Page 1

R

P.O. Box 292 Sunnybank Brisbane Australia. 4109

Phone: 61 7 38411388 Fax: 61 7 38411644

for

Innotech

Genesis

Systems

EDITION: 011100

Page 2

Page 3

© 2000 - All rights reserved

PROPRIETARY

No part of the Innotech Genesis II System’s hardware, software, firmware or documentation may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language

or computer language, in any form or by any means, without prior written permission of Innotech

Control Systems Australia.

While great efforts have been made to assure the accuracy and clarity of this document, Innotech

Control Systems Australia assumes no liability resulting from any omissions in this document, or

from misuse of the information obtained herein. The information in this document has been

carefully checked and is believed to be entirely reliable with all of the necessary information

included. Innotech Control Systems Australia reserves the right to make changes to any products

described herein to improve reliability, function, or design, and reserves the right to revise this

document and make changes from time to time in content hereof with no obligation to notify any

persons of revisions or changes. Innotech Control Systems Australia does not assume any liability

arising out of the application or any use of any product or circuit described herein; neither does it

convey license under its patent rights or the rights of others.

TRADEMARK

The term: WINDOWS used in this manual is a trademark of Microsoft Corporation.

Page 4

Page 5

Installation Instructions for Innotech Genesis Systems

TABLE OF CONTENTS

SECTION/PARAGRAPH PAGE

SECTION 1-PRELIMINARY INFORMATION .............................................................1-1

1-1. INTRODUCTION. .................................................................................................. 1-1

1-1.1. SYSTEMS COVERED BY THIS MANUAL. ............................................1-1

1-1.2. SCOPE OF THIS TECHNICAL MANUAL. .............................................1-2

1-2. SPECIAL CONSIDERATIONS. ............................................................................1-3

1-3. UNPACKING INSTRUCTIONS. ..........................................................................1-3

1-4. INSTALLATION PLANS. ......................................................................................1-3

1-5. TOOLS AND TEST EQUIPMENT. ......................................................................1-4

SECTION 2-MECHANICAL INSTALLATION .............................................................2-1

2-1. INTRODUCTION. .................................................................................................. 2-1

2-2. PHYSICAL DESCRIPTIONS. ...............................................................................2-1

2-2.1. CONTROLLERS. .........................................................................................2-1

2-2.1.1. Genesis II Digital Controller. ......................................................... 2-1

2-2.1.2. Genesis I Digital Controller. .. ........................................................ 2-3

2-2.1.3. Genesis II Mid Points Controller. ..................................................2-3

2-2.2. EXPANSION MODULES. ...........................................................................2-3

2-2.2.1. Local Expansion Modules. .............................................................2-3

2-2.2.2. Remote Expansion Modules. .......................................................... 2-4

2-2.2.2.1. Remote Module Interface. ........................................................2-5

2-2.2.2.2. Control Station Module. ...........................................................2-6

2-2.2.2.3. Multipoint Module. ...................................................................2-7

2-3. INSTALLATION INSTRUCTIONS. ....................................................................2-7

2-3.1. DIN RAILS. ...................................................................................................2-8

2-3.2. INSTALLATION GUIDELINES. ...............................................................2-9

2-4. DIFFERENCE DATA. ............................................................................................2-10

2-4.1. REM LIMITATIONS. ..................................................................................2-10

2-4.2. TYPICAL INSTALLATION. ......................................................................2-11

2-4.3. ADDITIONAL INSTALLATION GUIDELINES. ....................................2-12

SECTION 3-ELECTRICAL INSTALLATION ...............................................................3-1

3-1. INTRODUCTION. .................................................................................................. 3-1

3-2. ELECTRICAL INSTALLATION PRACTICES. ................................................3-1

3-3. CONTROLLER WIRING. .....................................................................................3-2

3-3.1. GENESIS II DIGITAL CONTROLLER. ..................................................3-4

3-3.1.1. Power Input. ....................................................................................3-5

3-3.1.2. Digital Inputs. ..................................................................................3-5

3-3.1.3. Digital Outputs. ...............................................................................3-6

3-3.1.4. Analogue Inputs. .............................................................................3-7

3-3.1.5. Analogue Outputs. ..........................................................................3-8

3-3.1.6. Pulse Counter Inputs. .....................................................................3-9

3-3.1.7. LEM/REM Connector. ...................................................................3-9

Edition: 011100

i

Page 6

Installation Instructions for Innotech Genesis Systems

TABLE OF CONTENTS – (Continued)

SECTION/PARAGRAPH PAGE

3-3.2. GENESIS II MID POINTS CONTROLLER. ............................................3-10

3-3.2.1. Power Input. ....................................................................................3-11

3-3.2.2. Digital Inputs. ..................................................................................3-11

3-3.2.3. Digital Outputs. ...............................................................................3-11

3-3.2.4. Analogue Inputs. .............................................................................3-11

3-3.2.5. Analogue Outputs. ..........................................................................3-12

3-3.3. GENESIS I DIGITAL CONTROLLER. ....................................................3-12

3-3.3.1. Digital Outputs. ...............................................................................3-12

3-3.3.2. Analogue Inputs. .............................................................................3-13

3-3.3.3. Analogue Outputs. ..........................................................................3-14

3-3.3.4. LEM Connector. ..............................................................................3-14

3-4. WIRING OF EXPANSION MODULES. ..............................................................3-14

3-4.1. LOCAL EXPANSION MODULES. ............................................................3-14

3-4.1.1. AIM Analogue Input Modules. ......................................................3-15

3-4.1.2. DIM Digital Input Modules. ...........................................................3-17

3-4.1.3. DOM Digital Output Modules. ......................................................3-18

3-4.2. REMOTE EXPANSION MODULES. ........................................................3-19

3-4.2.1. REM Power Connections. ..............................................................3-19

3-4.2.2. RS485 Comms Connections. ..........................................................3-20

3-4.2.3. RMI Remote Module Interface. .....................................................3-21

3-4.2.4. AI REM Analogue Input Module. .................................................3-22

3-4.2.5. AO REM Analogue Output Module. ............................................3-23

3-4.2.6. IDI REM. Opto Isolated Digital Input Module. ..........................3-24

3-4.2.7. DI REM Dry Contact Digital Input Module. ...............................3-24

3-4.2.8. DO REM Relay Output Module. ...................................................3-24

3-4.2.9. CS REM Control Station Module. .................................................3-25

3-4.2.10. MZS REM Multi Zone Station Module. .......................................3-25

3-4.2.11. MP REM Multipoint Module. ........................................................3-25

SECTION 4-COMMISSIONING ...................................................................................... 4-1

4-1. INTRODUCTION. .................................................................................................. 4-1

4-1.1. INSPECT THE INSTALLATION. .............................................................4-1

4-1.1.1. Mechanical Inspection. ...................................................................4-1

4-1.1.2. Electrical Inspection. ......................................................................4-2

4-1.2. CHECK INPUT AND OUTPUT WIRING. ................................................4-2

4-1.2.1. Checking Power Inputs. .................................................................4-2

4-1.2.2. Checking Digital Input Wiring. .....................................................4-5

4-1.2.2.1. External-Source Digital Inputs. ...............................................4-5

4-1.2.2.2. Internal-Source Digital Inputs. ................................................4-7

4-1.2.3. Checking Digital Output Wiring. ..................................................4-9

4-1.2.4. Checking Analogue Input Wiring. ................................................4-12

ii

Edition: 011100

Page 7

Installation Instructions for Innotech Genesis Systems

TABLE OF CONTENTS – (Continued)

SECTION/PARAGRAPH PAGE

4-1.2.4.1. Voltage Checks. ......................................................................... 4-14

4-1.2.4.2. Current Checks. .........................................................................4-15

4-1.2.4.3. Resistance Checks. .....................................................................4-17

4-1.2.5. Checking Analogue Output Wiring. .............................................4-17

4-1.3. INSTALL AISCs. ..........................................................................................4-18

4-1.4. SET JUMPER PLUGS. ................................................................................4-18

4-1.4.1. Address Jumpers. ............................................................................ 4-19

4-1.4.2. End-of-Cable Jumpers. ...................................................................4-19

4-1.4.3. Analogue Output Jumpers. ............................................................4-20

4-1.5. APPLY PARTIAL POWER. .......................................................................4-21

4-1.6. LOAD SOFTWARE AND CONFIGURE THE CONTROLLER(S). .....4-22

4-1.6.1. Loading Gen2Works. ......................................................................4-22

4-1.6.2. Configuring a Controller. ...............................................................4-22

4-1.7. INITIAL TESTS. .......................................................................................... 4-23

4-1.7.1. Gen2Mon Software. ........................................................................4-23

4-1.7.2. Performing Initial Tests. .................................................................4-24

4-1.7.2.1. First Phase Testing. ...................................................................4-24

4-1.7.2.2. Second Phase Testing. ............................................................... 4-25

4-1.7.2.3. Third Phase Testing. .................................................................4-25

4-1.8. FINAL SYSTEM CHECKOUT. ..................................................................4-26

APPENDIX A-NETWORK INSTALLATION. ................................................................A-1

A-1. OVERVIEW. ............................................................................................................A-1

A-2. GENESIS I AND GENESIS II PRODUCTS. .......................................................A-1

A-2.1. NET COMMS. ............................................................................................... A-1

A-2.2. GLOBAL POINTS. ....................................................................................... A-1

A-2.3. GENII RS485I ISOLATED RS485 COMMS. ............................................ A-2

A-3. GENESIS I AND GENESIS II CABLE SPECIFICATIONS. .............................A-2

A-4. INSTALLATIONS. .................................................................................................A-2

A-4.1. GENESIS II COMMS WIRING TOPOLOGY. ........................................A-3

A-4.1.1. Adding Modules to the Comms Link. ...........................................A-3

A-4.1.2. Linking Networks in Different Locations. ....................................A-4

A-4.1.3. Multi-Network Arrangement. ........................................................A-4

A-4.2. GENESIS COMMS WIRING CONSIDERATIONS. ...............................A-5

A-4.2.1. Genesis Comms Wiring Connections. ...........................................A-5

A-4.2.2. Genesis I Connections. .................................................................... A-7

A-4.2.3. Genesis II Connections. ..................................................................A-8

A-4.2.4. GENII POLY SWITCH Board. .....................................................A-9

A-4.2.5. GENII 485I Isolated RS485 Comms Card. ...................................A-10

A-4.2.6. GENII RPTR Repeater Module. ...................................................A-11

A-4.2.7. GENII MPI Modem and Printer Interface. ..................................A-12

A-4.2.8. Genesis I Non-Isolated Comms. .....................................................A-13

Edition: 011100

iii

Page 8

Installation Instructions for Innotech Genesis Systems

TABLE OF CONTENTS – (Continued)

SECTION/PARAGRAPH PAGE

A-4.2.9. Genesis II Non-Isolated Comms. ...................................................A-14

A-4.2.9.1. Hazardous Earth-Connections. ................................................A-16

A-4.2.9.2. Use of GENII POLY SWITCH Boards. ..................................A-18

A-4.2.10. Genesis II Isolated Comms. ............................................................A-20

A-4.2.11. Genesis II Comms. Isolated by Repeater. ....................................A-22

A-4.2.12. GENII MPI with Non-Isolated Comms. ........................................A-24

A-4.3. CABLE CONNECTION PROCEDURES. .................................................A-25

APPENDIX B- DATA SHEETS. ........................................................................................B-1

B-1. INTRODUCTION. ..................................................................................................B-1

LIST OF ILLUSTRATIONS

FIGURE PAGE

2-1. Digital Controller Plastic Lid Clamping Details. ....................................................... 2-2

2-2. Digital Controller Dimensions. ..................................................................................2-2

2-3. Genesis II Mid Points Controller. ..............................................................................2-3

2-4. Typical Local Expansion Module. .............................................................................2-4

2-5. Typical Remote Expansion Module. ..........................................................................2-5

2-6. GENII RMI Remote Module Interface. .....................................................................2-6

2-7. GENII CS Control Station Module. ...........................................................................2-6

2-8. Typical Enclosure Layout. .........................................................................................2-8

2-9. DIN Rail Dimensions. ................................................................................................2-9

2-10. Digital Controller Display, Viewing Angles. .............................................................2-9

2-11. Typical Remote System Layout. ................................................................................2-11

3-1. Computer-Generated Wiring Diagram, Example. .....................................................3-3

3-2. Genesis II Digital Controller Input/Output Terminals. ..............................................3-4

3-3. Driving Multiple Solid-State Relays. .........................................................................3-8

3-4. Genesis II MPC Input/Output Terminals. ..................................................................3-10

3-5. Genesis I Digital Controller Input/Output Terminals. ...............................................3-13

3-6. Analogue Input Module. ............................................................................................3-15

3-7. Analogue Input Module Wiring, Example. ................................................................3-16

3-8. Digital Input Module. .................................................................................................3-17

3-9. Digital Output Module. ..............................................................................................3-18

3-10. RS485 Comms Cable Connections. ...........................................................................3-21

3-11. RMI Remote Module Interface. .................................................................................3-22

3-12. AI REM Analogue Input Module. .............................................................................3-22

3-13. AO REM Analogue Output Module. .........................................................................3-23

3-14. CS REM Control Station Module. .............................................................................3-25

3-15. MP REM Multipoint Module. ...................................................................................3-26

3-16. MP REM, Digital Input Wiring. ................................................................................3-28

iv

Edition: 011100

Page 9

Installation Instructions for Innotech Genesis Systems

LIST OF ILLUSTRATIONS – (Continued)

FIGURE PAGE

4-1. Checking Power Input. ...............................................................................................4-4

4-2. Checking Digital Input Wiring. .................................................................................4-6

4-3. Checking Dry Contact Inputs. .................................................................................... 4-8

4-4. Checking Digital Output Wiring. ...............................................................................4-10

4-5. AISC Locations. ......................................................................................................... 4-12

4-6. Address Jumpers, Typical Settings. ...........................................................................4-20

4-7. End-of-Cable Jumper, Typical Location. ................................................................... 4-20

4-8. Setting Analogue Output Jumpers. ............................................................................4-21

A-1. Correct and Incorrect Bus Topology. .........................................................................A-3

A-2. Adding Modules to a Network. ..................................................................................A-3

A-3. Linking Networks in Different Locations. .................................................................A-4

A-4. Multi-Network Arrangement. ....................................................................................A-4

A-5. Network Nodes Considerations. ................................................................................A-5

A-6. Genesis Comms Wiring Connections. ....................................................................... A-6

A-7. Genesis I Connections. ...............................................................................................A-7

A-8. Genesis II Connections. .............................................................................................A-8

A-9. Genesis II POLY SWITCH Board. ............................................................................A-9

A-10. GENII 485I Isolated RS485 Comms Card. ................................................................A-10

A-11. GENII RPTR Repeater Module Connections. ...........................................................A-11

A-12. GENII MPI Modem and Printer Interface. ................................................................. A-13

A-13. Genesis I Non-Isolated Comms. ................................................................................ A-14

A-14. Genesis II Non-Isolated Comms. ...............................................................................A-15

A-15. Hazardous Connection Example, Circuit 1. ...............................................................A-16

A-16. Hazardous Connection Example, Circuit 2. ...............................................................A-17

A-17. Use of GENII Poly Switch Boards, Circuit 1. ...........................................................A-18

A-18. Use of GENII Poly Switch Boards, Circuit 2 ..............................................................A-19

A-19. Use of GENII 485I Card, Circuit 1. ...........................................................................A-20

A-20. Use of GENII 485I Card, Circuit 2. ...........................................................................A-21

A-21. Use of GENII RPTR Repeater Module, Circuit 1. ....................................................A-22

A-22. Use of GENII RPTR Repeater Module, Circuit 2. ....................................................A-23

A-23. Use of GENII MPI, Circuit 1. ....................................................................................A-24

A-24. Use of GENII MPI, Circuit 2. ....................................................................................A-25

A-25. Voltage Check, Isolated/Non-Isolated Digital Controller. .........................................A-26

A-26. Voltage Check, GENII MPI with Isolated/Non-Isolated RS485. ..............................A-27

A-27. Voltage Check, GENII RPTR Repeater Module. ...................................................... A-27

Edition: 011100

v

Page 10

Installation Instructions for Innotech Genesis Systems

LIST OF TABLES

TABLE PAGE

2-1. REM Resource Counts. ..............................................................................................2-10

3-1. Nominal Resistance for Wire Sizes at 20°C. .............................................................3-2

3-2. Genesis II Digital Controller Digital Inputs. ..............................................................3-6

3-3. Genesis II Digital Controller Digital Outputs. ...........................................................3-6

3-4. Genesis II Digital Controller Analogue Inputs. .........................................................3-7

3-5. Genesis II Digital Controller Analogue Outputs. .......................................................3-9

3-6. Pulse Counter Input Terminals. .................................................................................3-9

3-7. Genesis I Digital Controller Digital Outputs. ............................................................3-13

3-8. Genesis I Digital Controller Analogue Outputs. ........................................................3-14

3-9. Analogue Input Module Input Signal Connections. ...................................................3-16

3-10. Digital Input Module Signal Connections. ................................................................3-17

3-11. Digital Output Module Signal Connections. ..............................................................3-18

3-12. AI REM Analogue Input Signal Connections. ...........................................................3-23

3-13. AO REM Analogue Output Signal Connections. ......................................................3-23

3-14. IDI REM Digital Input Signal Connections. ..............................................................3-24

3-15. DI REM Digital Input Signal Connections. ...............................................................3-24

3-16. DO REM Relay Output Signal Connections. .............................................................3-25

3-17. MP REM Output Relay Connections. ........................................................................3-26

3-18. MP REM Digital Input Signal Connections. ............................................................. 3-27

4-1. Genesis System Power Inputs. ...................................................................................4-3

4-2. Digital Input Signal Voltages. ....................................................................................4-5

4-3. Analogue Input Checks. .............................................................................................4-13

4-4. Units Requiring Jumper Settings. ..............................................................................4-19

vi

Edition: 011100

Page 11

Installation Instructions for Innotech Genesis Systems

SECTION 1- PRELIMINARY INFORMATION

1-1. INTRODUCTION.

This manual is intended to provide qualified technical personnel with complete and easy-tofollow instructions for installation, checkout and commissioning of the various devices in the

Innotech Genesis Systems. Although the intent of this manual is to simplify the installation task,

instructions contained in this manual are based on the assumption that installation of a Genesis

System is will be accomplished by technically qualified personnel. Also, these instructions

presuppose that installation personnel are familiar with local regulations, codes and safety

requirements.

NOTE

Installers should familiarise themselves with the content of this

manual before attempting installation of the Genesis System.

1-1.1. SYSTEMS COVERED BY THIS MANUAL Because Innotech Genesis

Systems are intended for use in a variety of applications, the systems are designed on a

modular basis. Modularity provides the most economical and efficient means of adapting the

system to the customer’s specific requirements. Also, in seeking to improve customer

satisfaction through product improvement, Innotech often provides updates and revisions to its

Genesis product line. The modularity concept and equipment revisions result in a large array

of different types of hardware available to the customer.

The systems covered in this manual are the Genesis I and the Genesis II Systems. These

systems are based on one or more controllers as the major control units interconnected with

several ancillary units. These major control units included in this manual are:

• Genesis I Digital Controller

• Genesis II Digital Controller

• Genesis II Mid Points Controller (GENII MPC)

For purposes of explanation within this manual, a System is defined as one or more controller

units interconnected with various ancillary units for the purpose of performing specific

functions. A Genesis I System contains one or more Genesis I Digital Controllers as the

control unit(s). A Genesis II System consists of one or more Genesis II Digital Controllers

and/or GENII MPCs as the major control unit(s). Some of the ancillary units included in the

Genesis Systems are (refer to the System Description Manual for descriptions of these units):

• Several types of Local Expansion Module (LEMs)

• Several types of Remote Expansion Module (REMs)

• Genesis II Multipoint Module (GENII MP REM)

• Remote Module Interface (RMI)

• Miscellaneous Ancillary Units described in the individual Data Sheets in Appendix B.

Edition 011100

1-1

Page 12

Installation Instructions for Innotech Genesis Systems

The purpose of this manual is to provide clear and complete instructions for all phases of the

installation of the units that comprise your Genesis System. In order to provide the clearest

instructions possible with minimum confusion, instructions in this manual are based on the

following approach:

• For simplicity of explanation, installation instructions in this manual are based on the

assumption the system to be installed is a typical Genesis II System containing a single

Genesis II Digital Controller and the three types of LEMs. Installation information for

other configurations, such as a Genesis I System or a Genesis II System controlled by a

GENII MPC is also provided as additional data.

• Instructions for REMs and RMIs are the same as for LEMs, except where otherwise noted.

Difference data, if required, is included in each section.

• Data Sheets in Appendix B of this manual contain information needed for installation of

miscellaneous ancillary units. Separate instructions for these units are not provided in the

main part of the manual unless the data is not available on the Data Sheets.

• Basic electrical wiring information is provided in Section 3 and wiring instructions for

network systems is contained in Appendix A.

1-1.2. SCOPE OF THIS TECHNICAL MANUAL. This technical manual

contains:

• SECTION 1 – PRELIMINARY INFORMATION

• SECTION 2 – MECHANICAL INSTALLATION

• SECTION 3 – ELECTRICAL INSTALLATION

• SECTION 4 – COMMISSIONING

• APPENDIX A – NETWORK INSTALLATION

• APPENDIX B – GENESIS SYSTEM DATA SHEETS

This section of the manual contains installation-related information of a general nature such as

general safety considerations and pre-installation requirements.

Section 2 contains instructions and related data to facilitate the mechanical installation of

components of the Genesis System. Section 2 includes such information as physical

descriptions of the units, mounting dimensions and mechanical installation guidelines.

Section 3 is the ELECTRICAL INSTALLATION section and contains electrical wiring

information useful for installation of a basic “stand-alone” system. Section 3 is augmented by

network wiring information in Appendix A. Appropriate references are provided between

Section 3 and Appendix A for installation of network wiring.

Section 4, the COMMISSIONING Section, provides instructions for post-installation

inspection and checkout of the Genesis System, power application and initial set-up of the

various units that comprise the system.

Appendix A. provides detailed information for interconnecting various units in a network

configuration. This appendix should be used in conjunction with Section 3 when network

installation is involved. The two electrical installation areas: Section 3 and Appendix A are

purposely separated from each other in the interest of clarity and to simplify use of the manual.

1-2

Edition 011100

Page 13

Installation Instructions for Innotech Genesis Systems

Individual systems may include hardware items that are not represented in this manual. In

such cases, data sheets for the items are included in Appendix B. The contents of Appendix B

are different for each system configuration. Appendix B in your technical manual contains

only data sheets, if any, that are applicable to your system.

1-2. SPECIAL CONSIDERATIONS.

The following precautions and installation considerations must be observed to ensure personal

safety and to prevent damage to equipment.

• Local safety regulations, building codes and ordinances must be complied with during

installation. In cases of conflict with procedures in this manual, contact Innotech or its

authorised representative for clarification.

• To prevent damage to equipment, avoid applying electrical power to the equipment prior to

checkout, unless specifically instructed to do so in this manual.

• The Genesis System can be installed using common tools and test equipment. Only qualified

personnel, familiar with local codes and practices should install the system. Wiring should

only be performed by someone knowledgeable of electronics and wiring installation

practices. Refer to the appropriate documentation when installing items provided by other

manufacturers

1-3. UNPACKING INSTRUCTIONS.

The following unpacking instructions should be followed as soon as possible after the equipment

is delivered to the installation site:

a. Carefully unpack each item and set packing materials aside for future use.

b. Check the inventory against the packing list to make sure nothing is missing.

c. Inspect each item for damage.

d. Report any shortages or damaged items.

e. Collect all factory inspection sheets and similar data; place in an equipment history file.

f. Any items that are not to be installed immediately should be carefully returned to its

shipping container and stored in a safe place until 8t is time for it to be installed.

1-4. INSTALLATION PLANS.

The following installation data should be gathered and made available to the installation team:

• This Technical Manual.

• Computer-Generated Wiring Diagram - the Genesis configuration software can be used to

print a wiring diagram for the specific application. A copy of this wiring diagram is usually

provided at the time of hardware delivery. Procedures for printing additional copies of the

wiring diagram are contained in the Innotech Genesis II Direct Digital Controller User

Manual.

Edition 011100

1-3

Page 14

Installation Instructions for Innotech Genesis Systems

• Computer-Generated Materials List – the Materials List is also provided at the time of

hardware delivery. The list is printed out from the configuration software as is the wiring

diagram described above. The Materials List shows all the items of hardware required for

the specific application.

• For non-Innotech equipment, gather the manufacturer’s installation-related data such as

schematics, wiring diagrams, dimension diagrams, etc.

• Any other data source as it becomes known.

1-5. TOOLS AND TEST EQUIPMENT.

No special tools are required for installation of the Genesis Systems. Only common hand tools

are needed. A high impedance digital Volt-Ohm-Milliammeter is the only item of electronic test

equipment required

1-4

Edition 011100

Page 15

Installation Instructions for Innotech Genesis Systems

SECTION 2- MECHANICAL INSTALLATION

2-1. INTRODUCTION.

This section of the manual contains instructions and related data to facilitate the installation of

components of the Genesis I or Genesis II System. Because of the physical similarities of the two

systems, instructions contained in this section apply equally to the Genesis I and Genesis II

Systems, except where otherwise noted.

It is recommended that the main units of the Genesis System, such as the Digital Controller, Mid

Points Controller, Local Expansion Modules, and Remote Expansion Modules be mounted in

steel cabinets to minimise the effects of electromagnetic interference (EMI). Network

components, such as PCs, printers and modems, should be installed in accordance with standard

computer installation practises.

Because of the designed-in flexibility of the Genesis Systems, they can be installed in a wide

variety of configurations depending on the user’s preference. For this reason it is not possible to

include all the various installation configurations in this manual. Instead, this manual provides

examples of installations that are considered typical. Innotech recognises that the installation

examples described in this manual may not be in total agreement with the user’s requirements.

However, information in this document should be used as a guide for all installations, regardless

of whether the specific circumstances match the examples given. In all cases, installation

personnel should familiarise themselves with the information contained in this section.

NOTE

If required, additional installation recommendations can be provided

from Innotech Control Systems Australia upon request.

2-2. PHYSICAL DESCRIPTIONS.

The following paragraphs contain physical descriptions, including dimensions and installationrelated information, for the main units of the Genesis System. These paragraphs are intended to

provide the installer with sufficient information to permit proper installation of the various units.

For units of equipment not included in the following paragraphs, refer to the appropriate data

sheet in Appendix B.

2-2.1. CONTROLLERS. Controllers are the main processing units that provide over-

all control of the Genesis I or Genesis II systems. The types of controller units included in this

manual are:

• Genesis II Digital Controller

• Genesis I Digital Controller

• Genesis II Mid Points Controller (GEN II MPC)

2-2.1.1. Genesis II Digital Controller. The Genesis II Digital Controller is used

only with a Genesis II System. The controller’s case is made of ignition-resistant grade

ABS plastic which meets the Fire Rating requirements of AS420. The unit’s electronic

circuit boards are housed in a two-piece plastic case consisting of a base and a lid. The

Edition 011100

2-1

Page 16

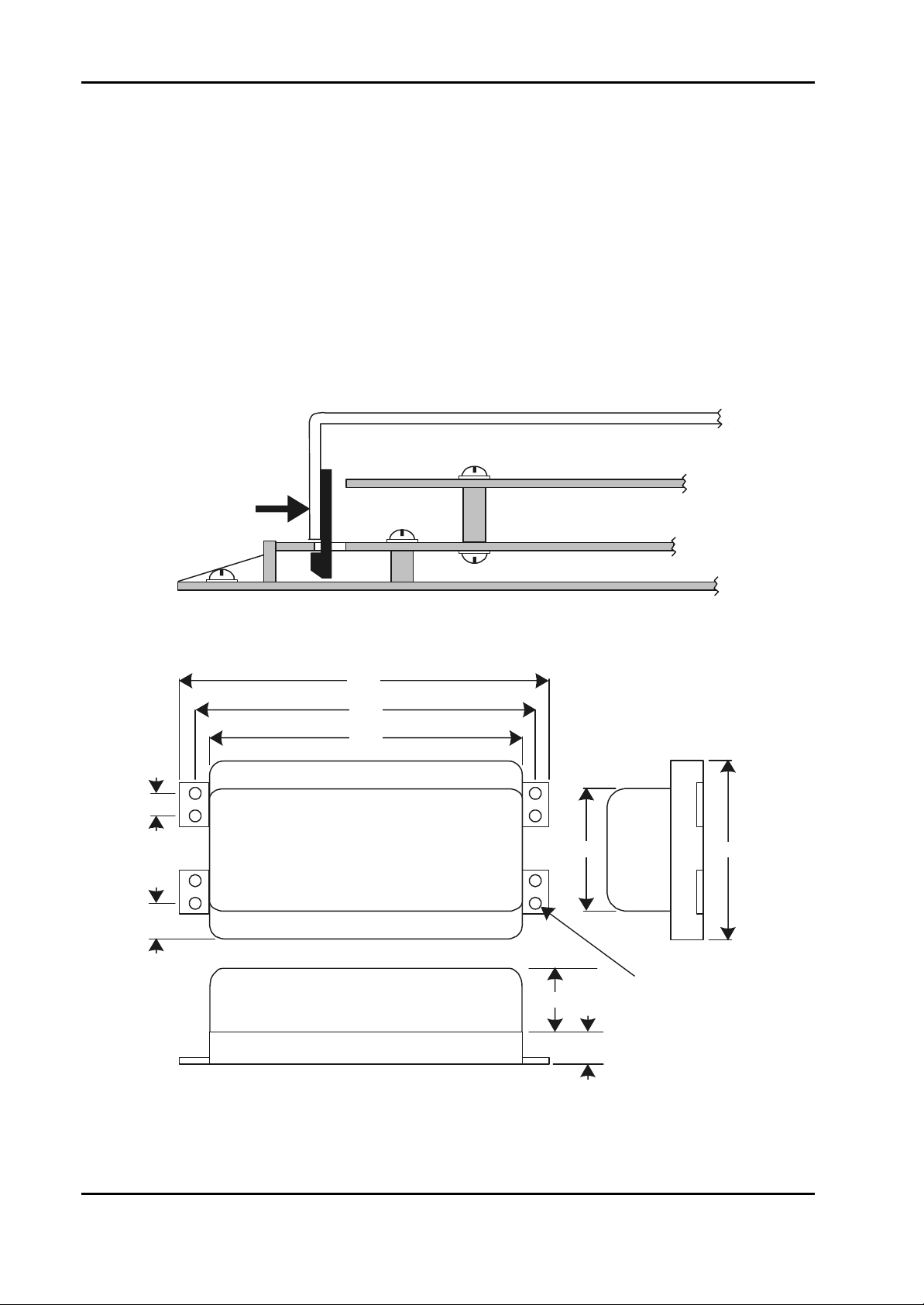

Installation Instructions for Innotech Genesis Systems

plastic base has eight mounting holes; each hole is 4mm in diameter. Not all of the eight

holes are required for mounting, providing the unit is securely installed.

There are four slots in the bottom circuit board (motherboard) - two slots at each end.

These slots facilitate the clamping of the plastic lid to the motherboard. To remove the

plastic lid from the motherboard, press firmly inwards at each end of the plastic lid-piece to

disengage the clip-in fitting and lift away simultaneously (see Figure 2-1). Installation of

the plastic lid is similar to the removal procedure; insert the clip-in fitting at one end of the

plastic lid into the slots provided on the motherboard. Then, clip the opposite end of the

plastic lid into the slots at that end of the motherboard. Pressing the two ends of the plastic

lid together can assist in the operation.

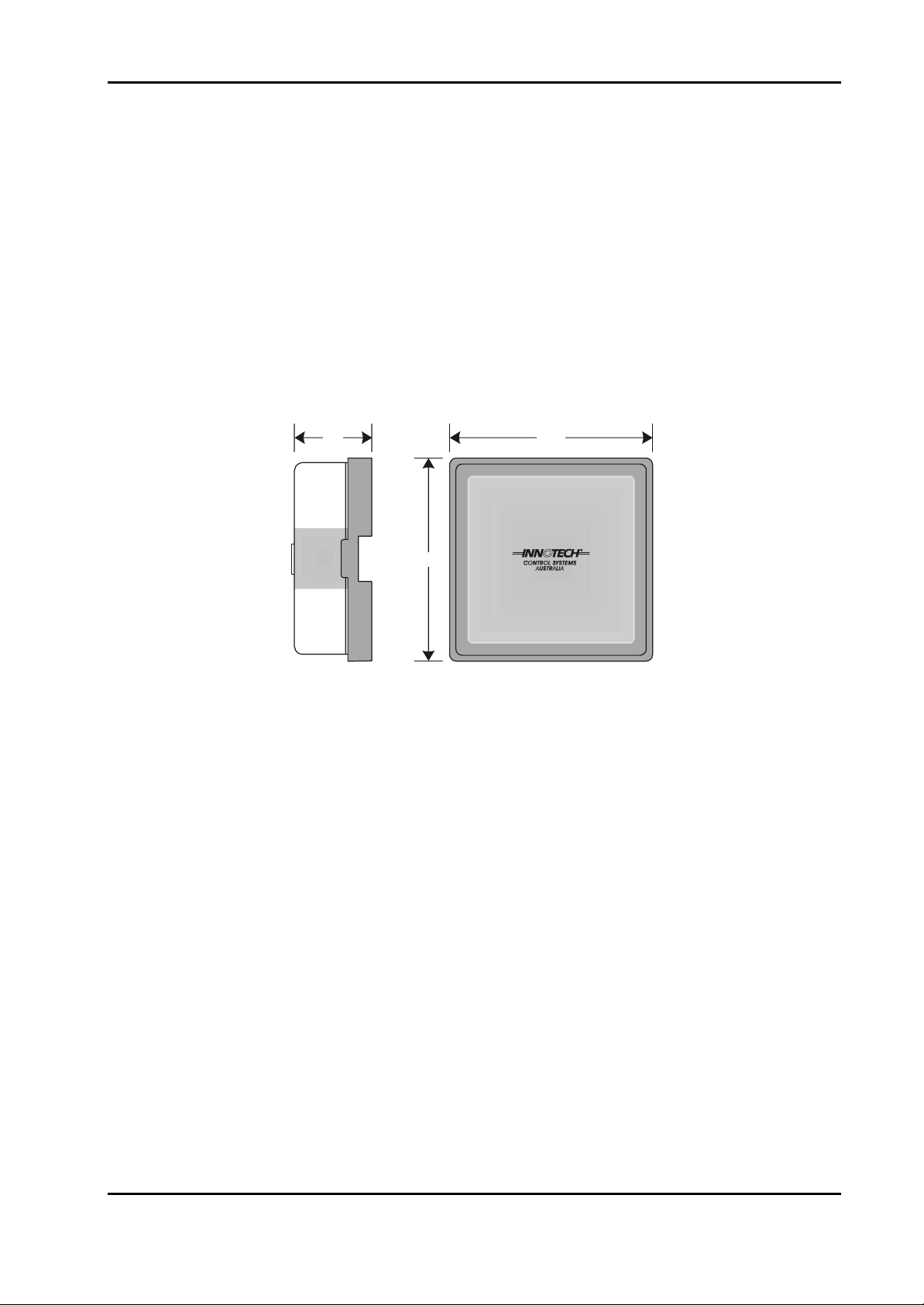

The Digital Controller’s outline dimensions are shown in Figure 2-2.

Plastic Lid Piece

Top Circuit Board

PRESS TO

RELEASE

Motherboard

12

25

Plastic Base Piece

Figure 2-1. Digital Controller Plastic Lid Clamping Details.

308

292

280

140

Mounting Hole

50

Typical of 8

50

180

4mm

2-2

ALL DIMENSIONS ARE IN MILLIMETRES

Figure 2-2. Digital Controller Dimensions.

Edition 011100

Page 17

Installation Instructions for Innotech Genesis Systems

2-2.1.2. Genesis I Digital Controller. The Genesis I Digital Controller is used only

in Genesis I Systems. The main physical difference between the Genesis I and Genesis II

controllers is that the Genesis I Digital Controller does not contain a display or operator’s

keyboard as does the Genesis II controller. This means that, unlike the Genesis II Digital

Controller, providing access to controls and indicators is not a consideration when installing

the Genesis I Digital Controller. The Genesis I and Genesis II Digital Controllers are

similar in all other respects, including dimensions.

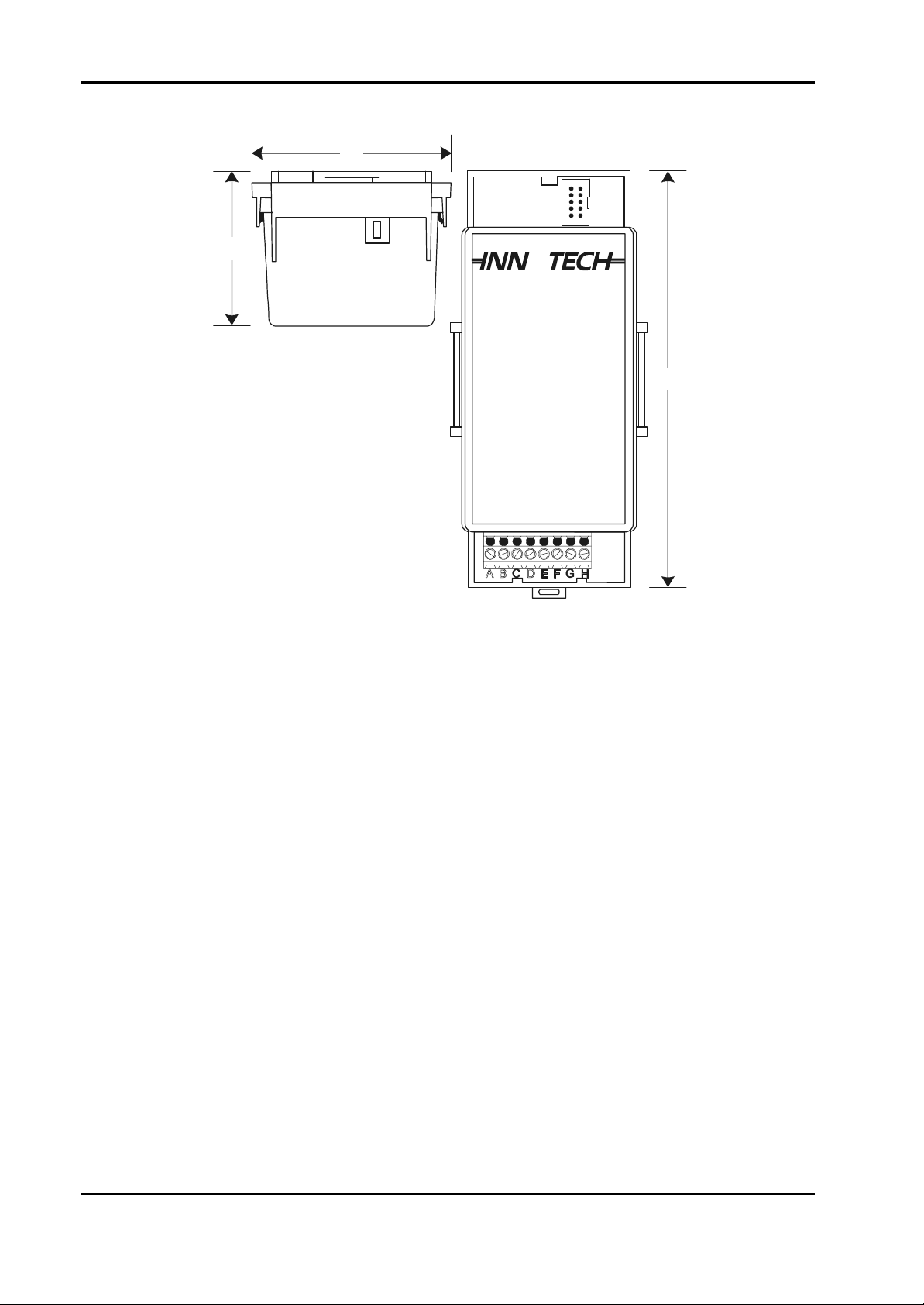

2-2.1.3. Genesis II Mid Points Controller. The GENII MPC Mid Points

Controller module (Figure 2- 3) is a state-of-the-art processing system that performs the

same controller functions as a digital controller. The GEN II MPC can be used in a Genesis

II System as the main controller or as a supporting controller. It is designed for DIN Railmounting inside a control panel. The MPC does not have external controls or indicators.

65

163

163

R

Figure 2-3. Genesis II Mid Points Controller.

2-2.2. EXPANSION MODULES. Expansion modules increase the capability of a

controller by allowing more input and output devices to be connected to it. The following

paragraphs describe two classes of expansion modules: Local Expansion Modules and Remote

Expansion Modules.

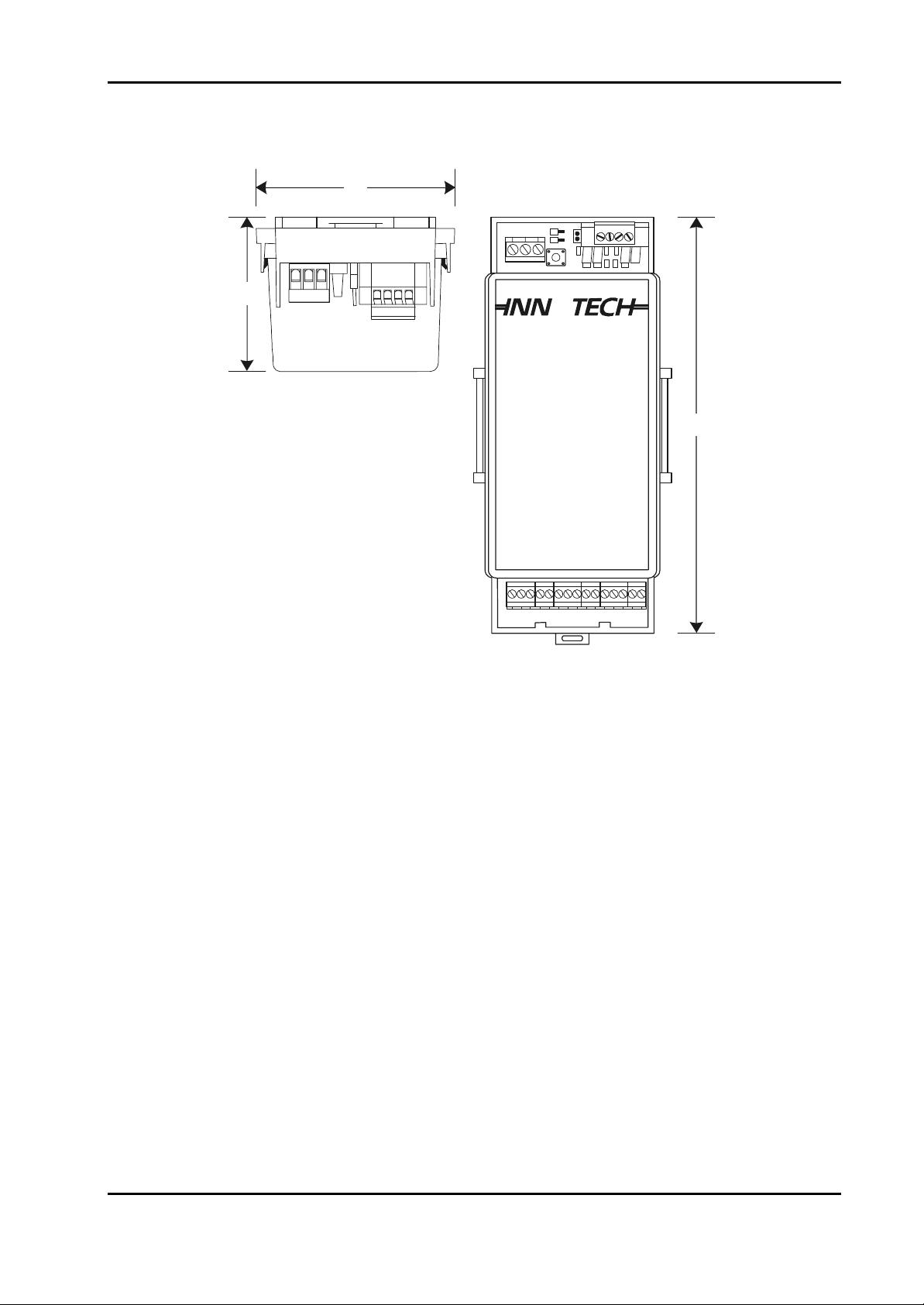

2-2.2.1. Local Expansion Modules. The term: Local Expansion Module (LEM) is

the collective name applied to the following types of units used to configure the hardware to

the customer’s requirements.

• Analogue Input Module (AIM)

• Digital Input Module (DIM)

• Digital Output Module (DOM)

Up to eight LEMs can be included in the system in any combination. They are designed for

easy mounting on standard DIN Rails. A typical LEM is shown in Figure 2-4. The LEM

shown in Figure 2-4 is a Digital Input Module; however the three types of LEM are similar

in appearance and are identical in their dimensions.

There are restrictions on how far apart the LEMs can be from each other and from the

controller; these requirements are explained in Paragraph 2-3.

Edition 011100

2-3

Page 18

Installation Instructions for Innotech Genesis Systems

57

ALL DIMENSIONS ARE

IN MILLIMETRES

75

DIN Rail

Mounted

GENESIS II

DIGITAL INPUT MODULE

R

155

Figure 2-4. Typical Local Expansion Module.

2-2.2.2. Remote Expansion Modules. The term: Remote Expansion Module

(REM) is the collective nomenclature applied to the several types of units used to configure

the hardware to the customer’s requirements. The REMs listed below are similar in

appearance and of the same approximate dimensions as the LEMs and perform the same

basic functions as the LEMs, but from a greater distance. However, REMs and LEMs

cannot be used together with the same Digital Controller or GENII MPC.

• GENII AI REM Analogue Input Module

• GENII AO REM Analogue Output Module

• GENII DI REM Digital Input Module

• GENII OPTO DI REM Opto-Isolated Digital Input Module

• GENII DO REM Digital Output Module (Also called a Relay Output Module)

Figure 2-5 shows a typical REM; the example shown is GENII AI REM. REMs are DIN

Rail-mounted.

In addition to the types of REMs listed above and represented by Figure 2-5, there are three

additional types of REMs or REM-related modules described in the following paragraphs:

• GENII RMI Remote Module Interface

• GENII CS REM Control Station Module

• GENII MP REM Multipoint Module

2-4

Edition 011100

Page 19

Installation Instructions for Innotech Genesis Systems

The system imposes restrictions on the total number and types of REMs that can be used

with a controller. These requirements are explained in Paragraph 2-4.1.

75

57

ALL DIMENSIONS ARE

IN MILLIMETRES

DIN Rail

Mounted

3

12

GEN II AI REM

ABCDEFGHIJKLMN

R

155

O

Figure 2-5. Typical Remote Expansion Module.

2-2.2.2.1. Remote Module Interface. The GENII RMI Remote Module

Interface (Figure 2-6) provides an interface between the Genesis II Digital Controller or

GENII MPC and the REMs. The Remote Module Interface is DIN rail-mounted close to

the controller and the REMs are installed at remote locations. Installation instructions

for the GENII RMI and the REMs are contained in Paragraph 2-4.

Edition 011100

2-5

Page 20

Installation Instructions for Innotech Genesis Systems

75

57

ALL DIMENSIONS ARE

IN MILLIMETRES

DIN Rail

Mounted

GENESIS II

REMOTE MODULE INTERFACE

R

155

Figure 2-6. GENII RMI Remote Module Interface.

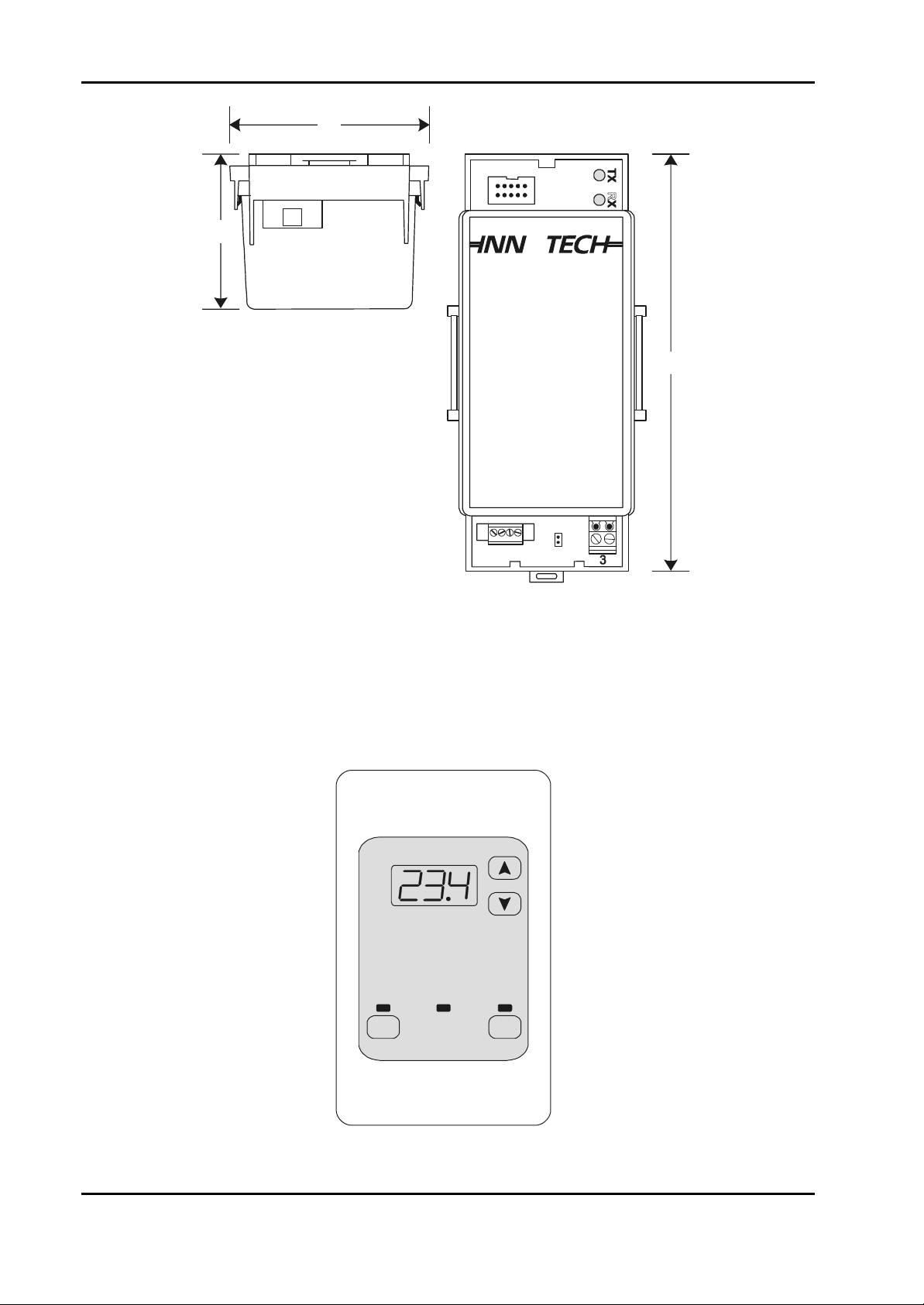

2-2.2.2.2. Control Station Module. The GENII CS REM Control Station

Module (Figure 2-7) is housed in a switch plate that mounts in a standard electrical wall

plate at a remote location. Mechanical installation instructions for the GENII CS

Module are not applicable; electrical installation instructions for the module are

contained in Section 3.

On

Off

System

Timer

2-6

Figure 2-7. GENII CS Control Station Module.

Edition 011100

Page 21

Installation Instructions for Innotech Genesis Systems

2-2.2.2.3. Multipoint Module. The GENII MP REM Multipoint Module is a

DIN Rail-mounted device that provides input/output expansion capability for the

associated Genesis II Digital Controller or GENII MPC. It is designed to be located at a

remote location. The GENII MP REM is enclosed in a square case made of flameresistant Astrene M650 IR plastic. It is identical in appearance and dimensions to the

GENII MPC (Figure 2-3).

NOTE

Unless otherwise noted, Installation Instructions are based on the

assumption that the system to be installed is a local Genesis II System

consisting of one Genesis II Digital Controller and three types of

LEMs. Installation Instructions for other types of hardware, such as:

Genesis I Digital Controllers, GENII MPCs, and REMs are contained

in Paragraph 2-4 - Difference Data.

2-3. INSTALLATION INSTRUCTIONS.

A steel enclosure is recommended to contain the system with the aim of minimising EMI from

surrounding equipment. To facilitate the number of cables entering and leaving the enclosure, the

minimum dimensions of slotted cable ducts should be 45mm x 45mm with 65mm clearance from

the cable ducts to the terminals of the units.

Where LEMs are used, every effort should be made to locate these units adjacent to the controller

to minimise problems with connecting cables due to the critical lengths and segregation

requirements.

The communications cable between the Digital Controller and the LEMs is an Innotechmanufactured item; part number GenII LEM Cable. The cable is made in 150mm segments;

therefore, it is important that the LEMs are located as close as possible to the Digital Controller

and placed side-by-side on the DIN rail.

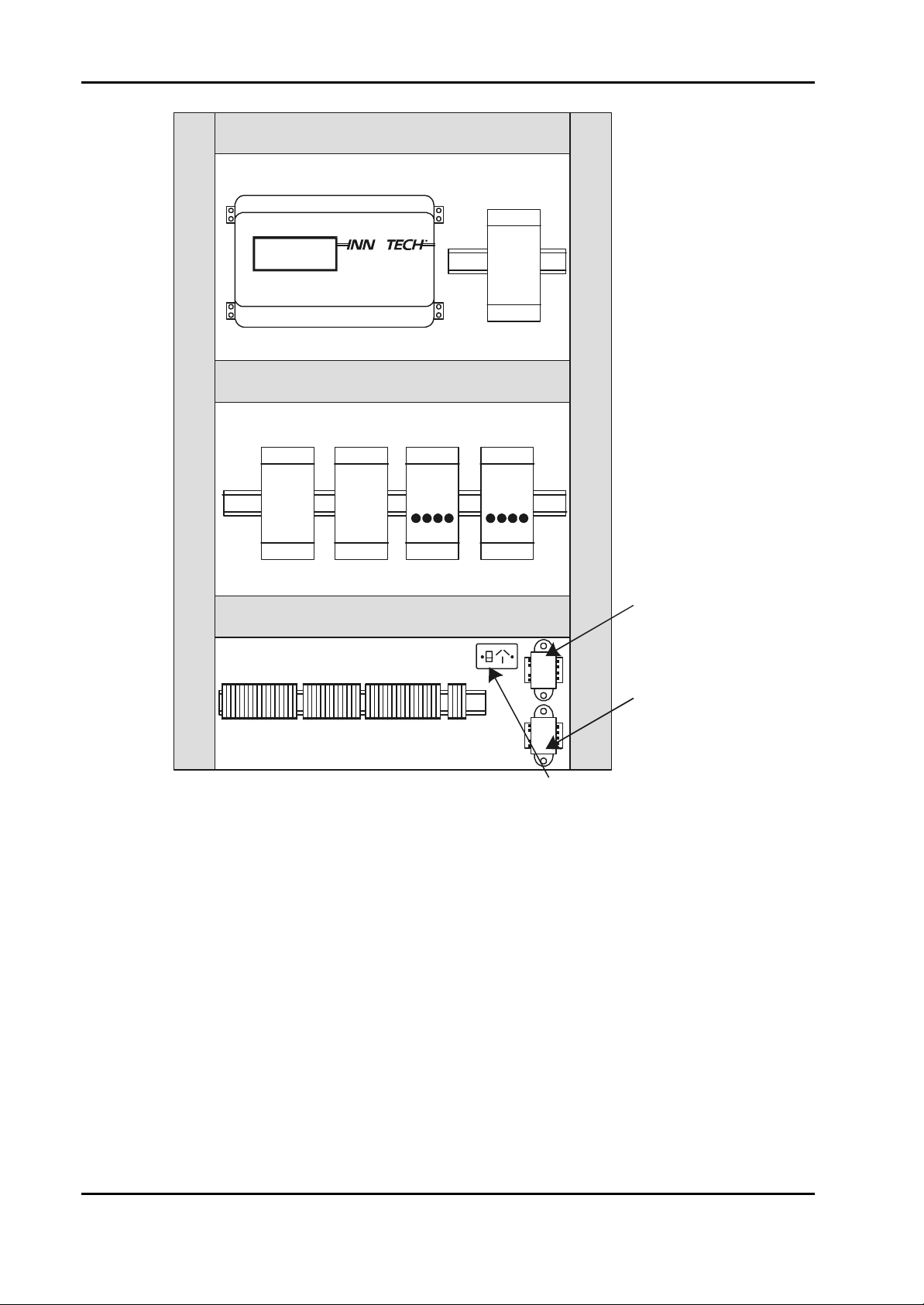

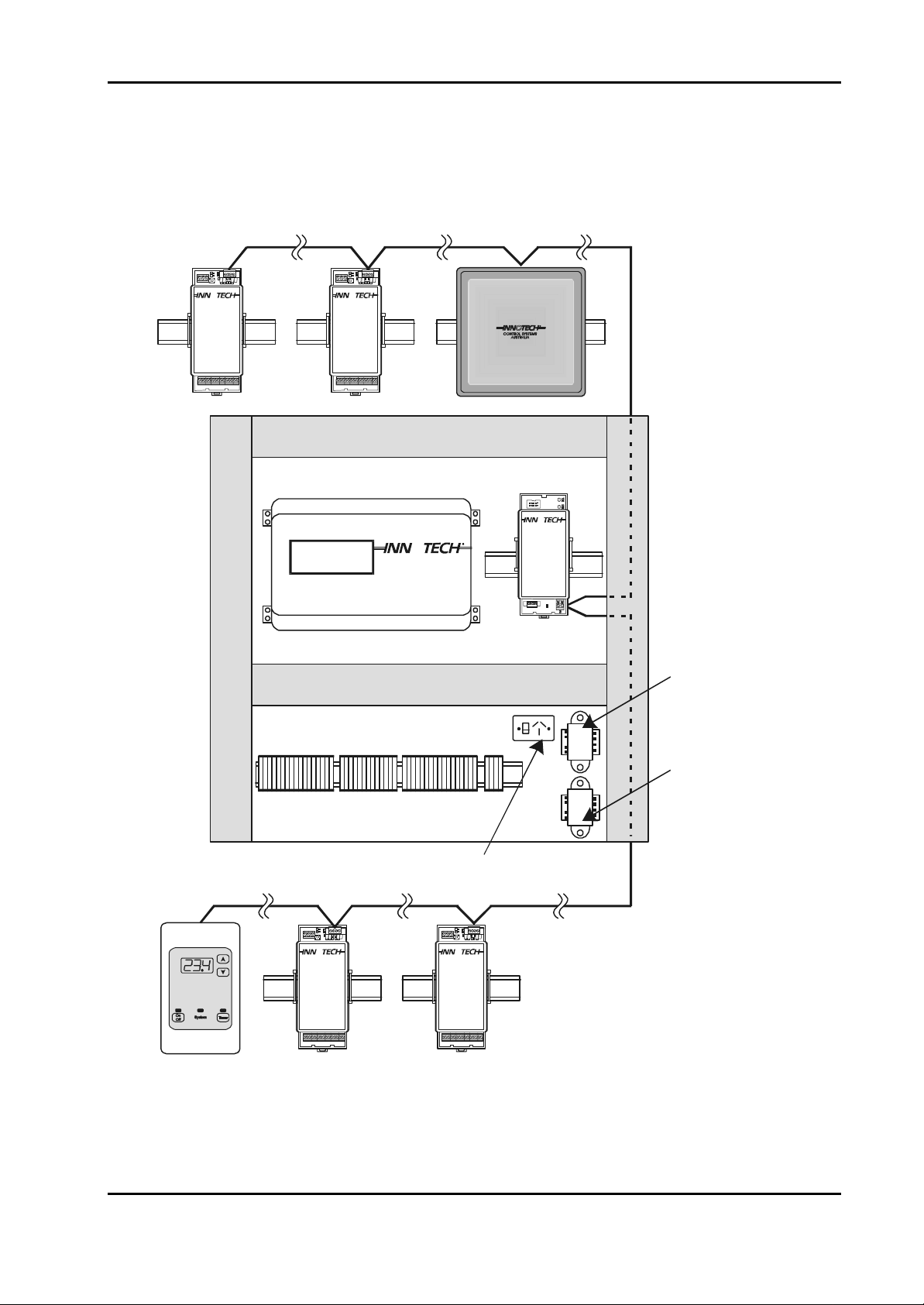

Figure 2-8 shows an example of a typical Genesis System layout in an equipment enclosure.

Edition 011100

2-7

Page 22

Installation Instructions for Innotech Genesis Systems

45mm Slotted Cable Duct

Panel Size

600 X 900mm

45mm Slotted Cable Duct

GENESIS II

R

See Note

45mm Slotted Cable Duct

See Note

D.I.M. D.I.M. D.O.M. D.O.M.

See Note

45mm Slotted Cable Duct

A.I.M.

45mm Slotted Cable Duct

Digital

Controller

Power

Transformer

Auxiliary

Power

Transformer

Terminal Strip

NOTE:

65mm Space Between Duct

Standard Power

Point (Outlet)

and Terminals in These Areas.

Figure 2-8. Typical Enclosure Layout.

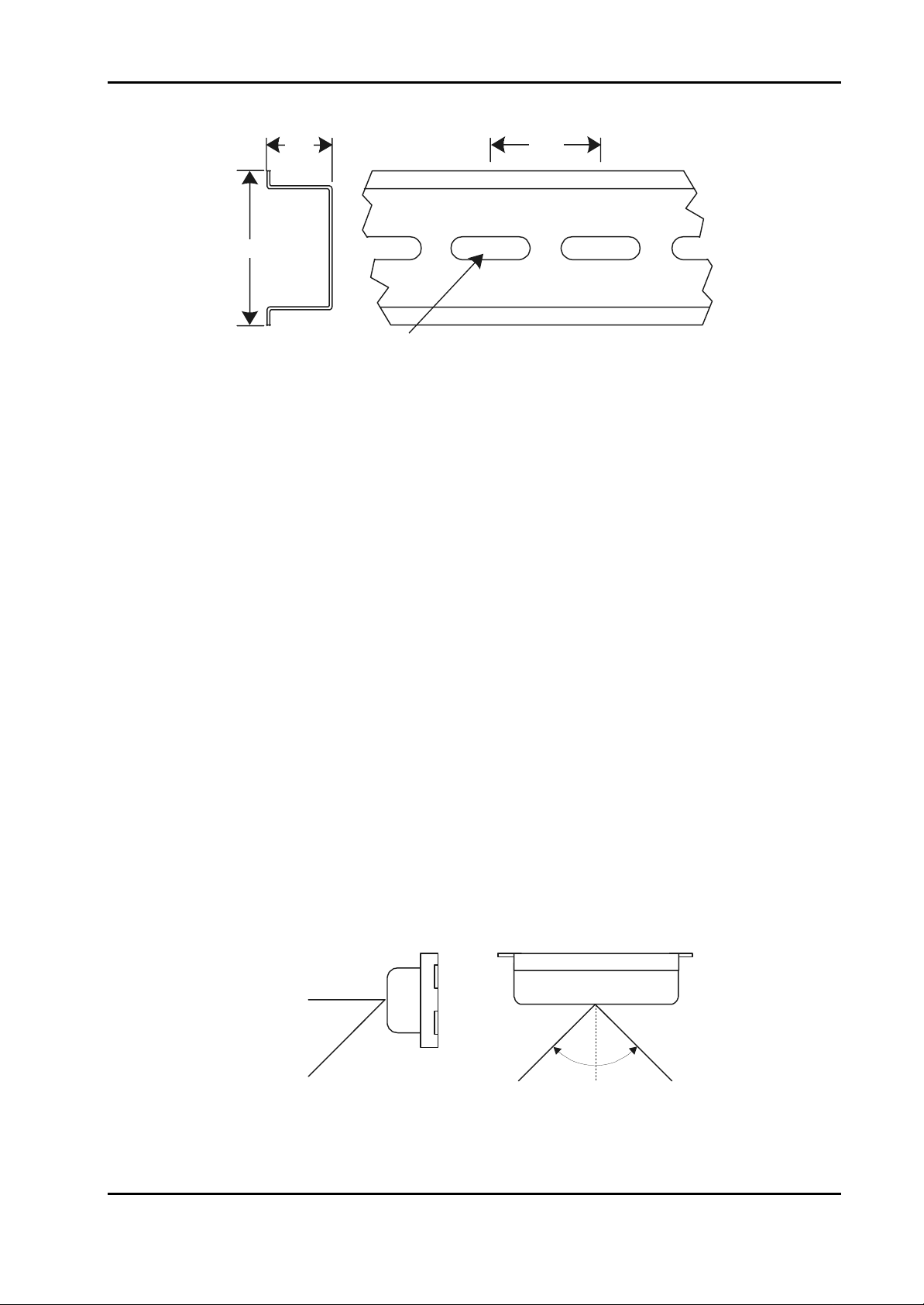

2-3.1. DIN RAILS. The DIN rail is an industry-standard item and is available from a

large number of commercial sources. The rail is usually manufactured from galvanised steel

and may be provided with a finish. It is typically available in 2-metre lengths. DIN rail cutters

are available commercially and are recommended; however, for smaller installations, a

hacksaw may be used to cut the rails to the required length. Figure 2-9 is provided to assist in

planning layout of the LEMs; the figure shows the dimensions of a typical DIN rail section.

2-8

Edition 011100

Page 23

Installation Instructions for Innotech Genesis Systems

15

35

Mounting Slot

18 X 5.2

ALL DIMENSIONS ARE IN MILLIMETRES

Figure 2-9. DIN Rail Dimensions.

25

2-3.2. INSTALLATION GUIDELINES. To ensure continued reliable operation of

the Genesis II System, the following installation guidelines should be observed:

• The Genesis II Digital Controller should be installed in a position that provides easy

access to the front panel and sufficient room for power, and input/output cabling. Also,

the Digital Controller should be mounted such that the controls are in easy reach of the

user.

• Install LEMs as close as possible to the Digital Controller and side-by-side on the DIN

rail. Refer to Paragraph 2-3 and Figure 2-8.

• Placement of the Genesis II Digital Controller should take into account the optimum

viewing angle of the Liquid Crystal Display (LCD), which is approximately 45o vertically

and 90o horizontally (see Figure 2-10).

• Do not mount any unit of the system near high voltage, high current cables or sources of

strong radio frequency emissions such as transmitter antenna cables.

• The ambient temperature of the Digital Controller and LEMs at the installation site should

not exceed the 0-40ºC temperature range. Ideally, the installation site should have a stable

ambient temperature close to 20oC.

• Mount the units in an area with minimum vibration and minimum exposure to mechanical

damage.

SIDE VIEW TOP VIEW

45

DEGREES

Edition 011100

90 DEGREES

Figure 2-10. Digital Controller Display, Viewing Angles.

2-9

Page 24

Installation Instructions for Innotech Genesis Systems

2-4. DIFFERENCE DATA.

This paragraph contains difference data unique to installation of the Genesis I Digital Controller,

the GENII MPC, Genesis II REMs and related devices. Installation Instructions provided in

Paragraph 2-3 are applicable except where stated otherwise.

2-4.1. REM LIMITATIONS. The following limitations apply to the installation of

REMs:

• LEMs and REMs cannot be used with the same Digital Controller or GENII MPC.

• REMs can only be used with Genesis II Digital Controllers that have been upgraded to

Version 4.0 firmware.

NOTE

The Version 4.0 Configuration Software automatically configures the

Digital Controller and produces a printout which lists the types and

quantities of REMs that can be used with a given Digital Controller.

The following information provides generalised REM type/quantity

requirements that can be used for planning purposes.

• Only one GENII RMI Remote Module Interface can be used with a Genesis II Digital

Controller or GENII MPC. It must be installed adjacent to the digital controller/MPC

• Up to 15 REMs can be connected to a single GENII RMI. However, each REM has a

Resource Count that represents its requirements for controller resources. In no case can

the Resource Count for a Digital Controller/GENII MPC exceed 36. Refer to Table 2-1

for a list of REM Resource Counts.

• The REMs must be installed within 500 metres of the RMI.

Table 2-1. REM Resource Counts.

TYPE OF REM RESOURCE

COUNT

GENII AI Analogue Input Module 6

GENII AO Analogue Output Module 3

GENII DI Digital Input Module 1

GENII OPTO DI Opto Isolated Digital Input Module 1

GENII DO Digital Output Module 1

GENII CS Control Station Module 4

GENII MP Multipoint Module 3

NOTE: The following examples illustrate the maximum number of REMs

allowed per digital controller or MPC:

a. 3 AIMs (3 x 6), 3 AOMs (3 x 3), 4 DIMs (4 x 1), 5 DOMs (5 x 1) = 36

(Maximum allowed Resource Count)

b. 5 DIMs (1 x 5), 5 OPTO DIs (1 x 5), 5 DOMs (1 x 5) = Resource Count 15

but maximum number of REMs allowed is 15

2-10

Edition 011100

Page 25

Installation Instructions for Innotech Genesis Systems

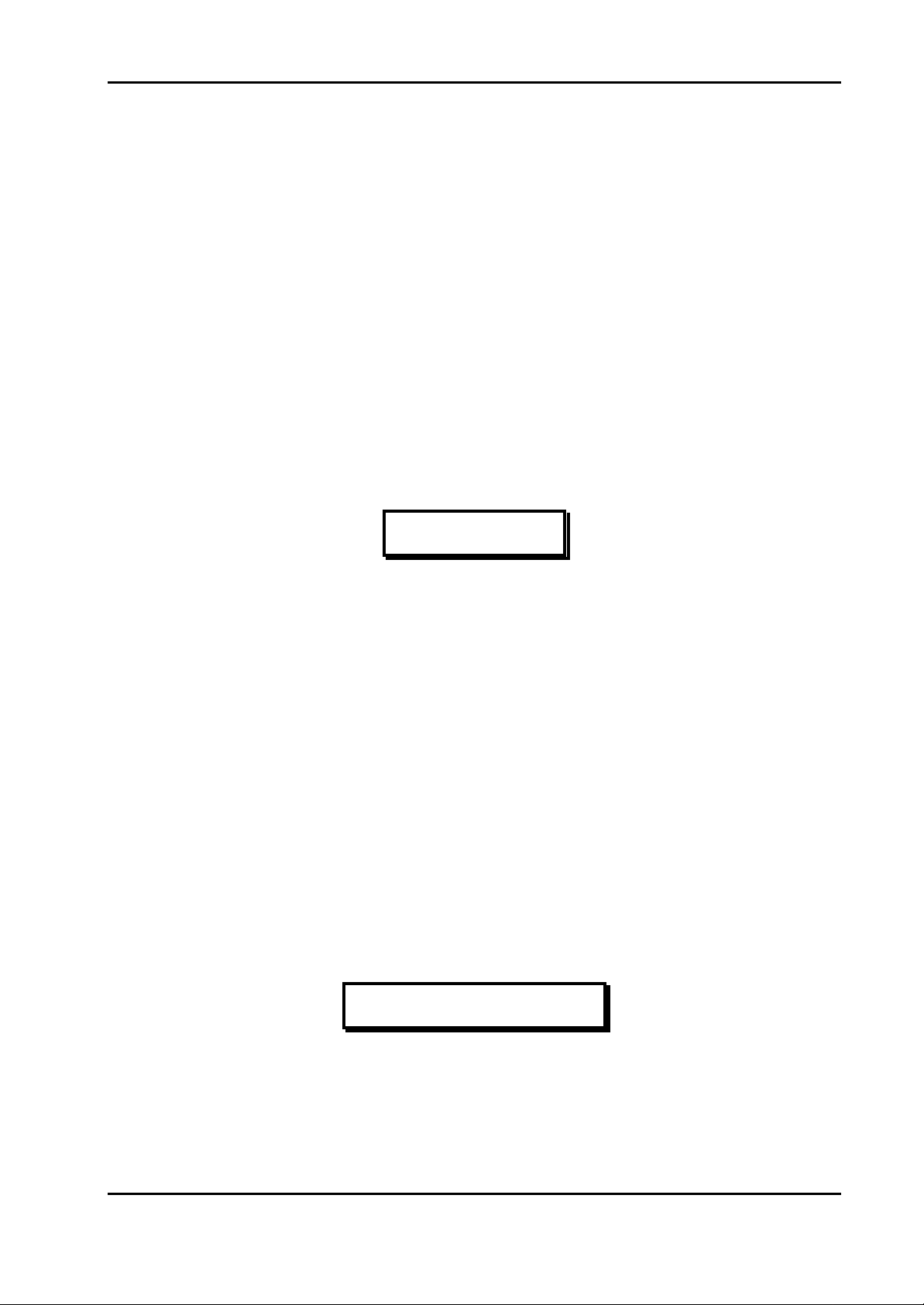

2-4.2. TYPICAL INSTALLATION. Figure 2-11 shows an example of a typical

installation using REMs.

GEN II AI

REM

(Note 3)

3

12

R

GEN II AIM REM

ABCDEFGHIJKLMNO

GEN II AO

REM

(Note 3)

3

12

R

GEN II AIM REM

ABCDEFGHIJKLMNO

45mm Slotted Cable Duct

Panel Size 600 X 900MM

GENESIS II

DIGITAL

CONTROLLER

Note 4

45mm Slotted Cable Duct

GEN II MP

REM

(Note 3)

GENESIS II

R

REMOTE MODULE INTERFACE

GEN II

R

RMI

Notes

1, 2

R

Digital

Controller

Power

Transformer

GEN II CS

REM

(Note 3)

45mm Slotted Cable Duct

Note 4

Terminal Strip

Standard Power Point (Outlet)

123

R

GEN II AIM REM

ABCDEFGHIJKLMNO

GEN II DO

REM

(Note 3)

123

GEN II AIM REM

ABCDEFGHIJKLMNO

GEN II DI

REM

(Note 3)

Auxiliary

Power

Transformer

Notes

1, 2

R

1.

See Appendix A for Wiring

NOTES

Requirements.

Cable run not to exceed

2.

500 metres.

See Paragraph 2-4.1 for

3.

limitations on number and

types of REMs.

65mm space between duct

4.

and terminals.

Edition 011100

Figure 2-11. Typical Remote System Layout.

2-11

Page 26

Installation Instructions for Innotech Genesis Systems

2-4.3. ADDITIONAL INSTALLATION GUIDELINES. For installation of the

Genesis II Digital Controller or GENII MPC system with REMs, observe the applicable

installation guidelines in Paragraph 2-3.2 and the following specific guidelines:

• Although the Genesis II Digital Controller should be mounted in a location providing easy

access to operating controls and indicators, this requirement does not apply to the Genesis

I Digital Controller and GENII MPC which have no external controls or indicators.

• Ensure the Digital Controller has been upgraded to Version 4.0 firmware to support the

REMs.

• Install the GENII RMI on a DIN rail mounting adjacent to the Digital Controller or GENII

MPC. The cable between the RMI and the Digital Controller/MPC must not exceed 1

metre in length.

• The Digital Controller/MPI can have only one GENII RMI connected to it.

• Local Expansion Modules cannot be connected to a Digital Controller/MPC that has a

GENII RMI module connected to it.

• REMs should be mounted in locations such that the cable run between the GENII RMI

and the REMs does not exceed 500 metres in length.

• REM units should be mounted on DIN rails in cabinets approved for switchgear or

industrial control equipment.

• Ensure that the types and quantities of REMs assigned to a controller are in accordance

with Paragraph 2-4.1.

2-12

Edition 011100

Page 27

Installation Instructions for Innotech Genesis Systems

SECTION 3- ELECTRICAL INSTALLATION

3-1. INTRODUCTION.

This section of the manual contains instructions and related data to facilitate the electrical

installation of the Genesis I or Genesis II System. Because of the electrical similarities of the two

systems, instructions contained in this section apply equally to the Genesis I and Genesis II

Systems, except where otherwise noted.

Because of the designed-in flexibility of the Genesis System, it can be installed in a wide variety

of configurations, depending on the user’s preference. For this reason it is not possible to include

all the various installation configurations in this manual. Instead, this manual provides examples

of installations that are considered typical. Innotech recognises that the installation examples

described in this manual may not be in total agreement with the user’s requirements. However,

information in this document should be used as a guide for all installations, regardless of whether

the specific circumstances match the examples given. In all cases, installation personnel should

familiarise themselves with the information contained in this section.

NOTE

If required, additional installation recommendations can be obtained

from Innotech Control Systems Australia upon request.

This section of the technical manual contains the following specific information:

• Electrical Installation Practices of a general nature

• Wiring information for controllers (Genesis I and II Digital Controllers and Genesis II Mid

Points Controller)

• Wiring information for expansion modules (Local Expansion Modules and Remote

Expansion Modules)

3-2. ELECTRICAL INSTALLATION PRACTICES.

This paragraph provides general information useable to qualified personnel installing the Genesis

Systems. More detailed information for wiring of controllers and expansion modules is contained

in subsequent paragraphs.

All wiring between the controller/expansion modules and system input/output devices, such as

sensors, fans, compressors, must be in accordance with the instructions in the applicable

instruction manual or data sheet.

ELECTRICAL POWER TO THE SYSTEM MUST BE TURNED

OFF THROUGHOUT THE INSTALLATION PROCESS. DO NOT

APPLY POWER TO ANY PART OF THE SYSTEM UNTIL READY

FOR COMMISSIONING (SEE SECTION 4).

Edition 011100

CAUTION

3-1

Page 28

Installation Instructions for Innotech Genesis Systems

NOTE

If any data presented in this manual disagrees with information in the

applicable instruction manual, information in the manufacturer’s

instruction manual takes precedence. Customers are encouraged to

contact Innotech Control Systems Australia for further information or

clarification of information presented herein. Use the address or

phone/fax number shown on the cover of this instruction manual.

Cabling plays an important role in the installation of the Genesis Systems. The following general

cabling guidelines should be observed:

• In all cases, use electromagnetic-shielded cable for sensor wiring.

• When necessary to protect cabling from physical damage, both shielding and physical

protection may be provided by running the cable in a metal conduit. Alternatively, use steel

wire armoured (SWA) cable, which also contains an electromagnetic shield.

• Avoid running cables in the vicinity of high voltage power cables or cables carrying switching

voltages/currents. This especially applies to sensor signal cables.

• Interconnecting cables must have multi-strand conductors with a cross-sectional area of 1mm

for each conductor.

• The earth cable to Genesis II enclosures must be 2.5mm

• For analogue inputs to the controller, a 16-conductor (0.5mm

2

.

2

) shielded cable is required.

2

Table 3-1 provides assistance in determining the cabling requirements for various installation

configurations. It shows the dimensions, wire gauge designations and resistance values per unit

length for common wire sizes. Use Table 3-1 to determine specific cabling requirements for your

installation.

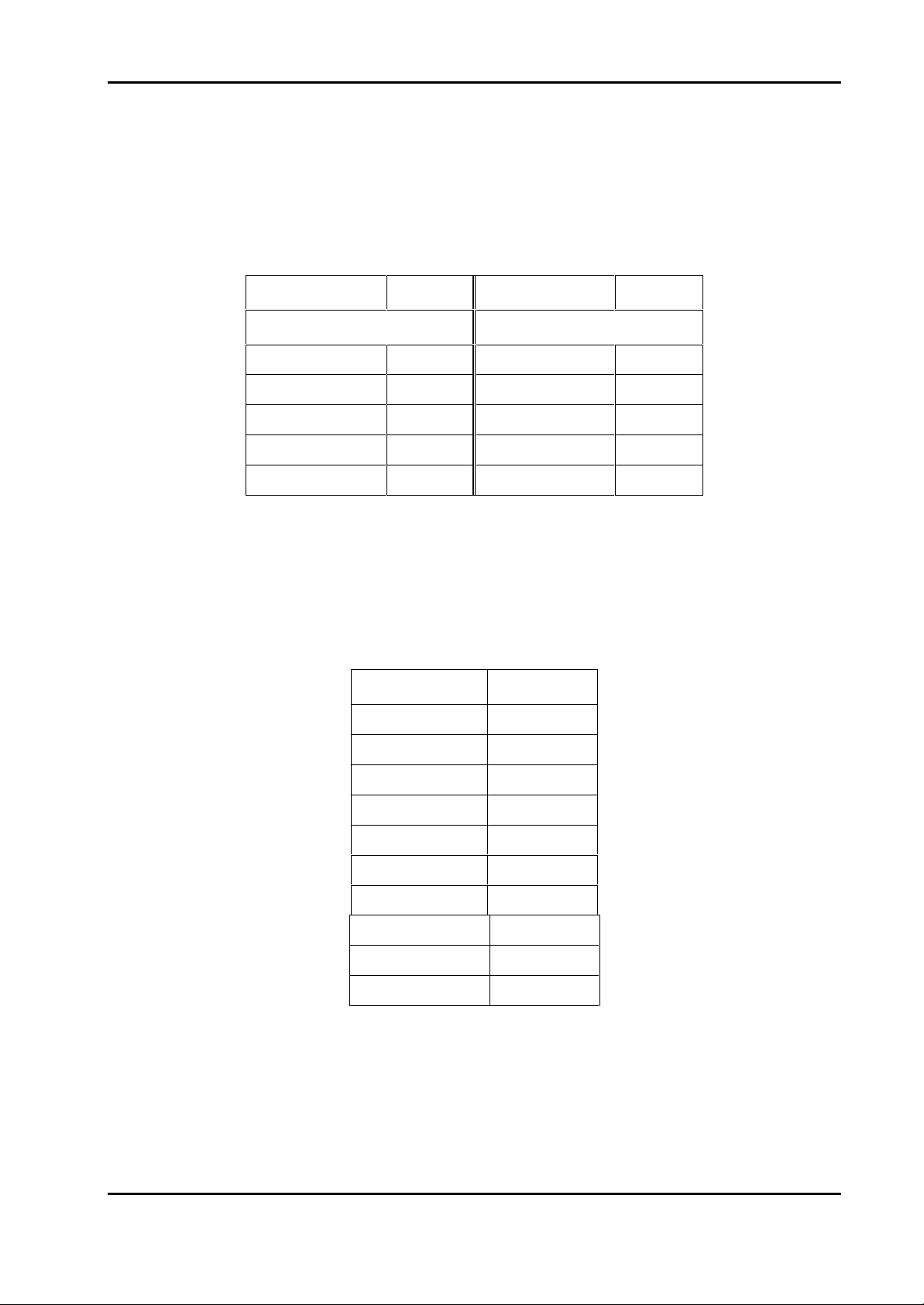

Table 3-1. Nominal Resistance for Wire Sizes at 20°C.

CONDUCTOR

AREA (mm2)

DIAMETER

(mm)

NEAREST

SWG OR

BWG

NEAREST

AWG

OHMS

PER 100

METRES

0.5 0.80 21 20 3.44

1.0 1.13 18 17 1.72

1.5 1.38 17 15 1.15

2.0 1.60 16 14 0.86

2.5 1.78 15 13 0.69

Notes:

1. SWG = Standard Wire Gauge, BWG = British Wire Gauge, AWG = American Wire Gauge.

2. All SWG, BWG & AWG numbers are for the next largest wire if a direct equivalent to the mm

wire size is not available.

2

3-3. CONTROLLER WIRING.

The following paragraphs contain input/output connection information for the Genesis II Digital

Controller, the Genesis II Mid Points Controller and the Genesis I Digital Controller. The

Genesis II Configuration Software, which is used to configure and program the controller,

3-2

Edition 011100

Page 29

Installation Instructions for Innotech Genesis Systems

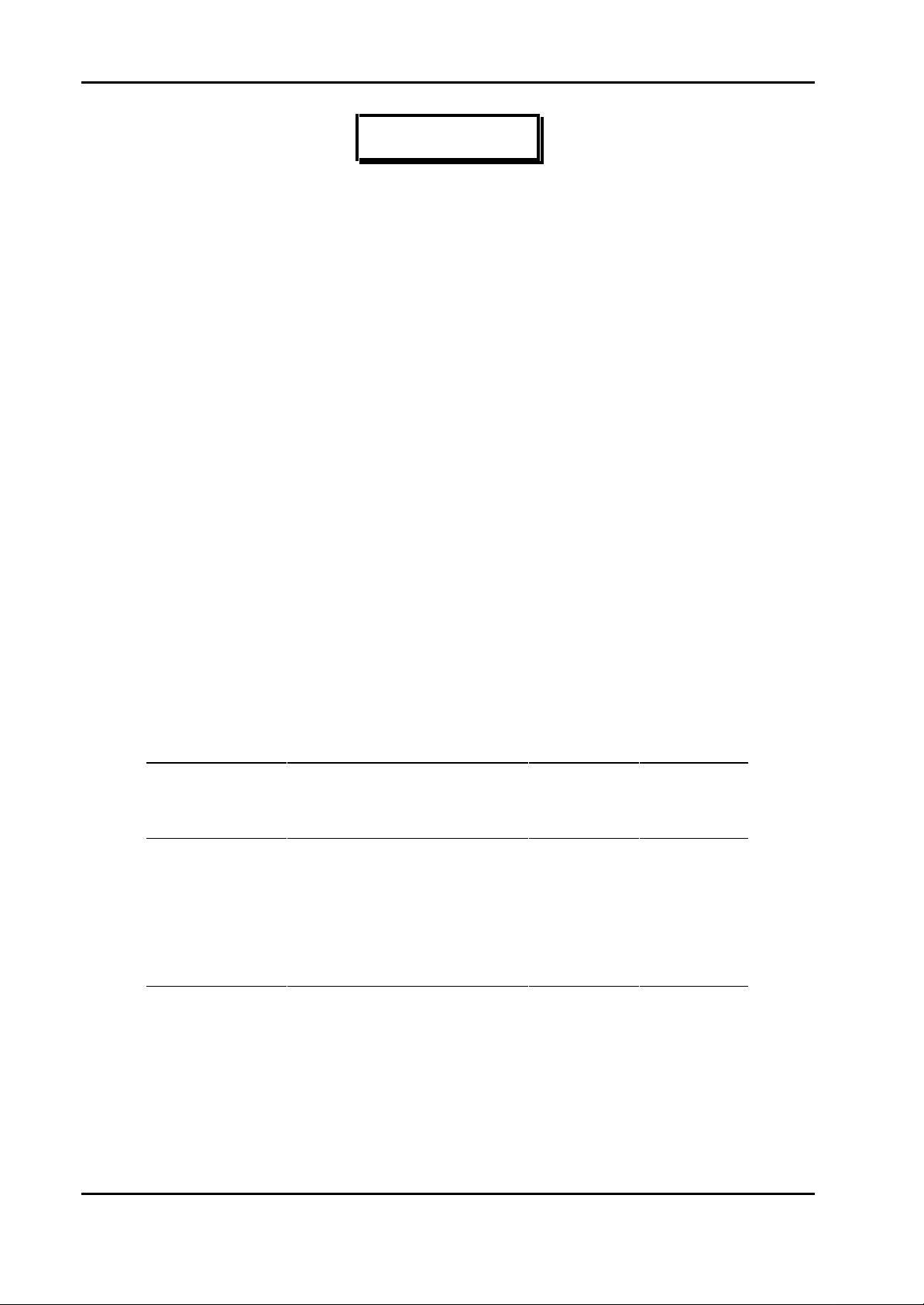

automatically produces a wiring diagram and materials list for the specific application. The

wiring diagram and materials list can be easily printed out and used for reference. Figure 3-1

shows a typical computer-generated wiring diagram. A printout of the wiring diagram and

materials list is usually provided at the time of hardware delivery.

NO NCCNCCNO NCCNO NCCNO NCCNO NCCNO NCCNO NO

SA Fan

Comp #1

DO #1 DO #2 DO #3 DO #4 DO #5 DO #6 DO #7

DIGITAL OUTPUTS

+

GND+24

21

-

Comp #2

Fault!

Alarm Panel Light

Air Compressor

Security Lights

Sprinkler Solenoid

VAV #3

SSR #3

VAV #4

SSR #4

Siren

DIGITAL INPUTS

DI1 DI2 DI3 DI4 DI5 DI6 DI7 DI8

Normally Open

Normally Open

Normally Closed

56 5758 59 60 61 62555453525150494847464544434241

DO #8

63 64

NCC

576 8 13 161514

838281

84

8887868580797877

Global Net

+

90 91 92 9389

-

C

+

-

01 03 04 05 06 07 08 09 10 11 12 13 14 15 16

65

1324 9 121110

66

6867

69

727170

7473

75

76

RS-485

VAV #1

SSR #1

VAV #2

SSR #2

VAV #5

SSR #5

ANALOGUE

OUTPUTS

RS-485

+

90 9189

+

93 9492

-

-

G

G

G

N

Alternative

Plug Style

ANALOGUE INPUTS

SCREEN MUST

GO HERE!

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TH7: Thermistor

AIM: <external>

RS-232

+

--------

+

+

+

+

+

+

+

SCR

SS

AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8

+

--------

+

+

+

+

+

+

+

12V PC

+

+

--

LEM COMMS

1817161514131211109876543

2019

36353433323130292827262524232221

37 38 3940

Air Flow Switch

A/H Button

Fridge Door Open

Sensor #1

Innotech Temperture

Sensor #2

Innotech Temperture

Sensor #3

Innotech Temperture

Sensor #4

Innotech Temperture

Sensor #5

Innotech Temperture

Sensor #6

Innotech Temperture

Switchboard Temp

Thermistor, Philips 10k

AI LEM #1, Terminal 3

NC

Innotech T emperature

Innotech T emperature

Innotech T emperature

Innotech T emperature

Innotech T emperature

Sensor #7

Sensor #8

Sensor #9

Sensor #10

Sensor #11

Edition 011100

GENESIS II DDCINNOTECH

(Wiring diagram - bottom board)

123

A1<not used>

SCREEN

DDC Terminal 35

JIHGFEDCBA

AI5 AI6 AI7 AI8 AI9

+

-----

+

+

+

+

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

TD1: 0-250 µAmps

Address

jumpers

A0

A2

A1

Local Expansion Module #1 (AI)

Figure 3-1. Computer-Generated Wiring Diagram, Example.

3-3

Page 30

Installation Instructions for Innotech Genesis Systems

M

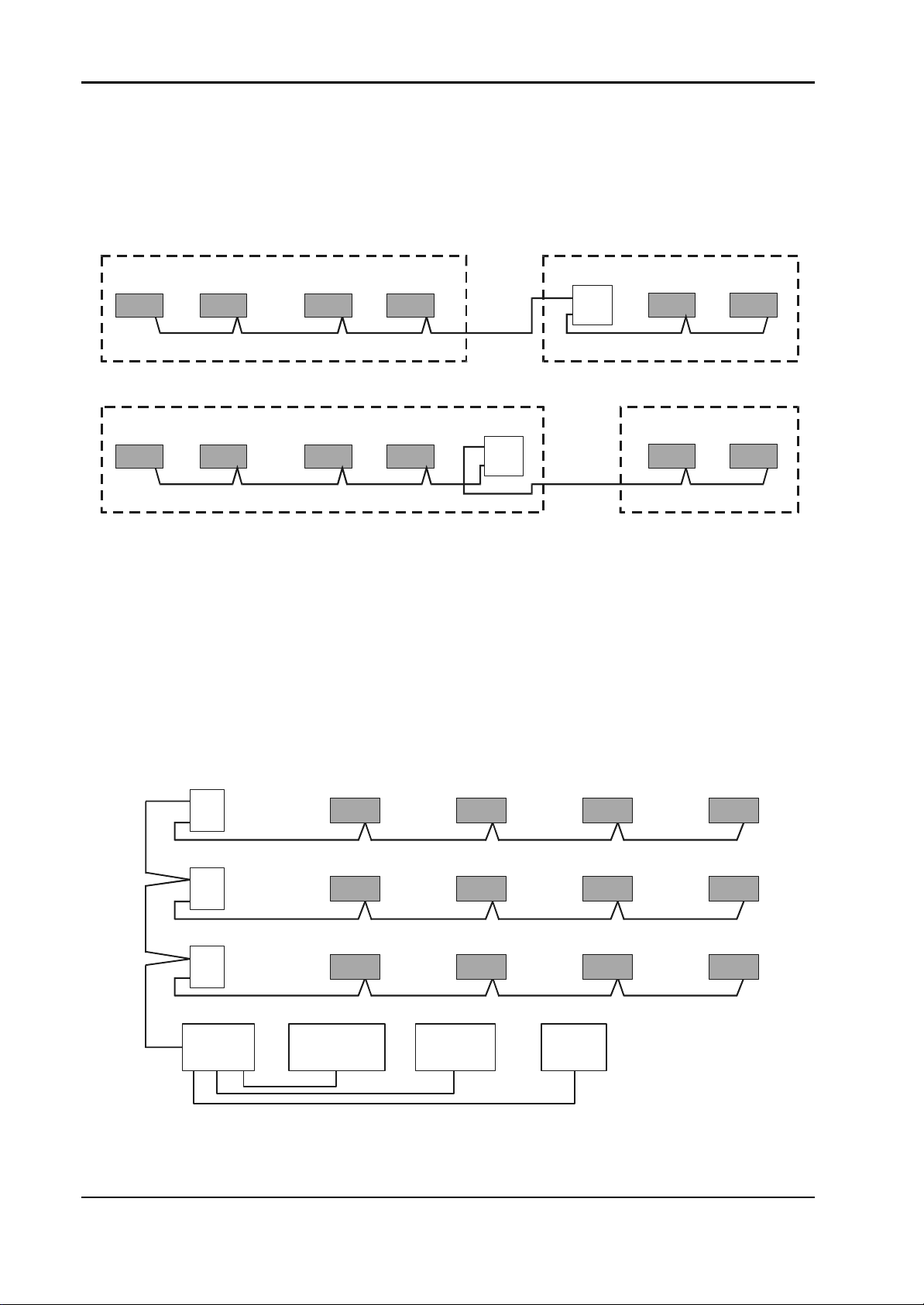

CTOR

M

CTOR

M

CTOR

M

CTOR

M

CTOR

RS

M

CTOR

M

CTOR

M

CTOR

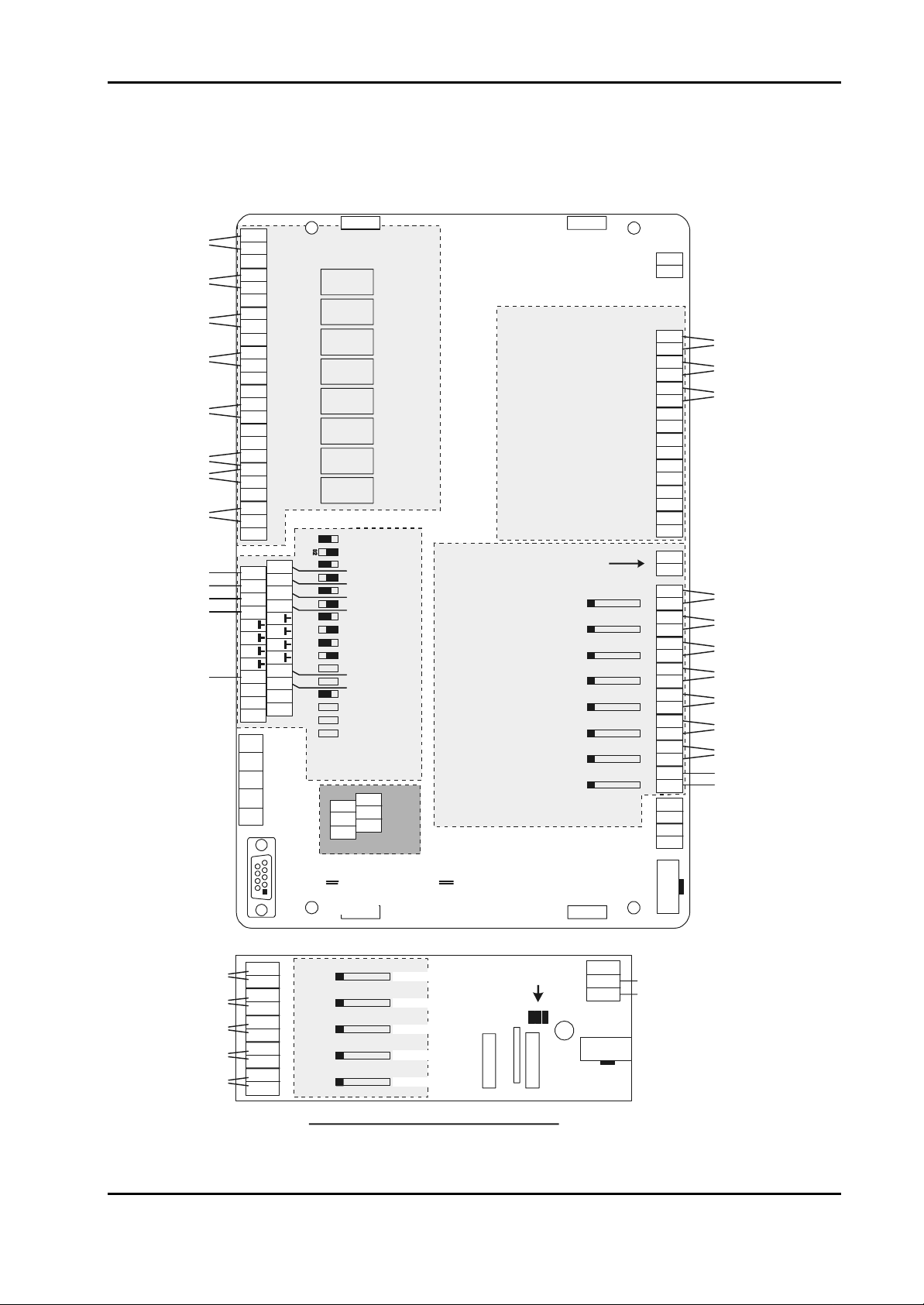

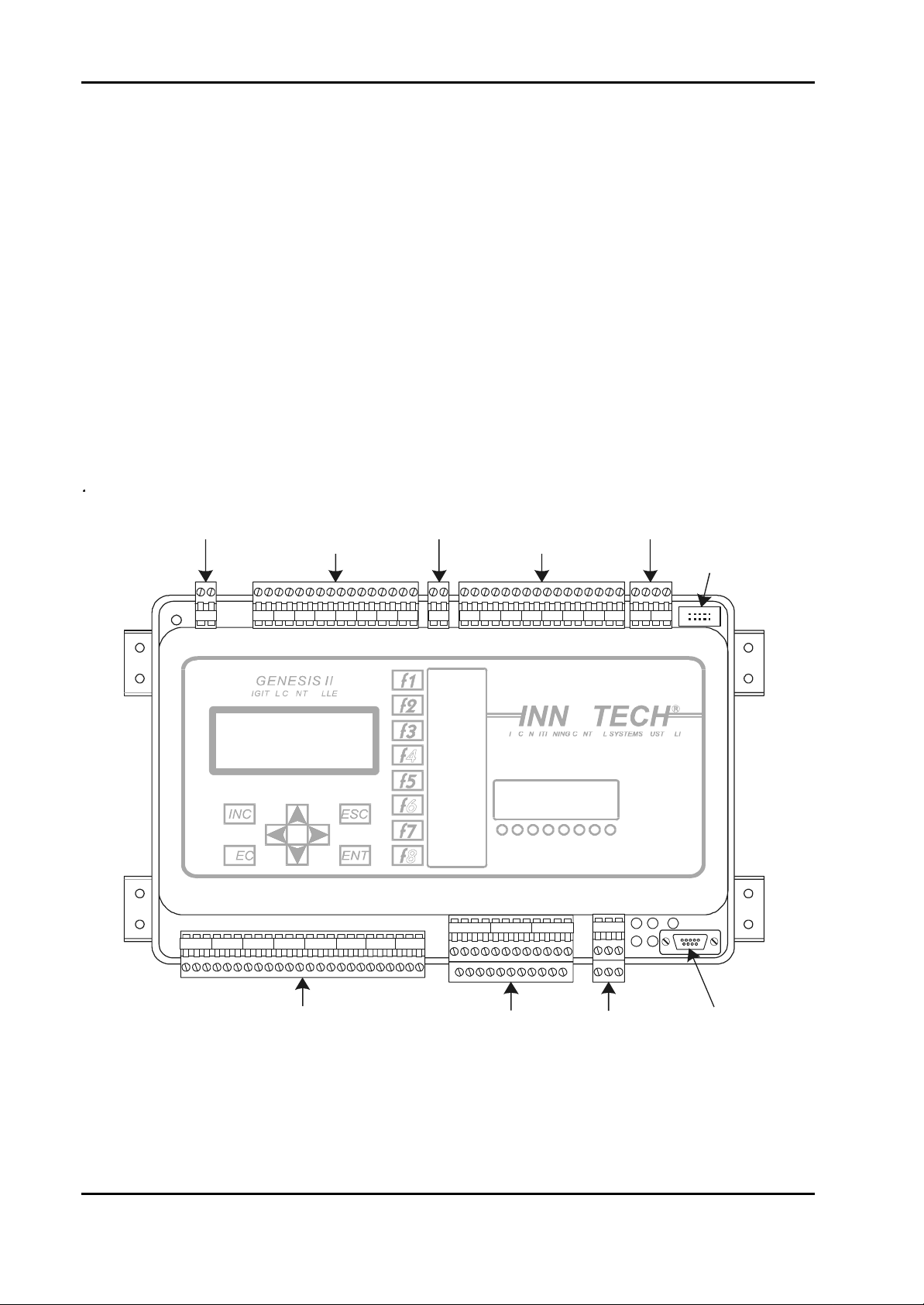

3-3.1. GENESIS II DIGITAL CONTROLLER. Figure 3-2 shows the

input/output connection groups for the Genesis II Digital Controller. The controller uses

Phoenix type plug-in terminal strips located around the controller’s perimeter. Both single row

and double row terminals are used. Terminals are grouped by function as follows:

• Power Input(Paragraph 3-3.1.1)

• Digital Inputs (Paragraph 3-3.1.2)

• Digital Outputs (Paragraph 3-3.1.3)

• Analogue Inputs (Paragraph 3-3.1.4)

• Analogue Outputs (Paragraph 3-3.1.5)

• Pulse Counter Inputs (Paragraph 3-3.1.6)

• Local/Remote Expansion Modules (LEM/REM) Connector (Paragraph 3-3.1.7)

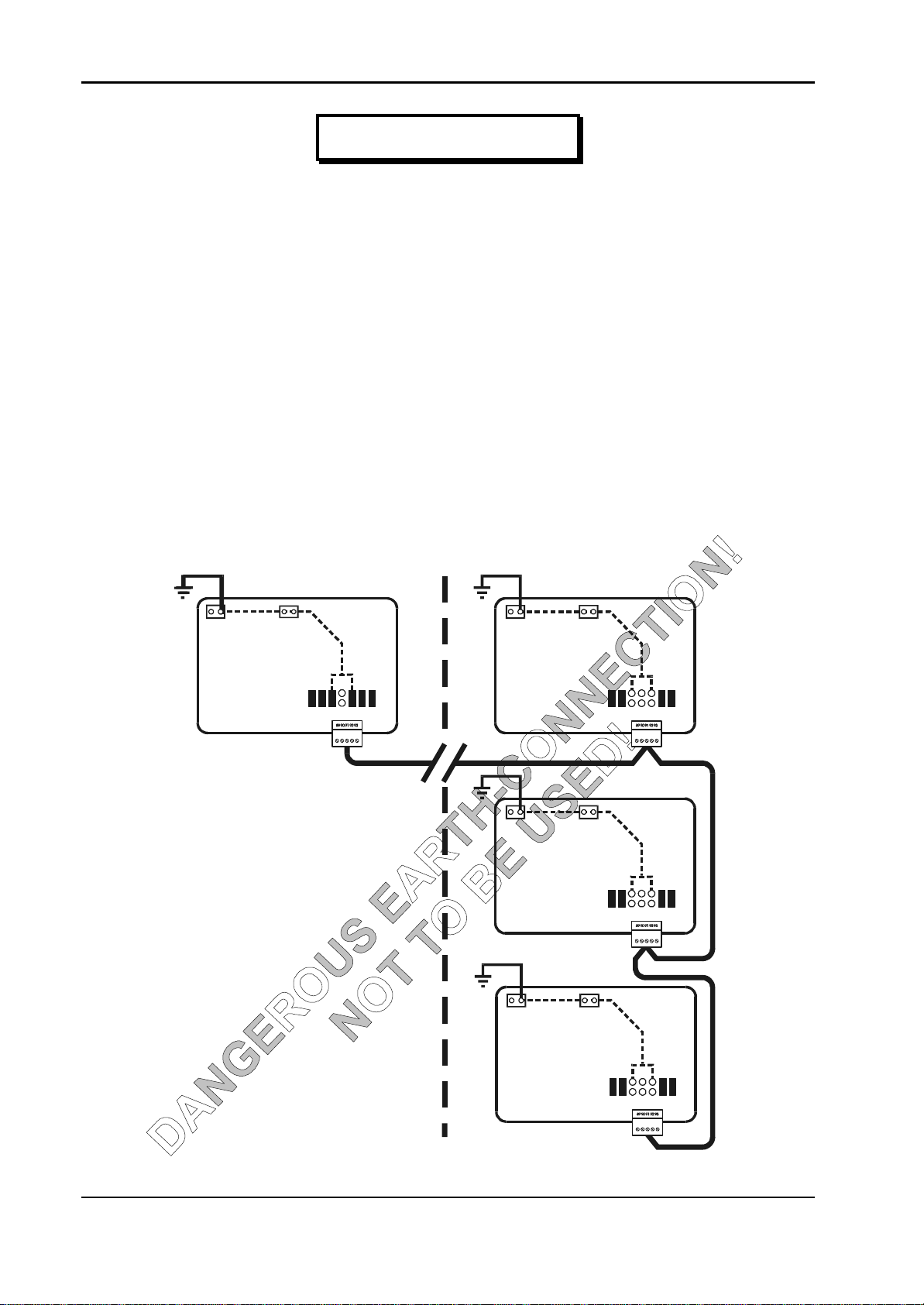

• RS485 Communications (Comms) Terminals (Appendix A)

• RS232 Connector (Appendix A)

24Vac POWERSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

POWER INPUTSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

POWER INPUTSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

POWER INPUTSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

POWER INPUTSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

L1L2L3

POWER INPUTSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

POWER INPUTSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

POWER INPUTSCREENSPULSE INPUTSDIGITAL INPUTSANALOGUE INPUTS

LEM/RE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

TOHEATERSTOHEATERSTOHEATE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

101112131415161718345678919202829303132333435362122232425262737383940

12

CONNE

12

ANALOGUEOUTPUT

3+ve4123+ve4123+ve4+

TERMINALS

484950515253545556575859606162636441424344454647727374757665666768697071899091

484950515253545556575859606162636441424344454647727374757665666768697071899091

484950515253545556575859606162636441424344454647727374757665666768697071899091

484950515253545556575859606162636441424344454647727374757665666768697071899091

484950515253545556575859606162636441424344454647727374757665666768697071899091

484950515253545556575859606162636441424344454647727374757665666768697071899091

484950515253545556575859606162636441424344454647727374757665666768697071899091

484950515253545556575859606162636441424344454647727374757665666768697071899091

POWER INPUT SCREENS PULSE INPUTS

DIGITAL INPUTS

ANALOGUE INPUTS

LEM/REM

CONNECTOR

12

48 49 5051 52 53 54 55 5657 58 59 606162 63 6441 42 43 4445 4647

10 11 12 13 1415 1617 183456789 19 20 28 29 30 31 3233 34 35 3621 22 23 2425 2627 37 38 39 40

89 90 91

75 7665 66 67 6869 70

727374

71

DIGITAL OUTPUTS

ANALOGUE

OUTPUTS

RS 485

COMMS

RS 232

CONNECTOR

Figure 3-2. Genesis II Digital Controller Input/Output Terminals.

3-4

Edition 011100

Page 31

Installation Instructions for Innotech Genesis Systems

3-3.1.1. Power Input. The Genesis II Digital Controller power requirements are:

• 24Vac ±10%, 50/60Hz at 1.0A, or

• 24Vdc ±10%, at 0.75A (Factory Modification is Required)

For 24Vac supply voltages, a safety transformer with a nominal rating of 30VA must be

used for the Digital Controller. The transformer must be in compliance with EN60742,

designed for 100% duty and fused in compliance with local safety regulations. A single

transformer may be used to supply voltage to more than one unit (such as a Digital

Controller and associated expansion modules) providing the planned load is well within the

transformer’s rating.

The transformer output terminal designated as AC Neutral must be solidly earthed to the

enclosure’s main earth link.

Power input terminals are Terminals 1 and 2 and connected as follows:

Terminal AC Supply DC Supply

1 24Vac +24Vdc

2 0Vac

(Neutral)

Note: Resistance between Terminal 2 and

earth must be 3 Ohms, or less

-24Vdc

3-3.1.2. Digital Inputs. The Genesis II Digital Controller’s eight digital input

channels (Terminals 3–18) provide the capability of directly interfacing to digital input

signal sources such as pushbutton switches and relay contacts. Because each digital input

channel is isolated, the power source for the signal must be external to the controller. This

signal source can be AC or DC. If the source is AC, it can be provided by the auxiliary

transformer. Signal power requirements are:

• 24Vac ± 15%, or

• 24Vdc ± 15% (Factory Modification Required)

There are two terminals associated with each digital input channel. If an external DC signal

source is used, the odd-numbered (left) terminal must be wired as positive and the evennumbered (right) terminal as negative.

Refer to Table 3-2 for digital input terminal number assignments. Signal names assigned to

the terminals are DI1+/− through DI8+/−. DI stands for Digital Input, the numeral

represents the channel number and the + or − indicates the signal polarity when using a DC

signal power source.

Edition 011100

3-5

Page 32

Installation Instructions for Innotech Genesis Systems

Table 3-2. Genesis II Digital Controller Digital Inputs.

TERMINAL SIGNAL TERMINAL SIGNAL

POSITIVE SIDE NEGATIVE SIDE

3 DI1+ 4 DI1−

5 DI2+ 6 DI2−

7 DI3+ 8 DI3−

9 DI4+ 10 DI4−

11 DI5+ 12 DI5−

13 DI6+ 14 DI6−

15 DI7+ 16 DI7−

17 DI8+ 18 DI8−

3-3.1.3. Digital Outputs. Each of the Genesis II Digital Controller’s eight digital

output channels (Terminals 41–64) consists of a single-pole, double-throw (SPDT) relay.

Three terminals assigned to each channel represent the associated relay’s Normally Open

(NO), Common (C) and Normally Closed (NC) contacts.

Digital output relay contacts are rated at 240Vac, 2A. Good practice is to use pilot relays

for the actual switching functions, particularly when it applies to inductive loads such as

coils, solenoids and motors. This protects the relays of the digital output channel and has

the advantage of allowing the pilot relays to be installed adjacent to the controlling

switchgear.

Refer to Table 3-3 for digital output terminal number assignments.

Table 3-3. Genesis II Digital Controller Digital Outputs.

TERMINAL SIGNAL TERMINAL SIGNAL TERMINAL SIGNAL

NORMALLY

OPEN (NO)

41 DO1NO 42 DO1C 43 DO1NC

44 DO2NO 45 DO2C 46 DO2NC

47 DO3NO 48 DO3C 49 DO3NC

50 DO4NO 51 DO4C 52 DO4NC

53 DO5NO 54 DO5C 55 DO5NC

56 DO6NO 57 DO6C 58 DO6NC

COMMON (C)

NORMALLY

CLOSED (NC)

3-6

59 DO7NO 60 DO7C 61 DO7NC

62 DO8NO 63 DO8C 64 DO8NC

Edition 011100

Page 33

Installation Instructions for Innotech Genesis Systems

3-3.1.4. Analogue Inputs. The Genesis II Digital Controller’s eight analogue input

channels (Terminals 21-36) allow the direct interface of various analogue inputs, such as

Thermistor, 0-10Vdc, 0-5Vdc and 4-20mA signals. Each analogue input channel is

configured to the type of input by the use of Analogue Input Signal Conditioners (AISCs).

These are small plug inserts installed during system commissioning (Section 4).

CAUTION

SPECIAL CONSIDERATION MUST BE MADE WHEN USING

LOOP-POWERED 4-20MA INPUTS. BECAUSE THIS TYPE OF

INPUT DRAWS 20MA FROM THE DIGITAL CONTROLLER, A

MAXIMUM OF TWO INPUTS OF THIS TYPE MAY BE USED.

THIS TYPE OF INPUT MUST NOT BE USED ON LOCAL OR

REMOTE EXPANSION MODULES.

NOTE

Terminals 19 and 20 (Figure 3-2) are provided for terminating

analogue cable screens.

There are two terminals associated with each of the eight analogue input channels.

Normally, the odd-numbered (positive) terminal is used for the active analogue input signal

from the sensor. The even-numbered (negative) terminal is used to provide the stimulation

for the sensor or a voltage reference (such as 0 Volts) for an active transducer.

Due to the sensitivity of the analogue input signals, screened cable must be used. The

screens should be terminated at Terminals 19 or 20.

Refer to Table 3-4 for analogue input terminal number assignments. Signal names assigned

to the terminals are AI1+/− through AI8+/−. AI stands for Analogue Input; the numeral

represents the channel number. The + indicates the active signal and the − indicates the

signal reference/return.

Table 3-4. Genesis II Digital Controller Analogue Inputs.

TERMINAL SIGNAL TERMINAL SIGNAL

ACTIVE REFERENCE

21 AI1+ 22 AI1−

23 AI2+ 24 AI2−

Edition 011100

25 AI3+ 26 AI3−

27 AI4+ 28 AI4−

29 AI5+ 30 AI5−

31 AI6+ 32 AI6−

33 AI7+ 34 AI7−

35 AI8+ 36 AI8−

3-7

Page 34

Installation Instructions for Innotech Genesis Systems

RS

RS

3-3.1.5. Analogue Outputs. Sixteen analogue output channels are provided. Each

channel can be configured, through the Genesis II Configuration Software, to operate in

either the Variable Mode or the Heat Valve Mode.

In the Variable Mode, the output is a voltage-analogue signal varying from 0 to +10 Volts

with a maximum current rating of 5mA. In the Heat Valve Mode, the output signal consists

of Pulse-Width Modulated (PWM), 0-10V, high-speed pulses at 5mA. For a description of

PWM as it applies to Heat Valve Operation, refer to the Innotech Genesis II Direct Digital

Controller User Manual.

When using PWM outputs, up to three solid state relays, connected in series, may be used

on each Heat Valve-configured analogue output channel. See Figure 3-3. A maximum of

eight analogue output channels can be applied to Heat Valve operation. For more than eight

Heat Valve outputs, it is recommended that Models IHV4002 or IHV4004 Heat Valves for

Solid State Relays be used. These heat valves are driven by the Digital Controller’s

analogue output channel in the Variable Mode. For more information on these devices,

refer to Data Sheet DS3.31 for Type IHV Heat Valves.

L1L2L3

L1L2L3

TOHEATERSTOHEATERSTOHEATE

TOHEATERSTOHEATERSTOHEATE

12

ANALOGUEOUTPUT

12

ANALOGUEOUTPUT

3+ve4123+ve4123+ve4+

TERMINALS

3+ve4123+ve4123+ve4+

TERMINALS

L3

TO

HEATERS

12

ANALOGUE

L1 L2

TO

HEATERS

12

12

TO

HEATERS

OUTPUT

TERMINALS

-

+

3+ve 4

3+ve 4

3+ve 4

Figure 3-3. Driving Multiple Solid-State Relays.

Refer to Table 3-5 for analogue output terminal numbers. There are 16 analogue active

signal terminals (AO1 through AO16), one for each channel and eight return (Common)

terminals. The fewer number of Common terminals is intended to reduce the overall

number of terminals.

Cable screening may be terminated into the Screens Terminals (19 and 20), space

permitting. Alternatively, all cable screens can be combined by soldering within the slotted

cable-routing ducts with a common 1mm2-earth lead connected to Terminals 19 or 20.

3-8

Edition 011100

Page 35

Installation Instructions for Innotech Genesis Systems

Table 3-5. Genesis II Digital Controller Analogue Outputs.

TERMINAL SIGNAL TERMINAL SIGNAL

65 AO1 77 AO5

66 AO2 78 AO6

67 AO3 79 AO7

68 AO4 80 AO8

69 Common 81 Common

70 Common 82 Common

71 Common 83 Common

72 Common 84 Common

73 AO9 85 AO13

74 AO10 86 AO14

75 AO11 87 AO15

76 AO12 88 AO16

3-3.1.6. Pulse Counter Inputs. A single, high-speed digital input is provided to

facilitate the counting of rectangular wave signals (0-12Vdc, from DC up to 25kHz). Refer

to Table 3-6 for terminal number assignments. Terminals 37 and 38 provide 12Vdc power

to the pulse source, if required. Terminals 39 and 40 are the pulse-input terminals. The

input is polarity sensitive so it is important that correct polarity be observed.