Page 1

User Guide

NICE900 Series

Integrated Door Operator Controller

Data code 19010269

User Guide

A02

Page 2

Preface

Preface

Thank you for purchasing the NICE900 series integrated door machine controller.

The NICE900 series integrated door machine controller (shorted as "the NICE900" or "the

controller" hereinafter) is a variable frequency controller specialized for driving the door

machine system such as elevator door, cold storage door, and subway door.

It integrates door open/close logic control and motor drive, and implements control on the

entire door system with door open/close commands from the external system. The NICE900

can drive the AC asynchronous motor and permanent synchronous motor (PMSM), and

supports two control modes, speed control and distance control. Applicable to various

applications, it can meet drive and control requirements of most door systems.

This manual describes correct use of the NICE900, including product features, safety

information and precautions, installation, parameter setting, commissioning, and

troubleshooting. Read and understand the manual before using the product, and keep it

carefully for reference to future maintenance.

Notes

•The drawings in the manual are sometimes shown without cover or protective guard. Remember

to install the cover or protective guard as specied rst, and then perform operations in

accordance with the instructions.

•The drawings in the manual are shown for description only and may not match the product that

you have purchased.

•The instructions are subject to change due to product upgrade, specication modication, as

well as the efforts to increase the accuracy and convenience of the manual.

•Contact our regional agent or customer service center if the manual delivered is lost or

damaged.

•Contact our customer service center if you have problems during the use.

•Email: UM@inovance.com

- 1 -

Page 3

Preface

Note

Approvals

Certication marks on the product nameplate indicate compliance with the corresponding certicates and

standards.

Certication Mark Directives Standard

EMC directives 2014/30/EU

CE

TUV - EN 61800-5-1

LVD directives 2014/35/EU EN 61800-5-1

RoHS directives 2011/65/EU EN 50581

EN 12015

EN 12016

UL

- UL61800-5-1

C22.2 No.14-13

● The above EMC directives are complied with only when the EMC electric installation

requirements are strictly observed.

● Machines and devices used in combination with this drive must also be CE certied and

marked. The integrator who integrates the drive with the CE mark into other devices has

the responsibility of ensuring compliance with CE standards and verifying that conditions

meet European standards.

● The installer of the drive is responsible for complying with all relevant regulations for

wiring, circuit fuse protection, earthing, accident prevention and electromagnetic (EMC

regulations). In particular fault discrimination for preventing re risk and solid earthing

practices must be adhered to for electrical safety (also for good EMC practice).

● For more information on certication, consult our distributor or sales representative.

- 2 -

Page 4

Preface

Contents

Preface ...................................................................................................................1

Chapter 1 Safety Information and Precautions.......................................................6

1.1 Safety Information ....................................................................................................... 6

1.2 Precautions ................................................................................................................. 9

Chapter 2 Product Information .............................................................................12

2.1 Designation Rules and Nameplate ............................................................................ 12

2.2 Structure .................................................................................................................... 12

2.3 NICE900 Models ....................................................................................................... 13

2.4 General Specications .............................................................................................. 13

Chapter 3 Mechanical and Electrical Installation .................................................. 16

3.1 Mechanical Installation .............................................................................................. 16

3.2 Electrical Installation .................................................................................................. 18

3.3 Peripheral Electrical Devices ..................................................................................... 20

Chapter 4 Operation and Trial Running ................................................................24

4.1 Operation Panel ........................................................................................................ 24

4.2 Basic Operations ....................................................................................................... 25

4.3 Command Source and Motor Auto-tuning ................................................................. 28

4.4 Door Open/Close Control Mode ................................................................................ 31

Chapter 5 Function Code Table ............................................................................ 42

5.1 Description of Function Codes .................................................................................. 42

5.2 Function Code Table ................................................................................................. 42

Chapter 6 Description of Function Codes.............................................................54

Group F0: Basic Parameters ........................................................................................... 54

Group F1: Motor Parameters .......................................................................................... 56

Group F2: Performance Control Parameters .................................................................. 59

Group F3: Door Open Running Curve Parameters ......................................................... 62

Group F4: Door Close Running Curve Parameters ......................................................... 65

Group F5: Door Open/Close Auxiliary Parameters ......................................................... 69

Group F6: Distance Control Parameters ......................................................................... 72

Group F7: Demonstration Function Parameters ............................................................. 76

- 3 -

Page 5

Preface

Group F8: Auxiliary Parameters ...................................................................................... 77

Group F9: Input and Output Function Parameters .......................................................... 79

Group FA: Display and Fault Parameters ........................................................................ 81

Group FP: User Parameters ............................................................................................ 87

Chapter 7 Maintenance and Troubleshooting.......................................................90

7.1 Maintenance .............................................................................................................. 90

7.2 Fault Information and Troubleshooting ...................................................................... 91

Revision History....................................................................................................96

Warranty Agreement .............................................................................................97

- 4 -

Page 6

1

Safety Information and Precautions

Page 7

Chapter 1 Safety Information and Precautions

DANGER

CAUTION

DANGER

CAUTION

DANGER

CAUTION

Chapter 1 Safety Information and Precautions

In this manual, the notices are graded based on the degree of danger:

•

indicates that severe personal injury or even death may result due to improper

operation.

•

indicates that personal injury or equipment damage may result due to improper

operation.

Read the following safety notices carefully so that you understand how to install, commission,

operate and maintain the equipment. Inovance assumes no liability or responsibility for any

injury or loss caused by improper operation of the equipment described in the manual.

1.1 Safety Information

■Before Installation

•Do not install the equipment if you nd the controller damaged upon unpacking.

•Do not install the equipment if the packing list does not conform to the product you receive.

•Handle the equipment with care during transportation. Otherwise, the equipment may be

damaged.

•Do not touch the components with your hands. Failure to comply will result in static electricity

damage.

■During Installation

•Mount the controller on incombustible surface such as metal. Keep it far away from ammable

materials. Failure to comply may result in a re.

•Do not loosen the xed screws of the components, especially the screws with red mark.

•Do not drop wire end or screw into the controller. Otherwise, the controller may be damaged.

•Install the controller in places free of vibration and direct sunlight.

- 6 -

Page 8

Chapter 1 Safety Information and Precautions

DANGER

DANGER

DANGER

DANGER

■At Wiring

•Wiring must be performed only by qualied personnel under instructions described in this

manual. Failure to comply may result in unexpected accidents.

•A circuit breaker must be used to isolate the power supply and the controller. Failure to comply

may result in a re.

•Tie the controller to ground properly according to the standard. Failure to comply may result in

electric shock.

•Never connect the power cables to the output terminals (U, V, W) of the controller. Pay attention

to the marks of the wiring terminals and ensure correct wiring. Failure to comply will result in

damage to the controller.

•Ensure that the cabling satises the EMC requirements and the local codes. Use wire sizes

recommended in the manual. Failure to comply may result in accidents.

•Use the shielded cable for the encoder, and ensure that the shield is reliably grounded at one

end.

•Use a twisted cable with twisted distance of 20−30 mm as the communication cable, and ensure

that the shield is reliably grounded.

■Before Power-On

•Check that the following requirements are met:

The voltage class of the power supply is consistent with the rated voltage class of the controller.

The input terminals (L, N) and output terminals (U, V, W) are correctly connected.

No short circuit exists in the peripheral circuit.

The wiring is secured.

Failure to comply will result in damage to the controller.

•For the PMSM, ensure that motor auto-tuning is performed before running for the rst time.

Failure to comply may result in motor runaway.

•Do not perform the voltage resistance test on any part of the controller because such test has

been done in the factory. Failure to comply will result in accidents.

•Cover the controller properly before power-on to prevent electric shock.

•All peripheral parts must be connected correctly under the instructions described in this manual.

Failure to comply may result in accidents.

- 7 -

Page 9

Chapter 1 Safety Information and Precautions

DANGER

DANGER

DANGER

CAUTION

DANGER

■After Power-On

•Do not open the cover of the controller after power-on. Failure to comply may result in electric

shock.

•Do not touch any input or output terminal of the controller with hands. Failure to comply may

result in electric shock.

•Do not touch the rotating part of the motor during the motor auto-tuning or running. Failure to

comply may result in personal injury.

•Do not change the factory parameters. Otherwise, the equipment may be damaged.

■During Running

•Do not touch the fan or the discharging resistor to check the temperature. Otherwise, you may

get burnt.

•Signal detection must be performed only by qualied personnel during operation. Failure to

comply will result in personal injury or damage to the controller.

•Avoid objects falling into the controller when it is running. Failure to comply will result in damage

to the controller.

•Do not start/stop the controller by opening or closing the contactor. Failure to comply will result

in damage to the controller.

■During Maintenance

•Do not repair or maintain the controller at power-on. Failure to comply will result in electric

shock.

•Repair or maintenance of the controller must be performed only by qualied personnel.

Otherwise, personal injury or equipment damage may result.

•Set the parameters again after the controller is replaced. All the pluggable components must

be plugged or removed only after power-off.

- 8 -

Page 10

Chapter 1 Safety Information and Precautions

Note

1.2 Precautions

1. Motor Insulation Test

Perform an insulation test on the motor under the following conditions:

- Before the motor is used for the rst time

- When the motor is reused after being stored for a long time

- During periodic inspection

This is to prevent the poor insulation of motor windings from damaging the controller.

The motor must be disconnected from the controller during the insulation test. A 500-volt

megameter is recommended for this test, and the insulation resistance must not be less

than 5 MΩ.

2. Motor Heat and Noise

The output of the controller is pulse width modulation (PWM) wave with certain harmonic

wave, and therefore, the motor temperature rise, noise, and vibration are slightly greater

than those at running with the mains frequency.

3. Voltage-sensitive device or capacitor on the output side of the controller

The controller outputs PWM waves, and therefore, do not install the capacitor for improving

power factor or lightning protection voltage-sensitive resistor on the output side of the

controller. Otherwise, the controller may suffer transient overcurrent or even be damaged.

4. Use outside the rated voltage

The controller must not be used outside the allowable voltage range specified in this

manual. Otherwise, components inside the controller may be damaged. If required, use

a corresponding voltage step-up or step-down device to match the power voltage to the

rated voltage range for the controller.

5. Surge Suppressor

The controller has a built-in varistor for suppressing the surge voltage generated when

the inductive loads (electromagnetic contactor, electromagnetic relay, solenoid valve,

electromagnetic coil and electromagnetic brake) around the controller are switched on or

off. If the inductive loads generate very high surge voltage, use a surge suppressor for the

inductive load or use a surge suppressor together with a diode.

Do not connect the surge suppressor to the output side of the controller.

6. Altitude and De-rating

In places where the altitude is above 1000 m and the cooling effect reduces due to thin air,

it is necessary to de-rate the controller. Contact Inovance for technical support.

- 9 -

Page 11

Chapter 1 Safety Information and Precautions

7. Disposal

The electrolytic capacitors in the main circuit and PCB board may explode when they are

burnt. Poisonous gas is generated when the plastic parts are burnt. Treat them as ordinary

industrial waste.

8. Adaptable Motor

- The standard adaptable motor is an adaptable four-pole squirrelcage asynchronous

induction motor and AC PMSM. Select the proper controller model according to the motor

ratings.

- To reach better control result, perform motor auto-tuning based on actual conditions. For a

PMSM, motor auto-tuning is mandatory.

- The controller might alarm or be damaged when a short circuit exists on cables or

inside the motor. Therefore, perform the insulation short circuit test when the motor and

cables are newly installed or during routine maintenance. During the test, disconnect the

controller from the tested parts

- 10 -

Page 12

2

Product Information

Page 13

Chapter 2 Product Information

NICE

A

D

S

0P2

NICE series

A

Controller

Mark Type

D

Elevator door

machine products

Mark Type

S Single-phase 220 V

Mark Voltage Class

0P2 200 W

Mark Power Rating

0P4 400 W

0P7 750 W

MODEL: NICE-D-A-S0P2-INT

INPUT: 1PH AC220-230V 2.7A 50Hz/60Hz

OUTPUT: 3PH AC0-230V 1.3A 0-99Hz 200W

Suzhou Inovance Technology Co.,Ltd.

Serial No.: 010150144C700061

Nameplate

Model

Rated input

Rated output

Serial No.

-INT

Version

Mark

-(a)

Other variants

-INT

International

Note (a): The model number may include a suffix

"XXXXXXXXXX", Where "XXXXXXXXXX" can be blank or

combination of any alphanumeric and/or symbols that

represents customer identity.

PRODUCT: Integrated Door Controller AC Drive

Product name

Certi-

ficates

Made in China

Manufacturer

Operation panel

Fan

Power switch

Reserved

Logo

Controller output terminal

Reserved

Door state

output terminal

Encoder and control

signal input terminal

Single-phase power

input terminal

Chapter 2 Product Information

2.1 Designation Rules and Nameplate

Figure 2-1 Designation rules and nameplate of the NICE900

2.2 Structure

Figure 2-2 Structure of the NICE900

- 12 -

Page 14

2.3 NICE900 Models

Table 2-1 NICE900 models

Chapter 2 Product Information

Model Input Voltage

NICE-D-A-S0P2

NICE-D-A-S0P4 1.0 5.4 2.3 400

NICE-D-A-S0P7 1.5 8.2 4.0 750

Single-phase 220 V

(-15% to 20%)

Power

Capacity

(kVA)

0.5 2.7 1.3 200

Input Current

(A)

Output

Current

(A)

2.4 General Specications

Item Specications

Maximum

output

frequency

Speed range

Basic

specications

Major functions

Protection functions

Speed stability

Startup torque

Frequency

resolution

Current

resolution

Carrier

frequency

99.00 Hz

1:50 (SVC)

1:1000 (CLVC)

SVC: sensorless vector control

CLVC: closed-loop vector control

±0.5% (SVC)

±0.05% (CLVC)

1 Hz/150% (SVC)

0 Hz/180% (CLVC)

0.01 Hz

0.01 A

2–16 kHz

Two auto-tuning modes are supported, with-load auto-tuning and

no-load auto-tuning.

For CLVC on the AC PMSM using a common ABZ encoder, opencollector output or push-pull output is supported.

For SVC, functions such as xed torque boost, customized torque

boost and over-excitation are supported.

Door width auto-tuning is supported.

Automatic demonstration is supported.

Automatic identication upon hindering is supported.

Controller overload protection (1 minute for 150% of rated current

, 1 second for 180% of rated current) is supported.

Protections on overvoltage, undervoltage, overcurrent, output

phase loss and inter-phase short circuit are supported.

Adaptable

Motor

(W)

- 13 -

Page 15

Chapter 2 Product Information

Item Specications

Indoors

Free from direct sunlight, dust, corrosive gas, combustible gas, oil

mist, vapor, drip and salt

Lower than 1000 m

Deratedif the altitude is above 1000 m

-10°C to +40°C

Derated if ambient temperature is within 45–50°C

-20°C to +60°C

Natural cooling for 0.2 kW

Forced air cooling for 0.4 kW and 0.75 kW

IP20

Indoors, clean and dry

Packed in standard box and transported by coach, train, aircraft

or ship.

15 m/s2 (1.5 g) when SIN vibration is 9–200 Hz

Environment

Installation

location

Altitude

Ambient

temperature

Humidity Less than 95% RH, non-condensing

Vibration < 5.9 m/s2 (0.6 g)

Storage

temperature

Cooling method

Ingress

protection

Storage

location

Transportation

Vibration during

transportation

- 14 -

Page 16

3

Mechanical and Electrical Installation

Page 17

Chapter 3 Mechanical and Electrical Installation

204.7

213.7

5

φ

4

-

66

Unit: mm

129

147

Hot air

Cold air

≥ 100

≥ 100

50≥

50≥

Chapter 3 Mechanical and Electrical Installation

3.1 Mechanical Installation

3.1.1 Installation Environment

Item Requirement

Ambient temperature -10°C to 50°C

Mount the controller on the surface of incombustible objects with

Heat dissipation

Mounting location

3.1.2 Physical Dimensions

Figure 3-1 Physical Dimensions of the NICE900

sufcient room for heat dissipation.

Install the controller on the base with screws vertically.

Free from direct sunlight, high humidity and condensation

Free from corrosive, explosive and combustible gas

Free from oil dirt, dust and metal powder

3.1.3 Mounting Clearance

The clearance that needs to be reserved varies with the power rating of the NICE900. The

following gure shows the clearance that needs to be reserved for mounting.

Figure 3-2 Clearance around the NICE900 for mounting

- 16 -

Page 18

Chapter 3 Mechanical and Electrical Installation

Fix the four

screws

Fix the four

screws

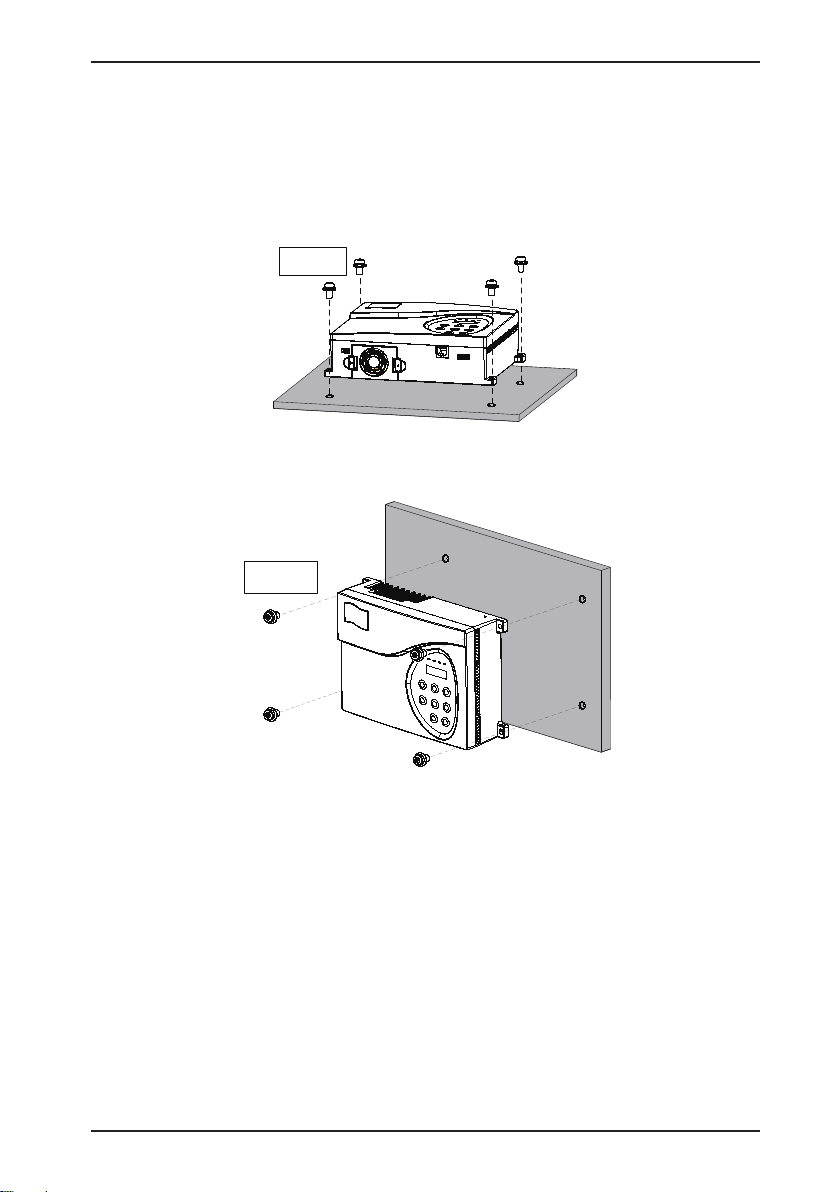

3.1.4 Mounting Orientation

Use 4 M4x15 screws (with elastic at washer) with the tightening torque of 1.2 N.m during

installation.

a) Horizontal installation

Figure 3-3 Horizontal installation diagram

b) Vertical installation

Figure 3-4 Vertical installation diagram

- 17 -

Page 19

Chapter 3 Mechanical and Electrical Installation

Single-phase

power input terminals

Reserved

Controller

output terminals

U

V

W

N/A

L

N

220 VAC

L N

Ground

P

PB

U

V W

L N

NICE900

Regen. resistor

(Terminal reserved)

3.2 Electrical Installation

3.2.1 Wiring and Description of Main Circuit Terminals

Figure 3-5 Main circuit terminal arrangement

Table 3-1 Main circuit terminal description

Terminal Name Description

Single-phase power input

L, N

terminals

P, PB Reserved

U, V, W Controller output terminals Connect the three-phase motor.

Grounding terminal Must be grounded.

Provide single-phase 220 VAC power supply.

These terminal are generally reserved, but they can be

connected with the external regen. resistor if required.

Figure 3-6 Main circuit wiring example

In the applications with large inertia such as the cold storage door, a regen. resistor is required.

Select a proper one according to the recommended models listed in the following table.

- 18 -

Page 20

Chapter 3 Mechanical and Electrical Installation

Reserved

Encoder and control

signal input terminal

TA

1

TC1

TB1

TA2

TB2

TC

2

TA3

TC3

TB

3

Door state

output terminal

+24V

PGA

PGB

PGZ

COM

DI1

DI

2

DI3

DI4

DI5

DI6

DI7

DI8

COM

+24V

COM

Table 3-2 Recommended regen. resistor models

Controller Model Power of Regen. Resistor (W) Resistance of Regen. Resistor (Ω)

NICE-D-A-S0P2 80 W ≥ 250 Ω

NICE-D-A-SOP4 80 W ≥ 200 Ω

NICE-D-A-SOP7 80 W ≥ 150 Ω

3.2.2 Wiring and Description of Control Circuit Terminals

Figure 3-7 Control circuit terminal arrangement

Table 3-3 Control circuit terminal description

Name Type Mark

Door state

output terminal

Relay output

and grounding

TA1/TB1/TC1

TA2/TB2/TC2

TA3/TB3/TC3

Relay output

- 19 -

Function

Description

Remarks

1. TA-TB: normally closed (NC)

TA-TC: normally open (NO)

Contact capacity:

250 ACV, 3A; 30 VDC, 1 A

2. Insulation voltage class

between contact and control

circuit: 2.5 kVAC

Page 21

Chapter 3 Mechanical and Electrical Installation

Name Type Mark

Internal 24 V

power supply

Encoder and

control signal

input terminal

Encoder input

Digital input DI1 to DI8 Digital signal input

Reserved

Software

burning

interface

+24V

COM

PGA Encoder phase A

PGB Encoder phase B

PGZ Encoder phase Z

RJ45

Function

Description

24 VDC power

supply

24 V power

common

Software burning

interface

Remarks

Used as the non-contact

switch or power supply for the

encoder.

Maximum output current: 200

mA

Isolated with the internal 24 V

power common terminal of the

controller

Open-collector output or pushpull output

Optocoupler isolation, low level

active

Input voltage range: 0–30 VDC

Input impedance: 3.3 kΩ

-

Check the peripheral wiring before power-on to ensure device and personal safety:

1. The wiring is performed according to the instructions.

2. All switches act reliably.

3. Check the inter-phase resistance of the main circuit to ensure that there is no short circuit

to ground.

4. The mechanical installation is proper.

5. Check that the resistance between the following points and the ground is close to innity.

- L, N and PE

- U, V, W and PE

- Encoder 24V, PGA, PGB, PGZ, COM and PE

3.3 Peripheral Electrical Devices

3.3.1 Selection of Peripheral Electrical Devices

Controller Model Air Switch (A) Contactor (A) Main Circuit Conducting Cable (mm2)

NICE-D-A-S0P2 10 10 2.5

NICE-D-A-S0P4 16 10 2.5

NICE-D-A-S0P7 16 10 2.5

- 20 -

Page 22

Chapter 3 Mechanical and Electrical Installation

3.3.2 Description of Peripheral Electrical Devices

Electrical Device Mounting Location Function Description

Air switch Power input side

AC input reactor Controller input side

AC output

reactor

Between the controller

output side and the motor,

close to the controller

It is used to cut off the controller’s power supply

and provide short circuit protection.

•Improve the power factor of the input side.

•Eliminate the higher harmonics of the input side

effectively,

•Protect the rectier bridge effectively.

•Eliminate the input current unbalance caused by

inter-phase unbalance.

If the controller is more than 100 m far away from

the motor, install the AC output reactor.

- 21 -

Page 23

Chapter 3 Mechanical and Electrical Installation

- 22 -

Page 24

4

Operation and Trial Running

Page 25

Chapter 4 Operation and Trial Running

CLOSE

STOP

RES

PRG ENTER

OPEN

D1 D2 D3 D4

Data display

Function indicator

Programming key

UP key

Down key

Confirm key

Shift key

Door open key Door close key

Stop/Reset key

PRG

ENTER

STOP

RES

Chapter 4 Operation and Trial Running

4.1 Operation Panel

You can modify the parameters, monitor the working status and run or stop the controller by

operating the operation panel shown as below:

Figure 4-1 Operation panel diagram

1. Indicator Descriptions

Table 4-1 Indicator descriptions

Indicator

Speed Control Distance Control

Meaning of ON at Stop

D1 DI1 signal active DI1 signal active External door close command

D2 DI2 signal active Phase A and B signal correct During door close

D3 DI3 signal active Phase Z signal active During door open

D4 DI4 signal active DI4 signal active External door open command

2. Description of Keys on the Operation Panel

Table 4-2 Description of keys on the operation panel

Key Name Function

Programming Enter or exit Level I menu.

Conrm

Stop/Reset

Enter the menu interfaces level by level, and conrm the parameter

setting.

Stop the running in the running state and reset the operation in the

fault state.

Meaning of ON During Running

- 24 -

Page 26

Chapter 4 Operation and Trial Running

OPEN

CLOSE

F0

F003

24.00

(Select the function

code group)

(Select the

function code)

(Set the value of

the function code)

Level-I menu

Level-II menu

Level-III menu

PRG

PRG

Not to save

the setting

ENTER

To save

the setting

ENTER

15.00

ENTER

Status parameter

PRG

F004

ENTER

PRG

Next function

code

(default display)

If there is a blinking digit, press

/ / to modify the digit.

PRG

ENTER

ENTER

PRG

Key Name Function

Shift

Select the displayed parameters in turn in the stop or running state,

and select the digit to be modied when modifying parameters.

Up Increase data or function code.

Down Decrease data or function code.

Door open Open the door in the operation panel operation mode.

Door close Close the door in the operation panel operation mode.

4.2 Basic Operations

4.2.1 Operation Procedure of the Operation Panel

The operation panel of the NICE900 adopts three-level menu, convenient for quick querying

and modication of parameters.

The three-level menu consists of function code group (Level I), function code (Level II), and

function code setting value (level III), as shown in the following gure.

Figure 4-2 Operation procedure on the operation panel

You can return to Level II from Level III by pressing

•After you press

, the system saves parameter setting first, and then goes back to

or

Level II and shifts to the next function code.

•After you press

Level II and remains at the current function code.

Here is an example of changing the value of F0-04 to 15.00 Hz.

, the system does not save parameter setting, but directly returns to

- 25 -

.

Page 27

Chapter 4 Operation and Trial Running

F015.00

PRG

F000

00.00

PRG

PRG

ENTER

ENTER

ENTER

PRG

F005

15.00

F004

Status parameter

(default display)

To save the

setting

If there is a blinking digit,

press / / to modify the digit.

F0

15.00

PRG

FA00

00.00

PRG

PRG

ENTER

ENTER

ENTER

PRG

FA03

FA02

FA

Status parameter

(default display)

If there is a blinking digit,

press / / to modify the digit.

Figure 4-3 Example of editing function code

In Level III menu, if the parameter has no blinking digit, it means that the parameter cannot be

modied. This may be because:

•Such a function code is only readable, such as actually detected parameter and running

record parameter.

•Such a function code cannot be modied in the running state and can only be changed at

stop.

4.2.2 Viewing Fault Information

When a fault occurs on the controller, the operation panel displays the fault code, based on

which, you can nd the cause of the fault and rectify the fault quickly.

The controller saves the last four fault codes, and details of the frequency, current, bus voltage

and DI/DO status at the latest fault are recorded.

Figure 4-4 Viewing fault information

- 26 -

Page 28

Chapter 4 Operation and Trial Running

Shift between parameters

displayed in running state

Running frequency

Bus voltage

Output voltage

Output current

Output torque

Door position pulse

Output terminal state

Frequency reference

Input terminal state

Shift between parameters

displayed in stop state

Door position pulse

Output terminal state

Frequency reference

for door open

Input terminal state

Frequency reference

for door close

F015.00

PRG

FP

PRG

FP00

0000

PRG

PRG

ENTER

ENTER

ENTER

PRG

FP01

1234

Status parameter

(default display)

If there is a blinking digit,

press / / to modify the digit.

4.2.3 Viewing Display at Running or Stop

In the stop/running state without fault, you can view the parameters circularly by pressing .

The parameters to be displayed are set in by setting FA-00 and FA-01.

Figure 4-5 Shift between parameters displayed in the running/stop state

4.2.4 Setting the Password

To protect the parameters more effectively, the NICE900 provides the user password

protection function. To cancel the password protection function, enter the password and set

FP-00 to 0.

The following gure shows an example of changing the password to 1234.

Figure 4-6 Changing the password

- 27 -

Page 29

Chapter 4 Operation and Trial Running

OPEN

CLOSE

STOP

RES

OPEN

CLOSE

STOP

RES

4.3 Command Source and Motor Auto-tuning

4.3.1 Command Source

The NICE900 supports four command sources, as described in the following table.

Function

Code

F0-02

Value Description

Operation panel control

It is mainly used in motor auto-tuning. The door machine runs at the

frequency set in F0-04.

0

(Default)

You can control door open or close by pressing

door machine by pressing

on the operation panel.

Door machine terminal control

1

Door open and close commands are input via DI terminal.

It is used in normal running state.

Door machine manual control

It is used in door width auto-tuning, during which the door machine

2

accelerates and decelerates.

The running and stop of the door machine are controlled by using the

operation panel.

Door machine auto demonstration

It is used in the door machine demonstration and trial running in the factory.

After door width auto-tuning is completed in distance control or peripheral

signals are connected properly in speed control, set the door machine auto

demonstration mode to start automatic running of the door machine.

3

Start demonstration by pressing

pressing

on the operation panel.

or

The demonstration time interval and times are set in group F7 parameters.

or

, and stop the

, and stop demonstration by

- 28 -

Page 30

Chapter 4 Operation and Trial Running

F905

.

1

2

.

.

RUN

command

Terminal

Function

Code

Value

Terminal

control

DI5

DI6

DI7

DI8

COM

Door open

Command

source

Door open

command

Door close

F906

F907

F908

F0-02 = 1

Control

system

Door close

command

■Door machine manual control (F0-02 = 1)

In this mode, the door open/close commands are given by DI terminal.

You can allocate the DI terminals with relevant signals in F9-01 to F9-08.

For example, connect the door open and close signals respectively to DI5 and DI6, as shown

in the following gure.

Figure 4-7 Door open/close control by DI terminal

4.3.2 Motor Auto-tuning

The following part takes the PMSM as an example to describe motor auto-tuning.

Follow the precautions for motor auto-tuning:

•The magnetic pole position must be identified before first-time running of the PMSM.

Otherwise, the PMSM cannot be used properly.

•After you change motor wiring or encoder wiring, or replace the encoder, the encoder

position angle must be identied again. Ensure that the magnetic position is consistent

with motor wiring during normal running.

•The motor rotates during auto-tuning. Ensure safety before starting motor auto-tuning.

- 29 -

Page 31

Chapter 4 Operation and Trial Running

F0-02 = 0 (Operation panel control)

F1-00 = 1 (PMSM)

Set F1-01

, F1

-02, F1-

03, F1-04,

and F1-05 according to motor

nameplate,

and set F2-14

Press ENTER. After "TUNE" is displayed,

press "OPEN" to start motor auto-tuning.

Perform trial running:

F0-04 = 5.00 Hz.

Press

"OPEN"

or "CLOSE" to

start trial running.

Restore the terminal control mode

(F0-02 = 1).

Connect the load.

F1-16 = 3

Disconnect the load

F1-16 = 4

Close the door properly

No-load

auto-tuning

Select

auto-tuning mode

Whether

Motor running and controller

output current are

normal?

End

Yes

No

With-load

auto-tuning

Check the mechanical part and

encoder signals

OPEN

CLOSE

Figure 4-8 Motor auto-tuning owchart (PMSM)

More descriptions about motor auto-tuning are as follows:

1. Before starting motor auto-tuning, ensure that the encoder signals are normal. If the door

closes and motor locked-rotor occurs after you start auto-tuning, it indicates that the motor

running direction is abnormal. You need to change the motor wiring or encoder wiring.

2. During no-load auto-tuning, the controller executes the forward or reverse running

command, and runs in the opposite direction after a period of time.

After several cycles of forward and reverse running, the controller calculates all parameters

and completes no-load auto-tuning. If Er20 is reported during auto-tuning, replace any two

of UVW phases and perform motor auto-tuning again.

3. During with-load auto-tuning, ensure that the door is fully closed. Press

motor slowly open the door at 25% of the rated speed and press

close the door after the door opens to a certain distance.

After three times of such operations, the controller calculates all parameters and completes

with-load auto-tuning.

4. During with-load auto-tuning, if the motor does not run or the running direction is

inconsistent with the actual door open/close command, it indicates that motor wiring is

- 30 -

to make the

to make the motor

Page 32

Chapter 4 Operation and Trial Running

Door open Door open

Door open limit

Door open slow-down

Door close limit

Door close slow-down

incorrect. You need to replace any two of UVW phases and perform motor auto-tuning

again.

5. The identied encoder zero position angle is viewed or modied in F1-14. This parameter

must not be modified after motor auto-tuning; otherwise, the controller may not run

properly.

This parameter obtained through with-load auto-tuning is not so accurate as that obtained

through no-load auto-tuning. Perform no-load auto-tuning if conditions are allowed.

6. If Er19 is reported during identication of the encoder zero position angle, check whether

encoder wiring is correct.

4.4 Door Open/Close Control Mode

The NICE900 supports two door open/close control modes, speed control and distance

control.

In speed control, the controller instructs deceleration at slow-down point and judge door open/

close limit based on the door open/close limit signal.

In distance control, the controller needs to identify the door width pulses correctly, and instructs

deceleration and judge door open/close limit based on the door open/close curve.

4.4.1 Speed Control Mode

1. Four travel switches need to be installed on the door for this mode. The controller

decelerates at the slow-down point and judges door open/close limit based on the door open/

close limit signal.

The following gure shows the installation positions of relevant signals (travel switch) of the

door machine system in speed control mode.

Figure 4-9 Installation position of signals of the door machine system

- 31 -

Page 33

Chapter 4 Operation and Trial Running

Door close

limit signal

Single

-

phase

220

VAC

power supply

M

Door motor

COM

DI1

DI2

DI3

DI4

Door close

slow-

down signal

Input common

U

V

W

L

N

TA

1

TC1

TB

1

TA3

TC3

TB

3

NICE900

Main circuit

Control circuit

Door open

slow-

down signal

Door open

limit signal

DI5

DI6

Door close input signal

Door open input signal

F9-01 = 13

F9-02

= 15

F

9-03 = 14

F9-04 = 12

F9-05 = 1

F

9-06

= 2

F9-09 =

2

F9-11 = 1

X5

Door close

limit

P24

X3

Door open

limit

B1

B

2

BM

Door open output

Door close output

Output common

Input

common

Function

code setting

Car top

board

MCTC-CTB

DI7

DI8

2. Check wiring of the door open/close signals for speed control.

The following gure takes Inovance elevator control system to describe wiring of the relevant

signals.

Figure 4-10 Typical system wiring for speed control

3. Related parameter setting

Function Code Parameter Name Value

F0-01 Door open/close control mode 0: Speed control

F0-02 Command source selection 1: Door machine terminal control

F9-01 DI1 function selection 13: Door close limit signal NO

F9-02 DI2 function selection 15: Door close slow-down point signal NO

F9-03 DI3 function selection 14: Door open slow-down point signal NO

F9-04 DI4 function selection 12: Door open limit signal NO

F9-05 DI5 function selection 1: Door open command

F9-06 DI6 function selection 2: Door close command

- 32 -

Page 34

Chapter 4 Operation and Trial Running

Door open command

ON

ON

ON

OFF

OFF

OFF

Door open

slow-down signal

Door open limit signal

Frequency

Time

F3-03

F3-00

F3-05

Door close command

ON

ON

ON

OFF

OFF

OFF

Door close

slow-down signal

Door close limit signal

Frequency

Time

F4-03

F4-00

F4-05

F4-09

F4-07

4. Door open/close running curve in speed control

Figure 4-11 Door open running curve in speed control

When the door open command is active, the door machine accelerates to the speed set in

F3-00. After the low speed door open time reaches the setting of F3-02, the door machine

accelerates to normal speed set in F3-03.

After the door open slow-down signal is active, the door machine decelerates to the speed

set in F3-05. After the door open limit signal is active, the door machine enters the door open

holding state with the holding torque set in F3-08.

Figure 4-12 Door close running curve in speed control

When the door close command is active, the door machine accelerates to the speed set in

F4-00. When the low speed door close time reaches the setting of F4-02, the door machine

accelerates to normal speed set in F4-03.

When the door close slow-down signal is active, the door machine decelerates to the speed

set in F4-05. When the door close limit signal is active, the door machine enters the door close

holding state:

•Holding speed: F4-07

•Holding time: F4-08

•Holding torque: F4-12

•Door vane retraction speed and time: F4-09 and F4-10

- 33 -

Page 35

Chapter 4 Operation and Trial Running

Single

-phase

220

VAC

power supply

COM

DI

1

DI2

DI

3

DI4

Input common

U

V

W

L

N

TA

1

TC

1

TB1

TA

3

TC

3

TB

3

NICE

900

Main circuit

Control circuit

DI

5

DI6

DI7

DI8

Door close

input signal

Door open

input signal

F9-05 = 1

F9-06 = 2

F9-09 = 2

F9-11 = 1

X5

Door close

limit

P24

X

3

Door open

limit

B1

B2

BM

Door open output

Door close output

Output common

Input

common

M

Door motor

Encoder

+24

V

COM

PGA

PGB

PGZ

Shield

grounded

Car top

board

MCTC-

CTB

Function

code setting

4.4.2 Distance Control Mode

1. The encoder needs to be installed for this mode. The controller judges the door position

based on the encoder signals. The door width pulses need to be identied at rst-time running.

The controller decelerates and judges door open/close limit based on the door open/close

curve.

The following gure takes Inovance elevator control system to describe wiring of the relevant

signals.

Figure 4-13 Typical system wiring for distance control

2. Check the encoder.

The pulse signal from the encoder is critical to accurate control of the system. Before

commissioning, check the following items carefully:

1) The encoder is installed reliably with correct wiring.

2) The signal cable and strong-current circuit of the encoder are laid in different ducts to

prevent interference.

3) The encoder cable is preferably directly connected to the controller. If the cable is not long

enough and an extension cable is required, the extension cable must be a shielded cable

and preferably welded to the original encoder cable by using the soldering iron.

- 34 -

Page 36

Chapter 4 Operation and Trial Running

F0-02 = 2 (Door machine manual control)

Set F6-00 = 1 to enable door width autotuning.

Press "OPEN" or "CLOSE" to start door

width auto-tuning.

The controller closes the door at the

frequency set in F6-01

Check that door

open/close is unhindered

End

The controller opens the door at door

close limit and closes the door again at

door open limit

After door close limit, the controller stores

the data obtained in F6

-02 and F6-03.

Door width = F6-02 + F6-03 x 10000

Set door open/close limit according to

system configuration (ship if not required)

4) The shield of the encoder cable is grounded on the end connected to the controller (only

one end is grounded to prevent interference).

3. Related parameter setting

Function Code Parameter Name Value

F0-01 Door open/close control mode 1: Distance control

F0-02 Command source selection 1: Door machine terminal control

F9-05 DI5 function selection 1: Door open command

F9-06 DI6 function selection 2: Door close command

4. Door width auto-tuning

Door width auto-tuning is required before running in distance control. During door open/close,

the controller records the pulses of door movement in real time, and judges door open/close

limit based on the door width pulses.

Pay attentions to the following precautions:

•Before performing door width auto-tuning in distance control for asynchronous motor,

check that the AB phase cables of the encoder are connected correctly.

•During door width auto-tuning, the door acting direction changes automatically; guarantee

personal safety before starting the operation.

•Check that there is no obstacle in the running track of the door before starting door width

auto-tuning. If the door is hindered by an obstacle, the controller considers that door open/

close limit is reached, resulting in incorrect auto-tuning data.

The following gure shows the door width auto-tuning owchart.

Figure 4-14 Door width auto-tuning owchart

- 35 -

Page 37

Chapter 4 Operation and Trial Running

Door open command

ON

ON

ON

OFF

OFF

OFF

Door open

slow-down pulse

Door open limit pulse

Frequency

Time

F3-03

F3-00

F3-05

F6-06 x door width

F6-05 x door width

F6-04 x door width

Door close command

ON

ON

ON

OFF

OFF

OFF

Door close

slow-down pulse

Door close limit pulse

Frequency

Time

F4-03

F4-00

F4-05

F6-09 x door width

F6-08 x door width

F4-09

F6-07 x door width

F4-07

5. Door open/close running curve in distance control mode

Figure 4-15 Door open running curve in distance control mode

When the door open command is active, the door machine accelerates to the speed set in F3-

00.

When the door open position reaches (F6-04 x door width), the door machine accelerates to

the speed set in F3-03.

When the door open position reaches (F6-05 x door width), the door machine enters the

deceleration and creeping state with the speed set in F3-05 and deceleration time set in F3-

06.

When the door open position reaches (F6-06 x door width), the door machine continues low

speed creeping, and then enters the door open holding state, with the holding torque set in F3-

08. The door position is reset to 100%.

After the door open command is cancelled, the torque holding state ends.

Figure 4-16 Door close running curve in distance control mode

When the door close command is active, the door machine accelerates to the speed set in F4-

00.

When the door close position reaches (F6-07 x door width), the door machine accelerates to

the speed set in F4-03.

When the door close position reaches (F6-08 x door width), the door machine decelerates to

the speed set in F4-05.

- 36 -

Page 38

Chapter 4 Operation and Trial Running

Door open

slow-down signal

Door open limit signal

Time

Door close command

Door open command

Frequency

F4

-00

F

3-05

F4-03

F3-03

F5-00 (Abnormality

deceleration time)

0

F3-00

When the door close position reaches (F6-09 x door width), the door machine decelerates

again to the speed set in F4-07. It is recommended that F6-09 ≥ 96.0%; reduce F6-09 if there

is pulse loss during door open/close.

Set the threshold for retracting the door vane in F6-20. After the door vane is retracted and

door limit is reached, the door machine enters the torque holding state, with the speed set in

F4-07 and holding torque set in F4-12. The door position is reset to 0.

After the door close command is cancelled, the torque holding state ends.

4.4.3 Door Close Hindered

Door close hindered means that one of the following conditions occur during door close:

•Light curtain/safety edge signal active

•Output torque larger than the door close hindered torque

•Door open command active

If door close hindered occurs, the NICE900 processes this abnormality in two ways: decelerate

to stop or re-open the door, selected in F4-14. This abnormality is judged based on the time or

torque.

1. Running curve of door open command active during door close in speed control mode

Figure 4-17 Running curve of door open command active during door close in speed control

mode

After the time reaches the deceleration time in F5-00, the controller re-opens the door at low

speed, and enters normal speed running state after the time set in F3-02.

After the door open slow-down signal is active, the controller enters the low speed running

state and opens the door to the open limit position, and then outputs the door open limit signal.

- 37 -

Page 39

Chapter 4 Operation and Trial Running

Running

frequency (Hz)

Hinder torque

(%)

F4-18 F4-17

F4-20

F4-19

V2 V1

T2

T1

Curve 1

2. Related parameter setting

Function

Code

F4-14

F4-15

F4-17

F4-18

Parameter

Name

Working mode

upon door

close hindered

Door close

hindered

judging time

Normal speed

at door close

hindered

Low speed

at door close

hindered

Setting Description

F4-14 = 2

Upon door close hindered, the controller stops

immediately, outputs the door close hindered signal,

and does not respond to the door close command

within 10s. However, if the controller receives the door

0: Reserved

1: Output door

close hindered

signal

2: Immediate

stop

3: Door reopen

close or RUN (door open/close) cancellation command

within the time, it executes door close immediately

rather than restricted by the 10s time counting.

F4-14 = 3

The controller re-opens the door upon door close

hindered, and does not respond to the external door

open/close commands during door re-open.

Door close hindered occurs on one of the following

conditions during door close:

•The light curtain/safety edge signal is active.

•The output torque is larger than the door close

hindered torque.

•The door close time exceeds the value of F5-02.

It is used to set the lter time when door close is

0–9999 ms

hindered. If it is set to 0, door close hindered is not

detected.

F4-18 to F1-04

12.00 Hz

0.00 Hz to F104

2.00 Hz

F4-19

F4-20

F5-00

Normal speed

torque

Low speed

torque

Abnormality

deceleration

time

0.00–150.0%

100.0%

0.00–150.0%

100.0%

0.1–5.0s

F4-17 to F4-20 are used to judge door close hindered.

Set them according to the requirement:

V1 (F4-17) ≥ V2 (F4-18), T1 (F4-19) ≤ T2 (F4-20)

The torque threshold for judging door close hindered

is curve 1 shown in the gure. The shadow part shows

that door close hindered occurs.

It is used to set the time for the system to decelerate

from the door close speed to 0 when door close is

hindered. Set this parameter to the minimum value

as possible when ensuring that over-current does not

occur during deceleration.

- 38 -

Page 40

Chapter 4 Operation and Trial Running

Function

Code

F5-02

Parameter

Name

Door close

time limit

Setting Description

It is used to limit the door close time. If the controller

does not receive the door close limit signal within the

0–9999s

time, it determines that door close is hindered, and

performs door re-open or zero speed holding based on

the setting of F4-14.

This parameter is invalid when it is set to 0.

- 39 -

Page 41

Chapter 4 Operation and Trial Running

- 40 -

Page 42

5

Function Code Table

Page 43

Chapter 5 Function Code Table

PRG

Chapter 5 Function Code Table

5.1 Description of Function Codes

The NICE900 series door machine controller has a total of 13 groups of function codes,

namely, F0 to F9, FA, FF and FP. FX–YZ in this manual indicates the function code whose

function code group is "X" and whose function code is "YZ". For example, F3-02 indicates

function code "2" in group F3.

To facilitate the setting of the function codes, the operation panel adopts three-level menu.

The function code group is Level-I menu, function code is Level-II menu, and the setting value

corresponds to Level-III menu.

The meaning of each column in the function code table is as follows:

Function Code Indicates the function code number.

Parameter Name Indicates the parameter name of the function code.

Setting Range Indicates the setting range of the parameter.

Default Indicates the default setting of the parameter at factory.

Unit Indicates the measurement unit of the parameter.

Property

Indicates whether the parameter can be modied (including the modication

conditions)

The symbols in the function code table are described as follows:

"☆": The parameter can be modied when the NICE900 is in either stop or running state.

"★": The parameter cannot be modied when the NICE900 is in the running state.

"●": The parameter is the actually measured value and cannot be modied.

"*": The parameter is factory parameter and can be set only by the manufacturer.

The system automatically restricts the modication property of all parameters to prevent mal-

function.

"Default Value" indicates the value after parameter update when you restore factory settings,

but the actually detected parameter values or recorded values are not updated.

To protect the parameters more effectively, the NICE900 provides the password protection.

5.2 Function Code Table

After pressing

corresponding to the following function code groups:

key and then or key, the Level-I menu is displayed,

- 42 -

Page 44

Chapter 5 Function Code Table

Group F0: Basic Parameters Group F7: Distance Control Parameters

Group F1: Motor Parameters Group F8: Auxiliary Parameters

Group F2: Performance Control Parameters

Group F3: Door Open Running Curve Parameters Group FA: Display and Fault Parameters

Group F4: Door Close Running Curve Parameters Group FF: Factory Parameters (Reserved)

Group F5: Door Open/Close Auxiliary Parameters Group FP: User Parameters

Group F6: Distance Control Parameters

Group F9: Input and Output Function

Parameters

Function

Code

F0-00 Control mode

F0-01

F0-02 Command source selection

F0-04

F0-05 Input signal quick setting 0–2 1 1

F0-06 Speed at low speed running 0.00 to F1-04 4.00 Hz

F0-07 Carrier frequency 2.0–16.0 kHz 8.0 kHz 0.1 kHz

F1-00 Motor type

F1-01 Rated motor power 0–750 W 1 1

F1-02 Rated motor voltage 0–250 V

F1-03 Rated motor current 0.001–9.900 A 100 V 1 V

F1-04 Rated motor frequency 1.00–99.00 Hz

F1-05 Rated motor speed 0–9999 RPM 24.00 Hz

Parameter Name Setting Range Default

Group F0: Basic Parameters

0: Sensorless vector control

(SVC)

1: Closed-loop vector control

(CLVC)

Door open/close mode

selection

Running frequency under

operation panel control

0: Speed control

1: Distance control

0: Operation panel control

1: Door machine terminal

control

2: Door machine manual

control

3: Door machine auto

demonstration

0.00 to F1-04 5.00 Hz

Group F1: Motor Parameters

0: Asynchronous motor

1: PMSM

8.0 kHz 0.1 kHz

Model

dependent

Model

dependent

Min.

Unit

1 1

1 1

0 1

0.01

0.01

1 V

0.001 A

0.01

Hz

Hz

Hz

Property

★

★

★

☆

★

☆

☆

★

★

★

★

★

★

- 43 -

Page 45

Chapter 5 Function Code Table

Function

Code

F1-06

F1-07

F1-08

F1-09

F1-10

F1-11 Shaft D inductance of PMSM 0.0–999.9 mH

F1-12 Shaft Q inductance of PMSM 0.0–999.9 mH

F1-13 Back EMF of PMSM 0–250

F1-14

F1-15 Real-time angle of PMSM 0.0–359.9°

F1-16 Motor auto-tuning mode

F2-00

F2-01 Speed loop integral time 1 0.01–10.00s 1.00s 0.01s

F2-02 Switchover frequency 1 0.00 to F2-05 5.00 Hz

F2-03

F2-04 Speed loop integral time 2 0.01–10.00s 1.00s 0.01s

F2-05 Switchover frequency 2 F2-02 to F1-04 30 1

F2-06

F2-07 Current loop integral gain 10–500 50 1

Parameter Name Setting Range Default

Stator phase resistance of

PMSM

Rotor phase resistance of

asynchronous motor

Leakage inductance of

asynchronous motor

Mutual inductance of

asynchronous motor

Magnetizing current of

asynchronous motor

Encoder zero position angle

of PMSM

Group F2: Performance Control Parameters

Speed loop proportional gain

1

Speed loop proportional gain

2

Current loop proportional

gain

0.00–99.99 Ω

0.00–99.99 Ω

0.0–99.99 mH

0–999.9 mH

0.001–9.900 A

0.0–359.9°

0: No auto-tuning

1: Static auto-tuning for

asynchronous motor

2: Complete auto-tuning for

asynchronous motor

3: No-load auto-tuning for

PMSM

4: With-load auto-tuning for

PMSM

0–100 15 1

0–100 15 1

10–500 120 1

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Model

dependent

Model

dependent

0 1

0.01 Ω

0.01 Ω

0.1 mH

0.001 A

0.1 mH

0.1 mH

Min.

Unit

0.01

mH

1

0.1°

0.1°

0.01

Hz

Property

★

★

★

★

★

★

★

★

★

●

★

☆

☆

☆

☆

☆

☆

☆

☆

- 44 -

Page 46

Chapter 5 Function Code Table

Function

Code

F2-08 Slip compensation coefcient 50%–200% 100% 1%

F2-09 Inertia compensation 0–9999 0 1

F2-10 Torque boost 0.0%–30.0% 8.0% 0.1%

F2-11 Over-excitation gain 0–200 64 1

F2-12 Initial position judging method

F2-13 Feedback speed lter level 0–20 0 1

F2-14 Encoder PPR 1–9999 2048 1

F2-15 Encoder direction selection

F3-00 Door open startup low speed 0.00 Hz to F3-03 5.00 Hz

F3-01

F3-02

F3-03 Door open normal speed 0.00 Hz to F1-04 15.00 Hz

F3-04 Door open acceleration time 0.1–999.9s 2.0s 0.1s

F3-05 Door open ending low speed 0.00 Hz to F3-03 3.00Hz

F3-06 Door open deceleration time 0.1–999.9s 1.5s 0.1s

F3-07

F3-08

F3-09 Door open hindered torque 0.0%–150.0% 80.0% 0.1%

F3-10 Door open startup torque 0.0% to F3-09 0.0% 0.1%

F3-11

F3-12 Door open limit low speed 0.00 Hz to F3-03 3 Hz

F3-13 Door re-open speed 0.00 Hz to F3-03 0 Hz

F4-00 Door close startup low speed 0.00 Hz to F4-03 4.00 Hz

Parameter Name Setting Range Default

1: Based on pulses

2: Using data of other tested

PMSM

0: Forward direction

1: Reverse direction

Group F3: Door Open Running Curve Parameters

Door open startup

acceleration time

Low speed running time for

door open startup in speed

control

Torque switchover threshold

at door open limit

Door open limit holding

torque

Door open hindered judging

time

Group F4: Door Close Running Curve Parameters

0.1–999.9s 1.0s 0.1s

0.1–999.9s 1.0s 0.1s

0.0%–150.0% 50.0% 0.1%

0.0%–150.0% 50.0% 0.1%

0–9999 ms 0ms 1 ms

1 1

1 1

Min.

Unit

0.01

Hz

0.01

Hz

0.01

Hz

0.01

Hz

0.01

Hz

0.01

Hz

Property

☆

★

☆

☆

★

☆

★

★

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

★

☆

☆

☆

☆

- 45 -

Page 47

Chapter 5 Function Code Table

Function

Code

F4-01

F4-02

F4-03 Door close normal speed 0.00 Hz to F1-04 12.00 Hz

F4-04 Door close acceleration time 0.1–999.9s 2.0s 0.1s

F4-05 Door close ending low speed 0.00 Hz to F4-03 2.00 Hz

F4-06 Door close deceleration time 0.1–999.9s 1.5s 0.1s

F4-07 Door close limit low speed 0.00 Hz to F4-03 1.00 Hz

F4-08

F4-09 Door vane retraction speed 0.00 to F4-03 2.00 Hz

F4-10

F4-11

F4-12

F4-13 Door close hindered torque 0.0%–150.0% 100.0% 0.1

F4-14

F4-15

F4-16

F4-17

F4-18

F4-19 Normal speed torque 0.00%–150.0% 100.0% 0.1%

F4-20 Low speed torque 0.00%–150.0% 100.0% 0.1%

F5-00

Parameter Name Setting Range Default

Door close startup

acceleration time

Low speed running time for

door close startup in speed

control

Low speed running time at

door close limit

Door vane retraction running

time

Torque switchover threshold

at door close limit

Door close limit holding

torque

Working mode upon door

close hindered

Door close hindered judging

time

Door close normal speed at

re emergency

Normal speed at door close

hindered

Low speed at door close

hindered

Group F5: Door Open/Close Auxiliary Parameters

Abnormality deceleration

time

0.1–999.9s 1.0s 0.1s

0.1–999.9s 1.0s 0.1s

0–9999 ms 300 ms 1 ms

0–9999 ms 500 ms 1 ms

0.0%–150.0% 50.0% 0.1%

0.0%–150.0% 30.0% 0.1%

0: Reserved

1: Output door close

hindered signal

2: Immediate stop

3: Door re-open

0–9999 ms 500 ms 1 ms

5.00 to F1-04 10.00 Hz

F4-18 to F1-04 12.00 Hz

0.00 Hz to F1-04 2.00 Hz

0.1–5.0s 0.3s 0.1

1 1

Min.

Unit

0.01

Hz

0.01

Hz

0.01

Hz

0.01

Hz

0.01

Hz

0.01

Hz

0.01

Hz

Property

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

☆

★

★

☆

☆

☆

☆

☆

☆

☆

- 46 -

Page 48

Chapter 5 Function Code Table

Function

Code

F5-01 Door open time limit 0–999.9s 30.0s 1s

F5-02 Door close time limit 0–999.9s 0s 1s

F5-03 Low speed running time limit 0–999.9s 0s 1s

F5-04

F5-05

F5-06 Door open curve 0, 1 1 1

F5-07

F5-08

F5-09

F5-10

F5-11

F5-12

F5-13

F5-14

F5-15

F5-16 Speed deviation threshold 0%–80% 50% 0%

F5-17

Parameter Name Setting Range Default

Delay of external door open

command

Delay of external door close

command

Start segment time of door

open acceleration S curve

Rising segment time of door

open acceleration S curve

Start segment time of door

open deceleration S curve

Falling segment time of door

open deceleration S curve

Start segment time of door

close acceleration S curve

Rising segment time of door

close acceleration S curve

Start segment time of door

close deceleration S curve

Falling segment time of door

close deceleration S curve

Start segment time of door

open acceleration S curve

Time for determining speed

deviation too large

0–999.9s 60.0s 1s

0–999.9s 60.0s 1s

10.0%–50.0% (acceleration/

deceleration time, start

segment + rising segment ≤

90%)

10.0%–80.0% (acceleration/

deceleration time, start

segment + rising segment ≤

90%)

10.0%–50.0% (acceleration/

deceleration time, start

segment + falling segment ≤

90%)

10.0%–80.0% (acceleration/

deceleration time, start

segment + falling segment ≤

90%)

0, 1 1 1

10.0%–50.0% (acceleration/

deceleration time, start

segment + rising segment ≤

90%)

10.0%–80.0% (acceleration/

deceleration time, start

segment + rising segment ≤

90%)

10.0%–50.0% (acceleration/

deceleration time, start

segment + falling segment ≤

90%)

10.0%–80.0% (acceleration/

deceleration time, start

segment + falling segment ≤

90%)

0–5000 ms 400 ms 1 ms

20.0% 0.1%

60.0% 0.1%

20.0% 0.1%

60.0% 0.1%

20.0% 0.1%

60.0% 0.1%

20.0% 0.1%

60.0% 0.1%

Min.

Unit

Property

☆

☆

☆

☆

☆

★

★

★

★

★

★

★

★

★

★

☆

☆

- 47 -

Page 49

Chapter 5 Function Code Table

Function

Code

F5-18

F5-19 Fault braking current 0.1%–150.0% 100% 0.1%

F6-00

F6-01 Door width auto-tuning speed 0 to F0-04 3.00 Hz

F6-02 Low bits of door width pulse 0–9999 0 1

F6-03 High bits of door width pulse 0–9999 0 1

F6-04

F6-05

F6-06

F6-07

F6-08

F6-09

F6-10 Output torque display 0.0-1–80.0% 0.0% 0.1%

F6-11

F6-12

F6-13

F6-14

F6-15

F6-16

F6-17

F6-18

Parameter Name Setting Range Default

Door close steady speed

delay

Group F6: Distance Control Parameters

Door width auto-tuning

function

Low speed running distance

of door open startup in

distance control

Door open slow-down point

in distance control

Door open limit point in

distance control

Low speed running distance

of door close startup in

distance control

Door close slow-down point

in distance control

Door close limit point in

distance control

Low bits of the door open

limit switch position

High bits of the door open

limit switch position

Position of the door close

limit switch

Torque setting for door width

auto-tuning or initial running

Low bits of the pulse of door

open slow-down point

High bits of the pulse of door

open slow-down point

Low bits of the pulse of door

close slow-down point

High bits of the pulse of door

close slow-down point

0–9999 ms 200 ms 1 ms

0: Disabled

1: Enabled

0.0%–30.0% 10.0% 0.1%

60.0%–90.0% 70.0% 0.1%

80.0%–99.0% 96.0% 0.1%

0.0%–30.0% 10.0% 0.1%

60.0%–90.0% 70.0% 0.1%

80.0%–99.0% 96.0% 0.1%

0–9999 0 1

0–9999 0 1

0–9999 0 1

0.0%–150.0% 80.0% 0.1%

0–9999 0 1

0–9999 0 1

0–9999 0 1

0–9999 0 1

0 1

Min.

Unit

0.01

Hz

Property

★

★

★

☆

★

★

☆

☆

☆

☆

☆

☆

☆

★

★

★

★

★

★

★

★

- 48 -

Page 50

Chapter 5 Function Code Table

Function

Code

F6-19

F6-20

F6-21 Door position feedback pulse 0.0%–99.9% 33.0% 0.1%

F7-00

F7-01

F7-02

F7-03

F8-00 Software version 0.00–99.99 1.00 0.01

F8-01 Module temperature 0–100°C 0°C 1°C

F8-02 Fault auto reset times 0–100 0 1

F8-03 Brake use ratio 0–100% 100% 1%

F8-04 Accumulative power-on time 0–9999 h 0 1

F8-05

F8-06 Accumulative running time 0–9999 h 0 1

F8-07

F8-08

F8-09

F8-10 Auxiliary function selection 0–9999 12 1

F8-12 Drive function selection 0–9999 0 1

F8-14 Overload coefcient 0–10.00 2.00 0.01

F9-00 Terminal lter time 0–100 ms 20 ms 1 ms

Parameter Name Setting Range Default

Pulse at door open limit

output

Pulse at door close limit

output

Group F7: Distance Control Parameters

Door open limit holding time

in demonstration mode

Door close limit holding time

in demonstration mode

Actual door open and close

times in demonstration mode

Limit of door open and close

times in demonstration mode

Reserved (working time:

minutes)

Reserved (working time:

minutes)

Accumulative working time

setting

Accumulative operation time

setting

0.0%–99.9% 0.0% 0.1%

0.0%–99.9% 0.0% 0.1%

1.0–999.9s 0.1s 2.0s

1.0–999.9s 0.1s 2.0s

0–9999 0 1

0–9999 0 1

Group F8: Auxiliary Parameters

0 0 1

0 0 1

0–9999 h 0 1

0–9999 h 0 1

Group F9: Auxiliary Parameters

Min.

Unit

Property

☆

☆

☆

★

★

☆

☆

●

●

★

☆

★

★

★

★

★

★

★

★

☆

☆

- 49 -

Page 51

Chapter 5 Function Code Table

Function

Code

F9-01 DI1 function selection

F9-02 DI2 function selection 0 1

F9-03 DI3 function selection 0 1

F9-04 DI4 function selection 0 1

F9-05 DI5 function selection 1 1

F9-06 DI6 function selection 2 1

F9-07 DI7 function selection 10 1

F9-08 DI8 function selection 6 1

F9-09

F9-10

F9-11

Parameter Name Setting Range Default

0: Invalid

1: Door open command

2: Door close command

3: External reset signal

4: Forbid terminal input

during door open

5: Forbid terminal input

during torque holding

6: Low speed door close

command

7: Fire emergency input

8 to 109: Reserved

10/110: Light curtain signal

NO/NC

11/111: Safety edge signal

NO/NC

12/112: Door open limit

signal NO/NC

13/113: Door close limit

signal NO/NC

14/114: Door open slow-

down signal NO/NC

15/115: Door close slow-

down signal NO/NC

16/116: Door lock signal NO/

NC

0: Invalid

1: Door open limit signal

Relay output selection (TA1/

TB1/TC1)

Relay output selection (TA2/

TB2/TC2)

Relay output selection (TA3/

TB3/TC3)

output 0

2: Door close limit signal

output 0

3: Door open limit signal

output 1

4: Door close limit signal

output 1

5: Fault signal output 1

6: Reserved

7: Door open limit signal

output 2

8: Door close limit signal

output 2

9: Door lock signal output

10: Door re-open signal

output

11: Hindering signal output

12: Door position feedback

output

0 1

2 1

5 1

1 1

Min.

Unit

Property

★

★

★

★

★

★

★

★

★

★

★

- 50 -

Page 52

Chapter 5 Function Code Table

Function

Code

FA-00 Display in running state 1–511 319 1

FA-01 Display in stop state 1–63 39 1

FA-02 1st fault type 0–30 0 1

FA-03 1st fault prompt 0–9 0 1

FA-04 2nd fault type 0–30 0 1

FA-05 2nd fault prompt 0–9 0 1

FA-06 3rd fault type 0–30 0 1

FA-07 3rd fault prompt 0–9 0 1

FA-08 4th fault type 0–30 0 1

FA-09 4th fault prompt 0–9 0 1

FA-10 5th fault type 0–30 0 1

FA-11 5th fault prompt 0–9 0 1

FA-12 Bus voltage upon latest fault 0–999.9 V 0 V 0.1 V

FA-13

FA-14

FA-15

FA-16

FA-17

FA-18 Terminal state display * * *

FA-19 Input signal display * * *

FA-20 Output signal display * * *

FA-21 Parameter display selection 0–9999 0 1

FA-22 Display 1 0–9999 0 1

FA-23 Display 2 0–9999 0 1