Inglis Washer-Dryer Installation Instructions Manual

If washer/dryer

does not operate...

• Check that the circuit breaker is not

tripped or the house fuse blown.

• Check that power supply cord is plugged

into wall receptacle.

• Check that washer lid or dryer door is

closed.

• Check that the round shipping piece has

been removed.

• Check that controls are set in a running or

When moving the

washer/dryer...

• Disconnect the power supply cord.

Tape power supply cord securely to

washer/dryer.

• Tape the dryer drum to the front panel.

Tape the lint screen in place. Tape the

dryer door closed.

• Wedge a blanket between the tub ring

and cabinet top to restrict tub movement.

• Turn front leveling legs all the way in.

If you need

assistance...

Check your Use and Care Guide for a tollfree number to call, or call the dealer from

whom you purchased this appliance. The

dealer is listed in the Yellow Pages of your

phone directory under ”Appliances —

Household — Major — Service and Repair.”

When you call, you will need the washer/

dryer model number and serial number. Both

numbers can be found on the model/serial

Part No. 3405982

Four-Wire Laundry System

Washer•Dryer – 240 Volt

Installation Instructions

IMPORTANT:

Installer: Leave Installation Instructions

with the homeowner.

Homeowner: Keep Installation Instructions

for future reference.

Save Installation Instructions for local

electrical inspector’s use.

IMPORTANT:

Read and save

these instructions.

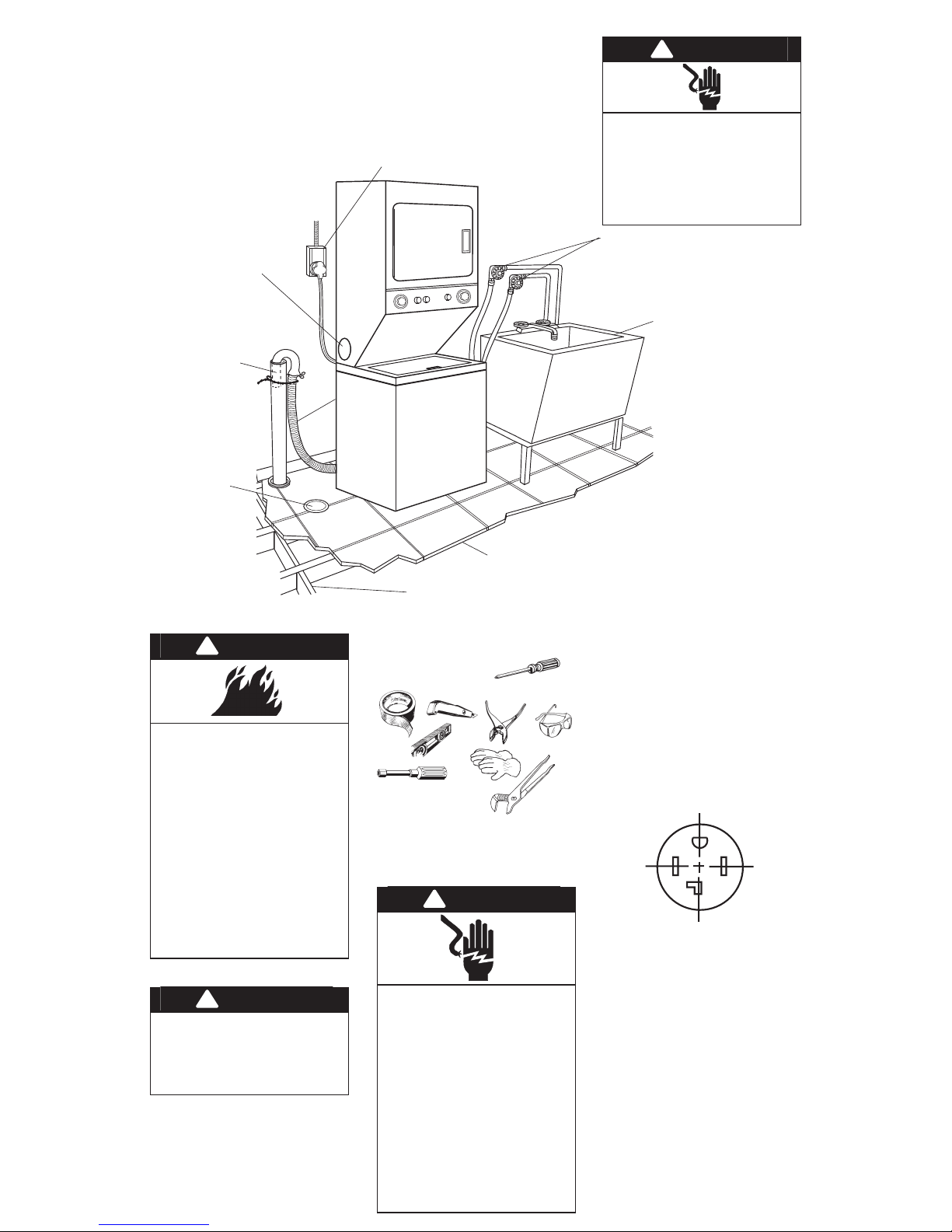

Electrical Shock Hazard

Electrical ground is required.

Do Not ground to a gas pipe.

Improper connection of the equipment-

grounding conductor can result in a risk of

electrical shock.

Check with a qualified electrician if you are

not sure this washer/dryer is properly

grounded.

Do Not change the power supply cord plug.

If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

Do Not have a fuse in the neutral or

grounding circuit.

Do Not use an extension cord with this

washer/dryer.

Failure to follow these instructions could

result in death or electrical shock.

Tools and materials

needed for

installation:

Panel A

level

Phillips

screwdriver

utility knife

duct

tape

Electric Shock Hazard

It is the customer’s responsibility:

To contact a qualified electrical installer.

To assure that the electrical installation is

adequate and in conformance with the

Canadian Electrical Codes, and all local

codes and ordinances.

Failure to follow these instructions can

result in death or electrical shock.

Fire Hazard

For your safety, the information in this

manual must be followed to minimize the

risk of fire or explosion or to prevent

property damage, personal injury or loss

of life.

Do Not use or store gasoline, paint,

thinners and other flammable materials

near washer/dryer. Fumes from such

materials could result in fire or explosion.

Never install washer/dryer up against

draperies or curtains or on carpet. To do

so may result in a fire.

Keep any and all items from falling or

collecting behind the washer/dryer.

Failure to do so may result in a fire.

Replace all access panels before

operating washer/dryer.

Failure to follow these instructions may

result in a fire.

Before you start...

Check location where washer/dryer will be

installed. Proper installation is your

responsibility. The washer/dryer must not be

installed or stored in an area where it will be

exposed to water and/or weather. Make

sure you have everything necessary for

correct installation.

Location should be large enough to fully

open dryer door 90°. (See Panel E for

“Recessed and closet installation

instructions” and “Product dimensions.”)

Check utilities: Proper electrical supply

must be available. See “Electrical

requirements”, Panel A.

Important : Observe all governing

codes and ordinances.

Grounded electrical outlet within (1.5m) 5 ft

of the center rear of cabinet is required. See

“Electrical requirements,” Panel A.

Dryer may be exhausted

from rear or left or right side.

Exhausting through the side

requires Side Exhaust Kit Part

No. 279823. See “Exhaust

requirements,” Panel B.

Standpipe drain system

needs a 5 cm (2 in)

diameter standpipe

with a minimum carryaway capacity of

64.4 litres (14.2 Imperial

gallons) per minute.

Top of standpipe must

be at least 71.1 cm

(28 in) high and no

higher than 121.9 cm

(48 in) from floor.

Floor drain system

requires a siphon

break, Part No.

285320, available

from your authorized

parts distributor.

10.2 cm (4 in)

metal exhaust

duct is required.

Level floor: Maximum

slope under

washer/dryer,

2.5 cm (1 in).

Hot and cold water faucets must be within

1.2 meters (4 feet) of the back of the

washer/dryer and provide water pressure of

34 to 690 kPa (5-100 psi).

Water heater: Set to deliver 60°C (140°F)

water to the washer.

Drain hose

may also be

installed to a

laundry tub

or floor drain

system.

See Panel D.

1/4" socket wrench

or nut driver

Check code requirements. Some codes limit

or do not permit the installation of

washer/dryer in garages, closets, mobile

homes and sleeping quarters. Contact your

local building inspector.

If a longer drain hose is

needed, Drain Hose Part

No. 388423, and Hose

Connection Kit Part No. 285442,

are available from your

authorized parts distributor.

Support: Floor must be sturdy enough

to support washer/dryer weight with

water and clothes of 170 kg (375 lb).

!

WARNING

!

WARNING

!

WARNING

Electrical

requirements

OBSERVE ALL GOVERNING CODES AND

ORDINANCES

1. A four-wire, single-phase, 120/240-volt,

60-Hz, AC only electrical supply is required

on a separate 30-ampere circuit, fused on

both sides of the line. (Time-delay fuse or

circuit breaker is recommended.)

2. This washer/dryer is equipped with a fourwire, 30-amp rated flexible-type power

supply cord. It must be plugged into a

mating 30-amp receptacle (NEMA-type

14-30R). See Figure 1.

Use 30-amp receptacle where local codes

permit flexible-type supply cord (pigtail).

G

Y

X

W

14-30R

4-wire receptacle

Figure 1

SEE RECESSED AND CLOSET

INSTALLATION INSTRUCTIONS

ON PANEL E .

Laundry tub drain system needs

a 75.7 litres (16.7 Imperial

gallons) laundry tub. Top of tub

must be at least 71.1 cm (28 in)

high and no higher than 121.9

cm (48 in) from floor.

Do Not store or operate washer/dryer

below 0°C (32°F) (some water may

remain in washer). Proper operation of

dryer cycles requires temperatures above

7°C (45°F). See Use & Care Guide for

“Winterizing” information.

Injury Hazard

More than one person is required to lift,

tilt, or move this washer/dryer because of

its weight and size.

Failure to follow these instructions may

result in injury.

!

WARNING

slip-joint

pliers that

open

to 3.8 cm

(1-1/2")

minimum

gloves

pliers

safety glasses

Panel B

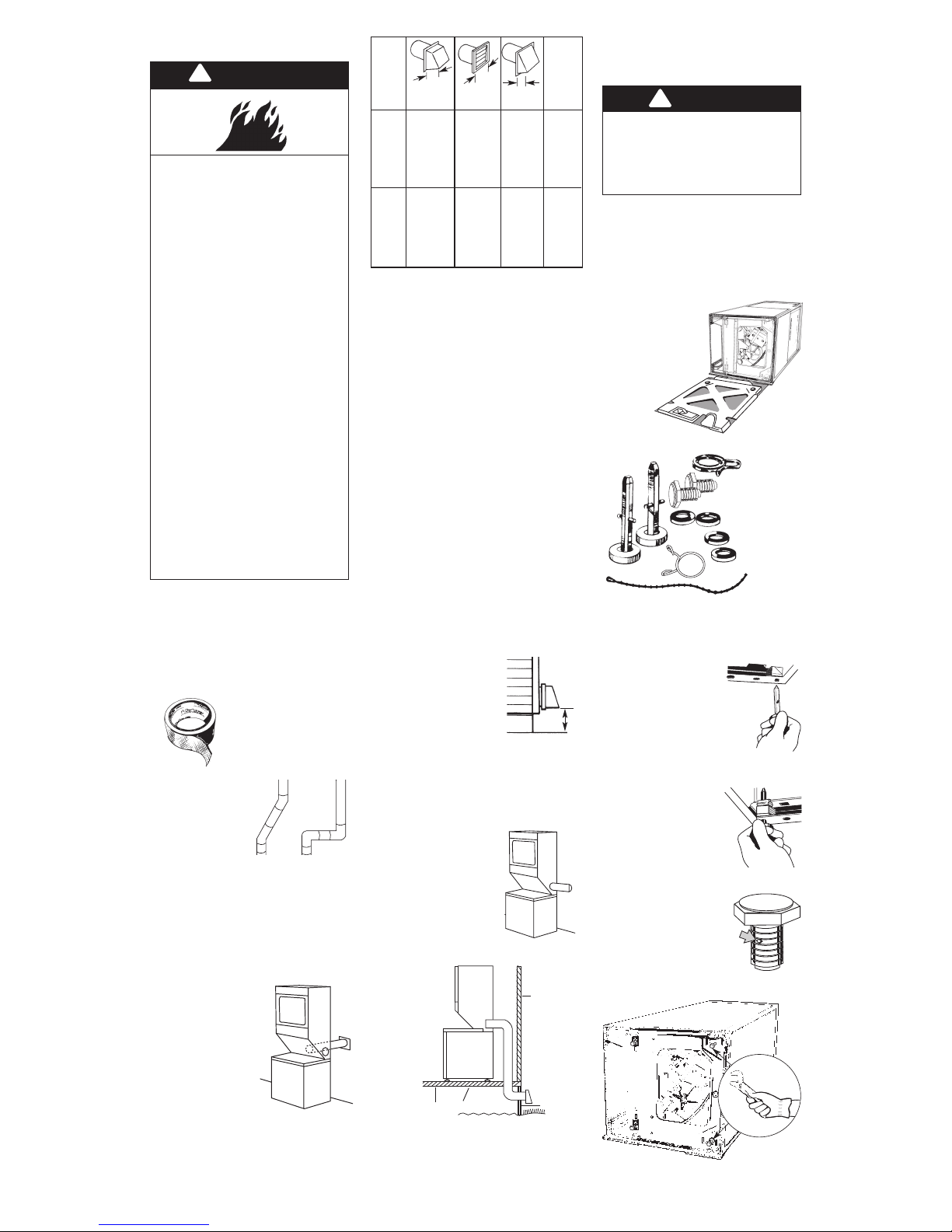

Exhaust requirements

Fire Hazard

Do Not use non-metal, flexible duct.

Do Not use metal duct smaller than

10.2 cm (4 in) in diameter.

Do Not use exhaust hoods with magnetic

latches.

Check that exhaust system is not longer

than specified. Exhaust systems longer

than specified will:

— Accumulate lint.

— Shorten the life of the product.

— Reduce performance and result in

longer drying times and increased

energy usage.

Failure to follow specifications may result

in a fire.

Do Not exhaust the dryer into a chimney,

furnace, cold air duct, attic or crawl space,

or any other duct used for venting.

Clean the exhaust system every year.

Do Not install flexible duct under wall,

ceiling or floor materials.

Accumulated lint could be fuel for a fire or

cause moisture damage.

Exhausting your dryer indoors is Not

recommended. The moisture and lint

indoors may cause:

— Lint to gather inside and around the

dryer and be a fuel for fire.

— Moisture damage to woodwork,

furniture, paint, wallpaper, carpet,

etc.

— Housecleaning problems and

possible health problems.

Failure to follow these instructions could

result in fire damage, injury or health

problems.

If using an existing exhaust system, clean lint

from entire length of exhaust system. Make

sure exhaust hood is not plugged with lint.

The exhaust system should be inspected and

cleaned yearly.

Replace any vinyl or metallized plastic foil

exhaust duct with rigid metal or flexible

metal duct.

!

WARNING

The exhaust duct can

be routed up, down,

left, right or straight out

the back of the washer/

dryer. Space

requirements are

provided on Panel E

and on the rear panel of

the washer/dryer. Use

the straightest path you

can, to avoid 90˚ turns.

Use duct tape to seal all

joints. Do Not use screws to

secure duct.

10.2 cm (4 in)

rigid metal pipe

is preferred. Plan

installation to use the

fewest number of

elbows and turns.

Metal flexible duct must

be fully extended and supported when the

dryer is in its final position. DO NOT KINK OR

CRUSH THE DUCT. The metal flexible duct

must be fully extended to allow adequate

exhaust air to flow.

Allow as much room as possible when using

elbows or making turns. Bend duct gradually

to avoid kinking. Remove excess flexible

duct to avoid sagging and kinking that may

result in reduced air flow.

For exhaust configurations other than those

listed in chart, the back pressure MUST not

exceed 0.5 cm (0.2 inches) water column at

the back of the washer/dryer. The back

pressure should be checked by a qualified

technician.

For exhaust systems not covered by the

exhaust length chart, see Service Manual,

Part No. 603197, available from your

authorized parts distributor.

Service check: The back pressure in any

exhaust system used must not exceed

0.5 cm (0.2 inches) of water column

measured with an incline manometer at the

point that the exhaust duct connects to the

dryer.

The maximum length using a 5.1 cm x 15.2 cm

(2 in x 6 in) rectangular duct with 2 elbows and a

6.4 cm (2-1/2 in) exhaust hood is 2.4 m (8 ft).

Exhausting the dryer outside is

recommended. Recessed installation that is

not exhausted outside must use Exhaust

Deflector Kit Part No. 694609, available from

your authorized parts distributor. See

“Recessed and closet installation

instructions,” Panel E, for unobstructed air

opening requirements.

If the washer/dryer is installed in a confined

area such as a bedroom, bathroom or

closet, it must be exhausted to the outside

and provision must be made for enough air

for combustion and ventilation. Check

governing codes and ordinances. Also refer

to the “Recessed and closet installation

instructions” on Panel E.

An exhaust hood should cap

the exhaust duct to prevent

exhausted air from returning

into dryer. The outlet of the

hood must be at least

30.5 cm (12 in) from the

ground or any object that

may be in the path of the

exhaust.

10.2 cm (4 in) outlet hood is preferred.

However, a 6.4 cm (2-1/2 in) outlet may be

used with short systems only. A 6.4 cm

(2-1/2 in) outlet can result in longer drying

times than other hood types. For permanent

installation, a stationary exhaust system is

required.

Mobile home exhaust requirements: The

washer/dryer must have an outside exhaust.

If the dryer is exhausted through the floor

and the area under the mobile home is

enclosed, the exhaust system must terminate

outside the enclosed area. Extension

beyond the enclosure will prevent lint and

moisture buildup under the mobile home.

Exhausting the dryer through

the side of the washer/dryer

requires the use of Side

Exhaust Kit Part No. 279823.

Follow kit instructions for

proper exhaust installation.

Mobile home installation

Injury Hazard

More than one person is required to lift,

tilt or move the washer/dryer because of

its weight and size.

Failure to follow this instruction may

result in injury.

!

WARNING

Truck only from the rear to prevent product

damage.

Now start...

With washer/dryer in laundry

area.

• 4 legs

• 1 drain hose

clamp

• 1 plastic

beaded strap

• 4 flat, waterhose washers

• 1 small clamp

rear legs

good

exhaust air flow

better

30.5 cm

(12 in)

minimum

front legs

13.1 m

(43 ft)

10.1 m

(33 ft)

7.0 m

(23 ft)

5.5 m

(18 ft.)

9.1 m

(30 ft)

7.3 m

(24 ft)

4.9 m

(16 ft)

3.1 m

(10 ft.)

12.5 m

(41 ft)

9.5 m

(31 ft)

6.4 m

(21 ft)

5.5 m

(18 ft.)

8.8 m

(29 ft)

7.0 m

(23 ft)

4.6 m

(15 ft)

2.7 m

(9 ft.)

7.3 m

(24 ft)

5.5 m

(18 ft)

3.1 m

(10 ft)

Not

recommended

11.0 m

(36 ft)

7.9 m

(26 ft)

4.9 m

(16 ft)

Not

recommended

0

1

2

3

0

1

2

3

rigid

metal duct

Maximum

length of

10.2 cm

(4 in) dia.

duct

flexible

metal duct

10.2 cm

(4 in)

10.2 cm

(4 in)

6.4 cm

(2-1/2 in)

NUMBER

OF 90°

TURNS

6.With one of the

front legs in hand, check

the ridges for a diamond

marking. That's how far the

leg is supposed to go into

the hole. Start to screw the

legs into the holes in the

front corners by hand.

4.Insert a rear-leveling

leg into the hole in the rear

corner on the bottom of the

washer/dryer. Push leg in until it

snaps into place. Do the same

same thing with the other leveling

leg in the other rear corner.

5.Push up one leg;

check to see that the other

leg goes down. Check the

other leg the same way. (If

legs do not adjust, repeat

Step 4.)

Use slip-joint pliers to finish turning the front

legs until you reach the diamond mark.

2.Remove

shipping cardboard

base.

1.Put on safety glasses and gloves.

Maximum length of the exhaust system

depends upon the type of duct used,

number of elbows and the type of exhaust

hood. The maximum length for both rigid

and flexible duct is shown in the chart.

3.Remove parts from plastic

package. Check that all parts were

included.

floor

skirting

outside

wall

enclosed area

Loading...

Loading...