Page 1

INSTALLATION AND

PROGRAMMING MANUAL

Section 0. Title and Document Version log. (This sheet)

Section 1. Installation Manual.

Section 2. Introduction to Programming and System Overview.

Programming Reference:

Section 3. General Options.

Section 4. Times.

Section 5. Areas.

Section 6. Zone Inputs.

Section 7. System Inputs.

Section 8. Auxiliary Outputs.

Section 9. Terminals.

Section 10. Communications.

Section 11. Users.

Section 12. Quick Programming. (Includes Programming record sheets)

Section 13. Index.

Contents

© 2002. Inner Range Pty. Ltd. Part Number: 630047

Page 2

p2 Section 0. Title. Version 1.02 CONCEPT IQ. Installation & Programming Manual.

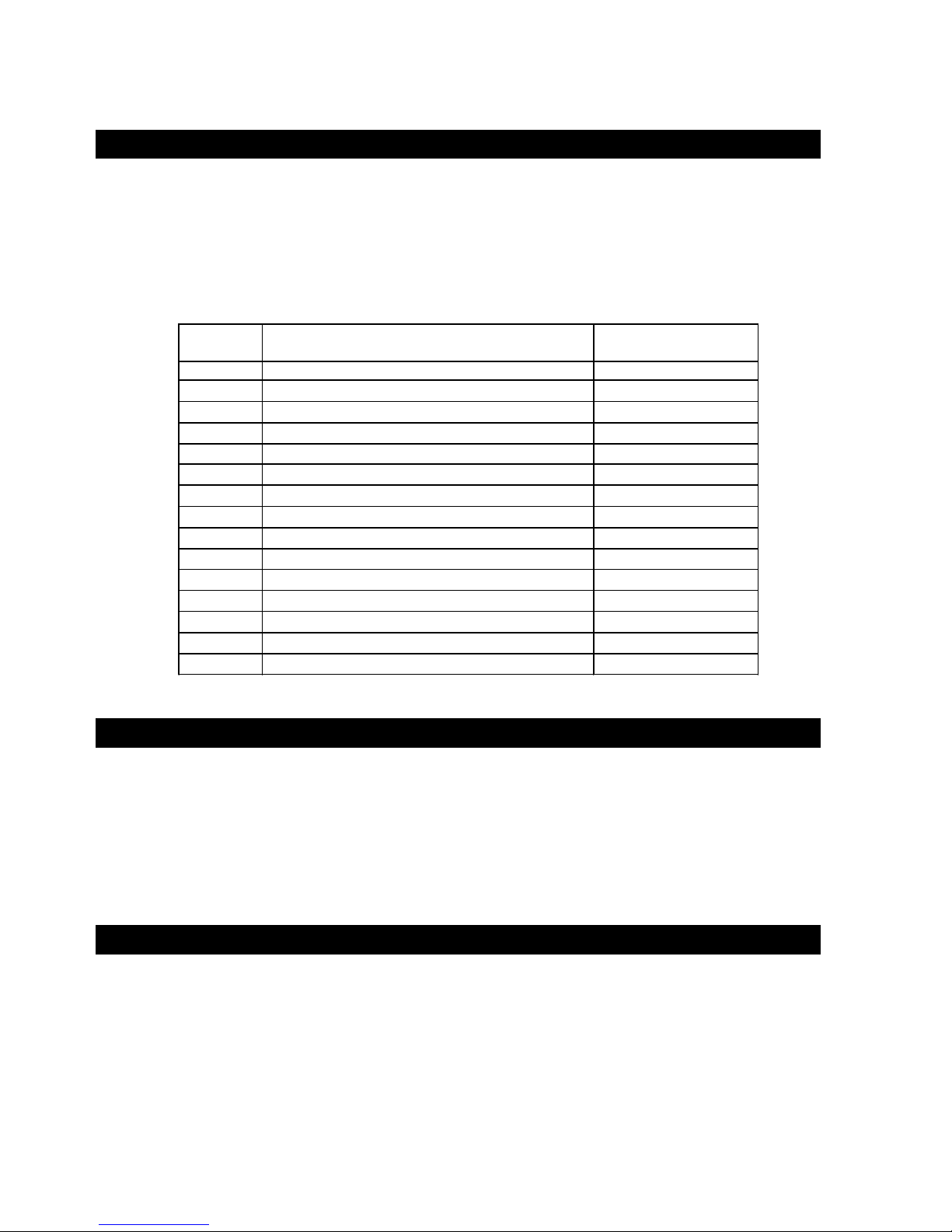

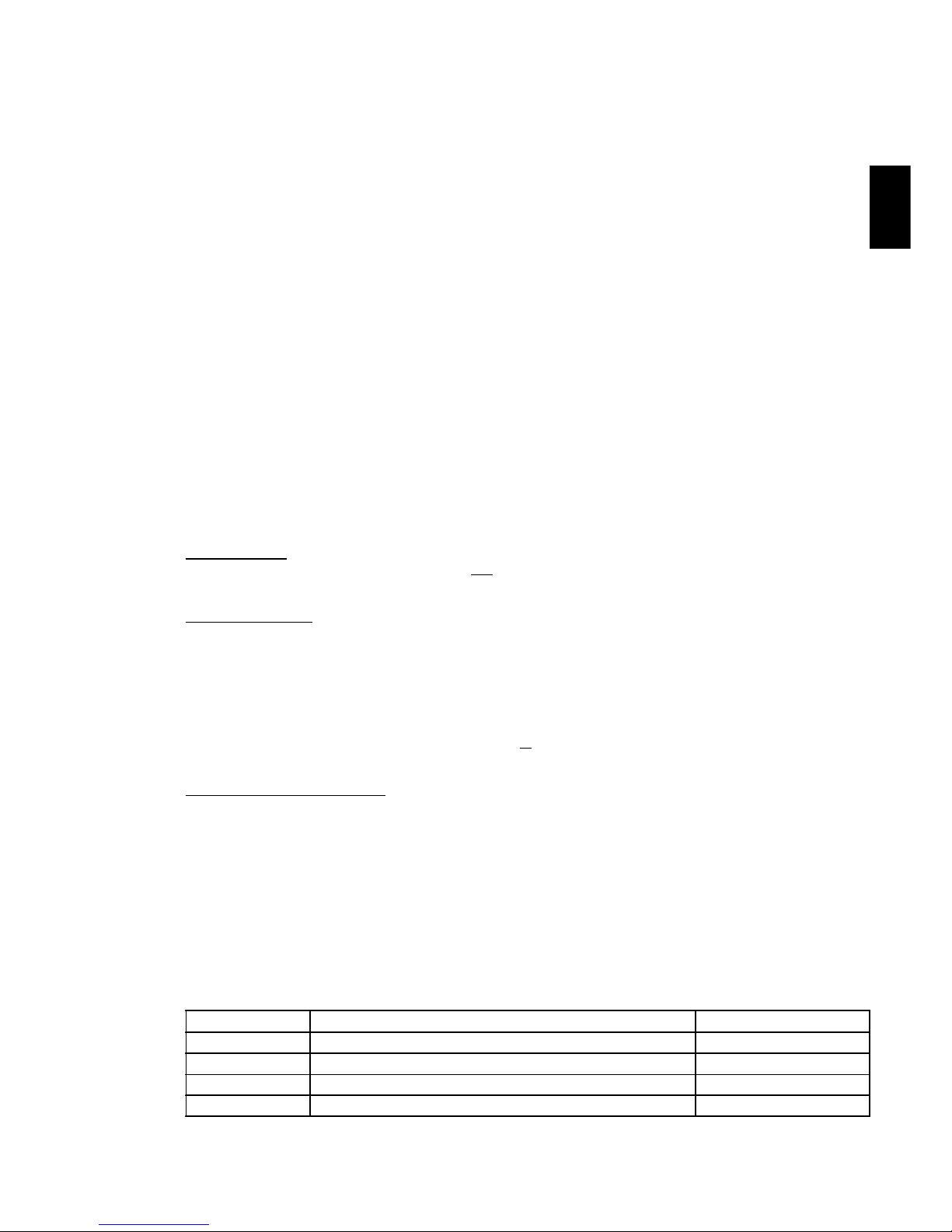

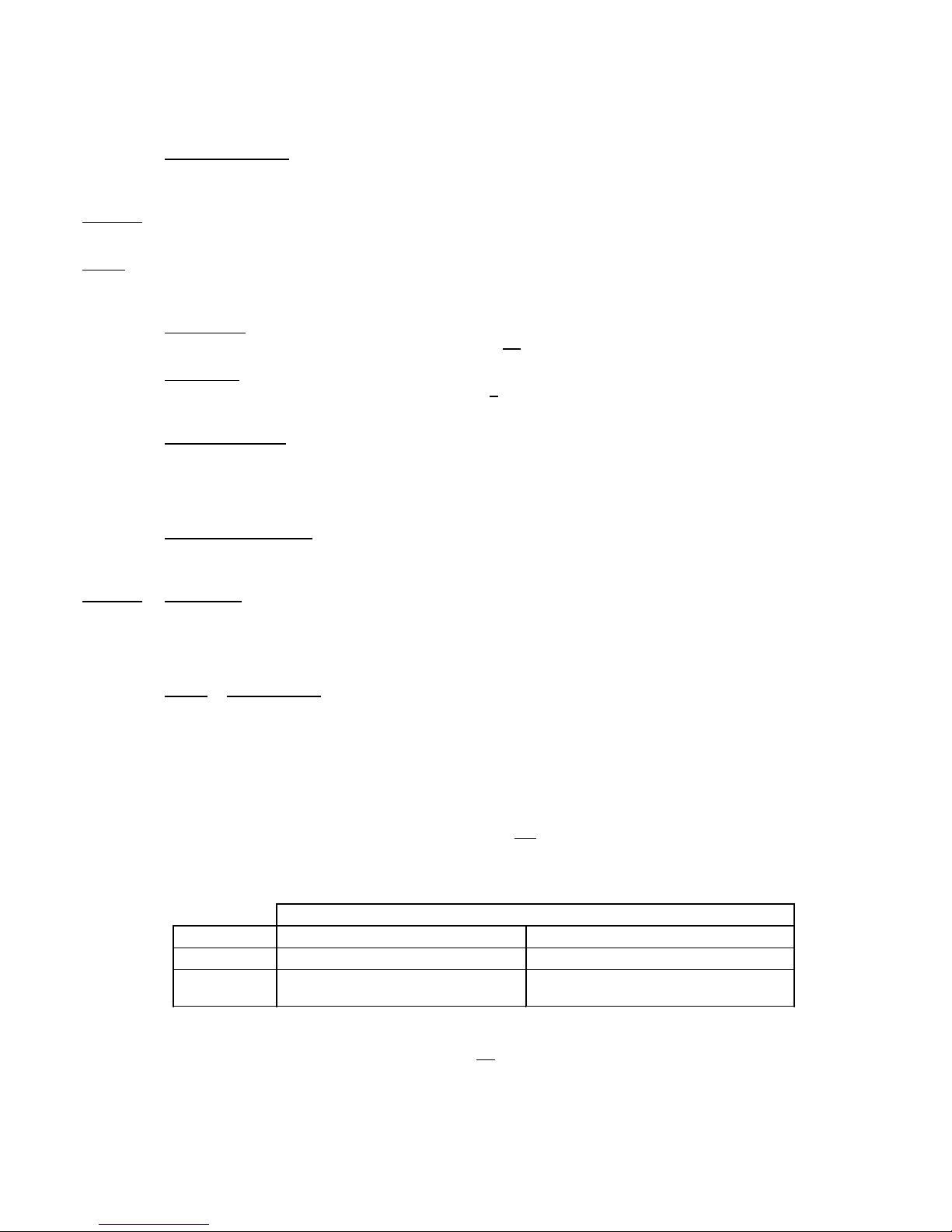

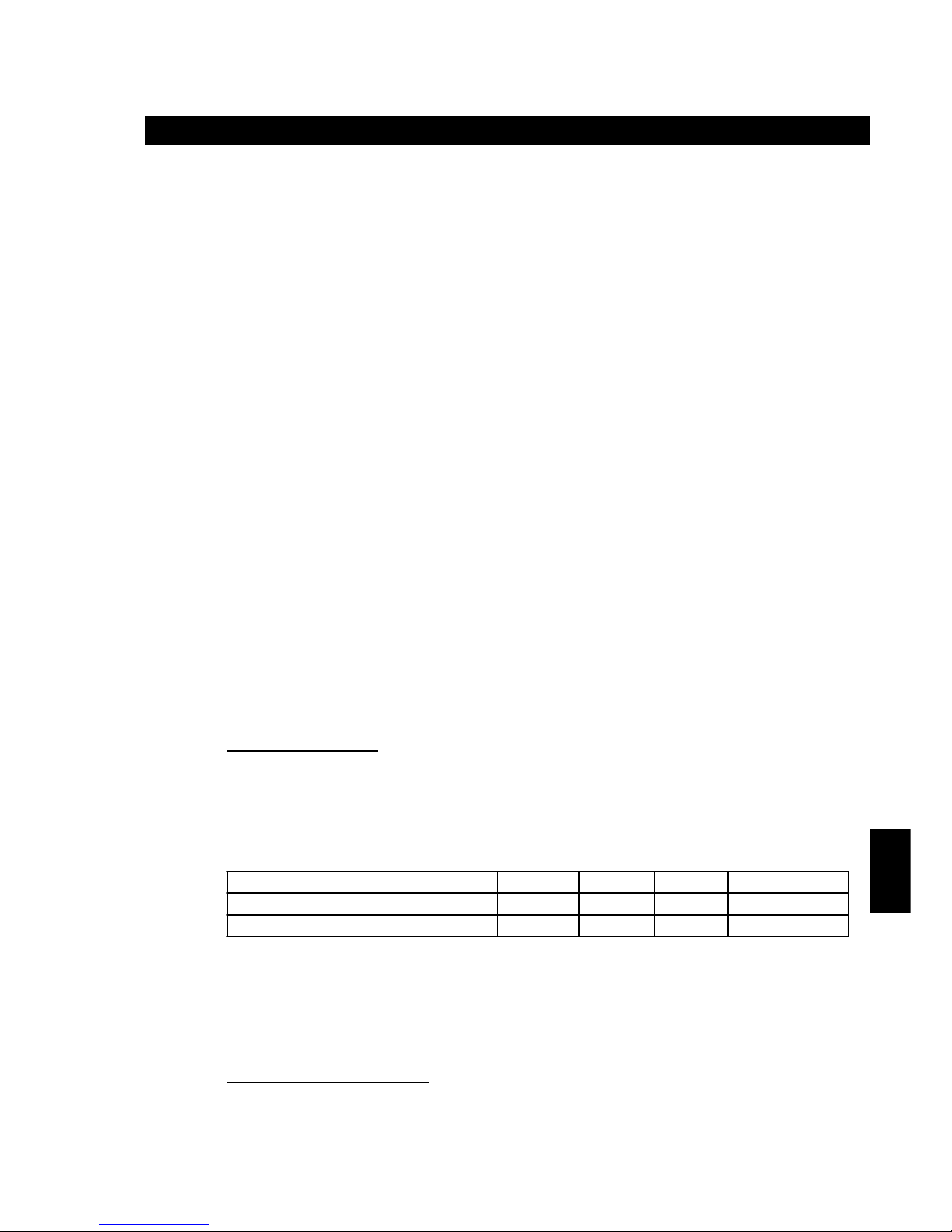

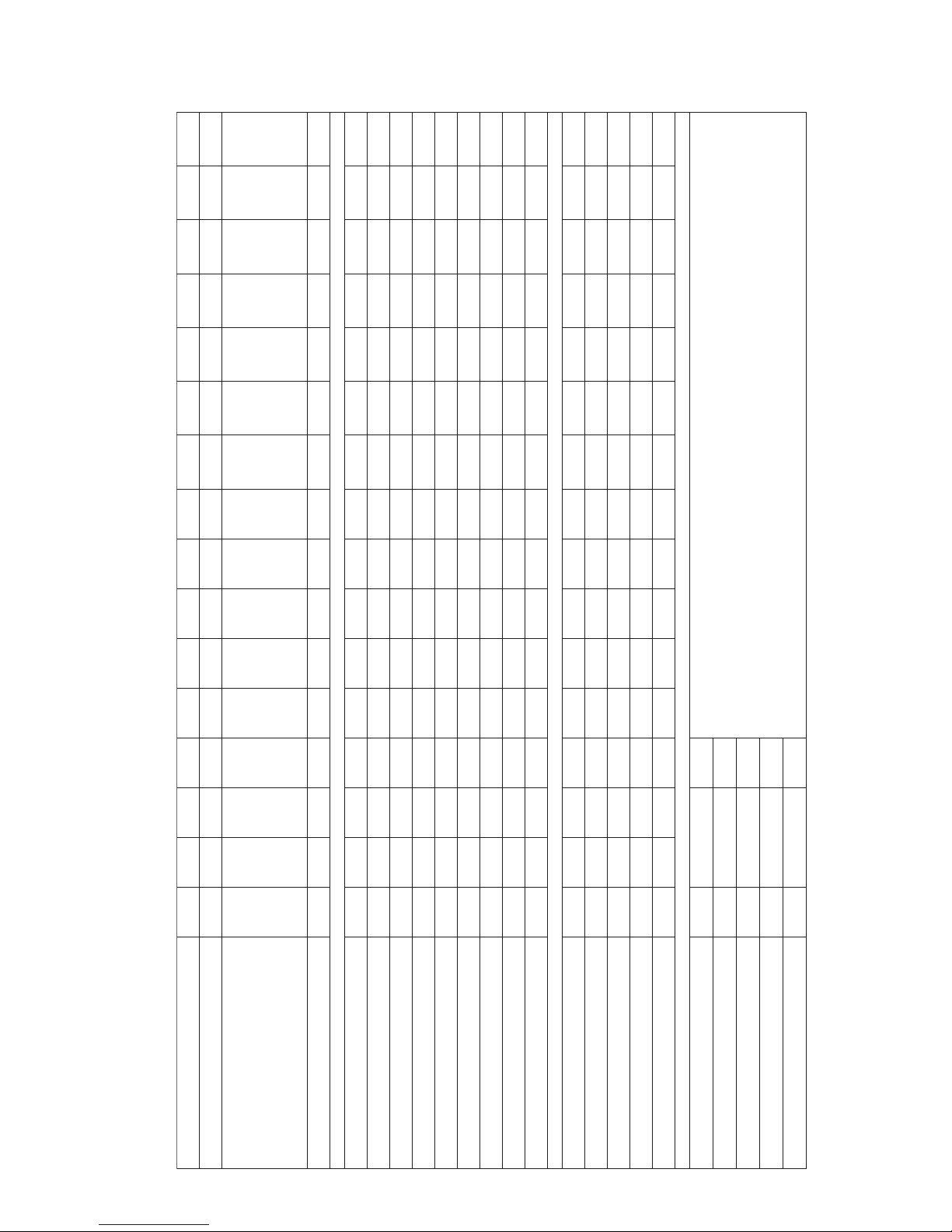

SECTION TITLE CURRENT VERSION

-AS AT 16 JAN 2002

0 Title and Document Version log (This sheet) 1.02

1 Installation Manual 1.01

2 Programming Introduction 1.01

3 General Options 1.01

4 Times 1.01

5 Areas 1.01

6 Zone Inputs 1.01

7 System Inputs 1.02

8 Auxiliary Outputs 1.01

9 Terminals 1.02

10 Communications 1.01

11 Users 1.01

12 System Planning & Programming record sheets 1.02

13 Index 1.02

Document Revisions

This table shows the current Version numbers of all documents in the “Concept IQ Installation and Programming Manual”.

This table can be used when checking the Website for updates. http://www.innerrange.com

When you replace any documents in this manual with new Versions, ensure that this table is updated or replaced with the

latest Version from the Website.

Inner Range Pty Ltd is proud of the reputation it has gained in the provision of high quality electronic products. Exhaustive

factory and field testing ensure that enhanced system programming features and additional hardware components operate

as expected prior to their release to our customers. Extensive function testing is carried out on every Inner Range Concept

product prior to it leaving the factory.

It is our intention to completely satisfy the requirements of our customers. To that end, Inner Range Pty Ltd stands behind

its products with confidence. A Two Year Warranty accompanies every Inner Range Concept product. Should any

Concept product fail to function as intended by the manufacturer within this period, it should be returned to the distributor

and the fault or symptom detailed. Inner Range will, at its own discretion, repair or replace the product as soon as possible.

This Warranty does not cover product failures occurring wholly or in part as a result of misuse, malicious damage,

accidental damage or acts of nature.

1) The manufacturer and/or it’s agents take no responsibility for any damage, financial loss or injury caused to any

equipment, property or persons resulting from the correct or incorrect use of the Concept IQ system and its

peripherals. The purchaser assumes all responsibility in the use of the Concept system and its peripherals.

2) Whilst every effort has been made to ensure the accuracy of this manual, Inner Range Pty Ltd assumes no

responsibility or liability for any errors or omissions. Due to ongoing development the contents of this manual is

subject to change without notice. Check regularly with your supplier or the Website for updates.

Disclaimer

Warranty

Page 3

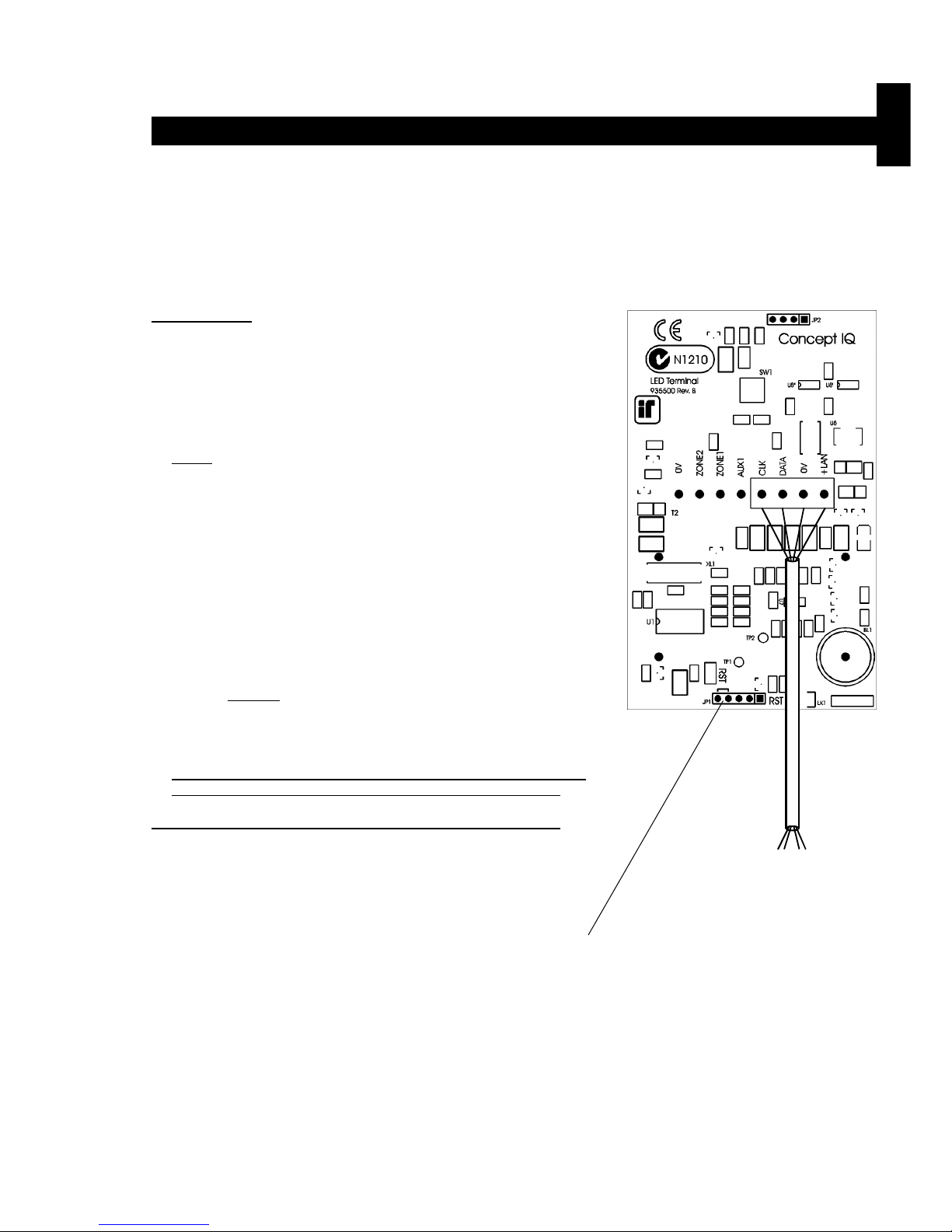

CONCEPT IQ. Installation & Programming Manual.

Install

p1

SECTION 1.

INSTALLATION.

1. Installer and Master User Operations (NEXT functions) ...........2

2. Control Module ...........................................................................3

3. LED Terminal..............................................................................7

4. Programming Key ....................................................................... 8

5. Enhanced LED Terminal.............................................................9

6. Expansion Card ..........................................................................11

7. DTMF Card .................................................................................13

NOTE: Factory Default PIN Codes:

User 1. Installer: 2 3 4 5

User 2. Master User: 0 1 2 3

Contents

Page 4

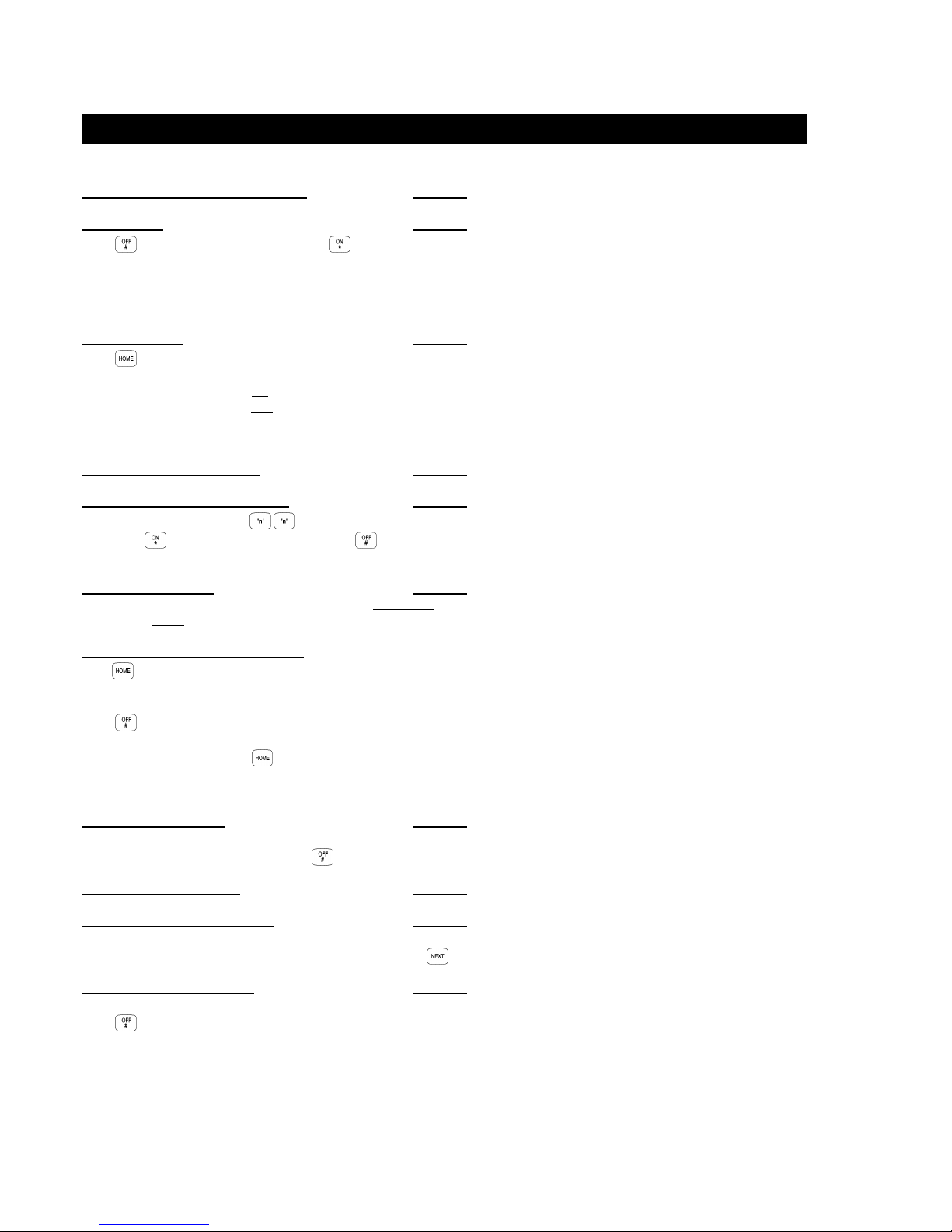

Section 1. Installation. CONCEPT IQ. Installation & Programming Manual.p2

Adding / Changing / Deleting Users. NEXT 20 See Section 11: Users

View history. NEXT 21

Press to view the Next Event. Press to view the Previous Event.

If the are no further events to be displayed, one long beep will sound.

History Event Types: Arm: <ARM> Lamp. Armed in Home Mode: <HOME> Lamp.

Dis-arm: <ARM> and <0> Lamp. Zone Input in alarm: <Zone 1> to <Zone 16> Lamp.

System Inputs in alarm: <0> Lamp.

Walk test mode. NEXT 22

Press to switch between Alarm Test Mode and Tamper Test Mode.

Any Zone Input in the Terminal’s Associated Area that goes into the Alarm (Un-sealed) or Tamper state will cause:

- The corresponding Zone Lamp to fast flash on an Alarm state in Alarm Test Mode.

- The corresponding Zone Lamp to slow flash on a Tamper state in Tamper Test Mode.

- The Siren to sound for 3 seconds.

- The Terminal beeper to emit a short beep.

Setting the Real-Time Clock. NEXT 23 See Section 4: Time Programming.

Auxiliary Control and Test mode. NEXT 24

Enter the Auxiliary Output number (1 or 2 digits);

then Press: to turn the Auxiliary ON OR: to turn the Auxiliary OFF..

When testing the Auxiliary, remember to return the Auxiliary to it’s original state before exiting Auxiliary Control Mode.

Fault Analysis mode. NEXT 25 See Section 7: System Inputs

System Inputs that are currently in Alarm will be indicated by Fast flashing on the relevant Zone Lamp. (See "System Input Mapping" in Section 7)

These Alarms cannot be acknowledged until the problem is rectified.

Acknowledge any previous Faults and Alarms.

Press . System Inputs that have been in Alarm but subsequently restored since the last Acknowledgement will be indicated by Slow flashing on the

relevant Zone Lamp. Note the datails of the Alarm/s displayed.

Press to Acknowledge and Clear any of the Faults or Alarms that are not currently in Alarm.

IMPORTANT NOTES: 1) Press to toggle between the “Current Alarms” & “Previous Alarms” displays.

2) Zone Self-test (Lamp 10) can only be cleared from “Zone Self Test Display” Mode (NEXT 26).

3) Door Alarm (Lamp 15) can only be cleared from “Acknowledge Door Alarms” Mode (NEXT 29).

Zone Self Test display. NEXT 26

The Zone 1 to Zone 16 Lamps will indicate any Zones that have failed the Zone Self Test so that appropriate action may be taken. e.g. A detector fault

may need to be rectified by the Installer. Press to acknowledge any Zone Self Test faults.

Edit Telephone numbers. NEXT 27 See section 10: Communications.

View Software Version number. NEXT 28

The 1st digit of the 4-digit Version number is displayed by the corresponding Zone Lamp flashing.

To display each of the remaining digits of the Version number press the key..

Acknowledge Door Alarms. NEXT 29

Door Alarms will be indicated by the relevant Zone Lamp 1 to 4. Note the datails of the Alarm/s displayed.

Press to Acknowledge any Door Alarms.

De-Isolate System Inputs. NEXT 90 De-Isolates any Isolated System Inputs.

Test Siren speaker and Strobe (Aux. 1). NEXT 91 Triggers Siren and Strobe (Aux 1) for 3 Seconds.

Battery Test. NEXT 92 Switches off the Battery charger for 5 seconds.

Test Transmission. (Test report) NEXT 93 Triggers Test report via selected Dialer format.

Day Alarm on / off. NEXT 94 Toggles Day Alarm Enabled/Disabled.

Reset Latching Auxiliaries. NEXT 96 Resets all latched Auxiliaries.

Answer Phone NEXT 97 Forces Control Module to answer incoming call.

Reset Smoke Detectors. NEXT 99 Triggers the “Smoke Detector Reset” Aux Event.

Installer and Master User Operations.

Page 5

CONCEPT IQ. Installation & Programming Manual.

Install

p3

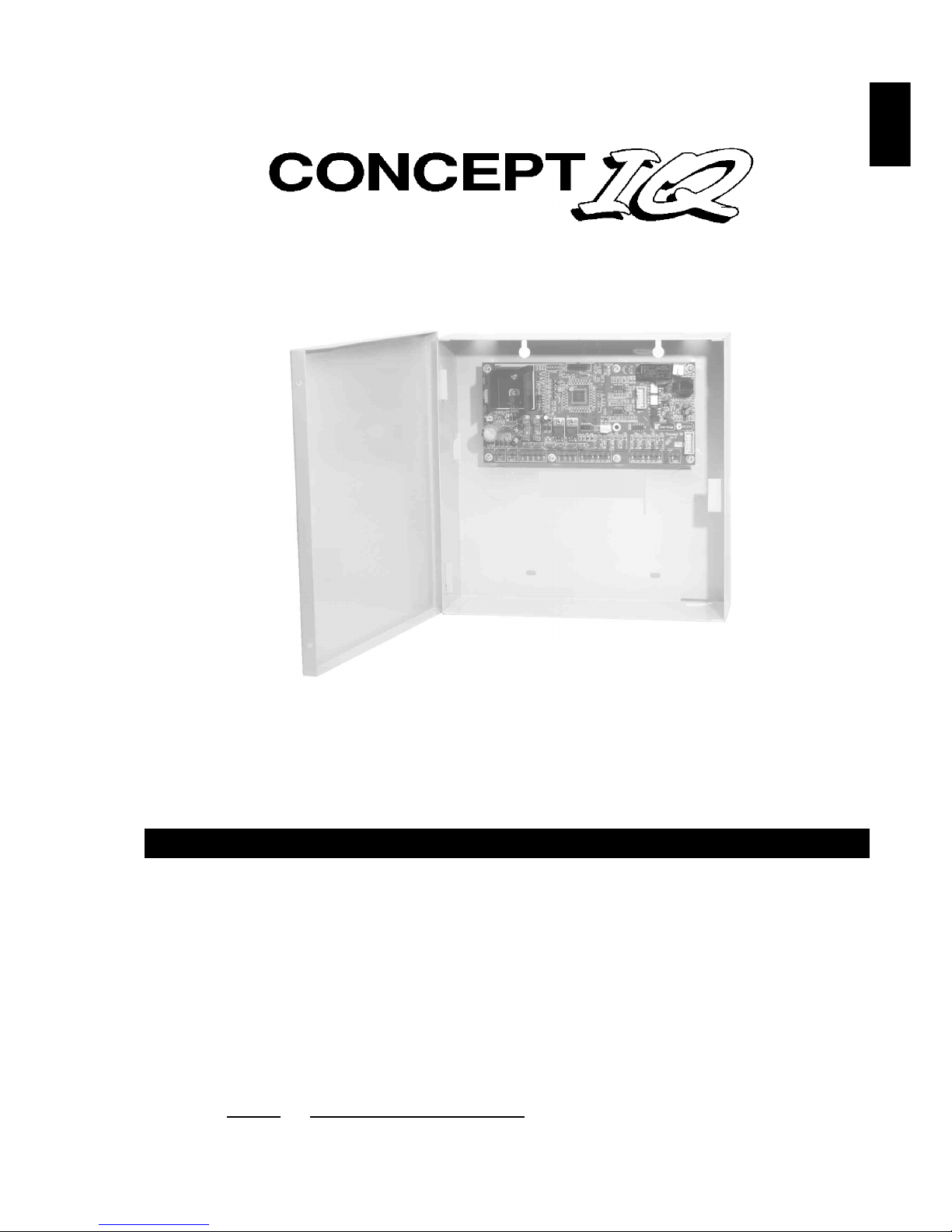

Control Module. 995501

Control Module Parts List

- Control Module PCB mounted in metal enclosure.

- User Manual.

- Installation Manual. (This document)

- Installation Kit containing:

- 4 x Pan Head Self-tapping screws 4x6mm. Used to secure the enclosure cover.

- 5 x plastic “D” bungs. Must be fitted to all unused cable entry cutouts in the cover.

- Telecom Line cord. (Note: Non-standard configuration. Only suitable for use with this product)

- 10 x 3k3 End-of-line resistors. (orange-orange-black-brown-brown) Used for Single EOL / Dual EOL / Zone Doubling.

- 10 x 6k8 End-of-line resistors. (blue-grey-black-brown-brown) Used for Dual EOL or Zone Doubling.

- 10 x 1k End-of-line resistors. (brown-black-black-brown-brown) Used for Zone Doubling.

- Tamper switch.

- Tamper switch bracket.

- 2 x 6 Way plug-on screw terminals. (Only for PCBs that do not have fixed terminal blocks fitted)

- 1 x 3 Way plug-on screw terminals. (Only for PCBs that do not have fixed terminal blocks fitted)

- 5 x 2 Way plug-on screw terminals. (Only for PCBs that do not have fixed terminal blocks fitted)

- 2 x 6.3mm Tamper switch connectors.

- Battery connection lead, 220mm, pre-assembled.

- 1 x 1 Amp M205 (20mm) Fuse. (Spare)

Electrical Specifications

Power Supply I/P: Plug pack Mains Supply: 240V AC -10% / +10%. 50 Hertz.

Plug pack Output: 16V AC. 1.0 Amperes.

PCB AC Input Voltage: 16V AC.

Battery Capacity: 12V. 7AH. Sealed Lead Acid Battery.

DC Operating Voltage (Batt I/P) 9.5 to 14 V DC. (Low Battery alarm activated at 11.2V +/- 0.3V)

Battery Input Fuse: 1 Ampere.

Power Supply O/P: Current: Total combined current required by devices connected to

“DET+” and “LAN+” must not exceed 600 milliAmps.

Fuse Protection: 1 Ampere. (DET+ and LAN+)

Auxiliary Outputs: OUT1 (Strobe) / OUT2 Max. switched current = 200mA per Auxiliary. (Open Collector)

Siren Output (SPK): Maximum Load: 8 Ohms. (i.e. 1 x 8 Ohm Speaker only. Additional speakers must

not be connected in parallel)

NOTES: 1) ALWAYS REPLACE FUSES WITH THE SAME FUSE TYPE AND VALUE!

2) See data supplied with detectors and output devices for current consumption.

Mechanical Specifications

Dimensions: Height: 260 mm. Width: 265 mm. Depth: 80 mm.

Weight: 4.2 kg. (Cabinet & cover, PCB and 7AH battery) Plug pack = 0.6kg

Environmental Specifications

Continuous Operating Temperature 0 to +50 °C

Storage Temperature -20 to +70 °C

Relative Humidity (Non condensing) 15 to 85 %

© 2001. Inner Range Pty. Ltd. Part No: 635501

Contents

Control Module Parts List ..............................................................................................................1

Specifications.................................................................................................................................1

Installation Procedure ....................................................................................................................2

Connection Details. Zone Inputs (Detectors), Tamper switch and Fuses ................................3

Mode 3 Telephone line connection ..............................................................................................3

Connection Details. Power, Warning devices & LAN.................................................................4

Control Module. Version 1.02

Page 6

Section 1. Installation. CONCEPT IQ. Installation & Programming Manual.p4

Installation Procedure

1. Installer. The system must be installed and maintained by a competent, qualified installer who holds appropriate

licences for Telecommunications and Security System cabling in accordance with local Regulations.

2. Location. The Control Module must be installed in a secure location near an AC Power outlet and Telephone line

connection. Install the unit where it will not be subject to temperature or humidity outside the specified range, and will

not come into contact with water, other liquids, high dust levels or chemical atmospheres.

Adequate ventilation must be provided around the cabinet (50mm min.) to ensure that heat from any other source does

not cause the Control Module to operate at an unsafe temperature.

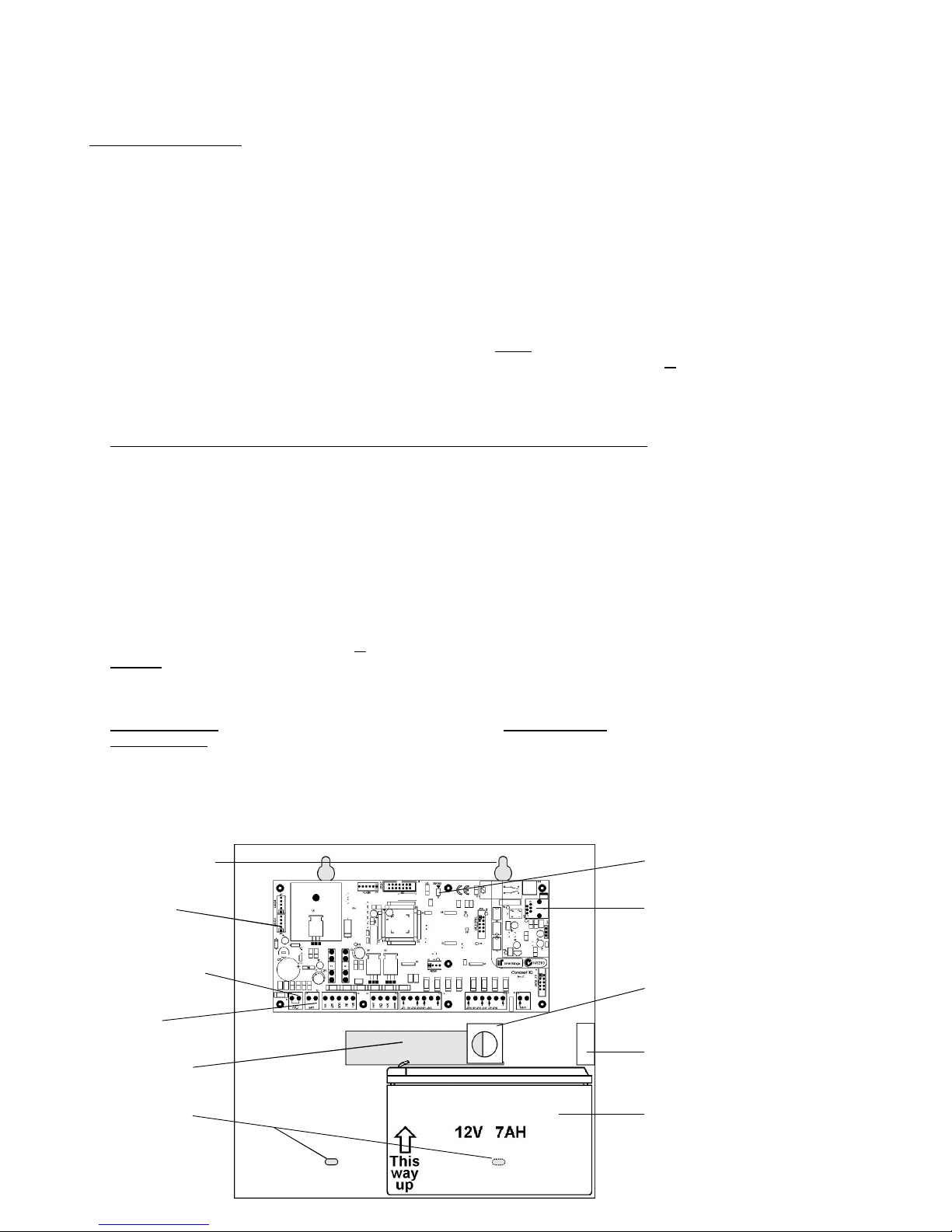

3. Positioning. Orientation of the cabinet MUST be as per the illustration below with the battery at the bottom.

Fit the Tamper switch into the hole provided in the Tamper switch bracket. The Tamper switch bracket must be

positioned in the slot provided and under the base of the cabinet, before the cabinet is secured to the wall.

When wired to the “TAMP” input, Tamper switch alarms if the cabinet is removed from the wall or the cover is opened.

4. Mounting. The cabinet must be secured to a flat, solid, vertical surface using appropriate fasteners through the 4 holes

provided in the base, and must be positioned to provide unhindered access for installation and maintenance.

The two mounting holes in the top of the cabinet are keyhole slots to assist with positioning.

When mounting onto flammable surfaces, a fire protection backplate MUST BE INSTALLED.

5. Power. Strip 5mm of insulation from the ends of the 3 Plug pack cable conductors. Terminate the 16VAC conductors

into the “AC” Input connections, and the Earth wire (Green/Yellow) into “BATT-” on the PCB.

CAUTION: Do not connect the Plug pack to an AC outlet until all wiring is complete and checked.

6. Battery. Connect the pre-assembled battery cable into the “BATT+” and “BATT-” connections on the PCB.

CAUTION: Do not connect the Terminals to the Battery until all wiring is complete and checked.

7. Cabling. All cabling must enter the cabinet via the existing cutouts provided in the rear and sides. Additional holes

must not be cut in the cabinet. Installation of Cables both inside the cabinet, and external to the cabinet, must conform

to the appropriate Standards for Security and Telecommunications systems.

Cables must be protected at the entry points by grommets or by allowing the conduit to protrude into the cabinet.

The “D” Bungs provided must be fitted to all unused cable entry cutouts.

DO NOT connect the LAN “CLK” & “DATA” wires to the Control Module until all LAN Modules (e.g. LED Terminals) are

Commissioned.

8. Diagnostics. The “STATUS” Lamp on the Control Module can be used to assist with troubleshooting and testing.

SLOW FLASHING: MicroProcessor OK (Running) FAST FLASHING: Controller is Dialing.

NOT FLASHING: MicroProcessor Not running, OR Programming Key Upload or Download in progress.

9. Cover. In order to comply with regulations the cover must always be correctly re-fitted following any installation or

maintenance work. Engage the hinges on the Left-hand side and fasten the cover tightly to the cabinet using all four (4)

of the screws provided. Screw holes are located on both edges of the two Right-hand side corners.

STATUS Lamp.

Step 8.

JP9. Mode 3 Line Socket

for connection to Telecom

Line. (Special cable

supplied must be used)

Tamper switch bracket.

(and Battery retainer)

Step 3.

Latch for optional lock.

12V, 7AH Battery position.

Step 6.

< Location of Side Cable

entries. Step 7.

^ ^

<

>

V

Top mounting holes

(x2). Step 4.

Port 0. Serial

Comms Port.

(Prog. Key or PC)

T1. 16V AC Power

connections. Step 5.

T3. Battery

connections. Step 6.

Rear cable entry

cutout. Step 7.

Bottom Mounting

Holes (x 2).

Step 4.

Page 7

CONCEPT IQ. Installation & Programming Manual.

Install

p5

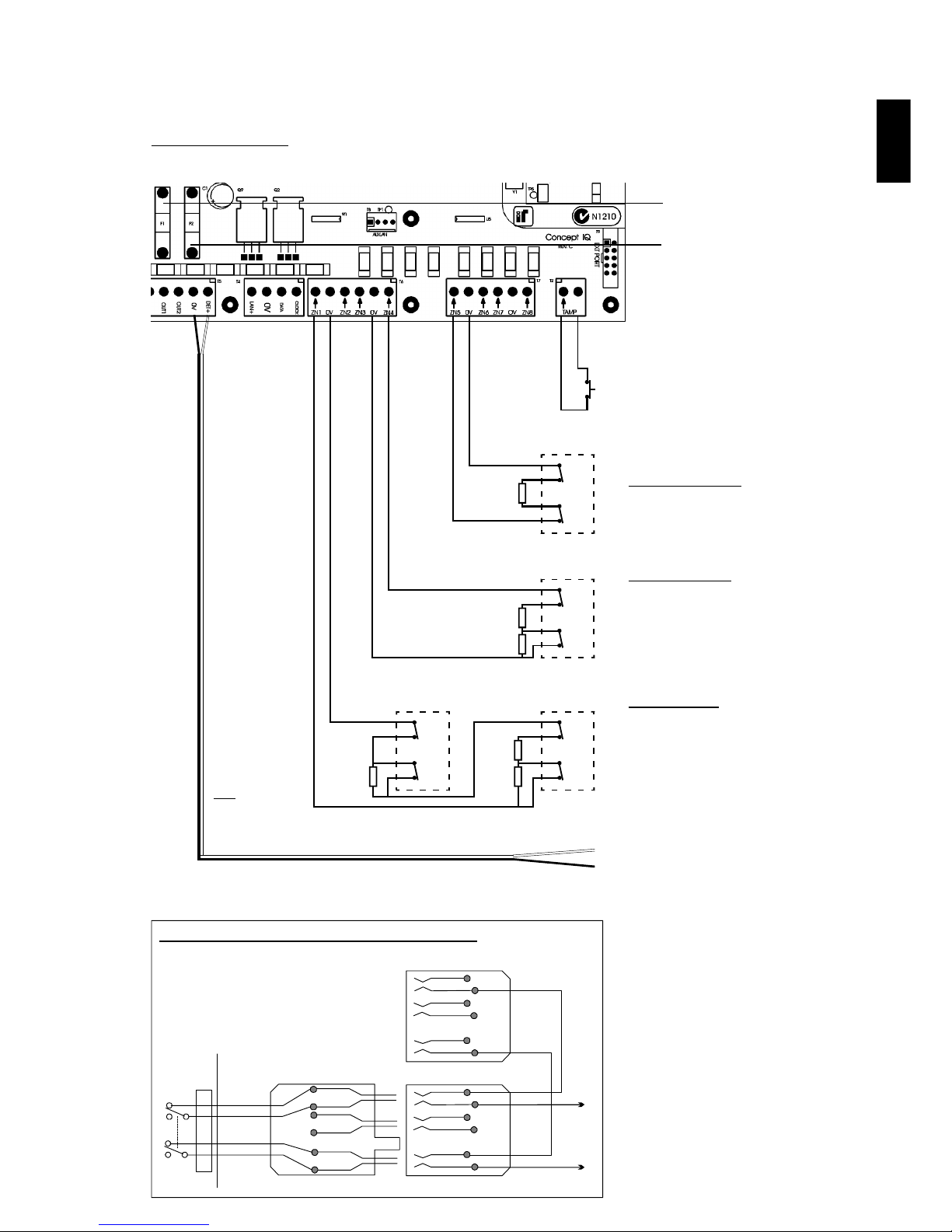

T2. “TAMP”. Dedicated Cabinet Tamper

input. Tamper switch supplied.

No End-of-line resistors necessary.

T6 and T7. Zone Input connections.

Single End-of-Line.

e.g.

3k3 Seal

Open Cct: Alarm

Dual End-of-Line.

e.g.

3k3 Seal

10k1 Alarm

Open Cct: Tamper

Short Cct: Tamper

Zone Doubling.

1k Seal

4k3 1st Zone in Alarm

7k8 2nd Zone in Alarm

11k1 1st & 2nd Zones in Alarm

Open Cct: Tamper

Short Cct: Tamper

T5. “DET+” and “0V”.

Detector Power connections.

12V Supply for Detectors and Auxiliary

Devices. Total combined current sourced

from “DET+” and “LAN+” must not exceed

600 milliAmps.

F1. Battery Input Fuse. 1A. M205.

Connection Details. Detectors, Tamper switch and Fuses

Minimum Cable spec: 14/0.2

Tamp.

Alarm

Detector

C

NC

C

NC

EOL Res.

3k3 Typ.

Tamp.

Alarm

Detector

C

NC

C

NC

EOL Res.

3k3 Typ.

6k8 Typ.

Tamp.

Alarm

2nd Detector

C

NC

C

NC

EOL

1k

6k8

Tamp.

Alarm

1st Detector

C

NC

C

NC

EOL

3k3

PSTN

Line

604 Socket

to other equipment.

604 Cable from

Concept IQ

(Supplied)

Mode 3 Telephone Socket Wiring for Australia

F2. PWR Fuse. 1A. M205.

1

2

3

4

1

2

3

4

5

6

5

6

1

2

5

6

3

4

JP9

Control

Module

1

2

5

6

NOTE: Zone Input connections.

“Normally Open” Alarm Contacts.

Normally Open Alarm Contacts (e.g. As

often found on Smoke Detectors) are

wired in the same manner as Normally

Closed contacts.

When programming the Zone Input,

Option 8 (“Normally Open”) in the “Zone

Options” must be selected. (Addresses

752 [Zone 1] to 767 [Zone 16] )

Control Module. Version 1.02

NOTE:

The 1k EOL

Resistor must

be fitted at the

2nd Detector.

Page 8

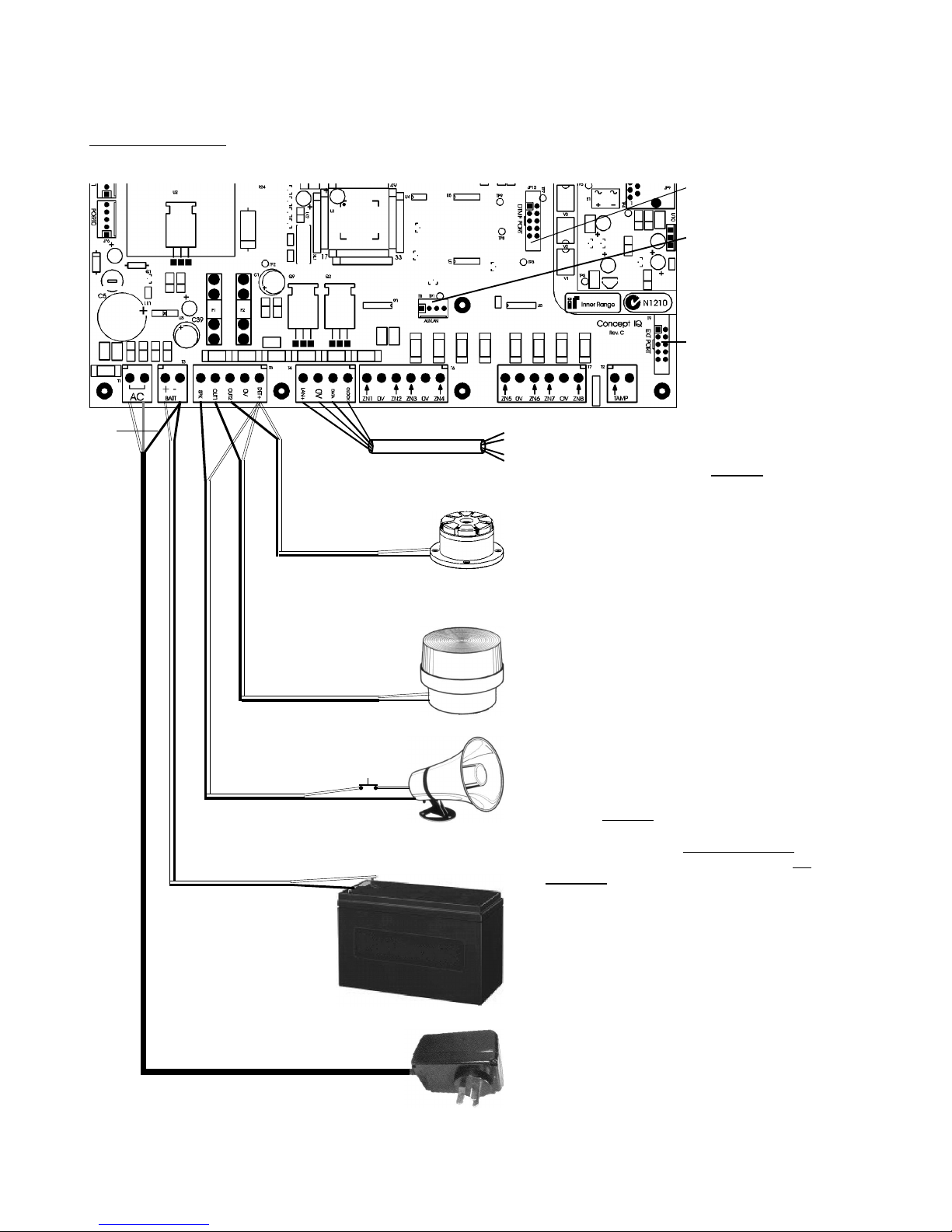

Section 1. Installation. CONCEPT IQ. Installation & Programming Manual.p6

T1. “AC”.

16V AC Input.

(Connect Green/Yellow Earth wire to T3 “-”)

T4. LAN connections to Terminals. (Up to 4)

Maximum run to furthest LAN Module: 100m.

Total LAN cabling: 150m maximum.

If twisted pair cable is used, DO NOT

combine “Clock” & “Data” on the same pair.

T9. Zone Input /

Auxiliary Output

Expansion Bus Port.

T3. “+” & “-”.

12V Sealed Lead Acid Battery connection.

Maximum Battery capacity: 7 AH

T5. “SPK” & “DET+”

Siren Speaker output.

Maximum load: 8 Ohms

Minimum Speaker rating: 10 Watts.

(i.e. 1 x 8 Ohm Speaker only. Additional

speakers must not be connected in parallel)

NOTE: A 6k8 Resistor must be connected

between “SPK” & “DET+” if Siren speaker not

connected.

T5. “OUT1” & “DET+” (Strobe)

Auxiliary 1 Output.

Normally used for Strobe.

Maximum switched current: 200 mA.

T5. “OUT2” & “DET+”.

Auxiliary 2 Output. General purpose Aux.

May be used for Piezo Siren.

(Program Aux 2 as Event Type 59)

Maximum switched current: 200 mA.

Minimum Cable spec: 14/0.2

Minimum Cable spec: 14/0.2

Minimum Cable spec: 14/0.2

Battery cable supplied.

4 Core Security Cable

recommended. (14/0.2)

CAUTION:

Total current sourced from

“DET+” and “LAN+” must not

exceed 600mA.

Connection Details. Power, Warning devices & LAN

T8. “Aux LAN”.

For temporary

connection of a

Terminal for

diagnostic purposes.

Siren cover Tamper

switch (Normally Closed)

Disclaimer: 1. The manufacturer &/or it’s agents take no responsibility for any damage, financial loss or injury caused to any equipment, property or

persons resulting from the correct or incorrect use of the system or it’s peripherals. The purchaser assumes all responsibility in the use of the system

and it’s peripherals.

2. While every effort has been made to ensure the accuracy of this manual, the manufacturer assumes no responsibility or liability for any errors or

omissions. Due to ongoing development, this manual is subject to change without notice.

JP10. DTMF/Voice

Card Port.

Earth

(Grn/Yell)

Page 9

CONCEPT IQ. Installation & Programming Manual.

Install

p7

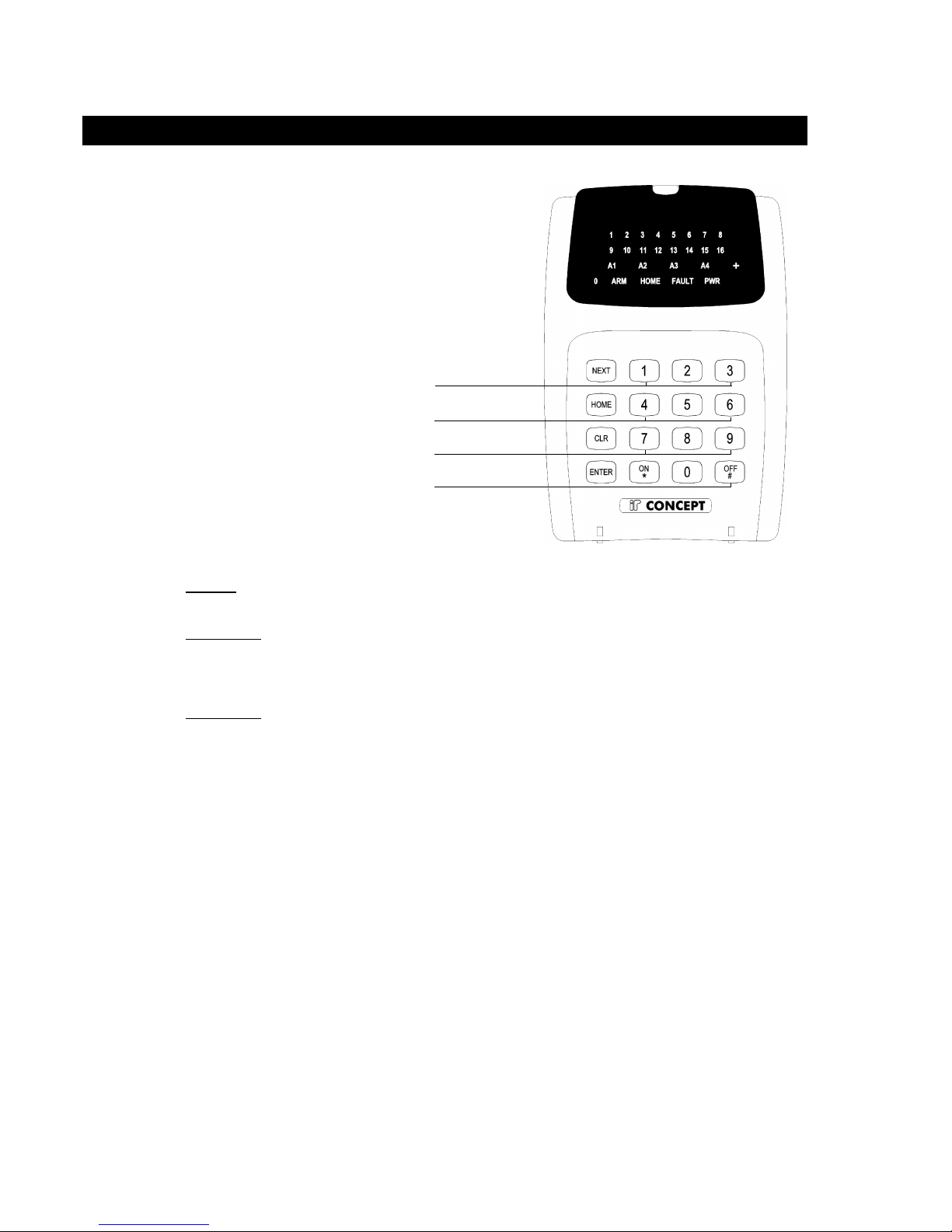

Standard LED Terminal. 995500

© 2001. Inner Range Pty. Ltd. Part No: 635500

The LED Terminal is the main operator interface for the Concept IQ system.

The Terminal provides status display of 16 Zone Inputs and 4 Areas along with indication of “Power”, “Fault”, “Home Mode”

and “Armed” conditions. Audible button press feedback is provided and the built-in Beeper also provides indication of

Alarms, Entry/Exit warnings, Auto-Arm warning, User Operation OK and User Operation Unsuccessful.

While the system can be programmed via Upload/Download software, the LED Terminal also provides the ability for the

Installer to program all system parameters.

LAN connections to the Control

Module T4 connector.

4 Core

Security Cable

recommended.

(14/0.2)

INSTALLATION.

Mounting the Terminal.

- The Terminal must be installed on a flat, vertical surface in an

appropriate location. Ensure that the display will be at, or slightly

below eye level, for all Users.

- Remove the rear mounting plate from the back of the Terminal.

- Cut suitable holes in the mounting surface for cable entry and the

fasteners. (The rear mounting plate can be used as a template)

NOTE: The Terminal is also designed to be mounted on plasterboard/

gyprock surfaces using a standard switch plate Mounting Clip. e.g.

Clipsal 154 or HPM 712. (84mm mounting centres)

- The rear mounting plate can now be installed using appropriate

fasteners through the holes provided. Remember to insert the LAN

cable and any other wiring through the cable entry cutout first.

- Connect the wiring into the Screw Terminal block T2.

- Clip the Terminal onto the rear mounting plate by first locating the

tongue at the top of the Terminal into the slot provided by the rear

mounting plate, then clip the bottom of the Terminal into place.

LAN connection. A maximum of 4 LAN Modules can be connected to

the system LAN. The LAN must be connected as follows:

- Recommended cable is 4 core or 6 core security cable 14/0.20.

(NOT twisted pair. Twisted pair cable [e.g. Category 5] may be used,

however, DO NOT combine “Clock” & “Data” on the same pair)

- Do not apply power to cable until all connections are made & checked.

- Maximum cabling distance from the Control Module to the furthest

Module must not exceed 100 metres.

- Maximum total LAN cabling in the system must not exceed 150 m.

- DO NOT connect the “CLK” & “DATA” wires to the Control Module until

all LAN Modules (e.g. Terminals) are Commissioned. (See below)

ADDRESSING & COMMISSIONING (Read “LAN connection” first)

1. Enable Terminal Configuration Mode.

Method 1: -Remove power from the Terminal.

-Hold down the <NEXT> and <HOME> keys.

-Re-apply power to the Terminal.

-Release the <NEXT> and <HOME> keys.

Method 2: -Hold down the <NEXT> and <HOME> keys.

-Short the “RST” (Reset) link on the rear of the Terminal.

-Release the <NEXT> and <HOME> keys.

2. Note the current Address setting. The current Address of the Terminal will be displayed via the Zone 1 to 4 Lamps.

The Zone Lamp number that corresponds to the current Address will flash.

3. Select the new Terminal Address number.

-Press the key that corresponds to the required Address (1 to 4) within 10 seconds, then press <ENTER>.

-When the <ENTER> key is pressed, the Terminal will exit Terminal Configuration Mode.

4. Initialize the LAN. If a new Terminal is added to an existing system, once the Terminal is configured and connected to

the system LAN, the LAN must be initialized by Removing and Re-applying power to the Control Module.

Remember to disconnect the battery also when removing power.

5. Area Assignment. Additional system programming allows Terminals to be configured for Single Area or Multi-Area

Mode (Address 961), and an “Associated Area” to be defined for each Terminal (Addresses 952 to 955).

Standard LED Terminal. Version 1.01

Page 10

Section 1. Installation. CONCEPT IQ. Installation & Programming Manual.p8

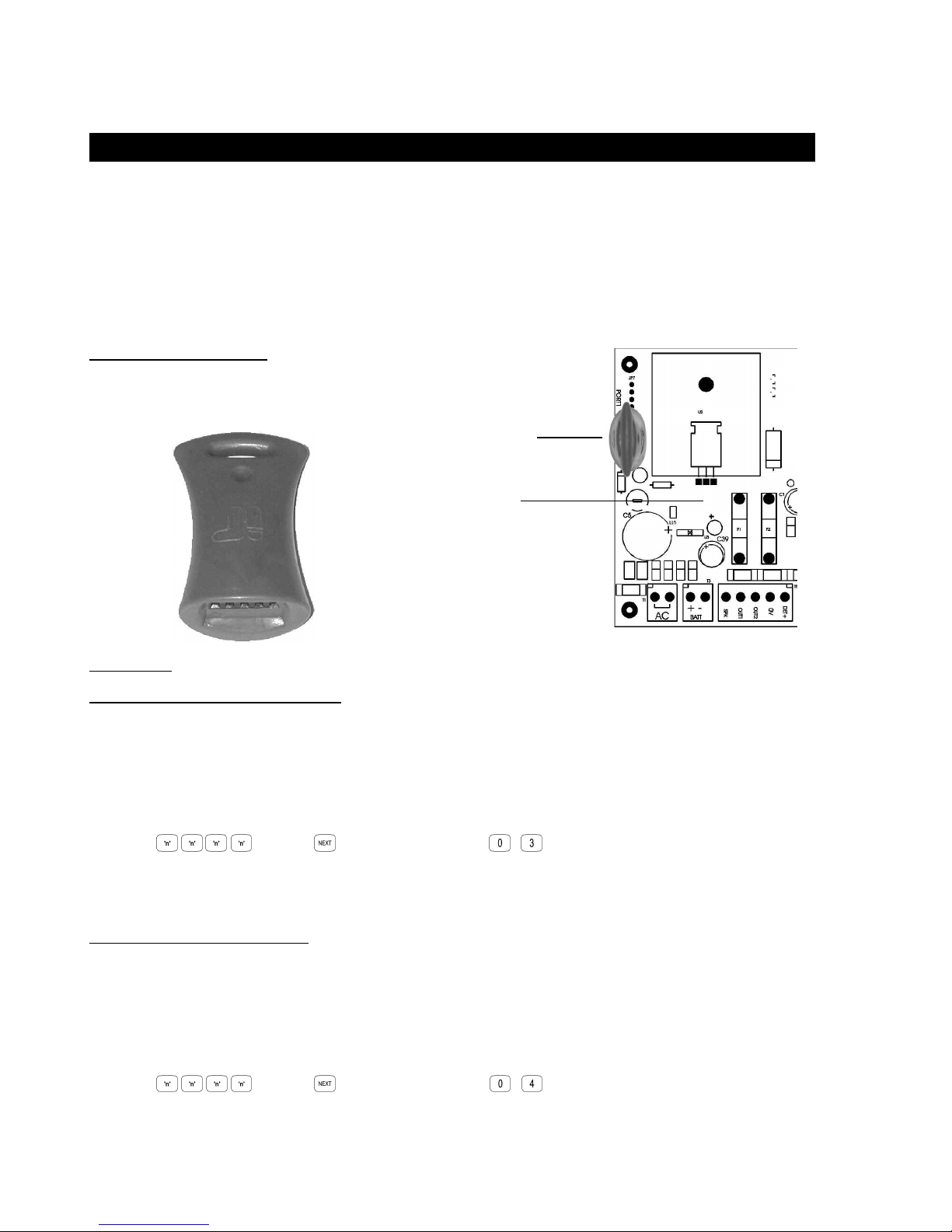

Programming Key. 995510

Programming Key Parts List

- Programming key.

- Instruction Manual. (This document)

The Concept IQ Programming Key is a portable non-volatile memory device housed in a convenient “key tag”.

The Programming Key connects directly to the Control Module Port 0 and allows the Installer to Upload the system

database from the Control Module, or Download a system database to the Control Module via a simple key press

sequence on the LED Terminal.

An indicator lamp is provided on the Programming key to monitor data transfer activity, and the LED Terminal provides

audible indication of Upload/Download Successful/Failed.

OPERATION.

Importing Data from the Programming Key.

This Mode allows the Installer to copy the programming contents of the Programming Key into the Control Module.

IMPORTANT NOTE: The new data will override the existing contents of the Control Module memory.

Connect the Programming Key to Serial Port 0 on the Control Module.

Select the Import Data Mode:

Enter PIN; ... , then , then the Mode number; , .

The Lamp on the Programming Key will flash slowly to indicate data is being copied.

The Terminal beeper will sound 3 short beeps if the operation was successful, or 1 long beep if unsuccessful.

Export Data to the Programming Key.

This Mode allows the Installer to copy the programming contents of the Control Module into the Programming Key.

IMPORTANT NOTE: The Control Module data will override the existing contents of the Programming Key.

Connect the Programming Key to Serial Port 0 on the Control Module.

Select the Export Data Mode:

Enter PIN; ... , then , then the Mode number; , .

The Lamp on the Programming Key will flash quickly to indicate data is being copied.

The Terminal beeper will sound 3 short beeps if the operation was successful, or 1 long beep if unsuccessful.

© 2001. Inner Range Pty. Ltd. Part No: 635510

Programming Key

connected to Port 0.

Control Module

Version 1.00

Page 11

CONCEPT IQ. Installation & Programming Manual.

Install

p9

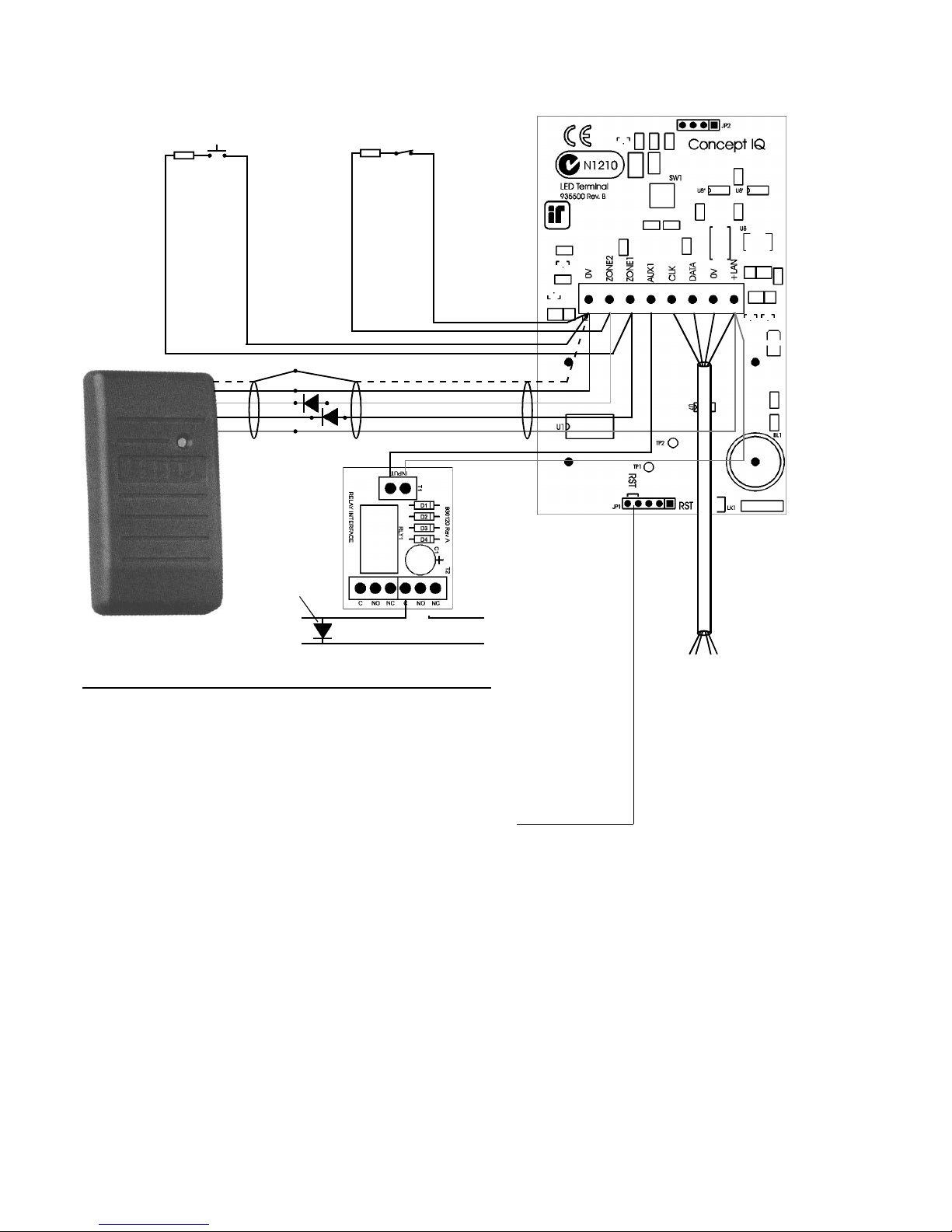

Enhanced LED Terminal. 995500EN

© 2001. Inner Range Pty. Ltd. Part No: 635500EN

The Enhanced LED Terminal is a versatile operator interface for the Concept IQ system providing standard LED Terminal

functions along with an interface for Door Access Control. The Terminal provides status display of a single “Associated”

Area and up to 16 Zone Inputs along with indication of “Power”, “Fault”, “Home Mode” and “Armed” conditions.

Audible button press feedback is provided and the built-in Beeper also provides indication of Alarms, Entry/Exit warnings,

Auto-Arm warning, User Operation OK and User Operation Unsuccessful.

While the system can be programmed via Upload/Download software, the Terminal also provides the ability for the Installer

to program all system parameters.

In addtion to these standard functions, the Enhanced Terminal also provides:

-Single low power open-collector Door Unlock Output. (Programmable un-lock time; 0 to 60 seconds)

-Two multi purpose inputs configurable as Wiegand Reader Data inputs and REX / Door Sealed.

INSTALLATION. Connection diagrams provided on the next page.

Mounting the Terminal.

- IMPORTANT: Enhanced Terminals must be installed on the inside (secure side) of the Door to be controlled.

- The Terminal must be installed on a flat, vertical surface in an appropriate location. Ensure that the display will be at, or

slightly below eye level, for all Users.

- Remove the rear mounting plate from the back of the Terminal.

- Cut suitable holes in the mounting surface for cable entry and the fasteners. (The rear mounting plate can be used as a

template)

NOTE: The Terminal is also designed to be mounted on plasterboard/gyprock surfaces using a standard switch plate

Mounting Clip. e.g. Clipsal 154 or HPM 712.

- The rear mounting plate can now be installed using appropriate fasteners through the holes provided. Remember to

insert the LAN cable and other wiring through the cable entry cutout first.

- Connect the wiring into the Screw Terminal block T2.

- Clip the Terminal onto the rear mounting plate by first locating the tongue at the top of the Terminal into the slot provided by the rear mounting plate, then clip the bottom of the Terminal into place.

LAN connection. A maximum of 4 LAN Modules can be connected to the system LAN.

- Recommended cable is 4 core or 6 core security cable 14/0.20. (NOT twisted pair. Twisted pair cable [e.g. Category 5]

may be used, however, DO NOT combine “Clock” & “Data” on the same pair.)

- Do not apply power to cable until all connections are made and checked.

- Maximum cabling distance from the Control Module to the furthest Module must not exceed 100 metres.

- Maximum total LAN cabling in the system must not exceed 150 metres.

- DO NOT connect the “CLK” & “DATA” wires to the Control Module until all LAN Modules (e.g. Terminals) are

Commissioned. (See next page)

Wiegand Reader connection. Note: Supports 12V Reader power supply only. (No 5V supply option)

- The Reader “+”, “-”, “D1” & “D0” wires must be connected to “+LAN”, “0V”, “Zone1” & “Zone2” on the Terminal using

Shielded RS232 Data cable. e.g. Tycab DMC6702, Electra EAS7206, Belden 9536, Alpha 1296C, etc.

DO NOT use Twisted pair cable or Security cable under any circumstances.

NOTE: Check that there is sufficient current still available from the LAN power to supply the Reader. If not, a separate

power supply must be used for the Reader power.

- Diodes must be inserted in series with each of the D0 and D1 connections. Cathode to Reader.

Ensure that appropriate insulating sleeve is fitted over the Diodes and solder connections.

- Maximum cabling distance from the Reader to the Terminal must not exceed 80 metres.

Door Reed switch and Request to Exit button (REX) connections.

- The “Normally Open” Request to Exit (REX) button (if used) is connected between the “Zone 1” Input and “0V”. A 6k8

Resistor must be connected in series with the button.

- The “Normally Closed” Reed switch (if used) is connected between the “Zone 2” Input and “0V”. A 6k8 Resistor must be

connected in series with the Reed switch.

Lock Relay connection.

- The Lock power must be switched via a Relay to provide isolation from the Terminal circuits.

e.g. 995085 -1A DPDT Relay Board, or 995083S -2x10A Relay Board.

- The Relay control input is connected to “+” and “AUX1” on the Terminal.

- The power to the lock must be wired from a separate lock power supply, through the appropriate Relay contacts, and

must not make any connection to the Terminal wiring.

Enhanced LED Terminal. Version 1.02

Page 12

Section 1. Installation. CONCEPT IQ. Installation & Programming Manual.p10

LAN connections to

the Control Module

T4 connector.

4 Core

Security Cable

recommended.

(14/0.2)

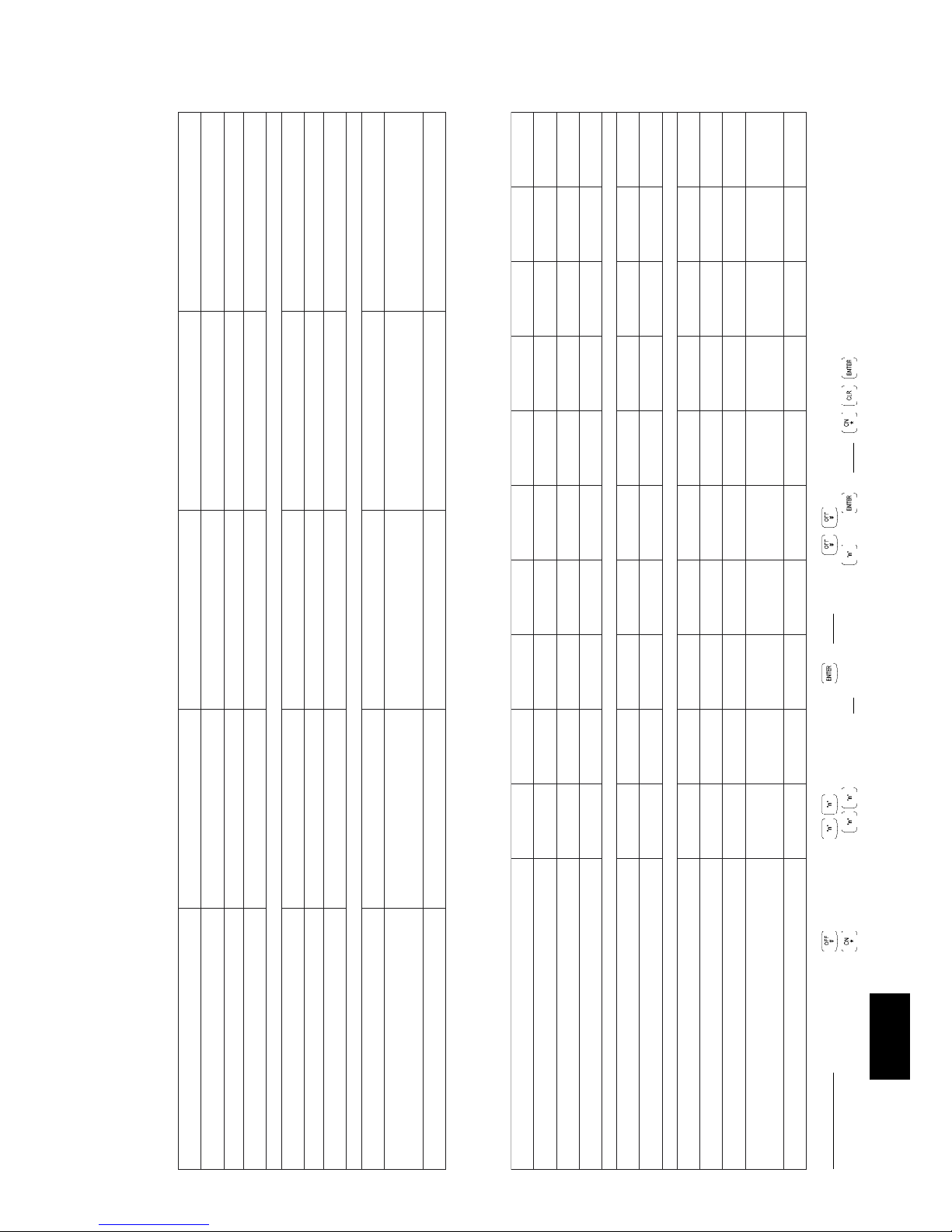

ADDRESSING & COMMISSIONING (Read “LAN connection” first)

1. Enable Terminal Configuration Mode.

Method 1: -Remove power from the Terminal.

-Hold down the <NEXT> and <HOME> keys.

-Re-apply power to the Terminal.

-Release the <NEXT> and <HOME> keys.

Method 2: -Hold down the <NEXT> and <HOME> keys.

-Short the “RST” (Reset) link on the rear of the Terminal.

-Release the <NEXT> and <HOME> keys.

2. Note the current Address setting. The current Address of the Terminal will be displayed via the Zone 1 to 4 Lamps.

The Zone Lamp number that corresponds to the current Address will flash.

3. Select the new Terminal Address number.

-Press the key that corresponds to the required Address (1 to 4) within 10 seconds, then press <ENTER>.

4. Note the current Door Alarm enable status.

After the Terminal Address has been entered as per Step 3, the display will now show the current Door Alarm enable

status: 0 = Disabled (Default)

1 = Enabled

5. Enable / Disable Door Alarm.

If an Enhanced Terminal is required to generate a Door Alarm for Door Forced or Door Held conditions, then “Door

Alarm” must be enabled for that Terminal.

-To Enable or Disable, select the option required (0 or 1) within 10 seconds, then press <ENTER>.

-When the <ENTER> key is pressed, the Enhanced Terminal will now exit Terminal Configuration Mode.

6. Initialize the LAN. If a new Terminal is added to an existing system, once the Terminal is configured and connected

to the system LAN, the LAN must be initialized by Removing and Re-applying power to the Control Module.

Remember to disconnect the battery also when removing power.

7. Area Assignment. Enhanced Terminals must be configured for Single Area Mode (Address 961), and an “Associated

Area” must be defined for each Terminal (Addresses 952 to 955).

8. Door Un-lock time. The system has a default Door Un-lock time of 5 seconds. If a different time is required, this value

can be edited at Address 872.

Request to Exit (REX) button

(Normally Open)

EOL Res.

6k8

Door Reed Switch

(Normally Closed)

EOL Res.

6k8

Shield

0V Black

D0 Green

D1 White

+ Red

To Lock -

Strike +

- From Lock

+ Power Supply

*

1A DPDT Relay

Board. 995085

* Pwr to Lock: Use NC

Pwr to Unlock: Use NO

4 Core

Security Cable

recommended.

(14/0.2)

Shielded RS232 Data cable.

Fit reverse

Diode across

Lock coil.

Page 13

CONCEPT IQ. Installation & Programming Manual.

Install

p11

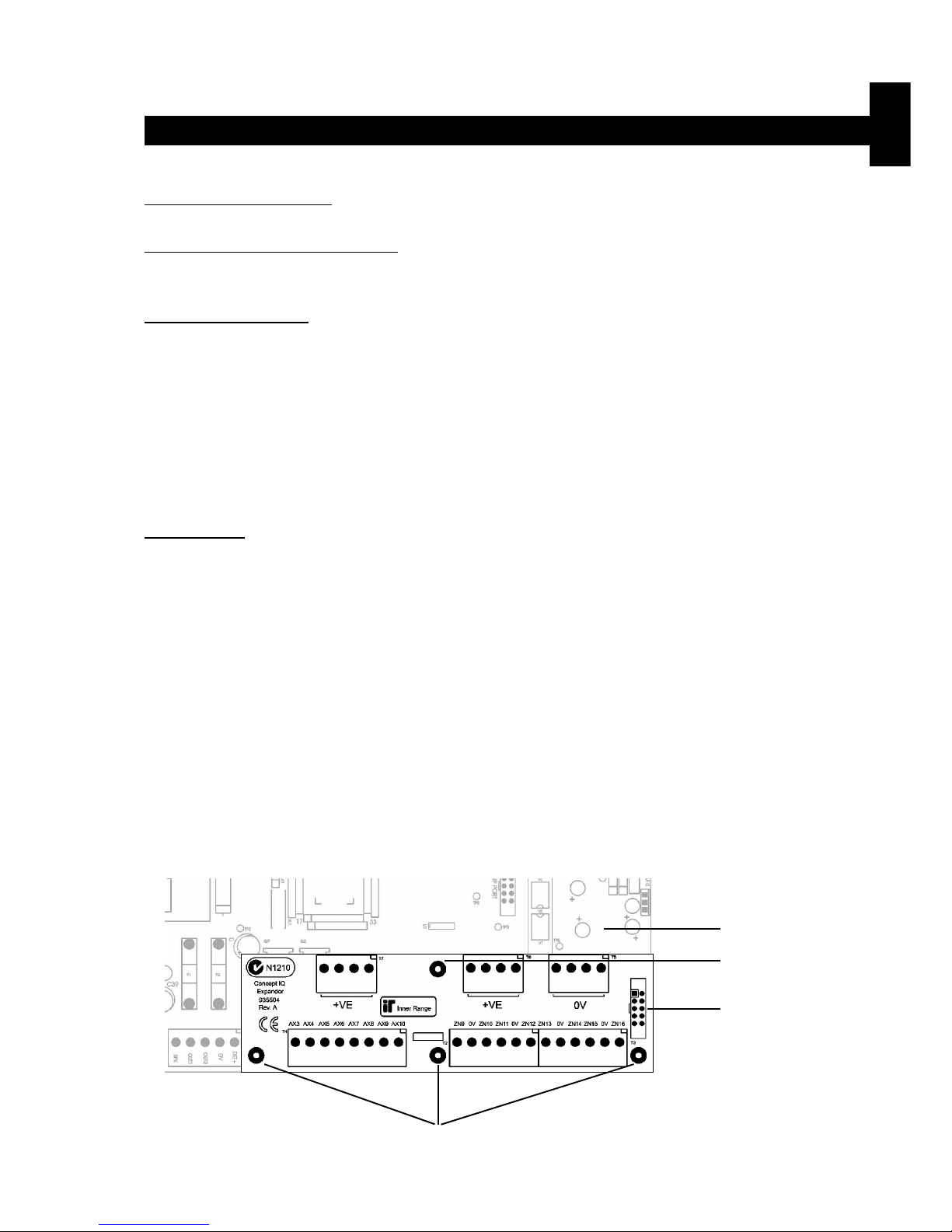

Expansion Card. 995503 / 995504

© 2001. Inner Range Pty. Ltd. Part No: 635504

Expansion Card Parts List

- Zone/Auxiliary Expansion Card.

- Installation Manual. (This document)

- Installation Kit containing:

- 3 x 20mm Brass PCB standoff.

- 1 x 20mm Threaded plastic PCB standoff.

- 1 x Pan Head M3x6mm screw.

- 2 x 6 Way plug-on screw terminals.

- 4 x 2 Way plug-on screw terminals.

- 10 x 3k3 End-of-line resistors. 8 x Zone Inputs, 2 x Spare. (orange-orange-black-brown-brown)

- 10 x 6k8 End-of-line resistors. 8 x Zone Inputs, 2 x Spare. (blue-grey-black-brown-brown)

The Expansion Card connects directly to the Control Module Expansion Port and is available in 2 Versions:

995503. Zone Expansion Card.

Provides 8 additional Zone Inputs and additional Detector power connections.

995504. Zone & Auxiliary Expansion Card.

Incorporates all Zone Expansion card features along with 8 additional low power open-collector Auxiliary Outputs and 4

additional +12V Auxiliary power outputs.

INSTALLATION.

- Remove all power to the Control Module. Remember to disconnect the Battery. See Note 1 below.

- Remove the 3 screws along the bottom edge of the Control Module PCB. (The screws adjacent to T4, T6 & T2)

- Fit the 3 Brass PCB standoffs in place of these 3 screws.

- Fit the Threaded plastic PCB standoff into the mounting hole on the Control Module PCB next to T8 (AUX LAN).

- Plug the Expander Card onto the box header T9 on the Control Module (“EXT PORT”).

- Secure the Expander Card to the 4 standoffs using the 3 screws removed from the Control Module and the additional

screw provided in the Installation kit.

- Connect the additional Zone Inputs and/or Auxiliary Outputs required.

- Reconnect the power and the Battery to the Control Module, then program the required Zones and Auxiliaries.

NOTES: 1) CAUTION: Shorting any of the pins on the Expansion Port connector whilst powered up, can result

in permanent damage to the Control Module and/or the Expansion Card.

2) Zone Doubling CANNOT BE USED on the system when an Expander Card is fitted.

See next page for Zone Input & Auxiliary Output wiring.

Location of Brass

PCB standoffs

Control Module.

Location of Threaded

plastic PCB standoff.

Expansion Port.

T9. “EXT PORT”.

Expansion Cards. Version 1.00

Page 14

Section 1. Installation. CONCEPT IQ. Installation & Programming Manual.p12

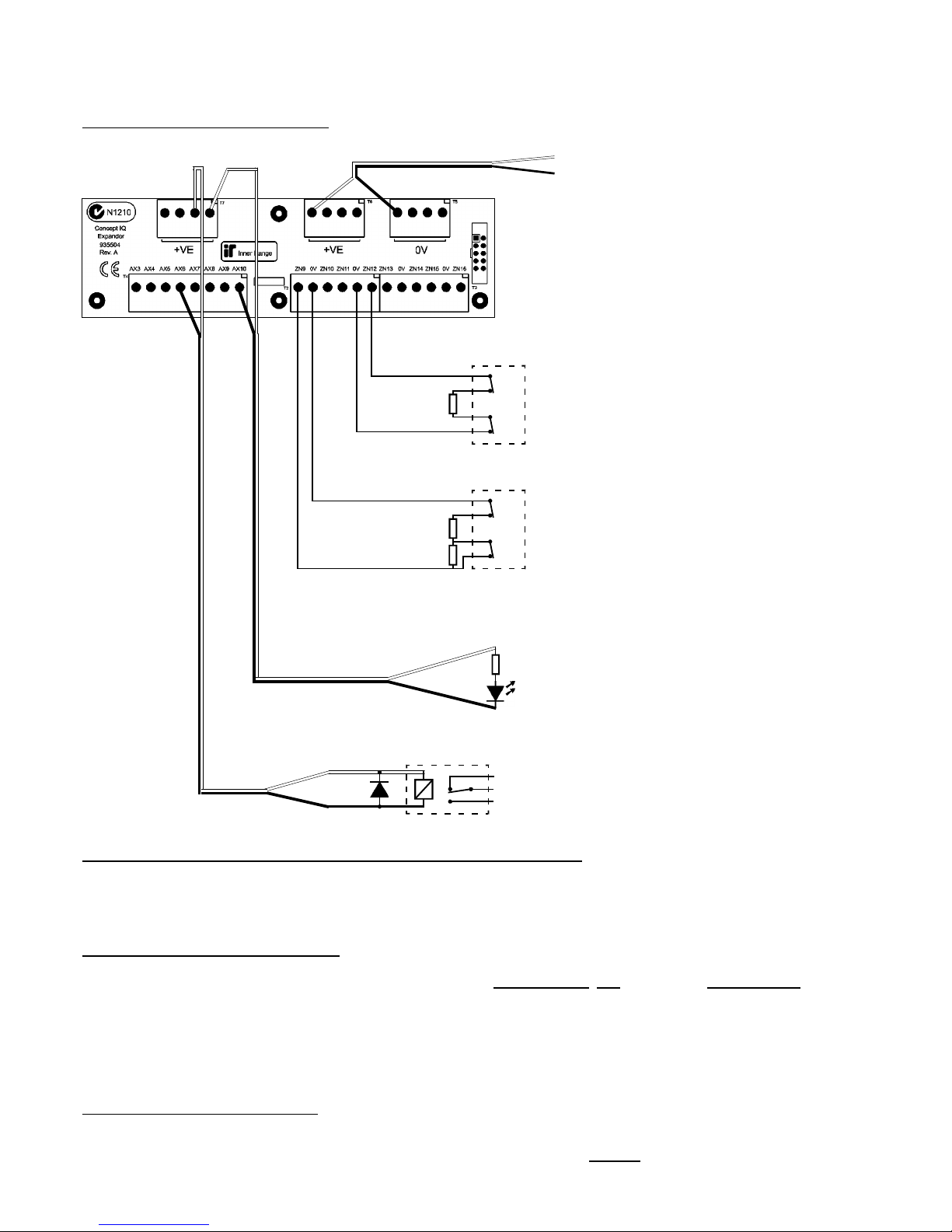

T2 and T3. Zone Input connections.

Single End-of-Line.

Dual End-of-Line.

T5 & T6. “+VE” and “0V”.

Detector Power connections.

12V Supply for Detectors.

Total combined current sourced from

“DET+” and “LAN+” on the Control

Module, and “+ve” on the Expander Card

must not exceed 600 milliAmps.

Minimum Cable spec: 14/0.2

Tamp.

Alarm

Detector

C

NC

C

NC

EOL Res.

3k3 Typ.

Tamp.

Alarm

Detector

C

NC

C

NC

EOL Res.

3k3 Typ.

6k8 Typ.

T4. Auxiliary Output connections.

995504 Only.

LED wiring.

(Note. Dropping Resistor can be any

value in the range of 1k to around 1k5.

e.g. 2 x 3k3 Resistors in parallel)

Relay wiring.

Relay coil voltage: 12V DC

Fit reverse diode across coil.

e.g. 1N4001 - 1N4004.

1k min.

Relay

NC

O

NO

EXPANDER CARD WIRING DIAGRAMS.

IMPORTANT NOTE. AUXILIARY POWER:

Total combined current sourced from “DET+” and “LAN+” on the Control Module, and “+ve” on the Expander Card

must not exceed 600 milliAmps.

If additional current is required, a separate, external Power Supply and backup battery must be used to provide power to

the required Auxiliary devices and/or Detectors.

e.g. 994051 2A Power Supply.

994055 Short-form Power Supply Board + 560001 Plug pack (For 1A PS), or 560004 In-line transformer (For 2A PS)

When a separate Power Supply is used:

1) The Power Supply must be installed close to the Control Module, and the 0V (or “-VE”) supply connections of the

Power Supply and the Control Module must be connected together using a heavy guage wire. (14/0.20 minimum)

2) The “+ve” supply connections of any system Module (“DET+”, “LAN+” or “+VE”) must not be connected to +ve of the

separate Power Supply.

NOTE: ZONE INPUT CONNECTIONS. “NORMALLY OPEN” ALARM CONTACTS.

Normally Open Alarm Contacts (e.g. As often found on Smoke Detectors) are wired in the same manner as Normally

Closed contacts. When programming the Zone Input, Option 8 (“Normally Open”) in the “Zone Options” must be selected.

(Addresses 752 [Zone 1] to 767 [Zone 16] )

Page 15

CONCEPT IQ. Installation & Programming Manual.

Install

p13

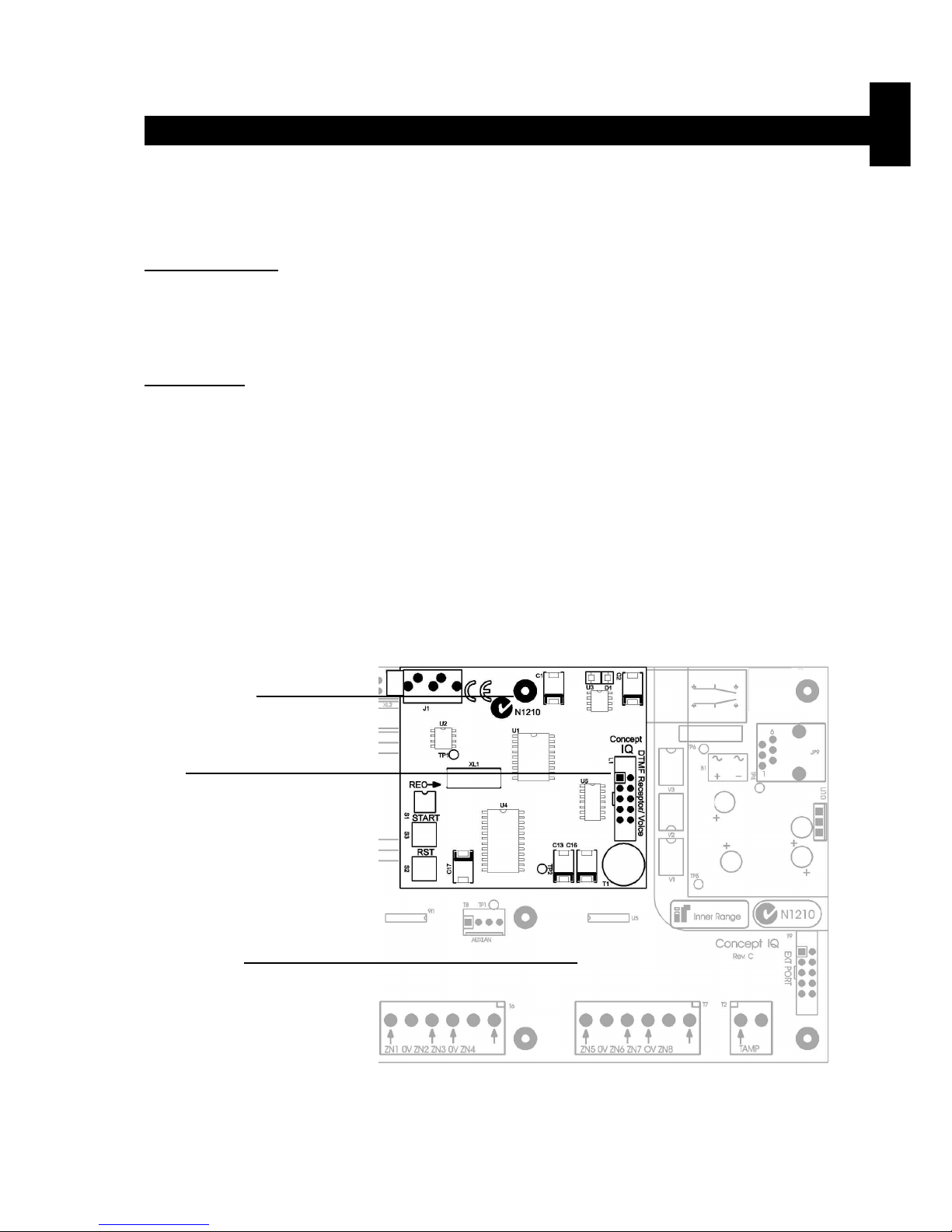

DTMF Card. 995505

© 2001. Inner Range Pty. Ltd. Part No: 635505

INSTALLATION.

- Remove the screw on the top edge of the Control Module PCB next to the STATUS Lamp.

- Fit the Brass PCB standoff in place of the screw.

- Plug the DTMF Card onto the box header JP10 on the Control Module (“DTMF PORT”).

- Secure the DTMF Card to the standoff using the screw removed from the Control Module.

- Program the required DTMF functions. See Installation & Programming Manual, Section 10: Communications.

DTMF Card Parts List

- DTMF Card.

- Installation Manual. (This document)

- 1 x 20mm Brass PCB standoff.

The DTMF Card connects directly to the Control Module DTMF Port to provide Telephone remote control.

Location of Brass

PCB standoff.

JP10.

“DTMF PORT”.

Control Module.

DTMF Card. Version 1.00

Page 16

Section 1. Installation. CONCEPT IQ. Installation & Programming Manual.p14

This page intentionally left blank.

Page 17

Section 2. Intro. Version 1.01 p1CONCEPT IQ. Installation & Programming Manual.

Intro

SECTION 2.

INTRODUCTION TO PROGRAMMING.

1. Introduction

1.1 System Overview .............................................................................................. 2

1.2 Types of Users..................................................................................................3

1.3 Default Users .................................................................................................... 3

2. The LED Terminal

2.1 Key Functions ................................................................................................... 4

2.2 Beeper Indications............................................................................................. 4

2.3 Lamp Indications ............................................................................................... 5

3 Installer Modes

3.1 Overview........................................................................................................... 6

3.2 Accessing the Installer Modes ........................................................................... 6

3.3 Mode 01. Programming Mode...........................................................................7

3.4 Mode 02. Defaulting Mode ................................................................................ 7

3.5 Factory Default Database settings .................................................................... 8

3.6 Mode 03. Import Data from Programming Key .................................................. 9

3.7 Mode 04. Export Data to Programming Key ......................................................9

3.8 Mode 05. Terminal Area Programming..............................................................9

4 Programming Techniques

4.1 The System Database ....................................................................................... 10

4.2 Selecting and Programming the Data.................................................................10

4.3 Example of Programming ..................................................................................11

5 Types of Data

5.1 Overview........................................................................................................... 12

5.2 “Value” Data......................................................................................................12

5.3 “Options” Data................................................................................................... 13

6 Recommended Programming Sequence .................................................................. 14

Contents

Page 18

p2 Section 2. Intro. Version 1.01 CONCEPT IQ. Installation & Programming Manual.

1. Introduction

1.1 SYSTEM OVERVIEW

The Concept IQ is an affordable, simple to use security system targeted at the domestic and small commercial

markets. The system has been designed for ease of use by the Installer and the End User.

System Hardware

The basic Control Module has the following hardware dimensions:

• Zones: 8 standard Zone Inputs or 16 doubled Zone Inputs.

• Auxiliaries: Total of 3. 1 Siren speaker / 1 Strobe / 1 General purpose.

• Serial Communications Port: RS232.

• External Device Bus.

• System LAN: Provides connectivity for up to 4 LAN Devices.

• IO Expansion Bus.

• Separate Tamper Input.

A variety of Peripheral devices can be connected directly to the Control Module:

• Programming Key.

• Plug-on Expansion Card options. 8 additional Auxiliary outputs and/or 8 additional Zone Inputs.

• DTMF communications Card.

• DTMF + Voice communications Card.

• Serial Adapter Cable for connection to PC.

The System LAN supports the following LAN Modules:

• Standard 16 Zone / 4 Area LED Terminal.

• Enhanced 16 Zone / 4 Area LED Terminal incorporating Input for a Wiegand Reader

and Input/Output facilities for access control functions.

• RF Terminal that adds 2 key or 4 key radio remote functionality.

Functional Description

Zone Inputs. Zone Inputs are individually programmed to define how they are to be processed. An appropriate

“Zone Type” is chosen and additional options relating to; Alarm Processing, Reporting, Siren,

Pulse counting, Testing, and type of Input Device can also be defined.

Global Zone options also allow system-wide parameters to be set for Pulse Counting, End-Of-Line

Resistor values and Zone Self Testing.

System Inputs. 20 System Inputs are also available for monitoring Faults and System Alarms such as; Power

Problems, Cabinet & Siren Tampers, Communication Problems, LAN & Battery Fuses, Zone Selftest Status, Keypad Emergency Alarms (Panic, Fire, Medical & Duress) and Access Control

violations. The Installer enables the Siren and Reporting options for each System Input required.

Automatic Battery Testing is available and triggers the Low Battery alarm if the test fails.

Areas. The system can be configured in Single Area or Multi Area Mode according to the site

requirements. Up to 4 Areas are available and Zone Inputs can be assigned to one or more Areas.

Each Area can be armed in “AWAY” or “HOME” modes.

Each LED Terminal can be configured for Multi-Area mode or assigned to a Single Area.

Siren. The Siren Speaker output supports a standard 8 Ohm Horn speaker and can generate 4 different

siren tones for Burglary, Fire, Medical & Panic alarms. The Siren time is programmable and any

System Input Alarms that are programmed to activate the Siren are differentiated from Zone Input

Alarms by a choice of 3 Siren tone-burst options.

Auxiliaries. Auxiliary outputs are extremely flexible thanks to a range of versatile programming options for

Security, Access control and Building/Home automation. A choice of over 50 “Auxiliary Types”

provides for Auxiliaries to; Annunciate different types of alarms, Indicate (mimic) individual Area or

Zone status, Indicate Entry, Exit, Auto-Arm & Zone Bypass conditions, Follow TimeZones, etc.

For each individual Auxiliary the output logic and On/Off actions can be tailored including an

optional timer that can be programmed in Minutes or Seconds.

Communications.The system offers “Contact ID” or “Domestic” dialing options. For a higher level of Dialer integrity a

Secondary telephone number can be programmed, Telephone line monitoring is provided and the

maximum number of dial attempts can be specified. A “Comms Fail” alarm is activated if the line is

Page 19

Section 2. Intro. Version 1.01 p3CONCEPT IQ. Installation & Programming Manual.

Intro

1.2 TYPES OF USERS

1.3 DEFAULT USERS:

The system has 3 special Users and 45 normal Users. The system can be configured for 4 digit or 6 digit PIN codes

depending on the requirements of the site. The normal Users can each be assigned a “User Type” and their “User

Areas” to define the items that they can control and the operations that they can perform.

Installer - User 1:

The Installer can perform all Installer operations, and all Master operations except for User programming and

Arming/Disarming. The Installer can only change their own PIN code. (Via Address 96. See Section 11: Users)

Master User - User 2:

The Master User can perform all the Master operations and has access to all Areas.

The Master operations include; Edit Users, View history, Walk test Zones, Set Real-time clock, Siren/Strobe/

Auxiliary Testing, Fault Analysis, View Software Version, Test Battery and Door Bell Enable/Disable.

The Master User can also perform all User operations. (This includes Arming / Dis-arming the system, Isolating

zones and Acknowledging alarms.)

The Master User automatically has permission to control all the Areas, Zones and Auxiliary outputs in the system.

These permissions cannot be changed for User 2.

Normal Users - User 3 to User 47:

Normal Users can perform a variety of operations such as Arming / Dis-arming , Isolating zones and Acknowledging

alarms with various levels of functionality as defined by the User’s “User Type”.

Any normal User can also be programmed as a Master User if required. In a Multi-Area system, a normal User

programmed as a Master User can only add a new User or edit existing Users who can access a subset of their own

Area list.

NOTE: DURESS CODES. A User PIN’s last digit + 1 will form a DURESS Code. e.g. If a user’s PIN is 1234, then

1235 will trigger a duress alarm, and if the user’s PIN is 1239, then 1230 will be a duress code.

tampered or the maximum attempts is reached. Daily, Weekly or Monthly Test reports can also be

sent at a specified time of day, or triggered manually by a Master User.

The Installer can dial in to the system from a PC for Upload/Download when required. Security is

provided by a PIN code requirement, and Callback and Fax Bypass options are available.

With the DTMF Card fitted, a User can dial in to the system, and using their PIN code, can perform

remote operations and obtain system status information.

On-board Serial Port is provided allowing connection of a Programming Key or PC for Upload /

Download.

Timers. An extensive range of Timers are provided catering for; Individual Area Exit/Entry delays, System

Siren time, Keypad lockout time and AC fail delay time. Four TimeZones are provided including

provision for up to 10 Holiday dates and automatic Daylight Saving adjustment is also catered for.

The TimeZones can be used to turn Auxiliaries On and/or Off and to control Areas.

User Functions. In addition to the User operations described in “Types of Users” below, the system provides a

number of options to simplify and/or enhance the User operations and feedback.

These include; Auto-Isolate on Arming, Quick Arming, Key-switch Arm/Disarm and Zone activity

display on LED Terminals.

The Default Installer PIN and Master PIN Codes should be changed as soon as possible after installation.

When choosing a new PIN Code, ensure that a PIN is chosen that will not be forgotten, while still providing security

against unauthorised access.

User Number Description Factory Default PIN code

User 1 Installer 2345 (or 234567)

User 2 Master User 0123 (or 012345)

User 3 to User 47 General Users (Can be programmed as a Master User) None

User 48 Reserved for system functions (e.g. Reporting Auto-arming etc.) Not applicable

Page 20

p4 Section 2. Intro. Version 1.01 CONCEPT IQ. Installation & Programming Manual.

2. The LED Terminal

2 or 3 Short Beeps: A User, Master or Installer function was successful.

1 Long Beep: A User, Master or Installer function has been unsuccessful.

When a wrong key is pressed, or an incorrect value/option is selected, the beeper tones

will sound at a lower pitch until a correct operation is successfully performed.

Continuous Short Beeps*: Entry Delay Timer, Exit Delay Timer or Auto-arm Warning.

*NOTE:

Single Area systems. All Terminals will beep in response to Exit delay, Entry delay or Auto-arm warnings.

Multi-Area systems. Only Terminals associated with a particular Area will beep in response to that Area’s

warning functions. IMPORTANT NOTE: Terminals not associated with an Area will only

beep on Area 1 warning functions.

2.2 BEEPER INDICATIONS.

PANIC. Keys 1 & 3 pressed simultaneously.

FIRE. Keys 4 & 6 pressed simultaneously.

MEDICAL. Keys 7 & 9 pressed simultaneously.

REX (Request to Exit) <OFF> key.

Enhanced Terminals only.

2.1 KEY FUNCTIONS.

NEXT Installer:

-Select an Installer Mode. After entering the Installer PIN code, press <NEXT> then the Mode number.

-Used to view data values above a value of 16. Press <NEXT> to step through the digits.

Master User:

-Select a Master User operation. After entering the PIN code, press <NEXT> then the Mode number.

HOME -In Single Area Mode: Used to Arm the system in Home Mode.

-In Multi-Area Mode: Used to Arm the specified Area in Home Mode.

Master User:

-Used to step through programming Addresses when programming Users or Telephone numbers.

-Used to toggle between Zone Test modes.

CLR -Set the data in the current Address to the Factory Default. (Press <*>, <CLR>, <ENTER>)

-Clear the data already entered if you have made a mistake.

-Logoff the Terminal. (Exit the current Mode of operation)

ENTER -Selects the specified programming Address. (After the PIN Code and the Address number have been

entered)

-Saves the data entered in a programming Address.

AUTO-LOGOFF: The Terminal will automatically logoff the operator if there is no keypad activity detected for 30

seconds. This is to protect the system against unauthorised operator activity.

Page 21

Section 2. Intro. Version 1.01 p5CONCEPT IQ. Installation & Programming Manual.

Intro

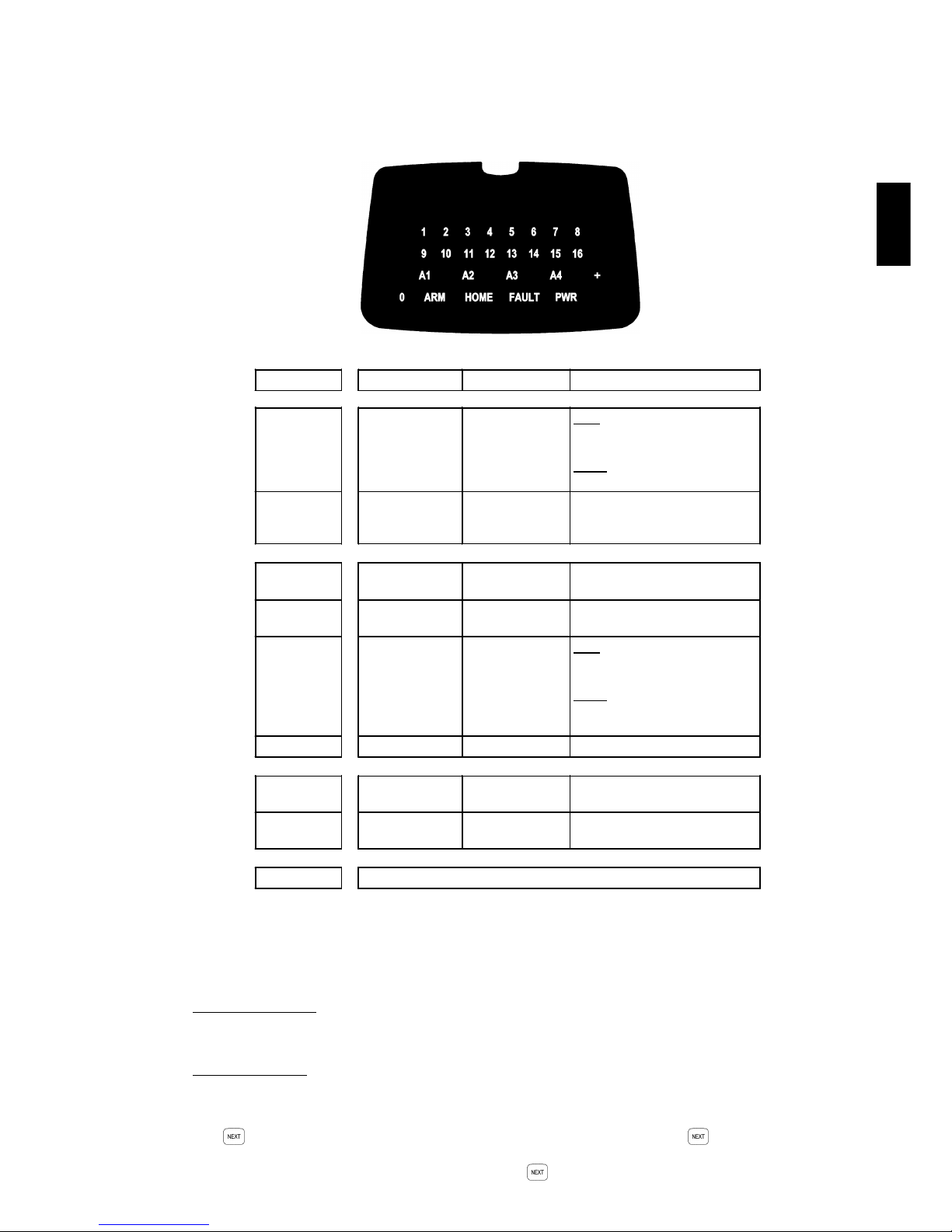

2.3 LAMP INDICATIONS.

2.4 DATA VALUE INDICATION VIA TERMINAL LAMPS.

Single digit numbers.

These are numbers between 0 and 16 and are displayed by the “0” Lamp and the Zone Lamps “1” to “16” on the

LED Terminal.

Multi digit numbers.

These are all other numbers ranging from 17 to 255.

These numbers are displayed one digit at a time by a sequence of flashing Lamps on the LED Terminal.

The “0” Lamp and the Zone Lamps “1” to “9” are used to display each digit in turn.

The key is used step through the digits. A short beep will sound each time the key is pressed to display

the next digit.

When the last digit in the sequence is displayed and the key is pressed again, a long beep will sound to

indicate that there are no more digits to display and the first digit will again be displayed.

Lamp ON OFF FLASHING

ZONE Lamps

1 to 16

When the Zone

is Un-sealed.

(If the "Zone

activity" option

enabled)

When the Zone

is Sealed.

FAST: *

When there has been an

Alarm / Tamper on the Zone.

SLOW: *

When the Zone has been Isolated.

AREA Lamps

A1, A2, A3, A4

Area is Armed.

(Multi-Area mode

only)

Area is Dis-armed. There has been an Alarm in the

Area.

(Multi-Area mode only)

ARM Area/s are armed

in normal mode.

System not armed

in normal mode.

-

HOME Area/s are armed

in home mode.

System not armed

in home mode.

-

FAULT § A system input is

currently in alarm *

No system inputs

are in alarm.

FAST: *

A system input has been in alarm

and must be acknowledged.

SLOW: *

When a System Input has been

Isolated.

PWR AC mains OK AC mains problem. -

ARM & HOME - - System is in "Isolate" mode.

(NEXT, 10)

FAULT & PWR - - System is in "Master Operations"

mode. i.e. NEXT functions.

0 Used to display values in programming mode.

NOTES: * Alarm indication takes priority over Isolate indication.

§ See "System Input Mapping and Functional Description" in Section 7.

Page 22

p6 Section 2. Intro. Version 1.01 CONCEPT IQ. Installation & Programming Manual.

3. Installer Modes

The Default Installer Code is 2345.

This Code should be changed as soon as possible after installation.

When choosing a new Installer Code, ensure that a PIN code is chosen that will not be forgotten, while still providing

security against unauthorised access.

Installer Operations require the Installer to Access a number of different Modes.

This is done by entering a valid Installer PIN code, then pressing the <NEXT> key before selecting the 2-digit Mode

number. e.g.

Enter PIN; ... , then , then the Mode number; ,

This key sequence must be used to access all the Operational Modes described in this section.

Remember that the <NEXT> “n”, “n” sequence must be preceded by the Installer PIN code.

e.g. To Enter Programming Mode:

Enter PIN; ... , then , then the Mode number; ,

NOTE: Upon entering Programming mode the first digit of the Primary Telephone Number at Address 16 will be

displayed.

The following pages provide full descriptions of each of the Installer Modes.

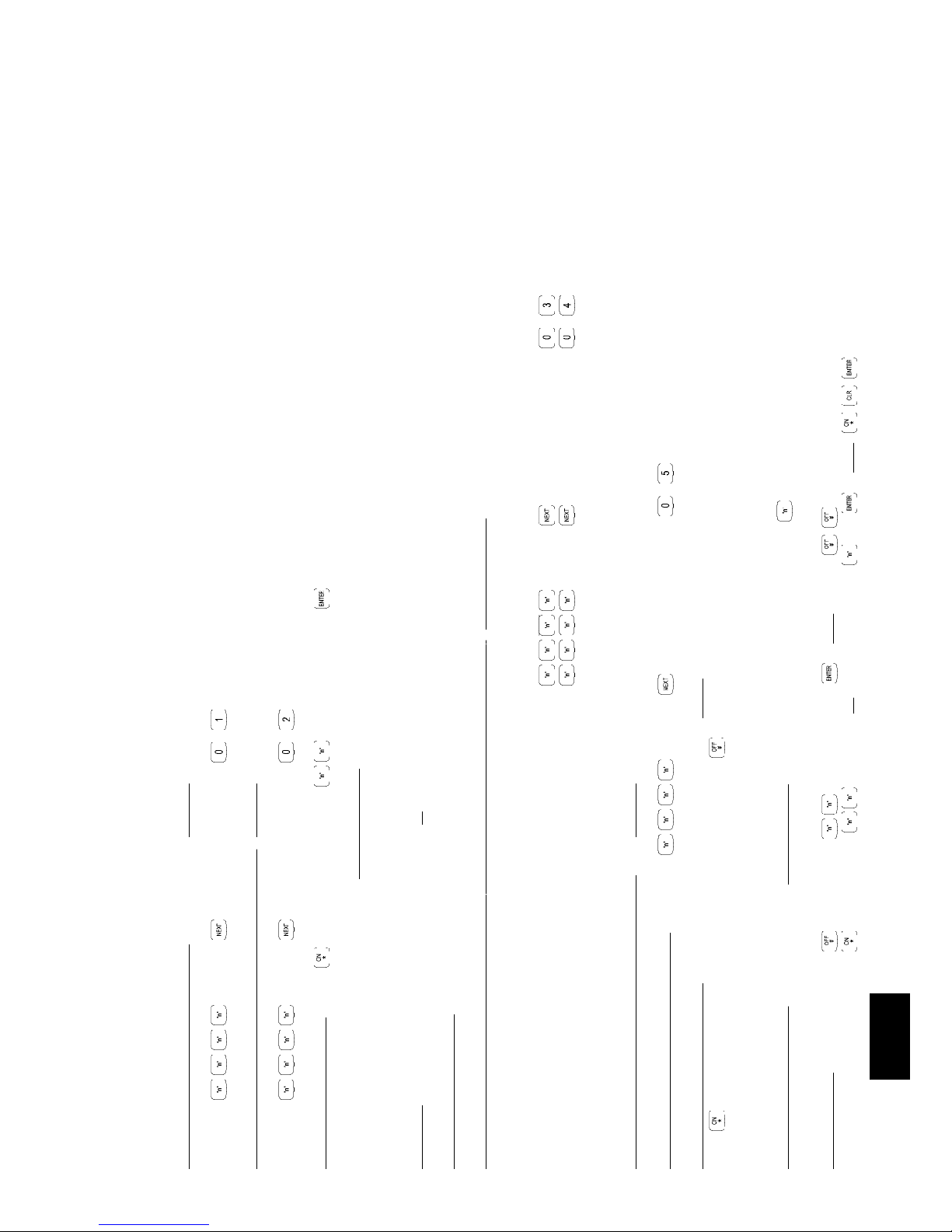

3.2 ACCESSING THE INSTALLER MODES.

In order to Program the system and perform other Installer operations, the Installer must access the appropriate

Installer Mode. There are 5 Installer Modes available.

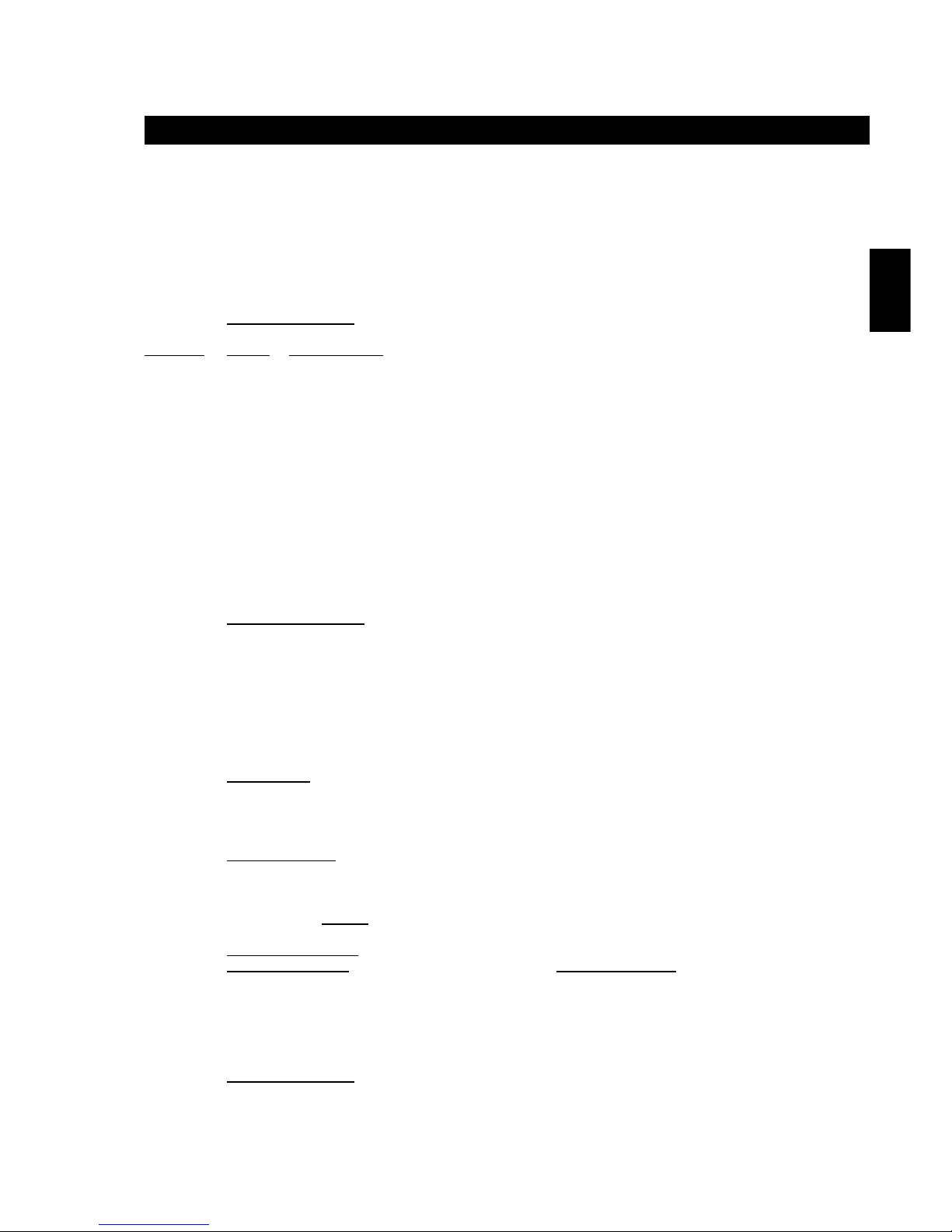

Installer Modes and Mode Indication.

3.1 OVERVIEW.

Mode Mode Name LED Terminal Indication

01 Programming Mode <HOME>, <FAULT> and <PWR> Lamps flashing

02 Default the Control Module. <HOME>, <FAULT> and <PWR> Lamps flashing

03

Import system programming from Programming Key. 3 beeps when complete. Long beep if unsuccessful.

(Lamp on Prog. key flashes slowly during transfer)

04

Export system programming to Programming Key. 3 beeps when complete. Long beep if unsuccessful.

(Lamp on Prog. key flashes quickly during transfer)

05

Terminal Programming. <HOME>, <FAULT> and <PWR> Lamps flashing

Page 23

Section 2. Intro. Version 1.01 p7CONCEPT IQ. Installation & Programming Manual.

Intro

3.4 MODE “02”. DEFAULTING THE CONTROL MODULE.

Defaulting the Control Module allows the Installer to clear any current system programming from the Control Module

and select a factory default database to simplify the programming task.

The Default Database options can be divided into 3 main options:

Option 0: The Control Module memory is completely cleared with the exception of the Installer and Master

User Codes.

Options 1 to 16: The Control Module memory is defaulted to the Factory settings shown in the table on the following

page AND the number of Zones specified by the Option selected, are programmed into Area 1.

Option 49: The Master Code is defaulted to the Factory setting and all other programming is left intact.

CAUTION: Defaulting the Control Module will erase all current programming stored in the memory before

implementing any Factory default settings. (With the exception of Default Option 49)

Select the Defaulting Mode:

Enter PIN; ... , then , then the Mode number; ,

The <HOME>, <FAULT> and <PWR> Lamps on the LED Terminal will flash simultaneously.

Select the Default Option

Press , then the Default Option (1 or 2 digits), then

DEFAULT OPTIONS:

0: Database is completely cleared except for Installer & Master Codes.

1: Database is defaulted to Factory Default settings AND 1 Zone is programmed into the system.

2: Database is defaulted to Factory Default settings AND 2 Zones are programmed into the system.

3 to 15: Database is defaulted to Factory Default settings AND the specified number of Zones are programmed

into the system. i.e. 3 Zones to 15 Zones.

16: Database is defaulted to Factory Default settings AND 16 Zones are programmed into the system.

49: Master Code Default. Only the Master code is reset to the factory default. All other programming remains

unchanged.

NOTES:

1) The product is dispatched from the factory Defaulted with Option 8 (Factory Default settings and 8 Zones)

2) In Default Options 1 to 16, the Zones programmed into the system are assigned to Area 1.

3) If Default options 9 to 16 are used, and Zones 9 to 16 are added using Zone Doubling (i.e. Not via an

Expander card), the “End-of-Line Resistor value” (Address 786) must be set to Type 14 - Zone Doubling.

Exit from Defaulting Mode

Press to exit.

Reset the Control Module:

Disconnect the AC Input and the Battery from the Control Module, then re-connect.

This mode allows the Installer to program all of the system data and options.

To Select Programming Mode:

Enter PIN; ... , then , then the Mode number; , .

See “Basic Programming Techniques” and “Types of Data” for more details of Programming Mode.

3.3 MODE “01”. PROGRAMMING MODE.

HARDWARE DEFAULT PROCEDURE.

The system can also be set to the Factory Default settings (Same as Default Option 8) via a hardware procedure.

- Disconnect the battery and remove power from the Control Module.

- Place a short circuit across Pins 2 & 3 of JP8 on the Control Module.

- Re-apply power to the Control Module and reconnect the battery.

- Remove the short circuit on JP8.

Page 24

p8 Section 2. Intro. Version 1.01 CONCEPT IQ. Installation & Programming Manual.

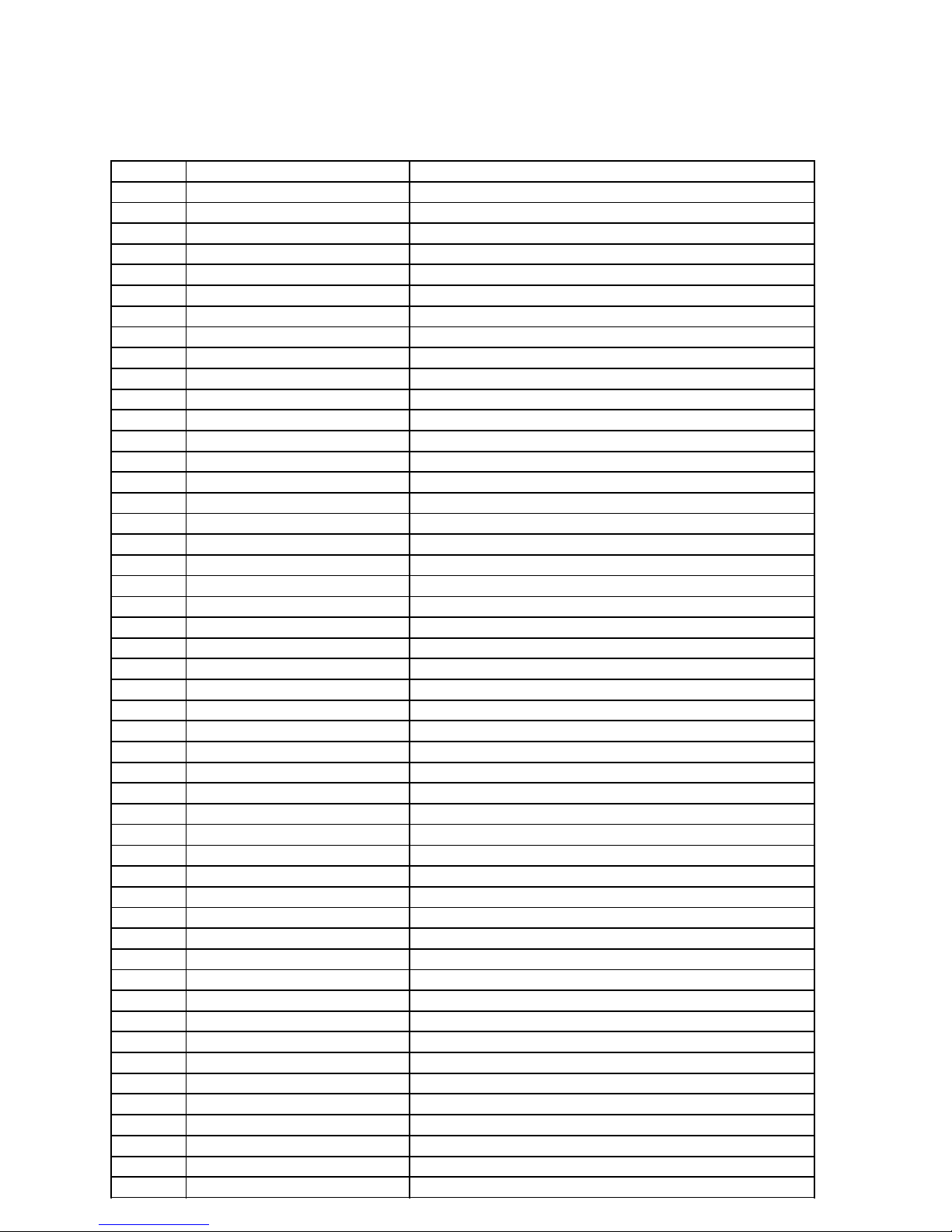

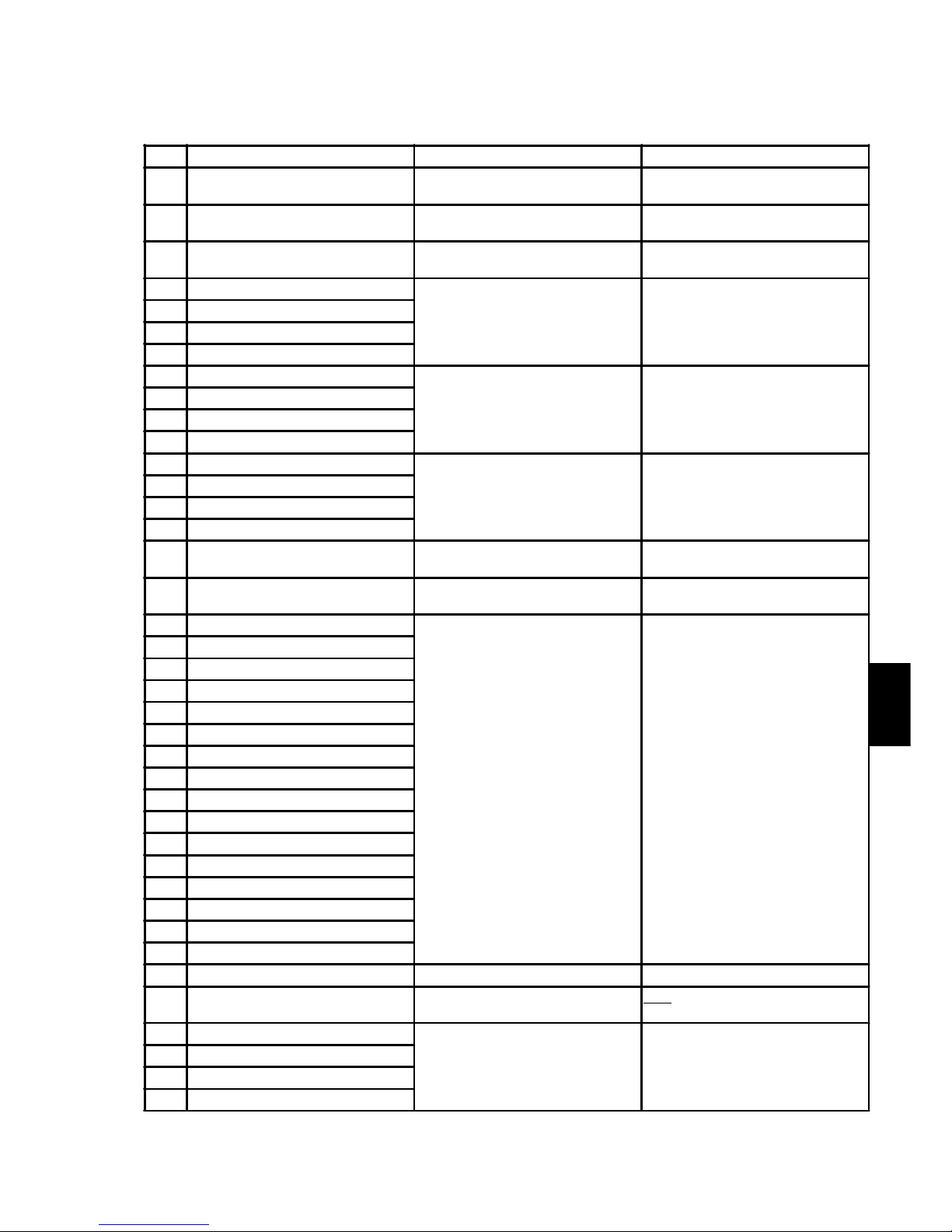

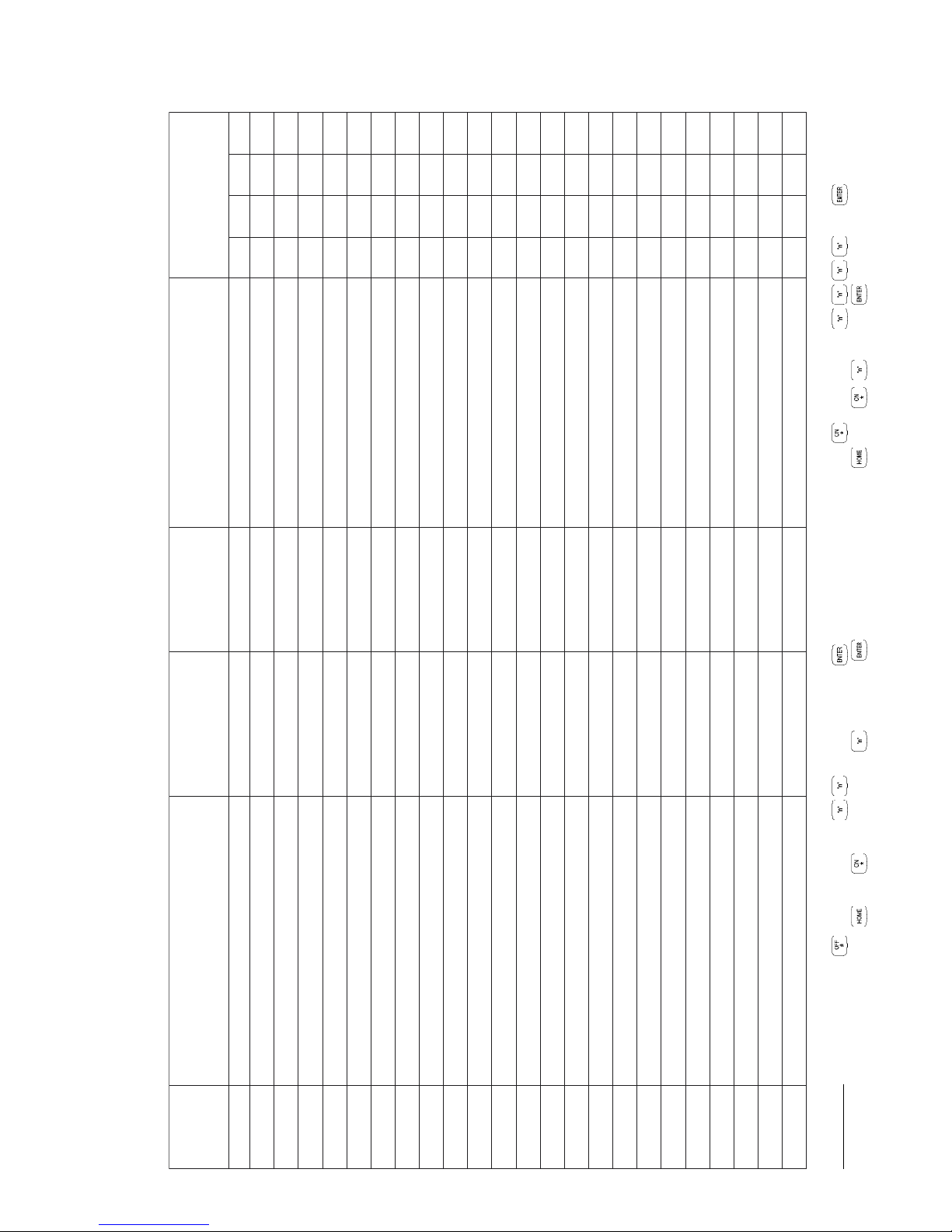

3.5 FACTORY DEFAULT DATABASE SETTINGS.

ADDRESS FUNCTION SETTING

16 and 32 Primary & Secondary Telephone Nos No numbers programmed

48 Reporting Format 0. None

49 Dialer options No options selected

50 Maximum attempts 10

51 to 53 Test Report Times No settings

54 Remote connect options 0. No Remote Connect

64 Callback Telephone Number No number programmed

80 Rings to Answer 16

81 Answering machine bypass 0. Disabled

82 Port 0 Comms Tasks 0. None

83 Port 0 Baud Rate 3. 9600

736 Zone Type. Zone 1 1. Delayed. (If Default Options 1 to 16 are selected)

737 Zone Type. Zone 2 2. Handover. (If Default Options 2 to 16 are selected)

738 to 751 Zone Type. Zone 3 to 16 as selected. 0. Instant. (If Default Options 3 to 16 are selected)

752 to 767 Zone Options No options selected.

768 to 783 Zone Area The number of Zones selected in the Default option are assigned to Area 1.

784 & 785 Max Pulse count & Pulse Time 0.

786 End-of-Line Resistor Type 3. Single End-of-line. 3k3

787 Self Test Period 0.

788 Siren Time 5 Minutes

789 Keypad Lockout Time 60 Seconds.

790 to 794 TimeZone 1 9:00 to 17:00. Monday to Friday

795 to 799 TimeZone 2 9:00 to 13:00. Saturday and Sunday

800 to 804 TimeZone 3 7:00 to 20:00. All days including Holidays. (Daytime)

805 to 809 TimeZone 4 20:00 to 7:00. All days including Holidays. (Night-time)

810 AC Report Delay Time 0

816 Auxiliary 1 Event Type 1. Burglary Alarm

817 to 825 Auxiliary 2 to 10 Event Type 0. None

832 to 841 Auxiliary 1 to 10 Time 0

848 Auxiliary 1 Response 2 & 3 Selected. On/Off when Event goes Valid/Invalid (Strobe Output)

849 to 857 Auxiliary 2 to10 Response 2 & 3 Selected. On/Off when Event goes Valid/Invalid

864 Spare

865 to 867 System Input Programming No settings programmed

868 General Options Options 4 & 8 selected. AC Mains sync & Zone activity display on Terminals

869 Emergency Options No options selected

870 & 871 Auto-Arm Timers 0.

872 Door Unlock Time 5 Seconds.

896 to 908 Area Client Codes No codes programmed

928 to 931 Area 1 to 4 Entry Delay Time Area 1: 30 Seconds. Area 2 to 4: 0 Seconds

936 to 939 Area 1 to 4 Exit Delay Time Area 1: 60 Seconds. Area 2 to 4: 0 Seconds

944 to 947 Area Arming Options No options selected

952 to 955 Terminal Associated Area No settings programmed

960 Multi Area Options No options programmed

961 Terminal Area Mode No options programmed

962 Spare

966 to 985 Holidays No Holiday dates programmed

986 & 989 Daylight Saving Start Month & End Month 0. Automatic Daylight Saving adjustment Disabled

987 & 990 Daylight Saving Start Week & End Week 5. Last Week of the Month

988 & 991 Daylight Saving Start Day & End Day 1. Sunday

Page 25

Section 2. Intro. Version 1.01 p9CONCEPT IQ. Installation & Programming Manual.

Intro

Terminal Programming allows the Installer to define which Area is to be associated with the LED Terminal.

NOTE: This Mode is only available if the Terminal is programmed for Multi-Area mode. (Address 960. Option 1

must be Selected)

Select the Terminal Programming Mode:

Enter PIN; ... , then , then the Mode number; ,

Select the Terminal Area Mode: (Not relevant to Enhanced Terminals which cannot be set to Multi-Area)

Press to Set the current Terminal to Single Area Mode.

Press to Set the current Terminal to Multi Area Mode.

Note that this operation will Edit the relevant option in Address 961, Terminal Area Mode.

When Single Area Mode is selected, the default “Associated Area” is Area 1 (General Area)

Select the Associated Area: (Single Area Mode must be selected in the previous step)

To select the Associated Area for the current Terminal, press the number (1 to 4) of the Area.

The Area selected will be displayed on the Area Lamps.

A long beep will sound if the terminal is not in Single Area Mode or the wrong key is pressed.

Note that this operation will Edit the data in the relevant Addresses 952 to 955, Terminal 1 to 4 Associated Area.

Press to exit Terminal Programming Mode.

3.6 MODE “03”. IMPORT DATA FROM THE PROGRAMMING KEY.

3.7 MODE “04”. EXPORT DATA TO THE PROGRAMMING KEY.

The Programming Key.

The Concept IQ Programming Key is a portable non-volatile memory device housed in a convenient “key tag”.

The Programming Key allows system programming to be uploaded from the Control Module or downloaded to the

Control Module by simply inserting the Programming Key into Serial Port 0 and performing a simple key sequence

on the LED Terminal.

A built-in Lamp on the Programming Key visually indicates when data transmission is active.

Importing Data from the Programming Key.

This Mode allows the Installer to copy the programming contents of the Programming Key into the Control Module.

IMPORTANT NOTE: The new data will override the existing contents of the Control Module memory.

Connect the Programming Key to Serial Port 0 on the Control Module.

Select the Import Data Mode:

Enter PIN; ... , then , then the Mode number; , .

The Lamp on the Programming Key will flash slowly to indicate data is being copied.

The Terminal beeper will sound 3 short beeps if the operation was successful, or 1 long beep if unsuccessful.

This Mode allows the Installer to copy the programming contents of the Control Module into the Programming Key.

IMPORTANT NOTE: The Control Module data will override the existing contents of the Programming Key.

Connect the Programming Key to Serial Port 0 on the Control Module.

Select the Export Data Mode:

Enter PIN; ... , then , then the Mode number; , .

The Lamp on the Programming Key will flash quickly to indicate data is being copied.

The Terminal beeper will sound 3 short beeps if the operation was successful, or 1 long beep if unsuccessful.

3.8 MODE “05”. TERMINAL AREA PROGRAMMING.

Page 26

p10 Section 2. Intro. Version 1.01 CONCEPT IQ. Installation & Programming Manual.

To Select the Data to be Viewed or Edited.

When in programming mode, the Memory Address to be viewed or edited can be selected by the following key

sequence:

Press , then the Address ... (2 or 3 digits - 16 to 988), then

Pressing will take you to the next Address.

(This does not apply to Data programmed in sequential Addresses such as PIN codes, Telephone Numbers and

Client codes)

The programming details of each Data Address in the following sections of this manual will only show the actual

Address number (nn...). Remember that the Installer must first access Programming Mode; and the Data Address

Number must be preceded by the <OFF / #> key.

To Edit the Data.

The Data Value at this Address will then be displayed on the Terminal, and can be changed by the following key

sequence:

Press , then the new Data Value or Option setting ... (1 to 16 digits*), then

* Depending on the type of Data required.

To set the Data in the current Address to the Factory Default setting:

Press , then , then

If you make a mistake while entering a value, press and enter that value again followed by the key.

Exiting the Installer Operations.

Press to exit any of the Installer Operations.

4.2 SELECTING AND PROGRAMMING THE DATA.

4. Programming Techniques

4.1 THE SYSTEM DATABASE.

The system programming is stored in Memory Addresses numbered 16 - 988.

Programming the system involves three steps:

1) Enter Programming Mode.

Then for each item of Data to be programmed;

2) Select the Memory Address to be programmed.

3) Program the new Data Value or Options for that Address.

Page 27

Section 2. Intro. Version 1.01 p11CONCEPT IQ. Installation & Programming Manual.

Intro

4.3 EXAMPLE OF PROGRAMMING.

This example shows how Zone 1 would be changed to the “Hand-over” Input Type.

Zone 1 Input Type is stored in Address 736.

STEP 1. Enter programming mode.

Enter Installer PIN code; ... , then , then the Programming Mode number; ,

STEP 2. Enter the Address to be changed.

Press , then the Address , then

STEP 3. Enter the new Data Value.

Press , then the new Data Value , then

(0 = Instant, 1 = Delayed, 2 = Handover, 3 = 24Hr Burglary, etc.)

STEP 4. Repeat Steps 2 and 3 to perform any additional programming required.

Press , to advance to the next Address. (i.e. Address 737 in this example)

OR

Press , then the new Address ... , then

Enter the new Data Value as before.

STEP 5. Exit the programming mode.

Press

Page 28

p12 Section 2. Intro. Version 1.01 CONCEPT IQ. Installation & Programming Manual.

5. Types of Data

5.2 “VALUE” DATA.

The range of Data values that can be stored in a Value Data Address is from 0 to 255.

Depending on the parameter being set, the range is often a lot smaller. The data can be either a single digit or a

multiple-digit number.

e.g. Remote Connect Options: 0 to 2, Zone Type: 0 to 9, Dial Attempts: 1 to 16,

TimeZone Start / End Hour 0 to 23, AC Fail report delay (M) 0 to 60, Area Entry Delay (S): 0 to 255,

etc.

Single digit numbers.

These are numbers between 0 and 16 and are displayed by the “0” Lamp and the Zone Lamps “1” to “16” on the

LED Terminal.

Multi digit numbers.

These are all other numbers ranging from 17 to 255.

These numbers are displayed one digit at a time by a sequence of flashing Lamps on the LED Terminal.

The “0” Lamp and the Zone Lamps “1” to “9” are used to display each digit in turn.

The key is used step through the digits. A short beep will sound each time the key is pressed to display

the next digit.

When the last digit in the sequence is displayed and the key is pressed again, a long beep will sound to

indicate that there are no more digits to display and the first digit will again be displayed.

E.g. If the value at the Address is 120.

When the Address is entered, The “1” Lamp will flash. (The flashing Lamp indicates that this value is a multi-digit

number)

When the <NEXT> key is pressed a short beep will sound and the “2” Lamp will now flash.

When the <NEXT> key is pressed again, a short beep will sound and the “0” Lamp will flash.

When the <NEXT> key is pressed again, a long beep will sound indicating there are no more new digits. The first

digit (“1” Lamp) will flash.

Sequential numbers.

Sequential numbers are a string of numbers where each digit is programmed into a series of sequential Addresses.

This type of Value Data makes it easier for the Installer to program data such as PIN codes, Telephone Numbers

and Client codes.

To select the data, only the Start Address is entered. The Start Address and each subsequent Address only

contains a single digit.

Once the Start Address for the data is selected, the Installer can then enter in the entire string of numbers without

having to perform any operation to select the subsequent Addresses.

See next page for example.

When in Programming Mode there are two types of data that are stored in the Programming Addresses.

The type of Data stored in each Address will depend on the type of parameter being defined.

1) “Value” data. A Numerical Data Value that:

- Selects an Option when there are more than 2 alternatives to select from. e.g. Reporting Format or User Type.

- Defines a Value or Quantity for a specific parameter. e.g. Entry and Exit Delay times or Number of Dial attempts.

- Defines a Sequence of numbers for a specific parameter. e.g. PIN codes, Client codes and Telephone numbers.

2) “Option” data. Data field that allows the Installer to select between two alternatives (Select/De-select, Enable/

Disable, Assign/Un-assign, etc.) for up to 8 Options or Items that relate to a particular feature.

(Similar to the Y / n options screens in Concept 3000 / Access 4000.)

e.g. Setting Dialer options, Assigning Areas to a User, Defining options for Individual Zone Inputs, etc.

5.1 OVERVIEW.

Page 29

Section 2. Intro. Version 1.01 p13CONCEPT IQ. Installation & Programming Manual.

Intro

5.3 “OPTION” DATA.

Option data is used to allow the Installer to select between two alternatives (Select/De-select, Enable/Disable,

Assign/Un-assign, etc.) for up to 8 Options or Items that relate to a particular feature.

Option Data is displayed on the Zone 1 to 8 Lamps on the LED Terminal.

When a Zone Lamp is ON, the option is Selected. (Enabled or Assigned)

When a Zone Lamp is OFF, the option is De-selected. (Disabled or Un-assigned)

Editing option data.

Option Data is programmed by first selecting the Address of the Data to be edited in the normal manner.

Any number of specific options are then Selected or De-selected by the following method:

1) Check the current setting of the option on the Zone Lamps.

2) For each option that needs to be changed, Press , then the option number (1 to 8), then .

This procedure toggles the setting of the selected option.

i.e. If the option was De-selected, it will be Selected. If the option was already Selected, it will be De-selected.

To Select ALL available options: Press , then , then .

To De-select ALL available options: Press , then , then .

To set ALL available options to the factory default settings: Press , then , then .

Example.

“Dialer Options” are Option Data and are programmed in Address 49. This data sets which types of events will be

reported via dialer: 1 Enable Alarms reported via dialer.

2 Enable Restores reported via dialer.

3 Enable Open / Close reported via dialer.

4 Enable Programming Change reported via dialer.

5 Enable Sending Open Report only if an alarm has occurred.

To Enable “Alarms”, “Restores” and “Open Report only after alarm”, the following procedure would be performed:

1) Enter Installer PIN code; ... , then , then the Programming Mode number; ,

2) Select the Address for Dialer Options. Press , then , then

3) Enable the three options required. (Assuming none of the options are currently enabled)

Press , then , then

Press , then , then

Press , then , then

(Remember that the same key sequence is used to Disable an option that is already Enabled.

4) Check Zone Lamps 1 to 8 to ensure that the required options have been selected successfully.

Zone Lamps 1, 2 and 5 should be ON. All other Zone Lamps should be OFF.

5) Select the next Address or Start Address to program, or Exit Programming Mode.

E.g. To program the data “1 Pause 9 8 7 6 5 4 3 2” as the Primary Telephone Number.

1) Enter Installer PIN code; ... , then , then the Programming Mode number; ,

2) Press , then the Start Address for the Primary Telephone Number , then

3) Press , then the new Data string , then

4) Select the next Address or Start Address to program, or Exit Programming Mode

(Note: The <Next> key is used to program a “PAUSE”).

Sequential Number data is displayed one digit at a time by a sequence of flashing Lamps in the same manner as

Multi-digit numbers described above.

Page 30

p14 Section 2. Intro. Version 1.01 CONCEPT IQ. Installation & Programming Manual.

6. Recommended Programming Sequence

1. Determine the number of Burglary Alarm Zone Inputs that will be connected to the system.

For ease of programming; If Entry/Exit Zones are to be used, it is recommended that:

-The Zone Input device that will start the Entry Timer is connected to Zone 1.

-The “Handover” Zone Input device (If required) is connected to Zone 2.

-Other Burglary Alarm Zone Input devices are connected to the lowest Zone Input numbers.

-Other types of Zone Input devices are connected to the higher Zone Input numbers.

2. Logon to the Terminal using the Installer PIN code and select Mode 2 - Defaulting the Control Module.

-Enter PIN, <NEXT>, 0, 2.

3. Select the Default Option that matches the number of Burglary Alarm Zone Inputs required.