Page 1

INSTRUCTION MANUAL

GAS-CHECK SF

AN INSTRUMENT FOR THE LOCATION AND

MEASUREMENT OF LEAKS IN SF6 FILLED

ELECTRICAL SWITCHGEAR.

6

User Manual iss 01

Software-Version V1.39BB

Page 2

Contents: Software version V1.39BB

Subject Description Page

3.0 General 2

3.1 Safety 2

4.0 System Properties/introduction 3

4.1 Console controls 3

5.0 Handgun displays and controls 4

5.1 Handgun analogue display 4

5.2 Handgun display LED’s 4

6.0 Handgun buttons 5

6.1 Top Caps 5

6.2 Filters 5

7.0 Getting started 6

7.1 Measuring operation 6

7.2 Possible fault conditions during operation 6

7.3 Low flow error 7

7.4 Flare stall 7

7.3 Low battery voltage 7

7.5 Switching OFF 7

8.0 Switching OFF in case of fault 7

8.1 User setup 8

8.2 Set volume/Contrast 8

9.0 Open Operator Level 8

9.1 Operator ID 8

9.2 Data printout 9

9.3 Clear data memory 9

9.4 Open Supervisor Level 9

9.5 Set alarm levels 9

9.6 Operator ID mode 9

10.0 Do not force operator ID 9

10.1 Force operator ID by name 9

10.2 Force operator ID by key code 10

10.3 Access codes 10

10.4 Changing passwords 10

10.5 Terminate and lock supervisor level 10

10.6 Open Tech level 10

11.0 Calibration 11

11.1 Set clock 11

Page 1

Page 3

12.0 User setup 12

12.1 Peak hold (gauge) 12

12.2 Peakhold (screen) 12

12.3 Display units 12

13.0 Desen Factor 1 13

13.1 Desen Factor 2 13

13.2 Standby mode 13

14.0 Standby delay 13

14.1 RS232 Protocol 13

14.2 Sound type 14

14.3 Sound begins at 14

14.4 Live tick 14

14.5 Filter threashold 14

14.6 Filter count 14

15.0 Tech data readout 14

15.1 Probe/Sensor/Filter life 15

15.2 Changing the Probe 15

16.0 Known problems. 15

16.1 Power Up During Transport. 15

16.2 Power Up after fuse has been removed 15

16.3 Pre set passwords on delivery 15

16.4 Settings on despatch 16

16.5 Citizen printer 16

16.6 Spares and consummables 16

3.0 GENERAL:

This manual is addressed to those responsible for and using this instrument and applies

to software version V1.37BB

3.1 SAFETY:

Please read this paragraph carefully before operating the instrument.

Do not open any part of the instrument, there are no user-serviceable parts inside.

Protect from moisture and water. Use in dry conditions.

Use only to leak test on voltage-free and grounded switchgear.

Touching a finger gently to the screen surface operates the touch screen.

DO NOT USE TOOLS TO TOUCH THE SCREEN.

Page 2

Page 4

4.0 SYSTEM PROPERTIES:

Introduction:

GAS-CHECK SF6 is a portable, mains-independent instrument for leak detection and

leak measurement of SF6 gas. Although designed for SF6, other gases with a high

affinity for electrons, such as refrigerant R12 may also be detected.

Although designed for operation without training, we recommend that this manual be

read before use. This manual and the instrument have been designed to be understood

by users whose first language is not English. Please advise us of any changes, which will

make this easier.

Two modes of operation are available, volume loss/time cc/sec (leak-detection) and

(ppm) concentration of SF6 in air.

All controls and displays required for detection are found in the hand unit. Accurate and

clear measurement is achieved from the console touch screen display.

Measurements can be stored in the instrument and later transferred to a printer or

computer. A battery-powered printer is available. Results may also be downloaded to a

computer via the RS2323 link.

The only item, which needs to be replaced in normal use, is the ‘Smart Sensor’ probe.

Smart Sensors contain a microchip programmed with specific sensor information. At

Switch ON, the console automatically reads sensor information.

Smart Sensors are not radioactive and contain nothing harmful. Life is approximately

200hours. Sensors are changed by switching OFF the instrument and plugging in a

replacement. Three (3) are supplied and available as exchange items.

The operation of the instrument and sensor require permanent and precise control by

software. Any faults give immediate error messages, which are then displayed on the

touch screen. This in conjunction with the sample flow monitoring function, ensures the

instrument reliably determines and displays all fault conditions.

All vital user parameters are password protected against unauthorised entry.

Access to the touch-screen is required for set-up only. If used outside or in difficult

conditions the transparent cover over touch-screen can be left locked.

4.1 CONSOLE CONTROLS:

1 Touch-screen for numeric leak rate display and parameter entry.

Two red on/off buttons located at the front and right side panel. Both are lit when the

instrument is on. White light combines mains supply and battery charge control. This

flashes while on charge and is permanently on when the battery is full.

A Key allows the transparent front cover to be locked during use.

Page 3

Page 5

5.0 Handgun Displays and Controls:

m

50

60

40

30

20

10

0

O

F

F

The following controls are found on the hand unit:

5.1 Analogue gauge: displays the response to leaks in %, rather than an absolute

value (displayed on the touch-screen), and shows the leak rate in the form of a

percentage of the alarm value. This is clearer and easier for an operator.

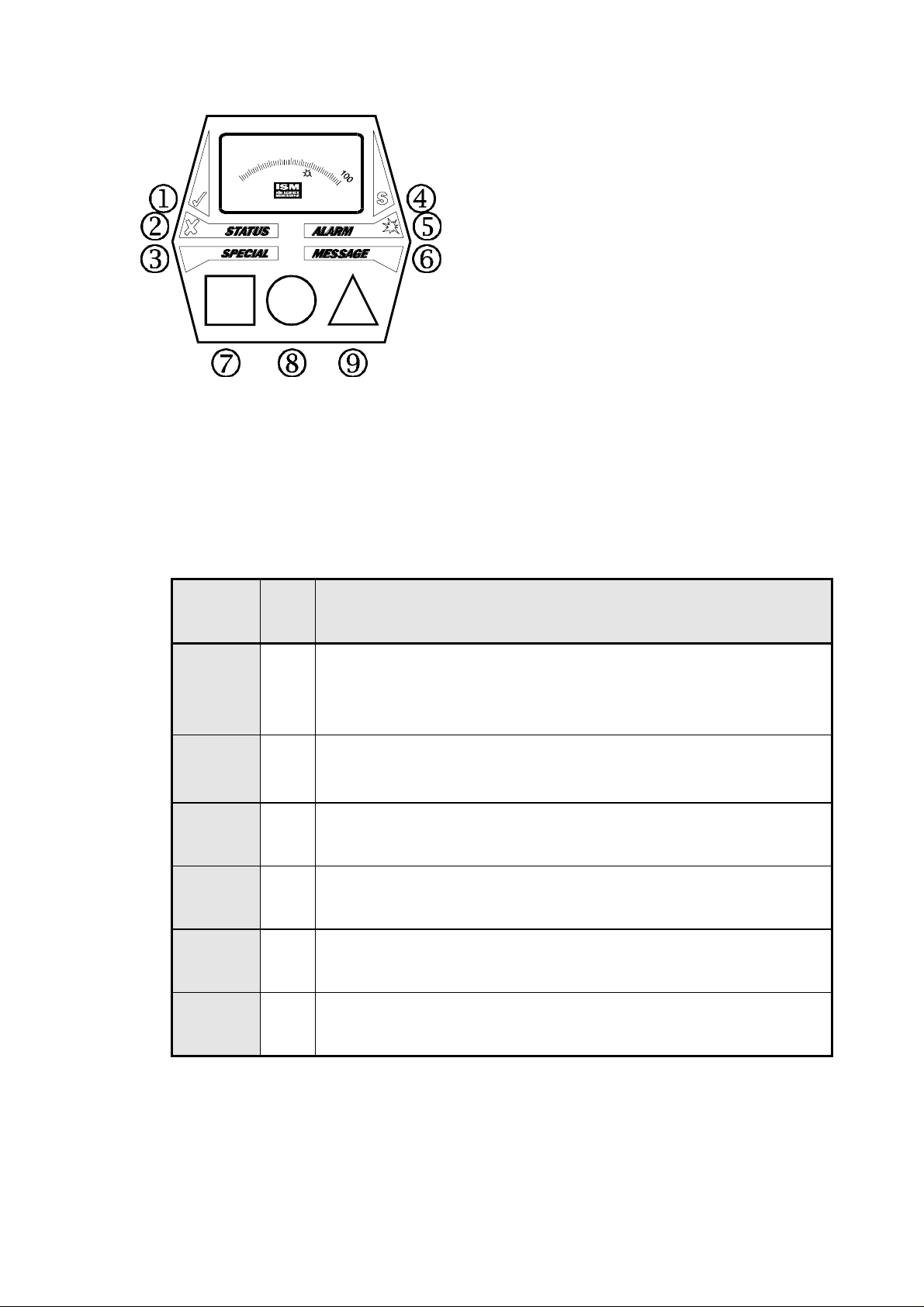

5.2 Handgun Six LEDs indicate status.

70

80

l

A

%

90

a

r

COLOUR No DESCRIPTION

Green

1

READY TO MEASURE. Normal operation. If ON, you may

confidently measure. This is OFF whenever the instrument is

in standby or programming mode, error condition, or the

actual reading is above 20% of the alarm level.

Red

2

NOT READY. This light is on whenever the instrument is in

the programming mode, or an error condition exists. It

flashes during standby mode.

Green

3

SPECIAL. Desensitise functions, flashes when one of them

is active.

Yellow

4

SIGNAL. Switches on whenever a reading above 20% alarm

level was taken. Reset by STORE or CLEAR key.

Red

5

ALARM. This light is on as long as a reading equal to or

above the alarm level is taken.

Yellow

6

MESSAGE. Prompts the operator to read a message that is

present on the LCD screen.

Page 4

Page 6

6.0 HANDGUN BUTTONS:

SQUARE: This has two functions: MEASURE MODE and SEARCH (bar graph) MODE.

On power-up the SEARCH mode is automatically selected, the touch screen displays a

bar graph. This is ideal for fast and ultra low-level leak detection (~10 E-8cc/sec). In this

mode high accuracy is not possible, just leak detection and location.

When a leak is discovered, the audible alarm sounds and the bar graph as well as the

handgun analogue gauge responds, usually full scale.

To change from SEARCH to MEASURE mode, press and hold the SQUARE button for 2

seconds, the RED light comes on and the display changes to 0.00. You are now in the

MEASURE high accuracy mode. If you have selected ‘Peak Hold Console’ leaks will be

measured and held ready for printing if required.

Pressing SQUARE once gives desensitise x1. The second press gives desensitise x2, as

pre set in USER SET-UP section in touch-screen. The LED marked SPECIAL flashes

slowly with x1, and faster with x2.

CIRCLE: This zeroes and cancels desensitise and may be used at any time. During the

short zero time the lights change from RED to GREEN. Do not leak test during this time.

During normal use it is recommended to press the CIRCLE key occasionally to

zero the detector to ambient conditions.

TRIANGLE: The RESULT STORE key. The peak reading shown on the touch-screen is

transferred to memory for later printout.

6.1: TOP CAPS: A choice of top caps are available, Standard (P1-100-0003),

extended (P1-100-0004), and extended with a Stainless Steel tip (P1-100-0005). This

has a 5mm diameter and is designed for leak searching in enclosed spaces or where

rough (welded) surfaces must be checked.

6.2 FILTERS: It is essential that FILTER (P1-100-0005) is always fitted. This

provides a small micron filter and provides a seal for the secondary sinter. This sinter

forms part of the detector vacuum cell and is critical to good stable and accurate

operation. The flow down the top cap past the filter and into the vacuum chamber is

constantly monitored. The vacuum automatically compensates for filter restriction, to a

point when accuracy is threatened. At this time the LOW FLOW ERROR is displayed and

the filter should be changed.

All these items are available ex stock from ISL or your local agent.

Page 5

Page 7

7.0 GETTING STARTED:

This assumes you have just received the instrument and it is NOT powered up.

1 Plug in the sensor and connect the handgun to the console. Align the red marks

and press home.

2 Connect to a mains electrical supply AC 85-265V.

An opening screen is now displayed which identifies the major components of the

instrument. You will hear the vacuum system initialising and a valve operation. This is

setting the required vacuum level. Approx. 20-30 seconds later, the instrument will enter

SEARCH MODE. High sensitivity leak searching can now begin.

You may find the display difficult to read due to different light levels. Tap the screen with

your finger, this will change to a menu. Touch Set Volume/Contrast you will now be

given a menu, move to Display Contrast (coarse) and press the ♦ move this to change

contrast. When the screen is right for you, press Exit.

Should this not be the case, please refer to paragraphs "Possible Fault Conditions

During Operation" and "Switching Off in Case of Fault" in this manual.

7.1 MEASURING OPERATION:

The GAS CHECK is ready to measure whenever the big digit leak rate display is visible

on the console screen 000 this will only happen while:

Sensor is working within operational limits.

Sample flow is correctly within tolerance.

All self-diagnostic checks are successful.

The green LED "READY" on the handgun will be on as long as the reading is below 20%

of the alarm value. Clear the reading by pressing the CIRCLE key.

7.2 POSSIBLE FAULT CONDITIONS DURING OPERATION

In case of a relevant fault condition, the status indication lights will change from "READY"

to "NOT READY" plus "MESSAGE". The operator should now read (and confirm) the

error message on the screen. The following fault conditions may occur:

Pressing the ZERO button before and after critical leak testing will zero the

instrument to ambient conditions and compensate for background levels of SF6 in

the air.

Page 6

Page 8

7.3 LOW FLOW ERROR:

The flow through the sensor is controlled by the vacuum pump. The level of vacuum

required to maintain the required flow can be seen in the lower LH screen. Should the

sample intake of the sensor be partially or totally blocked, the instrument will first try to

compensate by increasing the vacuum. If unsuccessful, an error is reported.

You have the choice to confirm one of the following instructions: TRY TO CONTINUE

Instrument will try to resume normal operation. This is useful if the blockage can be

overcome with a higher vacuum. The LOW FLOW ERROR may also occur if the sensor

cap was changed for the capillary probe, this needs higher vacuum to maintain the

sample flow. BEFORE changing probes and sensors ALWAYS switch OFF.

The ideal vacuum levels for a clean filter are: -100 to -300mb.

To fit the capillary probe, FIRST switch the instrument off. This allows the new flow levels

to be automatically compensated.

7.4 FLARE STALL:

This relates to sensor condition. Two reasons are possible for this.

1 Very high concentration of SF6 many times above the measuring range.

2 High vacuum in the probe caused by a partially blocked or aged sensor.

The instrument will attempt to compensate for these until a level is reached where the

detector will stall. At this point the instrument must be switched OFF and the sensor

changed.

7.5 LOW BATTERY VOLTAGE:

If the battery becomes discharged, the operator is warned of the pending shut down.

If main’s power cannot be made available, operation can be resumed for a short time, but

the instrument may now shut down at any time without further warning.

7.5 SWITCHING OFF:

During system shutdown, the processor updates the memory, releases vacuum, and

turns OFF the touch-screen. To shutdown, press one of the on/off keys for several

seconds. A time bar on the screen visualises the hold time.

When the time bar is complete, the button should be released. If it was held down longer,

the shutdown sequence will not finish properly.

8.0 SWITCHING OFF IN CASE OF FAULT:

Normally, shutdown is controlled as described above. Should this process be changed by

a serious failure, the instrument can still be switched off under hardware control. This

activates whenever one of the on/off keys is continuously held down for approx. 10

seconds.

Page 7

Page 9

8.1 USER SETUP:

This paragraph describes the parameters that determine the behaviour of the instrument.

The first step is always.

Activating the Menu System. In normal operation, the instrument can be taken to

programming mode by simply touching the touch-screen. From the main menus, items

can be selected.

Touching the screen will display the following menu structure:

Set volume / Contrast

Open Operator Level

Open Supervisor Level

Open Tech Level

Exit

In the following, it is presumed that this menu is displayed on the screen.

Passwords and Numeric Values must be entered as required. Numeric or alphanumeric

keypads appear as required. Just touch the appropriate buttons, using +/- to delete the

last digit and RETURN to confirm the entry.

In some cases, the present value of a parameter will already be entered. You may then

confirm or delete and re-enter.

8.2 Set volume / Contrast

Using the three slider type controls on this screen, select contrast for best visibility. Be

careful with the contrast, if you bring the slider to its extreme positions it is possible that

the screen appears blank. If this happens, and your finger is still on the screen, then run

it straight upwards until the screen contents reappears.

The - and + buttons are for fine adjusting the contrast. These provide better resolution

than the sliders. Every 5 presses advance the slider one step.

9.0 Open Operator Level

This menu displays to following:

9.1 Operator ID

If the operator's name is required on the data printout, the name can be entered here.

If the mode "Force Operator ID by Name" is active, this screen will automatically appear

after power up. If nothing is entered, normal operation is possible but data printout is not

possible.

Page 8

Page 10

9.2 Data Printout

If readings were stored using the STORE key on the hand unit, these can be printed or

transferred to a computer. After printout, the data memory is cleared. See section 16.5

page 15 for ISL supplied printer settings and information.

9.3 Clear Data Memory

Use this function prior to beginning a new set of measurements to remove invalid data

from memory.

Exit

Press to return to normal screen display.

9.4 Open Supervisor Level

Please enter access code: You need password entry, this is factory set at 000.

Enter 000 (or new code) then keypad press

9.5 Set Alarm Level

Enter the alarm level for the leak rate you wish to alarm at. This level alerts the "ALARM"

LED in the handgun.

Only the alarm level corresponding to the chosen mode ml/sec or ppm can be entered.

Valid alarm levels are for (leak rates) 0.5 E-6 / 5 E-7 ml/s to 20 E-6 / 200 E-7 ml/s, and 5

to 1000 ppm (concentration). Values beyond these limits are rejected.

9.6 Operator ID mode

It may be useful to be able to identify the operator from the data printout, there are two

stages to ensure this:

10.0 Do not force operator ID

Selected this if no data printouts are to be made.

10.1 Force Operator ID by name

Select this only If data printout is to carry an operator’s name.

If selected, the operators name entry screen is opened after power on. The operator may

now enter his name or short code. If nothing is entered, i.e. the entry is terminated with

the edit line empty, the instrument will operate normally, but data printout is not possible.

Page 9

Page 11

10.2 Force Operator ID by key code

If selected, a password (key code number) entry screen is opened after power up. The

operator is now required to enter his personal key code. If nothing or an invalid key code

is entered, data printout is not possible. A corresponding message must be confirmed

before operation is allowed.

Key codes can be assigned for 6 different operators, please refer to "Changing

Passwords" section 10.4.

10.3 Access codes

10.4 CHANGING PASSWORDS

Use one of the eight buttons to select the password you wish to change, then enter the

password as usual. The password can be up to 5 digits.

ATTENTION: Be careful when changing the Supervisor Level password. Should you by

mistake enter an incorrect password, you are in trouble!

10.5 Terminate and lock Supervisor level

Press this to return to main display.

10.6 Open tech level

Enter 000 (or new code) then keypad press

Page 10

Page 12

11.0 Calibration

The GAS CHECK SF6 is unique in that completely separate values are stored for each of

the display modes. This means that if you want to measure ppm or gm/yr these values

must be calibrated before use. Calibration follows the same easy routine as with cc/sec

calibration using the Portable Reference Leak. Regular calibration further improves the

precision of measurement over the standard (factory set) calibration.

For cc/sec (volume loss over time mode) You will need the Portable Reference Leak

(PRL), supplied as an option with the instrument and available from Ion Science Ltd.

The leak rate will be approximately 5x10-6cc/sec (5 E-6cc/sec)

Press Calibration. The screen now asks you to enter (or confirm) the leak rate of the PRL

(or gas concentration when in ppm mode). If this is to be changed, then use the keypad

to enter the SAME leak rate as printed on the PRL.

As long as the same PRL / gas concentration is used, this value needs to be entered only

once. Just press RETURN to confirm it each time you make a calibration.

On pressing RETURN the calibration process begins.

Background Air is measured first, which takes 4 seconds. A time bar is displayed along

with an audible ‘bleep’. The display then instructs the operator to put the probe to the

reference leak. When this is done, the final calibration step begins automatically and

takes 6 seconds.

During this time, it is important to hold the probe accurately in the reference leak,

otherwise an incorrect calibration may occur.

Should the leak be missed or the probe removed by mistake, just move the probe off the

leak. The time bar is then reset, and the process can be re started.

When calibration is complete, the instrument returns to normal mode. Now check the

portable reference leak, which should be the same reading (+/-5%). Repeat the

calibration if necessary, and remember to accurately hold the probe in the leak.

The Exit button can be used to abort calibration at any time. The original calibration

factor then remains unchanged.

11.1 Set clock

The clock keeps time even while the instrument is off. Adjustment may be necessary for

the following: Summer / winter time changeover, Different time zone

Normal long term adjustment.

If the battery has been disconnected. Should this happen, the instrument automatically

opens the set date/time screen after power on.

This is quite straightforward; use the -/+ pads to change and when correct press Exit.

Page 11

Page 13

12.0 User set-up

This gives access to a number of parameters which determine the behaviour of the

instrument. They are described as follows and all are selected using the up/down arrows

and changed using the -/+ buttons.

12.1 Peakhold (gauge). This due to the short recovery time after detecting a leak, this

function is helpful. The peak value will be held on the handgun display for the time you

select. In position OFF, no peak hold occurs.

12.2 Peakhold (screen) on the touch-screen, two leak rate displays are visible: the

main display in big digits, and the auxiliary display below it. One of them always shows

the ‘live’ reading, while the other holds a peak value (if selected). This is factory pre set

to AUX DISPLAY.

In this position (AUX DISP) the big display shows the live reading, while the auxiliary

display holds the peak. If set to MAIN DISPLAY, the peak hold is held on the big display,

while the auxiliary display shows the live reading.

The peak hold seen on the console display represents the value that is stored in memory

when the STORE key is pressed. Pressing either the STORE or CLEAR buttons resets

this.

12.3 Display units

The touch-screen display and alarm level entries, as well as reference leak values, will

operate in the units you select.

Use the +/- buttons to change between E-6 ml/sec, E-7 ml/sec, gm/yr and ppm.

For gm/yr and ppm measurements, all the above parameters are held separately and do

not need to be re-entered when changing between leak rate and concentration modes.

There is also a separate calibration factor for each mode.

Gm/yr (weight loss) and ppm (concentration) measurement should not be used for leak

detection. Leaks are measured in volume loss/time (ml/sec). .ppm mode demands a

higher sensitivity, than leak rate mode. When measuring low ppm concentrations the

display responds considerably slower. Response time depends on the actual

concentration and, at very low levels, may exceed 10 seconds.

In the present software version, the ppm mode is

still in an experimental state. Therefore all

information is approximate. For precise ppm

measurement it is recommended that calibration

is made to a 10ppm SF6 in air source. For more

information please contact ISL.

Desens Factors. Allow large leaks or large concentrations to be displayed.

Page 12

Page 14

13.0 Desens Factor 1. Factory pre-set at x5. On a high or ‘gross’ leak, press the

GREEN handgun pad once. This desensitises by x5; the Green (special) lamp will flash.

13.1 Desens Factor 2. Factory pre-set at x5. Pressing the GREEN handgun pad

again invokes a further desensitise, the lamp will flash faster.

To change the desens factor use the +/- buttons.

13.2 Standby mode

This useful feature allows you to programme a standby (sleep) time from when the

instrument is last used (or moved). This allows the instrument to save power and

component life.

When the instrument in the standby mode (sleeping) the "NOT READY" LED in the

handgun will flash slowly. The instrument returns to normal operation when the hand unit

is picked up or moved.

Pressing the +/- buttons gives these choices: Factory pre set to LIGHT + SENSOR.

NONE:

LIGHT:

LIGHT + SENSOR:

POWER DOWN:

In LIGHT + SENSOR mode the following will occur.

The touch-screen, screen contrast, sensor, and sample flow regulation are switched off.

Vacuum is released. Lifetime of all major components is saved.

If POWER DOWN is selected, the instrument will not ‘wake-up’ when handgun is moved.

Before standby mode is entered, a screen message and acoustic signal are given. At the

end of this signal, provided the handgun has not been moved the instrument enters

standby mode.

14.0 Standby delay

This is the delay after which the selected standby mode is entered. When choosing the

delay, consider the following:

For short delay times (up to 10 minutes) use the LIGHT + SENSOR option.

For longer delays when battery saving is a concern (more than 10mins) use POWER

DOWN. This shuts-down the instrument in the same way as pressing the OFF button.

14.1 RS232 Protocol

The serial interface supports all common handshake protocols. The required setting

depends on the device to be connected. For a computer, select . For a printer,

please see its manual for the appropriate protocol.

Other parameters are fixed at 9600, 8, N, 1.

Page 13

Page 15

14.2 Sound type

Using the +/- buttons select sound output you prefer. HARMONIC or TRADDITIONAL.

If more than one instrument is used in a confined space, it may be useful to set them to

different sound types.

14.3 Sound begins at

This allows you to set the display value at which the sound begins.

For leak detection, we suggest settings of 20.to.50%. If you use higher settings, leaks

may be missed. Irrespective of the level selected the handgun and touch-screen display

operates as normal and shows all response to leaks.

14.4 Live tick

If activated, a slow tick will be heard as long as GAS-CHECK P1 is ready to measure.

14.5 Filter Threshold. Factory pre-set to 5.

14.6 Filter Count. Factory pre-set to 10.

These parameters control the ppm mode signal filter. Although they are not supposed to

be modified by the user, here are some hints about their operation:

The main function of the filter is to block out short wave noise. "Filter Count" represents

the number of measuring cycles over which the signal must be continuously above or

below the average value.

For high signals, the filter is partially bypassed to gain acceptable rise times at high ppm

concentrations.

Higher values for both parameters result in better smoothing and the expense of longer

response times, especially with low concentrations.

Lower values sacrifice smoothing for improved response. Settings of "0" completely

bypass the corresponding filter branch.

Values of 5...10 for "Filter Threshold" and 5...20 for "Filter Count" have proven to be

average settings.

15.0 Tech. Date Readout

This is a log record of the complete instrument and sensor. It records use and status of

all major components. Serial numbers, hours of operation, and other data are displayed.

These are mainly for service purposes.

These cannot be selected or changed as they are simply a record.

Press EXIT to return to previous menu and EXIT to return to main display.

Page 14

Page 16

15.1 Probe/Sensor Lifetime/filter:

Sensor life is presently estimated to be 200 hours of continuous use in a normal

industrial atmosphere. Sensor life is affected only by contamination in the air sample

being drawn through probe. Therefore it is dependent on ambient conditions.

Filter: This is positioned between the top-cap and the sinter leading into the detector

vacuum chamber. To access the filter, first switch off, then remove the probe and hold it

upright. CAREFULLY unscrew the top-cap and the small brass filter will be seen on the

sinter housing. It is not possible to reclaim this filter. Part No P1 100 0005.

Dusty environments will slowly reduce the detector’s performance. At a point when this

threatens the ability to leak detect the sensor will shut down with a screen displayed

notice.

Bigger particles are captured in a filter and tend to obstruct it. The reduction in flow is

automatically compensated, but again only to a level which will not threaten performance.

On power up, the instrument first scans the characteristics of the new sensor and sets

these values in the console memory; this may take 10...50 seconds.

15.2 Changing the Probe To change the sensor, You Must Power Down.

Never unplug the probe while the red lights on the console are still on!

To remove the probe, just grip the plug at its sliding piece and pull it straight out.

When inserting the new probe, align the red marks at the plug and socket and push.

16.0 Known Problems

16.1 Power Up During Transport.

During environmental testing it was found that it is sometimes possible that should the

instrument be dropped, the force may switch the instrument ON.

Under normal circumstances, this is relatively harmless, as the handgun is normally

unplugged if the instrument is packed for travelling. In this situation as the instrument

does not recognise the sensor it powers down after a short time.

We recommend removing the fuse from the main’s socket prior to transportation,

particularly air transport.

16.2 Power Up after transportation if the fuse has been removed.

The real time clock must be set.

Make a calibration check and re-calibrate if required, using the Portable Reference Leak.

16.3 PRE-SET PASSWORDS AT DELIVERY:

On delivery, all passwords are set to 000. To change them, please refer to paragraph

’Changing Passwords’.

Page 15

Page 17

16.4

Settings on despatch as found in User Setup

Instrument serial Number P1 Date

Peak Hold (gauge) 0.5 s

Peak Hold (screen) AUX DISP

Display Units E-6 ml/s

Desen. Factor 1 5 x

Desen Factor 2 10 x

Standby Mode Light + sensor

Standby Delay 15 min

RS232 Protocol DTR/DSR

Sound Type HARMONIC

Sound begins at 20% Alarm

Live tick OFF

Filter Threshold 5

Filter Count 10

16.5

A Citizen dot matrix printer type iDP together with a mains transformer is supplied as an

option. Additional printer rolls can be obtained from ISL or from your local computer

printer supplier. Below the paper roll is a DIL switch having 4 switches. With DTR/DRS

selected from the user set-up ALL 4 SWITCHES MUST BE IN THE OFF POSITION.

Switch the printer ON using the side mounted slide switch. The POWER and SEL green

lights should be lit. Press SEL to turn OFF the light and use LF to advance the paper.

Now switch SEL ON and you can now print the stored results by tapping the screen,

entering OPEN OPERATOR LEVEL then DATA PRINTOUT. The printer will then

operate.

Note that if you try to print with SEL OFF the screen will show print in progress, and then

time out.

If you have entered your operator or company information in Operator ID see 9.1 page 8

This will appear in the printed message.

16.6 Spares & Consumables:

Description Part No

Sensor probe complete. P1 100 0000

Steel tipped top-cap (25mm) P1 100 0004 supplied in packs of 3

Filter P1 100 0005 supplied in packs of 10

Manual Iss 07

Software version V1.39BB

Compiled by Mel Vinton.

Page 16

Loading...

Loading...