Page 1

MAXIM Series Controllers

INSTALLATION INSTRUCTIONS

Page 2

Proprietary

No part of this technical manual may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language, in any form or by any means, without

prior written permission of Mass Electronics Pty Ltd.

Trademark

The term ‘Innotech’ used in this manual is a trademark of Mass Electronics Pty Ltd trading as

Innotech Control Systems Australia.

'Microso' and 'Windows' are registered trademarks of the Microso Corporation in the United States

and other countries.

Disclaimer

While great eorts have been made to assure the accuracy and clarity of this document, Mass

Electronics Pty Ltd assumes no liability resulting from any omissions in this document, or from

misuse of the information obtained herein. The information in this document has been carefully

checked and is believed to be entirely reliable with all of the necessary information included. Mass

Electronics Pty Ltd reserves the right to make changes to any products described herein to improve

reliability, function and design, and reserves the right to revise this document and make changes

from time to time in content hereof with no obligation to notify any persons of revisions or changes.

Mass Electronics Pty Ltd does not assume any liability arising out of the application or any use of any

product or circuit described herein; neither does it convey licence under its patent rights or the rights

of others.

Page 2 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 3

Document Management

Document Title:

Maxim Installation Instructions

Revision History

Version

Number

1.0 June 2011

2.0 November 2013 Contact Details Update, Style Update.

Date Summary of Changes

First release of Installation Instructions for Innotech MAXIM Series

Controllers.

Page 3 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 4

This page has been le intentionally blank.

Page 4 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 5

Contents

Chapter 1 - Preliminary Information ...............................................................9

1-1 Scope ........................................................................................................................ 10

1-1.1 Systems Covered by this Manual ............................................................................ 10

1-1.2 Terminology used in this manual ...........................................................................11

1-1.3 Document layout ..................................................................................................... 11

1-2 Overview of MAXIM Series Controllers .................................................................... 12

1-2.1 Primary Network Controllers .................................................................................. 12

1-2.2 Sub System Network Controllers ............................................................................13

1-2.3 Sub System Gateway (IG01) ....................................................................................13

1-3 Special Considerations ............................................................................................ 14

1-4 Tools and Materials .................................................................................................. 14

1-2.4 MAXIM I Controller ...................................................................................................14

Chapter 2 - Mechanical Installation ............................................................... 15

2-1 Overview .................................................................................................................. 16

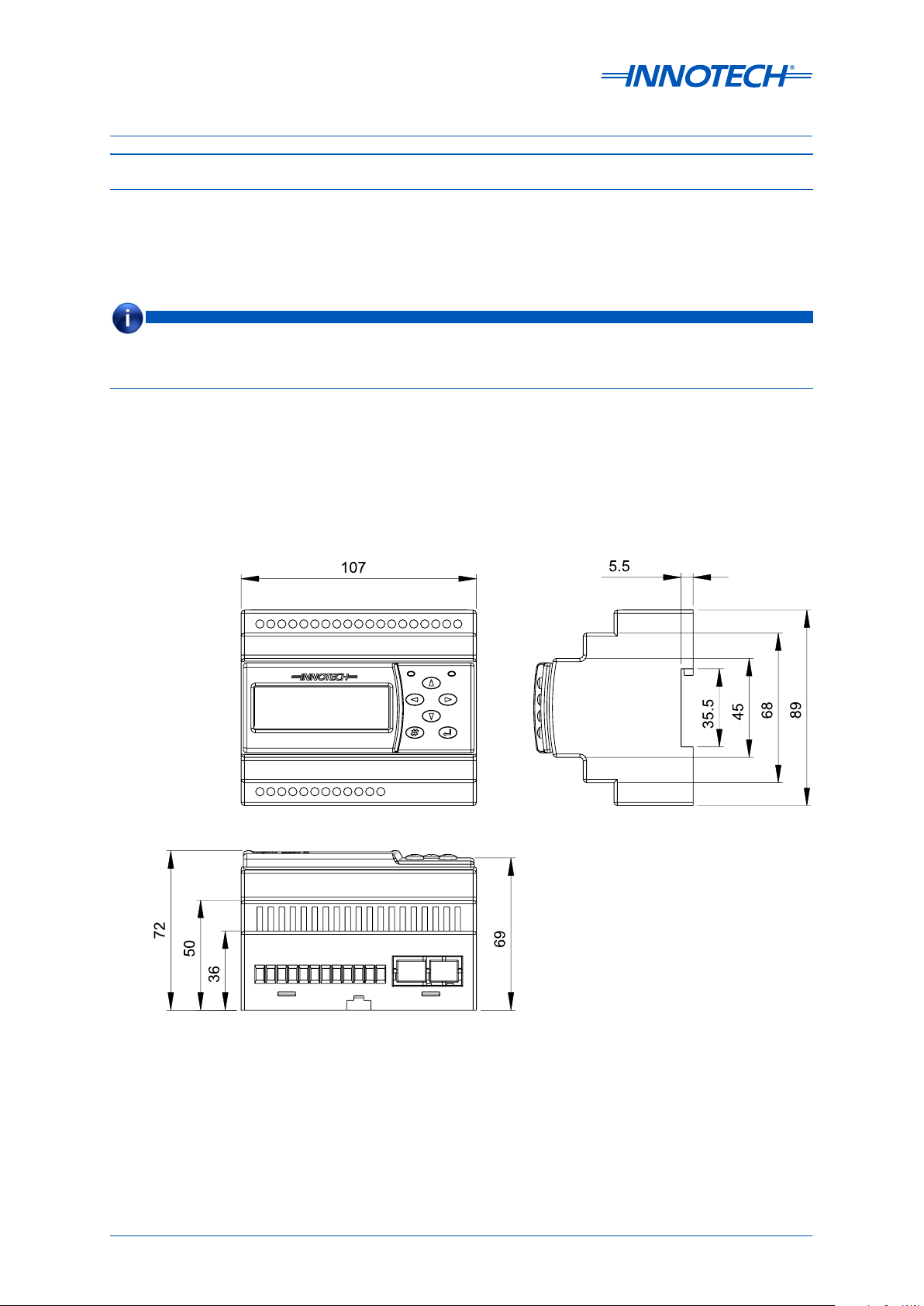

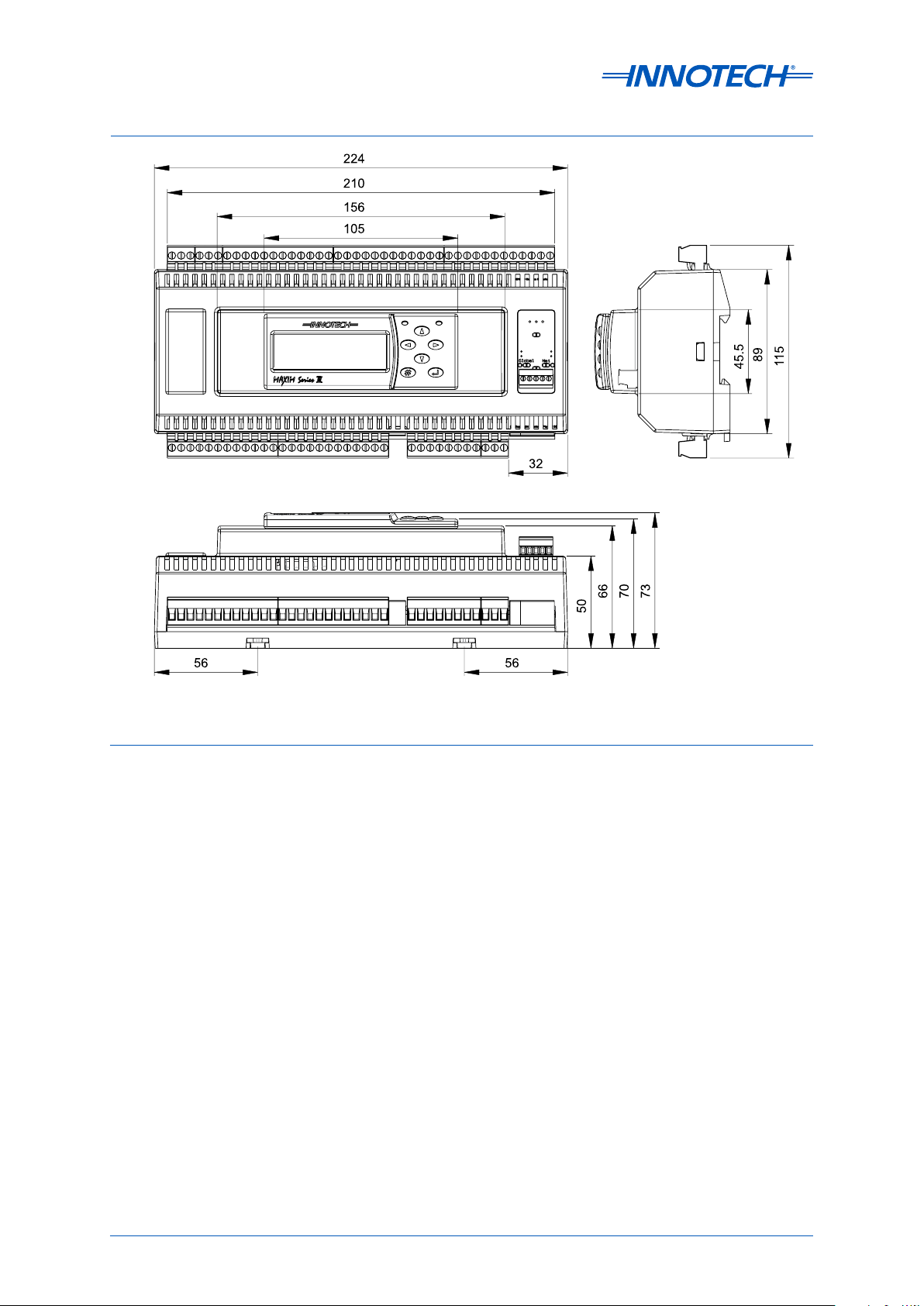

2-2 Physical Description and Dimension Diagrams .....................................................17

2-2.1 Overview ..................................................................................................................17

2-2.2 MAXIM I, II, III, and 1010 Controllers ........................................................................ 17

2-2.3 MiniMAX, MicroMAX, VAVMax, and IG01 ..................................................................18

2-3 General Installation Information ............................................................................20

2-3.1 Overview ..................................................................................................................20

2-3.2 General Installation Guidelines ..............................................................................20

2-3.3 Installing on DIN Rail ...............................................................................................21

Chapter 3 - Electrical Installation .................................................................23

3-1 Overview .................................................................................................................. 24

3-2 Electrical Installation Practices ............................................................................... 24

3-3 MAXIM Controller Wiring .......................................................................................... 24

3-3.1 MAXIM I, II, III, and 1010 Controllers ........................................................................ 26

3-3.2 MiniMAX Controllers (MM01 / MM02) ......................................................................32

3-3.3 VAVMax and MicroMAX Controllers .........................................................................34

3-3.4 IG01 Sub System Gateway .......................................................................................38

Page 5 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 6

Chapter 4 - Network Installation ..................................................................41

4-1 Overview .................................................................................................................. 42

Chapter 5 - Commissioning ..........................................................................43

5-1 Overview .................................................................................................................. 44

5-2 Inspect the Installation ........................................................................................... 44

Appendix A - Using the CT01 Commissioning Tool ...........................................53

A-1 Overview .................................................................................................................. 54

A-2 Connecting to Subsystem Network Devices ........................................................... 54

A-2.1 Connecting directly to controller on sub system network .................................... 54

A-2.2 Connecting to Sub System Gateway (IG01) ............................................................55

A-2.3 Connecting to sub system network .......................................................................56

A-2.4 CT01 Menus and Navigation ...................................................................................57

A-3 Logging onto the Controller .................................................................................... 57

A-4 VAVMax Settings .......................................................................................................58

A-5 Commissioning ........................................................................................................ 58

A-5.2 Configuring the K-Factor ......................................................................................... 59

A-5.1 Calibration of sensors .............................................................................................59

Customer Assistance ...................................................................................................... 60

Innotech Support ..............................................................................................................60

Page 6 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 7

List of Illustrations

Figure 2-1:

Figure 2-2:

Figure 2-3:

Figure 2-4:

Figure 2-5:

Figure 2-6:

Figure 2-7:

Figure 3-1:

Figure 3-2:

Figure 3-3:

Figure 3-4:

Figure 3-5:

Figure 3-6:

Figure 3-7:

Figure 3-8:

Figure 3-9:

Figure 4-1:

Typical Enclosure Installation ................................................................................16

MAXIM I and MAXIM II Controller Dimensions ........................................................17

MAXIM III and MAXIM 1010 Controller Dimensions ................................................18

MiniMAX, MicroMAX, VAVMax and IG01 Controller Dimensions.............................19

LCD Optimum Viewing Angle .................................................................................. 20

DIN Rail Dimensions ................................................................................................ 21

Installing MAXIM Controller on a DIN Rail ..............................................................21

MAXIM Series III Connection Details Generated with MAXCon Soware ..............25

MAXIM I controller terminal connection layout .....................................................26

MAXIM II controller terminal connection layout ....................................................26

MAXIM III controller terminal connection layout ...................................................27

MAXIM 1010 controller terminal connection layout ..............................................27

Analogue Output Driving Multiple Solid State Relays ........................................... 30

MiniMAX (MM01 & MM02) Controller Terminal Connection Layout ......................32

VAVMax and MicroMAX Controller Terminal Connection Layout .......................... 34

IG01 Sub System Gateway Terminal Connection Layout ...................................... 38

Innotech Network Diagram ....................................................................................42

Figure 5-1:

Figure 5-2:

Figure 5-3:

Figure 5-4:

Figure 5-5:

Figure 5-6:

Figure A-1:

Figure A-2:

Figure A-3:

Figure A-4:

Checking Power Input Voltage ...............................................................................46

Checking Universal Inputs for 0V ............................................................................47

Checking Digital Relay Output Wiring .................................................................... 48

Checking Analogue Output Voltage .......................................................................50

Checking Analogue Output Resistance ..................................................................51

End of Cable Jumper Locations on Sub Network Devices .................................... 52

Connecting the CT01 to a Sub System Network Device ........................................ 54

Connecting the CT01 to a Sub System Gateway IG01 ...........................................55

Connecting the CT01 to a Sub Network Device .....................................................56

CT01 Interface - Navigation and Menus .................................................................57

Page 7 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 8

List of Tables

Table 1-1:

Table 1-2:

Table 3-1:

Table 3-2:

Table 3-3:

Table 3-4:

Table 3-5:

Table 3-6:

Table 3-7:

Table 3-8:

Table 3-9:

Table 3-10:

Table 3-11:

Table 3-12:

Table 3-13:

Table 3-14:

Table A-1:

Document Structure ...............................................................................................11

Features of MAXIM Series Controllers ..................................................................... 12

MAXIM I, II, III and 1010 Power Source Specifications ...........................................28

MAXIM I, II, III and 1010 Controller Power Input Terminals ...................................28

Input/Output Range for Universal Inputs ..............................................................29

MAXIM 1010 Universal Outputs ...............................................................................31

MiniMAX Power Source Specifications ...................................................................32

MiniMAX Controller Power Input Terminals ........................................................... 33

MiniMAX Universal Inputs/Outputs ........................................................................ 33

MiniMAX Controllers: Modes of Operation for TRIAC Outputs .............................. 34

VAVMax and MicroMAX Power Source Specifications ............................................ 35

VAVMax and MicroMAX Power Terminals ...............................................................35

VAVMax and MicroMAX Universal Inputs/Outputs .................................................36

VAVMax and MicroMAX Controllers: Modes of Operation for TRIAC Outputs .......37

IG01 Sub System Gateway Power Source Specifications ...................................... 38

IG01 Sub System Gateway Power Terminals .........................................................39

Commissioning Menu .............................................................................................58

Page 8 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 9

MAXIM Series Controllers

INSTALLATION INSTRUCTIONS

Chapter 1 - Preliminary

Information

Page 10

MAXIM Installation Instructions

1-1 Scope

This manual is intended to provide qualified technical personnel with complete and easy-to-follow

instructions for installing, testing, and commissioning the MAXIM Series Controllers. Although every

eort has been made to simplify the installation process, it is assumed that qualified personnel

installing the MAXIM Series Controllers are familiar with local regulations, codes, and safety

requirements.

It is highly recommended that installers familiarise themselves with the content of this manual

before attempting to install the MAXIM Series Controllers.

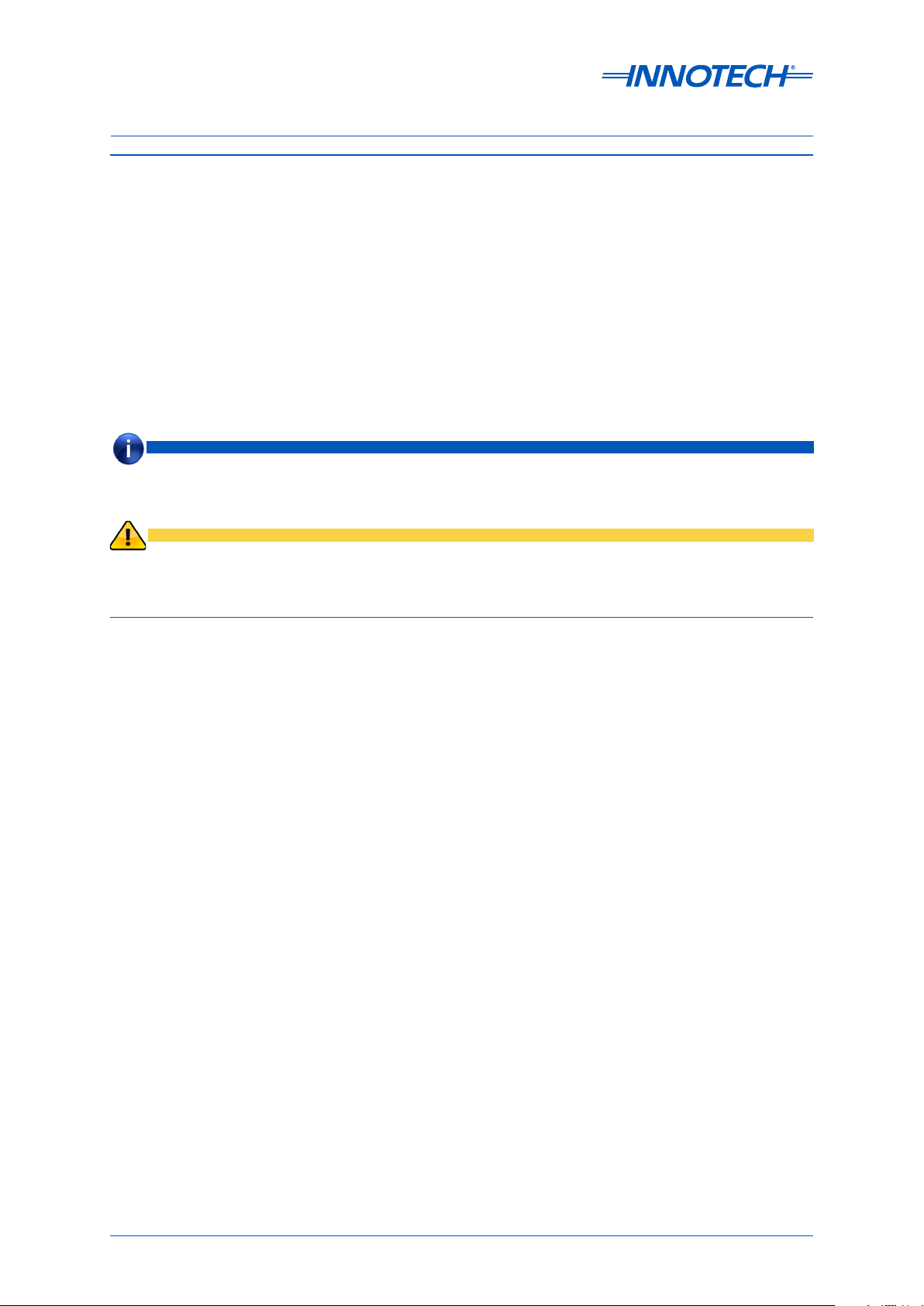

Throughout this manual there are icons used to illustrate important information and points of

caution, as illustrated and described below:

NOTE

Notes indicate useful information which should be read.

CAUTION

Cautions indicate critical information which must be read.

1-1.1 Systems Covered by this Manual

A system is defined as one or more MAXIM Series controllers interconnected with various ancillary

units for the purpose of performing specific functions. Systems are intended for use in a variety of

applications and are designed on a modular basis. Modularity provides the most economical and

eicient means of adapting the system to the specific customer requirements. In our attempts to

continuously improve overall customer satisfaction through product improvement, Innotech oen

provides updates and revisions to the MAXIM Series product line. The range of modules result in a

large array of dierent types of hardware available to the customer.

With the exception of the MAXIM 1 controller, all MAXIM Series controllers can either be used in

standalone applications to control external equipment, or in an Innotech network consisting of

multiple controllers and devices supporting Global and Net Comms traic. This manual covers the

following Maxim Series Controllers:

• MAXIM I

• MAXIM II

• MAXIM III

• MAXIM 1010

• MiniMAX (MM01)

• MiniMAX (MM02)

• MicroMAX (UM01)

• VAVMax (VM01)

• Sub System Gateway (IG01)

Page 10 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 11

MAXIM Installation Instructions

1-1.2 Terminology used in this manual

In order to simplify the instructions, common terminology and references to other Innotech products

are used throughout this manual. A brief description of some of the terminology is provided in this

section.

Net comms communication is the primary means of communication between Innotech hardware and

iComm soware.

Global comms communication is a means of sharing data among dierent Innotech controllers and

devices to carry out dierent functions.

Human Machine Interface (HMI) provides direct access for complete control and operation of various

Innotech controllers. The HMI basically consists of the Liquid Crystal Display (LCD) and the keypad for

direct interaction with the controllers.

1-1.3 Document layout

This technical manual consists of the following sections with a brief description of each section:

Table 1-1: Document Structure

Chapter Description

Chapter 1 - Preliminary

Information

Chapter 2 - Mechanical

Installation

Chapter 3 - Electrical

Installation

Chapter 4 - Network

Installation

This chapter contains general information such as general safety

considerations and an overview of the MAXIM Series controllers.

This chapter contains information such as physical descriptions of

the controllers, mounting dimensions, and mechanical installation

guidelines.

This chapter contains electrical wiring information and instructions.

This chapter provides a general network diagram and reference to the

Innotech Device Network Cabling Manual.

This chapter provides instructions for post-installation inspection of

Chapter 5 - Commissioning

the MAXIM System, and initial setup of the various units that comprise

the system.

Appendix A - Using the

CT01 Commissioning Tool

The Appendix provides instructions on using the CT01 for configuring

MAXIM Series controllers.

Page 11

© Mass Electronics Pty Ltd 2011Chapter 1 – Preliminary Information

Page 12

MAXIM Installation Instructions

1-2 Overview of MAXIM Series Controllers

This section of the manual provides general information for the MAXIM Series Controllers. The

subsequent sections include information on controllers that are installed on the primary network,

and those that are installed on the subsystem network. Information is also provided for the

Subsystem Gateway (IG01). The MAXIM Series controllers are ideal for air conditioning and building

automation, but yet flexible and powerful enough to suit a wide range of other applications.

The MAXIM family of controllers has a wide range of products to suit a broad range of customer

requirements and applications, as illustrated in the table below.

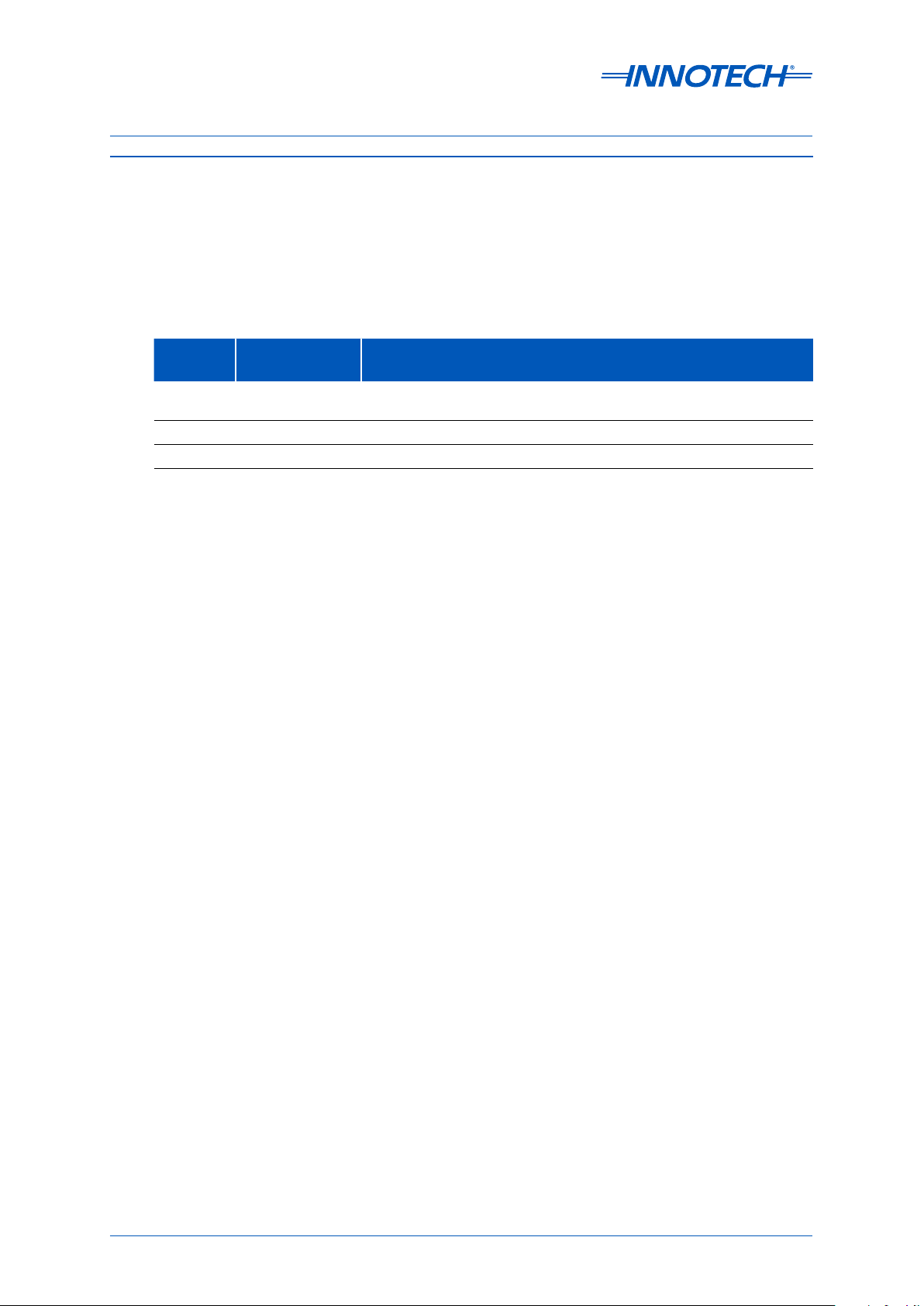

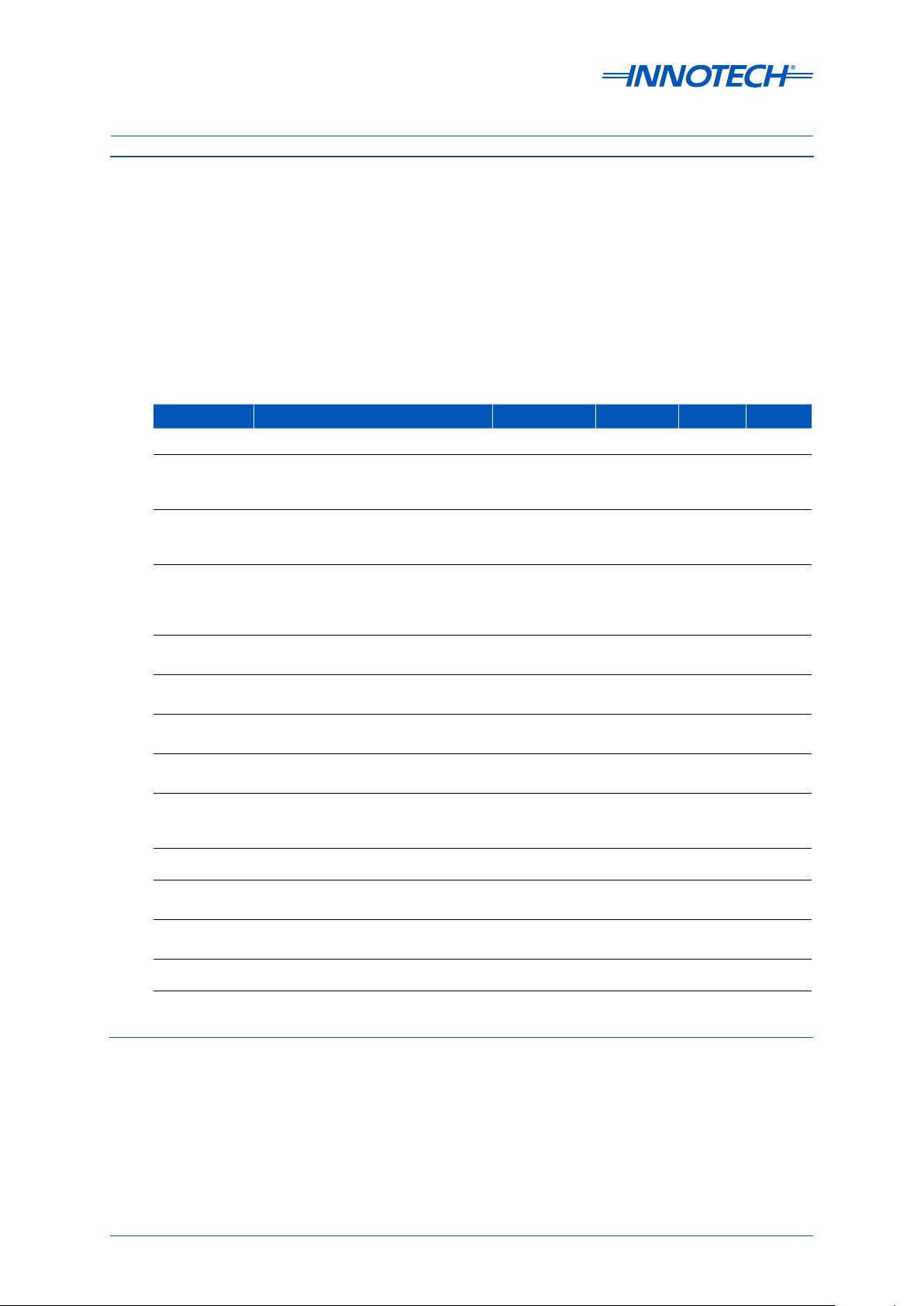

Table 1-2: Features of MAXIM Series Controllers

MAXIM Controllers MiniMAX MicroMAX VAVMax IG01

I II III 1010 MM01 MM02 UM01 VM01 IG01

Configurable

Universal

Inputs

Configurable

Universal

Outputs

Configurable

Universal

Inputs /

Outputs

Digital Relay

Outputs

Analogue

Outputs

TRIAC

Outputs

Thermistor

Input

Dierential

Pressure

Sensor

6 6 20 10 — — — — —

— — — 10 — — — — —

— — — — 7 7 2 2 —

6 6 12 — — — — — —

4 4 8 — — — — — —

— — -- — 4 4 4 4 –

— — — — — — 1 1 —

— — — — — — — 1 —

Net Comms RS232

Global

Comms

Sub Net

Comms

Ethernet — — Optional Optional — — — —

—

— — — — —

— — —

— — —

1-2.1 Primary Network Controllers

The controllers that can be installed on the primary network provide communication channels with

Net and Global comms functionality. These controllers can interface with other Innotech network

resources. The MAXIM Series controllers that can be installed on the Innotech primary network are:

• MAXIM II

• MAXIM III

• MAXIM 1010

• MiniMAX (MM01)

Page 12 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 13

MAXIM Installation Instructions

These controllers can operate in standalone applications, using the respective universal inputs,

universal outputs, analogue outputs, and digital outputs to transmit and receive information and

control external equipment, or as part of a network of Innotech devices that support Net and Global

comms communication.

However the MiniMAX (MM01) when installed in standalone applications does not provide Real Time

Clock (RTC) synchronization functionality.

1-2.2 Sub System Network Controllers

These controllers are primarily designed to be installed on the subsystem network to be managed

by the Sub System Gateway (IG01). The controllers on the subsystem network do not provide Global

comms functionality. The MAXIM Series controllers that can be installed on the Innotech subsystem

network are:

• MiniMAX (MM02)

• MicroMAX (UM01)

• VAVMax (VM01)

It is important to know that the VAVMax (VM01) and the MicroMAX (UM01) can operate in standalone

applications, using the respective inputs and outputs to receive information to control external

equipment, or as part of a primary network supporting Net comms communication. But in

standalone applications or when installed on a primary network, these controllers will not have all

of the respective features available. Features such as data logging, global points, alarms, and Real

Time Clock synchronization are ONLY available when these controllers are installed on a subsystem

network and managed by the Sub System Gateway (IG01).

Please refer to the datasheet of the relevant controller for more detailed information.

1-2.3 Sub System Gateway (IG01)

The Innotech® Sub System Gateway (IG01) is a gateway between the primary and subsystem

networks. It provides the ability to add subsystem networks of Innotech controllers with a single

communications channel for Net and Global comms functionality. The Sub System Gateway manages

the resources for all connected devices, reducing the load on master controllers in a large network

while reducing network traic. It provides the following functionality to all connected devices that

otherwise would not be available:

• Logging

• Battery backed Real Time Clock Synchronization

• Global points

• Alarms

The Innotech suite of soware can communicate with all devices that are connected to the Sub

System Gateway, providing the transfer of all global points between devices on the primary network

and subsystem network.

Please refer to the Sub System Gateway (IG01) Datasheet for more information.

Page 13

© Mass Electronics Pty Ltd 2011Chapter 1 – Preliminary Information

Page 14

MAXIM Installation Instructions

1-2.4 MAXIM I Controller

The MAXIM I Controller is unique in that it only operates in standalone applications, using the built

in universal inputs, analogue outputs, and digital outputs to transmit and receive information and

control external equipment. The MAXIM I controller cannot be installed on a network.

1-3 Special Considerations

The following precautions and installation considerations must be observed to ensure personal

safety and to prevent damage to equipment:

• Local safety regulations, building codes and ordinances must be complied with during

installation. In cases of conflict with procedures in this manual, contact Innotech or an authorised

representative for clarification.

• To prevent damage to equipment, avoid applying electrical power to the equipment prior to

commissioning, unless specifically instructed to do so in this manual.

• Only qualified personnel familiar with local codes and practices should perform the installation.

Wiring should only be performed by personnel with electronics knowledge and wiring installation

practices.

1-4 Tools and Materials

Other than those listed below, no special tools are required to install the MAXIM Series Controllers:

• Digital Multi Meter (DMM)

• Common hand tools

Page 14 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 15

MAXIM Series Controllers

INSTALLATION INSTRUCTIONS

Chapter 2 - Mechanical

Installation

Page 16

MAXIM Installation Instructions

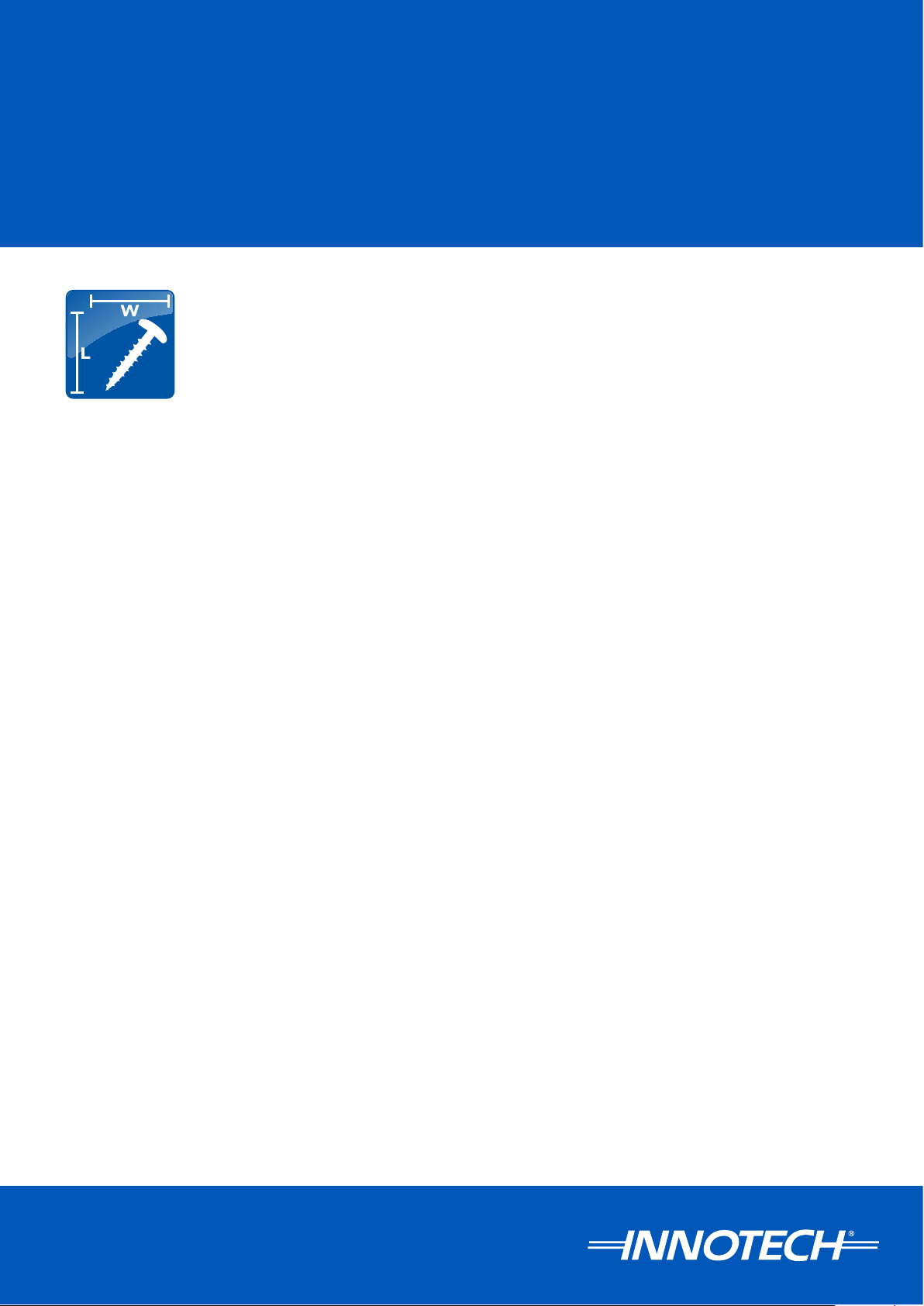

2-1 Overview

This section of the manual provides information to allow for the mechanical installation of the MAXIM

Series controllers. Physical descriptions and dimension diagrams are provided for all controllers,

followed by general installation instructions that include installing the MAXIM Series controllers on

industry standard DIN rail.

Innotech recognises that the installation examples described in this manual may not suit the

requirements of all customers. However this document should serve as a guide for all installations,

regardless of whether your particular installation is similar to that of provided examples. In all cases,

installation personnel should familiarise themselves with the information contained in this section.

NOTE

It is highly recommended that the MAXIM Series controllers be installed and mounted in a steel enclosure to

minimise the eects of Electro Magnetic Interference (EMI), as illustrated in Figure 2-1 below.

PRIMARY NETWORK

MAXIM II

IG01

IG01

Terminal Strip

MAXIM III

PRIMARY NETWORK

VM01 MM02

VM01

MM02

MM01

UM01

UM01

Digital

Controller

Power

Transformer

General Power

Outlet (GPO)

Auxillary

Power

Transformer

Figure 2-1: Typical Enclosure Installation

Page 16 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 17

MAXIM Installation Instructions

2-2 Physical Description and Dimension Diagrams

2-2.1 Overview

This section of the manual provides information on the general physical characteristics of the MAXIM

Series controllers, followed by dimension diagrams to help with the mechanical installation.

NOTE

Please note that ALL physical dimensions illustrated in this section are in millimetres.

2-2.2 MAXIM I, II, III, and 1010 Controllers

The MAXIM Series I, II, III, and 1010 controllers are housed in DIN cases and are suitable to be mounted

on DIN rail.

The exact dimensions of the MAXIM I and MAXIM II controllers are shown in Figure 2-2 below. Figure

2-3 on the next page shows the dimensions of the MAXIM III and MAXIM 1010 controllers.

Figure 2-2: MAXIM I and MAXIM II Controller Dimensions

Page 17

© Mass Electronics Pty Ltd 2011Chapter 2 – Mechanical Information

Page 18

MAXIM Installation Instructions

Figure 2-3: MAXIM III and MAXIM 1010 Controller Dimensions

2-2.3 MiniMAX, MicroMAX, VAVMax, and IG01

These controllers are housed in a compact DIN case and are suitable to be mounted on DIN rail. And

since these controllers are housed in a common case, the dimensions therefore for each controller

are the same, as illustrated in Figure 2-4 on the next page.

Page 18 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 19

MAXIM Installation Instructions

Figure 2-4: MiniMAX, MicroMAX, VAVMax and IG01 Controller Dimensions

2-2.3.1 VAVMax Dierential Pressure Input

The Dierential Pressure Input is only available on the VAVMax (VM01) controllers. It is used to

measure and respond to changes in air velocity pressure, which is determined by how the VAVMax

controller has been configured. The pressure sensor is factory calibrated for optimum performance

and is an extremely sensitive electromechanical device. Therefore the following guidelines should be

observed to prevent irreparable damage to the pressure sensor:

• Do NOT apply pressure from sources other than a pitot tube

• Do NOT apply excessive static or dierential pressure when connecting or disconnecting air supply

hoses to the VAVMax controller

• Do NOT drop the VAVMax controller

Listed below are the general operational parameters for the Dierential Pressure Input:

• 3000 Pa maximum static operating pressure

• 0 to +250 Pa dierential operating pressure

• -10 to +300 Pa maximum rated dierential pressure

• Accuracy rate of ±5FS

• Only non-corrosive gases are to be used

Page 19

© Mass Electronics Pty Ltd 2011Chapter 2 – Mechanical Information

Page 20

MAXIM Installation Instructions

2-3 General Installation Information

2-3.1 Overview

This section of the manual provides general installation guidelines to assist you with the mechanical

installation of the MAXIM Series controllers.

2-3.2 General Installation Guidelines

The following installation guidelines are provided to ensure continued and reliable operation of the

MAXIM Series controllers:

• The MAXIM I, II, III, and 1010 controllers should be installed in a position that provides easy

access to the optional HMI, and suicient room for power and input/output cabling. Placement

of the these controllers should account for the optimum viewing angle of the LCD, which is

approximately 80° vertically, and 80 ° horizontally, as illustrated in Figure 2-5 below.

• The controllers should not be exposed to high voltage, high current cables, or sources of strong

radio frequency emissions such as transmitter antenna cables.

• The ambient temperature of the MAXIM Series controllers at the installation site should not exceed

the normal operating temperature range recommended for the specific controller.

• The controllers should be installed in an area with minimum vibration and minimum exposure to

mechanical damage.

Figure 2-5: LCD Optimum Viewing Angle

Page 20 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 21

MAXIM Installation Instructions

2-3.3 Installing on DIN Rail

As mentioned earlier the MAXIM Series controllers are designed to be mounted on DIN rail. The DIN

rail is a set of dierent standardized rails widely used for mounting industrial control equipment

inside equipment racks.

Mounting Slot

18 x 5.2

* All dimensions are in

millimetres.

Figure 2-6: DIN Rail Dimensions

To install a MAXIM Series controller on a DIN rail, align the DIN rail clip on the top edge of the DIN rail.

Push down on the controller until you hear the DIN rail release tab snap onto the bottom edge, as

illustrated in Figure 2-7 below.

To remove the controller, pull the DIN rail release tab down until it releases from the bottom edge of

the DIN rail, and then pull the bottom of the controller away and li up.

Figure 2-7: Installing MAXIM Controller on a DIN Rail

Page 21

© Mass Electronics Pty Ltd 2011Chapter 2 – Mechanical Information

Page 22

MAXIM Installation Instructions

This page has been le intentionally blank.

Page 22 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 23

MAXIM Series Controllers

INSTALLATION INSTRUCTIONS

Chapter 3 - Electrical

Installation

Page 24

MAXIM Installation Instructions

3-1 Overview

This section of the manual provides information to assist in the electrical installation of the

MAXIM Series controllers, which can be installed in a wide variety of configurations to suit your

requirements.

Innotech recognises that the installation examples described in this manual may not suit the

requirements of all customers. However this document should serve as a guide for all installations,

regardless of whether your particular installation is similar to that of provided examples. In all cases,

installation personnel should familiarise themselves with the information contained in this section.

3-2 Electrical Installation Practices

Devices and equipment should be connected and wired according to their respective installation

instructions and technical documentation.

CAUTION

Please ensure that electrical power to the MAXIM Series controllers and all connected devices and equipment is

turned OFF throughout the installation process. Do NOT apply power to the controllers or any equipment until you

are ready for commissioning as per Chapter 5 – Commissioning.

NOTE

Customers are encouraged to contact Innotech Control Systems Australia or your nearest authorised distributor for

any clarification or further information regarding the installation process.

Cabling plays an important role in the installation of MAXIM Series controllers. Therefore shielded

cable for wiring must be used in all cases. It is also critical to avoid running cables in the vicinity

of high voltage power cables that carry switching voltages and high current. This is especially true

when wiring sensor signal cables.

3-3 MAXIM Controller Wiring

Once a configuration has been transferred to the controller, the MAXCon soware can be used to

generate the connection details for all inputs and outputs as per your configuration. The connection

details can be easily printed and will serve as a great reference to assist you in physically wiring your

particular MAXIM Series controller based on your site requirements. The connection details will show

the terminal and polarity for each configured input and output.

Please refer to MAXCon Online Help for further information on how to generate the connection

details.

An example of the connection details generated for a MAXIM Series III controller is illustrated in Figure

3-1 on the next page.

Page 24 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 25

MAXIM Installation Instructions

Innotech MAXIM Series III Controller (v6.20)

Figure 3-1: MAXIM Series III Connection Details Generated with MAXCon Soware

Page 25

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 26

MAXIM Installation Instructions

UNIVERSAL

ANALOGUE

UNIVERSAL

ANALOGUE

(RS485)

AO

Com

-

AO

1

+

AO

2

+

AO

3

+

AO

4

+

+

+ + + + +

- - - - - -

123456

UI UI UI UI UI UI

0V

24V

DO 1

Net

Comm

DO 2 DO 3 DO 4 DO 5 DO 6

Global

Comm

Shield

NO ComNOCom NO ComNOCom NO ComNO Com

+-+

-

3-3.1 MAXIM I, II, III, and 1010 Controllers

This section of the manual provides wiring information for MAXIM Series I, II, III, and 1010 controllers.

Information is provided on wiring a power source, and all associated inputs and outputs.

The general layout of the input and output terminals for each of these controllers is illustrated in

Figure 3-2 through Figure 3-5 below and on the next page.

POWER

INPUTS

DIGITAL RELAY

OUTPUTS

OUTPUTS

RS 232

PORT

Figure 3-2: MAXIM I controller terminal connection layout

POWER

INPUTS

OUTPUTS

Figure 3-3: MAXIM II controller terminal connection layout

DIGITAL RELAY

OUTPUTS

NET & GLOBAL

COMMS

Page 26 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 27

MAXIM Installation Instructions

(RS485)

PORT

Universal Inputs

Power

POWER UNIVERSAL INPUTS

DIGITAL RELAY

OUTPUTS

Figure 3-4: MAXIM III controller terminal connection layout

ANALOGUE

OUTPUTS

OPTIONAL

ETHERNET

NET & GLOBAL

COMMS

Universal Outputs Global &

Figure 3-5: MAXIM 1010 controller terminal connection layout

Page 27

Net Comms

RS485

Optional

Ethernet

Port

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 28

MAXIM Installation Instructions

3-3.1.1 Power Input

The MAXIM I, II, III, and 1010 controllers may by powered by either an AC or a DC power source. The

operating voltage must meet the requirements of Safety Extra Low Voltage (SELV) to EN60730. The

transformer used must be a safety transformer in compliance with EN60742 and be designed for

100% duty. It must also be sized and fused in compliance with local safety regulations. Power input

specifications for these controllers are detailed in Tab le 3-1 below.

Table 3-1: MAXIM I, II, III and 1010 Power Source Specifications

Controller AC Power Source DC Power Source

MAXIM I and II

MAXIM III

MAXIM 1010

24 V AC ±10%, 50/60 Hz,

Nominal Transformer

rating:

24 V AC ±10%, 50/60 Hz,

Nominal Transformer

rating:

24 V AC ±10%, 50/60 Hz,

Nominal Transformer

rating:

5VA

10VA

16VA

24 V DC ±10%

Nominal Transformer

rating:

24 V DC ±10%

Nominal Transformer

rating:

24 V DC ±10%

Nominal Transformer

rating:

5VA

10VA

16VA

A single transformer may be used to supply voltage to more than one controller, but you must ensure

that the planned load is well within the rating of the transformer. The transformer output terminal

designated as AC Neutral must be solidly earthed to the main earth link of the enclosure panel. The

power input terminals are Terminals 1 and 2 and are detailed in Table 3-2 below.

Table 3-2: MAXIM I, II, III and 1010 Controller Power Input Terminals

Ter minal AC Supply DC Supply

1 24VAC 24VDC

2 0VAC (Neutral) 0VDC

Page 28 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 29

MAXIM Installation Instructions

3-3.1.2 Universal Inputs

The MAXIM I, II, III, and 1010 controllers are equipped with Universal Inputs that can be configured to

suit a wide range of applications as described in Table 3-3 below. Each Universal Input has a signal

terminal (+) and a reference terminal (–).

Table 3-3: Input/Output Range for Universal Inputs

Input Type Input Range Output Range

Analogue 0-10VDC 0-10VDC

Thermistor

High Thermistor 100kΩ – 680kΩ -20°C to 100°C

Low Thermistor 662kΩ – 12kΩ -50°C to 20°C

Lux Sensor 1MΩ – 0Ω 3 to 2500 LUX

Voltage 0 – 10VDC OFF or ON

Digital

Contact Open or Closed OFF or ON

0 – 10V Square Wave

Voltage

Pulse Counter

Contact

20ms Min. ON Time

20ms Min. OFF Time

Open or Closed

20ms Min. ON Time

0 to 25 pulses per second

0 to 25 pulses per second

20ms Min. OFF Time

Voltage

Duty Cycle

Contact

0 – 1 Square Wave

1 – 13Hz

Open or Closed

1 – 13Hz

0 to 100%

0 to 100%

NOTE

Please note that the LUX Sensor input mode is suitable for switching based on ambient light levels, but is NOT

suitable for any operation which requires the accurate measurement or recording of light levels.

Page 29

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 30

MAXIM Installation Instructions

TERMINALS

HEATERS

L1 L2

L3

3-3.1.3 Analogue Outputs

The analogue outputs can be configured with MAXCon soware to either heat valve mode or variable

mode to suit your requirements. Each analogue output has a signal terminal (+) and a shared Com

terminal (–). As illustrated in the connection details in Figure 3-1, the + terminal is the active signal,

and the Com terminal is the signal reference of 0 V, which also can be referred to as ground.

It must be noted that on MAXIM Series I and II controllers only AO1 and AO2 can be configured to heat

valve mode. However on MAXIM Series III all 8 Analogue Outputs can be configured to heat valve

mode.

When an analogue output is configured to heat valve mode, the output is a Pulse Width Modulated

(PWM) signal of 0 or 10V DC with a maximum current rating of 5m A. When an analogue output is

configured to variable mode, the output is an analogue voltage signal varying from 0 to 10 VDC with a

maximum current rating of 5 mA.

When an analogue output is configured as a PWM signal in heat valve mode, up to three Solid State

Relays (SSR) connected in series may be used on each analogue output channel, as illustrated in

Figure 3-6 below. The SSRs must be capable of a trigger voltage of 3 to 32 V DC and zero switching.

ANALOGUE

1 2

TO

HEATERS

1 2

TO

HEATERS

TO

1 2

OUTPUT

-

+

Figure 3-6: Analogue Output Driving Multiple Solid State Relays

If up to 6 SSRs are to be wired in series, you can use the Analogue Output as 0 to 10V DC modulating

in conjunction with the Innotech Heat Valve (IHV) module. Please refer to the following datasheets

for more information on IHVs:

• DS3.31 for IHV Heat Valves

• DS3.32 for IHV42 Heat Valves

3+ve

4

3+ve

4

3+ve

4

Page 30 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 31

MAXIM Installation Instructions

3-3.1.4 Digital Relay Outputs

The digital relay outputs have two terminals assigned to each channel representing the Normally

Open (NO) and Common (COM) contacts of the associated relay. It is good practice to use pilot

relays for the actual switching functions, particularly when it applies to inductive loads such as coils,

solenoids, and motors. This protects the relays of the Digital Output channel, and allows for the pilot

relays to be installed adjacent to the controlling switch gear.

The Digital Relay Outputs are rated at 24VAC / DC, with a maximum current rating of 2 A supplied by a

Class 2 transformer.

3-3.1.5 Universal Outputs

The MAXIM 1010 controller is equipped with 10 Universal Outputs that can be configured with

MAXCon soware to suit a wide range of applications. Each Universal Output has a signal terminal

(+) and a reference terminal (–). The dierent types of outputs that the Universal Outputs can be

configured as, and the respective range for each are shown in Table 3- 4 below.

Table 3-4: MAXIM 1010 Universal Outputs

Output Type Range

Analogue Output 0 - 10 V DC @ 5mA

Heat Valve / PWM Output 0 / 12 V DC @ 45mA

High Current Digital Output 0 / 12 V DC @ 45mA

On MAXIM 1010 controllers, all Universal Outputs can be configured to heat valve mode. When

the Universal Output is configured to Heat Valve mode, the output is a Pulse Width Modulated

(PWM) signal of 0 or 12V DC with a maximum current rating of 45m A. When the Universal Output is

configured as an analogue output in variable mode, the output is an analogue voltage signal varying

from 0 to 10V DC with a maximum current rating of 5 m A.

In Digital Mode the output can drive 12 V DC relays to 0V DC (OFF) or 12V DC (ON) with a maximum

current rating of 45mA.

Page 31

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 32

MAXIM Installation Instructions

3-3.2 MiniMAX Controllers (MM01 / MM02)

This section of the manual provides wiring information for the MiniMAX MM01 and MM02 controllers.

Information is provided on wiring a power source and all associated inputs and outputs.

The general layout of the input and output terminals for each of these controllers is illustrated in

Figure 3-7 below.

Figure 3-7: MiniMAX (MM01 & MM02) Controller Terminal Connection Layout

3-3.2.1 Power Input

The MiniMAX controllers are powered by a 24 V AC power source. The operating voltage must meet the

requirements of Safety Extra Low Voltage (SELV) to EN60730. The transformer used must be a Class 2

safety transformer in compliance with EN60742 and be designed for 100% duty. It must also be sized

and fused in compliance with local safety regulations. Power input specifications for the MiniMAX

controllers are detailed in Ta b l e 3 -5 below.

Table 3-5: MiniMAX Power Source Specifications

Power Source Rating

24 V AC ±10%, 50/60 Hz, Nominal Transformer rating with maximum TRIAC load: 35VA

24 V AC ±10%, 50/60 Hz, Nominal Transformer rating with no TRIAC load: 10VA

Page 32 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 33

MAXIM Installation Instructions

A single transformer may be used to supply voltage to more than one controller, but you must ensure

that the planned load is well within the rating of the transformer. The transformer output terminal

designated as AC Neutral must be solidly earthed to the main earth link of the enclosure panel. The

dedicated power input terminals are Terminals 1 and 2 and are detailed in Table 3 - 6 below.

Table 3-6: MiniMAX Controller Power Input Terminals

Ter minal AC Supply

1 24VAC

2 0VAC (Neutral

3-3.2.2 Universal Inputs / Outputs

The MiniMAX controllers are equipped with seven Universal Inputs/Outputs which can be configured

with MAXCon soware to be used as inputs or outputs. Each Universal Input/Output has a signal

terminal (+) and a reference terminal (–). The types of inputs and outputs that can be configured and

the respective range for each are shown in Table 3-7 below.

Table 3-7: MiniMAX Universal Inputs/Outputs

UIO Type Input Range Output Range

Analogue Input 0 – 10 V DC 0 – 10V DC

Dry Digital Input Open or Closed OFF or ON

Voltage Digital Input 0 – 10 V DC OFF or ON

Thermistor Input 96 k Ω – 677Ω -20 ° C to 100°C

LUX Sensor Input

Dry Pulse Counter Input

Voltage Pulse Counter Input

20 k Ω – 400Ω

3 to 1000 LUX

0 – 10V Square Wave

1 to 13Hz

0 – 10V Square Wave

20ms Min. ON Time

20ms Min. OFF Time

0 to 2500 LUX

0 to 25 pulses per second

±1 pulse accuracy

0 to 25 pulses per second

±1 pulse accuracy

Analogue Output 0 to 100% 0 – 10 V DC

Digital Output OFF or ON 0 or 10 VDC

PWM Output 0 to 100% 0 to 100% Duty Cycle at 13Hz

When a UIO on a MiniMAX controller is configured as a Thermistor input type, it is designed to be used

with Innotech SEN Series Detectors. The sensing range and accuracy for the SEN Series Detectors is

as follows:

• Nominal sensing range: -5° C to 60 °C

• Accuracy +/-3.5%FS (R25 ° C = 10k Ω )

NOTE

It is not recommended to use the Pulse Counter on these controllers for accumulation as these controllers are not

equipped with battery backup or flash RAM. The MAXIM II, MAXIM III, and MAXIM 1010 controllers are better suited

for such situations.

Page 33

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 34

MAXIM Installation Instructions

3-3.2.3 TRIAC Outputs

The MiniMAX controllers are equipped with four TRIAC outputs used for switching the 24 VAC power

supply through to the outputs of the controller. There are four 24V terminals for each TRIAC output,

and two 0 V terminals that are shared by the four TRIAC outputs. The TRIAC outputs are rated at

a minimum current of 20m A and maximum current of 250 mA. The TRIAC outputs can operate in

two modes: Pulse Width Modulation (PWM) or Digital (ON/OFF). The output range for both modes of

operation are described in Table 3-8 below.

Table 3-8: MiniMAX Controllers: Modes of Operation for TRIAC Outputs

TRIAC Output Mode Output Range

Digital ON or OFF

PWM Output 0-100% (0-10VDC)

3-3.3 VAVMax and MicroMAX Controllers

This section of the manual provides wiring information for the VAVMax and MicroMAX controllers.

Information is provided on wiring a power source and all associated inputs and outputs.

The general layout of the input and output terminals for each of these controllers is illustrated in

Figure 3-8 below.

Figure 3-8: VAVMax and MicroMAX Controller Terminal Connection Layout

Page 34 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 35

MAXIM Installation Instructions

3-3.3.1 Power Input

The VAVMax and MicroMAX controllers are powered by a 24 VAC power source. The operating voltage

must meet the requirements of Safety Extra Low Voltage (SELV) to EN60730. The transformer used

must be a Class 2 safety transformer in compliance with EN60742 and be designed for 100% duty. It

must also be sized and fused in compliance with local safety regulations. Power input specifications

for the VAVMax and MicroMAX controllers are detailed in Table 3 - 9 below.

Table 3-9: VAVMax and MicroMAX Power Source Specifications

Power Source

24 V AC ±10%, 50/60 Hz, Nominal Transformer rating with maximum TRIAC load: 35VA

24 V AC ±10%, 50/60 Hz, Nominal Transformer rating with no TRIAC load: 10VA

A single transformer may be used to supply voltage to more than one controller, but you must ensure

that the planned load is well within the rating of the transformer. The transformer output terminal

designated as AC Neutral must be solidly earthed to the main earth link of the enclosure panel. The

dedicated power input terminals are Terminals 1 and 2 and are detailed in Table 3 -1 0 below.

Table 3-10: VAVMax and MicroMAX Power Terminals

Ter minal AC Supply

1 24VAC

2 0VAC (Neutral)

Page 35

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 36

MAXIM Installation Instructions

3-3.3.2 Universal Inputs / Outputs

The VAVMax and MicroMAX controllers are equipped with two Universal Inputs/Outputs which can

be configured with MAXCon soware to be used as inputs or outputs. Each Universal Input/Output

has a signal terminal (+) and a reference terminal (–). The types of inputs and outputs that can be

configured and the respective range for each is shown are Ta ble 3-11 below.

Table 3-11: VAVMax and MicroMAX Universal Inputs/Outputs

UIO Type Input Range Output Range

Analogue Input 0 – 10 V DC 0 – 10V DC

Dry Digital Input Open or Closed OFF or ON

Voltage Digital Input 0 – 10 V DC OFF or ON

Thermistor Input 96 k Ω – 677Ω -20 ° C to 100°C

LUX Sensor Input

Dry Pulse Counter Input

Voltage Pulse Counter Input

20 k Ω – 400Ω

3 to 1000 LUX

0 – 10V Square Wave

1 to 13Hz

0 – 10V Square Wave

20ms Min. ON Time

20ms Min. OFF Time

0 to 2500 LUX

0 to 25 pulses per second

±1 pulse accuracy

0 to 25 pulses per second

±1 pulse accuracy

Analogue Output 0 to 100% 0 – 10 V DC

Digital Output OFF or ON 0 or 10 VDC

PWM Output 0 to 100% 0 to 100% Duty Cycle at 13Hz

When a UIO on a VAVMax or a MicroMAX controller is configured as a Thermistor input type, it is

designed to be used with Innotech SEN Series Detectors. The sensing range and accuracy for the SEN

Series Detectors is as follows:

• Nominal sensing range: -5° C to 60 °C

• Accuracy ±3.5%FS (R25 ° C = 10k Ω )

NOTE

It is not recommended to use the Pulse Counter on these controllers for accumulation as these controllers are not

equipped with battery backup or flash RAM. The MAXIM II, MAXIM III, and MAXIM 1010 controllers are better suited

for such situations.

Page 36 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 37

MAXIM Installation Instructions

3-3.3.3 TRIAC Outputs

The VAVMax and MicroMAX controllers are equipped with four TRIAC outputs used for switching the

24V AC power supply through to the outputs of the controller. There are four 24 V terminals for each

TRIAC output, and two 0V terminals that are shared by the four TRIAC outputs. The TRIAC outputs

are rated at a minimum current of 20mA, and maximum current of 250mA. The TRIAC outputs can

operate in two modes: Pulse Width Modulation (PWM) or Digital (ON/OFF). The output range for both

modes of operation are described in Table 3 -12 below.

Table 3-12: VAVMax and MicroMAX Controllers: Modes of Operation for TRIAC Outputs

TRIAC Output Mode Output Range

Digital ON or OFF

PWM Output 0-100% (0-10VDC)

NOTE

The use of pilot relays is recommended when switching high voltage and inductive loads.

3-3.3.4 Fixed Thermistor Input

The VAVMax and MicroMAX controllers are equipped with a fixed thermistor input labelled TEMP. The

fixed thermistor input has a signal terminal (+) and a reference terminal (–). This input is designed

for use with the Innotech SEN Series Detectors. The sensing range and accuracy for the SEN Series

Detectors is as follows:

• Nominal sensing range -5° C to 60 °C

• Accuracy +/-3.5%FS (R25 ° C = 10k Ω )

Page 37

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 38

MAXIM Installation Instructions

POWER

ETHERNET

3-3.4 IG01 Sub System Gateway

This section of the manual provides wiring information for the IG01 Sub System Gateway. Information

is provided on wiring a power source and all associated inputs and outputs.

The general layout of the input and output terminals for each of these controllers is illustrated in

Figure 3-9 below.

SSG

COMMS

(RS485)

NET & GLOBAL

COMMS

(RS485)

Figure 3-9: IG01 Sub System Gateway Terminal Connection Layout

3-3.4.1 Power Input

The IG01 Sub System Gateway may by powered by either an AC or a DC power source. The operating

voltage must meet the requirements of Safety Extra Low Voltage (SELV) to EN60730. The transformer

used must be a safety transformer in compliance with EN60742 and be designed for 100% duty. It

must also be sized and fused in compliance with local safety regulations. Power input specifications

for these controllers are detailed in Table 3 -13 below.

Table 3-13: IG01 Sub System Gateway Power Source Specifications

AC Power Source DC Power Source

24 V AC ±10%, 50/60 Hz,

Nominal Transformer rating 8VA or greater

24 V DC ±10%

Nominal Transformer rating: 8VA or greater

Page 38 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 39

MAXIM Installation Instructions

A single transformer may be used to supply voltage to more than one controller, but you must ensure

that the planned load is well within the rating of the transformer. The transformer output terminal

designated as AC Neutral must be solidly earthed to the main earth link of the enclosure panel. The

dedicated power input terminals are Terminals 1 and 2 and are detailed in Table 3 -14 below.

Table 3-14: IG01 Sub System Gateway Power Terminals

Ter minal AC Supply DC Supply

1 24VAC 24VDC

2 0VAC (Neutral) 0VDC

Page 39

© Mass Electronics Pty Ltd 2011Chapter 3 – Electrical Installation

Page 40

MAXIM Installation Instructions

This page has been le intentionally blank.

Page 40 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 41

MAXIM Series Controllers

INSTALLATION INSTRUCTIONS

Chapter 4 - Network

Installation

Page 42

MAXIM Installation Instructions

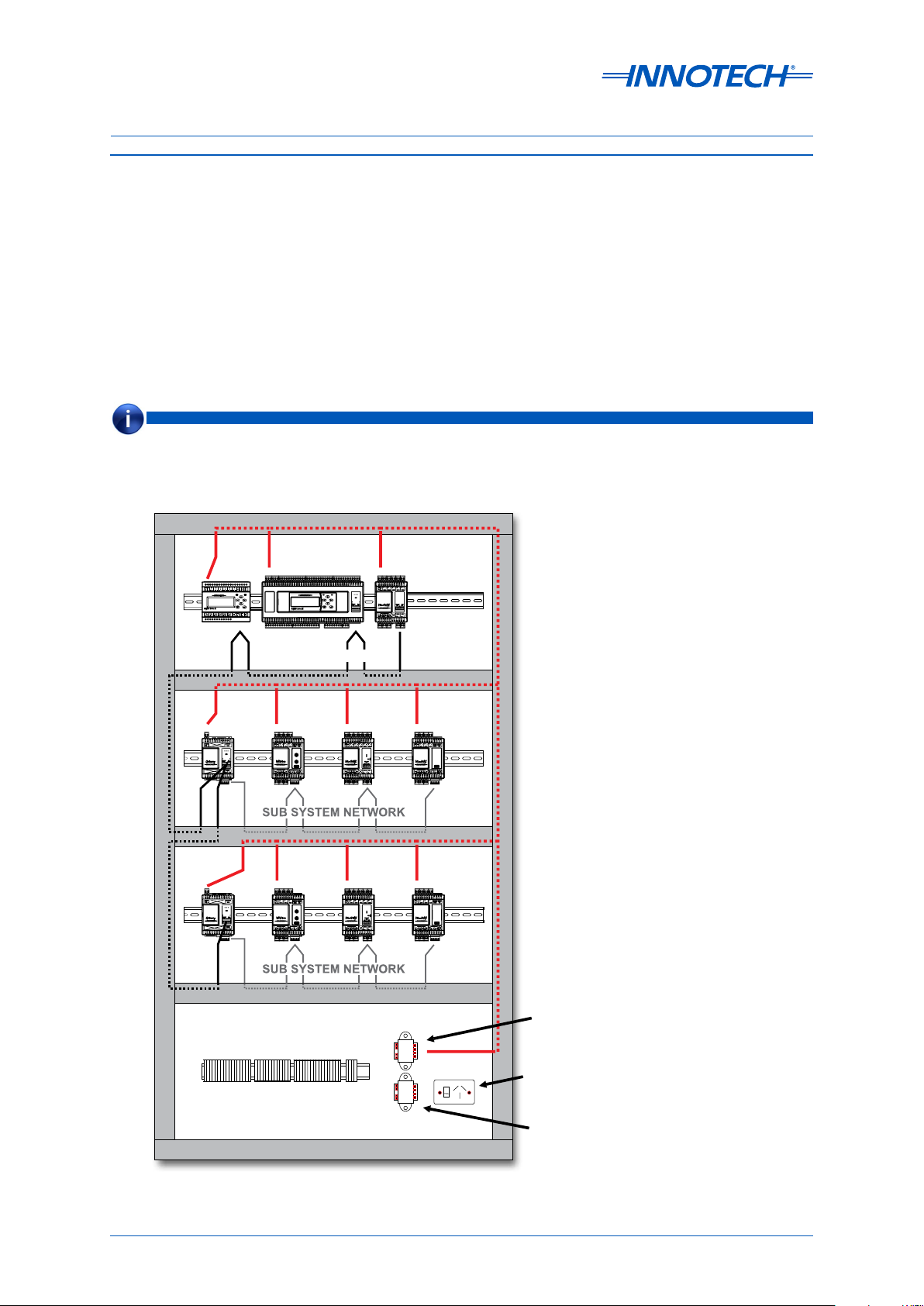

4-1 Overview

As mentioned in the Preliminary Information chapter, with the exception of the MAXIM I controller, all

other MAXIM Series controllers can be installed on a primary or a sub system network depending on

your specific model.

Installing a MAXIM Series controller on a network provides the ability to share data among all

controllers and devices on that network. Additionally it also provides the ability for the MAXIM Series

controllers to communicate with the Innotech iComm communication soware, adding advanced

Supervisory Control and Data Acquisition (SCADA) functionality.

The MAXIM Series controllers utilise RS485 balanced (dierential) communications when installed

on a network. Factors such as the type of network, cable distance, and single or multiple network

installation factors must be considered when carrying out a network installation.

An optional Ethernet port is also available on the Sub System Gateway (IG01), and MAXIM Series II, III,

and 1010 controllers for TCP/IP connectivity to your Local Area Network (LAN).

The MAXIM Series controllers have the flexibility to be installed in a wide range of applications.

Although it is not possible to cover all installation situations that may be encountered, following

some general guidelines and instructions will help to ensure the optimum installation for your

particular situation. Therefore please refer to the DS 99.04 Installation Manual for Innotech Device

Network Cabling for complete details and information on performing a network installation with

MAXIM Series controllers.

A general network diagram of Innotech hardware is illustrated in Figure 4-1 below.

Figure 4-1: Innotech Network Diagram

Page 42 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 43

MAXIM Series Controllers

INSTALLATION INSTRUCTIONS

Chapter 5 Commissioning

Page 44

MAXIM Installation Instructions

5-1 Overview

The commissioning process of the MAXIM Series controllers can only be performed once the

mechanical and electrical installation has been completed, and is intended to ready the controllers

for full operation. The subsequent sections provide detailed information and steps for the

commissioning process.

CAUTION

To prevent injury to personnel and damage to equipment, all electrical power must be turned OFF before starting

the commissioning process. This includes power to the MAXIM Series controllers, and power to the input and

output circuits and equipment. When working with live power ensure that all electrical safety standards for work

on live electrical systems meet local regulatory requirements. Do NOT apply power to any controller or circuit until

instructed to do so by the steps in this section.

5-2 Inspect the Installation

This section of the manual provides detailed steps to perform the final inspection of the installation

process. It is highly recommended that you perform a complete inspection of the mechanical and

electrical installation process to ensure proper operation of the MAXIM Series controllers.

NOTE

Customers are encouraged to contact Innotech Control Systems Australia or your nearest authorised distributor for

any clarification or further information regarding the installation process.

5-2.1 Mechanical Inspection

Please check the following items to complete the mechanical inspection of the installation process:

• Debris such as dust, metal chips, and moisture may have accumulated on the controllers

during the installation process. Please ensure that all controllers are free of any such debris by

thoroughly cleaning as necessary.

• Verify that all controllers are properly installed on DIN rail.

• Verify that cables entering and leaving the cable ducts do not make overly tight bends.

• Verify there is safe access to all MAXIM Series controllers for operation and maintenance.

• Verify that all controllers are installed in a location that is NOT subject to temperature extremes

beyond the normal operating temperature.

• Verify that all controllers are located clear of high current or high voltage cables, and away from

sources that may cause electrical interference.

Page 44 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 45

MAXIM Installation Instructions

5-2.2 Electrical Inspection

The electrical inspection of the installation process involves verifying all electrical connections

are completed properly, and that there are no external voltages present on any of the inputs and

outputs. The subsequent sections provide detailed information to perform a thorough electrical

inspection of all wiring connections completed during the electrical installation process.

Before proceeding further with the electrical inspection, please check and verify the following items:

• Verify that all electrical power, including power to ancillary equipment is turned OFF.

• Verify all connections have been completed correctly with reference to the connection details

generated for your particular installation.

• Verify that all steel enclosures are properly earthed.

• Verify that all wiring is routed clear of high current or high voltage cables, and away from sources

that may cause electrical interference.

• Verify that all cables and wiring are free from physical damage.

NOTE

Please ensure that the electrical installation process is completed in accordance with DS99.04 Innotech Cabling

Manual. Refer to the Cabling Manual for more detailed information.

Page 45

© Mass Electronics Pty Ltd 2011Chapter 5 – Commissioning

Page 46

MAXIM Installation Instructions

5-2.2.1 Checking Power Inputs

The power inputs must be inspected to ensure that the supplied voltage is within the specifications

of the particular controller, as illustrated in Figure 5-1 below. In cases where a DC power source is

utilised, correct polarity must be verified, and the 0 V terminal must be connected to ground. When

an AC power source is utilised you must verify that the AC Neutral wire is properly earthed and

connected to the 0 V terminal on the particular controller.

You can check and verify correct operation of the 24 VAC and 24V DC power supply inputs by

following the steps below:

1. Verify that the main power and the circuit breaker are both OFF.

2. Verify that the resistance between the main earth link of the enclosure and Terminal 2 of the

controller measures 3Ω or less.

3. Connect the red (+) test lead of your Digital Multi Meter (DMM) to the line voltage side (24V from

the transformer) of the circuit breaker, and the black (–) lead of the DMM to the 0V terminal of

the transformer.

4. Verify that the DMM is set to the proper range to measure 24V. In most cases the AUTO setting

will suit most measurements.

5. Ensuring that the circuit breaker remains OFF, now only turn the 240V supply power ON and

observe the reading on the DMM. The measured voltage should be 24V within ±10%. Please

note that the DMM must be set correctly to measure either AC or DC voltage depending on the

type of power source connected to the controller.

6. You can now turn the 240V supply power OFF and disconnect the DMM.

7. The above steps can be repeated to check the power inputs on other controllers.

24V

TRANSFORMER

From 240V

suply

24V

0V

EARTH

Figure 5-1: Checking Power Input Voltage

Circuit Breaker

OFF

1

2

DIGITAL CONTROLLER

24V

DMM

Page 46 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 47

MAXIM Installation Instructions

5-2.2.2 Checking Universal Inputs

Before any Universal Inputs are connected to a MAXIM Series controller, you MUST follow the steps

listed below to verify that 0V A C is measured across these inputs. Please note that the voltage will be

measured directly at the Universal Input wiring, and NOT at the controller, as illustrated in Figure 5-2

below. These steps do not apply if a DC source is connected to the Universal Inputs. In this case the

expected voltage to be measured would be that of the source voltage.

Please note that these instructions are also applicable in situations where a Universal Input / Output

on a MAXIM Series controller is configured as a Universal Input. The Universal Input / Output can be

commissioned according to whether it is configured as a Universal Input or a Universal Output.

1. Verify that ALL Universal Inputs are labelled and disconnected from the controller.

2. Verify that the power to the controller is turned OFF.

3. Verify that the power to the equipment to which the Universal Inputs are connected is turned

OFF.

4. Set the DMM voltage range to measure at least 25V AC; the AUTO setting will suit most

measurements.

5. Connect the red (+) lead of the DMM to the Universal Input wire labelled (+), and the black (–)

lead of the DMM to EARTH, as illustrated in Figure 5-2 below.

6. Observe and verify that the DMM measures 0 V AC across the Universal Input wiring. If the

reading is not 0V AC, this could possibly mean that the wiring is incorrect, or the Universal Input

source may not be turned OFF.

Once you have performed these steps and verified 0 V is measured across each Universal Input

wiring, reconnect the wiring one by one to the corresponding Universal Input terminal on the MAXIM

controller. It is important to observe the polarity when reconnecting the wiring to the controller.

CHECKING UNIVERSAL

INPUT SOURCE VOLTAGE

V

V

0V

AC

DC

Connected to equipment

or device

+

Disconnected from

MAXIM controller

EARTH

Figure 5-2: Checking Universal Inputs for 0V

Page 47

© Mass Electronics Pty Ltd 2011Chapter 5 – Commissioning

Page 48

MAXIM Installation Instructions

5-2.2.3 Checking Digital Relay Outputs

The Digital Relay Outputs on MAXIM Series controllers are interfaced through relays, each with Single

Pole Single Throw (SPST) contacts.

Before checking the Digital Relay Outputs, it is important to verify that there are no short circuits

in the external wiring, which can cause the contact current to exceed the maximum rating. Excess

current through the relay contacts can result in permanent damage to the controller.

The following is the general description of the process for safely checking the Digital Relay Outputs,

with detailed steps outlined on the next page. With power applied to the digital output circuits, but

NOT to the MAXIM controller, the output circuits are checked for correct operation. Visually check to

verify that devices connected between the NO and Com terminals are OFF. If the operational status

of these devices cannot be determined by simple observation (indicator lamp ON/OFF, etc.), a DMM

can be used to measure the voltage across the particular device to determine whether or not it is

energised.

The next step is to verify that the output circuits are energised when the Digital Relay Output is

closed. For circuits using the NO contacts, a jumper wire is temporarily connected between the NO

and Com terminals and the associated device is checked to verify that it is energised.

RELAY

ON

24V

AC

V

24V

DC

V

-

+

External

Relays

24V

0V

RELAY

OFF

0V

0V

AC

V

DC

V

-

+

Figure 5-3: Checking Digital Relay Output Wiring

MAXIM

CONTROLLER

TERMINALS

Page 48 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 49

MAXIM Installation Instructions

The steps below provide further details to check and verify proper operation of the Digital Relay

Outputs on MAXIM Series controllers, as illustrated in Figure 5-3 on the previous page.

1. Verify that the MAXIM controller on which the Digital Relay Outputs will be checked is powered

OFF. You must also verify that power is turned OFF to all of the digital output circuits to be

checked.

2. Beginning at the first device connected to the NO contacts, turn the power ON to the output

device.

3. Visually check to verify that devices connected between the NO and Com terminals are OFF.

If this cannot be verified by a simple visual observation, connect a DMM across the device to

measure the voltage. With the DMM set to the appropriate voltage, verify the that the measured

voltage reads 0V.

4. Verify that the device is OFF by either visual inspection of the device itself, or verifying that the

measured reading on the DMM is 0V.

5. Temporarily connect a jumper wire between the NO and Com contacts of the Digital Relay

Output to be checked. Verify that the jumper wire is of adequate size to temporarily carry the

load.

6. Now turn the power ON to the output device.

7. Verify that the device is ON by either visual inspection of the device itself, or verifying that the

measured reading on the DMM is the expected operating voltage of the device.

8. Turn the power to the output device OFF.

9. Remove the jumper wire connected in Step 6.

10. Repeat Step 2 through Step 10 for the remaining output devices connected to the NO contacts.

Page 49

© Mass Electronics Pty Ltd 2011Chapter 5 – Commissioning

Page 50

MAXIM Installation Instructions

5-2.2.4 Checking Analogue Outputs

The Analogue Output wiring on MAXIM Series controllers should be checked to verify that the output

terminals are free of any external voltage, to verify continuity through the external analogue circuit,

and to verify that the resistance of the external analogue voltage is suicient to avoid overloading the

analogue output circuit.

This procedure is applicable to controllers with dedicated Analogue Outputs, and also applicable to

those controllers equipped with Universal Outputs that have been configured to operate as Analogue

Outputs.

1. Verify that power to the MAXIM controller is turned OFF.

2. Turn the power ON for the Digital Inputs, Digital Outputs, and if applicable the Analogue Inputs.

This step is necessary to detect the presence of voltages at the analogue output terminals that

may be caused by “sneak” circuits or incorrect wiring.

3. Disconnect the active signal wire (+) from the first Analogue Output terminal.

4. Connect the red (+) lead of the DMM to the disconnected active signal wire labelled (+), and the

black (–) lead of the DMM to the Com terminal of the Analogue Output on the controller.

5. The DMM should measure 0V, as illustrated in Figure 5-4 below. Be sure to set the DMM

measurement range to measure the lowest possible voltage to ensure no voltage is present.

6. Change the DMM to measure resistance ( Ω). The DMM should measure a minimum resistance

of 2,000 Ω , as illustrated in Figure 5-5 on the next page. Depending on the DMM, a very high

reading in Mega Ω will indicate an open circuit condition that should be corrected.

7. Disconnect the DMM and reconnect the signal wire(+) that was disconnected in Step 3.

8. Repeat Step 3 through Step 7 for the remaining Analogue Outputs.

9. Turn the power OFF that was applied in Step 2.

CHECKING ANALOGUE

OUTPUT VOLTAGE

Connected to equipment

or device

0V

AC

V

DC

V

+

Figure 5-4: Checking Analogue Output Voltage

EARTH

Page 50 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 51

MAXIM Installation Instructions

Connected to equipment

or device

2000

AC

V

DC

V

+

CHECKING ANALOGUE

OUTPUT RESISTANCE

Figure 5-5: Checking Analogue Output Resistance

5-2.2.5 TRIAC Outputs

The following items should be checked and verified for proper operation of the TRIAC Outputs on

applicable controllers:

• Verify correct polarity of the wiring connected to the TRIAC outputs.

• Inspect the controlling device for any defects or problems.

• Verify that the current draw for any contactors are within the tolerance of the TRIAC outputs.

• Power ON the TRIAC output (force ON using MAXMon).

• Check the TRIAC output voltages and verify proper operation of the controlling device

CAUTION

A TRIAC output cannot be tested without a load applied. Therefore a load of a minimum current rating of 20mA

must be applied for correct operation of the TRIAC outputs.

Page 51

© Mass Electronics Pty Ltd 2011Chapter 5 – Commissioning

Page 52

MAXIM Installation Instructions

5-2.2.6 End-of-Line Jumpers

The End-of-Line (EOL) jumpers are required for MAXIM Series controllers that are installed on a

subsystem network. There are certain rules that must be followed for proper installation of End-ofLine jumpers.

If only one cable is connected into an RS485 Comms connector on a MAXIM controller installed on a

subsystem network, you must place the EOL jumper on that controller.

If two cables are connected to the same RS485 Comms connector, the jumper should NOT be

installed.

All controllers along the RS485 Comms on a sub system network should be carefully checked to verify

that the EOL jumpers are installed only on the last controller in the network.

NOTE

Refer to DS 99.04 Innotech Cabling Manual for EOLs and comms wiring when using repeaters, or more complex

wiring configurations.

Jumper Setting

Indicator

EOL Termination

Jumper

EOL Termination

Jumper

Jumper Setting

Indicator

EOL Termination

Jumper

Figure 5-6: End of Cable Jumper Locations on Sub Network Devices

Page 52 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 53

MAXIM Series Controllers

INSTALLATION INSTRUCTIONS

Appendix A - Using the

CT01 Commissioning Tool

Page 54

MAXIM Installation Instructions

A-1 Overview

The Commissioning Tool – Subsystem Network (CT01) is a Human Machine Interface (HMI) that

allows you to configure controllers on a Subsystem network. It provides full access and navigation

through the menu structure of the Subsystem controllers. You can use the CT01 to commission

the controllers as an alternative to the soware method. The CT01 can interface directly with the

following controllers:

• VAVMax (VM01)

• MiniMAX (MM02)

• MicroMAX (UM01)

It can also interface directly with the Subsystem Network using the provided adapter cable. Once

connected to a Subsystem network, the CT01 can be used to search, log onto, and access any

particular controller on that network.

The steps involved in commissioning your controllers using the CT01 are listed below:

• Connecting to the Sub System Network device.

• Logging onto the controller

• Configuring settings on a controller

• Commissioning the controller (Checking Max/Min airflows, Heater Bank testing & Temperature

Calibration)

A-2 Connecting to Subsystem Network Devices

There are three options when connecting the CT01 to the Sub System network, and each is described

and illustrated in the following sections.

A-2.1 Connecting directly to controller on sub system network

If you connect the CT01 directly to a controller on the sub system network, such as a VAVMax, you will

only be able to communicate to that particular controller. You will not be able to connect to other

controllers on the same network, as illustrated in Figure A-1.

Figure A-1: Connecting the CT01 to a Sub System Network Device

Page 54 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013

Page 55

MAXIM Installation Instructions

A-2.2 Connecting to Sub System Gateway (IG01)

When you connect the CT01 to the Innotech Sub System Gateway (IG01) using the provided adaptor

cable, the CT01 can communicate with all subsystem controllers on that network that are connected

to the IG01, as illustrated in Figure A-2 below.

Figure A-2: Connecting the CT01 to a Sub System Gateway IG01

NOTE

The subsystem network must be reconnected as it was before once the commissioning process is complete.

Page 55

© Mass Electronics Pty Ltd 2011Appendix A – Using the CT01 Commissioning Tool

Page 56

MAXIM Installation Instructions

A-2.3 Connecting to sub system network

When you connect the CT01 to the subsystem network at any point using the provided adaptor cable,

the CT01 can communicate with all controllers on the sub system network that are connected to the

IG01, EXCEPT for the controller that is directly connected to the CT01.

The IG01 will need to be unplugged from the subsystem network to allow this type of connection to

work, as illustrated in Figure A-3 below.

Figure A-3: Connecting the CT01 to a Sub Network Device

NOTE

The IG01 must be reconnected as it was before once the commissioning process is complete.

Page 56 © Mass Electronics Pty Ltd 2011Edition 2.0 dated 20/11/2013