User Instructions

86BPQ00001 2006-10 (ver. 1.2)

Table of Contents

Table of Contents..........................................................................................................2

1. Introduction..............................................................................................................4

1.1 About this manual ............................................................................................4

1.2 About ProfIPAQ................................................................................................4

1.2.1 Features: ..................................................................................................4

1.3 About PROFIBUS..............................................................................................5

Part 1 .....................................................................................................................6

2 ProfIPAQ-H/-HX/-L Installation and Maintenance..........................................................6

2.1 General ...........................................................................................................6

2.1.1 CAUTION ..................................................................................................6

2.1.2 Ex installation............................................................................................6

2.1.3 Default Settings.........................................................................................6

2.2 ProfiSoft Communication...................................................................................6

2.3 Short form Data (complete data in chapter Specifications)...................................7

2.3.1 Ex Data (also see certificate and control drawings).......................................7

2.4 Identification of the transmitter: See labels on the transmitter .............................8

2.5 Installation in an encapsulation .........................................................................9

2.5.1 Ambient temperature considerations ...........................................................9

2.5.2 ProfIPAQ-H/-HX (Gas)................................................................................9

2.5.3 ProfIPAQ-H/D/-HX/D (Dust)......................................................................10

2.5.4 ProfIPAQ-L..............................................................................................11

2.6 Connections...................................................................................................12

2.6.1 Connection Diagram.................................................................................12

2.6.2 LCD-W12 ................................................................................................12

2.6.3 Ex Bus connection: ..................................................................................12

2.6.4 Ex Cable requirements: ............................................................................13

2.6.5 ProfIPAQ SmartSense (low sensor isolation detection) ................................ 13

2.6.6 ProfIPAQ Sensor Aging.............................................................................13

2.7 Specification ..................................................................................................13

2.7.1 Input RTD 2-, 3- and 4-wire connection...................................................13

2.7.2 Input Resistance...................................................................................... 13

2.7.3 Input Thermocouple ................................................................................13

2.7.4 Input Voltage ..........................................................................................14

2.7.5 Double inputs for RTD, Thermocouple and Voltage..................................... 14

2.7.6 Output....................................................................................................14

2.7.7 General data ...........................................................................................14

2.7.8 Environment conditions (also see Ex data).................................................14

2.7.9 Resolution and Accuracy ..........................................................................14

2.7.10 Accuracy Specifications for RTD and Thermocouple Input ........................... 15

2.8 Dimensions....................................................................................................15

2.8.1 ProfIPAQ-H/-HX.......................................................................................15

2.8.2 ProfIPAQ-L..............................................................................................15

2.9 Service and repair .......................................................................................... 16

2.10 Ordering information ...................................................................................... 16

2.11 Accessories....................................................................................................16

3 Control Drawings for installation guidance ..................................................................17

2

Part 2 ...................................................................................................................19

4 ProfIPAQ Software and Programming.........................................................................19

4.1 INOR PC configuration software ProfiSoft ......................................................... 19

4.1.1 Installation..............................................................................................19

4.1.2 Overview. ...............................................................................................19

4.1.3 Input configuration .................................................................................. 20

4.1.4 Device information................................................................................... 21

4.1.5 Output configuration................................................................................22

4.1.6 Download and upload configuration to/from ProfIPAQ ................................ 23

4.1.7 View temperature ....................................................................................24

4.1.8 Change address with ProfiSoft .................................................................. 24

4.1.9 Customized Linearization, Datapair............................................................25

4.1.10 Error Correction.......................................................................................26

4.1.11 Settings .................................................................................................. 27

4.1.12 Password ................................................................................................ 27

5 ProfIPAQ in a ProfiBus system ................................................................................... 28

5.1 DDL-file.........................................................................................................28

5.2 GSD-file......................................................................................................... 28

5.3 PROFIBUS/ProfIPAQ parameters......................................................................29

6 Appendix A. Parameter table ..................................................................................... 32

6.1 Function Block Analog Input............................................................................ 32

6.2 Transducer Block Temperature Device ............................................................. 32

6.3 Physical Block Transmitter...............................................................................33

7 Appendix B. PROFIBUS Cabling..................................................................................34

7.1 Shielding and grounding .................................................................................34

7.2 Termination ................................................................................................... 35

8 WARRANTY.............................................................................................................. 36

3

1. Introduction

1.1 About this manual

This manual is intended to assist in installing, operating, and maintaining ProfIPAQ

temperature transmitters with PROFIBUS-PA, and it is divided into two parts;

Part 1: ProfIPAQ-H/-HX/-L Installation and Maintenance. Here you will find

connection drawings, mechanical drawings, electrical data, guidelines for mounting into

hazardous Ex location and accessories.

and

Part 2: Software and Programming. This describes ProfiSoft, the software to configure

the ProfIPAQ transmitters via the PC serial port.

It also contains some generic PROFIBUS information. ProfIPAQ transmitters DD are

integrated into Siemens Simatic PDM version 5.1 or higher. For use with an earlier version

of Siemens Simatic PDM and other software problems using Siemens Simatic PDM, consult

Siemens user’s manual.

1.2 About ProfIPAQ

ProfIPAQ is a line of temperature transmitters from INOR, designed according to the

latest PROFIBUS-PA standard for temperature transmitters, i.e. Profile 3.0, class A & B. At

present the following versions are available:

ProfIPAQ-H in-head for non-Ex and Non-Incendive gas (Zone 2) applications.

ProfIPAQ-H/D is a dust version of ProfIPAQ-H with dust tested housing for non-Ex and NonIncendive dust (Zone 22) applications.

ProfIPAQ-HX in-head for Intrinsic safe Ex ia/ib gas applications (Zone 0 and 1),

ProfIPAQ-HX/D is a dust version of ProfIPAQ-HX with a dust tested housing for Intrinsic safe

Ex ia/ib dust applications (Zone 21) applications and

ProfIPAQ-L DIN-rail mounted for non-Ex applications.

1.2.1 Features:

• PROFIBUS PA certified communication

• Easy setup via a separate INOR communication port as an alternative to PROFIBUS

• High accuracy measurement

• Linearizes for most temperature sensors.

• Custom linearization for other type of sensors with mV and ohm output.

• Accepts two input signals making it possible to do differential measurements, average

measurement, redundancy and sensor ageing control.

• FDE (Fault Disconnect Equipment) ensures that the ProfIPAQ transmitter won’t pull down

a whole segment in a PROFIBUS net if the transmitter fails internally.

• DDL and GSD files available

• Sensor monitoring functions: sensor break, sensor short circuit, low sensor isolation

• A separate LCD-indicator can be connected to the communication port of the transmitter.

4

1.3 About PROFIBUS

PROFIBUS-PA is an all-digital, serial, two-way communication system that interconnects

field equipment such as sensors, actuators, and controllers. Power supply and output digital

signal uses the same two wires. The physical layer is described in EN 61158-2 and the

protocol in EN 50170.

For more information concerning PROFIBUS, visit the PROFIBUS organization homepage at

address www.profibus.com. There you find a lot of information about the PROFIBUS

protocol, PROFIBUS tools, PROFIBUS news, GSD and DDL’s, competence center, FAQ’s and

more and there is a lot of interesting PDF’s for downloading.

5

Part 1

2 ProfIPAQ-H/-HX/-L Installation and Maintenance

2.1 General

Electrical temperature sensors such as RTDs and thermocouples produce low-level signals

proportional to temperature. The ProfIPAQ temperature transmitter converts the analogue

sensor signal to a digital signal that is relatively insensitive to lead length and electrical

noise. This digital signal is then transmitted over the bus to the configuration device and the

control system.

The ProfIPAQ transmitter is compatible with many RTD and thermocouple sensor types as

well as potentiometer and voltage input. Figure 12 shows the correct input connections to

the sensor terminals on the transmitter.

2.1.1 CAUTION

If the sensor is installed in a high-voltage environment and a fault condition or

installation error occurs, the sensor leads and transmitter terminals could carry

lethal voltages. Use extreme caution when making contact with the leads and terminals.

2.1.2 Ex installation

For a safe installation in hazardous area the transmitter must only be installed by

qualified personnel that are familiar with the national and international laws,

regulations, directives and standards (e.g. EN50039, En 50284, IEC 60079-14 and IEC

60079-17) that apply to the installation conditions.

2.1.3 Default Settings

The ProfIPAQ transmitter has a standard configuration when it is delivered from factory.

These settings can be changed by either the ProfiSoft software, via Simatic PDM system or

via any other system using the ProfIPAQ DDL.

Default Settings:

Address: 126

Input signal: Pt100, 4-wire

Output signal: °C

Filter: 0 s

Sensor Monitoring: Off

2.2 ProfiSoft Communication

Communication to ProfIPAQ via ProfiSoft and INOR Communication cable must

NOT be performed unless the area where the transmitter is located is known to

be non-hazardous. When installed in hazardous area always use the PROFIBUS

communication to change settings.

6

2.3 Short form Data (complete data in chapter Specifications)

Power supply 9 – 32 VDC

Isolation Input/Output 1500 VAC

Output ProfIbus PA Profile v. 3.0 Class A&B

Operating temperature ProfIPAQ-H/-HX -40 - +85 °C / -40 - +185 °F

ProfIPAQ-L -20 - +70 °C / -4 - +158 °F

2.3.1 Ex Data (also see certificate and control drawings)

ProfIPAQ-H / -H/D ProfIPAQ-HX / -HX/D

ATEX Approval

Gas II 3G Ex nL IIC T4-T6 II 1G Ex ia IIC T4-T6

Dust II 3GD Ex nL T 100°C II 1G/2D Ex ia IIC T 100°C

ProfIPAQ-H/ -H/D is intended to be connected to a standard power supply (Class 2) with

maximum supply voltage to the transmitter of 30 VDC or a FNICO power supply / Segment

coupler, mounted outside the hazardous area. The data for the transmitter is:

Bus-port (connector 6 and 7) Sensor port (1- 5) Comm.port

Ui = Vmax : 30 VDC Uo = Voc : 3,3 VDC Ui = Vmax : 8,0 VDC

Ii = Imax : no limit Io = Isc : 0,4 mA Ii = Imax : 450 mA

Pi = Pmax : no limit Po = Pt : 6,5 mW Pi = Pmax : 0,8 W

Ci : 1 nF Co = Ca : 500 µF Ci : 10 nF

Li : 10 µH Lo = La : 375 mH Li : 1 µH

For the ambient temperature:

T6: -40°C < Ta < +60°C / -40°F < Ta < +140°F

T5: -40°C < Ta < +75°C / -40°F < Ta < +167°F

T4: -40°C < Ta < +85°C / -40°F < Ta < +185°F

Dust: -30°C < Ta < +80°C / -22°F < Ta < +176°F

ProfIPAQ-HX / -HX/D is intended to be connected to a certified intrinsic safe power

supply / Segment coupler with FISCO data, mounted outside the hazardous area. The data

for the transmitter is:

Bus-port (connector 6 and 7)

Ui = Vmax : 17,5 VDC Uo = Voc : 17,5 VDC Ui = Vmax : 8,0 VDC

Ii = Imax : 380 mA Io = Isc : 56 mA Ii = Imax : 450 mA

Pi = Pmax : 5,32 W Po = Pt : 244 mW Pi = Pmax : 0,8 W

Ci : 1 nF Co = Ca : 166 nF Ci : 10 nF

Li : 10 µH Lo = La : 6 mH Li : 1 µH

For the ambient temperature:

T6: -40°C < Ta < +45°C / -40°F < Ta < +113°F

T5: -40°C < Ta < +60°C / -40°F < Ta < +140°F

T4: -40°C < Ta < +85°C / -40°F < Ta < +185°F

Dust: -30°C < Ta < +80°C / -22°F < Ta < +176°F

Sensor port (1- 5) Comm.port

7

2.4 Identification of the transmitter: See labels on the transmitter

Figure 1 Label 1 and 2 on peripheral of the transmitter ProfIPAQ-H 70PPH00001

Figure 2 Label 1 and 2 on peripheral of the transmitter ProfIPAQ-HX 70PPHX0001

Part no

Serial no (production date, Nyyww)

Figure 3 Label 1 and 2 on enclosure of the transmitter ProfIPAQ-H/Dxy 70PPHD0xy1 (e.g. 70PPHD0111)

Figure 4 Label 1 and 2 on enclosure of the transmitter ProfIPAQ-HXDxy 70PPHXDxy1 (e.g. 70PPHXD111)

Figure 5 Label 1 and 2 on enclosure of the transmitter ProfIPAQ-L 70PPL00001

Part no

Serial no (production

date, Nyyww)

8

2.5 Installation in an encapsulation

2.5.1 Ambient temperature considerations

The ProfIPAQ-H / -H/D / -HX / -HX/D transmitter is designed to operate within specifications

for ambient temperatures between –40 and 85 °C (–40 and 185 °F), also see ambient

temperatures depending on temperature class and Gas- or Dust-installation in section 2.3.1,

Ex data. Heat from the process is transferred via the thermowell to the transmitter housing.

If the expected process temperature is near or beyond specification limits, this may rise the

temperature in the transmitter housing (encapsulation) above specified ambient

temperature. Always verify that the temperature where the transmitter is mounted is not

above the specified limit. One way to reduce heat transfer via the thermowell is to increase

the length of the thermowell or to move the transmitter housing away from the heat source.

The same safety measures can be used when the temperature is below the specified

minimum temperature.

2.5.2 ProfIPAQ-H/-HX (Gas)

The transmitter may be mounted in a temperature sensor housing, in a box or on a DIN

rail. It is recommended to use INOR mounting accessories, see 2.11, Accessories.

For non-Ex application, a housing with IP 54 is recommended. Most temperature housings

fulfill this requirement.

For Ex n application (non-incendive, Zone 2, Category 3G) ProfIPAQ-H in a housing with at

least IP 54 is needed. The enclosure must fulfill the requirements of EN 60079-0 and EN

60079-15 regarding impact and IP degree, which easiest is achieved by using certified

enclosures, e.g. the housings approved together with ProfIPAQ-H/D / -HX/D.

For applications requiring installation into Zone 0 (Category 1G) or Zone 1 (Category 2G)

ProfIPAQ-HX is used, installed in an appropriate housing with an ingress protection of at

least IP20.

1 M4 Screw, special for ProfIPAQ-H/-HX

2 Spring

3 Locking washer

4 Sensor wires

5 Sensor protection tube

Figure 6 Mounting with Standard Mounting kit 70ADA00017

9

2.5.3 ProfIPAQ-H/D/-HX/D (Dust)

ProfIPAQ-HX/Dxy and ProfIPAQ-H/Dxy – D indicates it is a dust version with dust tight

connection head.

x indicates type of connection head: y indicates process entry:

x=1 INOR Connection head BI y=1 M24x1,5

x=2 INOR Connection head BS y=2 G ½”

x=3 INOR Connection head DANX (GR-A/BL) y=3 NPT ½”

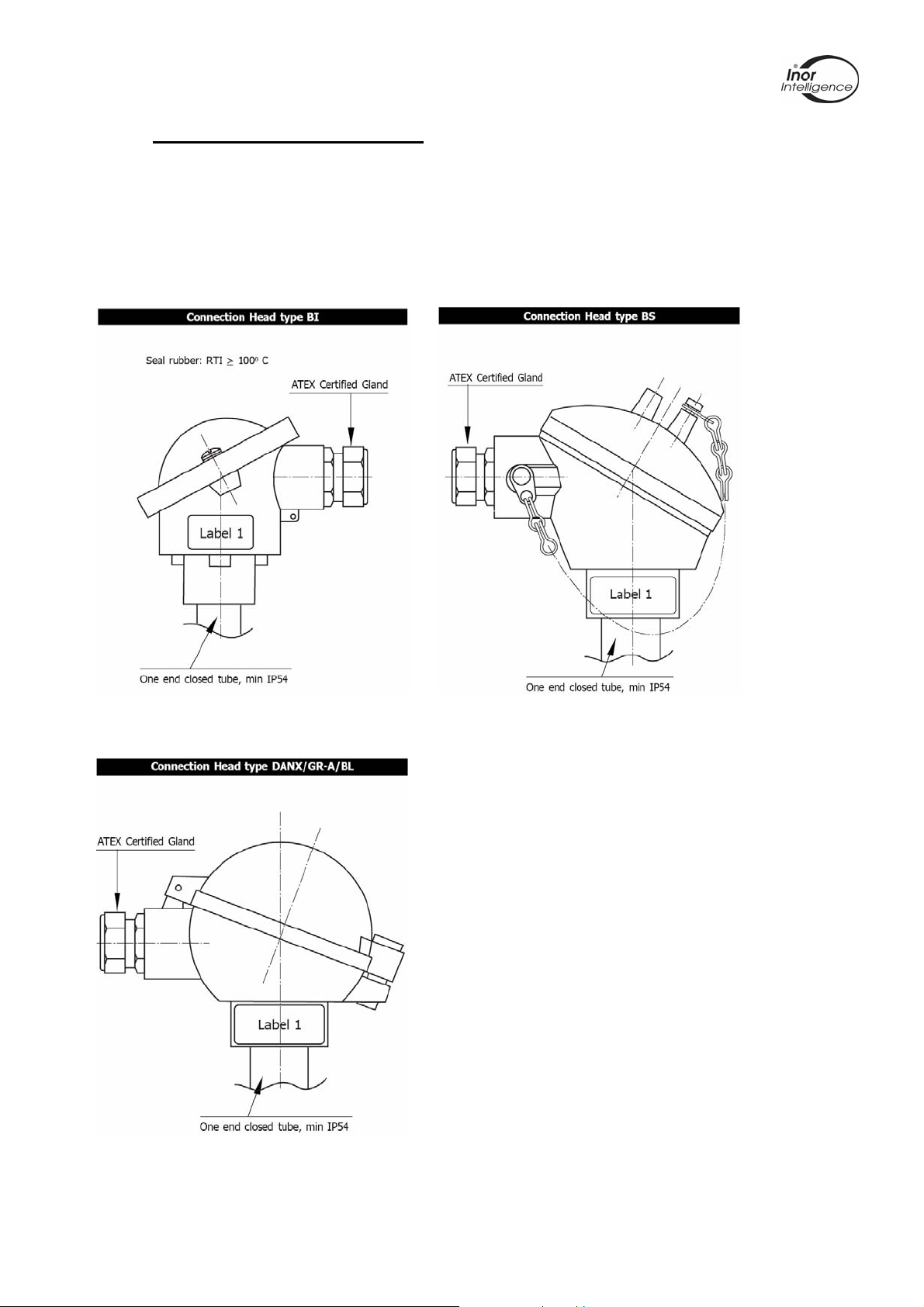

Figure 7 Connection head BI Figure 8 Connection head BS

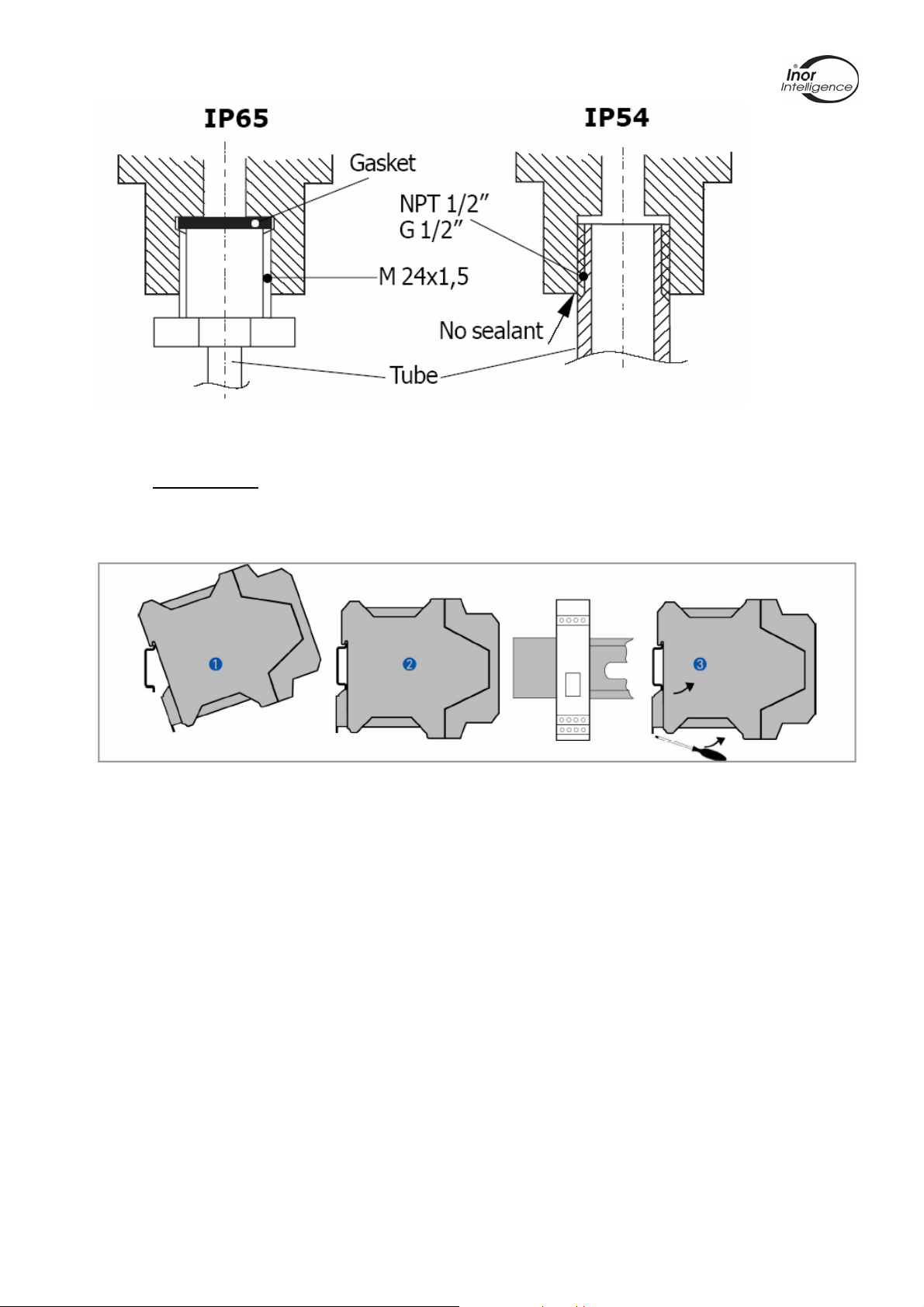

For dust-applications Category 2D (Zone

21) ProfIPAQ-HX/Dxy with at least IP 65 is

needed. Make sure the correct gasket is

used. Cable entries and blanking

elements, suitably Ex certified and

correctly installed, shall be used.

For dust-applications Category 3D (Zone

22) ProfIPAQ-H/Dxy with IP 54 is used.

Cable entries and blanking elements,

suitably Ex certified and correctly installed,

shall be used.

Figure 9 Connection head DANX

10

Figure 10 Connection head Sealing

2.5.4 ProfIPAQ-L

The ProfIPAQ-L transmitter is intended for mounting on a 35 mm DIN Rail and must not

be placed in Ex Hazardous area.

Figure 11 ProfIPAQ-L rail mounding and demounting

1 Place the transmitter on upper part of the rail

2 Press the transmitter down until it hangs on to the rail

3 To remove the transmitter, use a screw driver to loosen the hook from the lower

rail part and bend gently the transmitter upwards

11

Loading...

Loading...