Original

Op erating Instructions

and

Service Manual

c

innco systems GmbHR

Erlenweg 12 • D-92521 Schwarzenfeld • Germany

All rights reserved. We accept no liability for the content, especially for damages by existing,

non-existent or erroneous information.

It is not permitted to disclose or complement this document, partial or complete,

unless authorized by innco systems GmbHR.

Original

Op erating Instructions

and

Service Manual

CO3000, RC

c

innco systems GmbHR

Erlenweg 12 • D-92521 Schwarzenfeld • Germany

All rights reserved. We accept no liability for the content, especially for damages by existing,

non-existent or erroneous information.

It is not permitted to disclose or complement this document, partial or complete,

unless authorized by innco systems GmbHR.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 1 phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Contents

Contents

1 Controller CO3000 3

1.1 Brief Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Control Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Operational Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Power On/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.7 Activating Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.8 Referencing Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.9 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.10 Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.11 Device Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.12 Device Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.13 Device Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.14 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.15 Store Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.16 Recall Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.17 Tiltmast Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.18 Auto-Tilt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.19 Auto-Tilt Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.20 Setup Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.21 Limits Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.22 Limits Tiltmast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.23 VSWR Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1.24 Software Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2 Slider Setup 29

2.1 Brief Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.2 Antenna Polarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.3 Toothed Bar Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.4 Correction Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3 Remote Control 32

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 2

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1 Controller CO3000

1.1 Brief Description

The digital controller CO3000 is suited for the operation of antenna masts, turntables, slide bars

and other positioning equipment of innco and innco-systems.

It is operable in manual, semi-automatic and remote control mode.

The "Quick Move" buttons and the "Menu Wheel" enable an intuitive and quick operation.

A 7 display provides clear and precise information for each device.

1.2 Technical Data

Data interface IEEE488 / LAN

Device interface 4-port CAN-Bus via optical ber

Transfer rate 500kBit/s

Display 7 TFT 800x480 pixel

Voltage 100-240V AC (50/60Hz)

Approx. current consumption 20W

Fuse T 1,25A / 250V

Size 3HE 19 Rack mount

(427mm x 134mm x 300mm)

Approx. weight 3kg

Min. temperature 5◦C

Max. temperature 40◦C

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 3

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.3 Control Elements

Figure 1.1:

Front

Figure 1.2:

Back

1 - Power switch 8 - LAN (TCP/IP) port

2 - Horizontal softkeys 9 - USB port

3 - STOP button 10 - Fiberoptic CAN interface

4 - Vertical softkeys 11 - HCU interface (optional)

5 - Quick move buttons 12 - GPIB (IEEE 488) interface

6 - Data keypad 13 - Main switch / Power socket

7 - Menu wheel

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 4

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.4 Operational Controls

The buttons are lit when you can use them.

Figure 1.3:

Quick Move Buttons

The

"Quick Move"

buttons let you navigate left/right or up/down. You can also use these buttons

to move the active device.

Other than that, the polarization (horizontal/vertical) can be switched by using the

"H/V"

-button.

Figure 1.4:

Data Keypad

Use the data keypad for direct input of numerical values.

When a menu item is selected, there is no need to push the enter button - just start typing.

Lower keys:

•

"ESC"

exit active menu

•

"CLR"

delete last typed character

•

"Enter"

conrm input value

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 5

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

Figure 1.5:

Menu Wheel

The Menu Wheel is used to navigate through the menu by turning it clockwise or counter-clockwise.

Pressing the wheel has the same eect as the

"Enter"

button.

When a Tilt-Mast is connected, it switches between height and elevation input mode on main

display.

Also, the menu wheel is used to move the active device. By turning the wheel, the active device

increases or decreases its current position. The turning speed will aect the movement speed of

the device. This will be indicated by the following graphics:

Figure 1.6:

Speed indicator

Control elements which are able to be used will be displayed directly beneath the menu item.

Figure 1.7:

"Data Keypad"or"Menu Wheel"

| Up/Down | H/V | Left/Right (

"Quick Move"

)

To abort any running process or to stop the movement of a unit, please press the

"Stop"

Button.

Figure 1.8:

Stop Button

ATTENTION: This stopping procedure is NOT an emergency stop!

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 6

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.5 Power On/O

First, connect the power cable to the power socket.

Then, move the main switch into 'I'-position (ON).

Figure 1.9:

Main Switch / Power Socket

Press the

"Power"

button once, to turn on the controller.

Figure 1.10:

Power Button

Press and hold the

"Power"

button for 3 seconds, to shut o the controller.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 7

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.6 Initialization

By pressing the

"Power"

button, the following screen will be shown.

Figure 1.11:

Initialization Screen

During this time all devices which are currently connected to the CAN-bus will be detected and

initialized.

Figure 1.12:

Main Display

All connected devices will be shown in the main display and are ready to be used

(provided they have been referenced) - see chapter 1.8.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 8

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.7 Activating Devices

The device in the rst line is automatically activated.

Figure 1.13:

Activating; Main Display

To select an other device, press the vertical softkey next to the device name.

The selected device will be shown in yellow.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 9

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.8 Referencing Devices

Before operating, each device must be referenced. Referencing can be done any time.

In case the device has not been referenced,

"NOT REFERENCED"

will be shown in the display.

Figure 1.14:

Referencing; Main Display

Please reference devices in the following cases by pressing the

"Ref."

softkey.

•

A device has been connected to the controller for the rst time

•

The movement of a device has been interrupted (e.g. power loss, emergency stop)

•

An error has occurred at a device (e.g. activated limit switch)

Figure 1.15:

Referencing Device

Press the

"Device"

softkey and then the

"Start Referencing"

softkey

if you need to reference a device once more.

Press the

"Exit"

softkey to leave the setup and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 10

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.9 Settings

By pressing the

"Settings"

softkey, the following screen will be shown.

Figure 1.16:

Info

The

"Info"

softkey shows the

"Serialnumber"

and the

"Software version"

- they cannot be changed.

"IEEE-Address"

lets you set the desired IEEE-Address number.

"Brightness LCD"

will change the brightness of the display.

"Brightness Keys"

will change the brightness of the keys.

Press the

"Exit"

softkey to leave the setup and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 11

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.10 Network Settings

By pressing the

"Network"

softkey, the following screen will be shown.

Figure 1.17:

Network

"Mode"

changes from "DHCP" to "Static".

"IP Address"

lets you change the IP address of the controller.

"Netmask"

lets you change the netmask of the controller.

"Gateway"

lets you change the gateway of the controller.

"Port"

lets you change the network port of the controller.

"Hostname"

sets the name of the controller, which is shown in the network.

The

"Reset Page"

softkey resets the values on the active page to default settings.

The

"Reset Devices"

softkey resets the values of every referenced device to default settings.

Press the

"Exit"

softkey to leave the setup and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 12

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.11 Device Limits

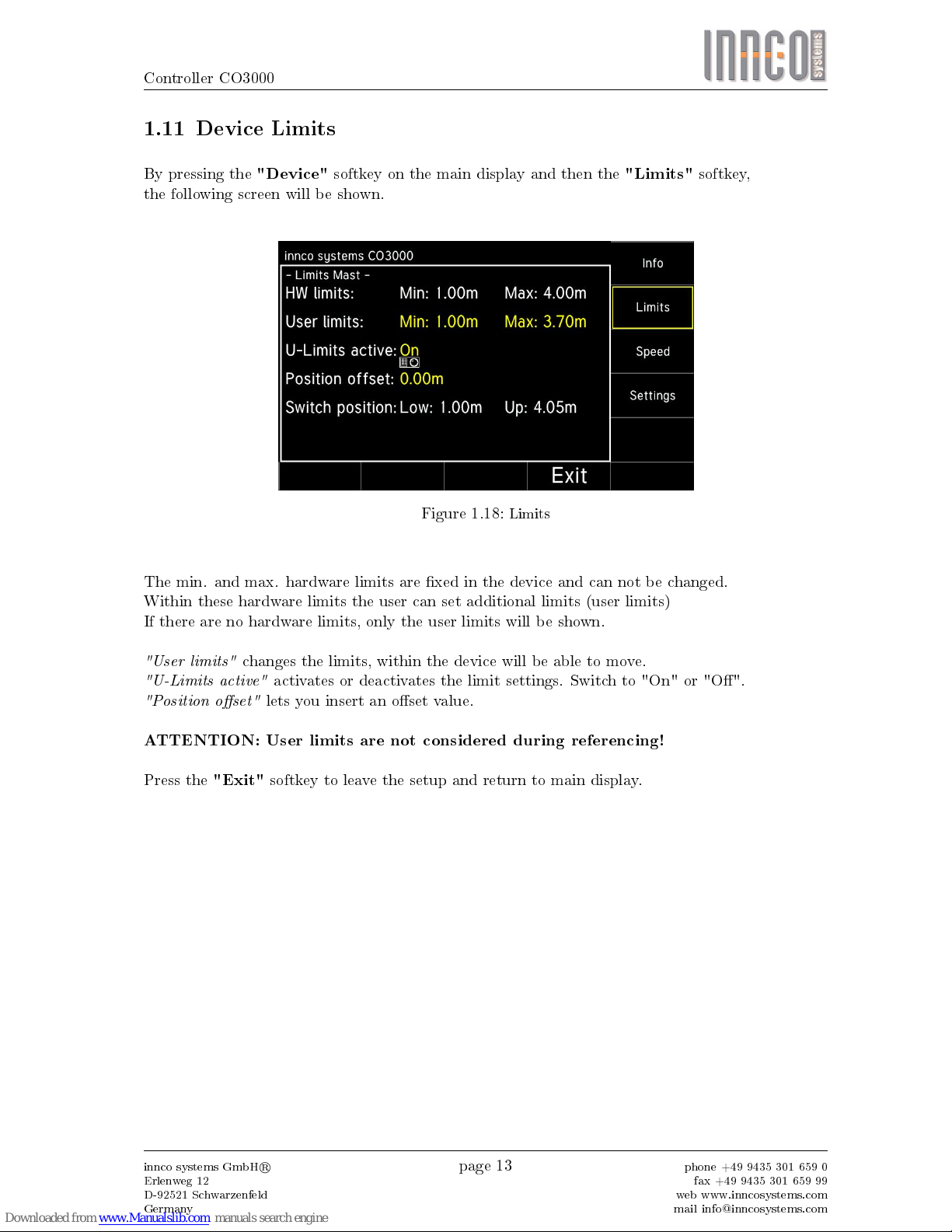

By pressing the

"Device"

softkey on the main display and then the

"Limits"

softkey,

the following screen will be shown.

Figure 1.18:

Limits

The min. and max. hardware limits are xed in the device and can not be changed.

Within these hardware limits the user can set additional limits (user limits)

If there are no hardware limits, only the user limits will be shown.

"User limits"

changes the limits, within the device will be able to move.

"U-Limits active"

activates or deactivates the limit settings. Switch to "On" or "O".

"Position oset"

lets you insert an oset value.

ATTENTION: User limits are not considered during referencing!

Press the

"Exit"

softkey to leave the setup and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 13

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.12 Device Speed

By pressing the

"Device"

softkey on the main display and then the

"Speed"

softkey,

the following screen will be shown.

Figure 1.19:

Speed

"Current speed"

lets you set the movement speed.

"Speed unit"

allows you to change the unit of measurement (mm/s, cm/s, m/s, inch/s)

Press the

"Exit"

softkey to leave the setup and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 14

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.13 Device Settings

By pressing the

"Device"

softkey on the main display and then the

"Settings"

softkey,

the following screen will be shown.

Figure 1.20:

Device Settings

"Name"

lets you rename the device individually.

"Position unit"

allows you to change the unit of measurement (mm, cm, m, inch).

"Mode"

changes from "Step" to "Continuous".

"Stepwidth"

species the step distance wich is run when in "Step" mode.

"Decimal place"

sets the number of decimal places shown on the results.

"Rounding"

lets you round the results. Switch to "On" or "O".

Press the

"Exit"

softkey to leave the setup and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 15

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.14 Positioning

Use the data keypad or the menu wheel to input a target position.

While the device is moving, a new position can be entered.

The device will stop and move to the new position.

1.15 Store Positions

By pressing the

"Store"

softkey on the main display, the following screen will be shown.

Figure 1.21:

Store Position

To store the position, just enter the position you would like to save, using the data keypad

(up to 4 positioins are storeable)

Please conrm the input values, using the

"Enter"

softkey,

otherwise the position will not be saved.

Saved positions will be shown on the right (Delete S1, Delete S2, ...)

Press the

"Delete ..."

softkey to delete a saved position from the memory.

Press the

"Exit"

softkey to leave the menu and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 16

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.16 Recall Positions

By pressing the

"Recall"

softkey on the main display, the following screen will be shown.

Figure 1.22:

Recall Stored Position

Press the

"Move to ..."

softkey to recall the saved position from the active device.

The device will immediately move to the restored position.

Press the

"Exit"

softkey to leave the menu and return to main display.

ATTENTION: The recall operation will be canceled if not completed!

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 17

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.17 Tiltmast Settings

The tiltmast positioner is a combination of minimum two devices:

•

mast with up/down and hor./vert. movement (polarization)

•

+ elevation unit with tilt up/down movement

or (optional)

•

mast + elevation unit (as above)

•

+ slider with forwards/backwards movement

The device is able to automatically correct the antenna elevation.

This occurs in relation to:

•

object height

•

antenna height

•

antenna length

•

measurement distance

When a mast with "Auto-Tilt" function is connected, the following screen will be shown.

Figure 1.23:

Main Display

Notes below the device name indicate, whether the respective function is activated.

e.g.

"AUTO-TILT"

or/and

"ANT-PROT"

will be shown when active.

First, the actual height is shown.

Above, you can see wether

"ANT-REF-H."or"MAST-HEIGHT"

is activated.

Second, the actual polarization is shown. (hor./vert.)

Third, the actual degree of elevation is shown.

By pressing the

"H/V"

button, the polarization axis will be switched.

Pressing the Menu Wheel lets you switch between height and elevation.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 18

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.18 Auto-Tilt

There are two types of measurement.

Mast Height and Antenna Reference Height

When the system is set to "MAST HEIGHT", the inserted height value will relate to

the mast basket reference mark.

When set to "ANT-REF-HEIGHT", the inserted height value will relate to

the antenna reference mark.

Please consider this while setting up and conguring the Tilt-Mast.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 19

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.19 Auto-Tilt Settings

By pressing the

"Device"

softkey in the main menu and then the

"Auto-Tilt"

softkey,

the following screen will be shown.

Figure 1.24:

Auto-Tilt O

To enable the

"Auto-Tilt"

function, it needs to be switched to "On" rst.

Figure 1.25:

Auto-Tilt On

"Auto-Tilt"

lets you activate/deactivate the elevation correction. Switch to "On" or "O".

"HEIGHT-AXIS MODE"

indicates which measurement type is being used.

"Object-Setup"

lets you choose the height of the object to be measured.

"Mast-Setup"

set

"ANT-REF-LENGTH"

and

"SETUP M-DISTANCE"

as shown on next page.

> it is preferred to set the "SETUP M-DISTANCE" directly after referencing a device.

"Auto-Distance"

will show if a "Slider" has been connected or not.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 20

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.20 Setup Drawing

Figure 1.26:

Setup Drawing

If there isnoslider connected, the

'SETUP M-DISTANCE'

is the same as Measurement Distance.

The mast will have to be moved manually into position or the antenna

will have to be moved to the correct position, using the polarisation-tube.

ATTENTION:

Moving the antenna will change the Ant.-Ref.-Length! If necessary, adjust!

For operation

with

slider, please use the Slider Setup manual.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 21

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.21 Limits Axis

The display shows the active axis on the top in green.

Figure 1.27:

Limits Tiltmast

Change the active axis by pressing the

"Change Axis"

softkey or the

"H/V"

button.

"User limits"

changes the limits, within the device will be able to move.

"U-Limits active"

activates or deactivates the limit settings. Switch to "On" or "O".

"Position oset"

lets you insert an oset value.

"Tilt Ant. Protection"

lets you set the minimum height, when at maximum tilt angle,

to protect the mounted antenna. Switch to "On" or "O".

Press the

"Exit"

softkey to leave the menu and return to main display.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 22

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.22 Limits Tiltmast

By pressing the

"Limits"

softkey, the following screen will be shown.

Figure 1.28:

Limits Tiltmast

The min. and max. hardware limits are xed in the device and can not be changed.

Within these hardware limits the user can set additional limits (user limits)

If there are no hardware limits, only the user limits will be shown.

ATTENTION:

User Limits are always referenced to the Mast Height - not to the Ant-Ref-Height!

"User limits"

changes the limits, within the device will be able to move.

"U-Limits active"

activates or deactivates the limit settings. Switch to "On" or "O".

"Position oset"

lets you insert an oset value.

"Tilt Ant. Protection"

lets you set the max. tilt-angle, when at 1m height,

to protect the mounted antenna. Switch to "On" or "O".

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 23

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.23 VSWR Settings

The VSWR positioner is a combination of two devices:

•

The slide with left and right movement

•

The turn unit with corrective rotation left and right (automatic correction is optional)

Figure 1.29:

The device is able to correct the antenna direction according to the antenna distance to DUT and

the slider center position.

The mentioned parameters can be adjusted in the "Extras" of the device settings.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 24

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

By pressing the

"Device"

softkey in the main menu and then the

"Extras"

softkey,

the following screen will be shown.

Figure 1.30:

VSWR Position

"Auto-Azimuth"

enables the direction correction. Switch to "On" or "O".

"Centre position"

set the centre position of the slider. (Reference for the 0◦position)

"Distance to DUT"

will aect the correction angle according to the following drawing.

Distance to DUT

Centre Position

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

Figure 1.31:

VSWR Setup

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 25

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

1.24 Software Update

If new software is available, it can be downloaded from our homepage or will be provided by our

service team.

For the update it is necessary to connect the CO3000 to a computer.

ATTENTION: Do not use a USB hub!

Connect the CO3000 USB port on the rear panel with a USB cable (Type A to Type B)

directly to a free USB port on the PC.

Windows will now load the USB driver for the CO3000.

No user interaction will be required.

If the CO3000 is connected to the PC for the rst time, a short message on the task bar

will appear, that the device is now ready to use.

Now the controller can be updated by starting the program "Updater.exe".

Figure 1.32:

Update Start

The update program shows:

"Connected"

and

"Controller Reboot required"

.

Please reboot the controller now. (Power o, then power on).

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 26

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

During reboot, the following screen will be shown on the controller.

Figure 1.33:

Update Mode Controller

After rebooting, the message

"Controller Reboot required"

will change to

"Ready to Update"

.

Figure 1.34:

Update Process

Please click

"Open File"

and choose the provided update le (*.CO3000 le type)

Now click

"Start Update"

to start update process.

The update process can take up to 10 minutes.

ATTENTION: Do not switch o or disconnect the controller during this time!

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 27

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Controller CO3000

After a successful update, the following screen will be shown.

Figure 1.35:

Update Done

The update software can now be closed and the USB cable disconnected.

The controller will reboot automatically and is ready to use.

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 28

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Slider Setup

2 Slider Setup

2.1 Brief Description

The slider is an additional unit to the antenna mast with auto-tilt function.

A toothed bar, mounted to the oor and a drive unit, mounted to the mast are the main components.

How to set up the toothed bar and the antenna mast is described in this manual.

2.2 Antenna Polarization

Please follow the steps as shown below. If necessary, take the controller manual at hand.

Figure 2.1:

Polarization Tube

•

Bring the mast basket into the maximum tilt position

•

Make sure, the antenna is in vertical position

•

Mount the adaptor and the antenna to the polarization tube

•

Adjust the polarization tube, to ensure the antenna does not collide with the mast

> If this is not possible, adjust the maximum tilt-angle in the controller's "User Limits" settings.

•

Make sure, the polarization tube is tightened rmly

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 29

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Slider Setup

2.3 Toothed Bar Setup

Figure 2.2:

Setup

•

Bring the antenna into 0◦position (horizontal)

•

Add the Ant.-Ref.-Length, the Measurement Distance and a little reserve (approx. 2-3cm)

This will be your

"Slider-Setup-Distance"

•

Mark the oor at the calculated Distance from the DUT

•

Place the toothed bar on the oor, so the mark on the oor matches the mark on the bar

•

Make sure, the direction of the bar's mark is pointing towards the DUT

•

Fix the bar to the oor (screw or tape)

•

Place the mast(-drive) on top of the toothed bar

•

Reference the mast as described in the CO3000 manual

•

After referencing, measure the"SETUP M-DIST" and insert it in the controller

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 30

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Slider Setup

2.4 Correction Modes

Distance Correction Height Correction

To correct dierences in distance, the slider will move forward or backward.

To correct dierences in height, the antenna will tilt up or down.

ATTENTION: It ist not possible to tilt in a negative direction!

innco systems GmbHR

Erlenweg 12

D-92521 Schwarzenfeld

Germany

page 31

phone +49 9435 301 659 0

fax +49 9435 301 659 99

web www.inncosystems.com

mail info@inncosystems.com

Remote Control CO3000

for Innco Systems devices

Document version: v2.10

Date: 2016-06-28

Written by: Thomas Witzenbichler (TW)

Tony Schinkowski (TS)

Valid from CO3000 SW Version: v1.02.60

Document-History

Version Date Author Changes CO3000 Version

v1.0 2012-08-22 TW Initial version v1.01.02

v1.1 2013-01-31 TW Changes GPIB index DS & CT v1.01.10

v1.2 2013-04-16 TW Gantry device added, Correction axis

documentation of XYZ-Positioner

v1.02.01

v1.3 2013-10-04 TW Compound device added. Mast-Rotator added v1.02.08

v1.4 2014-05-20 TW New speed command NSP added v1.02.11

v1.5 2014-07-28 TW Tiltmast (TMP) added

Tiltmast-Slider (TMS) added

v1.02.12

v1.6 2015-05-06 TS VSWR-Compound added v1.02.25

v1.7 2015-05-18 TS Updated Tiltmast (TMP) v1.02.26

v1.8 2015-06-30 TS Added FSM Compound v1.02.33

v1.9 2015-10-05 TS Added STATUS command, see

3.1 General Commands

v1.02.37

v1.10 2015-11-30 TS New Commands for

- Tiltmast (TMP) Antenna-Protection

- Tiltmast (TMP) Auto-Tilt

- Tiltmast (TMP+TMS) Auto-Distance

- VSWR-Compout Auto-Azimuth

- Gantry Antenna-Compensation

v1.02.38

v2.00 2016-06-07 TS Tiltmast (TMP): Reworked Auto-Tilt v1.02.50

v2.10 2016-06-28 TS Tiltmast (TMP): Reworked Auto-Distance v1.02.60

innco systems GmbH

Erlenweg 12

92521 Schwarzenfeld

phone: +49 (0)9435 301659 0

fax: +49 (0)9435 301659 99

e-mail: info@inncosystems.com

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3

web: www.inncosystems.com

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Table of Content

1 General............................................................................................................................................... 3

1.1 Terminology.................................................................................................................................................... 3

1.2 Other Terminology.......................................................................................................................................... 3

2 Remote System.................................................................................................................................. 4

2.1 Basic Information............................................................................................................................................ 4

2.2 Connecting via GPIB....................................................................................................................................... 4

2.3 Connection via Network (LAN / Ethernet)....................................................................................................... 5

2.4 Addressing Devices........................................................................................................................................6

2.5 Error messages............................................................................................................................................... 6

3 Remote Commands............................................................................................................................ 7

3.1 General Commands........................................................................................................................................ 7

3.2 Mast (MA), Minimast (MM).............................................................................................................................. 9

3.3 Twinmast (TW: TWX, TWZ), Tiltmast (TM: TMX, TMZ)................................................................................11

3.4 Rotary table (DT), Rotary unit (DE), Rotary disc (DS), Compact table (CT), Mast rotator (MR)..................13

3.5 XYZ-Positioner (XYZ: X, Y, Z)...................................................................................................................... 15

3.6 Field probe mast (FSM: FX, FY)................................................................................................................... 17

3.7 Slidebar (KMS).............................................................................................................................................. 19

3.8 Mast Positioner (MP).................................................................................................................................... 21

3.9 VSWR Compound (VSWR: VS, VSA).......................................................................................................... 23

3.10 VSWR Positioner (VSWR).......................................................................................................................... 26

3.11 Antenna stand (AS)..................................................................................................................................... 28

3.12 Gantry with Polarisation (GAP)................................................................................................................... 29

3.13 Gantry without Polarisation (GA)................................................................................................................ 31

3.14 Compound Device Mast (CD: CDH, CDP, CDE)........................................................................................33

3.15 Tiltmast (TMP: TMPM, TMPE).................................................................................................................... 35

3.16 Tiltmast Slider (TMS), Tiltmast-Positioner Extension.................................................................................38

4 Examples.......................................................................................................................................... 40

4.1 Opt Command............................................................................................................................................... 40

4.2 Addressing.................................................................................................................................................... 40

4.3 Reading current position............................................................................................................................... 40

4.4 Moving axes.................................................................................................................................................. 41

4.5 Error messages............................................................................................................................................. 41

4.6 Setting a Register......................................................................................................................................... 42

4.7 Polarisation................................................................................................................................................... 42

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

1 General

1.1 Terminology

IEEE488: External Parallel Data Bus

GPIB: General Purpose Interface Bus, or General Purpose Instrumentation Bus

EOI: End Or Identify

Listener GPIB condition of the device’s ability to receive messages

Talker GPIB condition of the device’s ability to receive messages

LF: Line Feed

LAN: Local Area Network, Network Connection

TCP/IP: Transmission Control Protocol / Internet Protocol, used by the LAN

Subnet Contiguous partial network within a LAN network

Hostname Unique name of a computer in the network

DHCP Dynamic Host Configuration Protocol, automatic IP address assignment

HTTP Hyper Text Transfer Protocol, Protocol for Websites

Socket Connection for exchanging data in networks and procedures

Network mask Bitmask for setting up subnets in a network

Gateway Protocol implementer for communicating via Internet

1.2 Other Terminology

nnn Floating point number, up to one decimal place, negative and positive

◦ e.g.: 0, 1, 0.0, 0.1, -100.5, 42.3

ppp Floating point number, up to one decimal place, only positive

◦ e.g.: 0, 1, 0.0, 0.1, 100.5, 42.3

iii Integernumber

◦ e.g.: 0, 1, 123, -456

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

2 Remote System

2.1 Basic Information

Using a GPIB or LAN connection, the CO3000 can be triggered and used to control devices

connected to it. The commands used for this are coded in simple, readable character strings. The

following applies to all connections:

Character set: ASCII 8Bit

All incoming and outgoing communications are completed with LineFeed “LF” (0x0A)

◦ for IEEE488, LF and/or EOI can be used

Maximum length of incoming character string: 64 bytes, including LF

Maximum length of outgoing character string: 64 bytes, including LF

All characters must be transmitted in capital letters. The separator is a space (0x20)

All commands sent to the CO3000 are confirmed with a return value for each

◦ Each command can however also be answered with an error message.

2.2 Connecting via GPIB

2.2.1 Connection

To connect remotely via GPIB, the PC must have a GPIB interface. There are several suppliers for

suitable add-on cards or USB adaptors, e.g. National and Agilent. You will need an IEEE-488 cable to

connect it with.

The CO3000 is delivered with the default GPIB address 7. This can be changed in the controller’s

settings.

2.2.2 Communication

Communication runs on the GPIB standard. To receive commands, the CO3000 must be addressed

as a listener and to send the return value it must be addressed as a talker. Return values can be read

several times.

Return values are available for reading immediately after being received and decoded.

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

2.3 Connection via Network (LAN / Ethernet)

The CO3000 can be operated in a normal TCP/IP network. It has no website. It is not possible to run it

via an internet browser!

2.3.1 Connection

The controller can be connected to a PC or switch by using a normal network cable (not crossover!) in

the network socket in the back of the CO3000.

2.3.2 Settings

DHCP mode (Preset) Static mode (Example)

Hostname CO3000 CO3000

IP address Automatic 192.168.0.42

Network mask Automatic 255.255.255.0

Gateway Automatic 192.168.0.1

Port 5025 5025

The CO3000 is delivered with the DHCP activated. If a static address is desired, this can be set on the

CO3000.

In its original setting, the hostname “CO3000” is preset. If you are operating several controllers on the

same subnet, the hostnames must be unique. Depending on the DHCP server you are using on the

network, various negative effects can occur on the network if several network-capable devices use the

same hostname. The hostname can be changed in the CO3000 settings.

The settings for the gateway are irrelevant in most cases, because the CO3000 does not make an

Internet connection.

2.3.3 Communication

No additional protocols such as HTTP are used. Sockets can be used for communication. The

commands can be written directly to the previously opened socket and the return values read from it.

When communicating via LAN, please note that unlike GPIB it is not possible to read a return value

from the CO3000 several times. A return value can only be read if a command has been sent to the

CO3000.

After receiving and decoding the command, the CO3000 will immediately send the return value to the

invoker. Depending on the network, it may take some time to receive the return value (> 100ms).

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

2.4 Addressing Devices

Each axis of a device is assigned an address between 0 and 15. If an address is already occupied by

a device, newly added devices will be assigned a higher address.

An exception to this address assignment is the polarisation axis of the mast devices. The polarisation

is described by itself in the sections under each device.

Example of numerical addressing:

Mast selection : LD 0 DV

Selecting a rotary table DT2: LD 5 DV

Selecting an X-axis of an XYZ positioner: LD 4 DV

In addition to numerical addressing, a device can also be triggered via a named address. This has the

advantage that a device can have a unique name in the remote system and be triggered by this name

even if a newly added device could change the numerical address.

Device names can be given out using the *OPT? Command. See 3.1. General Commands und

4.1.Opt Command

Named Addresses:

Mast selection: LD MA1 DV

Selecting a rotary table DT2: LD DT2 DV

Selecting an X-axis of an XYZ positioner: LD X1 DV

2.5 Error messages

All entries are confirmed with a return value. In case of an error, one of the four error codes is

returned.

“E - P” Power: Is sent after a loss of the power supply.

“E - S” Syntax: Is sent when there was an error in the command.

“E - V” Value: Is sent when a value is not within the limits.

“E - D” Device: Is sent hen a device fails to react for a long time. This means that the

motor is not moving. Is also sent when the addressed device does not

exist.

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3 Remote Commands

Important: Each command sent to the controller is confirmed with a return value. The return values

listed in the tables below are the values returned in case of success. In case of error, the error codes

listed under 2.4. Error Messages may be given at any command.

3.1 General Commands

General Commands

Command Return Description

ES 1 Emergency Stop

Stops all movements of all connected devices

LO 1 Log Out, leave remote-modus. Any currently executed device

movement will be completed.

*IDN? inncoCO3000/a

aa/bbb

Returns the identification string

aaa: Serial number, variable character string length

bbb: CO3000 Version number, variable character string length

*OPT? Depends on

device.

Without devices:

0,0,0,0,0,0,0,0,

0,0,0,0,0,0,0,0

Returns the named addresses of the connected devices. The

numerical address is derived from the index of named

addresses.

Example with Mast, Rotary Table and XYZ Positioner :

“MA1,DT1,0,0,X1,0,0,0,Y1,0,0,0,Z1,0,0,0”

- Mast MA1 has the address 0 (Index 0)

- Rotary Table DT1 has the address 1 (Index 1)

- Addresses of XYZ_Axes: 4, 8 and 12 (Index 4,8,12)

LD xxxn DV xxxn

(see above)

Load one axis of one device and enter remote-modus,

Addressing by name

Examples (compare with example of *OPT? above)

LD MA1 DV

LD DT1 DV

LD X1 DV

LD Y1 DV

LD Z1 DV

LD d DV d Lode one axis of one device and enter remote-modus,

Addressing by index

Index d starts at 0 (see *OPT? above)

Examples (compare with example of *OPT? above)

LD 0 DV

LD 1 DV

LD 4 DV

LD 8 DV

LD 12 DV

STATUS d ?

STATUS n ?

x, b, nnn EE

- or -

x, b, ppp EE

- or -

x, b, nnn EE, pp

- or -

x, b, nnn EE, pp

Query the status of the device and axis.

Can use numerical addressing (d) or name addressing (n).

d: Numerical address of the device

x: Name of the device

b: Busy status of the device (0=stopped 1=moving)

nnn, ppp: The current position of the device

EE: Unit, can be CM (Centimetre) or DG (Degree)

pp: Polarisation PV, PH, or P- (moving)

Example:

STATUS MA1 ?

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

General commands (work on selected device and axis)

Command Return Description

ST 1 Stops currently selected axis movement

Does not leave remote-modus

LD nnn EE RR

LD ppp EE RR

LD iii EE RR

Depends on

EE and RR

Load command, loads a value to a register

LD: Load

nnn, ppp, iii assigned register values

EE: Unit, valid character string:

- CM (Centimetre)

- DG (Degree)

- INT (Integer)

RR: Register, valid registers are described in each device

Example:

LD 350 CM UL

LD 123 CM NP

LD s SP s Sets the speed of the currently selected axis.

Valid values for s: 1-8,

1: minimum speed

8: maximum speed

Example:

LD 4 SP

LD ppp NSP ppp Sets the speed of the currently selected axis.

In cm/s or degree/s

LD nnn CM NP

LD ppp CM NP

LD nnn DG NP

LD ppp DG NP

1 New Position, Register is loaded using LD - see devices

Example:

LD 123 CM NP

GO 1

Moves the axis to the value in register NP

LD nnn CM NP GO

LD ppp CM NP GO

LD nnn DG NP GO

LD ppp DG NP GO

Load New Position and move the axis to this position

Example:

LD 123 CM NP GO

BU 0 or 1

BU = 1: Motor on; BU = 0: Motor off

This register shows if one of the motors is currently moving.

For mechanical reasons, the motor cannot implement the

movement immediately after the start command. It is therefore

necessary to wait until the mast starts moving before you can

use BU to check if the last command is complete. Even if the

mast has already reached its target BU will still remain at the

value 1 for approx. 0.5 seconds.

HO 1 Starts referencing for the selected device.

All axis of the device are referenced.

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.2 Mast (MA), Minimast (MM)

3.2.1 General

Supported devices

◦ Mast (MA): 0x21..

◦ Minimast (MM): 0x23..

All values are transmitted in CM (cm).

Negative values are not possible.

3.2.2 Register

Addressing

Command Return value Description

LD d DV d Load X-axis mast, numerical addressing

Valid values for d: 0, 4, 8, 12

LD MAd DV

LD MMd DV

Index of

MAd/MMd from

*OPT? return

Load X-axis mast, named addressing

Valid values for d: 1, 2, 3, ..

Read commands

Command Return value Description

CP ppp ppp: Current Position in cm

BU 0 or 1

Motor Operation Status

0: Motor is off

1: Motor is on

MP ppp

ppp: Mast position in cm

Changes the address to the X-axis of the mast. All

following commands will relate to the X-axis of the

mast.

P? 0 or 1 Polarisation, 0: horizontal, 1: vertical

UL ppp

ppp: Upper Limit X-axis in cm

LL ppp

ppp: Lower Limit X-axis in cm

SP 1 to 8

Current Speed X-axis

NSP ppp

Current speed X-axis in cm/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Write Commands

Command Return Value Description

LD ppp CM UL ppp Sets upper limit to ppp cm

This must not be greater than the hardware limits and

should not be less than the hardware’s lower device

limit.

LD ppp CM LL ppp Sets lower limit to ppp cm

This must not be less than the hardware limits and

should not be greater than the hardware’s upper

device limit.

LD s SP s Sets new speed for X-axis

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for X-axis in cm/s

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

UP 1

Moves the mast basket upwards until the upper limit

is reached or the command STOP(ST) is sent.

DN 1

Moves the mast basket downwards until the lower

limit is reached or the command STOP(ST) is sent.

PV 1 Polarise vertical

PH 1 Polarise horizontal

LD ppp CM NP 1 Load ppp cm in Register NP (New Position)

GO 1 Move the mast basket according to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.3 Twinmast (TW: TWX, TWZ), Tiltmast (TM: TMX, TMZ)

3.3.1 General

Supported devices

◦ Twinmast (TW): 0x2A.

◦ Tiltmast (TM): 0x28.., 0x29..

All values are transmitted in CM (cm) or DG (degrees).

Negative values are not possible.

3.3.2 Register

Addressing

Command Return value Description

LD x DV x Load X-axis Twinmast/Tiltmast, numerical addressing

Valid values for x: 0, 3, 6, 9, 12, 15

LD z DV z Load Z-axis Twin/Tilt-Mast, numerical addressing

Valid values for y: 3, 6, 9, 12, 15

LD TWXd DV

LD TWZd DV

LD TMXd DV

LD TMZd DV

Index of TWXd,

TWZd,.. from

*OPT? return

Load X-axis Twinmast (TW)

Load Z-axis Twinmast (TW)

Load X-axis Tiltmast (TM)

Load Z-axis Tiltmast (TM)

Valid values for d: 1, 2, 3, ....

Read Commands

Command Return Value Description

CP ppp ppp: Current position of the X-Axis in cm

TA ppp ppp: Current position of Z-Axis (Swing) in degree

BU 0 or 1

Motor Operational Status

0: Motor is off

1: Motor is on

MP ppp

ppp: Mast position of X-Axis in cm

Changes the address to the X-Axis of the Mast. All

following commands will relate to the X-Axis of the

Mast.

P? 0 or 1 Polarisation, 0: horizontal, 1: vertical

UL ppp

ppp: Upper Limit X-Axis in cm

LL ppp

ppp: Lower Limit X-Axis in cm

TL ppp

ppp: Swing Limit of Z-Axis in degrees

Maximum deviation from the horizontal position in

degrees downwards and upwards.

SP 1 to 8

Speed of the current axis

NSP ppp

Speed of the current axis. X-axis in cm/s, Z-axis in

Degree/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Write Commands

Command Return Value Description

LD ppp CM UL ppp Sets upper limit of X-Axis to ppp cm

ppp must not be greater than the hardware limits and

should not be less than the hardware’s lower device

limit.

LD ppp CM LL ppp Sets lower limit of X-Axis to ppp cm

ppp must not be less than the hardware limits and

should not be greater than the hardware’s upper

device limit.

LD ppp DG TL ppp

Sets swing limit of the Z-Axis to ppp degrees

Swing Limit: Maximum deviation of the horizontal

position in degrees upwards and downwards.

ppp must not exceed the hardware limits of the Z-

Axis.

LD s SP s Sets new speed for the currently selected axis: X or Z

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for the currently selected axis. X-axis

in cm/s, Z-Axis in degree/s

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

UP 1

Moves the mast basket (X-Axis) upwards until the

upper limit is reached

DN 1

Moves the mast basket (X-Axis) downwards until the

lower limit is reached

PV 1 Polarise vertical

PH 1 Polarise horizontal

TF 1 Swings downwards until the swing arm’s lower limit is

reached

TU 1 Swings upwards until the swing arm’s upper limit is

reached

LD ppp CM NP 1 Load ppp cm in Register NP (New Position),

X-Axis must be previously selected!

LD ppp DG NP 1 Load ppp Grad in Register NP (New Position)

Z-Axis must be previously selected!

GO 1 Moves the selected axis to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.4 Rotary table (DT), Rotary unit (DE), Rotary disc (DS),

Compact table (CT), Mast rotator (MR)

3.4.1 General

Supported devices

◦ Rotary table (DT): 0x1A.., 0x1B..0x19.., 0x18..

◦ Rotary unit (DE): 0x01.., 0x48..

◦ Rotary disc (DS): 0x04..

◦ Compact table (CT): 0x0400

◦ Mast rotator (MR) 0x0450

All values are transmitted in DG (degrees).

3.4.2 Register

Addressing

Command Return Value Description

LD d DV d Load Table, numerical addressing

- Rotary table d: 1, 5, 9, 13

- Rotary unit d: 3, 7, 11, 14

- Rotary disc d: 1, 5, 9, 13

- Compact table d: 1, 5, 9, 13

- Mast rotator d: 1, 5, 9, 13

LD DTd DV

LD DEd DV

LD DSd DV

LD CTd DV

LD MRd DV

Index of DTd,

DEd,.. from

*OPT? return

Load Table, named addressing

Valid values for d: 1, 2, 3, ...

Read Commands

Command Return Value Description

CP nnn nnn: Current Position in Grad

BU 0 or 1

Motor Operational Status, Return:

0: Motor is off

1: Motor is on

TP nnn

nnn: Table position in degrees

Changes the address to the table. All following

commands will relate to the table.

WL

nnn nnn: Limit in clockwise degrees

CL

nnn nnn: Limit in anticlockwise degrees

SP 1 to 8

Current speed

NSP ppp

Current speed in Degree/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Write Commands

Command Return Value Description

LD nnn DG WL nnn

Sets clockwise limit to nnn degrees

This must not be greater than the hardware limits and

should not be less than the hardware’s lower device

limit.

LD nnn DG CL

nnn Sets anticlockwise limit to nnn degrees

This must not be less than the hardware limits and

should not be greater than the hardware’s upper

device limit.

LD s SP s Sets new speed for the device

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for the device in degree/s

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

CW 1 Moves the table clockwise until the limit is reached

CC 1 Moves the table anticlockwise until the limit is

reached

LD nnn DG NP 1 Load nnn degrees in Register NP (New Position)

GO 1 Move the table to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.5 XYZ-Positioner (XYZ: X, Y, Z)

3.5.1 General

Supported devices

◦ XYZ-Positioner (XYZ): 0xA0..

All values are transmitted in CM (cm)

Negative values are not possible

Each axis of the positioner is controlled individually. Only one axis can be moved at a time. As

long as BU=1, no new command will be carried out.

3.5.2 Register

Addressing

Command Return Value Description

LD x DV x Load X-Axis, numerical addressing

Valid values for x: 4

LD y DV x Load Y-Axis, numerical addressing

Valid values for y: 8

LD z DV z Load Z-Axis, numerical addressing

Valid values for z: 12

LD Xd DV

LD Yd DV

LD Zd DV

Index of Xd, Yd,

Zd from *OPT?

return

Load X-Axis

Load Y-Axis

Load Z-Axis

Valid values for d: 1, 2, 3, ...

Read Commands

Command Return Value Description

CP ppp ppp: Current position of the current axis in cm

MP ppp

ppp: Position of the X-Axis in cm

Changes the address to the X-Axis of the positioner.

All following commands will relate to the X-Axis of the

positioner

BU 0 or 1

Motor Operational Status, current axis

0: Motor is off

1: Motor is on

UL

ppp: ppp: Upper limit, current axis, in cm

LL

ppp: ppp: Lower limit, current axis, in cm

SP 1 to 8

Speed of current axis

NSP ppp

Speed of the current axis. X-axis in cm/s, Y-axis in

cm/s, Z-axis in cm/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Write Commands

Command Return Value Description

LD ppp CM UL

ppp

Sets upper limit of the current axis to ppp cm

ppp must not be greater than the hardware limits and

should not be less than the hardware’s lower device

limit.

LD ppp CM LL ppp Sets lower limit of the current axis to ppp cm

ppp must not be less than the hardware limits and

should not be greater than the hardware’s upper

device limit.

LD s SP s Sets new speed for the currently selected axis: X or Z

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for the currently selected axis. X-axis

in cm/s, Y-axis in cm/s, Z-Axis in cm/s

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

UP 1

Moves the current axis in positive direction until the

upper limit is reached

DN 1

Moves the current axis in negative direction until the

lower limit is reached

LD ppp CM NP 1 Load ppp cm in Register NP (New Position),

Applies to current axis

GO 1 Moves the current axis to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.6 Field probe mast (FSM: FX, FY)

3.6.1 General

Supported devices

◦ Field probe mast (FSM): 0x58..

All values are transmitted in CM (cm)

For the X-Axis, only positive values are possible

For the Y-Axis, positive and negative values are possible

3.6.2 Register

Addressing

Command Return Value Description

LD x DV x Load X-Axis, numerical addressing

Valid values for x: 0, 4, 8

LD y DV y Load Y-Axis, numerical addressing

Valid values for y: 4, 8, 12

LD FXd DV

LD FYd DV

Index of FXd,

FYd from *OPT?

return

Load X-Axis

Load Y-Axis

Valid values for d: 1, 2, 3, ...

Read Commands

Command Return Value Description

CP ppp

nnn

ppp at X-Axis

nnn at Y-Axis

Current position of the current axis in cm

MP ppp

ppp: Position of the X-Axis in cm

Changes the address to the X-Axis of the field probe

mast. All following commands will relate to the X-Axis

of the field probe mast.

BU 0 or 1

Motor Operational Status, current axis

0: Motor is off

1: Motor is on

UL

ppp

nnn

ppp at X-Axis

nnn at Y-Axis

Upper limit of current axis in cm

LL

ppp

nnn

ppp at X-Axis

nnn at Y-Axis

Lower limit of current axis in cm

SP 1 to 8

Speed of current axis

NSP ppp

Speed of the current axis. X-axis in cm/s, Y-axis in

cm/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Write Commands

Command Return Value Description

LD ppp CM UL

LD nnn CM UL

ppp

nnn

ppp at X-Axis

nnn at Y-Axis

Sets upper limit of the current axis to the value in cm

ppp must not be greater than the hardware limits and

should not be less than the hardware’s lower device

limit.

LD ppp CM LL

LD nnn CM LL

ppp

nnn

ppp at X-Axis

nnn at Y-Axis

Sets lower limit of the current axis to the value in cm

ppp must not be less than the hardware limits and

should not be greater than the hardware’s upper

device limit.

LD s SP s Sets new speed for the currently selected axis: X or Y

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for the currently selected axis. X-axis

in cm/s, Y-Axis in cm/s

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

UP 1

Moves the current axis in a positive direction until the

upper limit is reached

DN 1

Moves the current axis in a negative direction until

the lower limit is reached

LD ppp CM NP

LD nnn CM NP

1 ppp at X-Axis

nnn at Y-Axis

Load the value in cm in Register NP (New Position),

Applies to current axis

GO 1 Moves the current axis to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.7 Slidebar (KMS)

3.7.1 General

Supported devices

◦ Cable measurement section/Slidebar: 0x4000, 0x4010

All values are transmitted in CM (Centimetres)

Negative values are not possible

3.7.2 Register and Commands

Addressing

Command Return Value Description

LD d DV d Load Slidebar, numerical addressing

Valid values for d: 2, 6, 10, 14

LD KMSd DV Index of MKSd

from *OPT?

return

Load Slidebar, named addressing

Valid values for d: 1, 2, 3, ...

Read Commands

Command Return Value Description

CP ppp ppp: Current Position in cm

BU 0 or 1

Motor Operational Status, return:

0: Motor is off

1: Motor is on

GP ppp

ppp: Glider Position in cm

Changes the address to the Slidebar. All following

commands will relate to the Slidebar.

FL

ppp ppp: Upper Limit in cm

BL

ppp ppp: Lower Limit in cm

SP 1 to 8

Current speed

NSP ppp

Current speed in cm/s

Write Commands

Command Return Value Description

LD ppp CM BL

ppp

Sets upper limit to ppp cm

This must not be greater than the hardware limits and

should not be less than the hardware’s lower device

limit.

LD ppp CM FL

ppp

Sets lower limit to ppp cm

This must not be less than the hardware limits and

should not be greater than the hardware’s upper

device limit.

LD s SP s Sets new speed for the device

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for the device in cm/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

BA 1 Moves the cable measurement section in a positive

direction until the upper limit is reached.

FO 1 Moves the cable measurement section downwards

until its lower limit is reached.

LD ppp CM NP 1 Load ppp cm in Register NP (New Position)

GO 1 Moves the cable measurement section to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.8 Mast Positioner (MP)

3.8.1 General

Supported devices

◦ Mast Positioner (MP): 0x4020

Negative values are not possible.

3.8.2 Register

Addressing

Command Return Value Description

LD d DV d Load X-Axis, numerical addressing

Valid values for d: 2, 6, 10, 14

LD MPd DV Index of MPd

from *OPT?

return

Load X-Axis

Valid values for d: 1, 2, 3, ...

Read Commands

Command Return Value Description

CP ppp ppp: Current Position in cm

BU 0 or 1

Motor Operational Status, return:

0: Motor is off

1: Motor is on

GP

ppp ppp: Mast Positioner Position in cm

Changes the address to the MP. All following

commands will relate to the MP.

FL

ppp ppp: Upper Limit in cm

BL

ppp ppp: Lower Limit in cm

SP 1 to 8

Current speed

NSP ppp

Current speed in cm/s

Write Commands

Command Return Value Description

LD ppp CM BL

ppp

Sets upper limit to ppp cm

This must not be greater than the hardware limits and

should not be less than the hardware’s lower device

limit.

LD ppp CM FL

ppp

Sets lower limit to ppp cm

This must not be less than the hardware limits and

should not be greater than the hardware’s upper

device limit.

LD s SP s Sets new speed for MP

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for the MP in cm/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

BA 1 Moves the MP in a positive direction until the upper

limit is reached

FO 1 Moves the MP downwards until the lower limit is

reached

LD ppp CM NP 1 Load ppp cm in Register NP (New Position)

GO 1 Moves the MP to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.9 VSWR Compound (VSWR: VS, VSA)

3.9.1 General

CO3000 Display shows: VSWRn

with n = the number of the VSWR, starting with 1 (e.g. VSWR1 or VSWR2)

A VSWR compound is comprised of two devices:

VSn = X-Axis (Device type: 0x4044)

VSAn = Azimuth (Device type: 0x0451)

All values are transmitted in CM (centimeter) or DG (degrees).

Negative values are not possible for CM.

3.9.2 Register

Addressing

Command Return Value Description

LD x DV x Load X-Axis, numerical addressing

Valid values for x: 2, 6, 10

LD a DV a Load Azimuth-Axis, numerical addressing

Valid values for a: 6, 10, 14

LD VSn DV x Load X-Axis of VSWRn

Valid values for n: 1, 2, 3, …

LD VSAn DV a Load Azimuth-Axis of VSWRn

Valid values for n: 1, 2, 3, …

Return value of *OPT? command deterimnes values for x and a

(Position of return value, starting with 0).

Example of return value for *OPT? command:

0,0,VS1,0,0,0,VSA1,0,0,0,VS2,0,0,0,VSA2,0

Here x=2 for VS1, a=6 for VSA1, x=10 for VS2, a=14 for VSA2

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Read Commands

Command Return Value Description

CP

ppp

ppp: Current Position in cm

BU 0 or 1

Motor Operational Status, Return:

0: Motor is off

1: Motor is on

GP

ppp ppp: VSWR Position in cm

Changes the address to VSWR. All following

commands will relate to the VSWR.

FL

ppp ppp: Upper Limit in cm (X-axis)

BL

ppp ppp: Lower Limit in cm (X-axis)

WL

nnn nnn: Limit in clockwise degrees (Azimuth-axis)

CL

nnn nnn: Limit in anticlockwise degrees (Azimuth-axis)

SP 1 to 8

Current speed (index)

NSP ppp

Current speed (numerical value)

in cm/s for X-axis

in degree/s for azimuth-axis

Write Commands

Command Return Value Description

LD ppp CM BL ppp Sets Upper Limit to ppp cm (X-axis)

This must not be greater than the hardware limits and

should not be less than the device’s lower limit.

LD ppp CM FL ppp Sets Lower Limit to ppp cm (X-axis)

This must not be less than the hardware limits and

should not be greater than the device’s upper limit.

LD nnn DG WL nnn

Sets clockwise limit to nnn degrees (Azimuth-axis)

This must not be greater than the hardware limits and

should not be less than the hardware’s lower device limit.

LD nnn DG CL

nnn Sets anticlockwise limit to nnn degrees (Azimuth-axis)

This must not be less than the hardware limits and

should not be greater than the hardware’s upper device

limit.

LD s SP s

Sets new speed (index)

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed (numerical value)

in cm/s for X-axis

in degree/s for azimuth-axis

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

BA 1 Moves until the upper limit is reached (positive direction)

(X-Axis)

FO 1 Moves until the lower limit is reached

(X-Axis)

CW 1 Moves clockwise until the limit is reached

(Azimuth-Axis)

CC 1 Moves anticlockwise until the limit is reached

(Azimuth-Axis)

LD ppp CM NP 1 Load ppp cm in Register NP (New Position)

(X-Axis)

LD nnn DG NP 1 Load nnn degrees in Register NP (New Position)

(Azimuth-Axis)

GO 1 Moves the selected axis to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.10 VSWR Positioner (VSWR)

3.10.1 General

Supported devices

◦ VSWR Positioner (VSWR): 0x4030

Negative values are not possible.

3.10.2 Register

Addressing

Command Return Value Description

LD d DV d Load X-Axis, numerical addressing

Valid values for d: 2, 6, 10, 14

LD VSd DV Index of CSd

from *OPT?

return

Load X-Axis

Valid values for d: 1, 2, 3, ...

Read Commands

Command Return Value Description

CP

ppp

ppp: Current Position in cm

BU 0 or 1

Motor Operational Status, Return:

0: Motor is off

1: Motor is on

GP

ppp ppp: VSWR Position in cm

Changes the address to VSWR. All following

commands will relate to the VSWR.

FL

ppp ppp: Upper Limit in cm

BL

ppp ppp: Lower Limit in cm

SP 1 to 8

Current speed

NSP ppp

Current speed in cm/s

Write Commands

Command Return Value Description

LD ppp CM BL ppp

Sets Upper Limit to ppp cm

This must not be greater than the hardware limits

and should not be less than the device’s lower

limit.

LD ppp CM FL ppp

Sets Lower Limit to ppp cm

This must not be less than the hardware limits and

should not be greater than the device’s upper limit.

LD s SP s Sets new speed for VSWR

Valid values for s: 1-8

LD ppp NSP ppp Sets new speed for VSWR in cm/s

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

BA 1 Moves the VSWR in a positive direction until the

upper limit is reached

FO 1 Moves the VSWR downwards until the lower limit is

reached

LD ppp CM NP 1 Load ppp cm in Register NP (New Position)

GO 1 Moves the VSWR to NP

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.11 Antenna stand (AS)

3.11.1 General

Supported devices

◦ Antenna stand (AS): 0x60..

The X-Axis is used here for polarisation!

Can only change polarisation

3.11.2 Register

Addressing

Command Return Value Description

LD d DV d Load X-Axis, numerical addressing

Valid values for d: 0, 4, 8, 12

LD ASd DV Index of ASd from

*OPT? return

Load X-axis (here for polarisation)

Valid values for d: 1, 2, 3, ...

Read Commands

Command Return Value Description

BU 0 or 1

Motor Operational Status of current axis

0: Motor is off

1: Motor is on

P? 0 or 1

Polarisation, 0: horizontal, 1: vertical

Control Commands

Command Return Value Description

ST 1 Stops all movements in all connected devices

PV 1 Polarises vertically

PH 1 Polarises horizontally

© innco systems GmbH Schwarzenfeld/Germany

Erlenweg 12, 92521 Schwarzenfeld/Germany Phone: +49 9435 301659 0 Fax: +49 9435 301659 99

Email: info@inncosystems.com

3.12 Gantry with Polarisation (GAP)

3.12.1 General

Supported devices

◦ Gantry with Polarisation (GAP): 0x5080 - 0x50FF

All values are transmitted in CM (cm) or DG (Degree)

3.12.2 Register

Addressing

Command Return Value Description

LD h DV h Load Height axis, numerical addressing

Valid values for h: 4

LD s DV s Load Swing axis, numerical addressing

Valid values for s: 8

LD p DV p Load Polarisation axis, numerical addressing

Valid values for p: 12

LD GAPHd DV

LD GAPSd DV

LD GAPPd DV

Index of GAPHd,

GAPSd, GAPPd