Ingersoll-Rand S9V2C080U5PSBA, S9V2B080U3PSBA, S9V2B040U3PSBA, S9V2B060U4PSBA, S9V2C100U4PSBA Installer's Manual

...Page 1

Installer’s Guide

Upflow/Horizontal and Downflow

Gas-Fired, Direct/Non-Direct Vent, 2–Stage

Condensing Variable Speed Furnaces

UUppffllooww,, CCoonnvveerrttiibbllee ttoo

HHoorriizzoonnttaall RRiigghhtt oorr

HHoorriizzoonnttaall LLeefftt

S9V2B040U3PSBA

S9V2B060U3PSBA

S9V2B060U4PSBA

S9V2B080U3PSBA

S9V2B080U4PSBA

S9V2C080U5PSBA

S9V2C100U4PSBA

S9V2C100U5PSBA

S9V2D120U5PSBA

DDoowwnnffllooww OOnnllyy

S9V2B040D3PSBA

S9V2B060D3PSBA

S9V2B080D3PSBA

S9V2B080D4PSBA

S9V2C100D4PSBA

S9V2C100D5PSBA

S9V2D120D5PSBA

NNoottee:: Graphics in this document are for representation

only. Actual model may differ in appearance.

D345855P01

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

February 2017

SSAAFFEETTYY WWAARRNNIINNGG

1188--CCEE0011DD11--11FF--EENN

Page 2

SAFETY SECTION— FURNACES

IInnggeerrssoollll RRaanndd hhaass aa ppoolliiccyy ooff ccoonnttiinnuuoouuss pprroodduucctt

aanndd pprroodduucctt ddaattaa iimmpprroovveemmeenntt aanndd iitt rreesseerrvveess tthhee

rriigghhtt ttoo cchhaannggee ddeessiiggnn aanndd ssppeecciiffiiccaattiioonnss wwiitthhoouutt

nnoottiiccee..

IImmppoorrttaanntt:: — This document pack contains a wiring

diagram and service information. This is

customer property and is to remain with

this unit. Please return to service

information pack upon completion of work.

WWAARRNNIINNGG

FFIIRREE OORR EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

Failure to follow safety warnings exactly

could result in a fire or explosion causing

property damage, personal injury or loss

of life.

—— DDoo nnoott ssttoorree oorr uussee ggaassoolliinnee oorr ootthheerr

ffllaammmmaabbllee vvaappoorrss aanndd lliiqquuiiddss iinn tthhee vviicciinniittyy ooff

tthhiiss oorr aannyy ootthheerr aapppplliiaannccee.. —— WWHHAATT TTOO DDOO IIFF

YYOOUU SSMMEELLLL GGAASS

•• DDoo nnoott ttrryy ttoo lliigghhtt aannyy aapppplliiaannccee..

•• DDoo nnoott ttoouucchh aannyy eelleeccttrriiccaall sswwiittcchh;;ddoo nnoott uussee

aannyy pphhoonnee iinn yyoouurr bbuuiillddiinngg..

•• IImmmmeeddiiaatteellyy ccaallll yyoouurr ggaass ssuupppplliieerr ffrroomm aa

nneeiigghhbboorr’’ss pphhoonnee.. FFoollllooww tthhee ggaass ssuupppplliieerr''ss

iinnssttrruuccttiioonnss..

•• IIff yyoouu ccaannnnoott rreeaacchh yyoouurr ggaass ssuupppplliieerr,, ccaallll

tthhee ffiirree ddeeppaarrttmmeenntt..

—— IInnssttaallllaattiioonn aanndd sseerrvviiccee mmuusstt bbee ppeerrffoorrmmeedd

bbyy aa qquuaalliiffiieedd iinnssttaalllleerr,, sseerrvviiccee aaggeennccyy,, oorr tthhee

ggaass ssuupppplliieerr..

WWAARRNNIINNGG

EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, ppeerrssoonnaall iinnjjuurryy oorr ddeeaatthh..

IInnssttaallll aa ggaass ddeetteeccttiinngg wwaarrnniinngg ddeevviiccee iinn ccaassee ooff aa

ggaass lleeaakk.. NNOOTTEE:: TThhee mmaannuuffaaccttuurreerr ooff yyoouurr ffuurrnnaaccee

ddooeess nnoott tteesstt aannyy ddeetteeccttoorrss aanndd mmaakkeess nnoo

rreepprreesseennttaattiioonnss rreeggaarrddiinngg aannyy bbrraanndd oorr ttyyppee ooff

ddeetteeccttoorr..

WWAARRNNIINNGG

EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, ppeerrssoonnaall iinnjjuurryy oorr ddeeaatthh..

NNeevveerr uussee aann ooppeenn ffllaammee ttoo ddeetteecctt ggaass lleeaakkss..

EExxpplloossiivvee ccoonnddiittiioonnss mmaayy ooccccuurr.. UUssee aa lleeaakk tteesstt

ssoolluuttiioonn oorr ootthheerr aapppprroovveedd mmeetthhooddss ffoorr lleeaakk

tteessttiinngg..

WWAARRNNIINNGG

EELLEECCTTRRIICCAALL SSHHOOCCKK,, FFIIRREE,, OORR

EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

ddaannggeerroouuss ooppeerraattiioonn,, pprrooppeerrttyy ddaammaaggee,, sseevveerree

ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

IImmpprrooppeerr sseerrvviicciinngg ccoouulldd rreessuulltt iinn ddaannggeerroouuss

ooppeerraattiioonn,, pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall

iinnjjuurryy,, oorr ddeeaatthh..

•• BBeeffoorree sseerrvviicciinngg,, ddiissccoonnnneecctt aallll eelleeccttrriiccaall

ppoowweerr ttoo ffuurrnnaaccee..

•• WWhheenn sseerrvviicciinngg ccoonnttrroollss,, llaabbeell aallll wwiirreess pprriioorr

ttoo ddiissccoonnnneeccttiioonn.. RReeccoonnnneecctt wwiirreess ccoorrrreeccttllyy..

•• VVeerriiffyy pprrooppeerr ooppeerraattiioonn aafftteerr sseerrvviicciinngg..

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE PPOOIISSOONNIINNGG

HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

TToo eennssuurree ffuurrnnaaccee iiss vveenntteedd pprrooppeerrllyy,, ddoo nnoott

rreeppllaaccee ffaaccttoorryy ssuupppplliieedd vveennttiinngg ccoommppoonneennttss wwiitthh

ffiieelldd ffaabbrriiccaatteedd ppaarrttss.. FFaabbrriiccaattiinngg ppaarrttss ccaann rreessuulltt

iinn ddaammaaggeedd vveennttss aanndd ccoommppoonneennttss aalllloowwiinngg

ccaarrbboonn mmoonnooxxiiddee ttoo eessccaappee tthhee vveennttiinngg ssyysstteemm..

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo nnoott aatttteemmpptt ttoo cchhaannggee tthhee vveennttiinngg ssyysstteemm..

FFoollllooww tthhee iinnssttaallllaattiioonn aanndd ooppeerraattiioonn iinnssttrruuccttiioonnss

ffoorr tthhee vveennttiinngg ssyysstteemm..

©2017 Ingersoll Rand All rights reserved

18-CE01D1-1F-EN

Page 3

SSAAFFEETTYY SSEECCTTIIOONN—— FFUURRNNAACCEESS

WWAARRNNIINNGG

FFIIRREE HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo nnoott iinnssttaallll tthhee ffuurrnnaaccee ddiirreeccttllyy oonn ccaarrppeettiinngg,, ttiillee

oorr ootthheerr ccoommbbuussttiibbllee mmaatteerriiaall ootthheerr tthhaann wwoooodd

fflloooorriinngg.. FFoorr vveerrttiiccaall ddoowwnnffllooww aapppplliiccaattiioonnss,,

ssuubbbbaassee ((bbaayybbaassee220055)) mmuusstt bbee uusseedd bbeettwweeeenn tthhee

ffuurrnnaaccee aanndd ccoommbbuussttiibbllee fflloooorriinngg.. WWhheenn tthhee

ddoowwnnffllooww ffuurrnnaaccee iiss iinnssttaalllleedd vveerrttiiccaallllyy wwiitthh aa

ccaasseedd ccooiill,, aa ssuubbbbaassee iiss nnoott rreeqquuiirreedd..

WWAARRNNIINNGG

HHAAZZAARRDDOOUUSS GGAASSEESS!!

EExxppoossuurree ttoo ffuueell ssuubbssttaanncceess oorr bbyy--pprroodduuccttss ooff

iinnccoommpplleettee ffuueell ccoommbbuussttiioonn iiss bbeelliieevveedd bbyy tthhee

ssttaattee ooff CCaalliiffoorrnniiaa ttoo ccaauussee ccaanncceerr,, bbiirrtthh ddeeffeeccttss,, oorr

ootthheerr rreepprroodduuccttiivvee hhaarrmm..

TThhiiss wwaarrnniinngg ccoommpplliieess wwiitthh ssttaattee ooff CCaalliiffoorrnniiaa llaaww,,

PPrrooppoossiittiioonn 6655..

WWAARRNNIINNGG

EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

PPrrooppaannee ggaass iiss hheeaavviieerr tthhaann aaiirr aanndd mmaayy ccoolllleecctt iinn

aannyy llooww aarreeaass oorr ccoonnffiinneedd ssppaacceess.. IInn aaddddiittiioonn,,

ooddoorraanntt ffaaddee mmaayy mmaakkee tthhee ggaass uunnddeetteeccttaabbllee

eexxcceepptt wwiitthh aa wwaarrnniinngg ddeevviiccee.. IIff tthhee ggaass ffuurrnnaaccee iiss

iinnssttaalllleedd iinn aa bbaasseemmeenntt,, aann eexxccaavvaatteedd aarreeaass oorr aa

ccoonnffiinneedd ssppaaccee,, iitt iiss ssttrroonnggllyy rreeccoommmmeennddeedd ttoo

ccoonnttaacctt aa ggaass ssuupppplliieerr ttoo iinnssttaallll aa ggaass ddeetteeccttiinngg

wwaarrnniinngg ddeevviiccee iinn ccaassee ooff lleeaakk.. TThhee mmaannuuffaaccttuurreerr

ooff yyoouurr ffuurrnnaaccee ddooeess nnoott tteesstt aannyy ddeetteeccttoorrss aanndd

mmaakkeess nnoo rreepprreesseennttaattiioonnss rreeggaarrddiinngg aannyy bbrraanndd oorr

ttyyppee ooff ddeetteeccttoorr..

WWAARRNNIINNGG

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo nnoott bbyyppaassss tthhee ddoooorr sswwiittcchh oorr ppaanneell lloooopp bbyy

aannyy ppeerrmmaanneenntt mmeeaannss..

WWAARRNNIINNGG

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo nnoott ttoouucchh aannyy ccoommppoonneennttss ootthheerr tthhaann tthhee MMeennuu

aanndd OOppttiioonn bbuuttttoonnss oonn tthhee IIFFCC wwhheenn sseettttiinngg uupp tthhee

ssyysstteemm oorr dduurriinngg ffaauulltt rreeccoovveerryy..

WWAARRNNIINNGG

FFIIRREE OORR EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo NNOOTT aatttteemmpptt ttoo mmaannuuaallllyy lliigghhtt tthhee ffuurrnnaaccee..

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE PPOOIISSOONNIINNGG

HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

FFoollllooww tthhee sseerrvviiccee aanndd//oorr ppeerriiooddiicc mmaaiinntteennaannccee

iinnssttrruuccttiioonnss ffoorr tthhee FFuurrnnaaccee aanndd vveennttiinngg ssyysstteemm..

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE PPOOIISSOONNIINNGG

HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

sseerriioouuss ppeerrssoonnaall iinnjjuurryy oorr ddeeaatthh..

MMaakkee ssuurree tthhaatt tthhee bblloowweerr ddoooorr iiss iinn ppllaaccee aanndd nnoott

aajjaarr.. DDaannggeerroouuss ffuummeess ccoouulldd eessccaappee aann

iimmpprrooppeerrllyy sseeccuurreedd ddoooorr..

WWAARRNNIINNGG

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDiissccoonnnneecctt ppoowweerr ttoo tthhee uunniitt bbeeffoorree rreemmoovviinngg tthhee

bblloowweerr ddoooorr.. AAllllooww aa mmiinniimmuumm ooff 1100 sseeccoonnddss ffoorr

IIFFCC ppoowweerr ssuuppppllyy ttoo ddiisscchhaarrggee ttoo 00 vvoollttss..

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

TThheessee ffuurrnnaacceess aarree nnoott aapppprroovveedd oorr iinntteennddeedd ffoorr

iinnssttaallllaattiioonn iinn ttrraaiilleerrss oorr rreeccrreeaattiioonnaall vveehhiicclleess..

IInnssttaallllaattiioonn iinn mmaannuuffaaccttuurreedd ((mmoobbiillee)) hhoouussiinngg iiss

oonnllyy aapppprroovveedd wwiitthh BBAAYYMMFFGGHH KKiitt..

18-CE01D1-1F-EN

3

Page 4

SSAAFFEETTYY SSEECCTTIIOONN—— FFUURRNNAACCEESS

WWAARRNNIINNGG

EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

IInn tthhee eevveenntt tthhaatt eelleeccttrriiccaall,, ffuueell,, oorr mmeecchhaanniiccaall

ffaaiilluurreess ooccccuurr,, sshhuutt ggaass ssuuppppllyy ooffff aatt tthhee mmaannuuaall

ggaass vvaallvvee llooccaatteedd oonn tthhee ssuuppppllyy ggaass ppiippiinngg ccoommiinngg

iinnttoo tthhee ffuurrnnaaccee bbeeffoorree ttuurrnniinngg ooffff tthhee eelleeccttrriiccaall

ppoowweerr ttoo tthhee ffuurrnnaaccee.. CCoonnttaacctt tthhee sseerrvviiccee aaggeennccyy

ddeessiiggnnaatteedd bbyy yyoouurr ddeeaalleerr..

WWAARRNNIINNGG

EEXXPPLLOOSSIIOONN HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseerriioouuss ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo nnoott ssttoorree ccoommbbuussttiibbllee mmaatteerriiaallss,, ggaassoolliinnee,, oorr

ootthheerr ffllaammmmaabbllee vvaappoorrss oorr lliiqquuiiddss nneeaarr tthhee uunniitt..

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo nnoott uussee sseemmii--rriiggiidd mmeettaalllliicc ggaass ccoonnnneeccttoorrss

((fflleexxiibbllee ggaass lliinneess)) wwiitthhiinn tthhee ffuurrnnaaccee ccaabbiinneett..

WWAARRNNIINNGG

IINNSSTTAALLLLAATTIIOONN WWAARRNNIINNGG —— HHIIGGHH

VVOOLLTTAAGGEE MMOOVVIINNGG PPAARRTTSS!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

BBooddiillyy iinnjjuurryy ccaann rreessuulltt ffrroomm hhiigghh vvoollttaaggee

eelleeccttrriiccaall ccoommppoonneennttss,, ffaasstt mmoovviinngg ffaannss,, aanndd

ccoommbbuussttiibbllee ggaass.. FFoorr pprrootteeccttiioonn ffrroomm tthheessee

iinnhheerreenntt hhaazzaarrddss dduurriinngg iinnssttaallllaattiioonn aanndd sseerrvviicciinngg,,

tthhee mmaaiinn ggaass vvaallvvee mmuusstt bbee ttuurrnneedd ooffff aanndd tthhee

eelleeccttrriiccaall ssuuppppllyy mmuusstt bbee ddiissccoonnnneecctteedd aanndd.. IIff

ooppeerraattiinngg cchheecckkss mmuusstt bbee ppeerrffoorrmmeedd wwiitthh tthhee uunniitt

ooppeerraattiinngg,, iitt iiss tthhee tteecchhnniicciiaann’’ss rreessppoonnssiibbiilliittyy ttoo

rreeccooggnniizzee tthheessee hhaazzaarrddss aanndd pprroocceeeedd ssaaffeellyy..

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

DDoo nnoott iinnssttaallll tthhee ffiilltteerr iinn tthhee rreettuurrnn dduucctt ddiirreeccttllyy

aabboovvee tthhee ffuurrnnaaccee iinn hhoorriizzoonnttaall aapppplliiccaattiioonnss..

IInnssttaallll tthhee ffiilltteerr rreemmootteellyy..

WWAARRNNIINNGG

SSAAFFEETTYY HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

TTuurrnn tthhee ppoowweerr ttoo tthhee ffuurrnnaaccee ooffff bbeeffoorree sseerrvviicciinngg

ffiilltteerrss ttoo aavvooiidd ccoonnttaacctt wwiitthh mmoovviinngg ppaarrttss..

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

FFuurrnnaaccee vveennttiinngg iinnttoo aann uunnlliinneedd mmaassoonnrryy cchhiimmnneeyy

oorr ccoonnccrreettee cchhiimmnneeyy iiss pprroohhiibbiitteedd..

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

TThhee cchhiimmnneeyy lliinneerr mmuusstt bbee tthhoorroouugghhllyy iinnssppeecctteedd

ttoo iinnssuurree nnoo ccrraacckkss oorr ootthheerr ppootteennttiiaall aarreeaass ffoorr fflluuee

ggaass lleeaakkss aarree pprreesseenntt iinn tthhee lliinneerr.. LLiinneerr lleeaakkss wwiillll

rreessuulltt iinn eeaarrllyy ddeetteerriioorraattiioonn ooff tthhee cchhiimmnneeyy..

WWAARRNNIINNGG

SSHHOOCCKK HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr

ddeeaatthh..

IIff aa ddiissccoonnnneecctt sswwiittcchh iiss pprreesseenntt,, iitt mmuusstt aallwwaayyss bbee

lloocckkeedd iinn tthhee ooppeenn ppoossiittiioonn bbeeffoorree sseerrvviicciinngg tthhee

uunniitt..

WWAARRNNIINNGG

EELLEECCTTRRIICCAALL SSHHOOCCKK HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn aann

eelleeccttrriiccaall sshhoocckk,, ffiirree,, iinnjjuurryy oorr ddeeaatthh..

TThhee ccaabbiinneett mmuusstt hhaavvee aann uunniinntteerrrruupptteedd oorr

uunnbbrrookkeenn ggrroouunndd aaccccoorrddiinngg ttoo NNaattiioonnaall EElleeccttrriiccaall

CCooddee,, AANNSSII// NNFFPPAA 7700 -- ““llaatteesstt eeddiittiioonn”” aanndd

CCaannaaddiiaann EElleeccttrriiccaall CCooddee,, CCSSAA CC2222..11 oorr llooccaall ccooddeess

ttoo mmiinniimmiizzee ppeerrssoonnaall iinnjjuurryy iiff aann eelleeccttrriiccaall ffaauulltt

sshhoouulldd ooccccuurr..

EEnnssuurree ccaabbiinneett hhaass aann uunniinntteerrrruupptteedd oorr uunnbbrrookkeenn

ggrroouunndd iinn aaccccoorrddaannccee wwiitthh NNaattiioonnaall EElleeccttrriiccaall

CCooddee,, AANNSSII// NNFFPPAA 7700 –– ‘‘llaatteesstt eeddiittiioonn’’ aanndd

CCaannaaddiiaann EElleeccttrriiccaall CCooddee,, CCSSAA CC2222..11 oorr llooccaall ccooddeess

ttoo mmiinniimmiizzee ppeerrssoonnaall iinnjjuurryy iiff aann eelleeccttrriiccaall ffaauulltt

sshhoouulldd ooccccuurr..

4

18-CE01D1-1F-EN

Page 5

SSAAFFEETTYY SSEECCTTIIOONN—— FFUURRNNAACCEESS

WWAARRNNIINNGG

OOVVEERRHHEEAATTIINNGG AANNDD EEXXPPLLOOSSIIOONN

HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee,, ppeerrssoonnaall iinnjjuurryy oorr ddeeaatthh..

SShhoouulldd oovveerrhheeaattiinngg ooccccuurr,, oorr tthhee ggaass ssuuppppllyy ffaaiill ttoo

sshhuutt ooffff,, sshhuutt ooffff tthhee ggaass vvaallvvee ttoo tthhee uunniitt bbeeffoorree

sshhuuttttiinngg ooffff tthhee eelleeccttrriiccaall ssuuppppllyy..

CCAAUUTTIIOONN

IIMMPPRROOPPEERR VVOOLLTTAAGGEE CCOONNNNEECCTTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee..

DDoo NNOOTT ccoonnnneecctt tthhee ffuurrnnaaccee lliinnee vvoollttaaggee ttoo aa GGFFCCII

pprrootteecctteedd cciirrccuuiitt..

CCAAUUTTIIOONN

CCOORRRROOSSIIOONN WWAARRNNIINNGG!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

DDoo nnoott iinnssttaallll tthhee ffuurrnnaaccee iinn aa ccoorrrroossiivvee oorr

ccoonnttaammiinnaatteedd aattmmoosspphheerree..

CCAAUUTTIIOONN

FFRREEEEZZEE CCAAUUTTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

WWhheenn tthhee vveenntt ppiippee iiss eexxppoosseedd ttoo tteemmppeerraattuurreess

bbeellooww ffrreeeezziinngg,, ii..ee..,, wwhheenn iitt ppaasssseess tthhrroouugghh

uunnhheeaatteedd ssppaacceess,, eettcc..,, tthhee ppiippee mmuusstt bbee iinnssuullaatteedd

wwiitthh 11//22 iinncchh ((2222..77 mmmm)) tthhiicckk AArrmmaafflleexx--ttyyppee

iinnssuullaattiioonn oorr eeqquuaall.. IIff tthhee ssppaaccee iiss hheeaatteedd

ssuuffffiicciieennttllyy ttoo pprreevveenntt ffrreeeezziinngg,, tthheenn tthhee iinnssuullaattiioonn

wwoouulldd nnoott bbee rreeqquuiirreedd.. IIff ddoommeessttiicc wwaatteerr ppiippeess aarree

nnoott pprrootteecctteedd ffrroomm ffrreeeezziinngg tthheenn tthhee ssppaaccee mmeeeettss

tthhee ccoonnddiittiioonn ooff aa hheeaatteedd ssppaaccee..

CCAAUUTTIIOONN

FFRREEEEZZEE CCAAUUTTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

WWhheenneevveerr yyoouurr hhoouussee iiss ttoo bbee vvaaccaanntt,, aarrrraannggee ttoo

hhaavvee ssoommeeoonnee iinnssppeecctt yyoouurr hhoouussee ffoorr pprrooppeerr

tteemmppeerraattuurree.. TThhiiss iiss vveerryy iimmppoorrttaanntt dduurriinngg

ffrreeeezziinngg wweeaatthheerr.. IIff ffoorr aannyy rreeaassoonn yyoouurr ffuurrnnaaccee

sshhoouulldd ffaaiill ttoo ooppeerraattee ddaammaaggee ccoouulldd rreessuulltt,, ssuucchh

aass ffrroozzeenn wwaatteerr ppiippeess..

CCAAUUTTIIOONN

IINNSSTTAALLLLAATTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

TThhee vveenntt ffoorr tthhiiss aapppplliiaannccee sshhaallll nnoott tteerrmmiinnaattee;; ((11))

OOvveerr ppuubblliicc wwaallkkwwaayyss;; oorr ((22)) NNeeaarr ssooffffiitt vveennttss oorr

ccrraawwll ssppaaccee vveennttss oorr ootthheerr aarreeaass wwhheerree

ccoonnddeennssaattee oorr vvaappoorr ccoouulldd ccrreeaattee aa nnuuiissaannccee oorr

hhaazzaarrdd oorr ccaauussee pprrooppeerrttyy ddaammaaggee;; oorr ((33)) WWhheerree

ccoonnddeennssaattee vvaappoorr ccoouulldd ccaauussee ddaammaaggee oorr ccoouulldd bbee

ddeettrriimmeennttaall ttoo tthhee ooppeerraattiioonn ooff rreegguullaattoorrss,, rreelliieeff

vvaallvveess,, oorr ootthheerr eeqquuiippmmeenntt..

CCAAUUTTIIOONN

SSHHAARRPP EEDDGGEE HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

BBee ccaarreeffuull ooff sshhaarrpp eeddggeess oonn eeqquuiippmmeenntt oorr aannyy

ccuuttss mmaaddee oonn sshheeeett mmeettaall wwhhiillee iinnssttaalllliinngg oorr

sseerrvviicciinngg..

CCAAUUTTIIOONN

FFRREEEEZZEE CCAAUUTTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

IIff ccoommpplleettee ffuurrnnaaccee sshhuuttddoowwnn iiss ddoonnee dduurriinngg tthhee

ccoolldd wweeaatthheerr mmoonntthhss,, pprroovviissiioonnss mmuusstt bbee ttaakkeenn ttoo

pprreevveenntt ffrreeeezzee--uupp ooff aallll wwaatteerr ppiippeess aanndd wwaatteerr

rreecceeppttaacclleess..

CCAAUUTTIIOONN

FFRREEEEZZEE CCAAUUTTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

CCaauuttiioonn sshhoouulldd bbee ttaakkeenn ttoo pprreevveenntt ddrraaiinnss ffrroomm

ffrreeeezziinngg oorr ccaauussiinngg sslliippppeerryy ccoonnddiittiioonnss.. EExxcceessssiivvee

ddrraaiinniinngg ooff ccoonnddeennssaattee mmaayy ccaauussee ssaattuurraatteedd

ggrroouunndd ccoonnddiittiioonnss tthhaatt mmaayy rreessuulltt iinn ddaammaaggee ttoo

ppllaannttss..

CCAAUUTTIIOONN

BBAACCKKUUPP WWRREENNCCHH RREEQQUUIIRREEDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

UUssee aa bbaacckkuupp wwrreenncchh oonn tthhee ggaass vvaallvvee wwhheenn

iinnssttaalllliinngg ggaass ppiippiinngg ttoo pprreevveenntt ddaammaaggee ttoo tthhee ggaass

vvaallvvee aanndd mmaanniiffoolldd aasssseemmbbllyy..

18-CE01D1-1F-EN

5

Page 6

SSAAFFEETTYY SSEECCTTIIOONN—— FFUURRNNAACCEESS

CCAAUUTTIIOONN

DDOO NNOOTT UUSSEE AASS CCOONNSSTTRRUUCCTTIIOONN

HHEEAATTEERR!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

GGaass ffuurrnnaacceess mmaannuuffaaccttuurreedd oonn oorr aafftteerr MMaayy 11,,

22001177 aarree nnoott ppeerrmmiitttteedd ttoo bbee uusseedd iinn CCaannaaddaa ffoorr

hheeaattiinngg bbuuiillddiinnggss oorr ssttrruuccttuurreess uunnddeerr

ccoonnssttrruuccttiioonn.. FFoorr nnoonn--CCaannaaddiiaann aapppplliiccaattiioonnss,, iinn

oorrddeerr ttoo pprreevveenntt sshhoorrtteenniinngg iittss sseerrvviiccee lliiffee,, tthhee

FFuurrnnaaccee sshhoouulldd NNOOTT bbee uusseedd aass aa ““CCoonnssttrruuccttiioonn

HHeeaatteerr”” dduurriinngg tthhee ffiinniisshhiinngg pphhaasseess ooff

ccoonnssttrruuccttiioonn uunnttiill tthhee rreeqquuiirreemmeennttss lliisstteedd iinn tthhee

ssaaffeettyy sseeccttiioonn ooff tthhee IInnssttaalllleerr''ss GGuuiiddee hhaavvee bbeeeenn

mmeett.. CCoonnddeennssaattee iinn tthhee pprreesseennccee ooff cchhlloorriiddeess aanndd

fflluuoorriiddeess ffrroomm ppaaiinntt,, vvaarrnniisshh,, ssttaaiinnss,, aaddhheessiivveess,,

cclleeaanniinngg ccoommppoouunnddss,, aanndd cceemmeenntt ccrreeaattee aa

ccoorrrroossiivvee ccoonnddiittiioonn wwhhiicchh mmaayy ccaauussee rraappiidd

ddeetteerriioorraattiioonn ooff tthhee hheeaatt eexxcchhaannggeerr..

CCAAUUTTIIOONN

IIGGNNIITTIIOONN FFUUNNCCTTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss ccaauuttiioonn mmaayy rreessuulltt iinn ppoooorr

iiggnniittiioonn cchhaarraacctteerriissttiiccss..

MMaaiinnttaaiinn mmaanniiffoolldd pprreessssuurree iinn hhiigghh aallttiittuuddee

iinnssttaallllaattiioonnss..

CCAAUUTTIIOONN

WWIIRRIINNGG IINNFFOORRMMAATTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

TThhee iinntteeggrraatteedd ffuurrnnaaccee ccoonnttrrooll iiss ppoollaarriittyy

sseennssiittiivvee.. TThhee hhoott lleegg ooff tthhee 112200 VVAACC ppoowweerr mmuusstt

bbee ccoonnnneecctteedd ttoo tthhee BBLLAACCKK ffiieelldd lleeaadd..

CCAAUUTTIIOONN

WWAATTEERR DDAAMMAAGGEE!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

IItt iiss rreeccoommmmeennddeedd tthhaatt aann eexxtteerrnnaall oovveerrffllooww ddrraaiinn

ppaann bbee iinnssttaalllleedd iinn aallll aapppplliiccaattiioonnss oovveerr aa ffiinniisshheedd

cceeiilliinngg ttoo pprreevveenntt pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall

iinnjjuurryy ffrroomm lleeaakkiinngg ccoonnddeennssaattee..

CCAAUUTTIIOONN

HHOOTT SSUURRFFAACCEE!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

ppeerrssoonnaall iinnjjuurryy..

DDoo NNOOTT ttoouucchh iiggnniitteerr.. IItt iiss eexxttrreemmeellyy hhoott..

CCAAUUTTIIOONN

FFUURRNNAACCEE SSEERRVVIICCEE CCAAUUTTIIOONN!!

FFaaiilluurree ttoo ffoollllooww tthhiiss wwaarrnniinngg ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

LLaabbeell aallll wwiirreess pprriioorr ttoo ddiissccoonnnneeccttiioonn wwhheenn

sseerrvviicciinngg ccoonnttrroollss.. VVeerriiffyy pprrooppeerr ooppeerraattiioonn aafftteerr

sseerrvviicciinngg.. WWiirriinngg eerrrroorrss ccaann ccaauussee iimmpprrooppeerr aanndd

ddaannggeerroouuss ooppeerraattiioonn..

6

18-CE01D1-1F-EN

Page 7

SSAAFFEETTYY SSEECCTTIIOONN—— FFUURRNNAACCEESS

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE PPOOIISSOONNIINNGG

HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhee sstteeppss oouuttlliinneedd bbeellooww ffoorr eeaacchh

aapppplliiaannccee ccoonnnneecctteedd ttoo tthhee vveennttiinngg ssyysstteemm bbeeiinngg

ppllaacceedd iinnttoo ooppeerraattiioonn ccoouulldd rreessuulltt iinn ccaarrbboonn

mmoonnooxxiiddee ppooiissoonniinngg oorr ddeeaatthh..

The following steps shall be followed for

each appliance connected to the venting

system being placed into operation, while

all other appliances connected to the

venting system are not in operation:

•• IInnssppeecctt tthhee vveennttiinngg ssyysstteemm ffoorr pprrooppeerr ssiizzee

aanndd hhoorriizzoonnttaall ppiittcchh aass rreeqquuiirreedd iinn tthhee

NNaattiioonnaall FFuueell GGaass CCooddee,, AANNSSII ZZ222233..11//NNFFPPAA

5544 oorr tthhee CCSSAA BB114499..11NNaattuurraall GGaass aanndd

PPrrooppaannee IInnssttaallllaattiioonn CCooddee aanndd tthheessee

iinnssttrruuccttiioonnss.. DDeetteerrmmiinnee tthheerree iiss nnoo bblloocckkaaggee

oorr rreessttrriiccttiioonn,, lleeaakkaaggee,, ccoorrrroossiioonn oorr ootthheerr

ddeeffiicciieenncciieess wwhhiicchh ccoouulldd ccaauussee aann uunnssaaffee

ccoonnddiittiioonn..

•• CClloossee aallll ddoooorrss aanndd wwiinnddoowwss bbeettwweeeenn tthhee

ssppaaccee iinn wwhhiicchh tthhee aapppplliiaannccee((ss)) ccoonnnneecctteedd ttoo

tthhee vveennttiinngg ssyysstteemm aarree llooccaatteedd.. AAllssoo cclloossee

ffiirreeppllaaccee ddaammppeerrss..

•• TTuurrnn oonn ccllootthheess ddrryyeerrss aanndd aannyy aapppplliiaannccee nnoott

ccoonnnneecctteedd ttoo tthhee vveennttiinngg ssyysstteemm.. TTuurrnn oonn

aannyy eexxhhaauusstt ffaannss ssuucchh aass rraannggee hhooooddss ssoo

tthheeyy aarree ooppeerraattiinngg aatt mmaaxxiimmuumm ssppeeeedd.. DDoo

nnoott ooppeerraattee aa ssuummmmeerr eexxhhaauusstt ffaann..

•• FFoollllooww tthhee lliigghhttiinngg iinnssttrruuccttiioonnss.. PPllaaccee tthhee

aapppplliiaannccee bbeeiinngg iinnssppeecctteedd iinnttoo ooppeerraattiioonn..

AAddjjuusstt tthhee tthheerrmmoossttaatt ssoo aapppplliiaannccee iiss

ooppeerraattiinngg ccoonnttiinnuuoouussllyy..

•• TTeesstt ffoorr ssppiillllaaggee ffrroomm ddrraafftt hhoooodd eeqquuiippppeedd

aapppplliiaanncceess aatt tthhee ddrraafftt hhoooodd rreelliieeff ooppeenniinngg

aafftteerr 55 mmiinnuutteess ooff mmaaiinn bbuurrnneerr ooppeerraattiioonn..

UUssee tthhee ffllaammee ooff aa mmaattcchh oorr ccaannddllee..

•• IIff iimmpprrooppeerr vveennttiinngg iiss oobbsseerrvveedd dduurriinngg aannyy ooff

tthhee aabboovvee tteessttss,, tthhee vveennttiinngg ssyysstteemm mmuusstt bbee

ccoorrrreecctteedd iinn aaccccoorrddaannccee wwiitthh tthhee NNaattiioonnaall

FFuueell GGaass CCooddee,, AANNSSII ZZ222211..11//NNFFPPAA 5544 aanndd//oorr

CCSSAA BB114499..11 NNaattuurraall GGaass aanndd PPrrooppaannee

IInnssttaallllaattiioonn CCooddee..

•• AAfftteerr iitt hhaass bbeeeenn ddeetteerrmmiinneedd tthhaatt eeaacchh

aapppplliiaannccee ccoonnnneecctteedd ttoo tthhee vveennttiinngg ssyysstteemm

pprrooppeerrllyy vveennttss wwhheenn tteesstteedd,, rreettuurrnn aallll ddoooorrss,,

wwiinnddoowwss,, eexxhhaauusstt ffaannss,, eettcc.. ttoo tthheeiirr pprreevviioouuss

ccoonnddiittiioonn ooff uussee..

CCAAUUTTIIOONN

VVEENNTTIINNGG RREEQQUUIIRREEMMEENNTT!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

FFoorr ccoonnddeennssiinngg ffuurrnnaacceess,, DDoo NNOOTT rruunn vveenntt

tthhrroouugghh cchhiimmnneeyy ffoorr wwoooodd bbuurrnniinngg oorr ooiill FFuurrnnaacceess

oorr iinncciinneerraattoorrss.. IIff rreemmaaiinniinngg ffrreeee aarreeaa bbeettwweeeenn

ssiinnggllee wwaallll fflluuee ppiippee aanndd mmaassoonnrryy cchhiimmnneeyy iiss ttoo bbee

uusseedd ffoorr aannootthheerr ggaass aapppplliiaannccee,, vveennttiinngg aarreeaa mmuusstt

bbee ssuuffffiicciieenntt ttoo vveenntt tthhaatt aapppplliiaannccee aanndd tthhaatt

aapppplliiaannccee mmuusstt bbee ccoonnnneecctteedd ttoo cchhiimmnneeyy wwiitthh

sseeppaarraattee eennttrryy ooppeenniinnggss..

IIMMPPOORRTTAANNTT –– TThhee ssiinnggllee wwaallll fflluuee ppiippee jjooiinnttss mmuusstt

bbee sseeaalleedd.. TThhee 9900°° eellbbooww ccoonnnneeccttiioonn ttoo vveerrttiiccaall

ppiippee mmuusstt bbee sseeaalleedd ttoo pprreevveenntt ccoonnddeennssaattee

lleeaakkaaggee ttoo bbaassee ooff mmaassoonnrryy cchhiimmnneeyy..

CCAAUUTTIIOONN

VVEENNTTIINNGG RREEQQUUIIRREEMMEENNTT!!

FFaaiilluurree ttoo ffoollllooww tthhiiss CCaauuttiioonn ccoouulldd rreessuulltt iinn

pprrooppeerrttyy ddaammaaggee oorr ppeerrssoonnaall iinnjjuurryy..

CCoonnddeennssiinngg ffuurrnnaacceess mmaayy bbee vveenntteedd tthhrroouugghh

UUNNUUSSEEDD cchhiimmnneeyyss.. DDoo NNOOTT rruunn vveenntt tthhrroouugghh

cchhiimmnneeyy ffoorr wwoooodd bbuurrnniinngg oorr ooiill FFuurrnnaacceess oorr

iinncciinneerraattoorrss oorr aannyy ootthheerr ggaass aapppplliiaannccee..

IIMMPPOORRTTAANNTT –– TThhee ssiinnggllee wwaallll fflluuee ppiippee jjooiinnttss mmuusstt

bbee sseeaalleedd.. TThhee 9900°° eellbbooww ccoonnnneeccttiioonn ttoo vveerrttiiccaall

ppiippee mmuusstt bbee sseeaalleedd ttoo pprreevveenntt ccoonnddeennssaattee

lleeaakkaaggee ttoo bbaassee ooff mmaassoonnrryy cchhiimmnneeyy..

CCAAUUTTIIOONN

EEQQUUIIPPMMEENNTT DDAAMMAAGGEE!!

UUVV lliigghhtt eexxppoossuurree ccaann ccaauussee tthhee ppllaassttiicc bblloowweerr

mmaatteerriiaall ttoo ddeetteerriioorraattee wwhhiicchh ccoouulldd lleeaadd ttoo BBlloowweerr

HHoouussiinngg DDaammaaggee..

FFoorr uunniittss ccoonnttaaiinniinngg aa ppllaassttiicc BBlloowweerr HHoouussiinngg,, DDoo

NNOOTT iinnssttaallll tthhiirrdd ppaarrttyy UUllttrraa--VViioolleett AAiirr CClleeaanneerrss

wwhheerree tthhee BBlloowweerr HHoouussiinngg ccaann bbee eexxppoosseedd ttoo UUVV

lliigghhtt..

For more information, visit www.IRCO.com or contact your

installing dealer.

Ingersoll Rand

800 Beaty St.

Davidson, NC 28036

18-CE01D1-1F-EN

7

Page 8

Table of Contents

Accessories. . . . . . . . . .. . . . . . . . . . .. . . . . . . . .. . . 9

Document Pack Contents. . . . . . . . . . . . . . . . . . 9

Furnace Installation Guidelines. . . . . . . . . .. . 10

Safety Practices and Precautions. . . . . . . . . . 10

General Guidelines . . . . . . . . . . . . . . . . . . . . . . 10

Locations and Clearances . . . . . . . . . . . . . . . . 11

Outline Drawings. . . . . . . . .. . . . . . . . .. . . . . . . . 12

Furnace General Installation. . . . . . .. . . . . . . . 18

S-Series Furnace Panel Removal . . . . . . . . . . 18

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Combustion and Input Check. . . . . . . . . . 22

Gas Valve Adjustment. . . . . . . . . . . . . . . . 23

High Altitude Derate. . . . . . . . . . . . . . . . . . 24

General Venting . . . . . . . . . . . . . . . . . . . . . . . . . 25

Special Case Venting . . . . . . . . . . . . . . . . . 26

Vent Terminations . . . . . . . . . . . . . . . . . . . 28

Attaching Vent Piping . . . . . . . . . . . . . . . . 28

Maximum Vent Length Table . . . . . . . . . . . . . 31

Horizontal Venting . . . . . . . . . . . . . . . . . . . . . . . 32

Horizontal Venting Through Wall

with Concentric Vent Kit . . . . . . . . . . . . . . 35

Venting Through The Roof . . . . . . . . . . . . 39

Air for Combustion and Ventilation. . . . . . . . 41

Duct Connections. . . . . . . . . . . . . . . . . . . . . . . . 44

Return Air Filters . . . . . . . . . . . . . . . . . . . . . . . . 56

Electrical Connections . . . . . . . . . . . . . . . . . . . 58

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . 58

Condensate Drain Instructions. . .. . . . . . . . .. 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Vertical Applications . . . . . . . . . . . . . . . . . . . . . 61

Horizontal Applications. . . . . . . . . . . . . . . 64

General Start-up and Adjustment. . . . . . . . .. 65

Preliminary Inspections . . . . . . . . . . . . . . . . . . 65

Lighting Instructions . . . . . . . . . . . . . . . . . . . . . 65

Control and Safety Switch

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Furnace Combustion Air Exhaust

Options. . .. . . . . . . . . . .. . . . . . . . .. . . . . . . . .. . . . 66

Upflow Furnace in Upflow Position —

Top Vented Combustion Air . . . . . . . . . . . . . . 68

Upflow Furnace in Upflow Position —

Left Side Vented Combustion Air. . . . . . . . . . 70

Upflow Furnace in Horizontal Left

Position — Side Vented Combustion

Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Upflow Furnace in Horizontal Left

Position — Top Vented Combustion

Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Upflow Furnace in Horizontal Right

Position — Left Side Vented

Combustion Air . . . . . . . . . . . . . . . . . . . . . . 81

Upflow Furnace in Horizontal Right

Position — Bottom Vented

Combustion Air . . . . . . . . . . . . . . . . . . . . . . 85

Downflow Furnace — Top Vented

Combustion Air . . . . . . . . . . . . . . . . . . . . . . 90

Downflow Furnace — Left Side

Vented Combustion Air. . . . . . . . . . . . . . . 92

Integrated Furnace Control Menu. . . . . . . . .. 96

Integrated Furnace Control Display

Codes . . . . . . . . . . . . . .. . . . . . . . . .. . . . . . . . .. . . . 99

Fault Code Recovery . . . . . . . . . . . . . . . . . . . . 100

Sequence of Operation . . . . . . . . .. . . . . . . . . . 101

8

18-CE01D1-1F-EN

Page 9

Accessories

SSAAFFEETTYY WWAARRNNIINN GG

Onlyqualified personnelshould installand servicetheequipment. Theinstallation, startingup, andservicing ofheating,ventilating, and

air-conditioning equipmentcan behazardousand requiresspecificknowledge andtraining. Improperly installed,adjusted oraltered

equipment byanunqualified personcould resultindeath orserious injury.Whenworking onthe equipment,observe allprecautionsin the

literatureand onthetags, stickers,andlabels thatareattached totheequipment.

18-CE01D1-1

Upflow/Horizontal and Downflow Gas-Fired, Direct

Vent, 2–Stage Condensing Variable SpeedFurnaces

UUppffllooww,,CCoonnvveerrttiibbllee ttoo

HHoorriizzoonnttaallRRiigghhttoorr

HHoorriizzoonnttaallLLeefftt

S9V2B040U3PSAA

S9V2B060U3PSAA

S9V2B060U4PSAA

S9V2B080U3PSAA

S9V2B080U4PSAA

S9V2C080U5PSAA

S9V2C100U4PSAA

S9V2C100U5PSAA

S9V2D120U5PSAA

DDoowwnnfflloowwOOnn llyy

S9V2B040D3PSAA

S9V2B060D3PSAA

S9V2B080D3PSAA

S9V2B080D4PSAA

S9V2C100D4PSAA

S9V2C100D5PSAA

S9V2D120D5PSAA

NNoottee::“Graphics inthis documentare forrepresentation

only.Actual modelmay differin appearance.”

Installer’s Guide

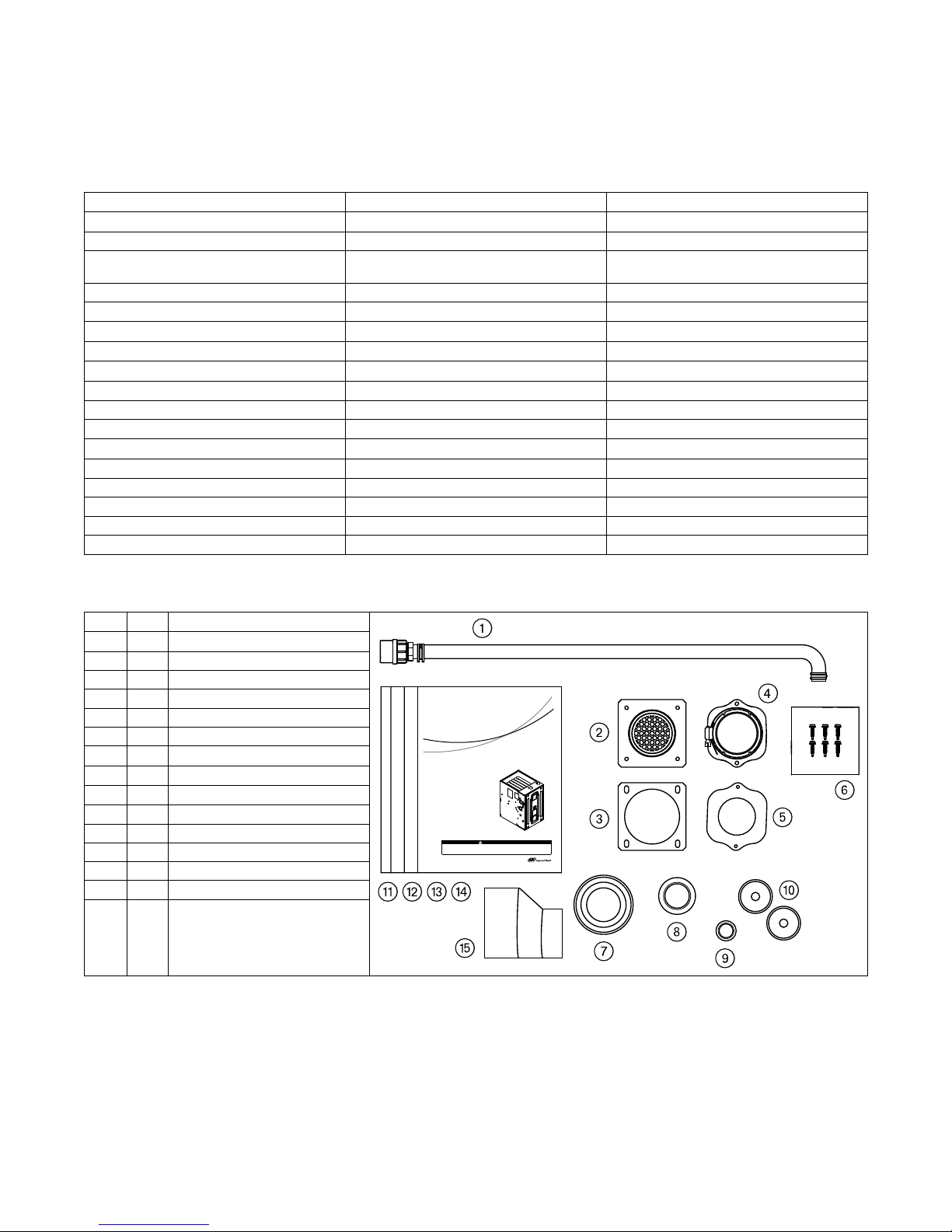

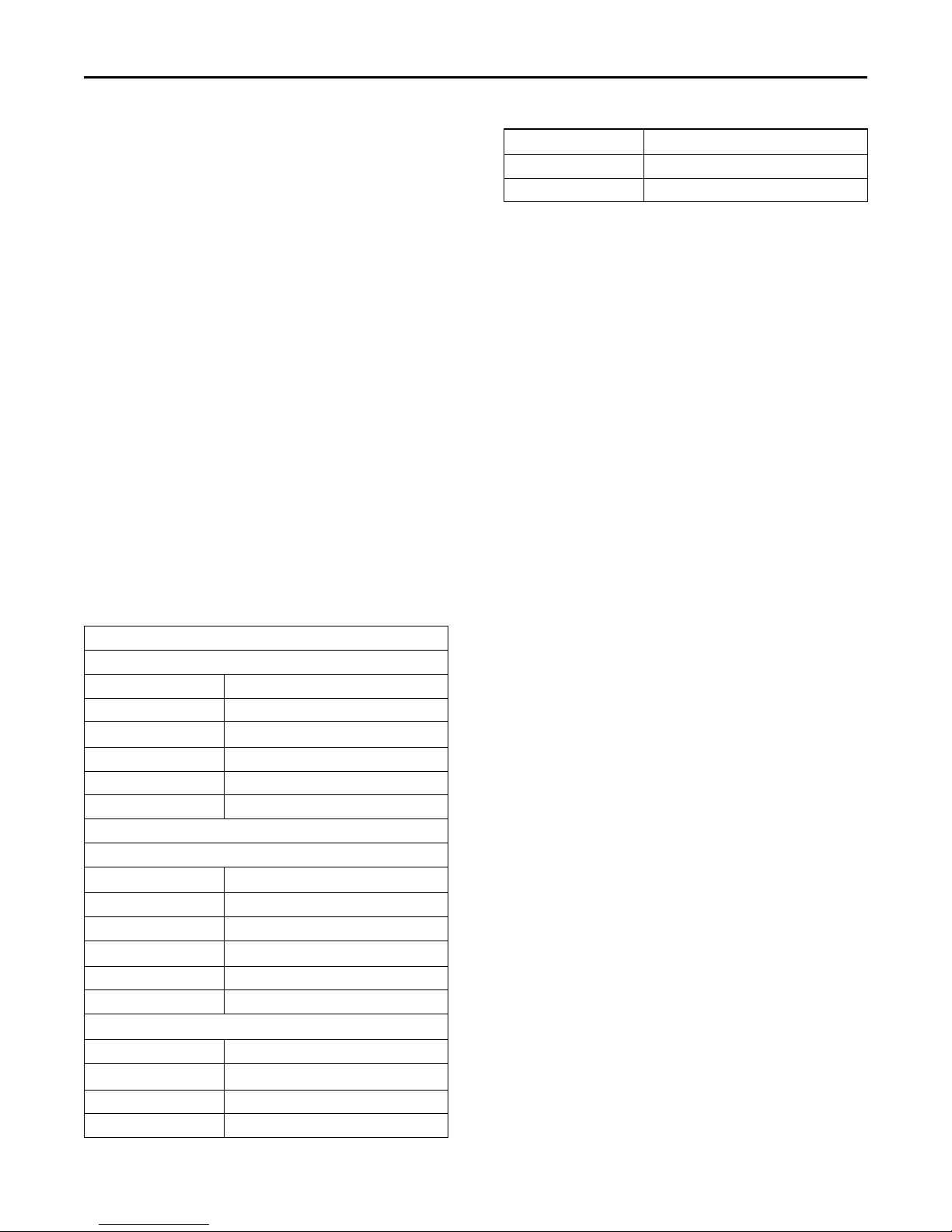

Table 1. Accessories

Model Number Description Use with

BAYHANG Horizontal Hanging Kit All Upflow Furnaces

BAYVENT200B Sidewall Vent Termination Kit All Furnaces

BAYVENTCN200B Sidewall Vent Termination Kit (Canada —

CPVC)

BAYAIR30AVENTA Concentric Vent Kit All Furnaces

BAYAIR30CNVENT

Concentric Vent Kit (Canada — CPVC) All Furnaces

BAYREDUCE Reducing Coupling (CPVC) All Furnaces

BAYLIFTB Dual Return Kit (B size extension) B Cabinet Upflow Furnaces

BAYLIFTC Dual Return Kit (C size extension) C Cabinet Upflow Furnaces

BAYLIFTD Dual Return Kit (D size extension) D Cabinet Upflow Furnaces

BAYBASE205

BAYFLTR206

BAYSLF1165AA

BAYFLTR203

(a)

Downflow Subbase All Downflow Furnaces

Filter Access Door Kit (Downflow only) All Upflow Furnaces

1” SlimFit Box with MERV 4 Filter All Upflow Furnaces

Horizontal Filter Kit B Cabinet Furnaces in Downflow/Horizontal

BAYFLTR204 Horizontal Filter Kit C Cabinet Furnaces in Downflow/Horizontal

BAYFLTR205 Horizontal Filter Kit D Cabinet Furnaces in Downflow/Horizontal

BAYLPSS400A LP Conversion Kit with Stainless Steel Burners All Furnaces

BAYMFGH200A Manufactured/Mobile Housing Kit All Furnaces

(a)

Airflow greater than 1600 CFM requires dual returns

All Furnaces

Document Pack Contents

Item Qty. Description

1 1 Condensate Drain Tube Assembly

2 1

3 1

Inlet Vent

Inlet Vent Gasket

4 1 Outlet Vent Assembly

5 1 Outlet Vent Gasket

6 6 Screws

7 1 Condensate Trap Grommet

8 1 Plug — Condensate/Gas

9 1 Plug — Electrical

10 2 Grommet — Condensate/Gas

11 1 Installer’s Guide

12 1 Service Facts

13 1 Owner Guide

14 1 Limited Warranty

15 1 2” to 3” Coupling — CPL00938

(a)

3” inlet vent supplied with S9V2D120UPSBA and S9V2D120DPSBA only. 2” inlet vent supplied with all other models.

(b)

Supplied with S9V2D120U5PSBA and S9V2D120D5PSBA only

(a)

(b)

18-CE01D1-1F-EN

9

Page 10

Furnace Installation Guidelines

The following sections give general guidelines for the

installation of the gas furnaces.

Safety Practices and Precautions

The following safety practices and precautions must be

followed during the installation, servicing, and

operation of this Furnace.

1. Use only with the type gas approved for this

Furnace. Refer to the Furnace rating plate.

2. Install the Furnace only in a location and position as

specified in “Locations and Clearances” of these

instructions.

3. Provide adequate combustion and ventilation air to

the Furnace space as specified in “Air for

Combustion and Ventilation” of these instructions.

4. Combustion products must be discharged

outdoors. Connect this Furnace to an approved vent

system only, as specified in the “Venting” section

of these instructions.

5. Never test for gas leaks with an open flame. Use a

commercially available soap solution made

specifically for the detection of leaks to check all

connections, as specified in the “Gas Piping”

section of these instructions.

6. Always install the Furnace to operate within the

Furnace’s intended temperature-rise range with a

duct system which has an external static pressure

within the allowable range, as specified on the unit

rating plate. Airflow within temperature rise for cfm

versus static is shown in the Service Facts

accompanying this Furnace.

7. When a Furnace is installed so that the supply ducts

carry air circulated by the Furnace to areas outside

the space containing the Furnace, the return air

shall also be handled by a duct(s) sealed to the

Furnace casing and terminating outside the space

containing the Furnace.

8. A gas-fired Furnace for installation in a residential

garage must be installed as specified in "Location

and Clearances" section of these instructions.

9. For non-Canadian applications, the furnace may be

used for temporary heating of buildings or

structures under construction only when the

following conditions have been met:

IImmppoorrttaanntt:: Gas furnaces manufactured on or after May

1, 2017 are not permitted to be used in

Canada for heating buildings or structures

under construction.

a. The Furnace venting system must be complete

and installed per manufacturer’s instructions.

b. The Furnace is controlled only by a room

Comfort Control (no field jumpers).

c. The Furnace return air duct must be complete

and sealed to the Furnace.

d. The Furnace input rate and temperature rise

must be verified to be within the nameplate

marking.

e. All air filters must be in place.

f. 100% of the Furnace combustion air

requirement must come from outside the

structure.

g. The Furnace return air temperature range is

between 55 and 80 Fahrenheit.

h. Clean the Furnace, duct work, and components

upon substantial completion of the construction

process, and verify Furnace operating

conditions including ignition, input rate,

temperature rise, and venting, according to the

manufacturer’s instructions.

10. IInn tthhee CCoommmmoonnwweeaalltthh ooff MMaassssaacchhuusseettttss,, tthhiiss

pprroodduucctt mmuusstt bbee ggaass ppiippeedd bbyy aa LLiicceennsseedd

PPlluummbbeerr oorr GGaass FFiitttteerr..

This Furnace is certified to leak 2% or less of nominal

air conditioning CFM delivered when pressurized to .5”

water column with all inlets, outlets, and drains sealed.

General Guidelines

The manufacturer assumes no responsibility for

equipment installed in violation of any code or

regulation.

It is recommended that Manual J of the Air

Conditioning Contractors Association (ACCA) or A.R.I.

230 be followed in estimating heating requirements.

When estimating heating requirements for installation

at Altitudes above 2000 ft., remember the gas input

must be reduced. See Combustion and Input Check.

MMaatteerriiaall iinn tthhiiss sshhiippmmeenntt hhaass bbeeeenn iinnssppeecctteedd aatt tthhee

ffaaccttoorryy aanndd rreelleeaasseedd ttoo tthhee ttrraannssppoorrttaattiioonn aaggeennccyy

wwiitthhoouutt kknnoowwnn ddaammaaggee.. IInnssppeecctt eexxtteerriioorr ooff ccaarrttoonn

ffoorr eevviiddeennccee ooff rroouugghh hhaannddlliinngg iinn sshhiippmmeenntt..

UUnnppaacckk ccaarreeffuullllyy aafftteerr mmoovviinngg eeqquuiippmmeenntt ttoo

aapppprrooxxiimmaattee llooccaattiioonn.. IIff ddaammaaggee ttoo ccoonntteennttss iiss

ffoouunndd,, rreeppoorrtt tthhee ddaammaaggee iimmmmeeddiiaatteellyy ttoo tthhee

ddeelliivveerriinngg aaggeennccyy..

Codes and local utility requirements governing the

installation of gas fired equipment, wiring, plumbing,

and flue connections must be adhered to. In the

absence of local codes, the installation must conform

with latest edition of the National Fuel Gas Code ANSI

Z223.1 / NFPA 54 • National Installation Code, CAN/CGA

B149.1. The latest code may be obtained from the

American Gas Association Laboratories, 400 N. Capitol

St. NW, Washington D.C. 20001.

1-800-699-9277 or www.aga.org.

10

18-CE01D1-1F-EN

Page 11

FFuurrnnaaccee IInnssttaallllaattiioonn GGuuiiddeelliinneess

These Furnaces have been classified as CATEGORY IV

furnaces in accordance with latest edition of ANSI

Z21.47 standards • CSA 2.3. Category IV furnaces

operate with positive vent static pressure and with a

flue loss less than 17 percent. These conditions require

special venting systems, which must be gas tight and

water tight. These Category IV Direct Vent Furnaces are

approved for installation in Manufactured/ Mobile

housing when used with BAYMFGH200A.

A manufactured (mobile) home installation must

conform with the Manufactured Home Construction

and Safety Standard, Title 24 CFR, Part 3280, or when

this Standard is not applicable, the Standard for

Manufactured Home Installations (Manufactured Home

Sites, Communities and Set-Ups), ANSI/NCS A225.1.

and/or MH Series Mobile Homes, CAN/CSA-Z240.

Locations and Clearances

The location of the Furnace is normally selected by the

architect, the builder, or the installer. However, before

the Furnace is moved into place, be sure to consider

the following requirements:

1. Is the location selected as near the chimney or vent

and as centralized for heat distribution as practical?

2. Do all clearances between the Furnace and

enclosure equal or exceed the minimums stated in

Clearance Table below?

Minimum clearance to combustible materials

Closet

Sides 0 In.

Back 1 In.

Top 1 In.

Front 0 In.

Bottom 0 In.

Flue 0 In.

24 In. minimum front clearance recommended for service

Horizontal Closet and Alcove

Right Side 0 In.

Left Side 0 In.

Back

Top 1 In.

Bottom 0 In.

Flue 0 In.

Horizontal Flue (discharge on left)

Closet

Right Side 0 In.

Left Side

Rear 1 In.

1 In.

0 In.

Top 1 In.

Bottom 0 In.

Flue 0 In.

3. Is there sufficient space for servicing the Furnace

and other equipment? A minimum of 24 inches

front accessibility to the Furnace must be provided.

Any access door or panel must permit removal of

the largest component.

4. Are there at least 3 inches of clearance between the

Furnace combustion air openings in the front panel

and any closed panel or door provided?

5. Are the ventilation and combustion air openings

large enough and will they remain unobstructed? If

outside air is used, are the openings set 12" above

the highest snow accumulation level?

6. Allow sufficient height in supply plenum above the

Furnace to provide for cooling coil installation, if

the cooling coil is not installed at the time of this

Furnace installation.

7. The Furnace shall be installed so electrical

components are protected from water.

8. If the Furnace is installed in a garage, it must be

installed so that the burners, and the ignition

source are located not less than 18 inches above the

floor and the Furnace must be located or protected

to avoid physical damage from vehicles.

9. The gas furnace must not be located where

excessive exposure to contaminated combustion

air will result in safety and performance related

problems. Avoid the following known

contaminants:

a. Permanent wave solutions

b. Chlorinated waxes and cleaners

c. Chlorine based swimming pool chemicals

d. Water softening chemicals

e. De-icing salts or chemicals

f. Carbon tetrachloride

g. Halogen type refrigerants

h. Cleaning solvents (such as

perchloroethylene)

i. Printing inks, paint removers, varnishes, etc.

j. Hydrochloric acid

k. Cements and glues

l. Antistatic fabric softeners for clothes dryers

m. Masonry acid washing materials

IMPORTANT: The Furnace must be installed level. The

only allowable variation would be slightly to the left

and/ or forward in upflow installations or slightly

toward the front in horizontal installations. This is

necessary for proper condensate drainage.

18-CE01D1-1F-EN

11

Page 12

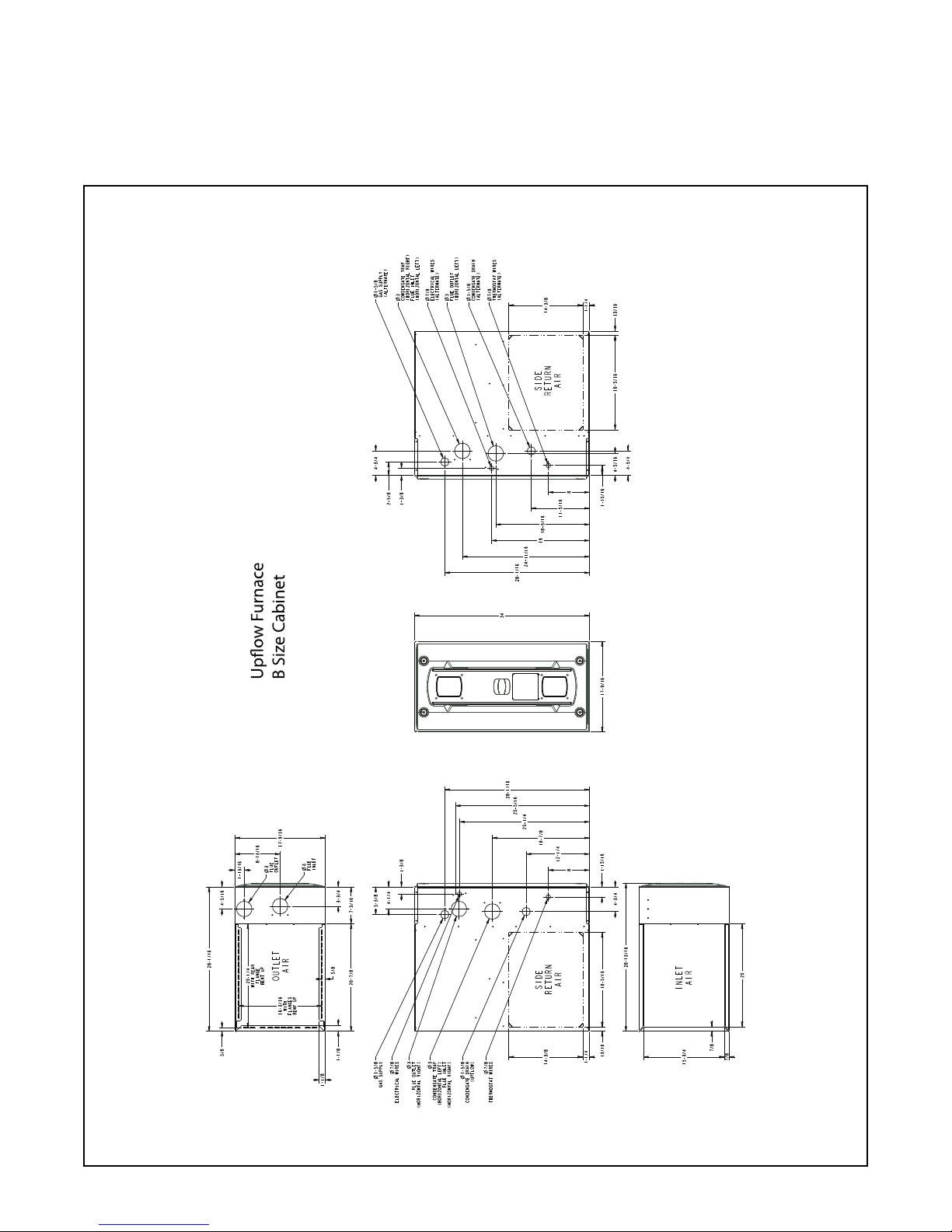

Outline Drawings

12

18-CE01D1-1F-EN

Page 13

OOuuttlliinnee DDrraawwiinnggss

18-CE01D1-1F-EN

13

Page 14

OOuuttlliinnee DDrraawwiinnggss

14

18-CE01D1-1F-EN

Page 15

OOuuttlliinnee DDrraawwiinnggss

18-CE01D1-1F-EN

15

Page 16

OOuuttlliinnee DDrraawwiinnggss

16

18-CE01D1-1F-EN

Page 17

OOuuttlliinnee DDrraawwiinnggss

18-CE01D1-1F-EN

17

Page 18

Furnace General Installation

Fits 5/16” Allen wrench

The following sections give general instructions for the

installation of the gas furnaces.

Note: Use a 5/16” Allen wrench to remove the front panel.

S-Series Furnace Panel Removal

18

18-CE01D1-1F-EN

Page 19

Gas Piping

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Important: When converting the gas piping from the factory default,

Upflow furnace with gas piping on left side

Downflow furnace with gas piping on left side Downflow furnace with gas piping on right side

the plug must be removed from the new gas piping

location and swapped with the grommet from the default

location. The upflow furnace default is left side gas

piping. The downflow furnace default is right side gas

piping.

Upflow furnace with gas piping on right side

18-CE01D1-1F-EN

19

Page 20

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Important: When converting the gas piping from the factory default,

Horizontal left furnace with gas piping out left side

Horizontal right furnace with gas piping out left side Horizontal right furnace with gas piping out right side

the plug must be removed from the new gas piping

location and swapped with the grommet from the default

location. The upflow furnace default is left side gas

piping. The downflow furnace default is right side gas

piping.

Horizontal left furnace with gas piping out right side

20

18-CE01D1-1F-EN

Page 21

The upflow/horizontal furnace is shipped standard for left side

installation of gas piping. An opening with plug is provided on the right

side for an alternate gas piping arrangement.

The installation of piping shall be in accordance with piping codes and

the regulations of the local gas company. Pipe joint compound must be

resistant to the chemical reaction with liquefied petroleum gases.

Important: If local codes allow the use of flexible gas appliance

connector, always use a new listed connector. Do not use

a connector which has previously service another gas

appliance.

Refer to the piping table for delivery sizes. Connect gas supply to the

unit, using a ground joint union and a manual shut-off valve. National

codes require a condensation drip leg to be installed ahead of the gas

valve.

The furnace and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig (3.5 kPa).

The furnace must be isolated from the gas supply piping by closing its

individual manual shut-off valve during any pressure testing of the

gas supply piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

Note: Maximum pressure to the gas valve for natural gas is 13.8" W.

C. Minimum pressure is 5.0" W.C. Maximum pressure to the

gas valve for propane is 13.8" W.C. Minimum pressure is 10.0"

W.C.

All gas fittings must be checked for leaks using a soapy solution before

lighting the furnace.DO NOT CHECK WITH AN OPEN FLAME!

For LP conversions on all S-Series Furnaces, use BAYLPSS400A

conversion kit with stainless steel burners.

When installing our furnaces in a manufactured house, use.

Manufactured Housing Accessory Kit, BAYMFGH200A.

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

NATURAL GAS ONLY

TABLE OF CUBIC FEET PER HOUR OF GAS

FOR VARIOUS PIPE SIZES AND LENGTHS

PIPE

SIZE

1/2 132 92 73 63 56 50 46

3/4 278 190 152 130 115 105 96

1–1/4 1050 730 590 520 440 400 370

This table is based on Pressure Drop of 0.3 inch W.C. and 0.6 SP.

GR. Gas

10 20 30 40 50 60 70

1 520 350 285 245 215 195 180

INPUT

RATING

BTUH

40,000 2 45 56

60,000 3 45 56

80,000 4 45 56

100,000 5 45 56

120,000 6 45 56

NUMBER OF

BURNERS

LENGTH OF PIPE

ORIFICE SIZES

MAIN BURNER ORIFICE

DRILL SIZE

NAT. GAS LP GAS

18-CE01D1-1F-EN

21

Page 22

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Combustion and Input Check

1. Make sure all gas appliances are off except the furnace.

2. Clock the gas meter with the furnace operating (determine the

dial rating of the meter) for one revolution.

3. Match the "Sec" column in the gas flow (in cfh) the table with the

time clocked.

4. Read the "Flow" column opposite the number of seconds clocked.

5. Use the following factors if necessary:

a. For 1 Cu. Ft. Dial Gas Flow CFH = Chart Flow Reading ÷ 2

b. For 1/2 Cu Ft. Dial Gas Flow CFH = Chart Flow Reading ÷ 4

c. For 5 Cu. Ft. Dial Gas Flow CFH = 10X Chart Flow Reading ÷ 4

6. Multiply the final figure by the heating value of the gas obtained

from the utility company and compare to the nameplate rating.

This must not exceed the nameplate rating.

Gas Flow in Cubic Feet Per Minute

2 Cubic Foot Dial

Sec. Flow Sec. Flow Sec. Flow Sec. Flow

8 900 29 248 50 144 82 88

9 800 30 240 51 141 84 86

10 720 31 232 52 138 86 84

11 655 32 225 53 136 88 82

12 600 33 218 54 133 90 80

13 555 34 212 55 131 92 78

14 514 35 206 56 129 94 76

15 480 36 200 57 126 96 75

16 450 37 195 58 124 98 73

17 424 38 189 59 122 100 72

18 400 39 185 60 120 104 69

19 379 40 180 62 116 108 67

20 360 41 176 64 112 112 64

21 343 42 172 66 109 116 62

22 327 43 167 68 106 120 60

23 313 44 164 70 103 124 58

24 300 45 160 72 100 128 56

25 288 46 157 74 97 132 54

26 277 47 153 76 95 136 53

27 267 48 150 78 92 140 51

28 257 49 147 80 90 144 50

22

18-CE01D1-1F-EN

Page 23

Gas Valve Adjustment

Changes can be made by adjusting the manifold pressure, or changing

orifices (orifice change may not always be required). To adjust the

manifold pressure:

1. Turn off all electrical power to the system.

2. Attach a manifold pressure gauge with flexible tubing to the outlet

pressure boss marked "OUT P" on White- Rodgers gas valve

model 36J.

3. Loosen (Do Not remove) the pressure tap test set screw one turn

with 3/32" hex wrench.

a. The pressure tap adjustment kit (KIT07611) contains a 3/32"

hex wrench, a 5/16" hose and a connector and can be

ordered through Global Parts.

4. Turn on system power and energize valve.

5. Adjust 1st stage gas heat by removing the low (LO) adjustment

regulator cover screw.

a. To increase outlet pressure, turn the regulator adjust screw

clockwise.

b. To decrease outlet pressure, turn the regulator adjust screw

counterclockwise.

c. Adjust regulator until pressure shown on manometer

matches the pressure specified in the table.

The input of no more than nameplate rating and no less than

93% of the nameplate rating, unless the unit is derated for

high altitude.

d. Replace and tighten the regulator cover screw securely.

6. Adjust 2nd stage gas heat by removing the high (HI) adjustment

regulator cover screw.

a. To increase outlet pressure, turn the regulator adjust screw

clockwise.

b. To decrease outlet pressure, turn the regulator adjust screw

counterclockwise.

c. Adjust regulator until pressure shown on manometer

matches the pressure specified in the table.

The input of no more than nameplate rating and no less than

93% of the nameplate rating, unless the unit is derated for

high altitude.

d. Replace and tighten the regulator cover screw securely.

7. Cycle the valve several times to verify regulator setting.

a. Repeat steps 5-7 if needed.

8. Turn off all electrical power to the system.

9. Remove the manometer and flexible tubing and tighten the

pressure tap screw.

10. Using a leak detection solution or soap suds, check for leaks at the

pressure outlet boss and pressure tap test screw.

11. Turn on system power and check operation of the unit.

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Fuel Manifold Pressure Settings (inches w.c.)

Fuel 2nd Stage Max. 1st Stage Max.

Natural Gas 3.5” W.C. 1.7” W.C.

LP Gas 10.0” W.C. 6.0” W.C.

18-CE01D1-1F-EN

23

Page 24

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

High Altitude Derate

Input ratings (BTUH) of these Furnaces are based on sea level

operation and should not be changed at elevations up to 2,000 ft. (610

m).

If the installation is 2,000 ft. (610 m) or above, the Furnace input rate

(BTUH) shall be reduced 4% for each 1,000 ft. above sea level.

Installations of this furnace at altitudes above 2,000 ft. (610 m) shall

be made utilizing the Vent Length table and/or Part Numbers for

Replacement Orifices table in these installation instructions.

The Furnace input rate shall be checked by clocking the gas flow rate

(CFH) and multiplying by the heating value obtained from the local

utility supplier for the gas being delivered at the installed altitude.

Input rate changes can be made by adjusting the Manifold Pressure

(min 3.0 - max 3.7 in. W.C. - Natural Gas) or changing orifices (orifice

change may not always be required).

If the desired input rate can not be achieved with a change in Manifold

Pressure, then the orifices must be changed. LP installations will

require an orifice change.

Important: Reinstall the replacement orifices to the same depth as

the orifices supplied with the equipment.

See the table for help in selecting orifices if orifice change is required.

Furnace input rate and temperature rise should be checked again after

changing orifices to confirm the proper rate for the altitude.

The vent length table shows the required vent lengths for installations

at various altitudes. Installations above 12,000 feet are not allowed.

Turn the main Gas Valve toggle switch within the unit to the "OFF"

position. Turn the external gas valve to "ON". Purge the air from the

gas lines. After purging, check all gas connections for leaks with a

soapy solution – DO NOT CHECK WITH AN OPEN FLAME. Allow 5

minutes for any gas that might have escaped to dissipate.

LP Gas being heavier than air may require forced ventilation. Turn the

toggle switch on the Gas Valve in the unit to the "ON" position.

PART NUMBERS FOR REPLACEMENT ORIFICES

DRILL SIZE PART

NUMBER

44 ORF00501 54 ORF00555

45 ORF00644 55 ORF00693

46 ORF00909 56 ORF00907

47 ORF00910 57 ORF00908

48 ORF01099 58 ORF01338

49 ORF00503 59 ORF01339

50 ORF00493

DRILL SIZE PART

NUMBER

The table lists the main burner orifices

used with the furnace. If a change of

orifices is required to correct the furnace

input rating refer to the part number for

replacement orifices table.

Installation of this furnace at altitudes

above 2000 ft (610m) shall be in

accordance with local codes, or in the

absence of local codes, the National Fuel

Gas Code, ANSI Z223.1/NFPA 54 or

National Standard of Canada, Natural

Gas and Propane Installation Code, CSA

B149.1.

Orifice

Twist Drill

Size If

Installed at

Sea Level

42 42 43 43 43 44 44 45 46 47

43 44 44 44 45 45 46 47 47 48

44 45 45 45 46 47 47 48 48 50

45 46 47 47 47 48 48 49 49 50

46 47 47 47 48 48 49 49 50 51

47 48 48 49 49 49 50 50 51 52

54 54 55 55 55 55 55 56 56 56

55 55 55 55 56 56 56 56 56 57

56 56 56 57 57 57 58 59 59 60

57 58 59 59 60 60 61 62 63 63

58 59 60 60 61 62 62 63 63 64

From National Fuel Gas Code — Table F-4

2000 3000 4000 5000 6000 7000 8000 9000 10000

Altitude Above Sea Level

and Orifice Required at Other Elevations

24

18-CE01D1-1F-EN

Page 25

General Venting

FIELD SUPPLIED

2” COUPLING

LABEL

SAYS

“TOP”

2" TO 3" COUPLING

CPL00938

BAYREDUCE may be

used in Canadian

applications to meet

ULC-S636

CPL00938 IS FACTORY

SUPPLIED ONLY WITH THE

120,000 BTUH UPFLOW

FURNACE MODELS

FIELD SUPPLIED

2” COUPLING

2" TO 3" COUPLING

CPL00938 IS FACTORY

SUPPLIED ONLY WITH THE

120,000 BTUH UPFLOW

FURNACE MODELS

CPL00938

BAYREDUCE may be

used in Canadian

applications to meet

ULC-S636

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

FURNACE EXHAUST MUST BE VENTED TO THE OUTDOORS. THESE

FURNACES ARE INDUCED DRAFT VENTED AND MUST NOT BE

CONNECTED TO ANY VENT SERVING ANOTHER APPLIANCE. PLEASE

NOTE THAT THESE FURNACES USE POSITIVE-PRESSURE VENT

SYSTEMS.

Proper venting is essential to obtain maximum efficiency from a

condensing Furnace. Proper installation of the vent system is

necessary to assure drainage of the condensate and prevent

deterioration of the vent system.

ETL has certified the design of condensing Furnaces for a minimum of

0" clearance from combustible materials to single wall plastic vent

pipe.

The recommended system is assembled from 2" or 3" plastic pipe and

fittings found in the Approved Vent Pipe Materials Table. Where the

system is routed to the outdoors through an existing masonry

chimney containing flue products from another gas appliance, or

where required by local codes, then 3" venting of Type 29- 4C

stainless steel must be used in place of PVC material.

These Furnaces have been classified as CATEGORY IV Furnaces in

accordance with ANSI Z21.47 “latest edition” standards. Category IV

Furnaces operate with positive vent pressure and with a vent gas

temperature less than 140°F above the dewpoint. These conditions

require special venting systems, which must be gas tight and water

tight.

3” Venting requirements

Important: To determine if your application requires 3” venting, see

the Maximum Vent Length Table.

Important: Horizontal venting application must use the 2” x 3” offset

reducing coupling. Vertical venting applications to not

require the reducing coupling to be offset.

When the vent pipe is exposed to temperatures below

freezing, e.g., when it passes through unheated spaces, etc.,

the pipe must be insulated with 1/2 inch (22.7 mm) thick

Armaflex-type insulation or equal.

If the space is heated sufficiently to prevent freezing, then the

insulation will not be required. If domestic water pipes are not

protected from freezing then the space meets the condition of

a heated space.

Note: If your furnace comes with a factory supplied 2" X 3" offset

reducing coupling it is used for 3" vent pipe installation. Make

sure the marking "TOP" is located on the top side of the pipe in

horizontal venting applications. The straight side of the

coupling must be on bottom for proper drainage of condensate.

Note: For Canadian applications, BAYREDUCE 2” x 3” offset reducing

coupling meets ULC-S636 requirements. Make sure the

marking "TOP" is located on the top side of the pipe. The

straight side of the coupling must be on bottom for proper

drainage of condensate in horizontal venting.

Note: When an existing Furnace is removed from a venting system

serving other gas appliances, the venting system is likely to be

too large to properly vent the remaining attached appliances.

Important: These Furnaces may be installed as Direct Vent (sealed

combustion) or as Nondirect Vent (single pipe). The

Furnaces are shipped DIRECT VENT with sealed

combustion.

Important: Products installed in Canada must use vent systems that

are certified to the Standard for Type BH Gas Venting

Systems (ULC S636) for Class II-A venting systems (up

to 65°C). Components of the vent system must not be

interchanged with other vent systems or unlisted pipe or

fittings. Plastic components, specified primers, and glues

must be from a single system manufacturer and not

intermixed with other system manufacturer's vent

system parts. In addition, the first three feet of the vent

pipe must be visible for inspection.

18-CE01D1-1F-EN

25

Page 26

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Special Case Venting

Special instructions for direct vent furnace air intake.

In certain applications, particularly when the furnace is located in a

basement, there are certain conditions that can be met where warm

humid air from the outside is drawn into combustion air piping. If the

area where the piping is located is conditioned below 70° F,

condensation could occur inside the piping and ultimately drain into

the furnace compartment, which could lead to premature component

failure.

We recommend following one of the options to prevent this condition

from occurring and possibly damaging components within the

furnace:

Option 1

If possible, slope the inlet combustion air piping away from the

furnace. Condensation that may occur will now drain outside of the

home. The combustion air outlet piping must remain sloped back to

the furnace.

Note: Inlet air piping is not considered to be part of the venting

system. The inlet air piping may be made from PVC.

26

18-CE01D1-1F-EN

Page 27

Option 2 — Top combustion air intake

If sloping the combustion air intake pipe is not possible, install a DWV

Tee as close to the furnace as possible with drain and trap to prevent

condensation from occurring in the furnace cabinet. Do not tee AC

condensate and combustion air condensate trap together.

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Option 3 — Side combustion air intake

If sloping the combustion air intake pipe is not possible, install a

sanitary Tee as close to the furnace as possible with drain and trap.

18-CE01D1-1F-EN

27

Page 28

Furnace

Vent

Air

Inlet

Furnace

Air

Inlet

Vent

Attic

Vent

(See Note)

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Vent Terminations

For DIRECT VENT APPLICATION: The Furnaces must be vented to

the exterior of the house and combustion air MUST come through the

inlet air pipe from OUTSIDE AIR.

Note: BAYVENT* accessories can be used for inlet and outlet

terminals when the pipes do not exit the structure together. For

Canadian applications, venting systems must meet ULC-S636

requirements.

For NONDIRECT VENT APPLICATION: The Furnace shall be vented

to the exterior of the house, but combustion air may enter from the

surrounding area as long as combustion air requirements are met.

(See AIR FOR COMBUSTION AND VENTILATION)

FURNACE VENT / INLET PIPE INSTALLATION IN TWO

PRESSURE ZONE CONFIGURATIONS ARE NOT ALLOWED

Note: For single pressure zone applications, see the Horizontal

Venting section.

The following are EXAMPLES ONLY.

EX. 1—

Example 1 shows the vent pipe exhausting through the roof and the

inlet air coming from the interior of the house. The inlet air coming

from the interior of the house must meet combustion requirements for

area, etc., as shown in the section AIR FOR COMBUSTION AND

VENTILATION in this Installer’s Guide.

Vent terminations

• BAYVENT200B

• BAYAIR30AVENTA

Vent terminations — Canadian applications. Meets ULC-S636

requirements.

• BAYVENTCN200B

• BAYAIR30CNVENT

EX. 2—

The inlet air does not have to come from outside the structure.

Example 2 shows the inlet air, may come from the attic if the

requirements for combustion air are met as shown in the section AIR

FOR COMBUSTION AND VENTILATION.

Note: If only the flue gas pipe is to the outside of the structure, a

straight section of pipe (long enough to exit the Furnace

cabinet) must be attached to the inlet air side with an elbow

(which is 5 to 10 equiv. ft.) installed on the end to prevent dust

and debris from falling directly into the Furnace.

Attaching Vent Piping

VENT FITTING MATERIAL – PLASTIC

Gas and liquid tight single wall vent fittings, designed for resistance to

corrosive flue condensate, MUST be used throughout.

Listed in the Approved Vent Pipe Materials table are designations for

different types of 2" and 3" size pipe and fittings that meet these

requirements. The materials listed are various grades of PVC, CPVC,

ABS, and DuraVent PolyPro®.

28

18-CE01D1-1F-EN

Page 29

ATTACHING VENT PIPING

FFuurrnnaaccee GGeenneerraall IInnssttaallllaattiioonn

Important: Products installed in Canada must use vent systems that

are certified to the Standard for Type BH Gas Venting

Systems (ULC S636) for Class II-A venting systems (up

to 65°C). Components of the vent system must not be

interchanged with other vent systems or unlisted pipe or

fittings. Plastic components, specified primers, and glues

must be from a single system manufacturer and not

intermixed with other system manufacturer's vent

system parts. In addition, the first three feet of the vent

pipe must be visible for inspection.

PIPE JOINTS: All joints must be fastened and sealed per manufacturer

instructions and local and national codes to prevent escape of

combustion products into the building.

MANUFACTURED MODULAR VENTING SYSTEMS

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE PPOOIISSOONNIINNGG

HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg mmaayy rreessuulltt iinn pprrooppeerrttyy

ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

SSeeee tthhee AApppprroovveedd VVeenntt PPiippee MMaatteerriiaallss ttaabbllee ffoorr

mmaannuuffaaccttuurreedd mmoodduullaarr vveennttiinngg ssyysstteemmss tthhaatt aarree

aapppprroovveedd ffoorr uussee wwiitthh tthhiiss pprroodduucctt.. FFoollllooww tthhee

mmaannuuffaaccttuurreerr’’ss iinnssttaallllaattiioonn iinnssttrruuccttiioonnss wwhheenn

iinnssttaalllliinngg tthhee vveennttiinngg ssyysstteemm..

For manufactured modular venting systems that are approved with

this product see PVC vent fitting material table. Do not drill into

polypropelene venting pipes

WWAARRNNIINNGG

CCAARRBBOONN MMOONNOOXXIIDDEE PPOOIISSOONNIINNGG

HHAAZZAARRDD!!

FFaaiilluurree ttoo ffoollllooww tthhiiss WWaarrnniinngg mmaayy rreessuulltt iinn pprrooppeerrttyy

ddaammaaggee,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr ddeeaatthh..

DDoo nnoott uussee cceemmeenntt oonn ppoollyypprrooppyylleennee vveennttiinngg

ssyysstteemmss.. FFoollllooww tthhee mmaannuuffaaccttuurreerr’’ss iinnssttaallllaattiioonn

iinnssttrruuccttiioonnss wwhheenn iinnssttaalllliinngg tthhee vveennttiinngg ssyysstteemm..

BONDING OF PVC

Note: It is recommended that the first joints from the Furnace be

connected and sealed with high temperature RTV. This will

enable the pipes to be removed later without cutting.

Be sure to properly support these joints.

Commercially available solvent cement for PVC must be used to join

PVC pipe fittings. Follow instructions on container carefully.

Pipe and Fitting – ASTM D1785, D2466, D2661, & D2665

PVC Primer and Solvent Cement – ASTM D2564

Procedure for Cementing Joints – Ref ASTM D2855

1. Cut pipe square, remove ragged edges and burrs. Chamfer end of

pipe, then clean fitting socket and pipe joint area of all dirt,

grease, moisture or chips.

2. After checking pipe and socket for proper fit, wipe socket and pipe

with cleaner-primer. Apply a liberal coat of primer to inside

surface of socket and outside of pipe.

DO NOT ALLOW PRIMER TO DRY BEFORE APPLYING CEMENT.

3. Apply a thin coat of cement evenly in the socket. Quickly apply a

heavy coat of cement to the pipe end and insert pipe into fitting

with a slight twisting movement until it bottoms out.

4. Hold the pipe in the fitting for 30 seconds to prevent tapered

socket from pushing the pipe out of the fitting.

5. Wipe all excess cement from the joint with a rag. Allow 15

minutes before handling. Cure time varies according to fit,

temperature and humidity.