherwise, or that the Prod uct will in all case s pr ovide ade quate war ning or protection.

Inovonics Corporation shall have no liability for any death, injury or damage, however

incurred, based on a claim that Inovonics Products failed to function.

held liable, directly or indirectly, for any loss or damage arising under this limited warranty or otherwise, regardless of cause or origin, Inovonics' maximum liability will not in any case exceed the purchase price of the Product, which will be fixed as liquidated damages and not as a penalty, and will be

the complete and exclusive remedy against Inovonics.

Warning: The User should follow all installation, operation and maintenance instructions.

User is strongly advised to conduct Product and systems tests at least once each week. Changes in

environmental conditions, electric or electronic disruptions and tampering, may cause the Product to

not perform as expected.

Inovonics does not

However, if Inovonics is

The

Warning: Inovonics warrants its Product to the User.

due prudence and taking necessary precautions for the safety and protection of lives and property

wherever Inovonics Products are installed. Inovonics strongly advises the User to program Products

to be supervised whenever used in applications affecting life safety. Users are warned that unsupervised devices are subject to undetected failure due to malfunction, battery failure, tampering, or

changes in environment.

The User is responsible for exercising all

Loading...

Loading...