Ingersoll-Rand R Series Installation, Operation & Maintenance Manual

REFRIGERATED AIR DRYERS

R Series VCD Dryer

INSTALLATION, OPERATION &

MAINTENANCE MANUAL

Service Department

1-800-526-3615

REV:1203 StarWatch ID:

r

r

w

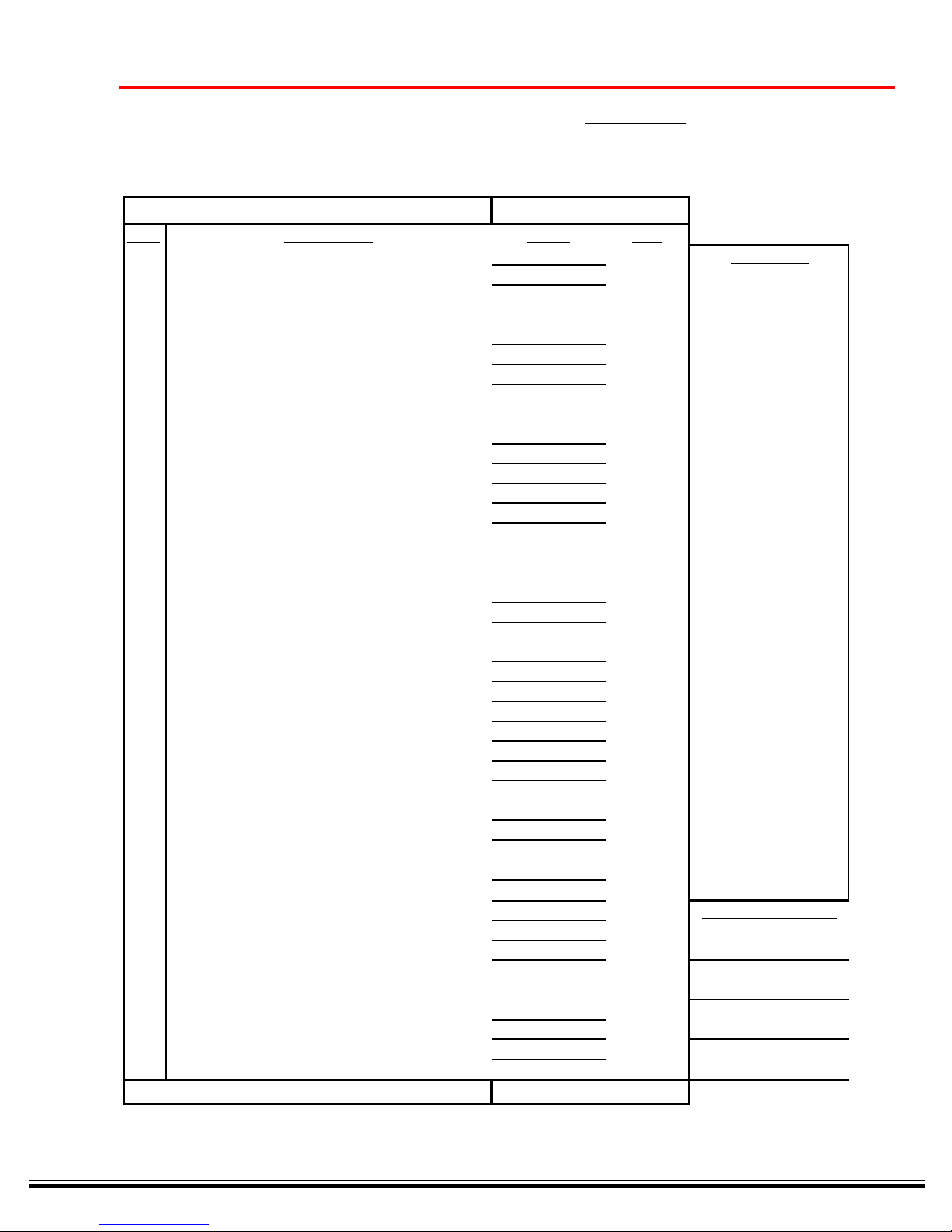

SPECIFICATIONS

Seria l No. Model

ITEM DESCRIPTION VALUE UNIT

1 -------------------Dryer Des ign Max Air Flow @ PSI SCFM/PSI Comments:

2 --------------------------------Dryer Design Max Air PSI PSI

3

-----------------Dryer Design Max Inlet Temperature °F

-----------------------------------------------Supply Voltage VOLT CHARGE: LBS.

4

5 -------------------------------------------------------------Cyc le HZ

6 ------------------------------------------------------------Phase PH

7

----------------------------------Number of Compressors ELEMENT:

8

9

--------------------------------Compres sor Hors e Power HP

10 --------------------------------------------------------------RLA AMPS

--------------------------------(copper) THHN Wire Size AWG #

11

11 ------------------------------Fuse / Circ uit Breaker Size AMP

------------------------------------------Nema Starter Size #

12

13 --------------------------------------------------------Overload AMPS

2

REFRIGERANT

REPLACEMENT

-------------------------------------------Crankcase Heate

14

-------------------------------Crankcase Heater Voltage VOLT

15

----------------------------------------------Number of Fans

16

17 -----------------------------------Fan Motor Horse Powe

18 -----------------------------------------------Max Amp Dra

--------------------------------(copper) THHN Wire Size AW G #

19

------------------------------------------------------Fuse Size AMP

19

--------(enter n/a if not used) Nema Starter Size #

20

---------------------------------------------Overload Setting AMPS

21

----------Water Condenser Max Inlet Temperature °F

22

--------Water Condenser Minimum Inlet Pressure PSI

23

-------------------------Control Transformer VA Rating VA

24

----------------Control Trans former Primary Voltage VOLT

25

WATTS

HP

AMPS

26 -------------Control Trans former Primary Fuse Size AMP Electrical Dwg No.'s

27

------------Control Trans former Secondary Voltage VOLTS

--------Control Trans former Secondary Fus e Size AMP

28

-----------------------------Refrigerant Low PSI Setting PSI

29

----------------------------Refrigerant High PSI Setting PSI

30

-------------------------------Fan Bank #1 PSI Settings ON / OFF

31

-------------------------------Fan Bank #2 PSI Settings ON / OFF

32

-------------------------------Refrigerant Oil PSI Setting PSI

33

Control Center SN: Rev. V

Processed By: , Date:

TABLE OF CONTENTS

3

Page

1. Pre-Installation.................... 4

• Inspection, Handling and Setup

• Cautions and Operating Warnings

2. Dryer Installation................. 4

• Location of Dryer

• Air line Plumbing

• Water Line Piping (Water Cooled Units)

• Electrical Connections

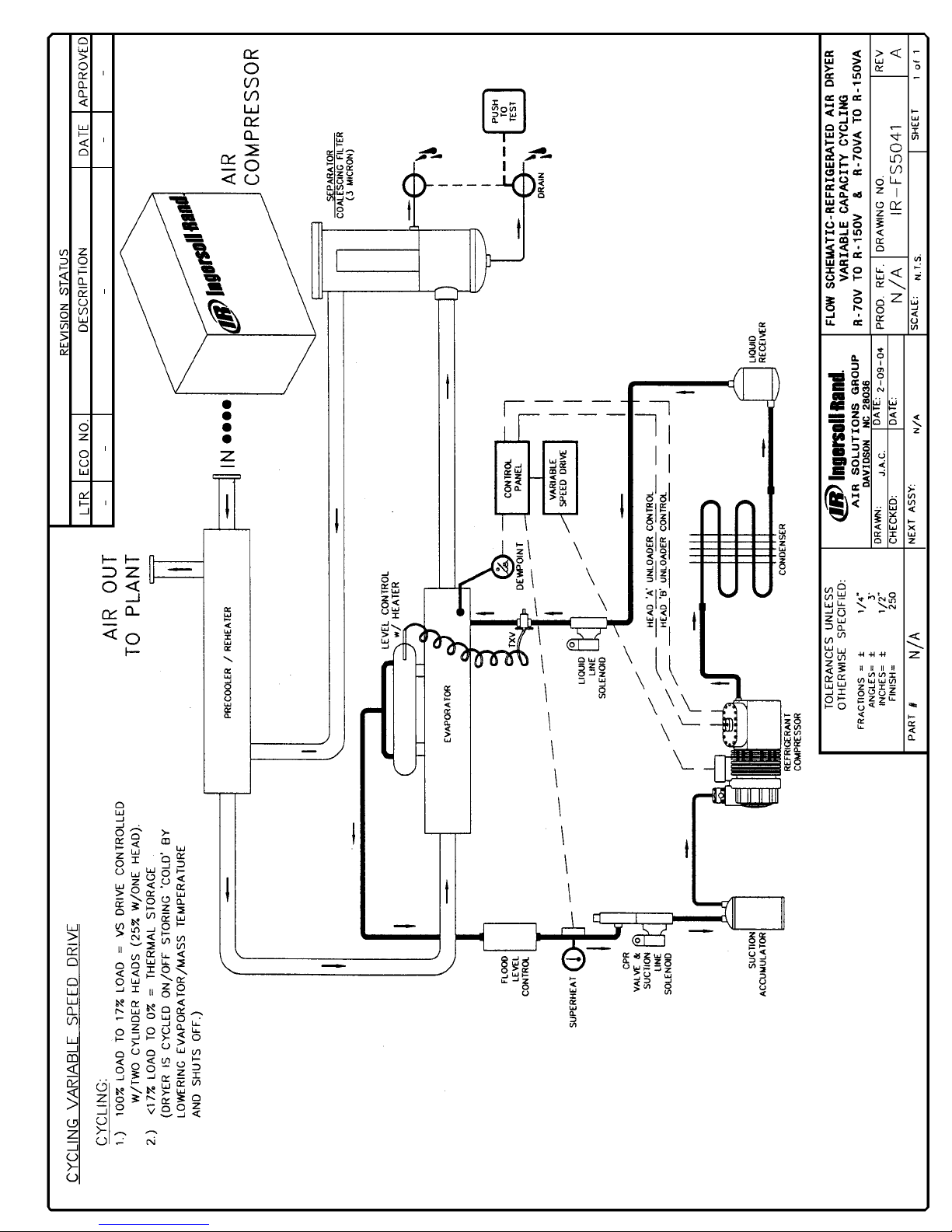

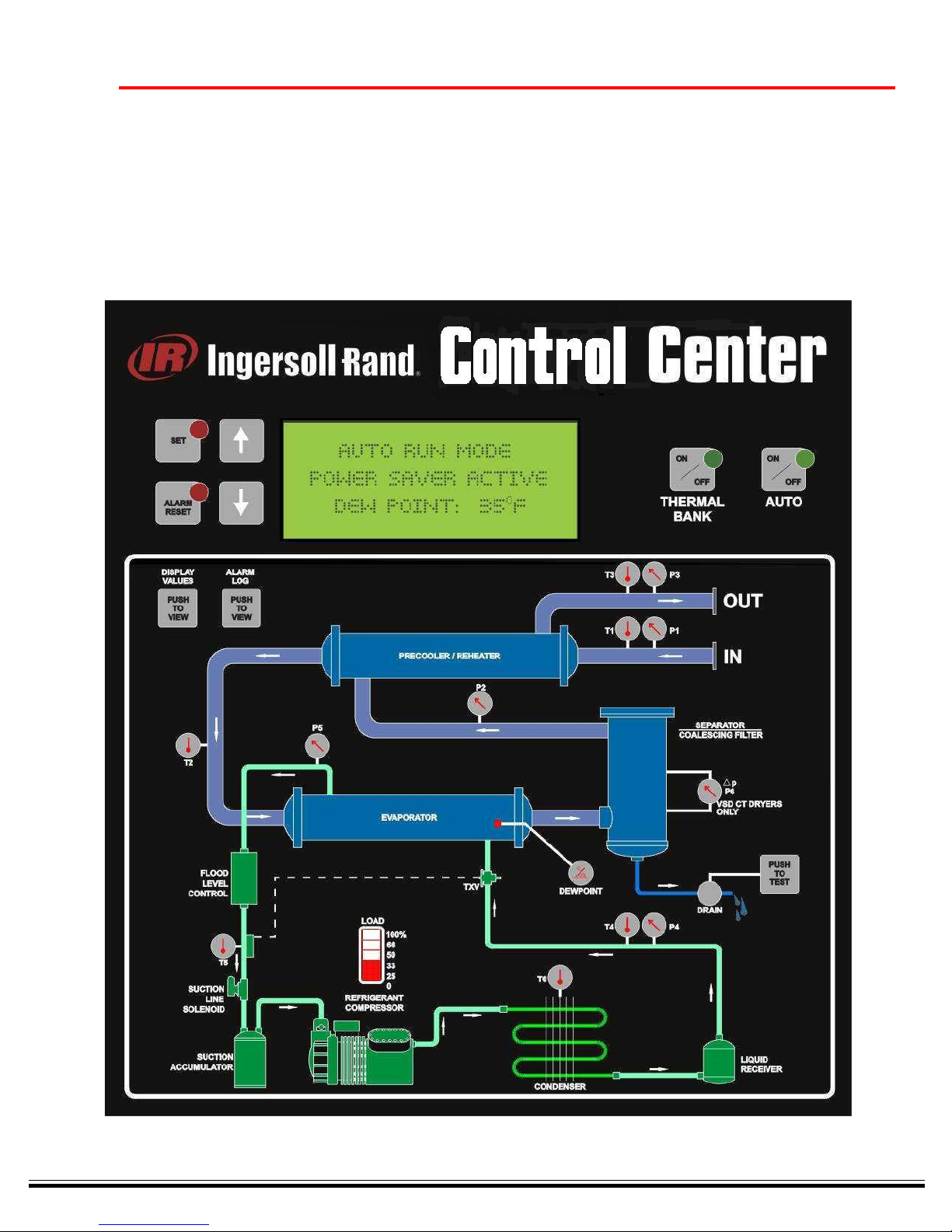

3. Principle of Operation.......... 4-5

• Air System

• Refrigeration System

• Operation

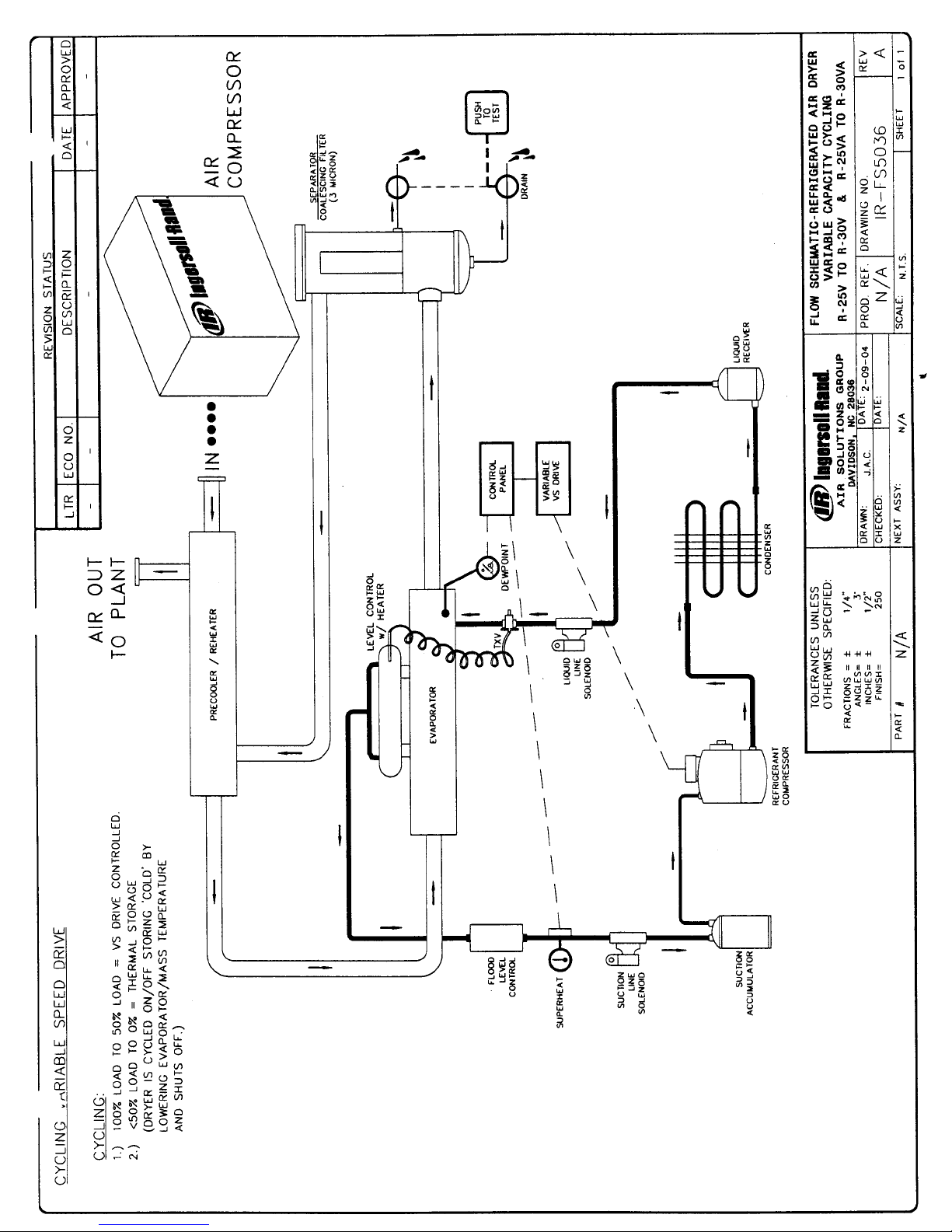

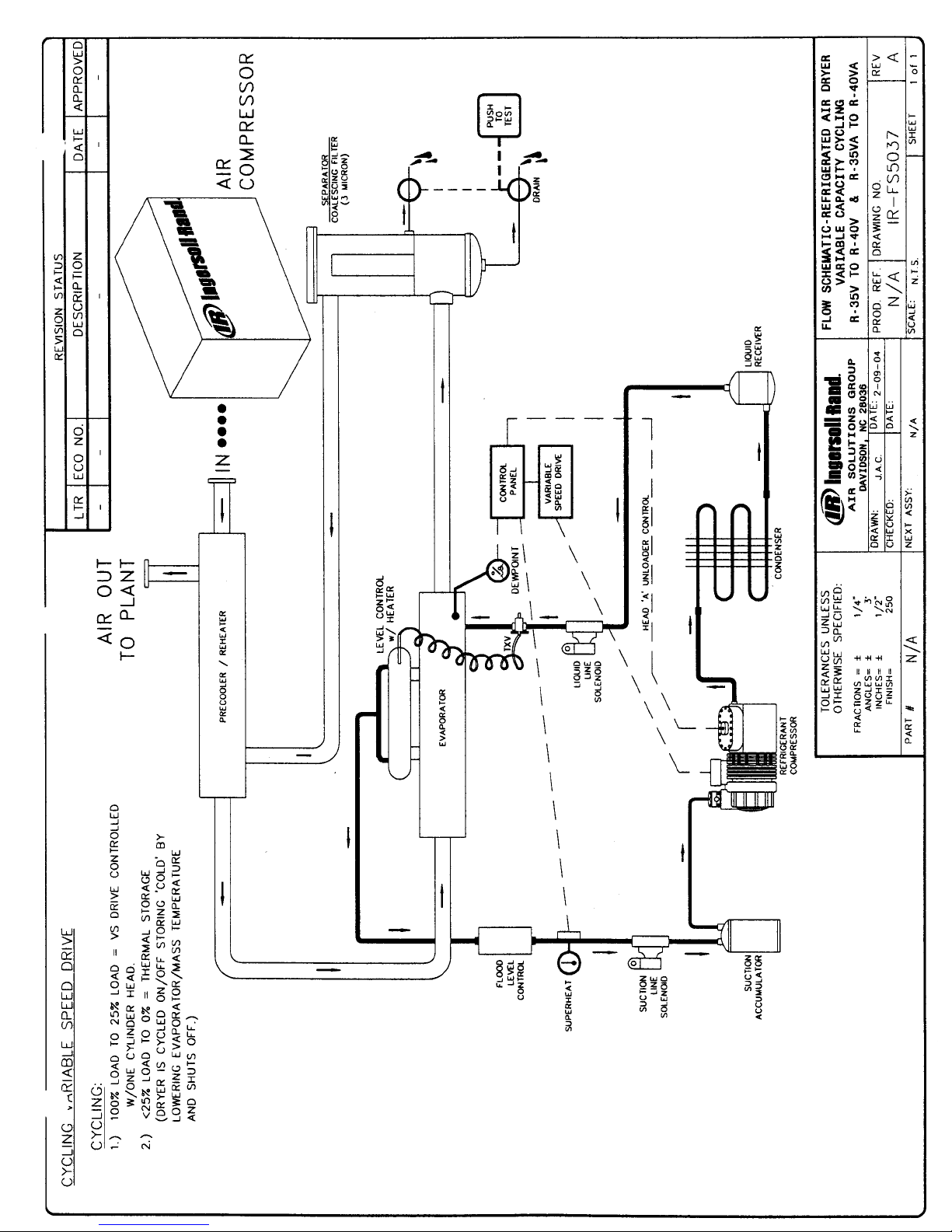

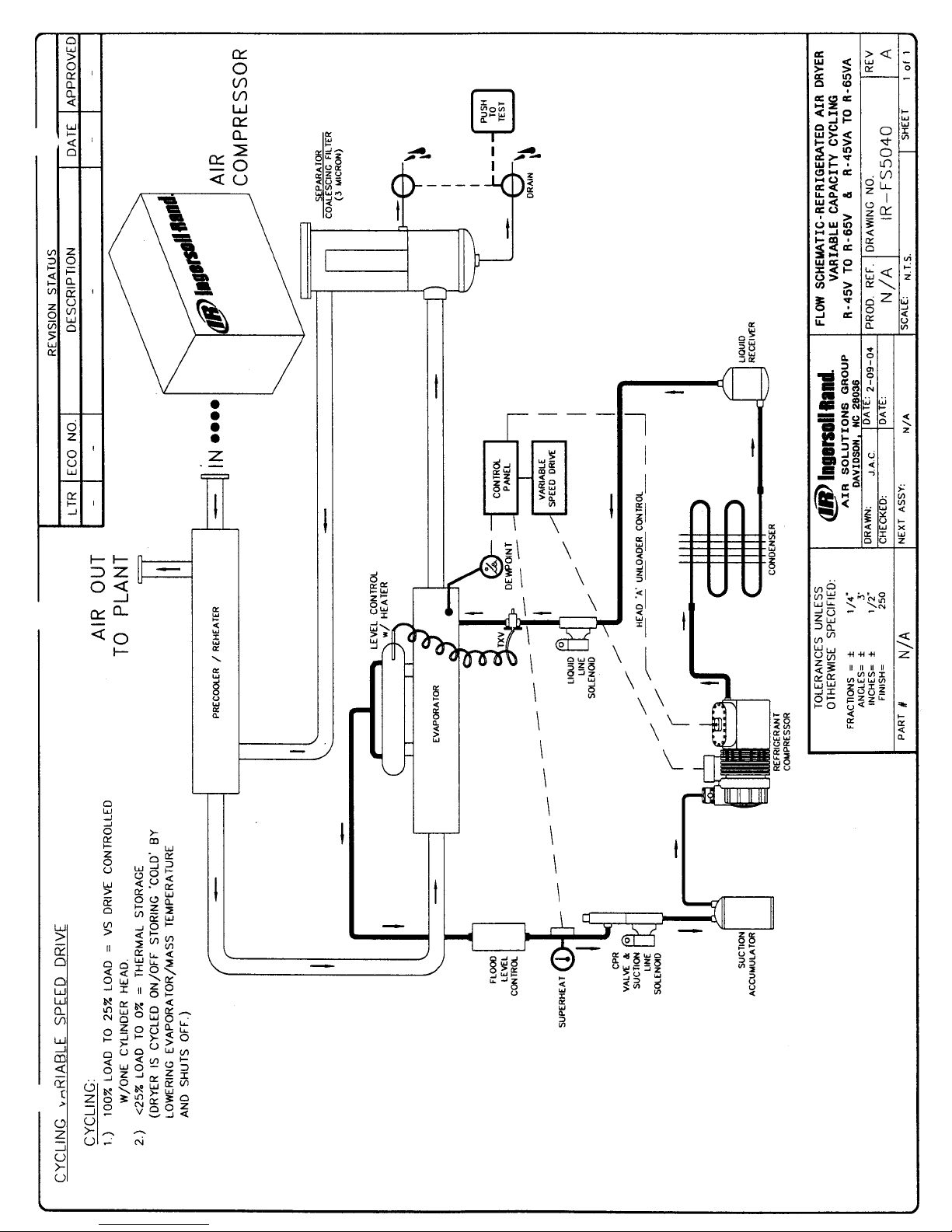

4. Flow Schematics ............... 6-9

5. Routine Maintenance

and Service.......................... 10

6. For The Refrigeration

Service Technician.............. 10-11

• Refrigerant, Oil and Dryers

• Evaporator Leaks

• Refrigerant Control Valves

• Drains

• Electronic Controls

• Factory Assistance

Page

7. Trouble Shooting Guide....... 12-13

8. Warranty.............................. 14-15

• Warranty procedure

• Maintenance records

• Coverage

• Standard Warranty

• Heat Exchanger Warranty

• Not covered by Standard Warranty

• Chargeable service calls

• Warranty registration

• International Warranty

• Disclaimer

• In conclusion

• Warranty registration card

(front & back)

9. Operational Controls...........16 - 36

10. Electricals & Applicable

Drawings.............................37 - 75

• Water Cooled

• Air Cooled

4

1. PRE-INSTALLATION

Inspection, Handling and Setup

Inspect the dryer carefully upon arrival and note any

damage on the freight bill. File a notice of concealed

damage if: (1) there are any dents in the cabinet; (2) the air

and drain pipes are not straight; (3) there is any sign of oil

on the skid floor. File these claims with the carrier

immediately!

Cautions and Operating Warnings

• Never work on unit under air pressure.

• Never work on unit when power is connected.

• Do not over pressurize unit.

• Install unit in a clean, cool (50º - 85ºF); well lighted

location.

• Do not shut unit off at disconnect switch except during

servicing. Unit must be turned on and off by the panel

switch located on the dryer.

• Do not pass air through the dryer while the dryer is in

the “OFF” position.

• Do not operate dryer at abnormal conditions (high flow,

high inlet temperature, high ambient, high inlet pressure, etc.)

2. DRYER INSTALLATION

Location of Dryer

Unless supplied for special conditions, the air cooled

dryers must be located in an area with an ambient temperature between 50º and 100ºF., and free from explosive

and corrosive fumes. High ambient temperatures affect the

outlet dew point of the dryer. For every 10ºF of ambient

temperature over 100ºF, a decrease of 6% of dryer performance is encountered with air cooled dryers. The unit

must not operate in an ambient of over 100ºF. For ambient

conditions of over 100ºF, water cooled dryers are suggested and are available upon request.

CAUTION – Three feet of space must be allowed between

all open grills and walls or other objects. If the dryer is

installed in a confined area, an exhaust system must be

provided to avoid excessive recirculation of hot room air.

Air line Plumbing

All connections are made to the outside of the cabinet as

follows:

• Air plumbing must be supported independently of the

dryer.

• If vibration is present, flexible metal hoses must be

installed to prevent it from being transmitted to the dryer.

• Use unions or flange joints.

• Bypass piping around the dryer is recommended for

ease in servicing or removal of unit if necessary.

• Direction of flow through the dryer must be observed. A

check valve on the outlet of the dryer to prevent back flow

and false loading is recommended.

NOTE: Use two wrenches when connecting to dryer piping

so as to prevent damage to internal air or water lines.

Water Line Piping (Water Cooled Units)

On water cooled units, install a strainer ahead of the water

inlet. Dryers are designed for 85ºF inlet water temperature.

Higher water temperature reduces dryer capacity. Minimum

water pressure is 25 psi. Maximum water pressure is 105

psi.

Electrical Connections

Before connecting electrical power to the dryer:

• Check for correct voltage and phase at electrical connection box.

• Install a fused disconnect switch near the dryer.

• Connect power to the stripped leads located in the

electrical connection box or to main lugs of contactor,

whichever is necessary.

(NOTE: All units must be externally grounded to protect

against the possibility of severe electrical shock.)

• CAUTION: Wire the dryer separately from the air

compressor. The dryer must NOT cycle on and off with

the air compressor.

• Phase rotation is only important if the dryer has a 3

phase condenser fan. Fans must PULL air through the

condenser coil.

• Crankcase heaters are pre-wired at the factory to the

line side of the terminal box or contractor. Heaters must

be energized at all times, therefore the main disconnect

must be left on except when servicing the dryer.

3. PRINCIPLE OF OPERATION

The VCD REFRIGERATED AIR DRYER is designed to

operate automatically and continuously from no load to full

load without freeze up.

Air System:

The major air system components are the air to air

PRECOOLER / REHEATER, the EVAPORATOR, and the

MECHANICAL SEPARATOR.

Hot, wet air enters the inlet of the precooler/reheater where it

is cooled by the outgoing air. The air then enters the

evaporator where it is cooled by the refrigerant causing the

air’s humidity to condense into liquid water.

Next the air travels to the separator. First, the air enters the

separator where bulk oil and moisture are removed from the

air stream through a combination of centrifugal action and

velocity reduction. After removal from the air stream, all

contaminants are ejected from the air system by Demand

Control Solenoid Drains.

From the separator, the cold dry air enters the outgoing side

of the precooler/reheater where it is reheated by the hot

incoming air.

The precooler/reheater serves a triple purpose. By precooling the incoming air, it conserves refrigeration use and by

5

reheating the outgoing air, it serves to eliminate sweating of

pipes in the plant air system. Most important, it increases

the temperature dew point split, preventing moisture from

condensing out of the compressed air when the air is

expanded.

Refrigeration System

The major components of this system are the COMPRESSOR, the CONDENSER, and the EVAPORATOR. The

compressor pumps high pressure, high temperature gas to

the condenser. The heat is dissipated through finned tubes

with the assistance of motor driven fans. On water cooled

units the heat is dissipated through a water filled tube and

shell condenser.

During the cooling process, the refrigerant changes from a

heat laden vapor to a liquid. This liquid refrigerant flows from

the condenser to the filter dryer, and then through the sight

glass which indicates refrigerant level. Immediately before

the inlet of the evaporator is a thermostatic expansion valve

which regulates the refrigerant flow to the evaporator as low

pressure cold liquid. The cold refrigerant cools the air in the

side of the evaporator. As the low pressure liquid refrigerant

absorbs the heat from the air it boils and changes to a

vapor. This low pressure, low temperature vapor is then

returned to the refrigerant compressor where it is again

compressed to a high pressure, high temperature gas, and

the refrigeration cycle repeats itself.

VCD Dryers are rated to deliver full capacity (SCFM at 35ºF

pressure dew point air) at 100 PSI line pressure, 100ºF.

inlet air, in 50º to 100ºF ambient, at 2 to 4 PSI pressure

drop. Higher line pressures, up to rated maximum and

cooler inlet air increases capacity. Free liquid water, low

pressures, higher air temperatures and condensable

chemical vapors, decrease capacity. Consult the factory for

proper dryer sizing.

5. START UP

NOTE: Please read and understand the entire operation and

maintenance manual prior to starting the dryer. This is a

brief start up procedure for those familiar with dryer operation.

CAUTION: There should be no air flow through the dryer

before or during start up. It is recommended that the dryer

be installed with bypass piping to better service the unit.

DRYER START UP PROCEDURE:

1) Make main electrical connection to dryer and apply

power. Refer to dryer name plate or manual to determine correct voltage. Leave power on unit for 8 hours

before proceeding.

2) On water cooled units make sure there is proper water

pressure and temperature supplied to the water condenser. (Min 25 psi and max 85º F water temperature)

3) Dryers are shipped with

TAGGED refrigeration service

valves closed. TAGGED service valves must not be

opened until main power is permanently applied.

However, ONLY TAGGED service valves must be

opened prior to start up.

• Locate TAGGED service valves.

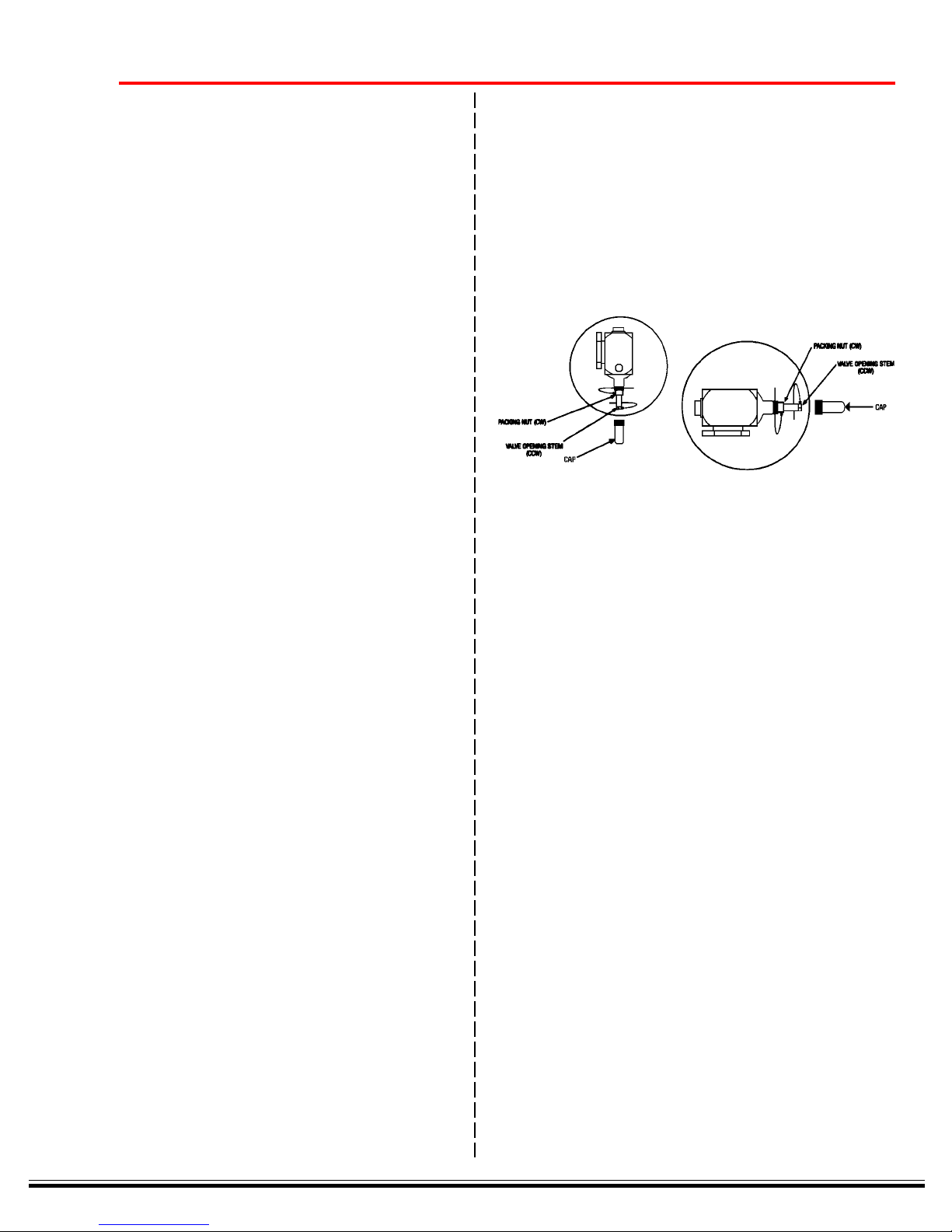

• Remove protective cap from valve stem. (see figure

below)

• Using a refrigeration service wrench or small crescent

wrench, turn the valve stem counterclockwise until it

stops. Occasionally it may be necessary to retighten

the packing nut (clockwise) if a leak is observed. The

valve will now be fully open.

• Replace cap.

• In case of refrigeration ball valves, you must turn 90

degrees to open as stated on valve. (See figure below)

4) Locate the compressor service toggle switch. This

service switch must be turned on immediately after

valves are opened.

· The refrigeration compressor may run briefly and then

stop. This process is called pump down. If storage

conditions were adverse, the compressor may make a

loud metallic hammering noise. If this happens, turn the

service switch off and wait half a minute, then turn back

on. Repeat this step until the compressor runs

smoothly, then stops. Leave the service switch in the

ON position.

5) The dryer is now ready to run. Turn the dryer on at the

control panel.

The digital display should start dropping.

6) With the dryer turned ON from the control panel and

cycling several times, you may now introduce compressed air to the dryer. Open the inlet and outlet

ISOLATION VALVES. Close the BYPASS VALVE.

7) Check automatic drain for proper operation. Drain

should open at regular intervals based on the drain

control settings or water level.

8) Restart dryer using this procedure after maintenance,

power failure or after prolonged shutdown periods.

CAUTION: Failure to follow the above steps in the order

shown MAY result in damage to equipment NOT covered

under warranty.

Operating Instructions:

Always:

• Turn dryer ON and OFF with control panel button.

Keep power to unit during off cycles.

• Start dryer and allow it to cycle several times prior

to allowing air flow through the dryer.

• Clean condenser when dirty.

• Keep ambient temperature under 100º F.

• Keep inlet temperature under 100º F.

• Check and clean Y-strainer periodically.

10

Never:

• Turn off main power disconnect except when

servicing.

• Allow air to flow through the dryer when it is not

running.

• Cycle dryer with air compressor

5. ROUTINE MAINTENANCE AND SERVICE

Air Cooled Condenser

Very little routine care is necessary for the VCD Dryer. The

most important step for an air cooled dryer is to keep the

air cooled condenser clean. The air is being taken in

across the condenser. Dirt from the ambient air will

accumulate on the finned tubes of the condenser coil. As

the dirt will accumulate on the rear of the condenser,

blowing from the inside out is most effective. In dusty

areas the simple, inexpensive installation of a furnace filter

will stop the majority of dirt entering the dryer’s condenser.

This should be changed when visibly dirty. If the condenser

does become dirty, an abnormally high refrigeration discharge pressure will occur. The unit may shut down on

high dew point or high pressure. This will greatly reduce

the life of the refrigeration compressor and could void the

warranty.

Separator/Coalescer Drains

Drains should be checked regularly. Failure of an automatic drain can result in extreme amounts of water and

debris in your air system.

6. FOR THE REFRIGERATION SERVICE

TECHNICIAN

IR recommends that only qualified and experienced refrigeration mechanics do repair work on these units. This

section is a list of hints and instructions for the skilled

serviceman.

Recharging Dryer – Refrigerant, Oil and Dryers

Consult the IR Service Department for the required charge

needed for each unit. The relatively large charges are

needed because of the flooded-shell evaporators. Use the

following to assess the adequacy of the charge when

unsure:

• The sight-glass should stay filled most of the time

when the dryer has its customary air load. It is normal

for the glass to break up when the condenser fan starts

if the load is light or when the unit unloads. It may

take time to refill when it reloads. Don’t charge to clear

the glass with no load; that will be too much.

• All units have a charging fitting on the evaporator shell.

The unit must be charged through this fitting and/or the

liquid line service valve. The best way is to dump liquid

into both ports with the dryer off, then start up and

continue feeding a full stream of liquid into the evaporator until charged.

Do not charge vapor. You want the charge installed as

fast as possible so the oil will be returned to the compressor as in normal operation.

Additional oil is added at the factory to compensate for the

migration with the freon. If a compressor is replaced,

remove the drain plug from the evaporator shell (on steel

shells) to drain any excess oil trapped. If that isn’t possible, it may be necessary to remove oil from the system

after start-up. Excess oil is indicated by noisy and vibrating compressor operation. Consult factory for recommended oil changes. Prolonged operation with insufficient

charge or a bad TXV may cause oil to be trapped in the

evaporator. If the compressor is still good, this oil will

return within a few minutes of operation with the correct

conditions. For R-404 & R-134 applications use synthetic

refrigeration oil.

Please replace both suction and liquid filter-dryers together

whenever the system has been exposed to air or water,

unless it’s brand new or you know how much gas has gone

through it. Solids will be caught in the suction drier even if

the system is dry.

Evaporator Leaks

If there is a leak between the tube and shell side of the

evaporator, the usual symptom is high head pressure,

because the air pressure is higher than the refrigerant

pressure.

To determine this, bypass airflow, stop dryer, and observe

head pressure after it stabilizes. 20 minutes is sufficient. If

the pressure is much higher than that corresponding to the

ambient temperature, there is air in the system. Purge air

at compressor discharge or receiver inlet to verify.

Gross leak-checking of the evaporator is done at the

separator drain with air pressure off and at least an hour

wait. If a leak is verified, it can often be fixed by removing

the bonnets, locating the leak with bubble soap and rerolling the leaky tubes. Split evaporator tubes can be

plugged with special tapered brass plugs.

WARNING: If the refrigerant has been seriously contaminated with water you probably won’t be able to dry it with

dryers or vacuum. Do a solvent cleanup on the evaporator

and suction accumulator or replace the evaporator.

Refrigerant Control Valves

Expansion valves: The superheat (+15º F) that the valve

control’s is created in the control evaporator or suction line

heat exchanger. There is liquid or zero superheat at the

main evaporator outlet to facilitate oil return and keep the

shell flooded. If there is superheat at the main evaporator

outlet or if the suction line to the compressor is warm to the

hand, 1) check the charge. If the sight-glass is full, 2) the

TXV may be defective or the liquid line is blocked. The TXV

superheat adjustment is not critical.

IR uses standard type valves.

• Don’t use any TCLE Alco valves. TCLE valves are too

slow.

• Use cross-ambient “C” or liquid “L” charges. Do not

use any pressure limiting or all-purpose “W” charges.

11

• We recommend that you increase the superheat setting

of the new valve about 5º F from the factory setting.

Turning the stem 2 turns in should be sufficient.

• Position the sensing bulb of the new valve just where

the old one was. It is crucial that the suction line be

clean and the bulb well insulated.

Solenoid Valves: The suction solenoid valve rarely causes

any trouble because the pressure difference across it is

never great. Unloader solenoids operate with greater

differentials. The VCD Dryer uses valves with a rated life of

more than two million operations. When they finally wear

out, the usual symptom is failure to close. The valves can

usually be restored by installing a diaphragm repair kit

available from IR.

Drains

The draining of water from the separator is the most crucial

part of the whole process. A complaint of “there’s more

water in the air now than there was before the dryer was

installed” is usually a drain problem.

The VCD Dryer has a demand operated drain. Operate the

drain manually and be sure that air blows out of the drain

line. Clean the strainer and solenoid valve if not.

The MRD demand Drain has a SINGLE point hermetically

sealed float switch. This extremely simple mechanism

resists fouling and wear.

2) Water freezes in the evaporator causing air pressure

drop.

3) There is erratic or out-of-range indication of dew point.

This is controller or sensor trouble. Consult factory for

details

4) Dryer won’t restart after you stopped it for a test. This is

normal if you stopped when it was below setpoint. It will

restart when the dew point temperature comes above the

controller setting.

Factory Assistance

Please do not hesitate to call the Ingersoll-Rand factory for

technical information and assistance. We have skilled

troubleshooting and engineering personnel who are thoroughly familiar with the equipment. A short call may save a

long troubleshooting experience. Call 1-800-526-3615.

Instructions for Ordering Parts

All parts orders should be placed with your local IngersollRand Service provider.

When ordering parts specify dryer model and serial number

(See nameplate on unit). Please call 1-800-526-3615.

Normally a single point drain will not work because the

switch would be constantly short cycling on/off and the

solenoid or switch would fail, —but the MRD Solved the

problem with timed electronic delay that allows the drain to

empty the vessel without loss of Compressed air.

Caution – Warning: remove all pressure before servicing

drain. Remove all air pressure and disconnect electrical

power from the drain

The MRD is easily disassembled for cleaning by removing

the four main bolts.

Yearly (or sooner) disassemble and clean vessel.

After disassembly be sure the float switch is mounted in the

same position (check arrow on float)

The dew point temperature is sensed by a sensing probe

inserted in one of the evaporator tubes. When air passes

over the probe, the air temperature controls the dew point

normally. When there is little or no air flow, the controller

sees the evaporator temperature and is able to prevent it

from going below freezing.

A malfunction of the control system can be suspected if:

1) Suction pressure is very low even when controller reads

over the set point or unit appears to be pumped down

and stopped when it shouldn’t be.

7. Trouble Shooting Guide

COMPRESSOR WILL NOT START. NO HUM:

• Line disconnect switch open. Close switch.

• Fuse removed or blown. Replace fuse.

• Overload tripped. Wait 5 to 20 minutes to reset. Check ambient

and inlet air temperatures, operating pressure and air flow rates

against rated capacities listed, to determine cause of overload.

• Loose or improper wiring. Check connections against schematic.

Tighten loose connections.

• Safety controls tripped (oil, temperature, refrigerant). Test controls

for malfunction by jumpering. Look for reason device tripped (high

head, low suction, oil loss). Correct any malfunctions such as

dirty condenser, high ambient, overloads. Replace faulty controls.

• Starter coils open or contact burnt. Replace coils and/or contacts.

COMPRESSOR WILL NOT START, HUMS, (Trips overload protector.)

• Loose or improper wiring

• Low line voltage, 10% of nameplate rating. Check line voltage with

voltmeter. Correct condition.

• Start winding open or shorted. Check with ohmmeter, referring to

motor schematic for correct value. Replace motor.

• Open or unbalanced phase ( 3 phase units). Check phases for

equal voltages (+/- 10%).

• Relay or contactor not closing. Examine contacts and coils for

burning, opens, shorts or sticking. Correct conditions.

• Compressor internal mechanical failure. Loss of oil may have

locked up compressor. If above steps do not apply, this may be

the cause. Replace compressor.

12

UNIT SHORT-CYCLES:

LOW OR NO OUTLET AIR PRESSURE:

• Motor overload cutting out. Check for high head pressure air

overload, high ambient clogged condenser.

• Defective overload protectors. Check currents. Replace if necessary.

• Low voltage or 3 phase unbalance. Voltages must be within 10%

on nameplate rating. Correct off specification conditions.

• Refrigerant shortage. Check for leaks. Repair and recharge.

• Low suction pressure or sticking expansion valve. Check valve

setting and operation. Adjust, repair or replace.

• Shorted motor winding.

• Incorrect or restricted piping. Look for restrictions in lines or too

small pipe sizes. Replace piping if needed.

• Evaporator and/or precooler clogged. If clogged, reverse flow and

flush with mild detergent. Evaporator frozen. Turn unit off to thaw.

WATER DOWNSTREAM OF DRYER:

• Test drain. Check the output for power from relay marked “drain” on

• Check for blockage in drain line.

• Clean “Y” strainer

DRAIN STAYS OPEN ALL THE TIME (DRAIN ALARM)

• Check the valve for debris. Clean if required.

• Check float switch. Dirty or defective.

• Check board. Relay stuck or defective.

13

control board. If no output, then replace board. If power is present

check wiring to solenoid and status of coil. If energized and valve is

not open clean valve or replace if needed.

14

INSTRUCTIONS FOR ORDERING REPAIR PARTS

When ordering parts, specify dryer model and serial

number. (See name plate of the unit).

All orders for parts should be placed with your local

Ingersoll-Rand Service Provider. Should you not know the

dealer in your area, contact IR at (800) 526-3615.

8. IR WARRANTY

The IR Warranty Philosophy…..

Warranty can be defined as a protection of investment.

Warranty policies can come in all different shapes and

sizes, however, the most important attribute to a successful

policy is its fairness to all parties involved. This brings us to

the explanation of components that make up the IR Warranty Philosophy.

Warranty Procedure

IR believes in giving the most expedient service possible to

our customers. In order to accomplish this the most

important step for our customer is to call us (1-800-526-

3615) immediately in the event of a potential warranty

situation. The phone call serves several purposes:

• It puts the customer in direct communication with the

factory assures them of factory support.

• It helps us to diagnose the problem and perhaps

remedy it over the phone. This saves everyone time. In

most cases we can determine the root cause of the

failure through a simple phone call.

• It helps us to assess any parts that may be needed for

repair. This eliminates time and travel by a service

company making one trip with parts in hand.

• It helps us to determine situations non related to the

dryer. After the phone call has been placed, and if

service is necessary, we will authorize a service house

in close proximity to the customer.

It is important when a call is placed to us for a potential

warranty situation, that the following information be provided:

• Model and serial number.

• Start-up date.

• Company name.

• Dryer location

• Phone number

• Contact Person

• Specific nature of complaint (Diagnostic code, high dew

point, etc..)

Important: IR reserves the right to deny any claim submitted without our knowledge and proper authorization.

Warranty Parts and Returns…

In the event a part is required to complete a warranty repair

the following steps will occur:

1. A standard parts order must be placed with our service

department (1-800-526-3615) along with a purchase

order number.

2. The customer that placed the order will receive an

invoice for the part. This is for memo billing only. The

invoice will also contain a Return Authorization Number

(RMA)

3. After the part has been replaced, the defective part that

was removed must be returned to us. The RMA must

accompany the returning part.

4. Upon receipt of the defective part we will issue a credit

against the original invoice.

5. If the part is not returned within 30 days the invoice will

stand open and chargeable.

Maintenance Records

It is recommended that detailed performance and regular

maintenance records are kept.

Detailed records are very valuable in troubleshooting &

diagnosing issues.

Coverage

Our refrigerated dryers are equipped with a two (2) year

parts & labor warranty. The heat exchangers are covered

by five (5) year warranty.

Our dryers are to be free from defects in material and

workmanship (under proper use, installation and maintenance) for the stated period of two years from the date of

start-up or 30 months from the date of shipment which ever

occurs first.

The heat exchanger warranty covers the first 60 months of

operation or 66 months from date of shipment

What is Not Covered by “Standard Warranty” for all

Dryer Lines

• Damage caused by accidents

• Damage caused by fire, theft, freezing, vandalism

• Damage caused by operation outside the rating

conditions

• Operation of the dryer in ambient temperature in

excess of 100ºF

• Operation of the dryer with inlet air temperatures in

excess of 100ºF

• Operation of the dryer in excess of rated SCFM

• Operation of the dryer in excess of rated PSIG (unless

specifically rated for abnormal conditions)

• Damage caused by corrosion due to environment and/

or chemical treatments

• Damage caused by lack of maintenance

• Damage caused by failure to follow requirements of the

maintenance schedule is not covered. Proof of proper

maintenance is the owner’s responsibility. Keep all

records and make them available if questions arise

about maintenance.

15

• Freight Damage – Freight damage is not covered

under warranty. Should your dryer incur freight

damage, file a claim with the carrier immediately. At

the option of the claimant, you may contact a local

contractor to do a thorough investigation and repair the

damaged dryer. You may also return the dryer to IR,

freight prepaid. The factory will perform the repairs

chargeable to the original consignee. The customer

would then include these costs on their claim.

• Dryer Alteration by Distributor or End User – This

warranty does not cover alteration of the dryer or failure

of dryer components caused by such alterations.

• Economic Loss – This warranty does not cover any

economic loss, extra expense including payment for

the loss of time, pay, inconvenience, storage, loss of

dryer use, dryer rental expense, lodging, meals, or

other travel costs.

• Maintenance – Performing normal maintenance

services as detailed in the maintenance schedule are

not covered and are at the customers expense including cleaning condenser, drains and filters.

Chargeable Service Calls

IR reserves the right to decline any warranty claim, with or

without proper authorization, in which non-warrantable

condition was found. In the event this occurs, the customer should be billed for the call as standard service.

In Conclusion

Our philosophy is clear. We will stand behind it and uphold

the most professional and expedient service to our distributors and ultimately our customers. We are always reviewing our warranty policy. We feel our policy is as good as

any in the industry. If you feel another manufacturers

warranty policy, as a whole, is better, submit the manufacturers literature and we will consider its qualities in our next

policy review.

Thank you for choosing an IR product !!

Warranty Registration

Each dryer comes with a service manual. In the last

pages of this manual there will be a warranty registration

card. The card must be filled out and returned to us within

30 days of start-up, to receive warranty.

International Warranty

Our policies cover equipment within the United States and

Canada. Any units shipped to or sold outside of the United

States or Canada will carry a two year, parts only warranty.

The IR Disclaimer

IR makes no other warranty of any kind whatsoever,

expressed or implied and all warranties of merchantability

and fitness for a particular purpose are hereby disclaimed

by IR. IR shall in no case be subject to any obligation or

liability whatsoever with respect to product or services

manufactured or furnished by IR or any acts of omission

relating thereto. The remedy provided under this warranty

shall be the sole, exclusive, and only remedy provided

available to the purchaser. Under no circumstances shall

IR be liable for any special, indirect, incidental or consequential damage, losses or delays however caused.

IR reserves the right to make changes in dryers built and/

or sold by them at any time without incurring any obligation to make the same or similar changes on dryers

previously built and/or sold by them.

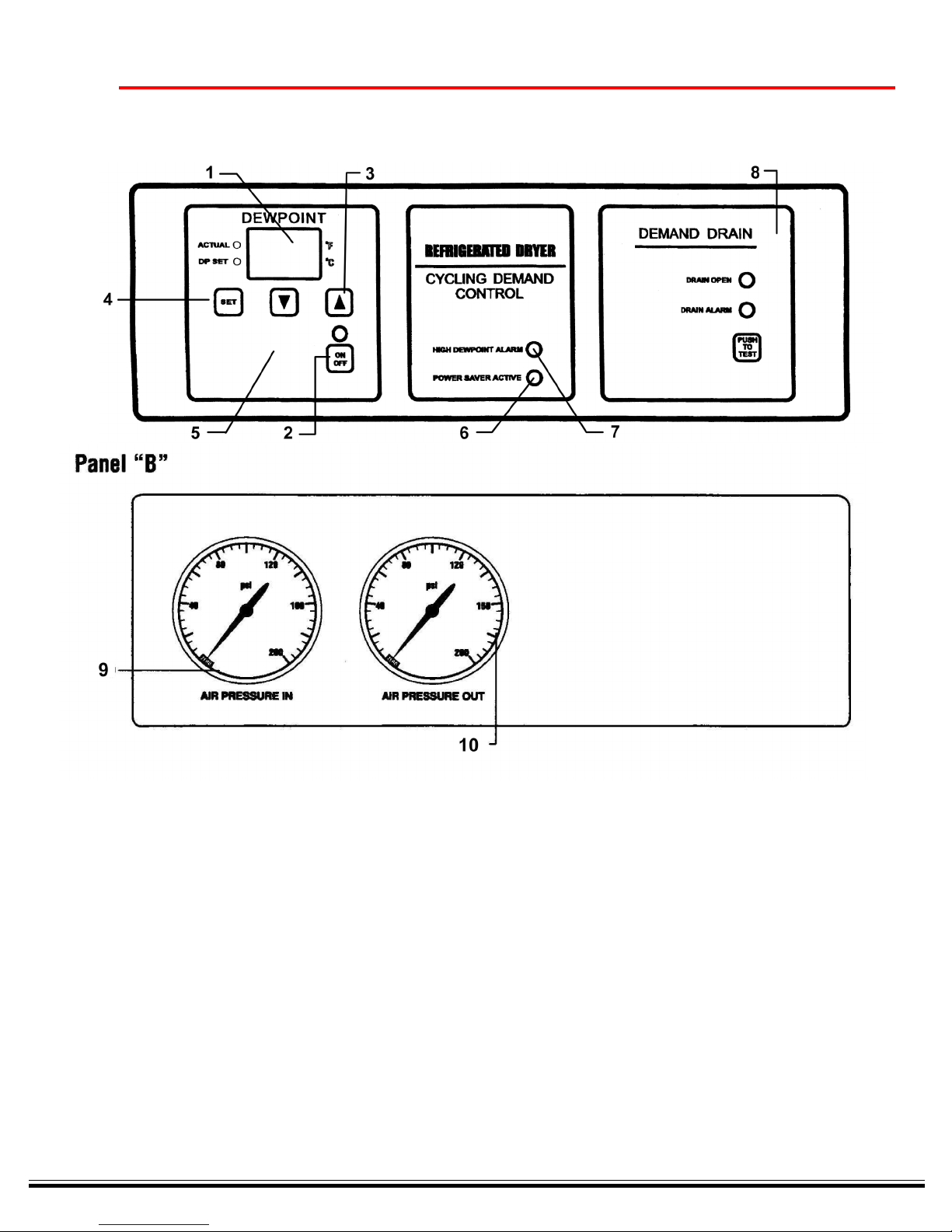

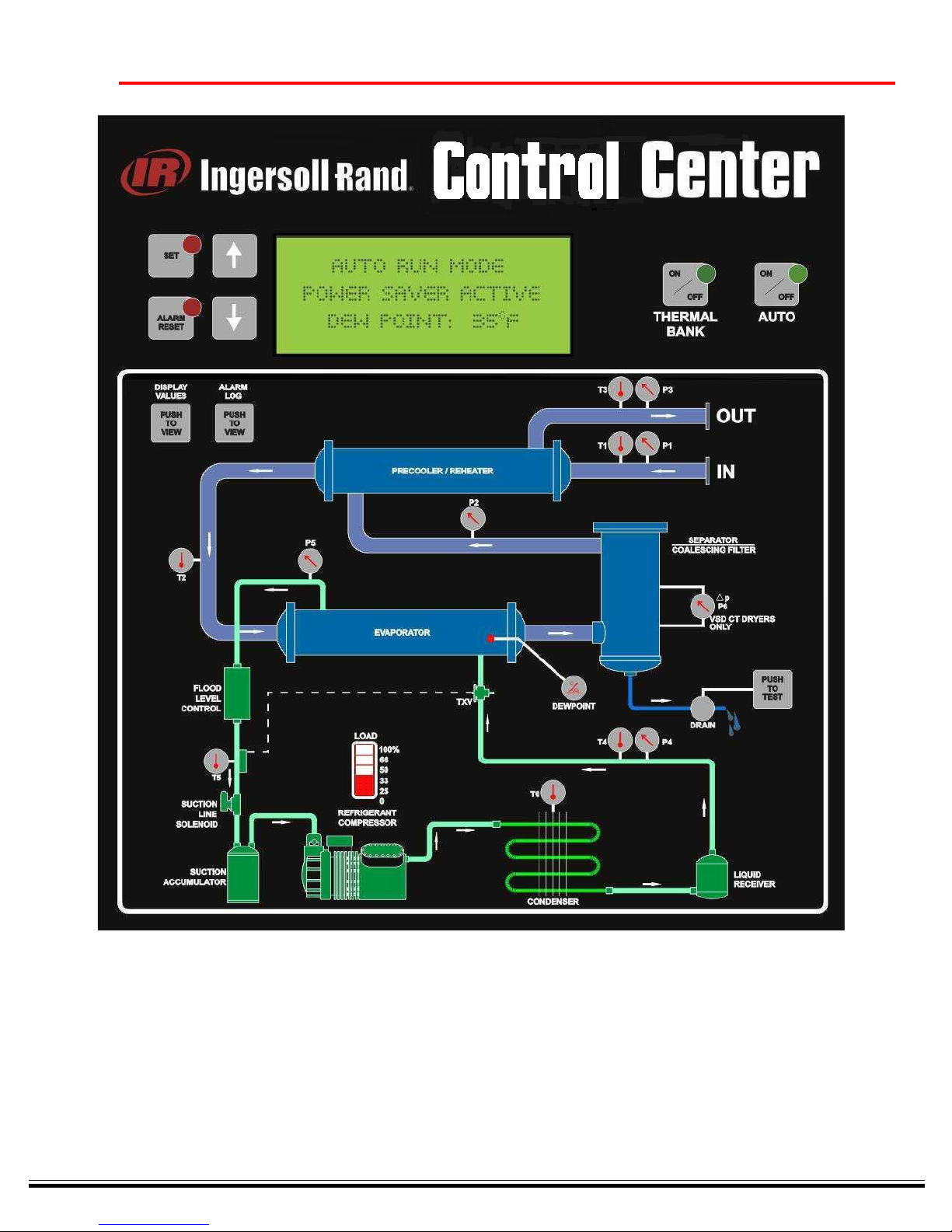

CONTROL PANEL

16

DISPLAYS and ALARMS

1) DEW POINT CONTROLLER AND DISPLAY.

Directly controls dew point and provides constant

digital display of dew point. Factory set at 36ºF.

During ACTUAL display mode, displays the dew

point temperature from 20º to 99º F or -6º to 37º C.

During DP SET mode, the unit displays dew point

set points from 34º to 50ºF in 1º steps, or 1º to

10ºC in 1/2 steps. (Note that the ones digit decimal

point is used to indicate 1/2º when displaying set

point in Celsius scale.) ºC LED- indicates that the

temperature is displayed in Celsius. ºF LED –

indicates that the temperature is displayed in

Fahrenheit. ACTUAL LED – indicates the display

is in ACTUAL mode. Display shows actual

temperature being measured by system. DP SET

LED - Indicates that the display is in programming

mode during which the set point can be changed

and stored. The dew point display also displays

the unit error codes when they occur. (see

Diagnostic codes)

2) ON/OFF BUTTON .LED - Indicates when the unit is

operating.

3) RAISE and LOWER BUTTONS. These are used to

adjust the set point values. The set point will

change once for each time pressed. If the button

is pressed and held, the set point will change one

step per second.

4) SET BUTTON. Toggles between Actual Display

mode and Set point Display mode. During the Set

point Display mode, the Raise and Lower keys are

used to select new set points which are stored in

nonvolatile memory when the mode is set back to

ACTUAL. If no keys are pressed within 15 seconds, the mode is automatically set to “ACTUAL”.

This switch is also used to select the temperature

scale that the unit will operate in. By pressing and

holding for 5 seconds the unit will toggle between

the Fahrenheit and Celsius scale.

5) HIDDEN BUTTON. Positioned in the bottom center

of the Dew Point window between the MODE keys.

When pressed, the display will show the external

suction temperature at the expansion bulb. It has

no further effect on operation. It may also be used

for other diagnostics and factory test purposes

6) POWER SAVER ACTIVE LED. Unit in mode of

minimal power consumption.

7) HIGH DEW POINT ALARM LED. Indicates that the

unit is in the High Dew Point condition. The high

dew point alarm light, with remote dry contacts, will

activate when the actual dew point is 15º F higher

than the dew point set point. Any diagnostic code

will activate the high dew point alarm immediately.

17

8) DRAIN CONTROL. Will operate by either a ‘LEVEL

FLOAT’ or ‘TIMED’ interval. If the dryer is equipped

with a Level Float (electrical connections to terminal

J9), the drain will respond to the float signal on

demand to operate the drain. The duration that the

drain valve is open, will be the amount of time it

takes for the fluid level to drop and reset the float

signal, plus, a pre-set time of a few seconds

thereafter. The drain valve will also operate automatically once every 30 minutes (independent to the

float signal). The 30 minute timed interval setting

can be adjusted down to 1 minute or raised up to 60

minutes if desired. To adjust the drain ‘Timed

Interval’ setting, press the SET button twice (note

that the Actual and DP Set LED’s will both extinguish). The value indicated in the display will be the

Timed Interval setting. Use the UP or DOWN arrow

to the desired timing set point. Pressing the SET

button again will return the display to reading the

dew point and the ‘Actual’ LED will once again

illuminate.

9-10) AIR INLET and AIR OUTLET PSI GAUGES.

Indicates that unit is pressurized. Unit must be

depressurized and bypassed before any service

work is done on air system. Excessive pressure

drop (more than 5 PSIG) across dryer indicates

water may be freezing in the evaporator.

EXTERNAL SENSORS, CONTROLS and RELAYS

DRAIN RELAY (K1) – This onboard relay opens the drain

valve according to drain controls.

SUCTION RELAY (K2) – This onboard relay turns on

according to the mode and dew point conditions and

opens the suction or liquid line valve when active.

UNLOADER RELAY (K3) – not applicable.

COMPRESSOR RELAY (K4) – This onboard relay

controls the compressor according to the mode and dew

point conditions.

HIGH DEW POINT RELAY (K5) – This onboard relay and

LED alarm turns on when the dew point is 15º F above

the set point. This is also active during any error

conditions.

DEW POINT SENSOR (Probe 1) – Resistive NTC sensor

for measuring dew point temperature.

SUCTION TEMPERATURE SENSOR (Probe 2) – Resistive

NTC sensor for measuring external suction temperature

at the expansion bulb (E3 Probe).

Optional Electronic Panel

MANUAL

18

PREFACE:

This document is intended to make familiar, the Control Center functionality. The ‘manual’, can serve as

a handy guide to quickly move through the operations of the dryer it is controlling. It is not intended to

replace the more comprehensive, specific ‘dryer manual’ that will show all other aspects of operation

and safety. It is IMPORTANT that both manuals be referenced for complete dryer understanding.

MENU TREE

a. STARTUP NULL SCREEN------------------------------------------------------------------------------------ [ 20 ]

• VCD - VARIABLE SPEED DRYER

-------------- PRE-STARTUP

--------------------- STARTUP

--------- CHANGE MODES

b. MAIN SCREEN --------------------------------------------------------------------------------------------------- [ 20 ]

• DISPLAY ORIENTATION

• TYPICAL SCREEN DISPLAYS

c. EVENTS ------------------------------------------------------------------------------------------------------------- [ 21 ]

• EMERGENCY STOP

• STANDBY

• DEWPOINT OPTION (not installed)

• ACTIVE ALARMS

• DEWPOINT ALARM

• NO FLOW

19

d. REVIEW ALARM LOG (‘J’ Series Menus) ---------------------------------------------------------------- [ 22 ]

e. DISPLAY SENSOR VALUES (‘K’ Series Menus) ------------------------------------------------------ [ 24 ]

• FLOW MONITOR (4-20mA / 1 to 5 volt input)

MAIN MENU

1. DEWPOINT SETTINGS (‘D’ Series Menus) ------------------------------------------------------------------------------------ [ 25 ]

• DEWPOINT SET

2. SETUP MENU (‘E’ Series Menus) -------------------------------------------------------------------------------------------------- [ 25 ]

• COMPANY INFORMATION ----------------------------------------------------------------------------------------------- [ 25 ]

PHONE & www MESSAGE

• PRODUCT INFORMATION ------------------------------------------------------------------------------------------------ [ 25 ]

TYPE OF DRYER & SN#

FACTORY DEFAULTS

GOTO ‘NULL’ STATE

CALIBRATION MENU (‘H’ Series Menus)

INLET PRESSURES

REHEATER PRESSURE

OUTLET PRESSURE

DISCHARGE PRESSURE

SUCTION PRESSURE

ELEMENT DP SETTINGS

FLOW RANGE SETTINGS

• DRAINS SETUP MENU (‘I’ Series Menus) ------------------------------------------------------ [ 27 ]

#1 DEMAND or TIMED OPERATIONS

#1 INTERVAL (Timed)

#1 DURATION

#1 AUTOTEST

#2 DEMAND or TIMED OPERATIONS

#2 INTERVAL (Timed)

#2 DURATION

#2 AUTOTEST

• COMMUNICATIONS MENU (‘F’ & ‘G’ Series Menus) ----------------------------------------- [ 28 ]

ADJUST CLOCK

STAR WATCH -Host to Control: YES

MODEM SETUP

MODEM ENABLE

MODEM TEST

MODEM RESET (Reprogram)

VIEW MODEM SETTINGS

3. SENSOR SETTINGS (‘C’ Series Menus)----------------------------------------------------------------- [ 28 ]

• P1: LOW INLET PRESSURE

• P1: HIGH INLET PRESSURE

• P2: REHEATER PRESSURE

• P3: OUTLET PRESSURE

• P4: DISCHARGE PRESSURE

• P5: SUCTION PRESSURE

• P6: SEPARATOR DP

• FLOW

20

4. TEMPERATURE SETTINGS (‘B’ Series Menus) ---------------------------------------------------------[ 29 ]

• T1: DRYER INLET SETPOINT

• T2: PRECOOLER SETPOINT

• T3: DRYER OUTLET SETPOINT

• T4: REFRIGERANT SETPOINT

• T5: SUCTION SETPOINT

• T6: AMBIENT/H2-0 SETPOINT

5. VIEW ALARMS (‘A’ Series Menus) ---------------------------------------------------------------------------[ 29 ]

• HIGH DEWPOINT

• LOW FLOW

• (E1/E2) DEWPOINT PROBE FAULT (OPEN OR SHORT)

• MOTOR OVERLOAD

• (E3) SUPERHEAT OUT OF RANGE

• (E4) LOW DEWPOINT

• (E5) DRYER OVERLOAD

• (E6) LOW FREON OR OIL PRESSURE

• (E7) HIGH FREON PRESSURE

• (WI) LOW AIR-IN PSI

• (W2) HIGH AIR-IN PSI

• (W3) COALESCER PSID

• (W4) HIGH INLET AIR TEMP

• (W5) HIGH AMBIENT / H2-0 TEMP

• (W6) DRAIN FAULT

• MODEM FAULT

KEY FUNCTIONS

21

1. UP ARROW Scroll Menu Up or Increment Value

2. DOWN ARROW Scroll Menu Down or Decrement Value

3. SET Enter Menu Selection, Enter Program Mode or Save to Memory

4. RESET ALARM Back-up Menu Level or Clear ‘Resetable’ Alarm

5. LOAD/UN-LOAD Load/Un-Load Mode Selector

6. THERMAL BANK Thermal Bank Mode Selector

7. AUTO RUN Auto Mode Selector - Automatically Sequences to Demand (#5 or #6)

8. DRAIN TEST Operates Both Drain System for Programmed Duration

9. DISPLAY VALUES Enters Sensor Menus - Indicates Current Values (Series ‘K’ Screens)

10.REVIEW ALARM LOG Enters Historical Log of Alarm Event (Series ‘J’ Screens)

a. STARTUP NULL SCREEN ------------------------------------------------------------------------------------------------------------------------------

Upon initialization, the display shows the ‘type’ of dryer the Control Center is configured to control.

• VCD - VARIABLE SPEED DRYER

INGERSOLL-RAND

VCD

REFRIGE DRYER (R404A)

S/N 00000 V 1.00

This is a fixed configuration. Once assigned to a dryer the Control Center will never be changed to any of the other

configurations. Note that the Control Center Serial Number and Firmware Version are also displayed on this null,

initialization screen.

PRE-STARTUP

Prior to starting up the dryer,’ the DISPLAY VALUES button may be selected to view groupings of sensors

(use the up/down arrows to scroll through the list) Depress the Display Values button a second time, or the

Alarm RESET button to return to the Main Screen. Also, all of the other screens and menus can be viewed

by using the up/down arrows. Simply position any particular menu choice into view and advance a menu

level by depressing the SET button. A return to the Main Screen can be achieved at any time by depressing

the Alarm RESET button. These screens may be viewed at any time, and at any state of operation.

22

The Main Screen will indicate SYSTEM INACTIVE prior to start-up (run mode), when returning to the Main

Screen from viewing any of the above Pre-Startup procedures.

SYSTEM INACTIVE

DEWPOINT 65°F

STARTUP

TO START the dryer select any of the three main operating modes by depressing their button.

• AUTO Mode (normal operations) dryer will automatically sequence.

CHANGING MODES

The dryer can change modes of operation by simply depressing the any desired mode button. To return the

dryer to an INACTIVE (SYSTEM OFF) state, depress the ‘current mode’ button as is indicated by the Mode

Pilot indicator (LED).

b. MAIN SCREEN ------------------------------------------------------------------------------------------------------------------------------------------

DISPLAY ORIENTATION There are several informational indications displayed on the Main Screen. They are

displayed on the four lines of the LCD.

1. The first line is the ‘message’ line. If all is normal, this line will indicate ALL SYSTEMS OK, else it will

indicate an alarm; for example, HIGH DEWPOINT. If more than one alarm is active, this message line

will ‘scroll’ between any and all messages.

2. The second line is the ‘mode’ line~. This line will indicate the dryers operations:

• SYSTEM INACTIVE,

• EMERGENCY STOP,

• AUTO RUN MODE,

• LOAD/UNLOAD MODE,

• THERMAL BANK MODE,

• SYSTEM OFF, and

• ALARM SHUT DOWN

3. The third line is the ‘process’ line. INITIALIZING, POWERSAVE ACTIVE or may be blank for all other

normal operations.

4. The forth line is dedicated to the current DEWPOINT value.

TYPICAL SCREEN DISPLAYS ------------------------------------------------------------------------------------------------------------

Below are a sampling of typical display screens; showing some of the possible system operations.

ALL SYSTEMS OK

AUTO RUN MODE

POWERSAVE ACTIVE

DEWPOINT 34°F

MOTOR OVERLOAD

ALARM SHUT DOWN

DEWPOINT 39°F

ALL SYSTEMS OK

LOAD/UNLOAD MODE

DEWPOINT 35°F

ALL SYSTEMS OK

SYSTEM OFF

23

DEWPOINT 65°F

STARWATCH ACTIVE

AUTO RUN MODE

DEWPOINT 33°F

c. EVENT -----------------------------------------------------------------------------------------------------------------------------------------------

EMERGENCY STOP -------------------------------------------------------------------------------------------

At any time the dryer’s E-STOP pushbutton is depressed, the dryer will immediately ‘stop’

operations (all output will be de-energized except for COMMON ALARM dry output relay

and the MODEM relay). To restart the dryer, the flashing mode (AUTO RUN, LOAD/

UNLOAD or THERMAL BANK) selector must be re-selected. Note - the E-STOP

pushbutton must be rotated and pulled ‘out’ to its normal position before the re-start can be

invoked.

ACTIVE ALARMS

EMERGENCY STOP!

DEWPOINT 35ºF

ALARM SHUT DOWN

When a ‘shut-down’ alarm occurs, the dryer will ‘stop’ operating and will require a Manual

Reset (see VIEW ALARMS section). Once the alarm has been reset and if the alarm

condition has been cleared, the system may be re-started. The current mode LED will be

flashing. When the mode selector button is depressed, the system will restart and the LED

will stop flashing and remain illuminated.

LOW REFRIDGERANT/OIL PSI

ALARM SHUT DOWN

DEWPOINT 35 F

24

_______________________________________________________________________________________________________

IMPORTANT:

___________________________________________________________________________________

All screens from section (d.) forward to the end of this manual are indicated with an alphanumeric

indication in the upper left corner of the display as a screen ID. The CONTROL CENTER will display these

ID’s as any given screen is selected within the menu tree. Please make note of any particular screen ID

when communicating with Ingersoll-Rand Service Providers, which may be in question.

d. REVIEW ALARM LOG ------------------------------------------------------------------------------------------------------------------------

When the Review Alarm Log pushbutton is depressed, the ‘1’ series screens will be displayed. Each ‘1’ screen

shows the status of a possible alarm. The UP/DOWN arrow will allow scrolling through 16 different alarm conditions.

The number appearing next the ‘DAYS SINCE LAST’, indicated the last time that the alarms condition has occurred.

A zero (0) indicates the current date. For example, 365 would indicate exactly one year since the occurrence of any

particular alarm. If ‘—’ is indicated, that means the selected alarm has never happened.

When an alarm is tripped, the ‘COMMON ALARM RELAY’ (K16) will energize if the ‘ALARM OUT’ is ENABLED.

There is a form ‘c’ dry contact available for the user on K16 (see schematic). To ‘DISABLE’ the ALARM OUT from

energizing the Common Alarm relay, use the SET and UP/DOWN arrow buttons. All alarms are factory default to

‘ENABLED’. The user can program any one, any combination, or all alarms to activate the Common Alarm relay.

J1 ALARM LOG

HIGH DEWPOINT

DAYS SINCE LAST: 1

ALARM OUT: ENABLED

J2 ALARM LOG

LOW FLOW

DAYS SINCE LAST: 25

ALARM OUT: ENABLED

J3 ALARM LOG

DP PROBE FAULT

DAYS SINCE LAST: 365

ALARM OUT: ENABLED

J4 ALARM LOG

MOTOR FAULT

DAYS SINCE LAST: - - -

ALARM OUT: ENABLED

J5 ALARM LOG

E3: HI SUPERHEAT ºF

DAYS SINCE LAST: - - -

ALARM OUT: ENABLED

J6 ALARM LOG

E4: LOW DEWPNT/PUMP DOWN

DAYS SINCE LAST: 0

ALARM OUT: ENABLED

J7 ALARM LOG

E5: DRYER OVERLOAD

DAYS SINCE LAST: - - -

ALARM OUT: ENABLED

Loading...

Loading...