Ingersoll-Rand SLB150, SLB200, SLB600, SLB300, SLB1200 User Manual

Form MHD56109

SLB150

3/4 ton

SLB200

1 ton

SLB300

1-1/2 ton

SLB600

3 ton

SLB1200

6 ton

F

R

E

E

L

O

A

D

(Dwg. MHP0829)

PARTS, OPERATION AND MAINTENANCE MANUAL

for

LEVER CHAIN HOIST MODELS

READ THIS MANUAL BEFORE USING THESE PRODUCTS. This manual

contains important safety, installation, operation and maintenance

information. Make this manual available to all persons responsible for

the installation, operation and maintenance of these products.

WARNING

Do not use this hoist for lifting, supporting, or transporting people or lifting or supporting

loads over people.

Always operate, inspect and maintain this hoist in accordance with American National

Standards Institute Safety Code (ASME B30.21) and any other applicable safety codes

and regulations.

Form MHD56109

Edition 9

July 2013

71480545

© 2013 Ingersoll-Rand

SAFETY INFORMATION

Indicates an imminently hazardous

situation which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation

which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation

which, if not avoided, may result in minor

or moderate injury or property damage.

Indicates information or a company

policy that relates directly or indirectly to

the safety of personnel or protection of

property.

DANGER

WARNING

CAUTION

NOTICE

WARNING

This manual provides important information for all personnel

involved with the safe installation, operation and proper

maintenance of this product. Even if you feel you are familiar

with this or similar equipment, you should read this manual

before operating the product.

Danger, Warning, Caution and Notice

Throughout this manual there are steps and procedures which, if

not followed, may result in a hazard. The following signal words

are used to identify the level of potential hazard.

• Do not use this hoist for lifting, supporting, or transporting

people or lifting or supporting loads over people.

• Hoists are designed to provide a 4 to 1 safety factor.

Supporting structures and load-attaching devices used in

conjunction with this hoist must provide adequate support to

handle all hoist operations, plus the weight of hoist and

attached equipment. This is the customer’s responsibility. If in

doubt, consult a registered structural engineer.

The National Safety Council, Accident Prevention Manual for

Industrial Operations, Eighth Edition and other recognized safety

sources make a common point: Employees who work near cranes

or assist in hooking on or arranging a load should be instructed to

keep out from under the load. From a safety standpoint, one factor

is paramount: conduct all lifting operations in such a manner that

if there were an equipment failure, no personnel would be injured.

This means keep out from under a raised load and keep out of the

line of force of any load.

The Occupational Safety and Health Act of 1970 generally places

the burden of compliance with the user, not the manufacturer.

Many OSHA requirements are not concerned or connected with

the manufactured product but are, rather, connected with the final

installation. It is the owner’s and user’s responsibility to

determine the suitability of a product for any particular use. It is

recommended that all applicable industry, trade association,

federal, state and local regulations be checked. Read all operating

instructions and warnings before operation.

Safety Summary

Ingersoll Rand hoists are manufactured in accordance with the

latest ASME B30.21 standards.

WARNING TAG

Each hoist is supplied from the factory with a multi-language

warning tag shown. If the tag is not attached to your unit, order a

new tag and install it. Refer to parts list for part number. Read and

obey all warnings and other safety information attached to this

hoist. Tag may be shown smaller than actual size.

Rigging: It is the responsibility of the operator to exercise

caution, use common sense and be familiar with proper rigging

techniques. Refer to ASME B30.9 for rigging information,

American National Standards Institute, 1430 Broadway, New

York, NY 10018.

WARNING

Failure to follow these warnings may result in

death, severe injury or property damage:

• Read manual before using this product.

• Do not lift, lower or pull more than

rated load.

• Do not lift people or loads over

people.

• Do not operate with twisted or damaged

chain or kinked, frayed or cut rope or strap.

• Do not operate lever hoist or puller with handle

extension (cheaters).

• Do not operate if damaged or malfunctioning.

• Do not operate when chain, rope or strap cannot

form straight line with load.

• Do not operate with other than manual power.

• Do not operate with open latch, twisted hook or

without a latch.

• Always keep minimum of 3 wraps of wire rope

or 2 wraps of strap on drum.

• Do not remove or obscure warning labels.

2 MHD56109 - Edition 9

SAFE OPERATING INSTRUCTIONS

The following warnings and operating instructions have been

adapted in part from American National Standard ASME B30.21

and are intended to avoid unsafe operating practices which might

lead to injury or property damage.

Ingersoll Rand recognizes that most companies who use hoists

have a safety program in force in their plants. In the event that

some conflict exists between a rule set forth in this publication

and a similar rule already set by an individual company, the more

stringent of the two should take precedence.

Safe Operating Instructions are provided to make an operator

aware of dangerous practices to avoid and are not necessarily

limited to the following list. Refer to specific sections in the

manual for additional safety information.

1. Only allow personnel trained in safety and operation of this

product to operate hoist.

2. Only operate a hoist if you are physically fit to do so.

3. When a “DO NOT OPERATE” sign is placed on hoist, do

not operate hoist until sign has been removed by designated

personnel.

4. Before each shift, the operator should inspect hoist for wear

or damage.

5. Never use a hoist which inspection indicates is worn or

damaged.

6. Periodically, inspect hoist thoroughly and replace worn or

damaged parts. Refer to “INSPECTION” section.

7. Lubricate hoist regularly. Refer to “LUBRICATION”

section.

8. Do not use hoist if hook latch has been sprung or broken.

9. Check that hook latches are engaged before using.

10. Never splice a hoist chain by inserting a bolt between links.

11. Only lift loads less than or equal to rated capacity of hoist.

Refer to “SPECIFICATIONS” section.

12. Never use hoist load chain as a sling.

13. Never operate a hoist when load chain is not centered under

top hook. Do not “side pull” or “yard.”

14. Never operate a hoist with twisted, kinked, “capsized” or

damaged load chain.

15. Do not force a chain or hook into place by hammering.

16. Never insert point of hook into a chain link.

17. Be certain load is properly seated in saddle of hook and hook

latch is engaged.

18. Do not support load on tip of hook.

19. Never run load chain over a sharp edge. Use a sheave.

20. When using two hoists to suspend one load, select two hoists

each having a rated capacity equal to or more than the load.

This provides adequate safety in the event of a sudden load

shift.

21. Pay attention to the load at all times when operating hoist.

22. Always ensure that you, and all other people, are clear of

load path. Do not lift a load over people.

23. Never use hoist for lifting or lowering people, and never

allow anyone to stand on a suspended load.

24. Ease slack out of chain and sling when starting a lift. Do not

jerk the load.

25. Do not swing a suspended load.

26. Do not leave a load suspended when hoist is unattended or

not in use.

27. Never weld or cut on a load suspended by the hoist.

28. Never use hoist chain as a welding electrode.

29. Do not operate hoist if chain jumping, excessive noise,

jamming, overloading, or binding occurs.

30. Keep load from hitting load chain.

31. Do not use a cheater bar or extended handle.

32. Never place hand inside throat area of a hook.

33. After use, or when in a non-operational mode, hoist should

be secured against unauthorized and unwarranted use.

34. Only operate hoist with manual power.

SPECIFICATIONS

General

The Lever Chain Hoist can be mounted to the suspension shaft of

a trolley or a permanent mounting structure. The hoist is designed

to lift and lower loads up to rated capacity with minimal lever

effort.

To determine hoist configuration refer to capacity and lot number

nameplate located on hand lever for model number information.

Series Hoist Capacity Lift Options

SLB = Silver Lever Hoist 150 = 3/4 metric ton / 750 kg

200 = 1 metric ton / 1,000 kg

300 = 1-1/2 metric ton / 1,500 kg

600 = 3 metric ton / 3,000 kg

1200 = 6 metric ton / 6,000 kg

Model Code Explanation

Example: SLB - 300 - 15

Series

Hoist Capacity

Lift (Hoist load chain/hook travel)

15 = 5 m (standard)

20 = 6 m

XX = Specify length

F = Hoist without load chain

S = Shipyard Hook

MHD56109 - Edition 9 3

CAUTION

CAUTION

NOTICE

WARNING

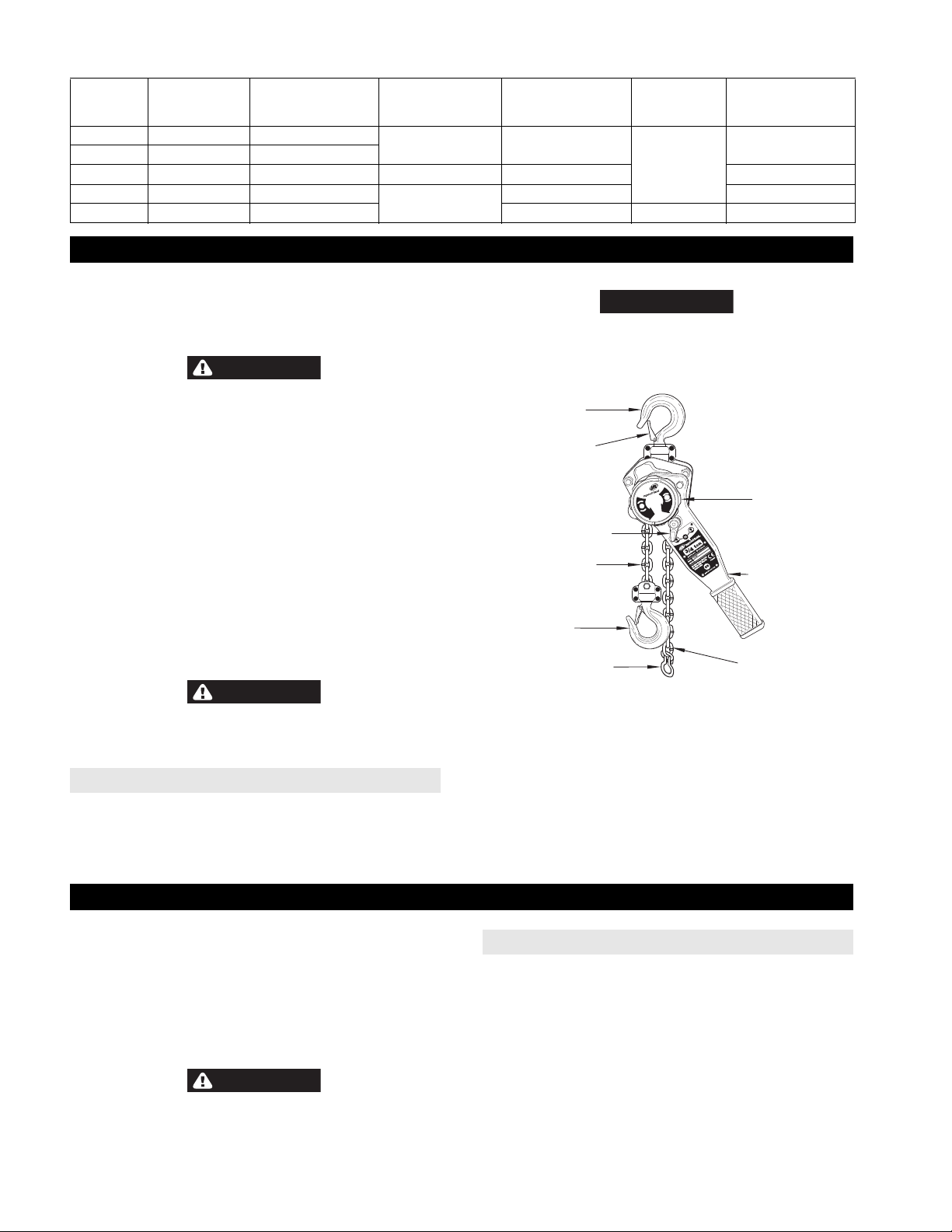

Specifications Table

To p Hook

Free Knob

Selector Lever

Load Chain

(Hook side)

Bottom

Hook

Hand Lever

Load Chain

(Anchor side)

Hook Latch

Chain Stopper

F

R

E

E

L

O

A

D

Model

No.

SLB150 3/4 18.5

SLB200 1 27

SLB300 1-1/2 24 7.1 x 21.2 0.34 11.0

SLB600 3 24

SLB1200 6 26 1.32 2 30.4

Capacity

(metric tons)

Lever Pull to lift

rated load (kg)

Load

Chain size (mm)

6 x 18 0.24

10 x 30

Wt. of chain per

0.3 m of lift (kg)

No. of chain

falls

1

1.66 20.0

Hoist Net Weight

with standard

1.5 m of lift (kg)

INSTALLATION

Prior to installing hoist, carefully inspect it for possible shipping

damage. Hoists are supplied fully lubricated from the factory.

Ensure load chain is lubricated prior to hoist operation.

• Owners and users are advised to examine specific, local or

other regulations, including American National Standards

Institute and/or OSHA Regulations, which may apply to a

particular type of use of this product, before installing or

putting hoist to use.

The SLB lever chain hoist can be used in any position provided it

is rigged to pull in a straight line from top hook to bottom hook.

• Each time a load is lifted, operation of load brake should be

checked by raising load slightly and stopping to ensure brake

will hold load before continuing to lift load.

7.03

The hoist body must be positioned so that it does not contact the

load or support members when in use. Ensure hand lever

movement is unrestricted.

When operating in limited areas suitable lifting attachments or

slings must be used to prevent hoist body and hand lever from

being obstructed.

• Ensure hoist top and bottom hooks are properly rigged and

hook latches are engaged, prior to use.

Initial Operating Checks

Operate hoist with a test load (10% of rated capacity) by raising

and lowering this load several times. Verify brake operation by

lowering same load to check load does not slip when lowering

stops.

OPERATION

The four most important aspects of hoist operation are:

1. Follow all safety instructions when operating hoist.

2. Allow only personnel trained in safety and operation of this

hoist to operate hoist.

3. Subject each hoist to a regular inspection and maintenance

procedure.

4. Be aware of hoist capacity and weight of load at all times.

(Dwg. MHP0830)

Familiarize operators and personnel responsible for hoist

installation and service with ASME B30.21 specifications and

this manual prior to placing unit into service. All requirements of

this specification, including testing should be met before

approving hoist for operation.

Positioning Unloaded Hook (Neutral Position)

Refer to Dwg. MHP0830 on page 4.

Check that chain stopper (54) is securely fastened in last link of

load chain anchor end. The load chain stopper is intended to

prevent load chain from becoming disengaged from hoist and is

not intended to support the load.

• The hoist is not designed or suitable for lifting, lowering or

moving persons. Never lift loads over people.

4 MHD56109 - Edition 9

CAUTION

WARNING

NOTICE

Lowering Load (DOWN Position - Payout)

WARNING

CAUTION

• Ensure load is properly seated in saddle of bottom hook.

In NEUTRAL “N” position hand lever does not engage ratchet

gear. The hand lever free-wheels until selector lever is shifted to

UP or DOWN position.

1. Set selector lever to NEUTRAL (center) position.

2. Turn free chain knob counterclockwise.

3. Grasp and pull one side of load chain or turn free knob until

desired hook location is achieved.

4. Connect hook to load. Pull anchor side of load chain or turn

free knob until chain slack is removed.

• Do not support or hang loads from load chain anchor end.

Brake may not hold load or operate correctly.

Lifting Load (UP Position - Haul-In)

Refer to Dwg. MHP0825 on page 5.

The following procedure assumes hoist is in NEUTRAL (center)

position and hook is attached to a load, but hoist is not supporting

the load.

1. Place selector lever in UP position.

2. Rotate free knob clockwise.

3. Pull anchor end of load chain until slack is removed.

4. Rotate (ratchet) hand lever in clockwise direction to raise

(haul-in) load.

• Ratchet may not engage and raise (haul-in) load until all

chain slack is removed and hoist is supporting load weight. If

hand lever movement does not produce lifting, apply tension

to anchor side of load chain while ratcheting until slack is

removed and hoist begins lifting load. If hoist does not operate

properly under load, remove load, inspect and repair hoist.

Refer to Dwg. MHP0825 on page 5.

• Do not continue lowering load after chain stopper has

contacted hoist body as damage may occur to hoist resulting in

a falling load which can cause severe injury, death or property

damage.

The following procedure assumes hoist selector lever is in UP

position, hoist is holding a load and the operator wants to lower

(payout) the load:

1. Place selector lever in DOWN position.

2. Rotate (ratchet) hand lever in counterclockwise direction to

lower (payout) load.

• To prevent injury or property damage always lower loads

until load chain becomes slack before shifting to NEUTRAL

position.

Storing the Hoist

1. Always store hoist in a no load condition.

2. Switch selector lever to NEUTRAL (center position).

3. Wipe off all dirt and water.

4. Oil the chain, hook pins and hook latch pins.

5. Hang in a dry place.

6. Before returning hoist to service follow instructions for

‘Hoists not in Regular Use’ in “INSPECTION” section.

Neutral

Free Chain Position

“Up”

(Haul In) Position

“Down”

(Payout) Position

Free

Knob

D

A

F

R

O

L

E

E

F

R

E

D

E

A

O

L

F

R

E

D

E

A

O

L

Selector

Lever

(Dwg. MHP0825)

MHD56109 - Edition 9 5

INSPECTION

WARNING

Twisted

DO NOT USE

Normal

Can Be Used

• All new, altered or modified equipment should be inspected

and tested by personnel trained in safety, operation and

maintenance of this equipment to ensure safe operation at

rated specifications before placing equipment in service.

Frequent and periodic inspections should be performed on

equipment in regular service. Frequent inspections are visual

examinations performed by operators or service personnel and

include observations made during routine equipment operation.

Periodic inspections are thorough inspections conducted by

personnel trained in the safety, operation and maintenance of this

equipment. ASME B30.21 states inspection intervals depend

upon the nature of the critical components of the equipment and

severity of usage.

Careful inspection on a regular basis will reveal potentially

dangerous conditions while still in the early stages, allowing

corrective action to be taken before the condition becomes

dangerous.

Deficiencies revealed through inspection, or noted during

operation, must be reported to designated personnel trained in

safety, operation and maintenance of this equipment. A

determination as to whether a condition constitutes a safety

hazard must be decided, and the correction of noted safety

hazards accomplished and documented before placing equipment

in service.

Records and Reports

Inspection records, listing all points requiring periodic inspection

should be maintained for all load bearing equipment. Written

reports, based on severity of service, should be made on the

condition of critical parts as a method of documenting periodic

inspections. These reports should be dated, signed by the person

who performed the inspection, and kept on file where they are

readily available for review.

Load Chain Reports

1. OPERATION. Check for visual signs or abnormal noises

which could indicate a potential problem. Check chain feed

through hoist and on 6 ton units the hook idler sheave. If

chain binds, jumps or is excessively noisy or “clicks,” clean

and lubricate the chain. If problem persists, chain may have

to be replaced. Do not operate hoist until all problems have

been determined and corrected.

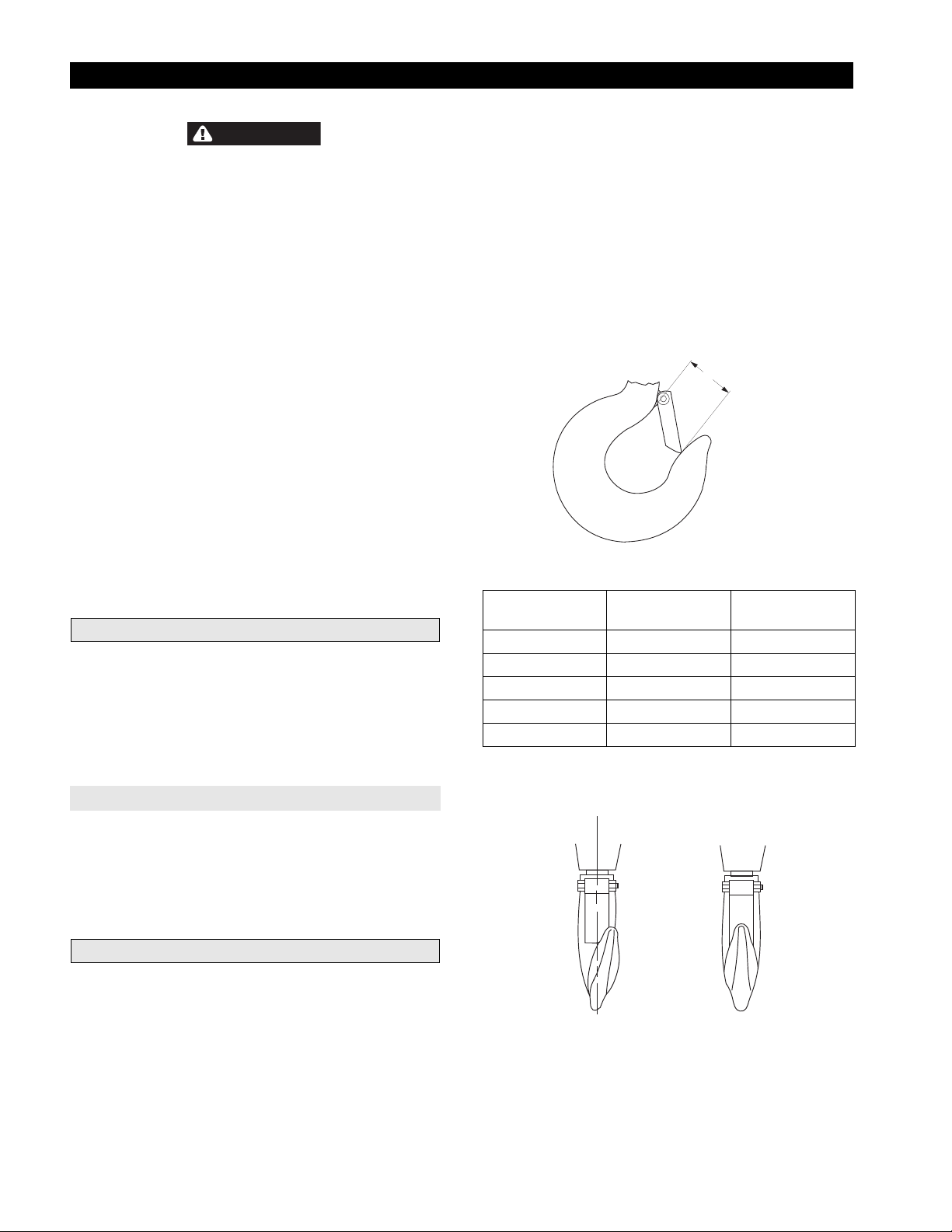

2. HOOKS. Check for wear or damage, increased throat width,

bent shank or twisting of hook. Replace hooks that exceed

the throat opening discard width (15%) shown in Table 1

(refer to Dwg. MHP0040 on page 6) or are twisted (refer to

Dwg. MHP0111 on page 6). If hook latch snaps past tip of

hook, hook is sprung and must be replaced. Check hooks

swivel easily and smoothly. Repair or lubricate as necessary.

Throat Width

(Dwg. MHP0040)

Tabl e 1

Model No.

SLB150 29 31

SLB200 32 35

SLB300 35 39

SLB600 44 48.3

SLB1200 50 55

3. HOOK LATCHES. Check operation of hook latches.

Replace if broken or missing.

Throat Width

(mm)

Discard Width

(mm)

Records should be maintained documenting the condition of load

chain removed from service as part of a long-range load chain

inspection program. Accurate records will establish a relationship

between visual observations noted during frequent inspections

and the actual condition of the load chain as determined by

periodic inspection methods.

Frequent Inspection

The lever chain hoist should be inspected at the beginning of each

shift. Visual inspections should also be conducted during regular

service for any damage or evidence of malfunction which appears

between regular inspections.

(Dwg. MHP0111)

6 MHD56109 - Edition 9

Loading...

Loading...