INID XS series, SmartReader XS PIN, MultiSmart XS PIN, SmartReader XS, MultiSmart XS Installation Manual

...

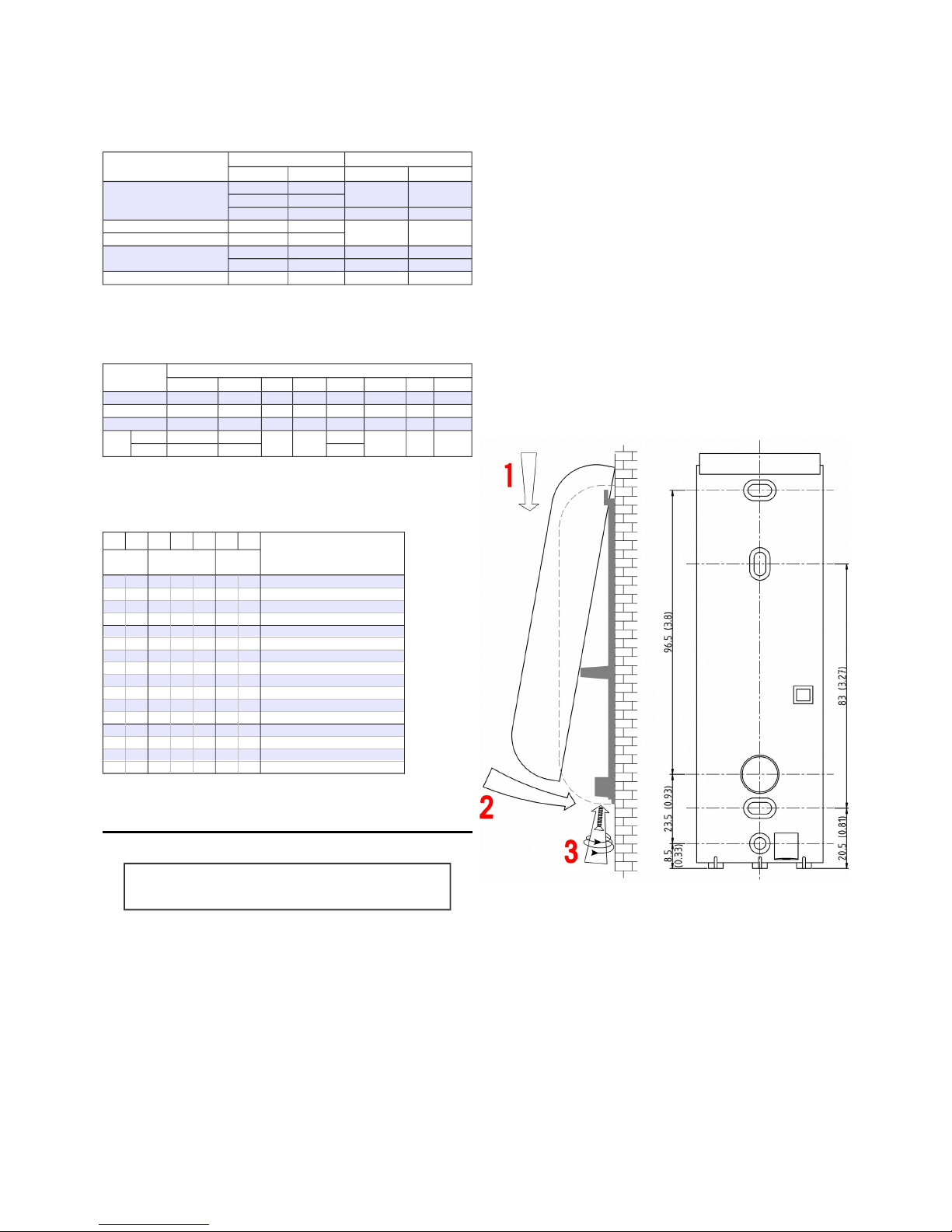

INID XS readers Installation Manual

Models

number name interfaces

article

number

5040C INID SmartReader XS PIN WG/C&D/TTL + RS485 500-5040C

5000C INID SmartReader XS WG/C&D/TTL + RS485 500-5000C

5045C INID MultiSmart XS PIN WG/C&D/TTL + RS485 500-5045C

5005C INID MultiSmart XS WG/C&D/TTL + RS485 500-5005C

5240C INID SmartProx XS PIN WG/C&D/TTL + RS485 500-5240C

5200C INID SmartProx XS WG/C&D/TTL + RS485 500-5200C

Classifications

UL 294: destructive attack level IV, line security level I,

endurance level IV, standby power level I

ULC S319: class III

Specifications

Dimensions

143 x 50 x 25 mm / 5⅝ x 2 x 1 inch

Operating temperature

-25° to 65° C / -15° to 150° F

Protection class

IP54 Complete protection against contact, protection

against dust deposit.

Protection from splashed water.

Power Supply

All models 7.0 - 24 Volt DC

models

Watts

mA

at V

min

at 12 VDCat V

max

avg peak avg peak avg peak avg peak

5000C INID SmartReader XS 1,50 2,35 215 340 125 200 65 100

5040C INID SmartReader XS PIN 1,50 2,55 215 365 125 215 65 110

5005C INID MultiSmart XS 1,50 2,35 215 340 125 200 65 100

5045C INID MultiSmart XS PIN 1,50 2,55 215 365 125 215 65 110

5200C INID SmartProx XS 0,85 2,00 125 290 75 170 40 85

5240C INID SmartProx XS PIN 0,85 2,00 125 290 75 170 40 85

Note: Ohms’ Law may be used to estimate current at other voltages.

Parts included (1 each)

Reader front

Mounting backplate

Enclosure screw (Torx #8)

Installation manual

Certifications

CE, FCC, IC, UL, ULC

FCC ID: YAB-MSX SRDR (MultiSmart XS readers)

YAB-SPX SR DR (SmartProx XS readers)

YAB-SRXSR DR (SmartReader XS readers)

IC: 8908A -MSXSRD R (MultiSmart XS readers)

8908A- SP XSRD R (SmartProx XS readers)

8908A- SRXSRDR (SmartReader XS readers)

Consult your National Authority if any authorization is needed for

these products.

Warning (part 15.21)

Changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate

the equipment.

Compliance statement

This device complies with part 15 of the FCC Rules and with the

Industry Canada license-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Le présent appareil est conforme aux CNR d’Industrie Canada

applicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux deux conditions suivantes :

(1) l’appareil ne doit pas produire de brouillage, et

(2) l’utilisateur de l’appareil doit accepter tout brouillage

radioélectrique subi, même si le brouillage est susceptible d’en

compromettre le fonctionnement.

Information to the User (Part 15.105 (b))

Note: This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

— Reorient or relocate the receiving antenna.

— Increase the separation between the equipment and receiver.

— Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

— Consult the dealer or an experienced radio/TV technician for help.

Complies with: CAN ICES-3 (B)/NMB-3(B)

Operation

When a credential is read successfully, the LED bar lights briefly, the

sounder sounds a short tone and the credential associated code is sent

to the Host system.

The LED bar and sounder are also controllable by the Host system.

When a PIN is entered the data is sent to the Host system; at each key

press a click sound is produced and the LED bar lights briefly. The

backlight of the PIN code lights up after a successful credential read, or

at the first key press.

Reader output formats are determined by the personalization of the

credential and/or configuration of the reader; on SmartReader and

MultiSmart readers the behaviour of the LED bar and sounder can be

modified through configuration.

When the reader detects a tamper status, the LED bar flashes red and

the tamper output is activated; on SmartReader and MultiSmart

readers this behaviour can be modified through configuration.

Document 100.14.IS.01 v1.30, effe ctive from SN1632-0001 page 1 of 2 printed on Aug 8, 2016

INID BV

Overweg 5

1713 HX Obdam

The Netherlands

Phone: +31 (0)226 450 009

Web: www.inid-readers.com

INID XS readers Installation Manual

Cable specifications

Shi elded ca ble is requ ired for ULC S3 19 compl iance.

The use of stranded conductors cable is highly recommended.

Restrict oversizing the cable to a maximum of two sizes.

interface

max. cable length min. conductor size

1)

meters feet mm

2

AWG

Wiegand

61 200

0.25 24

91 300

152 500 0.34 22

Clock / Data 25 80

0.25 24

TTL serial 1.5 5

RS485 (cable power)

61 200 0.25 24

152 500 0.34 22

RS485 (local power) 1220 4000 0,16 25

1)

With a 12 V supp ly. With a 24 V supply, minimum conductor size is AWG 24 (0.25mm2) for

all interfaces and len gths.

For locally powered readers the minimum conductor size is AWG 25 (0.16mm2) for all

interfaces and lengths.

Connector Assignments

interface

connector position

1 2 3 4 5 6 7 8

Wiegand LED1-green LED2-red D1 D0 BUZZER TAMPER GND POWER

Clock/Data LED1-green LED2-red DATA CLOCK BUZZER TAMPER GND POWER

TTL serial LED1-green LED2-red TXD TXE RXD TAMPER GND POWER

RS485

standard LED1-green LED2-red

TRX+ TRX-

N.C.

TAMPER GND POWER

OSDP INPUT 1 INPUT 2 INPUT 3

Caution

Floating communication lines may cause spurious emissions, invalidating certification.

Ensure all communication lines are properly biased and terminated.

SmartProx XS DIP switch settings

1 2 3 4 5 6 7

factory default:

all switches off.

card

type

output

format

PIN

format

1)

off off H-PX & A-PX

off on EM4102

on off PX light

on on QKEY

off off off AUTO (H-PX & A-PX only)

off off on WG 26

off on off WG 32

off on on WG 34

on off off WG 37

on off on WG 40

on on off WG 42

on on on ABA 10

off off WG 4

off on WG 8

on off WG 4+4

on on CLK/DTA trk2 ABA

Note

Selecting AUTO format for cards EM4102, PX light or QKEY will cause

unpredictable behaviour.

1)

Not functional in readers without PIN pad.

Installation instructions

All wiring shall be in accordance with appliccable

codes and regulations

(USA: ANSI/NFPA70; Canada: CSA C22.1)

1. Determine an appropriate position for the reader; a height of

140 cm (55 inches) above floor level on the doorjamb at the lock

side of the door is recommended.

Observe applicable building codes and safety regulations in

determining the reader position.

Notes:

╺ Mounting readers in close proximity of each other wil reduce

performance. The minimum recommended mounting distance

side-by-side or back-to-back is 125mm (5”). Closer mounting will

reduce performance, or cause unintentional reads on the other

reader; magnetic shielding may be necessary in that case.

╺ Mounting the reader on a metal surface will reduce performance,

a plastic separator of at least 6mm (¼”) is recommened.

╺ See Application Note AN100.14001 on the INID website for more

details.

2. Drill two pilot holes for mounting the backplate and one hole for the

cable, see drawing for measurements.

3. Pull the cable trough the hole in the backplate; protect the cable

against sharp edges and any damage from chafing.

4. Mount the backplate using flat head screws with a shank size of

4mm (5/32”, #7) or smaller; other screw types or sizes may cause

irrepairable damage to the reader.

5. Prepare the end of the cable and wires, eliminating any loose or

frayed strands; for stranded conductors, the use of ferrules is highly

recommended.

Keep the wire ends as short as practical.

6. Connect the wires to the connector according to the interface type.

Wire ends, termination resistor leads and optional permanent links

shall be kept as short as possible.

Use an appropriate sized screwdriver and do not over-tighten the

connector screws.

7. Place the reader front section over the hinge of the backplate (see

drawing) and close the reader, keeping the wiring in the lower part

of the reader housing. DO NOT use excessive force, retract the

cable if necessary.

8. Test the reader: apply power and present a valid credential. The

LED bar should flash and the sounder should produce a short tone

indicating a successful read. If the Host system is connected to the

LED bar and sounder inputs these should follow the functionality of

the Host system.

Note:

The reader must be fully closed or the tamper circuit will

activate, indicated by a flashing LED bar.

9. The reader front can now be secured to the backplate using the

supplied enclosure screw.

use ON LY flat head screws, maximum shank size 4mm (5/32”, #7)

Document 100.14.IS.01 v1.30, effe ctive from SN1632-0001 page 2 of 2 printed on Aug 8, 2016

Loading...

Loading...