Page 1

Chimei-Innolux Corporation

BT140GW01 V.4 LCD MODULE SPECIFICATION

( ) Preliminary Specification

(●) Final Specification

Customer Checked & Approved by

Dell

Approved by Checked by Prepared by

MKT PD PM

www.jxlcd.com

www.jxlcd.com

楊竣傑 柯瑞峰 詹銘斯 黃雅怡

I Chimei-Innolux Corporation

No.160 Kesyue Rd., Chu-Nan Site, Hsinchu Science Park,

Date: 2010/05/25

Chu-Nan 350, Miao-Li County, Taiwan

Tel: 886-37-586000 Fax: 886-37-586060

Page 2

Version: 8

Record of Revision

Version Revise Date Page Content

InnoLux copyright

All rights reserved,

Copying forbidden.

0

1 2009/12/07 18 Module Label

2 2010/03/09

3 2010/04/06

23/24 Drawing

25 EDID

4 2010/04/15 8 Typical Operating Condition

14 Backlight Driving Condition

5 2010/04/16 8 Typical Operating Condition

6 2010/04/23 20 Label

2009/11/25

www.jxlcd.com

www.jxlcd.com

All First Edition issued

20 Packing Form

22 Packing Form

5 PIN Assignment

13 Timing Table

7 2010/04/28 5 Pin Assignment

8 Typical operating conditions

11 Power Sequence Table

15 Optical Specification

21~24 Label

8 2010/04/29 Appendix EDID

9 2010/05/25 23~24 ME drawing

Page 3

Contents: Page

SPEC NO.

PAGE

BT140GW01 V.4

3/28

1 . General Specifications

2 . Electrical Specifications

2-1 Pin Assignment

2-2 Absolute Maximum Ratings

2-3 Electrical Characteristics

3 . Optical Specifications

4. Reliability Test Items

5. Safety

6. Display Quality

7. Handling Precaution

8. Label Definition

4

5

7

8

15

18

19

19

19

20

9. Packing Form

10. Mechanical Drawings

Appendix

www.jxlcd.com

www.jxlcd.com

22

23

25

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 4

1. General Specifications

NO. Item Specification Unit

1 Display resolution (pixel) 1366(H) X 768(V), HD resolution

2 Active area 309.40(H) X 173.95(V) mm

3 Screen size 14.0 inches diagonal Inches

4 Pixel pitch 0.2265(H) X 0.2265(V) mm

5 Color configuration Stripe

SPEC NO.

PAGE

BT140GW01 V.4

4/28

6 Overall dimension

7 Weight

8 Surface treatment Glare, 3H

9 Input color signal 6 bit LVDS

10 Display colors 262K (6 bit)

11 Optimum viewing direction 6 o’clock

12 Backlight W-LED

13 RoHS RoHS compliance

www.jxlcd.com

www.jxlcd.com

324(W) X 192.5(H) X 5.2(D) (max)

350Max.

mm

Grams

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 5

2. Electrical Specifications

2-1 Pin Assignment

a. Panel connector

Connector Part No.: 20455-040-12 (I-PEX) /

User’s connector Part No:

Pin No Symbol Description Remark

1 DIAG_LOOP Plug detection pin

2 VCC Power Supply (+3.3V)

3 VCC Power Supply (+3.3V)

4 V

5 BIST BIST function enable (+3.3V)

6 Clk

7 DATA

8 Rxin0- Differential Data Input

9 Rxin0+ Differential Data Input

10 GND Ground

11 Rxin1- Differential Data Input

12 Rxin1+ Differential Data Input

13 GND Ground

14 Rxin2- Differential Data Input

15 Rxin2+ Differential Data Input

16 GND Ground

17 CLK- Differential Clock Input

18 CLK+ Differential Clock Input

www.jxlcd.com

19 NC No connection (Reserve)

20 NC No connection (Reserve)

21 NC No connection (Reserve)

22 GND Ground

23 NC No connection (Reserve)

24 NC No connection (Reserve)

25 GND Ground

26 NC No connection (Reserve)

27 NC No connection (Reserve)

28 GND Ground

29 NC No connection (Reserve)

30 NC No connection (Reserve)

31 LED_GND LED Ground

32 LED_GND LED Ground

33 LED_GND LED Ground

34 DIAG_LOOP Plug detection pin

35 LED_PWM PWM dimming signal input

36 LED_EN LED enable pin (3.3V)

37 NC No connection (Reserve)

38 V_LED LED power supply 6V~21V

39 V_LED LED power supply 6V~21V

40 V_LED LED power supply 6V~21V

www.jxlcd.com

DDC Power +3.3V

EDID

EDID

EDID

20453-040T-12 (I-PEX) or equivalent

DDC Clock

DDC Data

GS13401-1110S-7H (Foxconn )

SPEC NO.

PAGE

B2~B5,DE,Hsync,Vsync

BT140GW01 V.4

5/28

R0~R5,G0

G1~G5,B0,B1

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 6

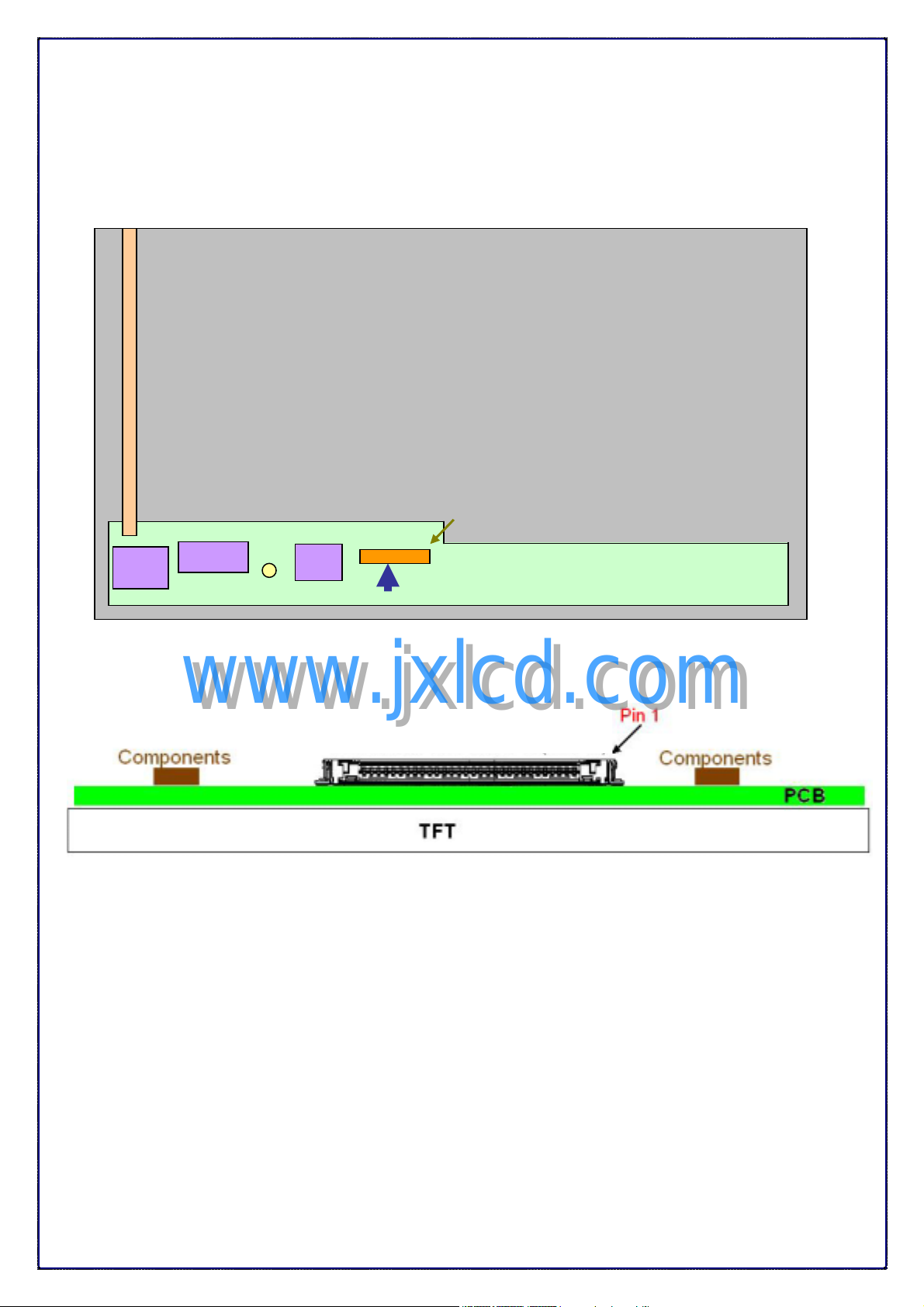

r

b. General Block Diagram(Rear-side)

LED

Drive

FPC

GS13401-1110S-7H

DC/DC

www.jxlcd.com

www.jxlcd.com

T-CON

VR

Connector plug in direction

Pin1

GS13401-1110S-7H (Foxconn )

SPEC NO.

PAGE

BT140GW01 V.4

6/28

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 7

V

2-2. Absolute Maximum Ratings

SPEC NO.

PAGE

BT140GW01 V.4

7/28

Parameter Symbol

Min. Max.

Power input voltage V

Signal input voltage V

Operating temperature T

Storage temperature T

Re-screw - 5 Times

Assured torque at side mount - 2 kgf.cm

Note 1: The relative humidity must not exceed 90%, non-condensing at temperatures of 40°C or

less. At temperatures greater than 40°C, the wet bulb temperature must not exceed 39°C.

Note 2: The unit should not be exposed to corrosive chemicals.

Relative Humidity (%RH)

-30 -20 -10 0 10 20 30 40 50 60 70

www.jxlcd.com

100

90

www.jxlcd.com

80

70

60

50

40

30

20

10

Operation Range

Storage Range

0

Temperature (°C)

- 0.3 4.0 V At 25°C

CC

- 0.3 4.0 V At 25°C

IN

0 50 °C Note 1

OP

- 20 60 °C Note 2

ST

alues

Unit

Remark

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 8

2-3. Electrical Characteristics

a. Typical operating conditions

Item Symbol Min. Typ. Max. Unit Remark

SPEC NO.

PAGE

BT140GW01 V.4

8/28

Power input voltage

Permissive power input ripple

Power input current

Power consumption

Differential input high

threshold voltage

Differential input low

LVDS

interface

Note 1: The specified input current and power consumption are under the V

Note 2: LVDS waveform diagram

Rxin+/CLK+

Rxin-/CLK-

threshold voltage

Common input

voltage

Terminating resistor

Rush current

LED rush current

www.jxlcd.com

www.jxlcd.com

f

=60Hz (frame frequency) condition whereas mosaic pattern is displayed.

V

V

3 3.3 3.6 V

CC

V

- - 0.1 V

RF

I

- 300 330 mA Note 1

CC

P

- 1 1.2 Watts Note 1

C

V

- - +100 mV

LVT H

V

-100 - - mV

LVT L

V

1.0 1.2 1.4 V

LVC

R

90 100 110 ohm

T

I

- - 1.5 A Note 3

Rush

I

LED-Rush

- - 3.0 A Note 4

V

LVC

V

LVC

=3.3 V, 25°C,

cc

=1.2V,

Note 2

=1.2V,

Note 2

V

LVT H

V

LVT L

V

LVC

GND

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 9

SPEC NO.

PAGE

BT140GW01 V.4

9/28

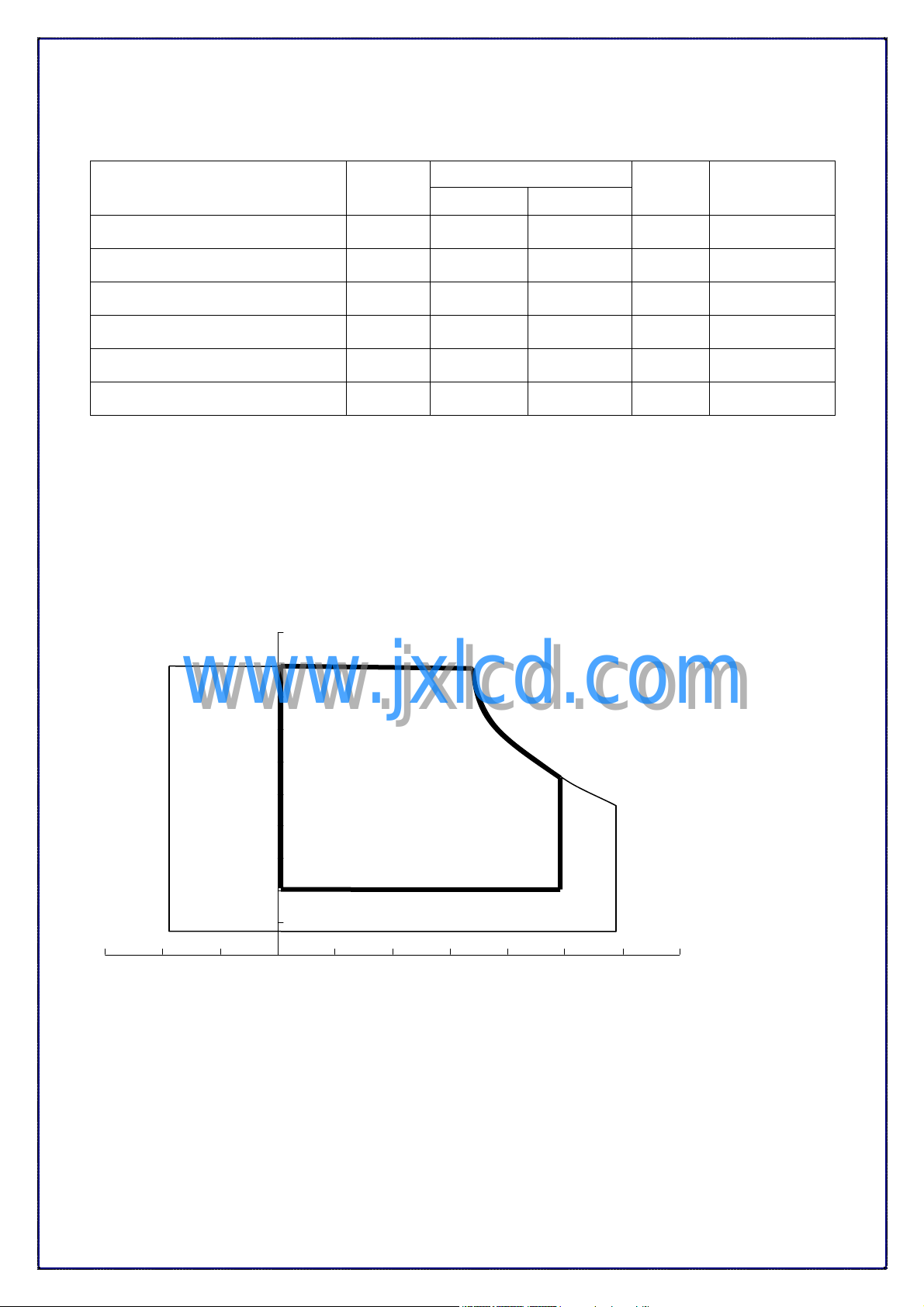

Note 3: Test condition

(1) Pattern: Black pattern

(2) V

= 3.3 V, V

CC

rising time = 470 μs ± 10%

CC

Control signal

(High to low)

90%

10%

V

CC

Ton=470µs±10%

(3) Test circuit

3.3 V

R1

47K

R2

www.jxlcd.com

www.jxlcd.com

12V

C3

1uF

1K

R3

47K

M1

2SK1059

C2

10000pF

M2

2SK1399

FUSE

C1

1uF

VCC ( LCD input)

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 10

_

SPEC NO.

PAGE

BT140GW01 V.4

10/28

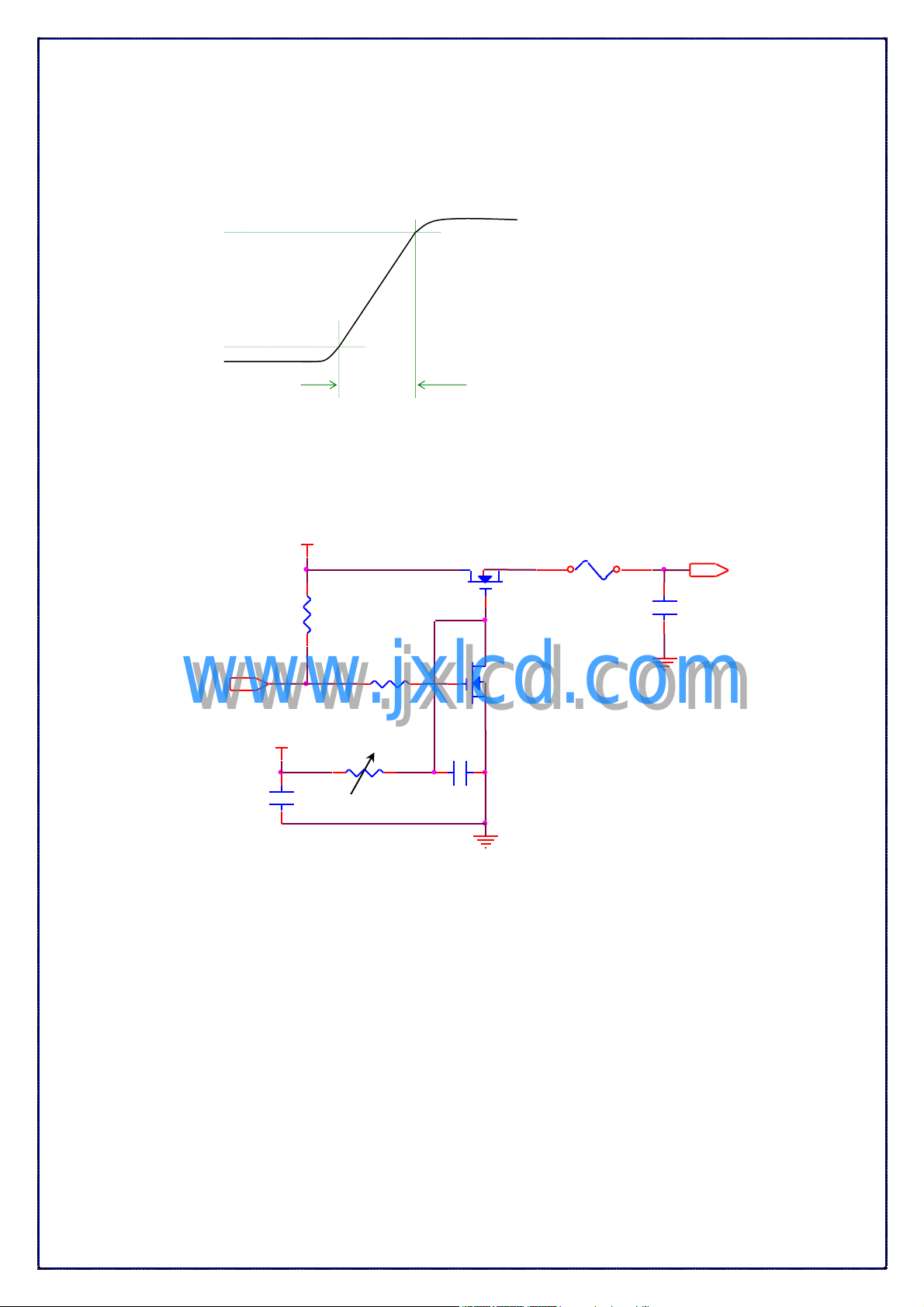

Note 4: Test condition

(1) Pattern: LED duty 100%

(2) V_LED = 12.0V, V_LED rising time = 470

μs ± 10%

Control signal

(High to low)

90%

10%

V

LED

Ton=470µs±10%

(3) Test circuit

12 V

R1

47K

www.jxlcd.com

www.jxlcd.com

21V

C3

1uF

R2

1K

R3

47K

M1

2SK1059

C2

10000pF

M2

2SK1399

FUSE

C1

1uF

V_LED

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 11

b. Power sequence

SPEC NO.

PAGE

BT140GW01 V.4

11/28

Power supply for LCD, VCC

Interface data signal, V

(LVDS signal of transmitter)

Backlight on/off

Power sequence timing table

Parameter

T1 0.5 - 10 ms

T2 0 - 50 ms

i

Min. Typ. Max.

90%

10%

0V

T1

T

2

0V

OFF OFF

Value

Valid Data

T

3

Backlight

T

On

90%

10%

T

T

T

5

4

7

6

Units

T3 200 - - ms

www.jxlcd.com

T4 200 - - ms

www.jxlcd.com

T5 0 - 50 ms

T6 0.5 - 10 ms

T7 400 - - ms

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 12

c. Display color vs. input data signals

Signal Name Description Remark

R5 Red Data 5 (MSB)

R4 Red Data 4

R3 Red Data 3

R2 Red Data 2

R1 Red Data 1

R0 Red Data 0 (LSB)

Red-pixel Data

G5 Green Data 5 (MSB)

G4 Green Data 4

G3 Green Data 3

G2 Green Data 2

Red-pixel data. Each red pixel's brightness data

consists of these 6 bits pixel data.

Green-pixel data. Each green pixel's brightness

data consists of these 6 bits pixel data.

SPEC NO.

PAGE

BT140GW01 V.4

12/28

G1 Green Data 1

G0 Green Data 0 (LSB)

Green-pixel Data

B5 Blue Data 5 (MSB)

B4 Blue Data 4

B3 Blue Data 3

B2 Blue Data 2

B1 Blue Data 1

www.jxlcd.com

www.jxlcd.com

B0 Blue Data 0 (LSB)

Blue-pixel Data

Signal for 1 DCLK cycle (t

Blue-pixel data. Each blue pixel's brightness data

consists of these 6 bits pixel data.

)

CLK

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 13

d. Input signal timing

Timing table

Description Symbol Min Typ Max Unit

Frame rate -- 40 60 -- Hz

SPEC NO.

PAGE

BT140GW01 V.4

13/28

Clock freq. 1/t

Line cycle time tH 1400 1498 1800

Line width-active tHd 1366 1366 1366

Frame cycle time tV 780 790 900 tH

V width-active tVd 768 768 768 tH

DE

DE

www.jxlcd.com

t

www.jxlcd.com

CLK

t

Vd

t

Hd

45 71 85 MHz

CLK

t

V

t

H

t

CLK

t

CLK

DCLK

e. Display position

D(1, 1) D(2, 1) …… D(683, 1) …… D(1365, 1) D(1366, 1)

D(1, 2) D(2, 2) …… D(683, 2) …… D(1365, 2) D(1366, 2)

.

.

.

D(1, 384) D(2, 384) …… D(683, 384) …… D(1365, 384) D(1366, 384)

.

.

.

D(1, 767) D(2, 767) …… D(683, 767) …… D(1365, 767) D(1366, 767)

D(1, 768) D(2, 768) …… D(683, 768) …… D(1365, 768) D(1366, 768)

……

……

.

.

.

.

.

.

……

……

.

.

.

.

.

.

.

.

.

.

.

.

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 14

f. Backlight driving conditions

Parameter Symbol Min. Typ. Max. Unit Remark

SPEC NO.

PAGE

BT140GW01 V.4

14/28

LED forward voltage V

LED forward current

Power consumption

Input PWM frequency F

Duty ratio - 5 100 % Note 1

LED life time - 15,000 Hr T = 25°C , Note 2

Note 1: PWM duty ratio linearity guarantees 20~100%

Note 2: LED life time definition is Brightness decrease to 50% of initial or abnormal lighting.

g. Module function block

www.jxlcd.com

www.jxlcd.com

LED driver

controller

3 3.2 3.4 V

F

IF 20 mA

P

3 W

LED

190 2000 Hz T = 25°C

PWM

LED Light-bar

TFT-LCD

Source driver

Timing

Step-up regulator

& reference voltage

generator

LVDS connector

rms

rms

EDID

EEPROM

T = 25°C

T = 25°C

T = 25°C

Gate driver

LVDS DATA BUS mini-LVDS & CONTROL BUS POWER I2C BUS

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 15

SPEC NO.

PAGE

BT140GW01 V.4

15/28

3. Optical specifications

Ambient temperature = 25°C

Item Symbol Condition

Specification

Min. Typ. Max.

Unit Remark

Response time

Contrast ratio CR

Viewing angle

Brightness

(5 points average)

www.jxlcd.com

www.jxlcd.com

Tr+Tf θ= 0°

θ= 0°

Top

Bottom

Left

Right

170 200 nit Note 2,5

Y

L

Wx

Wy

Rx

Ry

Gx

Gy

CR≧10

CR≧10

CR≧10

CR≧10

θ= 0°

500 600 Note 2,4

15

30

40

40

-0.03

8 16 ms Note 3

deg Note 2,4,6

0.313

0.329

0.586

0.355

0.323

0.57

+0.03

Note 2

Bx

B

y

Color Gamut NTSC CIE1931 45 % -

δ

0.8

W(5)

White uniformity

0.65

δ

W(13)

Cross talk Ct 2% Note 8

Note 1: To be measured in dark room.

Note 2: To be measured with a viewing cone of 2°by Topcon luminance meter BM-5A.

Note 3: Definition of response time:

The output signals of BM-7 are measured when the input signals are changed from “Black” to

“White” (falling time) and from “White” to “Black” (rising time), respectively. The response time

interval is between 10% and 90% of amplitudes. Refer to figure as below.

0.163

0.141

Note 2,7

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 16

(

Avg

)

SPEC NO.

PAGE

BT140GW01 V.4

16/28

100%

S

i

90%

g

n

a

l

(

R

e

l

a

t

i

v

e

v

a

l

u

10%

e

)

0%

Note 4: Definition of contrast ratio:

Contrast ratio is calculated with the following formula:

Note 5: Driving current for LED should be 20 mA.

Note 6: Definition of viewing angle

Contrast ratio

Luminance is measured at the following thirteen points (1~13):

Y

= (Y3+ Y5+Y7+Y11 +Y12) / 5

L

www.jxlcd.com

www.jxlcd.com

Tr

of 5pts

=

"Black"

L white (Avg of 5pts.)

L

Black (Avg of 5pts.)

"White""White"

Tf

Note 7: Definition white uniformity

Luminance is measured at the following thirteen points (1~13):

δ

Minimum brightness of thirteen points

W(13) =

δ

W(5) =

Maximum brightness of thirteen points

Minimum brightness of five points

Maximum brightness of five points

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 17

13 point measuring locations refer to the point 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 and 13.

5 point measuring locations refer to the point 3, 5, 7, 11 and 12.

SPEC NO.

PAGE

BT140GW01 V.4

17/28

Note 8:

1/2

A

www.jxlcd.com

www.jxlcd.com

32 gray level 32 gray level

Unit: percentage of dimension of display area

l L

l L

l / LA x 100%= 2% max., LA and L

A-LA’

l / LB x 100%= 2% max., LB’ and LB’ are brightness at location B and B’

B-LB’

1/6

B

1/6

1/2

2/3 1/3

are brightness at location A and A’

A’

1/2

A’

0 gray level

1/6

1/6

1/3

1/2

B’

2/3

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 18

4. Reliability test items

Test Item Test Condition Judgment Remark

SPEC NO.

PAGE

BT140GW01 V.4

18/28

High temperature storage

Low temperature storage

High temperature & high

humidity operation

High temperature operation

Low temperature operation

Thermal Shock

(Non-operation)

Electrostatic discharge (ESD)

Vibration

(Non-operation)

Mechanical shock

(Non-operation)

www.jxlcd.com

Note 1: Pass: Normal display image with no obvious non-uniformity and no line defect.

Fail: No display image, obvious non-uniformity, or line defects.

Note 2: Evaluation should be tested after storage at room temperature for more than one hour.

www.jxlcd.com

Partial transformation of the module parts should be ignored.

60°C, 240 hours

-20°C, 240 hours

50°C, 80% RH, 240 hours

(No condensation)

50°C, 240 hours

0°C, 240 hours

-25°C / 30 mins ~ 65°C / 30 mins

100 cycles

150 pF, 330Ω,

Contact: ±8kV, Air: ±15kV

1.5G / 10-500 Hz, Sine wave, 30 min/cycle,

1cycle for each X, Y, Z

220G/2ms, Half sine wave, ±X, ±Y, ±Z one

time for each direction

Note 1 Note 2

Note 1 Note 2

Note 1 Note 2

Note 1 Note 2

Note 1 Note 2

Note 1 Note 2

Note 1

Note 1 Note 2

Note 1 Note 2

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 19

SPEC NO.

PAGE

BT140GW01 V.4

19/28

5. Safety

5-1. Sharp edge requirements

There will be no sharp edges or corners on the display assembly that could cause injury.

5-2. Materials

a. Toxicity

There will be no carcinogenic materials used anywhere in the display module. If toxic materials

are used, they will be reviewed and approved by the responsible InnoLux Toxicologist.

b. Flammability

All components including electrical components that do not meet the flammability grade UL94-V0

in the module will complete the flammability rating exception approval process. The printed circuit

board will be made from material rated 94-V0 or better. The actual UL flammability rating will be

printed on the printed circuit board.

c. Capacitors

If any polarized capacitors are used in the display assembly, provisions will be made to keep

them from being inserted backwards.

6. Display quality

The display quality of the color TFT-LCD module should be in compliance with the InnoLux

incoming inspection standard.

www.jxlcd.com

www.jxlcd.com

7. Handling precaution

(1) Do not apply rough force such as bending or twisting to the module during assembly.

(2) To assemble or install module into user’s system can be only in clean working areas. The

dust and oil may cause electrical short or worsen the polarizer.

(3) It’s not permitted to have pressure or impulse on the module because the LCD panel and

backlight will be damaged.

(4) Always follow the correct power sequence when LCD module is connecting and

operating.

(5) Do not pull the I/F connector in or out while the module is operating.

(6) Do not disassemble the module.

(7) Use a soft dry cloth without chemicals for cleaning, because the surface of polarizer is

very soft and easily scratched.

(8) It is dangerous that moisture come into or contacted the LCD module, because moisture

may damage LCD module when it is operating.

(9) High temperature or humidity may reduce the performance of module. Please store LCD

module within the specified storage conditions.

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 20

SPEC NO.

PAGE

BT140GW01 V.4

20/28

8. Label Definition

8-1. Module label

BT140GW01 V.4 AB1400001 40X

Z1 Z2 Z3 Z4 Z

23 mm

(a) Model Number : BT140GW01 V.4

(b) Product Number : AB140000140X

(c) Serial ID I : Z

Serial ID includes the information as below:

Manufactured Date: Year: 0~9, for 2000~2009

Month: 1~9 & A~C for Jan.~Dec.

Date: 1~9 & A~Z (exclude I, O, Q, U) for 1th~31th

Serial No.: Module manufactures sequential number.

5 Z 6-Z 7-Z8 Z9 Z10 Z 11 Z 12

Z2 Z3 Z4 Z 5 Z

1

www.jxlcd.com

www.jxlcd.com

73 mm

- Z 7 - Z

6

CN-0HR1VT-XXXXX-

XXX

-XXXX-A00

Made In China

DP/N 0HR1VT

Z

8

9 Z10

Z

Serial No.

INL internal use

INL internal use

INL internal use

Year, Month, Date.

INL internal use

Z

12

11

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 21

8-2. Carton label

PKG ID (3S) 72870XXXXXZ1Z2Z3Z4Z5Z6Z7Z8Z9019JTPZ10Z11

152.4mm

SPEC NO.

PAGE

BT140GW01 V.4

21/28

REV A00

DP/N 0HR1VT

101.6mm

Vendor ID︱Loc ID

72870∣XXXXX

Box Qty

10Z11

Z

Made in

China

Mfg ID

XXXXX

Serial ID :

www.jxlcd.com

www.jxlcd.com

(3S) 72870 XXXXX Z1Z2 Z3 Z4 Z5 Z6 Z7 Z8 Z9 0HR1VT Z10Z

11

Box Quantity

Dell Part Number

Unique Number

Date Code

Mfg ID

Vendor ID

Identifier

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 22

p

r

9. Packing Form

Lowe

Carton

SPEC NO.

PAGE

Cushion

Step E

BT140GW01 V.4

22/28

www.jxlcd.com

www.jxlcd.com

Ste

F

Upper Cushion

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 23

10. Mechanical Drawings

10-1 Front Side

SPEC NO.

PAGE

BT140GW01 V.4

23/28

www.jxlcd.com

www.jxlcd.com

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 24

X

T

10-2 Rear side

BT140GW01 8YBXXXXX-

INL SN: Z1Z2Z3Z4-Z5 -Z6-Z7Z8Z9-Z10Z11-Z12Z 13Z14Z15-Z16-Z1-7Z18Z19

SPEC NO.

PAGE

BT140GW01 V.4

24/28

-

XXXXX

-

A00

-

XXXX

0HR1VT

-

-

Made In China

DP/N 0HR1V

CN

XX

BT140GW01 V.4 AB1400001 40X

Z1 Z2 Z3 Z4 Z 5 Z 6-Z 7-Z8 Z9 Z10 Z 1 1 Z 12

www.jxlcd.com

www.jxlcd.com

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 25

SPEC NO.

PAGE

BT140GW01 V.4

25/28

Appendix: EDID Code

Byte Value Value

(hex)

0 Header

1 Header

2 Header

3 Header

4 Header

Header

5 Header

6 Header

7 Header

8 EISA manufacture code = 3 Character ID “INL”

9 EISA manufacture code (Compressed ASCII)

0A Panel Supplier R eserved – Product Code

0B Panel Supplier Reserved – Pro duct Co de

0C LCD module Serial No - Preferred but Optional (“0” if not used)

0D LCD module Serial No - Preferred but Optional (“0” if not used)

0E LCD module Serial No - Preferred but Optional (“0” if not used)

0F LCD module Serial No - Preferred but Optional (“0” if not used)

EDID Version

Vendor / Product

Display

Parameters

Panel Color

Coordinates

Week of manufacture-->--

10

Year of manufacture – 1990 (ex. 2005-1990=15) -->2010

11

12 EDID structure version # = 1

13 EDID revision # = 3

14 Video I/P definition = Digital I/P (80h)

15 Max H image size = 31 cm

16 Max V image size = 18 cm

17 Display gamma = (gamma ×100)-100 = Example: ( 2.2×100 ) – 100 = 120

18 Feature support ( no DPMS, Active off, RGB, timing BLK 1)

19 Red/Green Low bit (RxRy/GxGy)

1A Blue/White Low bit (BxBy/WxWy)

1B Red x Rx=0.58

1C Red y Ry=0.34

1D Green x Gx=0.31

1E Green y Gy=0.55

1F Blue x Bx=0.155

20 Blue y By=0.155

21 White X Wx=0.313

22 White Y Wy=0.329

www.jxlcd.com

www.jxlcd.com

Field Name and Comments

(hex) (binary)

00

FF

FF

FF

FF

FF

FF

00

25

CC

14

00

00

00

00

00

00

14

01

03

80

1F

12

78

0A

87

F5

94

57

4F

8C

27

27

50

54

00000000

11111111

11111111

11111111

11111111

11111111

11111111

00000000

00100101

11001100

00010100

00000000

00000000

00000000

00000000

00000000

00000000

00010100

00000001

00000011

01000000

00011111

00010010

01111000

00001010

10000111

11110101

10010100

01010111

01001111

10001100

00100111

00100111

01010000

01010100

23 Established timings 1 (00h if not used)

hed

Establis

Timings

24 Established timings 2 (00h if not used)

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

00

00

00000000

00000000

Page 26

SPEC NO.

PAGE

BT140GW01 V.4

26/28

25 Manufacturer’s timings (00h if not used)

26 Standard timing ID1 (01h if not used)

27 Standard timing ID1 (01h if not used)

28 Standard timing ID2 (01h if not used)

29 Standard timing ID2 (01h if not used)

2A Standard timing ID3 (01h if not used)

2B Standard timing ID3 (01h if not used)

2C Standard timing ID4 (01h if not used)

2D Standard timing ID4 (01h if not used)

2E Standard timing ID5 (01h if not used)

2F Standard timing ID5 (01h if not used)

30 Standard timing ID6 (01h if not used)

Standard Timing ID

31 Standard timing ID6 (01h if not used)

32 Standard timing ID7 (01h if not used)

33 Standard timing ID7 (01h if not used)

34 Standard timing ID8 (01h if not used)

35 Standard timing ID8 (01h if not used)

36 Pixel Clock/10,000 (Pixel Clock=71MHz) (LSB)

37 Pixel Clock/10,000 (Pixel Clock=71MHz) (MSB)

38 Horizontal Active = 1366 pixels (lower 8 bits)

39 Horizontal Blanking (Thbp) = 132 pixels (lower 8 bits)

www.jxlcd.com

3A Horizontal Active/Horizontal blanking (Thbp) (upper4:4 bits)

3B Vertical Active = 768 lines

3C Vertical Blanking (Tvbp) = 22 lines (DE Blanking typ. for DE only panels)

3D Vertical Active : Vertical Blanking (Tvbp) (upper4:4 bits)

3E Horizontal Sync, Offset (Thfp) = 48 pixels

3F Horizontal Sync, Pulse Width = 32 pixels

40 Vertical Sync, Offset (Tvfp) = 1 lines Sync Width = 4 lines

41 Horizontal Vertical Sync Offset/Width upper 2 bits

Timing Descripter #1

42 Horizontal Image Size =309 mm

43 Vertical image Size = 174 mm

44 Horizontal Image Size / Vertical image size

45 Horizontal Border = 0 (Zero for Notebook LCD)

46 Vertical Border = 0 (Zero for Notebook LCD)

47

48 Pixel Clock/10,000 (Pixel Clock=71MHz) (LSB)

49 Pixel Clock/10,000 (Pixel Clock=71MHz) (MSB)

4A Horizontal Active = 1366 pixels (lower 8 bits)

Timing

4B Horizontal Blanking (Thbp) = 132 pixels (lower 8 bits)

Descripter #2

4C Horizontal Active/Horizontal blanking (Thbp) (upper4:4 bits)

www.jxlcd.com

Non-interlaced, Normal, no stereo, Separate sy nc, H/ V p ol Negat i ves, DE only note:

LSB is set to “1” if panel is DE-timing only. H/V can be ignored.

00

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

BC

1B

56

84

50

00

16

30

30

20

14

00

35

AE

10

00

00

18

BC

1B

56

84

50

00000000

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

00000001

10111100

00011011

01010110

10000100

01010000

00000000

00010110

00110000

00110000

00100000

00010100

00000000

00110101

10101110

00010000

00000000

00000000

00011000

10111100

00011101

01010110

10000100

01010000

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 27

4D Vertical Active = 768 lines

4E Vertical Blanking (Tvbp) = 22 lines (DE Blanking typ. for DE only panels)

4F Vertical Active : Vertical Blanking (Tvbp) (upper4:4 bits)

50 Horizontal Sync, Offset (Thfp) = 48 pixels

51 Horizontal Sync, Pulse Width = 32 pixels

52 Vertical Sync, Offset (Tvfp) = 1 lines Sync Width = 4 lines

53 Horizontal Vertical Sync Offset/Width upper 2 bits

54 Horizontal Image Size =309 mm

55 Vertical image Size = 174 mm

56 Horizontal Image Size / Vertical image size

57 Horizontal Border = 0 (Zero for Notebook LCD)

58 Vertical Border = 0 (Zero for Notebook LCD)

59 Module “A” Revision = Example: 00, 01, 02, 03, etc.

5A Flag

5B Flag

5C Flag

5D Dummy Descriptor

5E Flag

5F Dell P/N 1st Character "H"

60 Dell P/N 2nd Character "R"

61 Dell P/N 3rd Character "1"

62 Dell P/N 4th Character "V"

www.jxlcd.com

63 Dell P/N 5th Character "T"

64 LCD Supplier EEDID Revision #

65 Manufacturer P/N "1"

Timing Descripter #3

66 Manufacturer P/N "4"

Dell specific information

67 Manufacturer P/N "0"

68 Manufacturer P/N "G"

69 Manufacturer P/N "W"

6A Manufacturer P/N "0"

6B

6C Flag

6D Flag

6E Flag

6F Data Type Tag:

70 Flag

71 Reserved

72 Reserved

73 Reserved

74 Reserved

Timing Descripter #4

75 Reserved

76 Reserved

www.jxlcd.com

Manufacturer P/N (If <13 char, then terminate with ASCII code 0Ah, set remaining

char = 20h) "1"

SPEC NO.

PAGE

BT140GW01 V.4

27/28

00

16

30

30

20

14

00

35

AE

10

00

00

00

00

00

00

FE

00

48

52

31

56

54

80

31

34

30

47

57

30

31

00

00

00

00

00

00

00

00

00

00

00

00000000

00010110

00110000

00110000

00100000

00010100

00000000

00110101

10101110

00010000

00000000

00000000

00000000

00000000

00000000

00000000

11111110

00000000

01001000

01010000

00110000

01010110

01010100

10000000

00110000

00110100

00110000

01000111

01010111

00110000

00110000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

00000000

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Page 28

77 Reserved

78 Reserved

79 Number of LVDS receiver chips = ‘01’ or ‘02’

7A BIST Enable: Yes = ‘01’ No = ‘00’

7B (If <13 char, then terminate with ASCII code 0Ah, set remaining char = 20h)

7C (If <13 char, then terminate with ASCII code 0Ah, set remaining char = 20h)

7D (If <13 char, then terminate with ASCII code 0Ah, set remaining char = 20h)

SPEC NO.

PAGE

BT140GW01 V.4

28/28

00

00

01

01

0A

20

20

00000000

00000000

00000001

00000001

00001010

00100000

00100000

7E Extension flag (# of optional 128 EDID extension blocks to follow, Typ = 0)

7F Checksum (The 1-byte sum of all 128 bytes in this EDID block shall = 0)

Checksum

www.jxlcd.com

www.jxlcd.com

00

4B

00000000

10001011

ALL RIGHTS STRICTLY RESERVED. ANY PORTION OF THIS DOCUMENT SHALL NOT BE REPRODUCED, COPIED, OR

TRANSFORMED TO ANY OTHER FORM S WITHOUT P ERMISSION FROM Chimei-Innolux

Loading...

Loading...