GEN-1

(INIVEN]

DIVISION OF CONOLOG

CORP.

INSTRUCTION MANUAL

IT-30DSP

PROGRAMMABLE FSK TONE TRANSMITTER

Fig.

1.

IT-30DSP

DESCRIPTION: The IT-30DSP

is

a programmable frequency shift keyed (FSK) tone transmitter

intended for the use

on

the transmitting end of a communication channel

in

supervisory control,

telemetry and data transmission applications. A transmitter/receiver combination may

be

used over

voice grade circuits including carrier, wire line, fiber optics, and microwave.

Each transmitter module

is

field programmable for a specific center frequency and frequency shift

(bandwidth/baud rate) via DIP switches. Operational modes inciude two frequency (2F) or three

frequency (3F) keying, carrier on/off (Request-To-Send, RTS) and when communicating with a

similarly equipped receiver, inverted keying and flasher (keying of both mark and space

simultaneously).

Utilizing state of the art design and crystal controlled Digital Signal Processing (DSP) techniques

provides for improved performance, flexibility, and reliability.

FEATURES:

• Voltage keying inputs provided

on,

each unit (optical keying optionai).

• Front paneilevei adjustment.

• DIP switch programmable - no need tor external equipment to change trequency, bandwidth or

mode ot operation.

• Cost saving design while maintaining reliability and quality.

•

12

Year

Warranty.

SPECIFICATIONS:

Output Level: Front panel adjustable to

+5

dBm.

Output Impedance:

15

KQ

minimum.

Keying inputs: Mark and Space, High impedence 3-30 Vdc.

Keying methods: CMOS, TTL, RS232, Dry contact, Opto isolation, Voltage (various inputloutput

interfaces available).

Operating Frequency Range: 200-3800

Hz.

(See programming charts)

Operating Bandwidths:

50,

60,

85, 120, 170, 240, 300, or 600

Hz.

Standard.

Indicators: Front panel mounted tor mark, space,

RTS

(Request-To-Send), and CD/carrier

on

CTS (Clear-To-Send).

Spectral Purity: Harmonic content: 70dB below carrier level. Spurious signals

at

adjacent

channels: 70dB below carrier.

Bias distortion: Less than 7% with channel

keyed

in

accordance

to

programmed bandwidth,

back to back Transmitter/Receiver.

Environmental Requirements: Temperature Range: -30 to +70 C (-22 to +158

F)

Relative

Humidity: 95% maximum, non-condensing at

40

C (104

F).

Power Requirements: +12 Vdc ± 35% (7.8

to

16.2 Vdc), 130 ma @

12

V

SAFETY:

Standard safety precautions must

be

followed at all times when installing, operating,

servicing, and repairing this.)equipment. INIVEN/CONOLOG

CORP.

assumes no liability

for failure to observe standard or specifically noted safety requirements or to use this

equipment for purposes other than intended.

GROUNDING: A suitable ground

is

required to reduce the hazard of shock. Refer

to

the

enclosed module, chassis, and/or cabinet 'wiring diagram for ground connection locations.

ENVIRONMENT: Operation of any electrical equipment

in

any area containing gases, fumes,

wet, or damp

is

a potential safety hazard. Necessary precautions should

be

taken.

MANUAL: Operators and maintenance personnel should read this manual before installing

the equipment and placing it

in

service. Only properly trained personnel with proper tools and

equipment should operate, maintain, repair, or service this equipment.

SHOCK: Potentially dangerous electrical shock can occur whenever working

on

this product.

Protective measures and safety procedures should

be

observed

at

ali

times.

THEORY

OF

OPERATION:

GENERAL: The unit generates

an

audio tone which changes frequency when the input

is

keyed. The keying inputs are referred

to

as

mark and space.

In

the two frequency mode,

the audio tone output

is

at a frequency plus or minus the shift (programmable)

of

the

programmed center frequency. Upon keying (applying a voltage), the transmitter changes

state to the opposite frequency.

In

a two frequency system, the center frequency

is

not

produced.

In

a three frequency unit the center frequency

is

normally generated when neither a

mark or space output

is

present. When the transmitter is keyedtothe space frequency the

receiver space output

is

activated and when the transmitteriskeyed to the mark frequency

the receiver mark output

is

activated. Only one keying input should

be

on

at a given time

unless the IT-30DSP and receiver are set to operate

in

flasher mode. The Flasher option

on

the IT-30DSP allows the unit to shift between mark and space frequencies rapidly when both

inputs are

keyed

simultaneously.

A third keying input

is

available which allows the audio tone output to

be

turned on/off.

The

RTS

(carrier on/off) input permits the transmitter to

be

usedinsystems requiring a quiet

line until communications

is

need such

as

a polling or data system.

PROGRAMMING: Upon applying power to the unit, the Digital Signal Processor (DSP) (U5)

reviews the program information

of

octal inverting buffers(U12

& U

13)

which have been set

by switches

SW1

and SW2.

INPUT: Standard inputs are via

02, 03,

OS

and associated circuitry. The input informationisfed

to

(U4) octal

bus

driver along with the mode of operation settings

of

SW3.

(US)

Stores the

information

in

memory (RAM).

DSP(Digital Signal Processing): The microprocessor

(US)

operating parameters are determined

by

the two EPROM's (2K x 8-bit) U6 &

U7.

Ali

sine wave generation and keying input information

is

then processed

in

(US)."',

WATCH

DOG TIMER: (U9)

is

a watch dog timer which recycles the microprocessor should its

software sequence fail to perform

as

required. The timer effectively restarts the program to eliminate

having to re-initiate power

up

of the module.

OUTPUT: The digital signal

is

processed through (U14) digital to analog converter and then passes

through a low pass filter consisting of L

1,

L2

and associated capacitors (C10 - C14) Iimiting the

signals to 4kHz. Variable resistor (R24) adjust the signal level which

is

amplified by operational

amplifier (U16). The signal

is

coupled to the line via transformer T1.

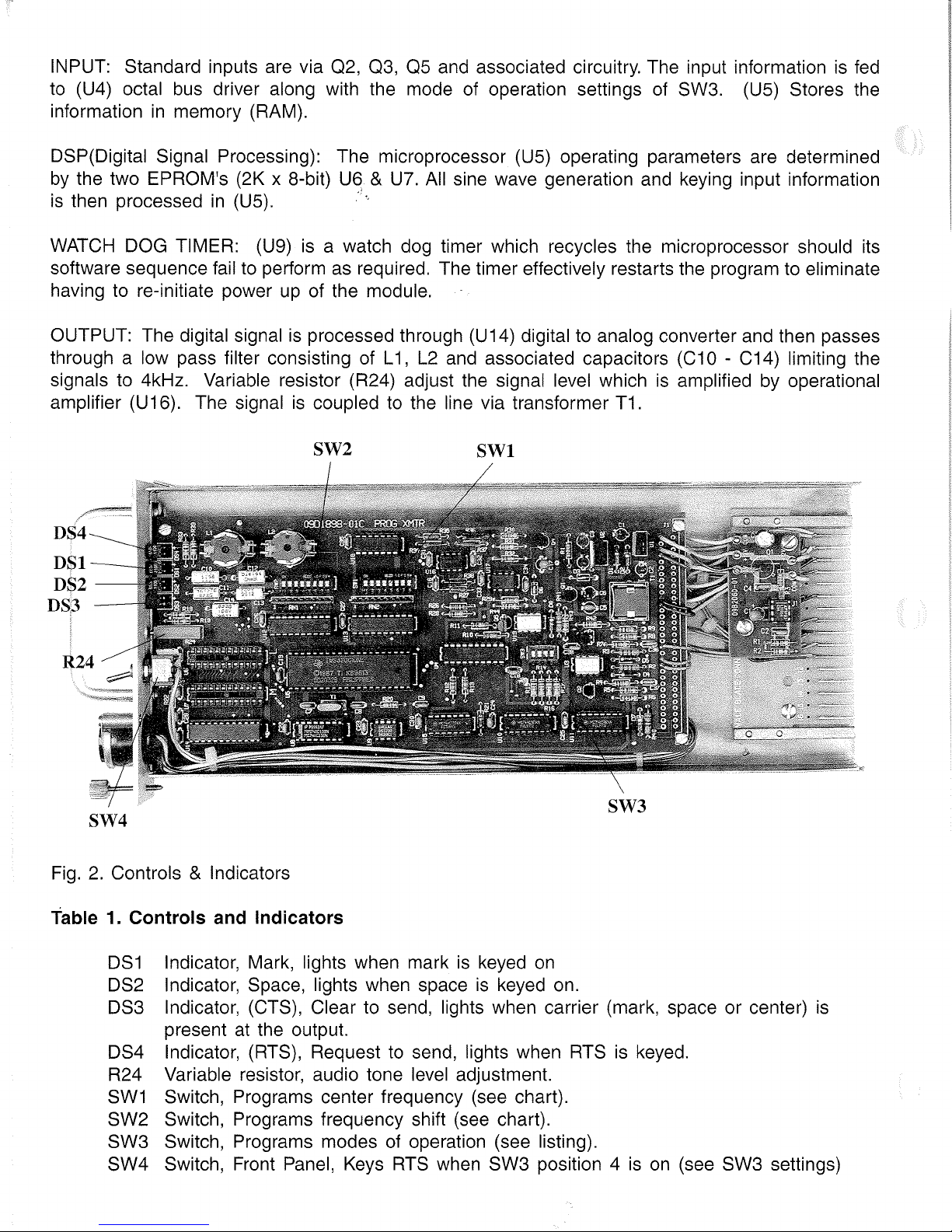

SW2

DS4

DSl--

DS2

DS3

SW4

Fig.

2.

Controls & Indicators

Table 1. Controls and Indicators

SWl

SW3

DS1

Indicator, Mark, lights when markiskeyed

on

DS2 Indicator, Space, lights when space

is

keyed on.

DS3 Indicator, (CTS), Clear to send, lights when carrier (mark, space or center)

is

present

at

the output.

DS4 Indicator, (RTS), Request to send, lights when

RTSiskeyed.

R24 Variable resistor, audio tone level adjustment.

SW1

Switch, Programs center frequency (see chart).

SW2 Switch, Programs frequency shift (see chart).

SW3 Switch, Programs modes

of

operation (see listing).

SW4 Switch, Front Panel, Keys

RTS

when SW3 position 4ison

(see SW3 settings)

@@

}

SPACE

KEYING

}.MARK KEYING

+12VDC INPUT

l----f-

COMMON

>---+-}

PHONE

LINE

OUTPUT

>---+-} RTS/CARRIER KEYING

11

@{,:;\

®

W

\SJ@

@

@@

IT-30DSP

Fig.

3.

Terminai Block (TB1)

INSTALLATION:

UNPACKING: This equipment may

be

supplied loose, mountedinan

individual chassis ' stacked

interconnected chassis, or as part of a rack or cabinet. Follow the procedure for the type of system

supplied.

Loose and/or equipment mounted

in

an

individual chassis will be packedinits own shipping carton.

Inspect the carton for possible damage

in

transit. Open each carton carefully and remove the

contents. Inspect the equipment for possible damage. Verify

ali

items of value have been removed

prior to discarding any packing materia!.

NOTE:

Itissuggested the carton

be

retained for possible onward shipment.

Interconnected chassis or equipment supplied

in

racks or cabinets will

be

suppliedinspecial boxes,

wood crates, or if shipped via air-ride

van

without any case. Inspect the crate or other packing for

possible damage

in

transit. Carefully remove the equipment from the container and inspect it for

possible damage. Verify

ali

items of value have been removed from the crate prior

to

discarding

any packing material and refer to the note above.

Should transit damage

be

found please notify INIVEN immediately.

MOUNTING: After unpacking follow the appropriate mounting procedure.

Loose module: (The following

is

for new installations - replacementofan

existing module will

have

the termi

nai

block already mounted. Each new unitisshipped with the terminai block plugged into

the rear of the unit. There are also four 6-32 screws shipped with

it

to mount the terminai block

to

the chassis. Locate the desired position within the chassis for which the moduleisto

be

placed.

Viewing the chassis from the front, the recommended arrangement

is

a power supply

on

the extreme

left then followed

by

transmit and or receive modules working towards the right of the chassis.

Interconnected Chassis or equipment mounted

on

shipping rails

is

to

be

mounted similar

to

an

individual chassis. When shipping rails are provided the equipmentisto

be

placed near the desired

location. Remove the screws holding the shipping rails and then remove the rails. Slide the equipment

into the rack or cabinet and secure it with proper screws for the mating hardware being used.

Tighten ali screws.

Systems provided

in

a rack or cabinet from the factory must

be

secured

to

the floor or wall

as

required. Mounting hardwareisnot sqpplied due to the various surfaces

and

mounting methods.

CAUTION: EQUIPMENT MOUNTED

IN

SWING RACK TYPE CABINETS MUST

BE

SECURED

TO

THE MOUNTING SURFACE PRIOR

TO

OPENING THE SWING RACK

TO

PREVENT THE

CABINET FROM FALLlNG.

VENTILATION: Proper ventilation

is

required for most electronic equipment. Enclosed cabinets or

rooms where this equipment

is

mounted should

be

kept at temperatures within the limits of the

equipment. Operation above these limits may affect reliability.

ELECTRICAL CONNECTIONS: User connections are made via the terminai blocks

on

the rear

of

the chassis. Each unit

in

the Gen 1 SERIES

of

equipment will contain these connections

in

the

instruction manual for the specific individual module.

On

equipment supplied wired from the factory

or

on

wired chassis and cabinets

an

"as supplied" drawing will

be

included with the equipment.

External wiring should

be

in

accordance with the "as supplied" drawing when supplied.

For safety reasons power

on

the leads to

be

connected to the unit are to be de-energized

during installation.

Methods of making the wiring connections to the terminai blocks vary and based

on

local practice.

Itissuggested number 20

AWG

size insulated wire, stripped portion tinned,

be

used. Approximately

1/4" of the insulation

is

to

be

removed and insertedinthe terminai block.

Module power and tone lines may

be

daisychained should the application require.

Tighten all connections and insure exposed wires do not touch each other or the chassis.

INITIAL STARTUP & LEVEL CHECKS:

FREQUENCY SELECTION: With the module removed from the chassis. Select the desired

bandwidth and center frequency from the enclosed charts. Refer to figure 2 for switch location.

EXAMPLE: For

an

85

baud channel at 1615

Hz

center frequency, set SW2 position 3 to "ON"

(only a single position within SW2

is

to be "ON"

at

any one time). Set

SW1

positions

1,

4,

& 7

to "ON" (be sure

all

other positions

on

SW1

are "OFF").

MODE OF OPERATION: Set SW3 to the desired mode of operation

as

detailed below. Refer to

figure 2 for switch location.

SWITCH SW3 SETTINGS:

Ali Positions "OFF": 3F Operation. Keying the Mark input produces a Mark frequency out,

keying the Space input provides a Space frequency

outo

The center frequency will

be

output

when the inputisidle.

Position 1 "ON" only: 3F Operation, Inverted Output. Keying the Mark input produces a Space

frequency out, keying the Space input produces a Mark frequency

outo

The center frequency

will

be

output when the inputisidle.

Position 2 "ON" only: 2F Operation. Keying the Mark input produces the Mark frequency when

keyed. The Space frequency

is

output when the inputisidle. The keying leads should

be

on

the Mark input.

00

not use this option with position 3inthe "ON" position.

Position 3 "ON" only: 3F Operation, FLASHER. The transmitter will shift at 20msec intervals

between Mark and Space when the Mark and Space inputs are keyed at the same time. (This

operation will not function if the position 2

isinthe "ON" position).

Position 4 "ON" only: (RTS). When position 4

is

on,

the front panel switchisactivated. When

position 4

isinthe off position, the front panel switch will not

be

able

to

turn off the output(s).

RTS

can also

be

keyed from the

RTS

input

on

the rear terminai block when the front panel

switch (SW4)

is

in

the "OFF" position. This option may

be

used

in

all modes.

Positions 1

& 2 "ON": 2F operation, Inverted Output. Keying the Mark input produces a Space

frequency output. The Mark frequency

is

output when the inputisidle. The keying leads should

be

on

the Mark input.

00

not use this option with position 3inthe "ON" position.

ADJUSTMENTS: The transmitter contains a front panel LEVEL adjustment (R24) (see figure 2 for

location). Each transmitter

is

shipped from the factory with the level adjustment set at

-6

dBm,

which

is

adequate for most applications.

The following equipment

is

recommended to perform the initial startup

and

level

checks

at:

1.

Digital multimeter with dB readout function; Fluke 8060A or equivalent.

2.

Flatblade screw driver with 1/8 inch wide tip or potentiometer adjustment too!.

3.

Optionai - Card Extender.

WARNING:

00

NOT INSERT THE UNIT INTO A RACK WITH THE POWER ON.

INITIAL SETTINGS: With the power (+12Vdc) and phone line wired to the terminai blocks

on

the

rear of the chassis, connect the test leads of the multimeter (dB mode) across the "tone out"

on

the terminai block.

Turn

on

the power and note the reading

on

the multimeter (the tone output

on

the terminai block should

be

connected to the line or if this

is

not possible, terminated

in

a

600 ohm resistor). Adjust R24(LVL ADJ) with a screwdriver or adjustment tool to the desired level.

Only one transmitter should be

on

the line during this adjustment or a composite level will

be

read, which

is

not a true reading of the transmitter output level. The "as set" level should

be

recorded for future reference.

When two or more transmitters are connected on one communications line, each individual

transmitter level should be adjusted at a reduced level

in

order for the combined (composite)

signals not to exceed the desired output level. Refer to the chart below for recommended levels

referenced to 0 dBm. The recommended dBm levels may also

be

used as reference for any

desired level setting

in

dB.

-,

"

MULTIPLE TONE

OUTPUT LEVELS

Number af dB RMS V

Channels

- Level

600 n

1 0

0.7746

2

-3 0.5484

3

-4.8 0.4457

4

-6

0.3882

5

-7

0.3460

6

-7.8

0.3156

7 -8.5 0.2911

8

-9

0.2748

9

-9.5 0.2595

10 -10 0.2449

11

-10.4 0.2339

12 -10.8

0.2234

13

-11.1

0.2158

14

-11.5 0.2061

15 -11.8 0.1991

16

-12

0.1946

17 -12.3

0.1880

18 -12.5 0.1837

19 -12.8 0.1774

20 -13 0.1734

21

-13.2

0.1695

22 -13.4

0.1656

23 -13.6 0.1618

24 -13.8

0.1582

EXAMPLE: For two transmitters with a desired composite level of

-6

dBm, reduce the desired

level of each transmitter by 3 dB (from the chart below) and set each to

-9

dBm.

ALL

SAFETY PROCEDURES ARE TO BE STRICTLY ADHERED

TO

AND ONLY QUALlFIED

MAINTENANCE, OPERATORS, OR SERVICE PERSONNEL ARE TO PERFORM

WORK

ON THIS

EQUIPMENT.

L1FE

THREATENING VOLTAGES AND CURRENTS ARE PRESENT WITHIN THIS

EQUIPMENT. OBTAIN

ALL

REQUIRED APPROVALS PRIOR

TO

PLACING IN OR OUT OF

SERVICE. ANY UNAUTHORIZED MODIFICATIONS TO THIS EQUIPMENT

WILL

VOID THE

WARRANTY.

NOTE:

In

the event a replacement module is being installed check all switch settings prior to

installation. Comparison with the removed module is one convenient method.

FOR 50 BAUD

OPERATLON

SET POSITION 1 OF SW2 "ON"

To

Obtain Center

Set Listed Positions

Freq.

Hz

of

SW1

to

"ON"

365

4

465

1,4

565

2,4

665

1,2,4

765 3,4

865

1,3,4

965

2,3,4

1075

1,2,3,4

1175

5

1275 1,5

1375 2,5

1475

1,2,5

1575

3,5

1675

1,3,5

1775 2,3,5

1875

1,2,3,5

2000

4,5

2100

1,4,5

2200

2,4,5

2300

1,2,4,5

2400

3,4,5

2500

1,3,4,5

2600

2,3,4,5

2700

1,2,3,4,5

2800 6

2900 1,6

3000

2,6

3100

1,2,6

3200 3,6

3300

1,3,6

3400 2,3,6

3500

1,2,3,6

FOR 60

BAUD

OPERATION

SET POSITION 2 OF SW2 "ON"

To

Obtain Center Set Listed Positions

Freq.

Hz

of

SW1

to

"ON"

420

4,6

540

1,4,6

660

2,4,6

780

1,2,4,6

900

3,4,6

1020

1346

1140

2,3,4,6

1260

1,2,3,4,6

1380 5,6

1500

1,5,6

1620 2,5,6

1740

1,2,5,6

1860

3,5,6

1980

1,3,5,6

2100

2,3,5,6

2220

1,2,3,5,6

2340

4,5,6

2460

1,4,5,6

2580

2456

2700

1,2,4,5,6

2820

3456

2940 1

3456

3060

23456

3180

123456

3300

7

3420

1,7

FOR

85

BAUD OPERATION

SET POSITION 3 OF SW2 "ON"

Ta Obtain Center Set Listed Pasitians

Freq. Hz af

SW1

ta"'mN"

425

27

595 1 2 7

765 3,7

935

1,3,7

1105

2,3,7

1275

1,2,3,7

1445

4,7

1615

1,4,7

1785

2,4,7

1955

1,2,4,7

2125

3,4,7

2295

1,3,4,7

2465

2,3,4,7

2635

1,2,3,4,7

2805

5,7

2975

1,5,7

3145

2,5,7

3315

1,2,5,7

3485 3,5,7

FOR 120 BAUD OPERATION

SET POSITION 4 OF SW2

"ON"

Ta Obtain Center

Set Listed Pasitians

Freq. Hz

af

SW1ta"ON"

480

1 3,5,7

720

2,3,5,7

960

1,2,3,5,7

1200

4,5,7

1440

1,4,5,6

1680

2,4,5,7

1920

1,2,4,5,7

2160

3,4,5,7

2400

1,3,4,5,7

2640

2,3,4,5,7

2880

1,2,3,4,5,7

3120

6,7

3360

1,6,7

FOR 170 BAUD OPERATION

SET POSITION 5 OF SW2 "ON"

Ta Obtain Center

Set Listed Pasitians

Freq. Hz

af

SW1ta"ON"

850

267

1190 1

267

1530

367

1870

1,3,6,7

2210

2,3,6,7

2550

1,2,3,6,7

2890

4,6,7

3230

1,4,6,7

FOR 240 BAUD OPERATION

SET POSITION 6 OF SW2

"ON"

Ta

Obtain Center

Set

listed

Pasitians

Freq. Hz

af

SW1ta"ON"

600

2467

1080

1

2467

1560

3467

2040

1,3,4,6,7

2520

2,3,4,6,7

3000

1,2,3,4,6,7

FOR 300

BAUD

OPERATION

SET POSITION 7 OF SW2

"ON"

Ta Obtain Center Set

listed

Pasitians

Freq. Hz af

SW1ta"ON"

1020 5,6,7

1700

1,5,6,7

2380

2,5,6,7

3060

1,2,5,6,7

FOR 600 BAUD OPERATION

SET POSITION 8 OF SW2

"ON"

Ta Obtain Center

Set Listed Pasitians

Freq. Hz

af

SW1ta"ON"

1360

3,5,6,7

2720

1,3,5,6,7

Circuit

Symbol

C14,6

C5,

18-35

C7-9

C10

C11

C12

C13

C14

C16

C17

C36, 37

R1

R2,

3

R4,

7

R5,

8

R6,

9

R10-13,

32

R14-17, 28

R18, 19, 23

R20

R21

R22

R24

R26

R27

R29

R30

R31

R34-36

R37

01,2,4, 5

03

06

DS14

01-5

U1

U2

U3

U4

U6,

7

U5

U10,

11

U8

U9

U 12, 13

U15

U14

U16

U17

U18

Table

1.

Replaceable parts IT-30DSP

Description

CAPACITORS:

Capacitor, tantalum dipped, 1

uF,

20V,

+/-10%

Capacitor;.ceramic,

.1

uF,50V,

+/-20%

Capacitor, ceramic,

18pF,

100V,

+/-5%

Capacitor, metalized polycarbonate,

.01

uF,

100V,

+/--3%

Capacitor, metalized polycarbonate, .0082uF,

100V,

+/-2%

Capacitor, metalized polycarbonate, .027uF, 100V, +/-3%

Capacitor, metalized poJycarbonate, .0022uF,

100V,

+/-3%

Capacitor, metalized polycarbonate, .022uF,

100V,

+/-3%

Capacitor, ceramic,

100pF,

50V,

+/-5%

Capacitor, tantalum,

4.7uF,

35V,

+/-10%

Capacitor, ceramic,

330pF,

100V, +/-5%

RESISTORS:

Resistor, carbon, 6.2K, 1/4 watt, +/-5%

Resistor, carbon, 5.6K, 1/4 watt, +/-5%

Resistor, carbon, 50K, 1/4 watt, +/-5%

Resistor, carbon, 20K, 1/4 watt, +/-5%

Resistor, carbon, 1.0K, 1/4 watt, +/-5%

Resistor, carbon, 100K, 1/4 watt, +/-5%

Resistor, carbon, 10K, 1/4 watt, +/-5%

Resistor, carbon, 680(, 1/4 watt, +/-5%

Resistor, carbon, 4.7K, 1/4 watt, +/-5%

Resistor, carbon, 3.9K, 1/4 watt, +/-5%

Resistor, carbon, 2.4K, 1/4 watt, +/-5%

Resistor, variable, 50K, 3/4 watt, 10 turn

Resistor, metal film, 1.18K, 1/4 watt,

+/-1

%

Resistor, metal film, 10K, 1/4 watt,

+/-1

%

Resistor, carbon, 33K, 1/4 watt, +/-5%

Resistor, carbon, 27K, 1/4 watt, +/-5%

Resistor, carbon, 220K, 1/4 watt, +/-5%

Resistor, metal film, 100K, 1/4 watt,

+/-1

%

Resistor, metal film, 105K, 1/4 watt, +/-1%

SEMICONDUCTORS:

Diode, avalanche,

400V,

1A

Diode, zener, 5.6V

Diode, general purpose

LEO,

red

Transistor, NPN

NOT USED

IN

STANDARD APPLlCATIONS

Negative voltage regulator, 5 Vdc

Dual phototransistor

Octel/bus driver, non-inverting

EPROM, 2K x 8bit

Digital signal processor (DSP)

Counter, binary resettable SYNC/ASYNC

3 line to 8 line decoder/demultiplexer

Watchdog timer

Octal inverting buffer, 3 state

Ouad 2input nand schmidt trigger

14bit DAC

Dual operational amplifier

Dual amplifier

Hex inverter

INIVEN Part

Number

DT20V105K

CM-Z5U-D-104-M

CM-NPO-E-180-J

MPC32E103H

MPC32E822G

MPC32E273H

MPC32E222H

MPC32E223H

CM-NPO-D-101-J

DT35V475K

CM-NPO-D-331-J

RCF07J622

RCF07J562

RCF07J503

RCF07J203

RCF07J102

RCF07J104

RCF07J103

RCF07J681

RCF07J472

RCF07J392

RCF07J214

3008P-1-503

RN55D1181 F

RN55D1002F

RCF07J333

RCF07J273

RCF07J224

RN55D1003F

RN55D1053F

1N4004

1N752A

1N914

550-1106-RED

2N4401

MC79M05CT

MCT6

MM74HC244N

CY7C291-50WC

TMS320C10NL

MM74HC161N

MM74HC138N

DS1232

MM74HC240N

MM74HC132N

AD7840JN

TL0821P

TL081CT

MM74HC04N

Circuit

Symbol

T1

SW1,2

SW3

SW4

Y1

Description

MISCELLANEOUS COMPONENTS:

Transformer, INIVEN

Switch, DIP 8 position

Switch, push

b1:.l,tton

Switch, toggle '

Crystal, quartz,20 MHz.

INIVEN Part

Number

CC1992-00

ADF-08

ADF-04

7101SYZB

SE200-AS

Table1.Replaceable Parts, Voltage Converter board:

Circuit

Symbol

C4

C1

C2

C3

R3

R1

R2

01

Ui

Description

CAPACITORS:

Capacitor, ceramic,

0.1

uF,

50V,

+/-20%

Capacitor, tantalum,

10uF,

35V,

+/-20%

Capacitor, ceramic, 0.047uF,

50V,

+/-10%

Capacitor, electrolytic,

100uF,

35V,

+/-10%

RESISTORS:

Resistor, carbon, 2.2K, 1/4 watt, +/-5%

Resistor, carbon, 20K, 1/4 watt, +/-5%

Resistor, carbon, 200K, 1/4 watt, +/-5%

SEMICONDUCTORS:

Transistor, NPN

Switched capacitor voltage converter

INIVEN Part

Number

CM-Z5U-D-104M

DT35VI06M

CM-X7R-D-473K

ER35V107

RCF07J222

RCF07J203

RCF07J204

2N4401

LT1054CN8

NOTES

WARRANTY AGREEMENT

We

hereby certify that the INIVEN product line carries a warranty for any part whicll

fails during normal operation or service for

12

Years.

A defective part should

be

returned

to the factory, shipping charges prepaid, for repair f.o.b. Somerville, New Jersey.

In

case

INIVEN cannot promptly return the unit

to

you,itwill endeavor to provide a loaner until

the repair or replacement

is

returned

to

you. Any unauthorized repairs or modifications

will void the warranty. This warranty

is

contingent upon the commercial availability of parts

as purchased

by

INIVEN. However,

in

the event that failureisless than two years from

the date of delivery of the product, INIVEN will accept full responsibility.

INIVEN 5 Columbia

Rd.

Somerville,

NJ

08876

PRINTED

IN

U.S.A.

INIVEN TM 5 Columbia

Rd.

Somerville,

NJ

08876

908-722-3770

FAX

908-722-5461 800-526-3984

Loading...

Loading...