Page 1

Innotech Device Network Cabling

INSTALLATION INSTRUCTIONS

Page 2

Proprietary

No part of this technical manual may be reproduced, transmitted, transcribed, stored in a retrieval

system, or translated into any language or computer language, in any form or by any means, without

prior written permission of Mass Electronics Pty Ltd.

Trademark

The term ‘Innotech’ used in this manual is a trademark of Mass Electronics Pty Ltd trading as

Innotech Control Systems Australia.

Disclaimer

While great eorts have been made to assure the accuracy and clarity of this document, Mass

Electronics Pty Ltd assumes no liability resulting from any omissions in this document, or from

misuse of the information obtained herein. The information in this document has been carefully

checked and is believed to be entirely reliable with all of the necessary information included. Mass

Electronics Pty Ltd reserves the right to make changes to any products described herein to improve

reliability, function, or design, and reserves the right to revise this document and make changes

from time to time in content hereof with no obligation to notify any persons of revisions or changes.

Mass Electronics Pty Ltd does not assume any liability arising out of the application or any use of any

product or circuit described herein; neither does it convey licence under its patent rights or the rights

of others.

Edition 3.0 dated 05.12.2013

Page 2

© Mass Electronics Pty Ltd 2007

Page 3

Document Management

Document Title:

Innotech® Device Network Cabling Installation

Instructions

Revision History

Version

Number

1.7 October 2007 Initial Document Release.

1.8 May 2008 Added REM EOL Information. Section 4 Revised.

1.9 July 2008 Technical Update.

2.0 October 2009

3.0 December 2013

Date Summary of Changes

Added UM01, IG01, IG02 & IG03. Updated information for maximum

cable lengths, maximum devices before repeater, updated

descriptions and graphics.

File Type Converted, Style Update, Contact Details Update, Added

Maxim 1010 & IWS01.

Page 3

© Mass Electronics Pty Ltd 2007

Page 4

This page has been le intentionally blank.

Edition 3.0 dated 05.12.2013

Page 4

© Mass Electronics Pty Ltd 2007

Page 5

Contents

Chapter 1 - Common Requirements ..............................................................11

1-1 Definition of RS485 or EIA-485 .................................................................................12

1-1.1 Termination ............................................................................................................. 12

1-1.2 Biasing ...................................................................................................................... 12

1-1.3 Communications speed ..........................................................................................12

1-2 Definition of Earth Types ......................................................................................... 13

1-3 Earth Points ..............................................................................................................13

Chapter 2 - Primary Networks ......................................................................15

2-1 Continuous Screen .................................................................................................. 18

2-2 Management of other devices on the Primary Network ........................................ 19

2-2.1 HMIs and Converters ...............................................................................................19

2-2.2 Control Stations (ICS) and DynaLite Gateway (IG02) ............................................. 20

2-2.3 Earth Connections ................................................................................................... 21

2-3 BACnet Gateway (IG03) ............................................................................................ 23

2-4 Older Controllers .....................................................................................................23

2-5 Isolated Devices ....................................................................................................... 23

2-6 Dual Channel Repeaters .......................................................................................... 24

2-6.1 Older Repeaters .......................................................................................................24

2-6.2 New Repeaters .........................................................................................................25

2-7 End of Line Termination (EOL) ................................................................................ 25

Chapter 3 - Sub Network Devices .................................................................. 27

3-1 REM Network ............................................................................................................ 28

3-1.1 So Earth .................................................................................................................30

3-1.2 End of Line Termination (EOL) ................................................................................ 30

3-2 Sub System Network ...............................................................................................32

3-2.1 VAVMax (VM01) and MicroMAX (UM01) .................................................................... 33

3-2.2 MiniMAX (MM02) ....................................................................................................... 33

3-3 IR11 Single Channel Repeater ................................................................................. 33

3-4 Network with VAVMax, MiniMAX and MicroMAX devices ........................................ 33

3-5 End of Line Termination (EOL) ................................................................................ 34

Page 5

© Mass Electronics Pty Ltd 2007

Page 6

Chapter 4 - General Specifications ................................................................37

4-1 Network Specifications ...........................................................................................38

4-2 Cable Specifications ................................................................................................ 38

4-2.1 Primary Network .....................................................................................................39

4-2.2 Sub Networks ...........................................................................................................39

Chapter 5 - Glossary ....................................................................................41

5-1 Glossary of Terms.....................................................................................................42

Chapter 6 - Factory Settings for RS485 EOL Termination ................................. 43

6-1 Factory Settings ....................................................................................................... 44

Customer Assistance ...................................................................................................... 46

Innotech Support ..............................................................................................................46

Edition 3.0 dated 05.12.2013

Page 6

© Mass Electronics Pty Ltd 2007

Page 7

List of Illustrations

Figure 2-1:

Figure 2-2:

Figure 2-3:

Figure 2-4:

Figure 2-5:

Figure 2-6:

Figure 2-7:

Figure 2-8:

Figure 2-9:

Figure 2-10:

Figure 2-11:

Figure 2-12:

Figure 2-13:

Figure 3-1:

Figure 3-2:

Figure 3-3:

Figure 3-4:

Typical Screen Connections ...................................................................................18

Earth Connection ....................................................................................................18

Incorrect HMI or Converter Comms Connection ...................................................19

Correct HMI or Converter Comms Connection ......................................................19

Incorrect Station IG02 Comms Connection ...........................................................20

Correct Station IG02 Comms Connection .............................................................. 20

Correct Station ICS / IG02 Network Connection .................................................... 20

End of Run Mounted HMIs or Converters ............................................................... 21

Remote Mounted HMIs or Converters ....................................................................22

Options to eliminate earth potential dierences between networks .................. 22

Correct Wiring of Innotech BACnet Gateway Communications ............................23

Old Style Repeater ..................................................................................................24

New Style Repeater .................................................................................................25

REM Network ........................................................................................................... 30

Simple REM Network...............................................................................................30

REM Network with Repeater ...................................................................................31

REM Network with Controller in the Middle of the run .........................................31

Figure 3-5:

Figure 3-6:

Figure 3-7:

Figure 3-8:

Figure 3-9:

Figure 3-10:

REM Network with Repeater in the Middle of the run ...........................................32

Sub System Network Connections ......................................................................... 33

Simple Sub System Network ..................................................................................34

Sub System Network with a Repeater.................................................................... 34

Sub System Network with IG01 in the middle of a run..........................................35

Sub System Network with a Repeater in the middle of a run ...............................35

Page 7

© Mass Electronics Pty Ltd 2007

Page 8

List of Tables

Table 1-1:

Table 2-1:

Table 3-1:

Table 3-2:

Table 4-1:

Table 5-1:

Table 6-1:

Earth Types ..............................................................................................................15

Primary Network Digital Controllers and Devices ................................................. 18

REM Network Controllers and Devices ................................................................... 30

Sub System Network Controllers and Devices ......................................................34

Repeater Requirements ..........................................................................................40

Primary Network Digital Controllers and Devices ................................................. 44

Factory Settings for RS486 End of Line Termination ............................................. 46

Edition 3.0 dated 05.12.2013

Page 8

© Mass Electronics Pty Ltd 2007

Page 9

Technical Manual Overview

The Installation Manual for Innotech Device Network Cabling is part of a series of technical manuals

designed to provide the customer with complete and comprehensive documentation supporting the

Innotech Digital Control system. It contains detailed information for the primary network and the two

sub networks.

• Network Connections

• Earth connection rules

• End Of Line Termination

• Descriptions on dierent comms hardware improvements

About this Manual

This instruction manual is intended to provide the user with complete and easy-to-follow instructions

for installation of Innotech Communication networks. In preparing these instructions, Innotech

assumed that the installer is familiar with the installation of RS485 Communication networks.

The following instructions and procedures are presented at a technical level that assumes familiarity

with networks and local electrical rules and regulations.

Because each network is designed to be configured to its own application requirements and since

each customer's application is dierent, no two sites will be the same. However, the following rules

and information will cover any possible scenarios.

Organisation of this Manual

This instruction manual has six sections:

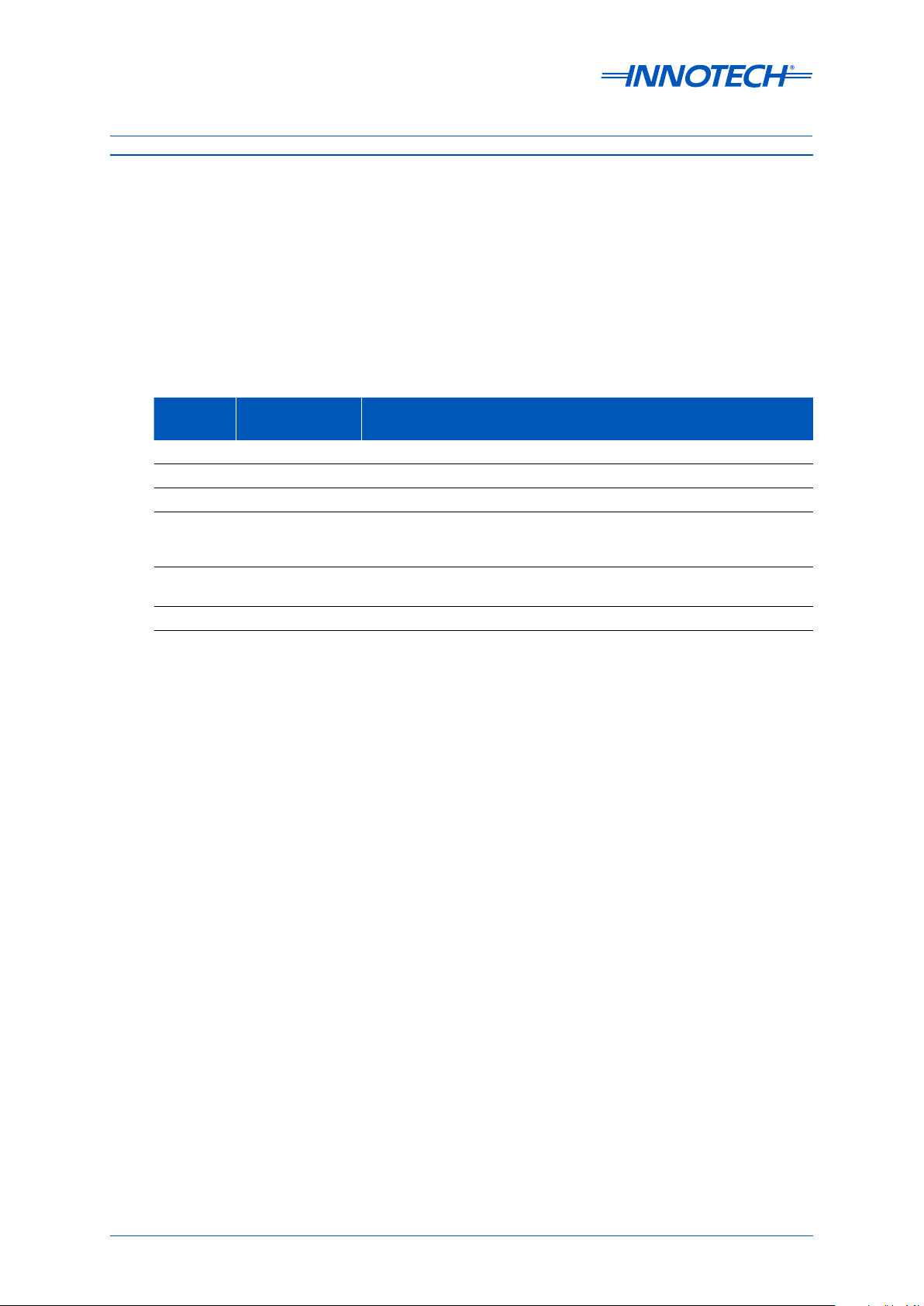

Table 1: Document Organisation

Chapter

Number

Chapter 1

Chapter 2 Primary Networks

Chapter 3

Chapter 4

Chapter 5 Glossary of Terms

Chapter 6

Chapter Title Description

Common

Requirements

Sub Network

Devices

General Cable

Specifications

Factory Settings for

RS485 End of Line

Termination (EOL)

Provides a description of the common network requirements.

Provides a description of the primary network and how each

device can be connected to the network and a total overview of

the network requirements.

Provides a description of Sub Network Devices and how each

device can be connected to the network and a total overview of

the network requirements.

The two types of sub networks are the Remote Expansion

Modules, (REM’s) and the Sub System Network.

Provides a list of the general network rules that apply to all networks and the cable specifications.

The Glossary of Terms is intended to ensure that the contents of

this manual are clear and easily understood by the reader.

The glossary contains simple explanations of the technical terms

used in this manual; explanations are given in non-technical

language where possible.

Provides a table of the Factory Settings for RS485 End of Line

Termination (EOL).

Page 9

© Mass Electronics Pty Ltd 2007

Page 10

This page has been le intentionally blank.

Edition 3.0 dated 05.12.2013

Page 10

© Mass Electronics Pty Ltd 2007

Page 11

Innotech Device Network Cabling

INSTALLATION INSTRUCTIONS

Chapter 1 - Common

Requirements

Page 12

Innotech Device Network Cabling Installation Instructions

1-1 Definition of RS485 or EIA-485

The term RS485 is outdated and was replaced with the latter specification called EIA-485 [TIA-485]

balanced (dierential) communication interface however the industry still uses RS485 and it is still

used in this manual.

‘Balanced’ means that two signal wires are required to produce an alternating signal pattern. i.e. if

the [+] terminal is measuring +5V then the [-] terminal is reading 0V, conversely if the [-] terminal is

measuring +5V then the [+] terminal is reading 0V.

For reliability, when interconnecting dierent equipment, 3 wires are required. Typically those are

named [+, -, 0V or S]. [+/-] and are used for data. [S] is the signal reference. Instead of having an

individual third wire for [S], the shield from the Shielded Twisted Pair (STP) cable is used.

The RS485 interface is operating in ‘half duplex’ mode. Meaning only one transmitter can be active

at the time but many receivers can listen simultaneously. A period of ‘silence’ is used to free the

interface for another transmitter to become active.

Two more terms are frequently mentioned in conjunction with RS485.

1-1.1 Termination

EOL: Will be referred to as ‘End of Line’ termination, in this manual.

A resistor (load) connected between terminals [+/-] of typically 120 Ohms.

There is one resistor connected at each end of a cable.

It is sometimes user selectable or fixed internally to the device.

1-1.2 Biasing

These are referred to as ‘Pull-up/Pull-down’ or ‘Idle-line failsafe’ resistors.

A weak current limited power supply individually connected to terminals [+ and -] to define the 485

interface to be Idle or silent when no transmitter is active, which is important to operate reliably in

‘half duplex’ mode.

The idle bias level can be checked with a voltmeter measuring between terminals [+ and -].

The reading is to be greater than +/-200mV.

NOTE

Ensure that there is no comms activity while measuring.

1-1.3 Communications speed

Faster is not always better. Speed is a trade o between cable length and cable quality, link

reliability, controller processing capability, cost and data quantities.

There is no doubt that increasing network speed makes networks more diicult to set up or fault find.

Therefore it is important to take care during installations on where, how and what cables are routed

between controllers.

The selected speeds of Innotech networks of controllers and wiring instructions in this manual are

set out to achieve the best reliability.

Edition 3.0 dated 05.12.2013

Page 12

© Mass Electronics Pty Ltd 2007

Page 13

Innotech Device Network Cabling Installation Instructions

1-2 Definition of Earth Types

There are three types of earth referred to in this document:

• Bonded, hard or clean

• So

• Floating

These definitions are listed below in relation to the Innotech networks.

Table 1-1: Earth Types

Typ e Description

Bonded,

Hard or

Clean

So

A bonded, hard or clean earth is defined as a low impedance earth point with little

or no chance of conducted noise either already present or likely to be created when

bonded to a circuit. For Innotech’s reference we also explicitly mean there is no

potential dierence to true earth.

A so earth is where there is a path to earth via a circuit. This provides a tie to earth so

potential dierences are minimised. This path has higher impedance than a bonded

earth. This does force strong earth currents, i.e. leakage currents from large AC motors,

to remain on the proper heavy gauge earth wires, while leaving the so earth paths

unaected. So whilst having multiple earth connections we have not created any

eective earth loops.

So earth is oen used in 24 V supplied devices. The ‘tie to earth’ is in fact a ‘tie to 0 V’

because there is no dedicated earth terminal available. It is therefore expected that

the 0 V is earthed near the supply transformer.

Floating

Floating simply means that there is no path to an Earth point at all provided by the

device, not even a so earth path. A floating device has no earth.

1-3 Earth Points

It is imperative that the screen is earthed at one point only and this is defined as any point along a

network that is the best earth point along its length. Where ‘best’ earth point, is the point with least

amount of earth potential fluctuations. i.e. A controller in the basement of a high rise building is

closest to a good earth point than a controller in the plant room on top of the roof.

While there are internal jumpers on some devices to link the ‘S’ terminal internally to earth, there are

variants in hardware types and revisions, simply connect a bonded earth as shown externally. This

will suit all installations, regardless of age. If a repeater is installed each side of the repeater is to be

treated as a separate standalone network and each must have an earth connected.

NOTE

When there is more than one connection point to earth the screen becomes a conductor and no longer performs

correctly. Care should be taken to ensure only one bonded earth point is ever connected on a primary network.

Refer to Chapter 2-6 for details on use of a Repeater in a primary network.

Chapter 1 – Common Requirements

Page 13

© Mass Electronics Pty Ltd 2007

Page 14

Innotech Device Network Cabling Installation Instructions

This page has been le intentionally blank.

Edition 3.0 dated 05.12.2013

Page 14

© Mass Electronics Pty Ltd 2007

Page 15

Innotech Device Network Cabling

INSTALLATION INSTRUCTIONS

Chapter 2 -

Primary Networks

Page 16

Innotech Device Network Cabling Installation Instructions

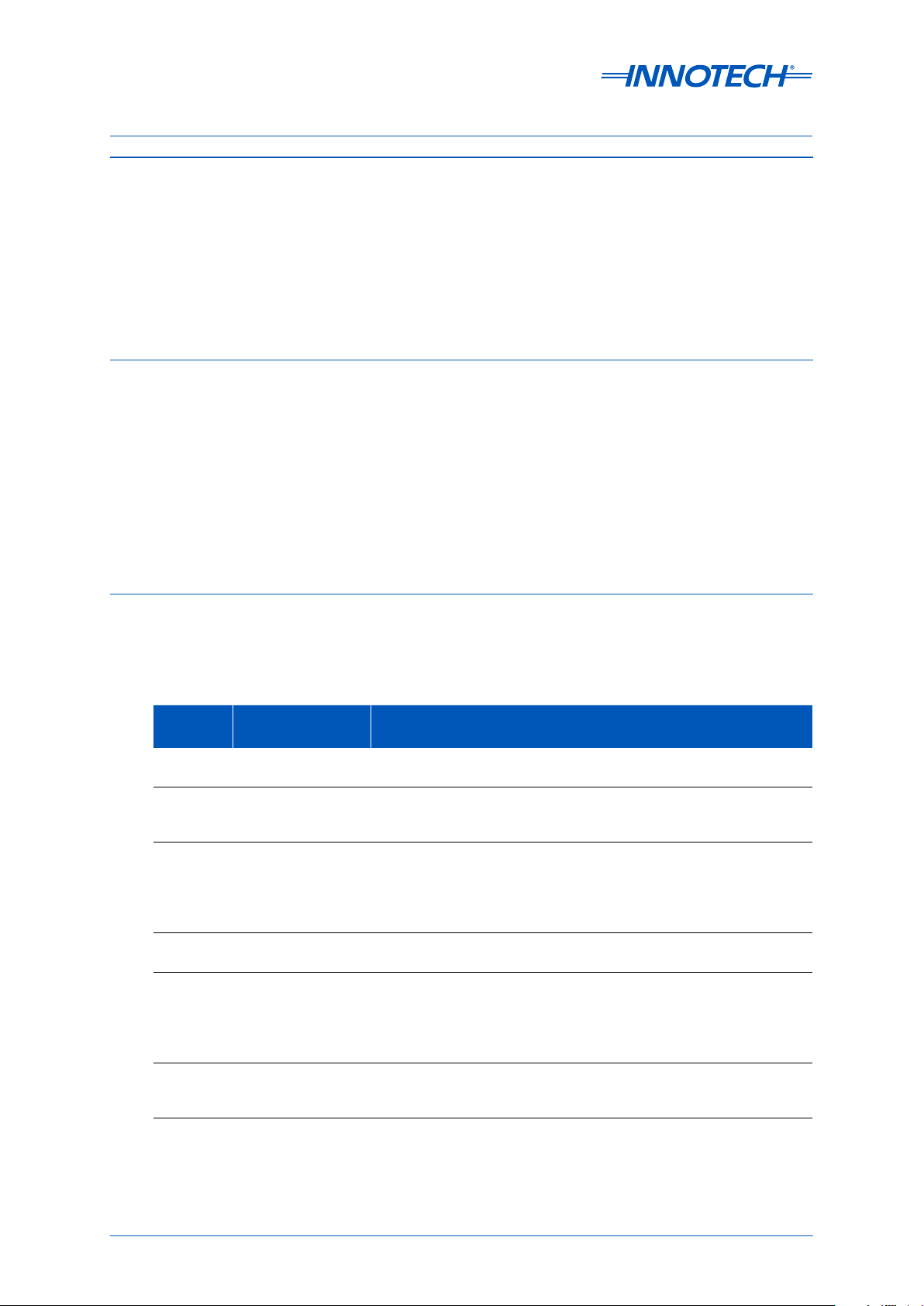

Primary Network Devices

There are twenty-three devices that connect directly to the primary Innotech network. These are

listed in table 1 below:

Table 2-1: Primary Network Digital Controllers and Devices

Part

Number

GENIIxLD

MPCIILN

GENESIS II V4

GENII MPC

GENESIS II V3

MAXIM 1010

Comms

Ter minal s

G+ S N+G- N-

G+ S N+G- N-

G+ S N+G- N-

G+ S N+G- N-

G+ SG-

N+ SN-

G+ S N+G- N-

Comms Isolation Screen Type Description

Fully isolated

Fully isolated

Optional

Full Isolation Card

Fully isolated

Optional

Full Isolation Card

Robust

High protection

So Earth to Earth

power terminal 3

So Earth to Earth

power terminal 3

Tie Terminal

So Earth to Earth

power terminal 3

Tie Terminal

So Earth to power

supply 0V terminal

Genesis Version 5

Hardware

MPC Version 6

Hardware

Genesis Version 4

Hardware (obsolete)

MPC Version 4

Hardware

Genesis Version 3

Hardware (obsolete)

Maxim 1010

MAX3xLx

MAX2Lx

MM01

GENII

VIEWPORT

MP01

G+ S N+G- N-

G+ S N+G- N-

G+ S N+G- N-

-

S2

+

S1

-

S2

+

S1

Robust

High protection

Robust

High protection

Robust

High protection

Fully isolated

Fully isolated

So Earth to power

supply 0V terminal

Tie Terminal

So Earth to power

supply 0V terminal

So Earth to power

supply 0V terminal

So Earth to Earth

power terminal 3

Maxim Series 3

Hardware

Maxim Series 2

Hardware

Mini Maxim Controller

Viewport Network

Display

MiniPort Maxim

Network Display

Edition 3.0 dated 05.12.2013

Page 16

© Mass Electronics Pty Ltd 2007

Page 17

Innotech Device Network Cabling Installation Instructions

Table 2-1 Continued

Part

Number

GENII RPTR

IR12

GENII MPI

CONV 232

CONV E

CONV USB

ICS01

Comms

Ter minal s

G+ S N+G- N-

G+ S N+G- N-

G+ S N+G- N-

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

Comms Isolation Screen Type Description

Fully isolated

Fully isolated

Optional

Fully Isolated

So Earth to Earth

power terminal 3

So Earth to power

supply 0V terminal

Tie Terminal

Fully isolated Floating Earth

Fully isolated Floating Earth

Repeater 9600 baud

(obsolete)

Repeater dual channel

(auto detect dual

baud)

Modem Printer

Interface

RS232 to RS485

converter

Ethernet to RS485

converter

Fully isolated Floating Earth USB to RS485 converter

Fully isolated

So Earth to Earth

power terminal 3

Control Station type 1

ICS02

IG01

IG02

IG03

IWS01

-

S2

+

S1

G+ S N+G- N-

-

S2

+

S1

PC

N

S

+

+PC-

PC

N

S

+

+PC-

Fully isolated

Robust

High protection

Fully isolated

N

Robust

-

High protection

N

Robust

-

High protection

So Earth to Earth

power terminal 3

So Earth to power

supply 0V terminal

So Earth to power

supply 0V terminal

So Earth to power

supply 0V terminal

So Earth to power

supply 0V terminal

Control Station type 2

Sub System Gateway

Dynalight Gateway

BACnet Gateway

innSIGHT Supervisor

Web Server

Chapter 2 – Primary Networks

Page 17

© Mass Electronics Pty Ltd 2007

Page 18

Innotech Device Network Cabling Installation Instructions

There are a number of rules that apply to the comms connection of a primary network.

Some of these are explained in detail in Chapter 1 of this manual.

Primary network rules:

• The screen must be continuous

• Only one point earthed on the screen

• Even if a network has a number of devices with a so earth, one hard earth is still required on that

network

• The Net and Global networks should have the same length cable run and path

• If a repeater is installed, each side of that repeater is a separate network and each requires a

bonded earth connection on the screen

• Using isolated devices, devices with isolated comms cards or using an isolated MPI does not alter

any of these rules

• There are no End of Line termination (EOL) requirements on the primary network

2-1 Continuous Screen

The screen on a primary network needs to be continuous. That means it remains unbroken along its

entire length. As there is one ‘S’ terminal on a typical primary network device both the global and net

screens are to be connected to this tie terminal.

G+ S N+G- N-

GLB Comms

NET Comms

Figure 2-1: Typical Screen Connections

NOTE

When there is more than one connection point to earth the screen becomes a conductor and no longer performs

correctly. Care should be taken to ensure only one bonded earth point is ever connected on a primary network.

Refer to Chapter 2-6 for details on use of a Repeater in a primary network.

Device Device Device

G+ S N+G- N-

G+ S N+G- N- G+ S N+G- N-

Figure 2-2: Earth Connection

Edition 3.0 dated 05.12.2013

Page 18

© Mass Electronics Pty Ltd 2007

Page 19

Innotech Device Network Cabling Installation Instructions

2-2 Management of other devices on the Primary Network

When other controllers such as Viewports or converters are added to the primary network they must

be installed in a manner that does not interrupt the integrity of the primary network. A lot of current

devices will have the so earth option and are fully isolated from the factory. There is no issue mixing

the current style earth connection with previous models of hardware on the primary network if the

following rules are applied.

These HMIs and converters will be referred to as so earth devices with respect to comms screen

termination.

For any so earth type device connected to a primary network there are some general rules for

connection.

• Do not break the continuity of the screen

• Use the ‘S1’ terminal for both the entering and leaving screen termination

• You must earth the system at a single bonded earth point. This is regardless of the number of so

earth points connected

• Attempt to ensure the net and global networks are the same length and follow the same path

2-2.1 HMIs and Converters

Typically all converters or HMIs will connect to the NET network and do not connect to the Global

network. This will present a few variations in how this device could be connected to the network. It is

important to ensure that the screen is kept continuous.

The below connection is wrong because it breaks the continuity of the screen creating a situation

where potential dierences in earth current between Device 1 and Device 2 can occur, therefore the

reliability of the comms connection may be compromised.

Figure 2-3: Incorrect HMI or Converter Comms Connection

In the correct example, notice that the NET comms screen is in ‘S1’ terminal only. If you were to

use the ‘S1’ and ‘S2’ terminals you would break the continuity of the NET screen. This could cause

a potential dierence between each side of the HMI or converter and possibly introduce network

reliability issues.

The HMI or converter must have the Earth terminal or the 24V neutral, connected to earth where

available. This will provide the path for the so earth.

DeviceDevice

HMI / ConV

Figure 2-4: Correct HMI or Converter Comms Connection

Chapter 2 – Primary Networks

Page 19

© Mass Electronics Pty Ltd 2007

Page 20

Innotech Device Network Cabling Installation Instructions

2-2.2 Control Stations (ICS) and DynaLite Gateway (IG02)

Control Stations and DynaLite Gateways connect to the Global network and do not connect to the Net

network. This will present a few variations in how these devices could be connected to the network.

It is important to ensure that the screen is kept continuous.

This style of connection applies to all globally connected devices.

The rules of application are similar to that of the HMI or Converter connections in the prior section.

You must ensure the global and net cable lengths are the same.

-

S2

+

S1

Figure 2-5: Incorrect Station IG02 Comms Connection

-

S2

+

S1

Figure 2-6: Correct Station IG02 Comms Connection

In this correct example you can see that the GLB comms screen is in ‘S1’ terminal only. If you were to

use the ‘S1’ and ‘S2’ terminals you would break the continuity of the GLB screen. This could cause a

potential dierence between each side of the ICS / IG02 and possibly introduce network reliability

issues.

The ICS / IG02 must have the earth terminal or the 24V neutral, connected to earth where available.

This will provide the path for the so earth.

Device

Figure 2-7: Correct Station ICS / IG02 Network Connection

Edition 3.0 dated 05.12.2013

Page 20

Device ICS / IG02

© Mass Electronics Pty Ltd 2007

Page 21

Innotech Device Network Cabling Installation Instructions

2-2.3 Earth Connections

The earth connection type on HMIs and converters depends on the typical application of the device.

A potential earth dierence between main installations and remote HMIs can cause problems in the

network.

An attempt must be made to eliminate the earth potential dierences between the Net comms

and Global comms network cabling. This applies to any so or floating earth device connected to a

primary network.

The list below indicates the dierent types of earth connections.

• The GENII VIEWPORT has terminal 3 for the dedicated earth connection. It is used for the so earth

path of the comms screen terminal

• The MP01 MiniPort has terminal E for the dedicated earth connection. It is used for the so earth

path of the comms screen terminal

NOTE

Where either the GENII VIEWPORT or MP01 MiniPort may have the 24V neutral earthed there is no link to the earth

terminal. Therefore a hard earth connection to the earth terminal is still required.

• The CONV E should have the 24 V supply earthed on the secondary of the transformer as best

practice. The CONV E has a floating type screen connection

• The CONV USB and the CONV 232 are isolated or floating devices and where they have a so earth

type comms connector fitted there is no path to earth available at these devices

The following indicates how a network can be practically wired to eliminate earth potential

dierences and problems that may occur between the Net and Global networks.

1. When the HMI or converter is mounted at the end of a run, the Global can finish at the last

controller. It is suicient to run NET only from the last controller to the HMI or converter.

Figure 2-8: End of Run Mounted HMIs or Converters

Chapter 2 – Primary Networks

Page 21

© Mass Electronics Pty Ltd 2007

Page 22

Innotech Device Network Cabling Installation Instructions

2. In the wrong example below, the cable run for the NET comms is significantly longer than that

of the Global comms. This can cause an earth potential dierence between the net and global

screen resistances and therefore unequal current flows which can cause network problems.

Figure 2-9: Remote Mounted HMIs or Converters

To rectify the above incorrect wiring situation you must use one of the following options:

• Branch o earth screens at the single comms earth point where the Net cable is routed through the

HMI without the Global cable. This is the Hard Earth.

• Keep the Net and Global network cables the same length and following the same path

Screen Wires mus t

be taken from Global

comms, an d to and

from the HMI on the

Net comms . All screens

must be te rminated to

a Hard Ear th

Figure 2-10: Options to eliminate earth potential dierences between networks

NOTE

Generally in all installations care must be taken when selecting the best earth point. Good earth points are usually

close to the earth stake and away from heavy power equipment. Heavy power equipment causes earth currents

and therefore the earth point is subject to potential dierences in current interference, and as such is usually not a

good choice.

Edition 3.0 dated 05.12.2013

Page 22

© Mass Electronics Pty Ltd 2007

Page 23

Innotech Device Network Cabling Installation Instructions

2-3 BACnet Gateway (IG03)

The BACnet Gateway is dierent to any other Innotech device in that it acts as a Network Master. It

has a PC and Net Comms connection. As there is only a single shield terminal the shield for each

network should be connected to this terminal. All other Innotech wiring guidelines should be

followed.

The BACnet network should always be totally separated from the Innotech network and any BACnet

specific wiring rules should be adhered to.

PC

PC

+

-

Figure 2-11: Correct Wiring of Innotech BACnet Gateway Communications

N

S

N

+

-

2-4 Older Controllers

There are some earlier devices, version V3, V3.1 and V3.2 Genesis and MPC controllers that do have

jumpers available to internally connect the ‘S’ terminal to either the 0 V terminal or a separate Earth

terminal.

NOTE

These jumpers have not been fitted at point of manufacture to suit the style of earth connection recommended in

this document.

2-5 Isolated Devices

Regardless of the type of isolation used in either the current model devices (all now standard with

fully isolated so earth) or older series controllers (plug-in optional isolation card), there is no

eect on the primary network earth requirements. The isolation is not on the primary network, but

between the primary network and the power supply of only that respective controller. All network

rules apply as stated.

Chapter 2 – Primary Networks

Page 23

© Mass Electronics Pty Ltd 2007

Page 24

Innotech Device Network Cabling Installation Instructions

2-6 Dual Channel Repeaters

NOTE

For information regarding the conditions when a repeater should be added to the Primary Network please refer to

Chapter 4 of this manual.

When a repeater is added to a network it eectively creates two separate networks.

This means users must apply all the rules to each side of the repeater as if they were actually two

completely separate networks. All primary network rules apply without variation.

All repeaters do have So Earth features. They do not negate the need for a hard earth on either

side of the repeater network sections. It is not recommended to earth both ports (1 & 2) right at the

repeater as this would defeat some of the advantages of the port isolation. Port 2 (remote port)

should always be earthed on the remote side.

CAUTION

Hazardous Voltage between Earth-Connections

When the Digital Controllers are supplied and earthed from two dierent switchboards, a hazardous situation

can be created. One earth connection is at the local switchboard and the second earth connection is by way of the

screen of the comms cable. In the event of a fault, there could be full supply voltage dierence between the two

earth connections. Always measure the voltage between Port 1 & 2 screens before handling. Use appropriate safety

precautions.

2-6.1 Older Repeaters

The GENII RPTR is the earlier version repeater, easily identified by the fact that it is housed in a square

surface mount enclosure. On these older repeaters Port 1 and Port 2 are isolated from each other;

however Port 1 is internally connected to the main electronic circuits. Due to this; Port 2 is better

isolated and has a higher level of tolerance with respect to comms protection.

It is best to ensure that if there is a long run and the converter is in building A and running to building

B; Port 2 is used to feed Building B. As shown in Figure 9.

The power terminal earth connection is a safety earth because the GENII RPTR is supplied with 240

VAC. This terminal is NOT connected to the So Earth terminal located between Comm Ports 1 & 2.

NOTE

The earth on the RPTR is connected to the so earth terminal as a requirement.

Figure 2-12: Old Style Repeater

Edition 3.0 dated 05.12.2013

Page 24

© Mass Electronics Pty Ltd 2007

Page 25

Innotech Device Network Cabling Installation Instructions

2-6.2 New Repeaters

New repeaters are identified by the fact that they are mounted in a DIN rail mount enclosure. Neither

have a separate earth terminal as it is a 24 V AC powered device, however the 24 V supply must be

earthed on the 0V side for safety and to make use of the So Earth feature.

• The IR12 is the current dual channel and dual baud rate repeater

• The IR11 is the current single channel dual baud rate repeater

• The IR12 and IR11 are fully isolated and both Port 1 and Port 2 oer the same level of protection.

That means that both Ports 1 & 2 can be used for the remote site connection.

NOTE

The earth on the IR12 must be connected to the so earth terminal.

Figure 2-13: New Style Repeater

2-7 End of Line Termination (EOL)

Due to specific design parameters relating to the bias of the network and network configurations, the

Primary network has currently no need for End of Line Terminations (EOL).

Chapter 2 – Primary Networks

Page 25

© Mass Electronics Pty Ltd 2007

Page 26

Innotech Device Network Cabling Installation Instructions

This page has been le intentionally blank.

Edition 3.0 dated 05.12.2013

Page 26

© Mass Electronics Pty Ltd 2007

Page 27

Innotech Device Network Cabling

INSTALLATION INSTRUCTIONS

Chapter 3 -

Sub Network

Devices

Page 28

Innotech Device Network Cabling Installation Instructions

Sub Network Devices

The Innotech Sub Networks are both two wire networks.

These comprise of the REM network and the Sub System Network.

The REM network is a Remote Expansion Module Network. Providing remote I/O expansion devices

controlled via a Genesis controller. This network is a 38.4K baud network.

The Sub System Network is a network of small point devices such as VAVMax, MiniMAX and MIcroMAX.

This network is a 115K baud network.

Below are some general rules for connection for all Sub Network Devices.

• Every Sub System Network device has a so earth connection

• Every REM network device has a so earth connection

• Every REM must have an earth connected

• All Repeaters, VAV Maxims or Mini Maxims must have the 0V of the power supply earthed

• Always fit End Of Line Terminators (EOL) on both ends of each network section

3-1 REM Network

There are seventeen devices that exist on the REM network. These are listed below:

Table 3-1: REM Network Controllers and Devices

Part Number

GENII RMI

IR11

GENII DI REM

GENII IDI REM

GENII DO REM

Comms

Ter minal s

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

Screen Type Description

So Earth Remote Module Interface

So Earth to power

supply 0V terminal

So Earth Digital Input REM

So Earth Isolated Digital Input REM

So Earth Digital Output REM

Repeater single channel (auto detect dual

baud)

Edition 3.0 dated 05.12.2013

Page 28

© Mass Electronics Pty Ltd 2007

Page 29

Innotech Device Network Cabling Installation Instructions

Table 3-1 Continued

Part Number

GENII AI REM

GENII AO REM

GENII PI REM

GENII CS REM

GENII CSAH

REM

GENII CSFAH

REM

GENII MZS REM

Comms

Ter minal s

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

Screen Type Description

So Earth Analogue Input REM

So Earth Analogue Output REM

So Earth Pulse Input REM

So Earth Control Stations REM

So Earth Control Stations REM

So Earth Control Stations REM

So Earth Control Stations REM

-

S2

+

GENII MZSAH

REM

GENII MP405

REM

GENII MP414

REM

GENII MP423

REM

GENII MP432

REM

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

-

S2

+

S1

So Earth Control Stations REM

So Earth Multi Point REM

So Earth Multi Point REM

So Earth Multi Point REM

So Earth Multi Point REM

The REM network is a two-wire network that communicates at 38.4K baud. It is required that the EOL

jumpers are fitted correctly and that each device is earthed correctly.

Chapter 3 – Sub Network Devices

Page 29

© Mass Electronics Pty Ltd 2007

Page 30

Innotech Device Network Cabling Installation Instructions

The only device on a REM network without an earth terminal is the IR11 repeater. It must have the 0 V

of its power supply earthed.

REM Device REM Device REM Device

Figure 3-1: REM Network

3-1.1 So Earth

All REM devices have a so earth and as such the Earth must be connected to the terminal ‘E’. This

provides the required path to earth. It is not suicient to have the 0V earthed on the 24V powered

devices as these are separated.

3-1.2 End of Line Termination (EOL)

All REM’s have EOL jumpers and these must be fitted correctly. See the figures below.

There are many variations to network layouts the following four examples provide a guide to correct

jumper application.

Figure 3-2: Simple REM Network

EXAMPLE 1:

This example shows a GENIIELD controller with a straight forward network of REM’s.

NOTE

Both ends must have the EOL jumpers fitted.

Edition 3.0 dated 05.12.2013

Page 30

© Mass Electronics Pty Ltd 2007

Page 31

Innotech Device Network Cabling Installation Instructions

Figure 3-3: REM Network with Repeater

EXAMPLE 2:

This example shows a GENIIELD controller with a network of REM’s and an IR11 repeater fitted.

As in section one, once a repeater is installed there are eectively two networks and each must have

the EOL jumpers fitted.

NOTE

Both ends must have the EOL jumpers fitted.

Figure 3-4: REM Network with Controller in the Middle of the run

EXAMPLE 3:

This example shows a GENIIELD controller with a network of REM’s where the controller is in the

middle of the run.

NOTE

Both ends of a run muse have the EOL jumpers fitted. It does not need to be a primary device.

Chapter 3 – Sub Network Devices

Page 31

© Mass Electronics Pty Ltd 2007

Page 32

Innotech Device Network Cabling Installation Instructions

Figure 3-5: REM Network with Repeater in the Middle of the run

EXAMPLE 4:

This example shows a GENIIELD controller with a network of REM’s where there is a repeater fitted

and it is located in the middle of a run.

3-2 Sub System Network

The Sub System Network is a sub network that connects to the Innotech primary network via a

gateway. The Sub System Gateway IG01 is a data concentrator for the Sub System Network.

The Sub System Network is a two wire network that communicates at 115K. It is a requirement that

the EOL jumpers are fitted correctly and that each device is earthed correctly.

No devices on the Sub System Network have an earth terminal. All devices must have the 0V earthed.

There are currently five devices that exist on the Sub System Network. See the table below:

Table 3-2: Sub System Network Controllers and Devices

Part Number

VM01

MM02

UM01

IG01

IR11

Comms

Ter minal s

P+ + -P- S

-

S2

+

S1

P+ + -P- S

P+ + -P- S

-

S2

+

S1

Screen Type Description

So Earth VAV Maxim

So Earth Mini Maxim

So Earth Micro Maxim

So Earth Sub System Gateway

So Earth Repeater Single Channel

Edition 3.0 dated 05.12.2013

Page 32

© Mass Electronics Pty Ltd 2007

Page 33

Innotech Device Network Cabling Installation Instructions

3-2.1 VAVMax (VM01) and MicroMAX (UM01)

The VAVMax and MicroMAX have a 5 way connector where the terminals are made up of P+ P- C+ CSHLD. This is due to the fact that the Sub System Network Commissioning Tool (CT01) is powered by

the P+ and P- terminals. These terminals have dierent pin spacing to the primary network terminals

and while they look similar, they are not, and can’t be interchanged.

3-2.2 MiniMAX (MM02)

These MiniMAX controllers have the REM style of comms connector.

When used in conjunction with VAVMax or MicroMAX controllers, care should be taken to ensure only

the S1 terminal is used to maintain the continuity of the screen.

3-3 IR11 Single Channel Repeater

NOTE

For information regarding the conditions when a repeater should be added to a Sub Network please refer to

Chapter 4 of this manual.

The IR11 single channel repeater has the REM style connectors.

When used in conjunction with VAVMax or MicroMAX controllers, care should be taken to ensure only

the S1 terminal is used to maintain the continuity of the screen.

CAUTION

Hazardous Voltage between Earth-Connections

When the Digital Controllers are supplied and earthed from two dierent switchboards, a hazardous situation

can be created. One earth connection is at the local switchboard and the second earth connection is by way of the

screen of the Comms cable. In the event of a fault, there could be full supply voltage dierence between the two

earth connections. Always measure the voltage between Port 1 & 2 screens before handling. Use appropriate safety

precautions.

3-4 Network with VAVMax, MiniMAX and MicroMAX devices

VM01

P+ + -P- S

UM01

P+ + -P- S

Figure 3-6: Sub System Network Connections

The figure above indicates that the screen is to be continuous for the entire network run. Devices with

the S1 and S2 screen terminals use only the S1 terminal.

IR11

-

S2

+

S1

MM02

-

S2

+

S1

Chapter 3 – Sub Network Devices

Page 33

© Mass Electronics Pty Ltd 2007

Page 34

Innotech Device Network Cabling Installation Instructions

3-5 End of Line Termination (EOL)

All devices on the Sub System Network have EOL jumpers and these must be fitted correctly. This is

shown in the figure below. There are many variations to network layouts. The following 4 examples

provide a guide to correct jumper application. These are similar to the REM network.

Figure 3-7: Simple Sub System Network

EXAMPLE 1:

This example shows a Sub System Gateway with a network of VAVMax and MiniMAX Controllers.

NOTE

Both ends must have the EOL jumpers fitted.

Figure 3-8: Sub System Network with a Repeater

EXAMPLE 2:

This example shows a Sub System Gateway with a network of VAVMax and MiniMAX Controllers with a

repeater in the middle.

NOTE

Both ends must have the EOL jumpers fitted.

Edition 3.0 dated 05.12.2013

Page 34

© Mass Electronics Pty Ltd 2007

Page 35

Innotech Device Network Cabling Installation Instructions

Figure 3-9: Sub System Network with IG01 in the middle of a run

EXAMPLE 3:

This example shows a Sub System Network with VAVMax and MiniMAX controllers where the IG01 is in

the middle of the run.

NOTE

Both ends of a run must have the EOL jumpers fitted, it does not have to be a primary device.

Figure 3-10: Sub System Network with a Repeater in the middle of a run

EXAMPLE 4:

This example shows a Sub System Network with VAVMax and MiniMAX controllers, with a repeater

where the repeater is in the middle of the run.

NOTE

Only one side of the repeater is in the middle of a run. The repeater has the EOL jumper fitted on port 1 but not on

port 2.

Chapter 3 – Sub Network Devices

Page 35

© Mass Electronics Pty Ltd 2007

Page 36

Innotech Device Network Cabling Installation Instructions

This page has been le intentionally blank.

Edition 3.0 dated 05.12.2013

Page 36

© Mass Electronics Pty Ltd 2007

Page 37

Innotech Device Network Cabling

INSTALLATION INSTRUCTIONS

Chapter 4 - General

Specifications

Page 38

Innotech Device Network Cabling Installation Instructions

4-1 Network Specifications

The network type and baud rate determine the maximum recommended cable specifications. For

cable runs longer than the recommended lengths an Innotech Repeater IR11 or IR12 should be used.

Repeaters may also be required if the number of devices connected to a network segment exceeds

the maximum allowable number of devices for the specific network.

Table 4-1: Repeater Requirements

Network

Typ e

Primary

Network

Sub System

Network

REM

Network

Maximum

Number of

Devices

128 31

63 31 115200 200m

15 N/A 38400 600m

Maximum Number of

Devices Before a Repeater

is Required

Maximum Cable

Baud Rate

9600/4800 1000m

57600/38400 400m

Length Before

Repeater is Required

4-2 Cable Specifications

Innotech recommends the use of cables specifically designed for RS485 networks. There are many

cables on the market that meet the specifications for RS485 networks.

Best reliability is achieved through a cable consisting of 2 individually shielded twisted pairs of low

capacitance. Such cables also provide excellent mechanical strength and lowest electrical resistance,

which is beneficial for maximum length cable runs.

Some CAT6 cable types may also be suitable in certain applications. Care should be taken when using

CAT6 for Primary Networks as they frequently omit shielding. CAT6 cables should be shielded in order

to provide reliable communications.

Edition 3.0 dated 05.12.2013

Page 38

© Mass Electronics Pty Ltd 2007

Page 39

Innotech Device Network Cabling Installation Instructions

4-2.1 Primary Network

Any cable that meets or exceeds all the stated specifications is suitable for use.

Primary Network Minimum Requirements:

• 2 twisted pairs

• Minimum conductor cross section AWG24 (0.205mm²)

• Stranded core type is recommended (7 strands of 0.193mm)

• Conductor resistance 80 Ohms / km or less

• Overall Foil screened cable with a wire drain

• Less than 50pf capacitance per metre between conductors

• Less than 80pf capacitance per metre between conductor and screen

• Impedance 100 – 120 Ohms

• Sheath thickness 0.8mm 240V rated

• Equivalent to the Belden Part #8102

NOTE

CAT6 STP (Shielded Twisted Pairs), where each pair is individually shielded, are suited for use with multiple

RS485 communications channels such as the Innotech Primary Comms network. Shielding is required because of

increased pair to pair capacitance, which is the primary culprit for Global/Net channel cross talk.

4-2.2 Sub Networks

CAT6 FTP (Foil Screened Twisted Pair) cable is suitable for single RS485 communications channel

networks.

Any cable that meets all the stated specifications is suitable for use.

Sub System Network Minimum Requirements:

• 1 twisted pair

• Minimum conductor cross section AWG24 (0.205mm²)

• Stranded core type is recommended (7 strands of 0.193mm)

• Conductor resistance 80 Ohms / km or less

• Overall Foil screened cable with a wire drain

• Less than 50pf capacitance per metre between conductors

• Less than 80pf capacitance per metre between conductor and screen

• Impedance 85 – 115 Ohms

• Sheath thickness 0.3mm 240V rated

Chapter 4 – General Specifications

Page 39

© Mass Electronics Pty Ltd 2007

Page 40

Innotech Device Network Cabling Installation Instructions

This page has been le intentionally blank.

Edition 3.0 dated 05.12.2013

Page 40

© Mass Electronics Pty Ltd 2007

Page 41

Innotech Device Network Cabling

INSTALLATION INSTRUCTIONS

Chapter 5 - Glossary

Page 42

Innotech Device Network Cabling Installation Instructions

5-1 Glossary of Terms

This section defines terms used frequently in this document.

Table 5-1: Primary Network Digital Controllers and Devices

Ter m Description

EOL End of Line

I/O Input / Output

GLB Global

Only one transmitter can be active at the time but many receivers can listen

Half Duplex

HMI Human Machine Interface

REM Remote Expansion Module

STP Shielded Twisted Pair

VAV Variable Air Volume

simultaneously. A period of ‘silence’ is used to free the interface for another

transmitter to become active.

Edition 3.0 dated 05.12.2013

Page 42

© Mass Electronics Pty Ltd 2007

Page 43

Innotech Device Network Cabling

INSTALLATION INSTRUCTIONS

Chapter 6 - Factory

Settings for RS485 EOL

Termination

Page 44

Innotech Device Network Cabling Installation Instructions

6-1 Factory Settings

The tables in this section list the Factory Settings for RS485 End of Line Termination.

Table 6-1: Factory Settings for RS486 End of Line Termination

O - Fitted open C - Fitted Closed O/NA - Open with no adjustment available

Part Number Part Summary

MAX1 Series

MAX2 Series

MAX3 Series

MAX1010

MM01

GENII V5 DDC

Series

MPCIILN

VM01

UM01

MM02

MAXIM I Controller,

Standalone

MAXIM II Controller, Primary

Network

MAXIM III Controller, Primary

Network

MAXIM 1010 Controller,

Primary Network

MiniMAX Controller, Primary

Network

Direct Digital Controller,

Primary Network

Mid Points Controller, REM

Jumper

VAVMax Controller, Sub

System Network

MicroMAX Controller, Sub

System Network

MiniMAX Controller, Sub

System Network

EOL

REM

-- -- --

-- -- O/NA

-- -- O/NA

-- -- O/NA

-- O/NA O/NA

C -- O

C -- O

-- O O

-- O O

-- O --

GENII MPI Series Modem Printer Interface -- -- O

CONVUSB Converter, USB – RS485 -- O/NA O/NA

EOL

Subnet

EOL

Primary

Remarks

No headers

fitted

No headers

fitted

No headers

fitted

Open is

labelled as

‘NODE’

Open is

labelled as

‘NODE’

Headers Global

/ NET are

fitted without

jumpers

CONV232 Converter, RS232 – RS485 -- O/NA O/NA

CONVE Converter, Ethernet – RS485 -- O/NA O/NA

GENII VIEWPORT

MP01

IG01 Sub System Gateway -- O O/NA

IG02 Innotech Dynalite Gateway -- -- O/NA

IG03 BACnet Gateway -- -- O/NA

Edition 3.0 dated 05.12.2013

Human Machine Interface

Genesis, RS485

Human Machine Interface

Maxim, RS485

Page 44

-- -- O

-- -- O

© Mass Electronics Pty Ltd 2007

No Jumper

fitted

No Jumper

fitted

Header and

Jumper are not

fitted

MS/TP jumper

should be

open, however

specific BACnet

instructions

take

precedence.

Page 45

Innotech Device Network Cabling Installation Instructions

Table 6-1 Continued

O - Fitted open C - Fitted Closed O/NA - Open with no adjustment available

Part Number Part Summary

IWS01

ICS01

ICS02

IR11

IR12

innSIGHT Supervisor Web

Server

Innotech Control Station, Set

Point

Innotech Control Station, Set

Point & Fan

Innotech Repeater, Single

Channel

Innotech Repeater, Dual

Channel

GENII RMI Remote Module Interface C -- --

GENII IDI REM

Opto Isolated Digital Input

Module

GENII DO REM Relay Output Module O -- --

GENII DI REM

Dry Contact Digital Input

Module

GENII AO REM Analogue Output Module O -- --

EOL

REM

EOL

Subnet

EOL

Primary

Remarks

-- -- O/NA

Header and

-- -- O/NA

Jumper are not

fitted

Header and

-- -- O/NA

Jumper are not

fitted

C C -- 2 Jumpers

-- -- O 4 Jumpers

O -- --

O -- --

GENII AI REM Analogue Input Module O -- --

GENII PI REM Pulse Input Module O -- -GENII MP405

REM

GENII MP414

REM

GENII MP423

REM

GENII MP432

REM

GENII CS REM

GENII CSAH REM

GENII CSFCAH

REM

GENII MZS REM

GENII MZSAH

REM

Multipoint Remote Expansion

Module

Multipoint Remote Expansion

Module

Multipoint Remote Expansion

Module

Multipoint Remote Expansion

Module

Control Station Remote

Expansion Module

Control Station Aer Hours

Remote Expansion Module

Control Station With 3 Speed

Fan Remote Expansion

Module

Multi Zone Station Remote

Expansion Module

Multi Zone Station Aer Hours

Remote Expansion Module

O -- --

O -- --

O -- --

O -- --

O -- --

O -- --

O -- --

O -- --

O -- --

GENII WMI Wireless Module Interface O -- --

Chapter 6 – Factory Settings for RS485 EOL Termination

Page 45

© Mass Electronics Pty Ltd 2007

Page 46

Innotech Support

Innotech provides technical information on the Web to assist you with using its products.

At www.innotech.com.au, you can find technical manuals, user instructions, and data sheets for all

our products.

For direct product support or product information, contact your local distributor, or an Innotech

representative.

You can contact us via email, fax, or postal mail:

Website: www.innotech.com.au

Email: sales@innotech.com.au

Fax: +61 7 3421 9101

Mail: Innotech Control Systems

P.O. Box 292

Sunnybank

QLD 4109

Australia

Edition 3.0 dated 05.12.2013

© Mass Electronics Pty Ltd 2007Page 46

Loading...

Loading...