Page 1

Fault Finding Guide for the R90-160 IU

More than Air Answers

Online answers: http://www.air.irco.com

PHONE: 1-800-820-0308

WSV June 07

Page 2

Safety First

Compressed air and electricity can be dangerous. Before undertaking any work on the compressor,

ensure that the electrical supply has been isolated and the compressor has been relieved of all

pressure. Use proper Lock Out Tag Out procedures to ensure you and your coworkers safety.

Keep all parts of the body and any hand-held tools or other conductive objects, away from exposed

live parts of the compressor electrical system. Maintain dry footing, stand on insulating surfaces and

do not contact any other portion of the compressor when making adjustments or repairs to exposed

live parts of the compressor electrical system. Close and lock all access doors when the compressor

is left unattended.

Do not use extinguishers intended for Class A or Class B fires on electrical fires. Use only

extinguishers suitable for class BC or class ABC fires. Attempt repairs only in clean, dry, well lighted

and ventilated areas. Connect the compressor only to electrical systems that are compatible with its

electrical characteristics and that are within it’s rated capacity.

WARNING

Imposing a normal or emergency stop on the compressor will only relieve pressure upstream

of the minimum pressure valve on top of the separator tank. If maintenance work is required

downstream of this valve, ensure that all pressure is relieved at the process vent point

external to the compressor This state is advised by selecting PACKAGE DISCHARGE

PRESSURE on the control panel.

2

Page 3

Table of Contents

Page

1. Overview of the Eiger control system ----------------------------------------------------------- 4

2. S3 Intellisys Controller Operating Instructions --------------------------------------------------5

3. S3 Intellisys Controller Software Navigation ---------------------------------------------------6

4. S3 Intellisys Controller Fault Indicators ---------------------------------------------------------7

5. Eiger Fault Finding ---------------------------------------------------------------------------------8-13

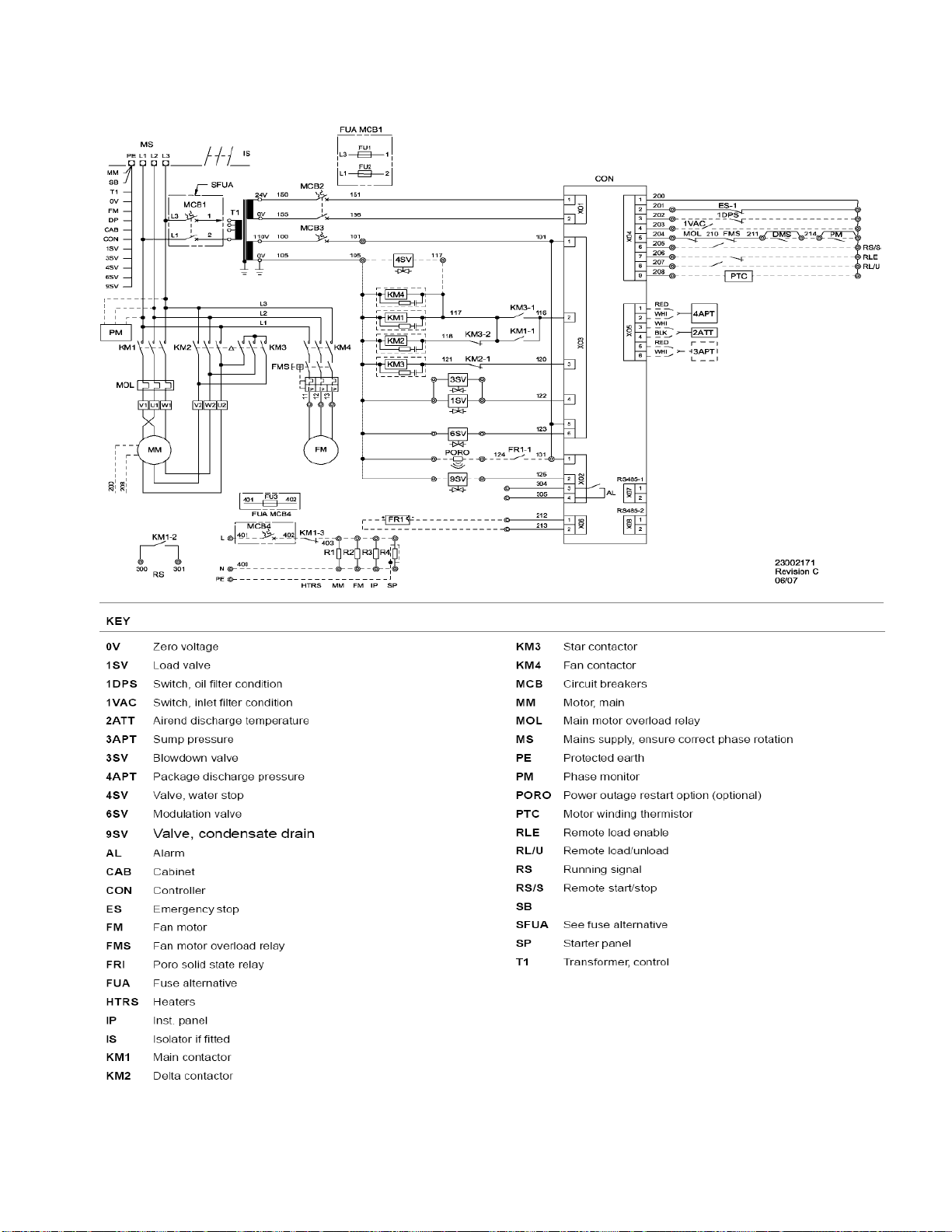

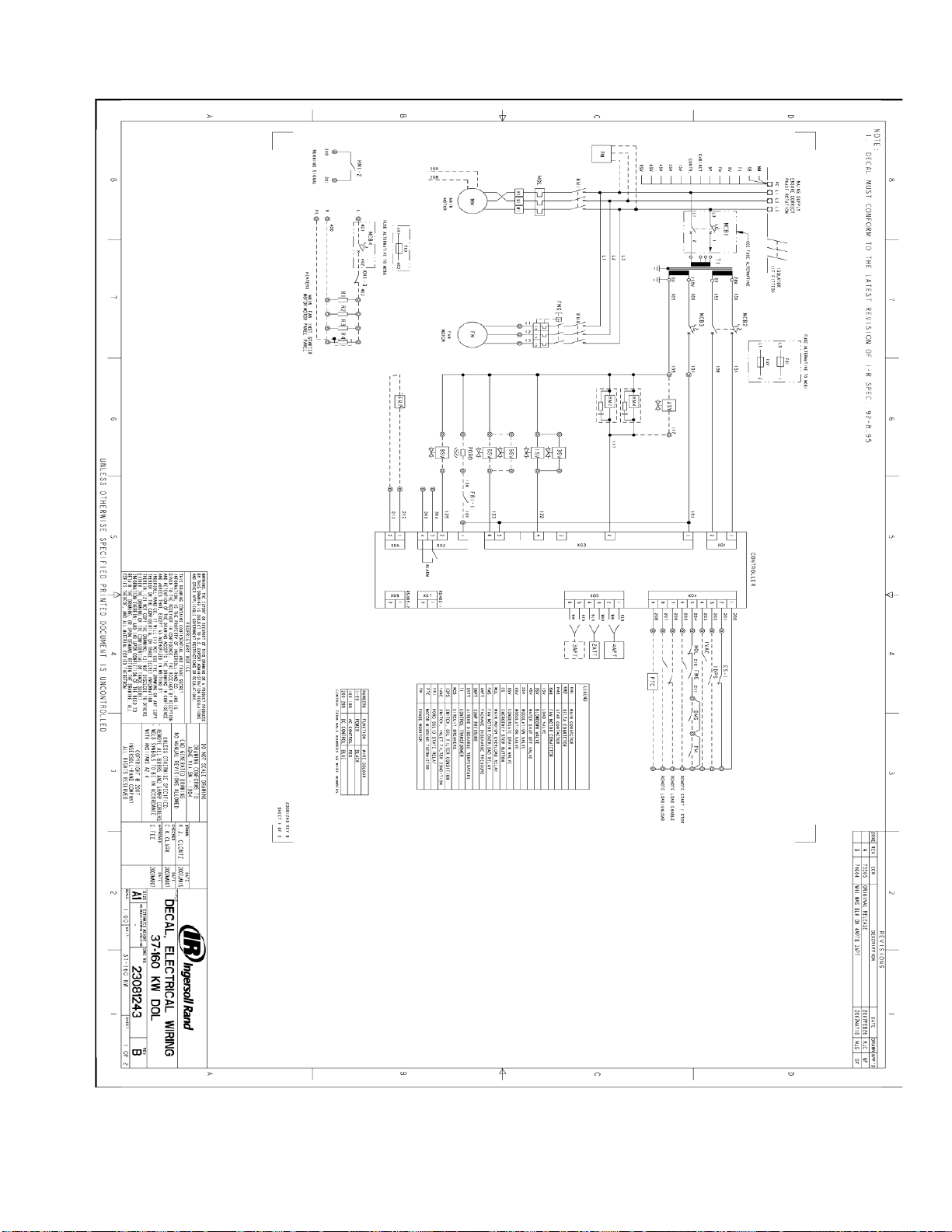

6. Star Delta Electrical Schematic -------------------------------------------------------------------14-15

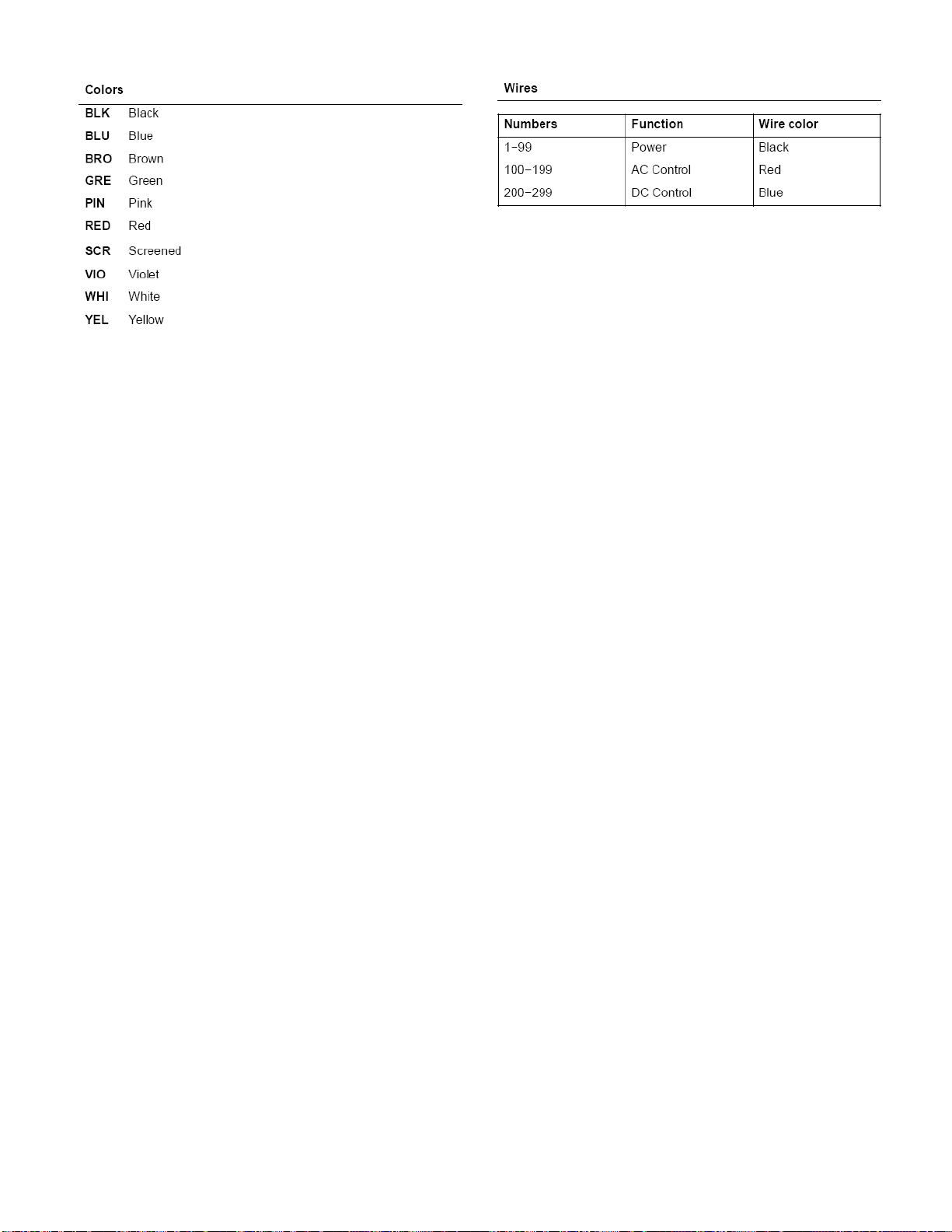

7. Soft Start Electrical Schematic --------------------------------------------------------------------16-17

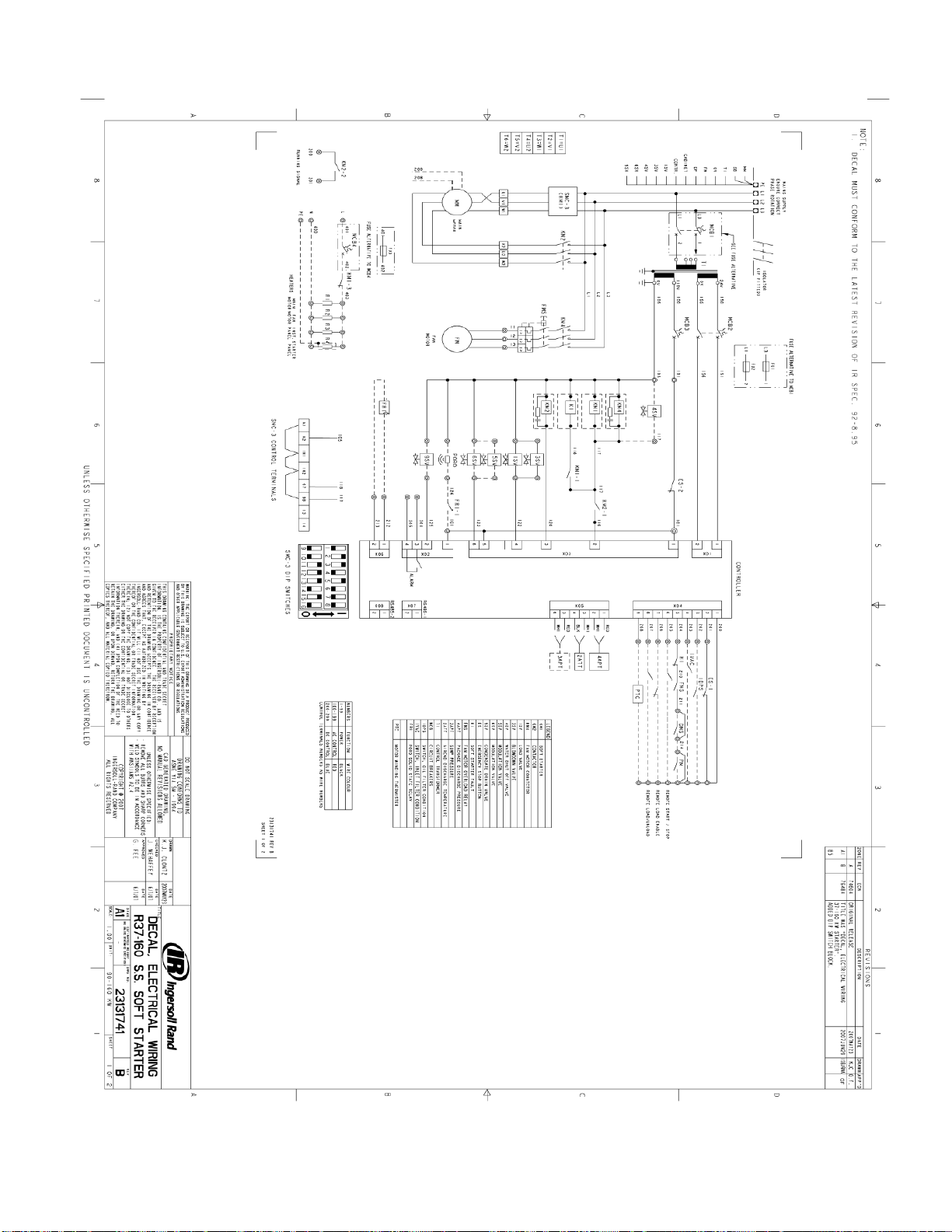

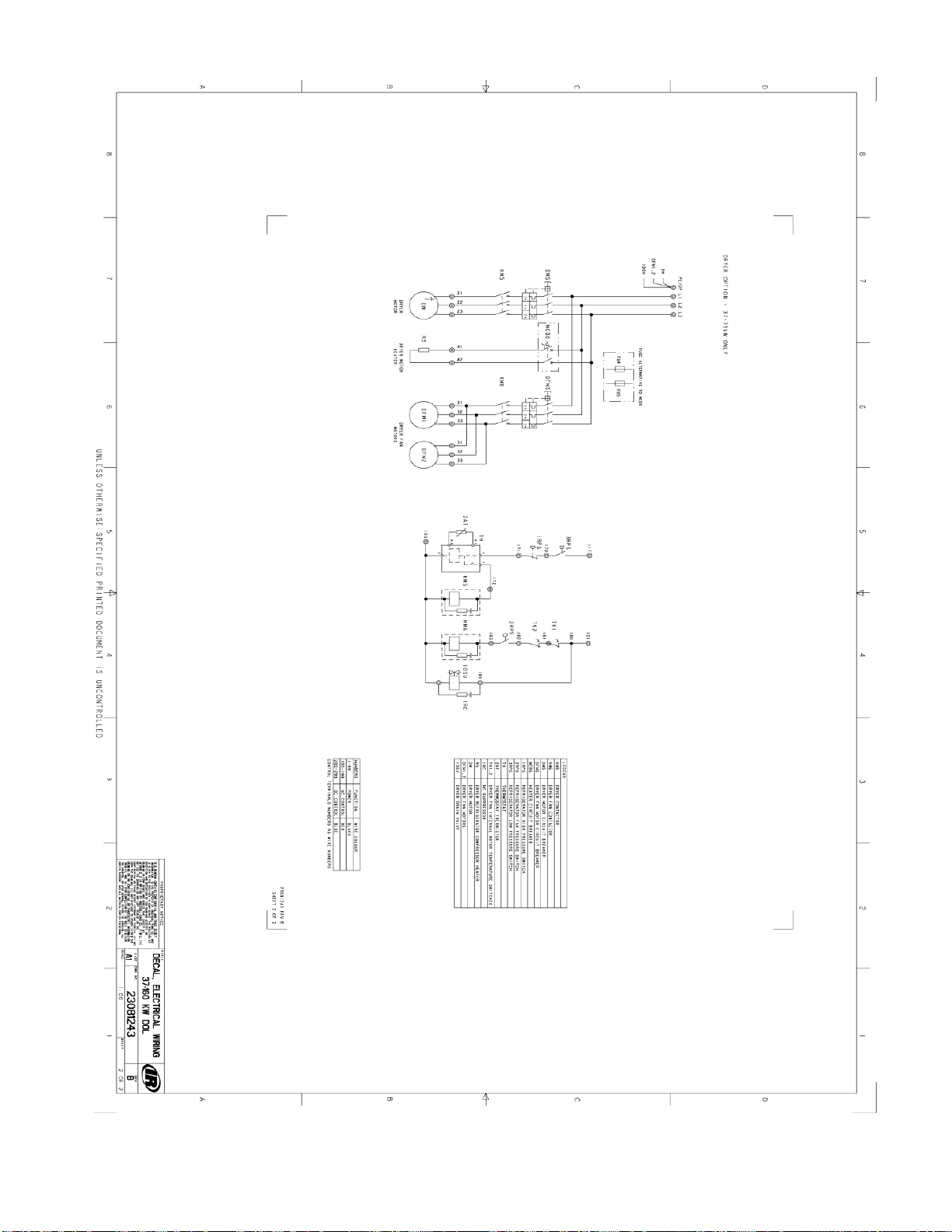

8. Line Start Electrical Schematic -------------------------------------------------------------------18-19

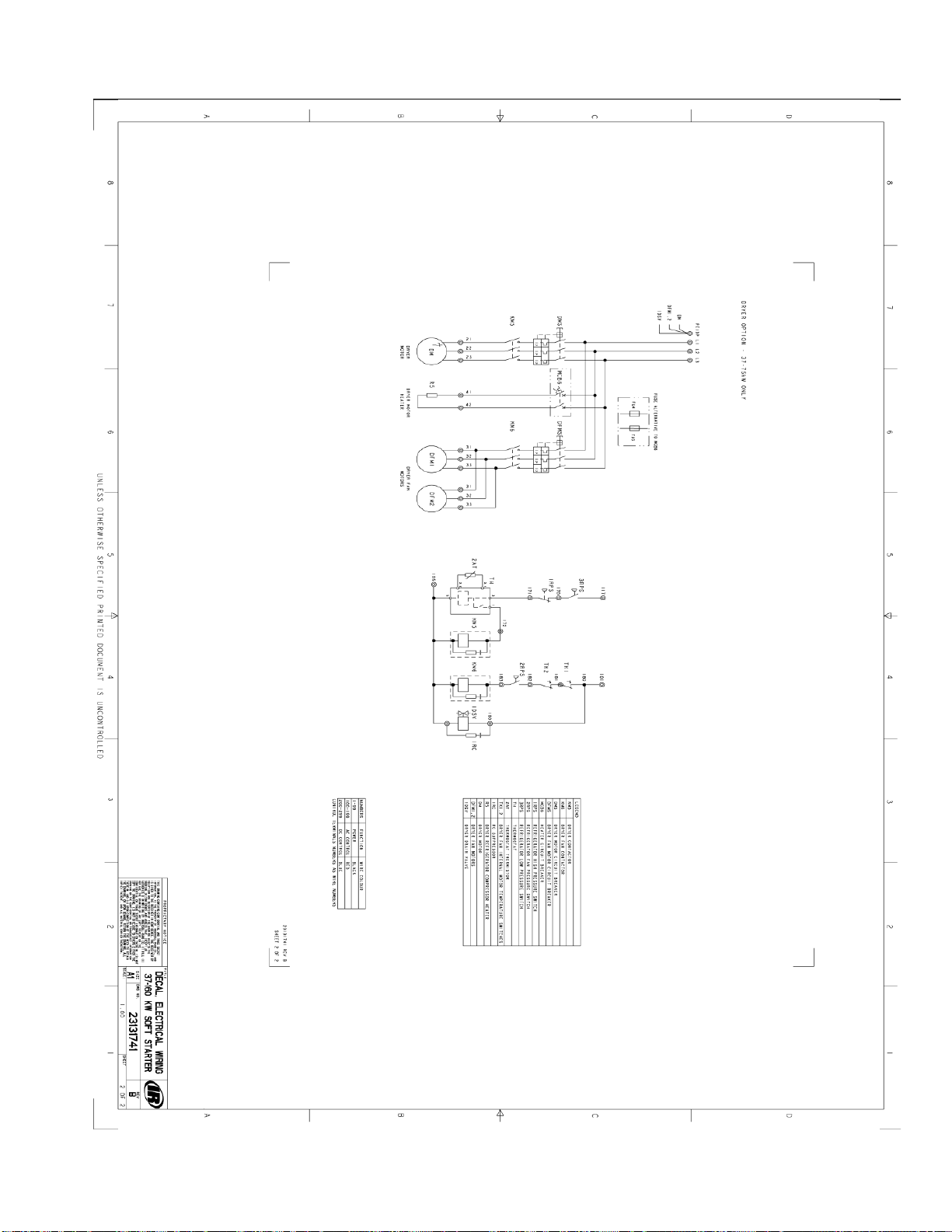

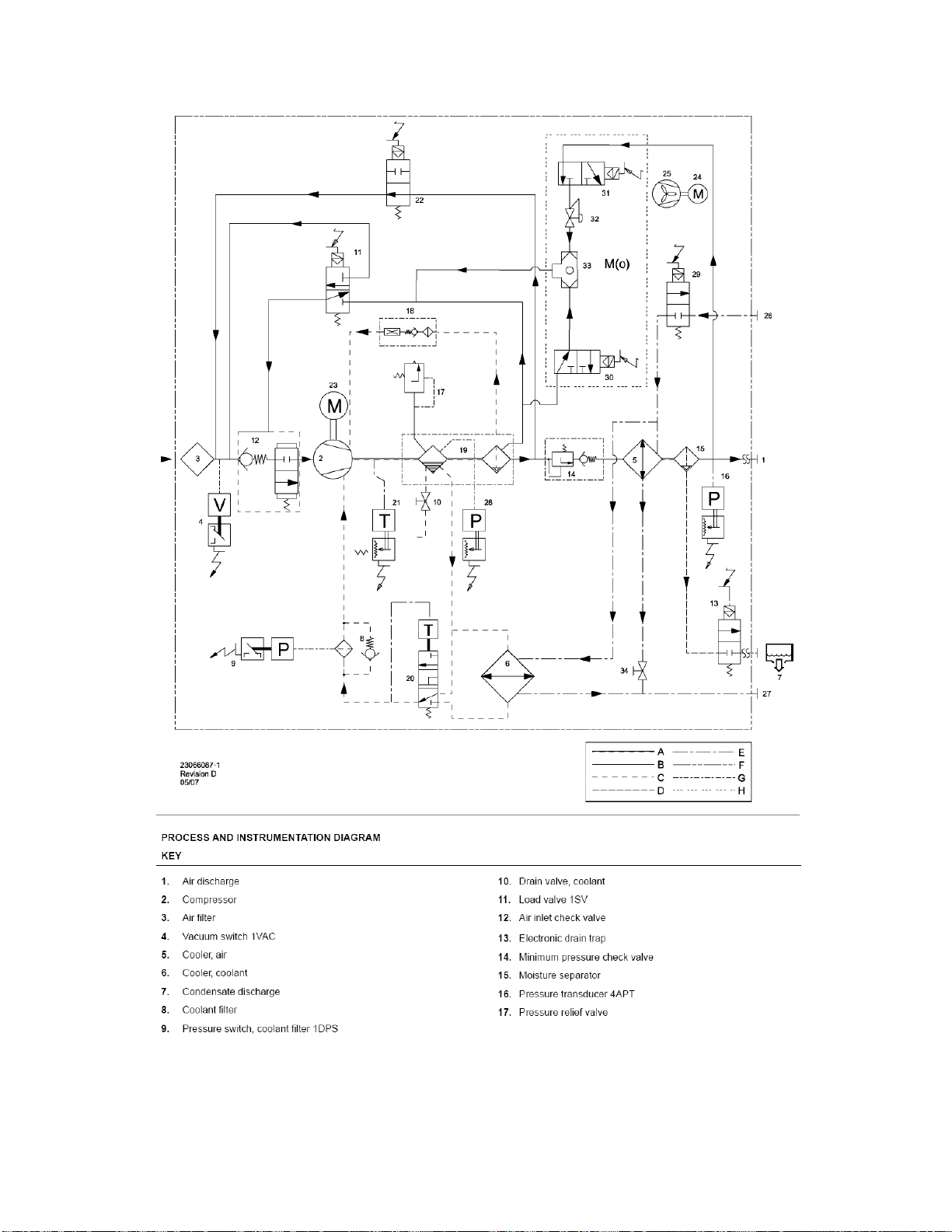

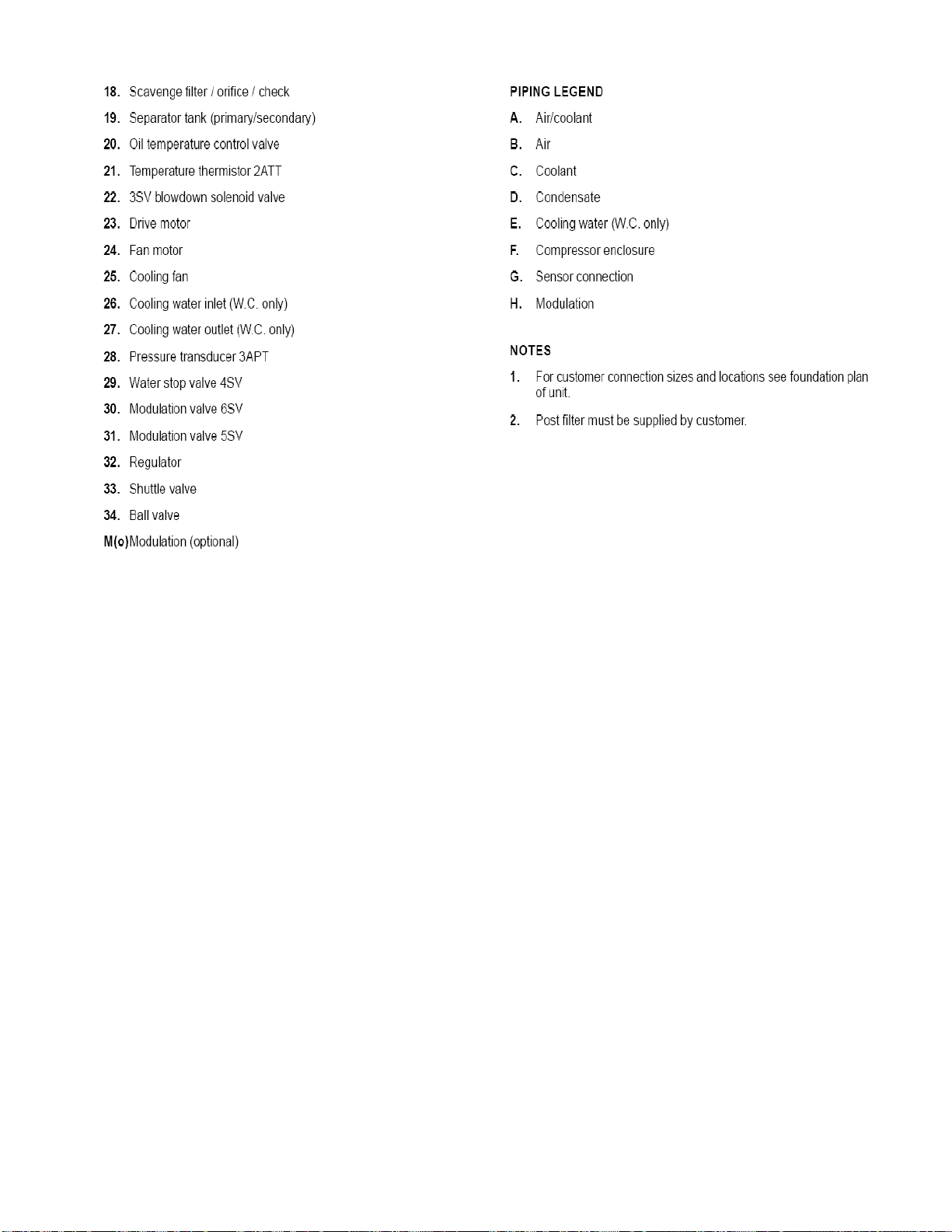

9. Process and Instrumentation Diagram ------------------------------------------------------------20-21

10. General Overview of the Compressor ------------------------------------------------------------22

11. Input/Output and Alarm Information for The Intellisys S3 Controller -----------------------23-25

• Analog Inputs/Outputs Information and Comments

• Digital Inputs/Outputs

12. S3 Intellisys Controller Serial Communications Information --------------------------------26

13. Eiger Maintenance Intervals ----------------------------------------------------------------------27-30

14. S3 Intellisys Input/Out Overview ---------------------------------------------------------------- 31

15. S3 Intellisys Fault Descriptions ------------------------------------------------------------------ 32-33

16. S3 Intellisys Operator Display Icons ------------------------------------------------------------ 34-41

17. Eiger Options ----------------------------------------------------------------------------------------42

• Low Ambient

• PORO

• Scheduled Start Stop

• Integral Sequencing

• Modulation Option and Adjustments ----------------------------------------------------43-44

16. Table 12 Standard S3 Menu Structure and Parameters ---------------------------------------45-48

17. Table 13 Modbus Register Listing ---------------------------------------------------------------49-50

18. Trip Codes List -------------------------------------------------------------------------------------51

19. Appendix 1 Thermistor Temperature Resistance Chart (2ATT) ---------------------------- 52-57

20. General Specifications for Eiger Packages ----------------------------------------------------- 58-79

3

Page 4

Overview of the Eiger Control System

The S3 Intellisys controller is used to control the operations of the air compressor. The following

troubleshooting guide will allow you to troubleshoot the compressor components. The controller will come in

two standard configurations, one is STD (standard) the other is ENH (enhanced). The difference is the options

that are enabled in the software of the controller when the compressor is ordered. If the compressor is ordered

with a standard controller the compressor can be upgraded to an enhanced unit with an upgrade kit CCN

23083637. The upgrade kit includes instruction for retrofitting a standard controller to an enhanced controller.

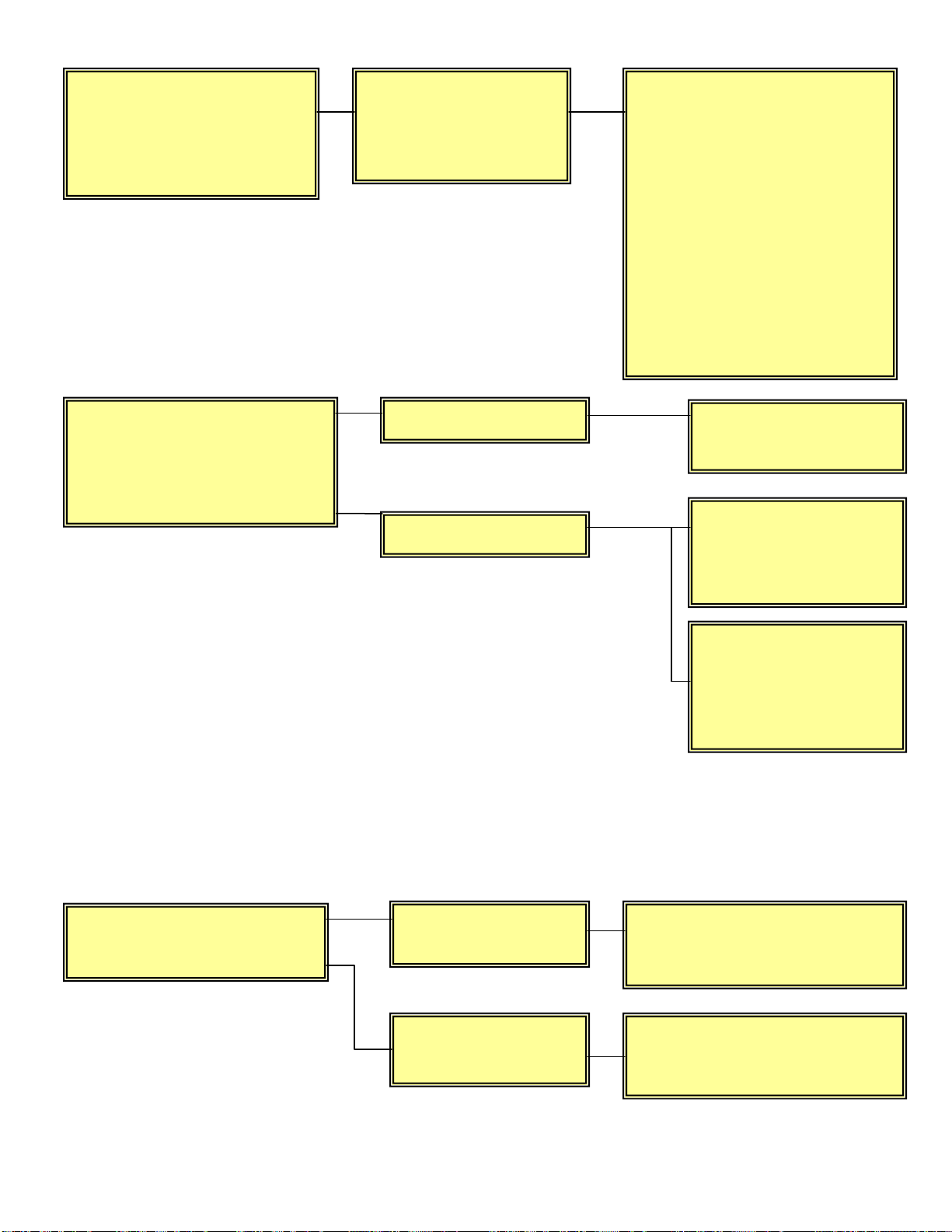

The controller has 3 analog inputs, 8 digital inputs, 6 relay outputs, 1 analog output and two serial 485

communication ports. The controller has a 24VAC input while the internal power supply is a 24 VDC unit that

must sustain a 40 ms power loss before resetting. The S3 controls all aspects of machine operation including

starting, stopping, loading and unloading, safety shutdowns, and user interface as well as compressor remote

connectivity to other devices.

This controller is different than other Intellisys controllers in that the relay outputs are not solid state triacs,

they are relays that are turned on an off by an internal 24 VDC power supply controlled by the internal

software. There will be no voltage leakage as you find with triacs. So fault finding will be easer due to fact that

if a relay output is on or off due to a problem with the controller simply replace the controller, there are no user

serviceable parts. The analog output (X06 term 1-2) for the PORO horn ( 4-20 Ma output ) simply energizes

the solid state relay when the unit starts after a power outage.

A user interface shows the status of the compressor while it is running. The display uses ISO symbols to

convey information to the operator and it will be necessary to learn the symbols as well as the menu structure to

troubleshoot the compressor. Pass codes are required to enter the Set up Access screen, and Fault History

(0000), and Advanced Set Up (0101). These codes are provided in this manual and the operator’s manuals. This

troubleshooting guide also includes the pass code for the Factory Setup that is to only be used by IR service

technicians and not given to customers (Code is 1954). The next pages give an overview of the buttons on the

controller as well as the ISO symbols and software navigation.

4

Page 5

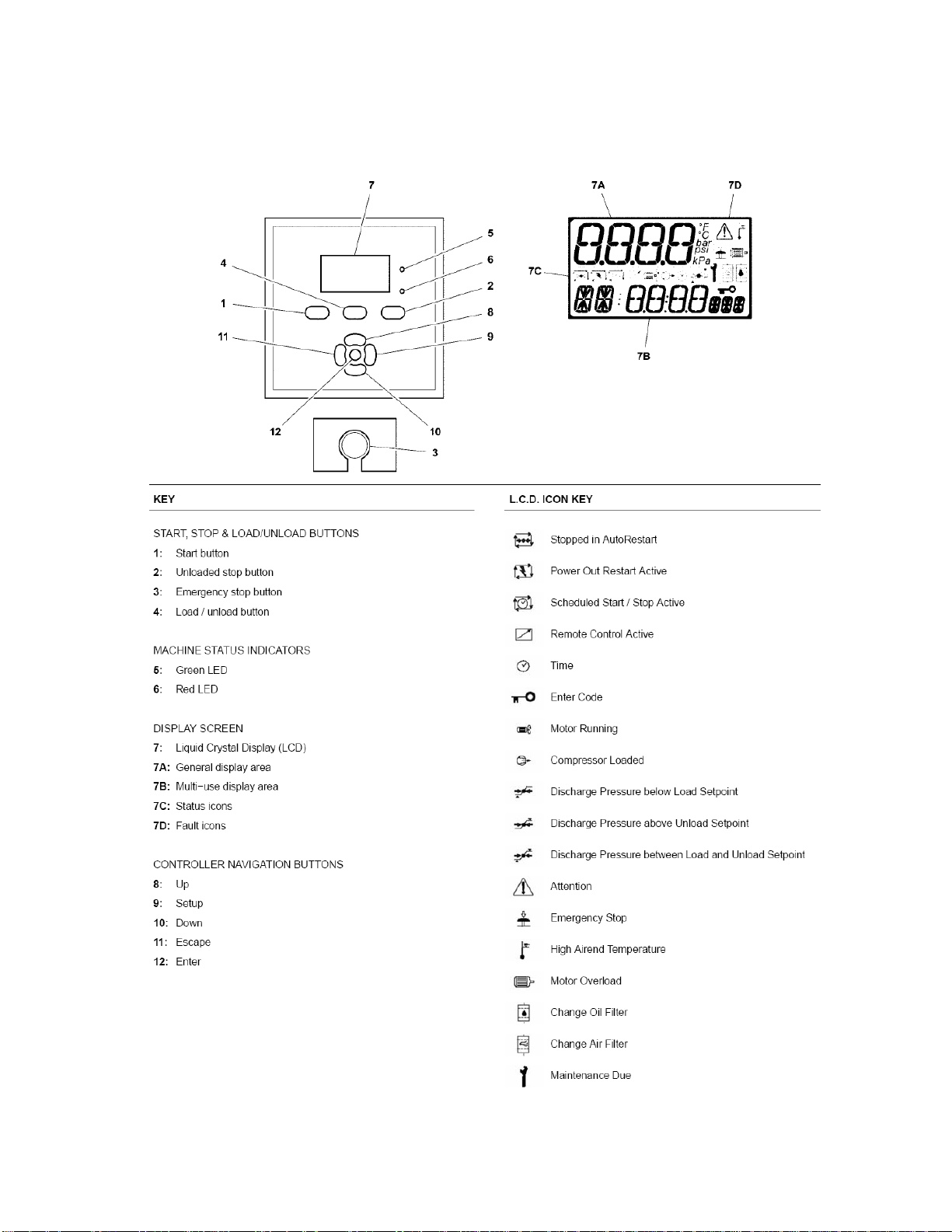

S3 Intellisys Controller Operating Instructions

5

Page 6

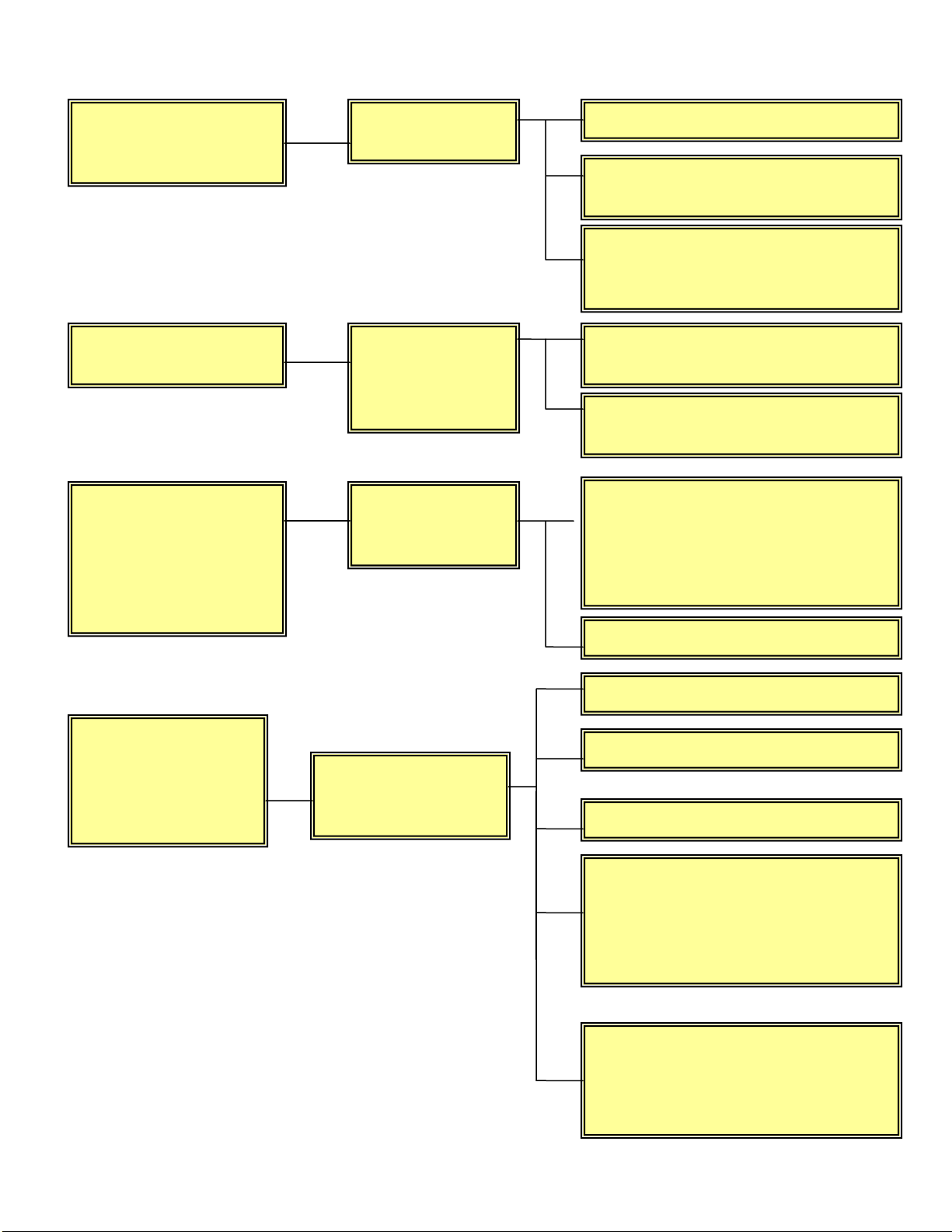

Software Navigation

6

Page 7

020 Tr

Motor PTC Open (High Motor Temperature)

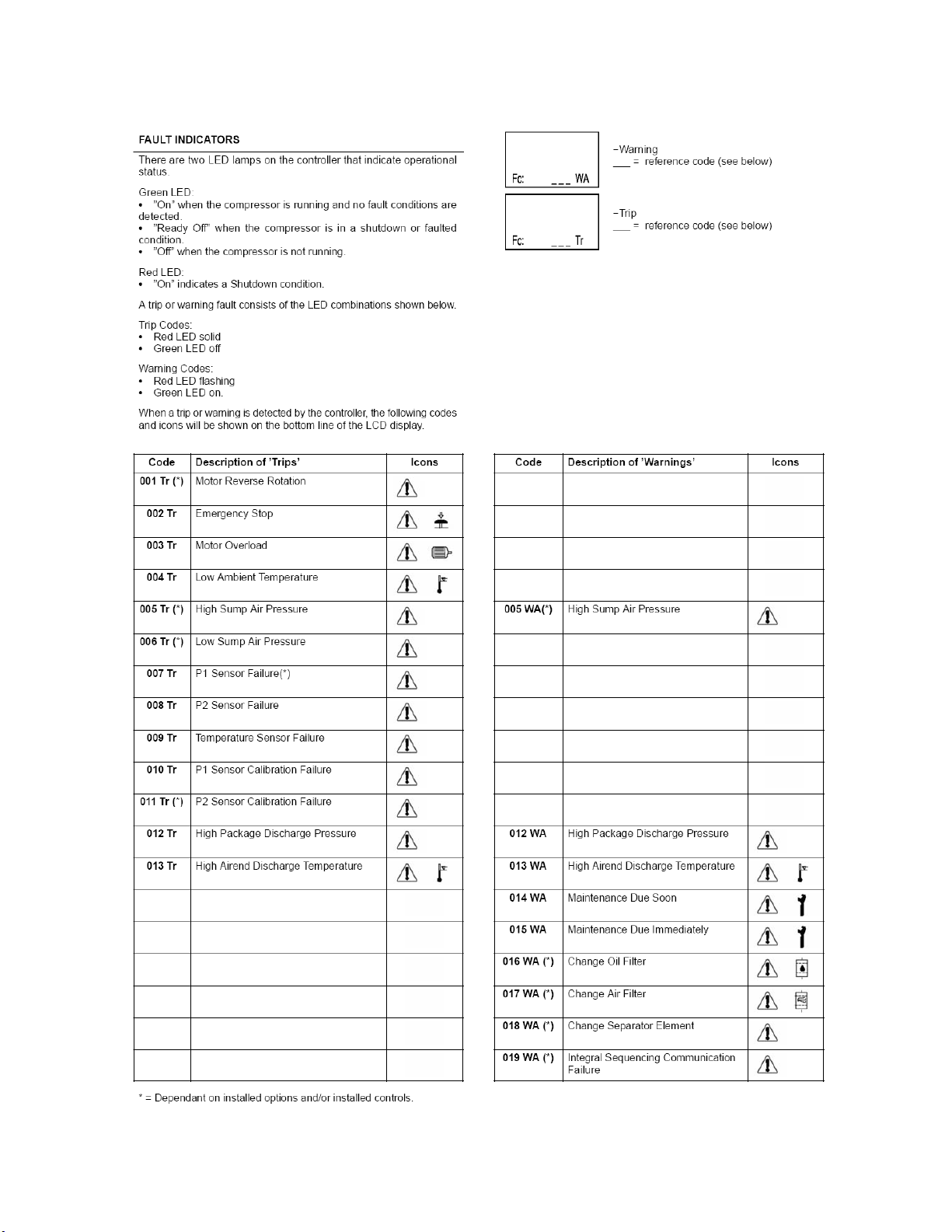

Eiger Controller Fault Indicators

7

Page 8

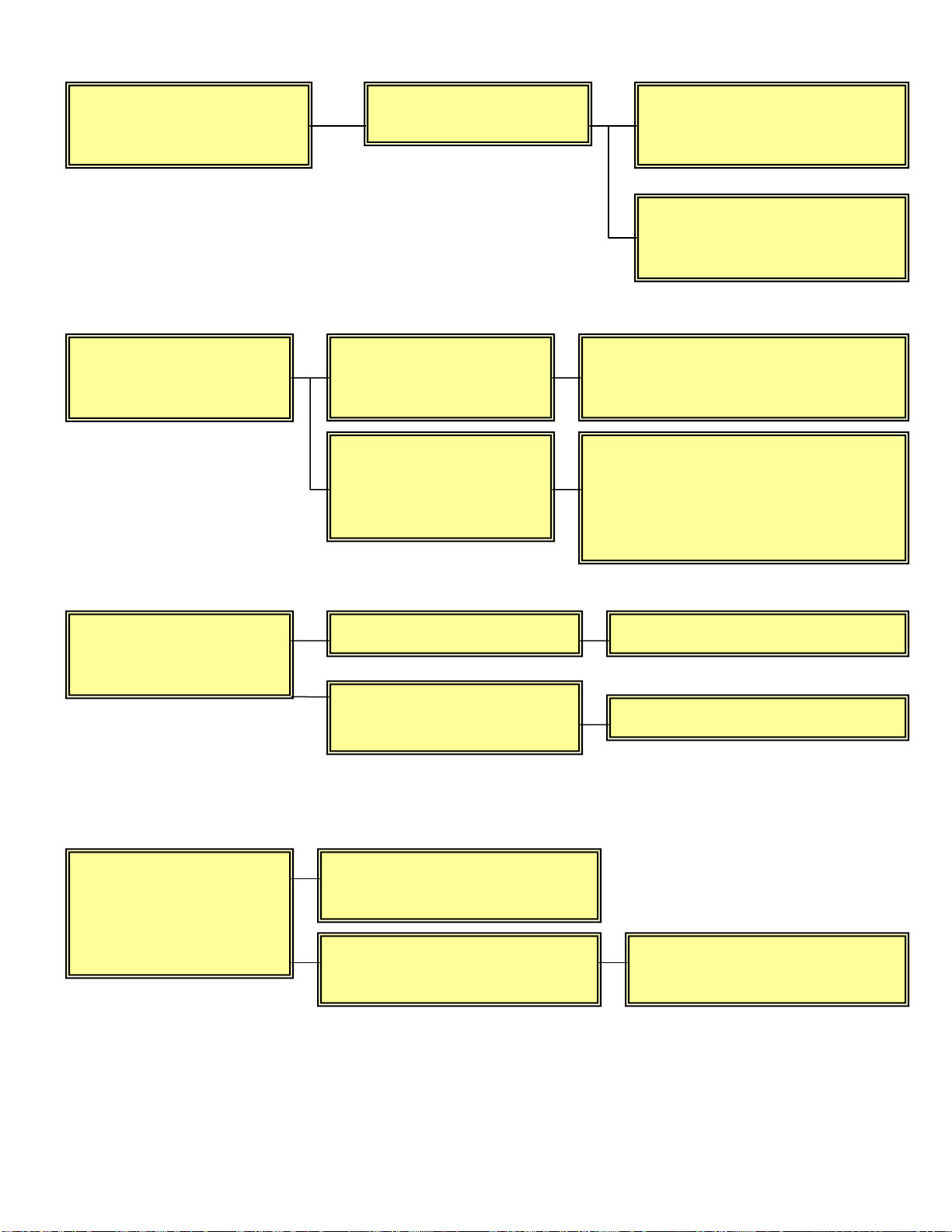

Eiger Fault Finding

’Power on’. L.E.D.

does Not

illuminate.

Intellisys indicates

a tripped condition.

Compressor is

stopped but

Intellisys indicates

that it is still

running (STD

controller only)

Control Voltage

not available

Control Circuit

Interrupted By a

Safety Circuit

Device

Control voltage

not available to

relay inputs

Check the control fuses.

Confirm Incoming Power is correct

voltage

Check the transformer secondary

windings for 24 VAC control

voltage and 110 VAC.

Check machine for indicated fault

and repair.

Attempt to ’reset’ the controller by

removing power to the controller.

Check MCB3 for voltage, Controller

has no power to relay outputs.

This controller has no provision to

detect a power loss to the relay

outputs.

Reset controller

Compressor trips

indicating a high

compressor

temperature.

Fault T 13, W 13

Insufficient Coolant

Circulation,

insufficient cooling.

Check coolant level

Check Temperature sensors

Check thermostatic valve

AC, Check cooling air flow, cooler

restrictions, exhaust vents, inlet

restrictions.

WC, check water flow, strainer,

and water temperature

Excessively high ambient

Temperature / Humidity

(i.e. greater than 46C (115F).

8

Page 9

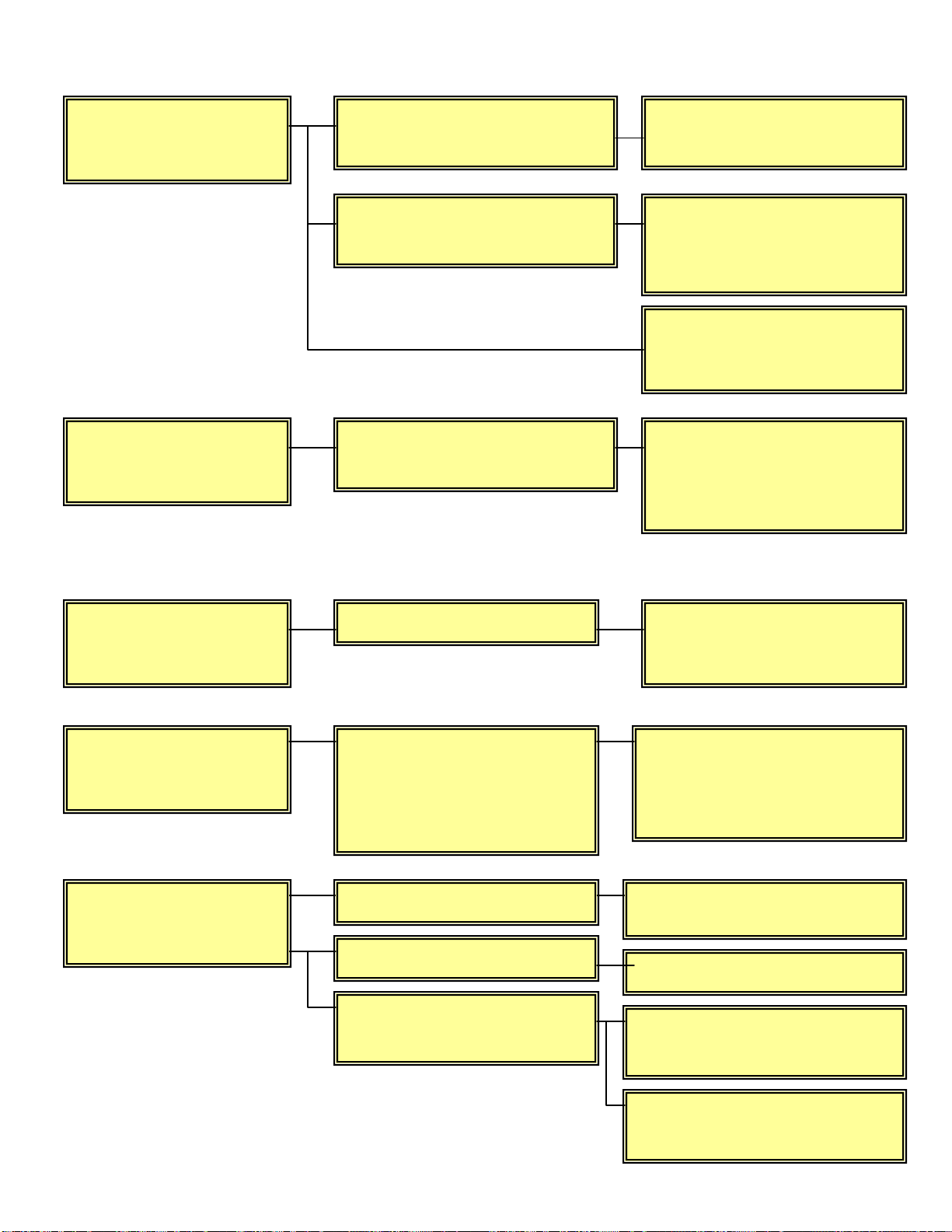

Compressor trips and

indicates motor

overload.

Fault T 3

Excessive current has

caused the motor

overload to trip

Check the actual operating

pressure and lower the

setting if it is too high.

Isolate the electrical supply

and check that the air end

and motor rotate freely.

Check the separator element

for excessive pressure drop.

Set the motor overload on

star-delta at .67 * FLA * SF

of motor name plate data

tag. Measure current at

bottom of MOL

Compressor shutdown

display shows

OVERPRESSURE.

Fault T 12, W 12

Isolation valve

Blowdown system

Open the valve and

restart.

Check the operation of

the load solenoid

mechanically and

electrically

Check the operation of

the unloader valve −

strip and clean if

necessary.

Compressor will not

build up rated pressure.

Air Demand too

high

Offline pressure set

too low

9

Check for leaks, open service

valves or exceptionally high

demand.

Check the offline pressure

setting.

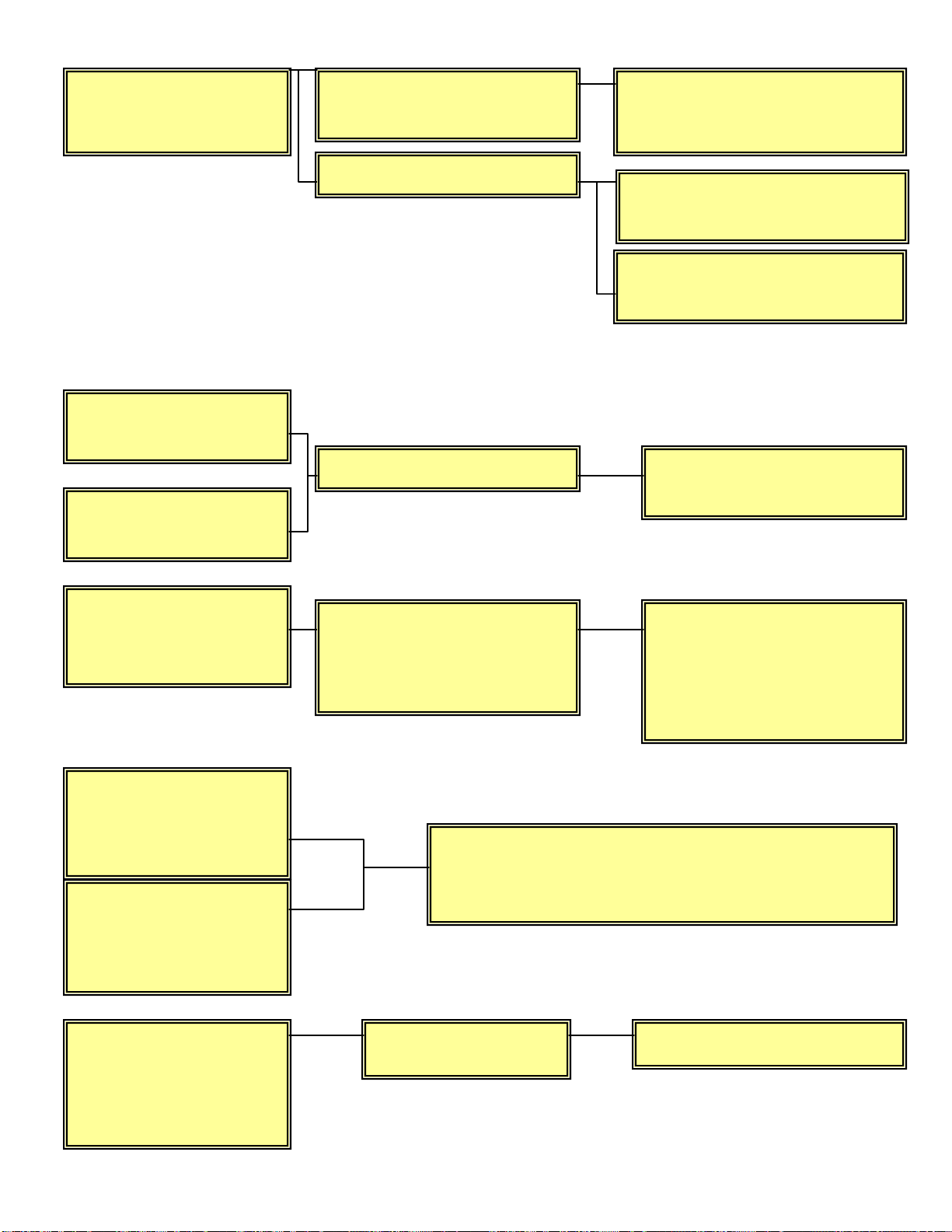

Page 10

p

Compressor will not

load.

Inlet valve not opening

Check that the valve is free

to open.

Check the operation of the

load solenoid valve 1SV.

Compressor fails to

deliver rated

capacity.

Excessive coolant

consumption.

Check the operation of

the inlet valve.

Check the operation of

the load solenoid valve

1SV.

Blocked scavenge line

Ruptured or fouled

separator element

Check the offline/online pressure

setting.

Check the inlet filter for

contamination. The L.E.D. should

indicate if it is blocked.

(ENH controller only)

Clear the blockage.

Change the element.

Rapid cycling or

receiver will not

blow down to

unloaded running

ressure.

System is not using enough

air, increase consumption.

Minimum pressure valve

(MPV) stuck open.

10

Strip the MPV, examine and

repair if necessary.

Page 11

(

)

Safety valve blows

when compressor

loads.

.

Motor reverse

rotation

Fault T 1

Emergency Stop

Fault T 2

Low ambient

temperature

Fault T 4

High sump air

pressure.

Faults T 5, W 5

Minimum pressure valve

(MPV) stuck closed.

Safety valve faulty

Incoming power wired to

package incorrectly

Emergency stop activated

Compressor will not start

below 2 deg C (28 deg F),

unless fitted with low

ambient option (−10_C)

14 deg F

MPV stuck closed Strip MPV, examine and repair

Blocked separator element

Blow down system

ineffective

11

Strip the MPV, examine and

repair if necessary.

Check the setting of the

safety valve and the rated

pressure.

Blocked separator element

Check differential pressure

and replace element

Change any 2 of the

incoming power wires to

change motor rotation

Clear fault hazard twist

emergency stop button to

reset.

Wait until compressor

package air temperature

rises above minimum starting

temp requirement.

Replace separator element

Check the operation of the

load solenoid valve.

Check un-loader valve − strip

and clean if necessary.

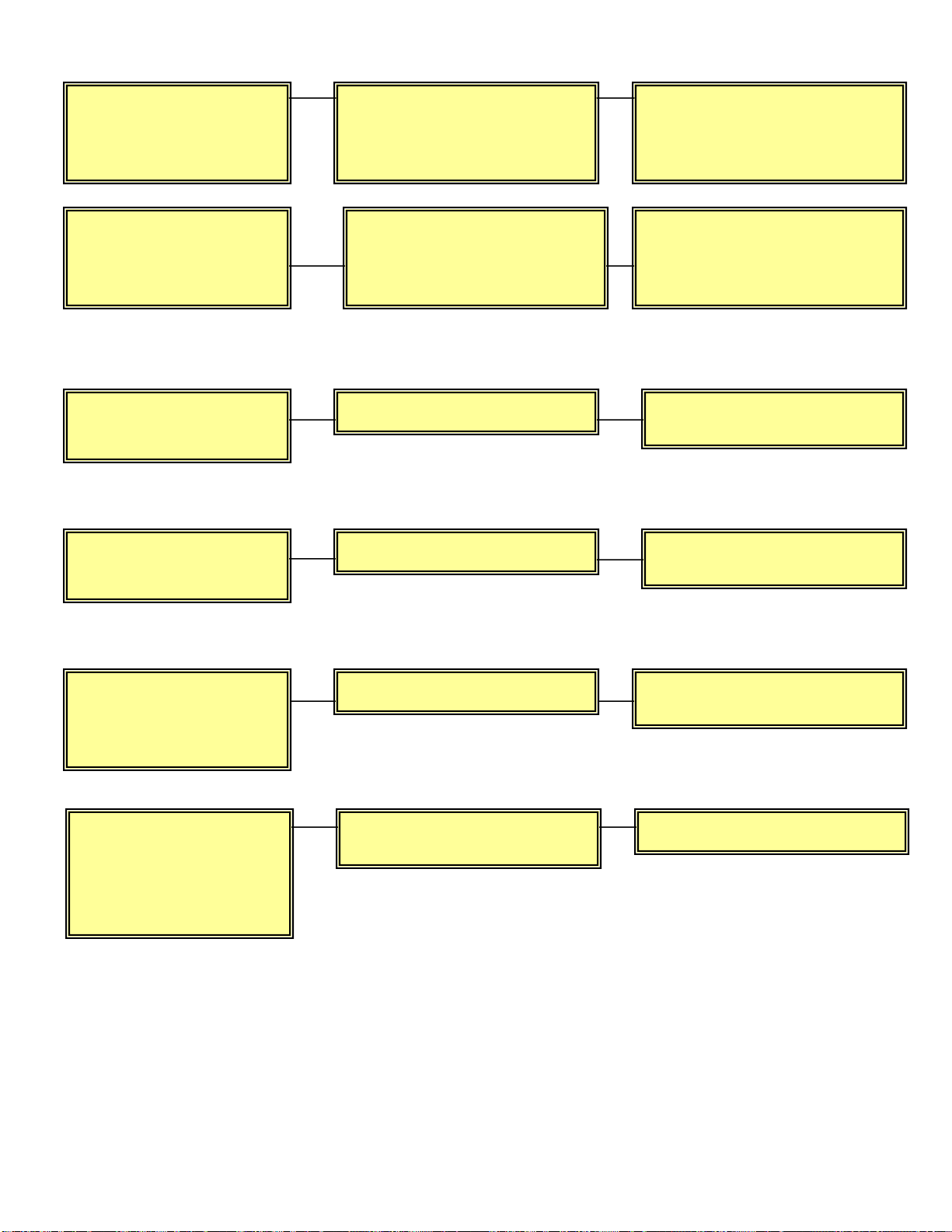

Page 12

Low sump air

pressure.

Fault T 6

P1 Sensor Failure

Fault T 7

P2 Sensor Failure

Fault T8

Temperature Sensor

Failure

Fault T 9

P1 Sensor

calibration

failure.

Fault T 10

P2 Sensor

calibration

failure.

Fault T 11

Incoming power wired to

package incorrectly

Check main motor rotation if

incorrect change any two wires

to reverse rotation.

Inlet valve not opening

Check valve and make sure it

operates freely

Check load solenoid valve and

controller operation.

Check wiring to transducer Recalibrate Transducer or

Replace

Controller measured value

is outside of the +/- 10 %

range of the full scale value.

Check resistance using

chart on pages 52-57.

Replace sensor if resistance

does not equal ambient

temp.

Check sensor connection and calibrate or replace if

necessary

Motor PTC Open

(High Motor Temp)

Fault T 20

Check for overload

condition

12

Checking motor cooling

Page 13

Maintenance due

soon.

Fault W 14

Maintenance timer has

reached 1800 hrs of runtime

or 7884 hours clock time.

Reset time in factory set up

menu using access code

1954

Maintenance due

immediately.

Fault W 15

Change oil filter.

Fault W 16

Change air filter.

Fault W 17

Maintenance timer has

reached 2000 hrs of runtime

or 8760 hours clock time

Change oil filter

Change air filter Check air pressure switch

Reset time in factory set up

menu using access code

1954

Check differential pressure

switch for fault

for fault

Change separator

element

Fault W 18

Integral sequencing

communication

failure.

Fault W 19

Change separator element Recalibrate sump pressure

transducer. (3APT)

Wiring or communication

fault

Check wiring

13

Page 14

Star Delta Wiring Diagram

14

Page 15

15

Page 16

Soft Start Wiring Diagram

16

Page 17

17

Page 18

Line Start Schematic

18

Page 19

19

Page 20

Process and Instrumentation Diagram

20

Page 21

21

Page 22

GENERAL OVERVIEW OF THE COMPRESSOR

The compressor is an electric motor driven, single stage screw compressor, complete with

accessories piped, wired and base plate mounted. It is a totally self contained air compressor

package. The standard compressor is designed to operate in an ambient range of 2_C to 46_C (35_F

to 115_F). The standard maximum temperature of 46_C (115_F) is applicable up to an elevation of

1000m (3280ft) above sea level. Above this altitude significant reductions in ambient temperature are

required if a standard motor is to be used. Compression in the screw type air compressor is created

by the meshing of two (male & female) helical rotors.

The air/coolant mixture discharges from the compressor into the separation system. This system

removes all but a few PPM of the coolant from the discharge air. The coolant is returned to the

cooling system and the air passes to the after cooler and out of the compressor through the moisture

separator (optional).

Air is pulled into the machine by the cooling fan and is pushed through the combined cooler / after

cooler. By cooling the discharge air and passing it through the separator, much of the water vapor

which is naturally present in the air, can be removed.

The coolant system consists of a sump, cooler, thermostatic valve and a filter. When the unit is

operating, the coolant is pressurized and forced to the compressor bearings. The compressor load

control system is automatic ’On−Off line’. This is accomplished by the Intellisys S3 Controller

monitoring the discharge pressure and operating the SV1 solenoid valve. When the load valve is on

(Loading) the blow down solenoid valve SV3 is off and this logic reverses when the unit unloads. The

compressor will operate to maintain a set discharge line pressure and is provided with an auto restart

system for use in plants where the air demand varies widely. Panel instrumentation is provided to

indicate the compressor operating conditions and general status.

CAUTION

LOW DEMAND APPLICATIONS

During periods of low demand, the compressor may not reach its normal operating

temperature. Sustained operation at low demand can result in the build up of condensate in

the coolant. If this situation occurs, the lubricating characteristics of the coolant can be

impaired which may lead to damage of the compressor.

THE COMPRESSOR SHOULD BE ALLOWED AMPLE LOADED RUNNING TIME.

22

Page 23

Input/Output and Alarm Information for

Intellisys S3 Controller

1.0 Hardware Input / Output Information

Each I/O and software function is labeled as STD where the function is available in the standard

controller (Rapidly Developing Economies) and ENH where the function is available in the enhanced

controller (RDE – Options and Developed Markets).

1.1 Analog Inputs - 10 bit resolution. .5% Full scale accuracy. Pressure Transducer, 2 Wire, 4-

20 ma, Loop Powered.

Sensor Range Description Control Term

STD 4APT 0-232 Psi Package Discharge X05 1-2

ENH 3APT 0-232 Psi Sump, Wet Side X05 5-6

Temperature, 2 Wire, 10 K ohm Thermistor, see appendix 1 for Resistance table!

Sensor Range Description Control Term

STD 2ATT -34 to 124 °C (255 F) Air end Discharge X05 3-4

1.2 Analog Output - 0-20ma, 24Vdc, max load 500 Ohms, .020ma resolution,

Output Description Control Term

STD #1 PORO Horn (Using Solid State Relay) X06 1-2

Analog Inputs Comments

STD Pressure Input Calibration - Initiates an automatic calibration routine for reading and

correcting the pressure transducer inputs with a known zero Psi input. A zero offset calibration should

be performed by first the user verifying the pressure applied to the pressure transducer is in fact 0

PSI. Initiating this calibration routine will read and store a new zero offset value for the analog inputs.

This value is used as an offset for all future pressure readings. The display (UI) should indicate to the

user that a zero Psi reading has been successfully made and stored for the new zero PSI offset value

by displaying a successful message or icon. If when reading the analog input for the 0 PSI value, the

actual reading is greater than +/- 10% of the scale, the calibration will not be performed for that

particular sensor and the previous pressure offset value will be retained. A Sensor Calibration Failure

will be displayed indicating which input has failed and also adding an entry into the Alarm Log. If the

Developed Markets features are enabled, the Sump Pressure transducer will be present and should

be calibrated along with the Package Discharge Pressure transducer. Span calibration is not

accessible by the customer. The calibration is done through the advanced set up menu as shown in

the flow chart on page 6.

23

Page 24

1.3 Digital Inputs - 24 Vdc internally supplied source, 200ma max,

DI #1 = 140 ma., DI #2 - #7 = 10 ma., DI #8 = 1.4 ma. typical current.

Input Fault Description Control Term

STD #1 Open Emergency Stop X04 1-2

ENH #2 Closed Oil Filter Condition X04 1-3

ENH #3 Closed Inlet Filter Condition X04 1-4

STD #4 Open Motor Over load (Main, Fan, Dryer) X04 1-5

*ENH #5 Remote Start and Stop X04 1-6

*ENH #6 Remote Load Enable X04 1-7

*ENH #7 Remote Load/Unload X04 1-8

ENH #8 Motor PTC X04 1-9

*IEO and ASC can control the compressors using an ISCII module

connected to digital inputs #5, #6 and #7.

1.4 Digital Outputs - Internal relay, 24 Vdc @ 8 Adc, 240 Vac @ 8Aac

resistive,

Output Description Control Term

Control Voltage Input, DO #1- #3 X03 1

STD #1 Starter Contact 1M X03 2-Comn

STD #2 Starter Contact 1S X03 3-Comn

STD #3 Load / Blowdown Solenoid Valve X03 4-Comn

Control Voltage Input, DO #4 X03 5

ENH #4 Modulation X03 6-Comn

STD #5 Condensate Drain X02 1-2

STD #6 General Alarm Contact (NO) X02 3-4

Digital Output Comments

STD Star Delta Logic Using Two Digital Outputs - Combine 1M / 2M on one common output, a

normally closed electrical interlock (KM3-2) from the 1S (KM3) contactor keeps the 2M (KM2)

contactor from energizing anytime the 1S (KM3) contactor is energized.

Electrical interlocks are wired such that when the 1S (KM3) output is de-energized at Star Delta

transition time causing the 1S (KM3) contactor to open, the 1S normally closed interlock (KM3-2) falls

back to the closed position energizing the 2M (KM2) contactor.

A second electrical interlock from the 1S (KM3) contactor is wired in series with the 1M (KM1)

contactor to insure the 1S (KM3) is pulled in before the 1M (KM1) will be energized. An interlock from

the 1M (KM1) contactor is used to seal around the 1S (KM3-1) contact to allow the 1M (KM1) contact

to remain energized when the 1S (KM3 contact is de-energized at the Star Delta transition.

STD Allen Bradley SMC-3 Soft Start Logic Using Two Digital Outputs

Outputs X03-2 and X03-3 can be configured to operate an Allen Bradley SMC-3 soft starter. The

operating sequence of X03-2 and X03-3, when the soft starter starting method is selected, follows.

X03-3 energizes immediately at the start command. 1/2 seconds later X03-2 energizes. Both outputs

maintain an energized state while the motor is given a run signal. When the motor is given a stop

signal the operating sequence of X03-2 and X03-3 are reversed from the starting sequence.

24

Page 25

STD Common Fault Relay - This is an output provided for customer use. This relay energizes

during normal operation and returns to its Normally Open, N.O., state, when a shutdown or trip

condition is detected. The Fault relay should only toggle when the controller has detected a Shutdown

or Trip (Alarm) condition.

STD Condensate Drain - This is an output provided to control a condensate drain solenoid valve.

This output is a timed output that toggles on for a period of time defined by the Condensate Drain

Time set point. The drain valve remains off for a period defined by the Condensate Drain Interval

Time set point.

Condensate Drain Time Default - 5 Sec

Minimum - 1 Sec

Maximum - 30 Sec.

Condensate Interval Time Default - 180 Sec

Minimum - 90 Sec

Maximum - 300 Sec

ENH Modulation - The modulation output is used to turn on the modulation solenoid valve anytime

the modulation set point is turned on and the machine is in a loaded state. If the modulation set point

is turned off the output remains off.

1.5 Control Power Supply - 24 VAC +/- 20%, 24 VA, 50/60 Hz, Floating -non-grounded, and

the controller must sustain a 40ms power outage before resetting.

Input Description Control Term

Supply Controller Power X01 1-2

I/O Functionality

STD Contact De-bounce Times are not adjustable and are for information only. .

Dig Input #

1 50 ms

2 15 sec

3 15 sec

4 2 sec

5 2 sec - Closed

.5 sec - Open

6 50 ms

7 50 ms

Delay Time

STD Combine MOL FOL into a common digital input called Motor Overload. Overload contact

current must be minimum 17vdc and 5 ma.

ENH Remote Start / Stop using a single contact.

25

Page 26

1.6 Intellisys S3 Serial Communications - RS-485, 500 to 1000 Meters

Port Description Control Term

ENH Port #1 Integral Sequencing, X4I, X8I X07 1-2

CMC Multi-485, Serial Programming

ENH Port #2 Remote Monitor / Control, X08 1-2

Modbus RTU

STD Port#2 Modbus Read Only X08 1-2

Serial Communications Comments

ENH Serial Port #1 - S1 Integral Sequencing, X4I, X8I, Hardware - RS485, 2 Wire Half Duplex,

Opto-isolated, and capable for communicating up to 4000 ft from a host device. Software - CMC

Multi-485.

ENH Serial Port #2 - IEO, ASC, Remote Monitoring and control of the compressor. Hardware -

RS485, 2 Wire Half Duplex, Opto-isolated,and capable for communicating up to 4000 ft from a host

device. Software - Modbus Slave, RTU, Selectable Baud Rate, 2 Stop bits, 8 Data bits, No Parity.

Modbus Baud Rate - Selectable from any one of the following standard Baud rates. 1200, 2400,

4800,9600, 19200, 38400, 57600, 76800, 115200.

Modbus Registers - See Paragraph 13 “Modbus Register Listing” for the compete register listing

with detailed descriptions. Modbus Commands Supported - At a minimum Modbus 03 Read Holding

Register, and 06 Preset Single Register.

This serial port must be capable of connecting to a multi-drop, RS485 network with up to 32

devices functioning as a Modbus Slave only. This serial port will be exposed to all Modbus network

traffic intended for any device on the network. Serial communication handling must not hinder safe

and timely machine control. The serial port should be capable of servicing communications at least

twice per second. Any serial communications intended for this slave device must be responded to

within 500 milliseconds.

ENH Serial Control - Starting the compressor using serial communications can be accomplished

only if RC, Remote Control, is set to Modbus control. See Section12

For Modbus control commands to operate, the Status Register (1) bit 0 must be set High for all

Status Register write commands to enable and maintain Host control. To remain in Host control

mode, serial communications (any serial communication) must be maintained with a maximum of 2

seconds between communications. If for any reason serial communications is lost (not accessed

within 2 seconds), the compressor reverts to Local control and continues to run using the local set

points.

The compressor is started by placing the compressor in Host Control, Status Register 1, bit 0 to a

1 (Host), and bit 1 to a 1 (Run) or a Hex 03 command. This will start the compressor and place it in a

run condition. If the pressure is such that the compressor needs to run (depending on the mode of

operation) the compressor will start and run until the compressor no longer needs to run to maintain

pressure. When the compressor is in a run mode, but no longer needed to make air, the compressor

motor will be stopped in “Auto Restart” but will restart any time air is needed. Local Control stopping

should always remain active and of the highest priority for safety of the compressor. If the compressor

is stopped locally, all remote control operation is cancelled The Units of Measure for the Pressures

read serially will always be read in PSI and temperatures in Deg F.

26

Page 27

1.7 Remote Control The compressor will not automatically restart after a power failure unless a

PORO kit is installed. The compressor can be restarted using the Green start button only if the

compressor is getting a remote run command.

1,8 Auto Stop Timer The auto stop timer has a range of 30 to 360 seconds. Zero (0) can be

selected, which will prevent the motor from stopping. The machine will only load/unload without ever

stopping the motor.

1.9 Eiger Maintenance Intervals

STD Multiple level maintenance intervals

STD 150 Hours Runtime -150 Hrs after the initial start-up of the compressor, one time timer.

STD 2000 Hours Runtime - 2000 hours of compressor runtime since the last maintenance timer reset.

STD 8760 Hours Real Time Clock Time - (1Yr) after initial startup of the compressor or after the

maintenance timers have been reset.

STD Maintenance Indicator - How to display time to maintenance; the maintenance timer will display

the maintenance timer value in hours and in percentage, (2000 or 8760) closest to reaching its

respective predetermined maintenance interval time. Once the maintenance timer value reaches 10%

(or 90%) of the preprogrammed time, (1800 hrs of runtime or 7884 hours clock time) the Wrench Icon

will flash. Once the maintenance timer value reaches 0% (or 100%) of the preprogrammed time,

(2000 hrs of runtime or 8760 hours clock time) the Red LED will flash (Warning) and wrench icon

should be on continuously and remain on until maintenance is performed and the timers are reset.

STD Reset Maintenance Timer - Once service has been performed the Maintenance Timer values

can be reset by entering the Factory Setup Menu and scrolling to the Maintenance Timer Reset

screen and performing the reset. If for any reason a time other than 2000 hours needs to be entered it

can be done in the Maintenance rest menu. Simply set the hours wanted and press enter.

27

Page 28

Maintenance

28

Page 29

Maintenance

29

Page 30

Maintenance

30

Page 31

S3 Controller Input/Output Overview

AI = Analog Input

DI = Digital Input

DO = Digital Output

31

Page 32

S3 Fault Descriptions

2.0 Faults An Intellisys S3 – A WARNING will not shutdown the compressor. The warning will

remain on the display until acknowledged. It can be cleared by pressing the “C” clear key. A log will

be retained of the warnings / trips that have occurred. An Intellisys S3 TRIP will shutdown the

compressor and must be manually cleared by pressing the “C” clear key. The trips will remain on the

display until acknowledged. The trips displayed will take precedence over the warnings. A log will be

retained of the warnings / trips that have occurred.

Trip Faults Comments

ENH Motor Reverse Rotation - Sump pressure has not indicated a positive pressure, 2 seconds

after the machine has loaded, first time after a power-up. This time is increased to 6 seconds if the

soft starter option is turned on. Once correct motor rotation is verified, this is not checked again until

power is removed from the controller.

STD Emergency Stop - Emergency Stop low level contact has opened.

STD Motor Overload - Main motor or Fan motor Overload contact has opened.

STD High Package Discharge Pressure – refer to table in section 12 - (Not Adjustable, Information

Only)

STD High A/E Discharge Temperature - refer to table in section 12 - (Not Adjustable, Information

Only)

STD Low Ambient Temperature - The air-end temperature sensor is measuring a temperature less

than 2°C. The compressor will be in an alarm state and not start if the temperature is below 2°C. The

compressor will start if the temperature is above 2°C. This is only active if Low Ambient, LA, option is

installed.

ENH Low Sump Air Pressure - The sump air pressure has not increased above 15 psi. This is

measured 15 seconds after starting and operational anytime the compressor is running.

ENH High Sump Air Pressure - refer to table in section 12 (Not Adjustable, Information Only)

STD Discharge Pressure Sensor Failure - The discharge pressure sensor input reading is beyond

the normal measurement range below 3.4 ma or above 20.8 ma.

ENH Sump Pressure Sensor Failure - The sump pressure sensor input reading is beyond the

normal measurement range below 3.4 ma or above 20.8 ma.

STD / ENH Sensor Calibration Failure - A sensor calibration has been attempted and the measured

value is outside of the +/- 10 % Full Scale value.

ENH Motor PTC Trip The motor TC is open due to high motor Temperature.

Warning Faults

STD High Package Discharge Pressure - refer to table 12 (Not Adjustable, Information Only)

ENH High Sump Pressure – refer to table 12 (Not Adjustable, Information Only)

STD High Air end Discharge Temperature - refer to table 12. (Not Adjustable, Information Only)

STD Maintenance Due soon - refer to table 12 (Not Adjustable, Information Only)

STD Maintenance Due immediately - refer to table 12 (Not Adjustable, Information Only)

ENH Change Oil Filter -

ENH Change Inlet Filter -

ENH Change Separator Filter -

ENH Integral Sequencing Communication Failure -

32

Page 33

Fault History

STD Retention of Fault History last 15 trip and warning faults with compressor information.

Real Time Clock

STD The real time clock will be used to count down the 8760hrs before maintenance. This time is

reset when the maintenance hour indicator is reset. The customer can not view the clock.

User Interface

Buttons - The 8 buttons located on the controller are to be a raised membrane button used to

activate the membrane switch. The icon and button oval are not raised.

Fault Symbols

LED Indicators - Green - On when the compressor is running and no fault conditions are detected.

“Ready” Off when the compressor is in a Shutdown - Faulted condition. Off when the compressor is

not running.

Red - Flashing indicates a Warning condition. (Along with the Green LED still illuminated). On Solid

indicates a Shutdown condition.

33

Page 34

S3 Intellisys Operator Display Icons

The backlight for the LCD should be left on all the time as long as this does not significantly reduce

the life of the backlight.

Icons in the standard LCD display:

--------------------Shutdown in Auto Restart (Pressure Control)

-------------------Power Out Restart Active (PORO)

-------------------Scheduled Start / Stop Active

------------------Change Air Filter Warning

------------------Change Oil Filter Warning

34

Page 35

Status Display - When power is applied to the controller the LCD check will

be performed for 3 seconds and the Controller Software

Version will be displayed.

Status Icons indicating machine operational or fault status will be continuously displayed for all Status

displays.

Compressor Running Unloaded

(Manual Unloaded)

Compressor Running and Loaded

(Flash Icon when the compressor is

Unloaded due to pressure)

Remote Control Active

Disch Press Below Load Set point

Disch Press Between Load and

Unload Set points

Disch Press Above Unload Set point

Stopped Auto Restart

35

Page 36

PORO Active

I(Arrow to point to the left)

Scheduled Start / Stop Active

Pressing the Up and Down arrow buttons will toggle through the following items to be displayed in the

Multi-use display area. If no buttons are pressed within 30 seconds, the display should revert back to

the default display item. Package Discharge Pressure with Units should be continuously displayed for

all Status and Setup displays.

Satus screen Data in Yellow will only be displayed is ENH

Default Ae: 0 0 0 0 °C Airend Discharge Temp

(1) Ip: 0 0 0 0 PSI Sump Pressure

(2) DL: 0 0 0 0 PSI Delta pressure DL will not be displayed while running unloaded

(3) Rn: _ _ _ _ 000 Run Hours ------------------------------------------

(4) Ld: _ _ _ _ 000 Load Hours -------------------------------------------

(5) Mn _ _ _ _ 000 Maintenance Hours (before Maintenance due) -

(6) Mn _ _ _._ Maintenance % (% of hours before Maint due) ---------------

(7) IS_ _ _ _ Displays the number of hours before Sequencing occurs if IS is enabled

Setup screen Data in Yellow will only be changeable in an ENH controller. The data will be viewable

in a STD controller.

36

Page 37

Setup Display - The Setup Display is entered by pressing the Menu button while the compressor is

not running mode. The Setup display can be exited by pressing the Clear button. A security code of 0

0 0 0 will be required to enter the Setup Display.

CD: 0 0 0 0 Pass Code

If no buttons are pressed within 30 seconds, the display will revert back to the default Status display

item.

Un: 0 0 0 0 PSI Unload Pressure -------------------------------------------

Ld: 0 0 0 0 PSI Load Pressure --------------------------------------------

As: 0 0 0 0 SEC Unloaded Run Timer ------------------------------

Md: _ _ _ _ On_ Modulation On/Off ------------------------------------------

Eu: _ _ _ _ _°C Engineering Units

Dt: 0 0.0 0 _00 Current Date

Tm: 0 0:0 0 _ _ _ Current Time ------------------------------------------

Setup screen Data in Yellow will only be changeable in an ENH controller. The data will be viewable

in a STD controller.

37

Page 38

Trip History Menu - The Trip History display is entered by pressing the Up arrow from the Setup

Menu display. The display will default to the most recent Trip and will automatically cycle through the

recorded values. The last 15 Trips will be recorded. The Trip History can be cycled through by

pressing the Up and Down arrows to select the desired Trip for viewing. The Status Icons should be

displayed as the recorded status

he machine was in when the Trip occurred. The following information will be automatically scrolled

through for each Trip.

Fc: _ 0 0 1 _ _ _ Fault Code

Pd: _ _ 6 5 PSI Package Discharge Pressure

Ae: 2 2 1.0 °F Airend Discharge Temperature

Rn: _ _ _ _ 1 2 3 Run Hours

Sp: _ _ 6 9PSI Sump Pressure

Dt: 1 0.3 0 _06 Date

Tm: 1 0:0 5 Time

Advanced Setup Menu - If the Password entered in the Pass Code entry screen is 0 1 0 1, the

Trip History display is entered by pressing the Up arrow from the Shutdown History display.

Pd: _ C A L _ OK Package Discharge Pressure

Transducer Calibration

Ip: _ C A L _ OK Sump Pressure Transducer

Calibration

: 0 0 0 0 SEC Star Delta Time --------------------------------------------

Sf: 0 0 0 0 SEC Soft Starter Time ---------------------------------------------

Cd: 0 0 0 0 SEC Condensate Drain Time -------------------------------------------

Ci: 0 0 0 0 SEC Condensate Interval Time -----------------------------------------

Sd: 0 0 0 0 Service due Timer --------------------------------------

Ss: _ _ _ _ OFF Scheduled Start Stop --------------------------------------

On/Off

38

Page 39

St: 0 0:0 0 _ _ _ Scheduled Start Time -----------------------------

Sp: 0 0:0 0 _ _ _ Scheduled Stop Time ----------------------------

Po: off PORO on/off --------------------------------------

Pt: 0 0 1 0 SEC PORO Time -----------------------------

Lt: 0 0 2 0 SEC Low Ambient Load Delay Time --------------------------------

RC: 0 0 0 0 _ Remote Control Selection -------------------------------------

Is: _ _ _ _ OFF Integral sequencing --------------------------------------

Cn: 0 0 0 1 Multi 485 Compressor # -------------------------------------

Ad: 0 0 0 1 _ _ _ Modbus Address --------------------------------------

Bd: _ _ _ 9 6 0 0 Modbus Baud Rate --------------------------------------

39

Page 40

Fault Indicators- Trips - Red Trip LED on solid, green LED off. When a trip or warning is

detected by the controller, the following codes and icons should be displayed on the bottom line of the

LCD display.

T Indicates Trip

T20 Motor PTC Trip

40

Page 41

Warnings - Red Alarm LED flashing, green LED on

W Indicates Warning

Environmental Requirements -

continuously in ambient temperatures between 35°F (2°C) and 115°F (46°C) with non condensing

humidity from 0-95% from the front of the controller. The temperature at the rear of the controller can

reach 60C.

All units shall be designed such that the package can operate

41

Page 42

EIGER OPTIONAL FEATURES

STD Low Ambient - The low ambient kit is designed to protect the compressor when starting in

temperatures below 2° C. The temperature is measured at the air-end discharge. The temperature is

read using the standard Air-end temperature sensor. When the Low ambient option is installed and

selected and the A/E Discharge Temperature is measured to be below 2°C, the compressor will be

started when commanded but will delay to load a period of time defined by the Low Ambient Delay

Time, Section 12. This will allow the coolant temperature to rise above an allowable level before

loading the compressor in cold environments. When the Low ambient option is not installed the

machine will not start if the A/E Discharge Temperature is below 2°C. The machine will trip on a Low

ambient fault. This trip will be logged in the fault table. The user can re-start the compressor by

holding the start button in for 10 seconds. Each time the compressor faults on a Low Ambient trip the

customer will have to manually restart and the trip will be recorded in the fault table.

STD Power Out Restart - At loss of power to the machine, a software or hardware flag is set

indicating the operational status of the compressor. Once power returns, the flag is evaluated and the

compressor is returned to its previous operational state. PORO when enabled will be active in all

Local and Remote control modes of the compressor. For PORO to execute, the PORO option must

be installed and the PORO enable must be set to ON in the factory set-up menu. The customer then

has visibility to turn off/on and set the time delay of the PORO option in the advanced set-up menu.

Assuming this is the case, if power is lost to the compressor while the unit is running or is stopped in

auto start/stop, the control will store in memory the current operating conditions.

When power returns to the unit, the control will first verify the PORO option is installed, enabled and

turned ON. Next the control will check to see if the unit was running or stopped in auto start/stop

when power was lost. If it is determined this was the case, it will start the PORO sequence. The

control will energize the PORO horn and start a count down on the display. The RED light will flash

indicating a Warning condition and the horn will blow for the number of seconds (see table 12) the

operator set in the PORO time set point. At the end of the count down the horn will stop blowing and

the compressor will start. The PORO count down can be stopped at anytime by pressing the Stop /

Reset button on the user interface. Pressing any button will cause the horn to stop blowing and the

count down to stop. The control will power up normally in a ready to start mode. If unit is being

operated using remote control, the compressor will not automatically restart after power returns if

PORO kit is not installed.

ENH Scheduled Start / Stop - This is an auto start / stop mode of operation based on the Real

Time Clock current time. A Scheduled Start Time set point is used to automatically start the

compressor when the current time equals the Scheduled Start Time entered for the set point. A

scheduled Stop Time set point is used to automatically stop the compressor when the current time

equals the Scheduled Stop time entered for the set point. This mode of operation can be turned on

and off by selecting the desired mode in the Scheduled Start Stop

On/Off Set point, When Scheduled Start/Stop is turned on and the current time equals the Scheduled

Start Time set point, and the compressor is

not currently running, the compressor will automatically activate the output for the PORO horn for 10

seconds (hard coded) to warn anyone in the surrounding area that the compressor is about to start.

The UI will display a Warning message “Scheduled Start in X seconds”. X is a countdown from 10 to

0 seconds. After 10 seconds the compressor will automatically start as long as the compressor is not

in a Fault condition or manually stopped by pressing the Stop / Reset button. When Scheduled

Start/Stop is turned on, and the current time equals the Scheduled Stop Time set point, and the

compressor is currently running, the compressor will automatically stop. The compressor can

42

Page 43

manually be re-started by any of the standard starting methods. Pressing the control panel start

button, or if Remote Control has been turned on, closing the Remote Start signal or sending a serial

start command.

ENH Integral Sequencing - It will be possible to sequence three Intellisys controllers without a

system controller. This is possible through a cable connecting, up to three Intellisys S3 controllers,

and using one of the controllers as a system controller.

MODULATION CONTROL OPTION

Modulation hardware extends the control types to Modulation (capacity control) and Automatic

Control System when the compressor switches between ’On/Off line’ and modulation as demand

varies. Safety of operation is provided for as the compressor will shut down if excessive

temperatures, electrical overload conditions, or system over pressure should occur.

For those plants which have relatively high constant air demand relative to the compressor capacity,

the recommended control mode is modulation. The modulation control system retains the features of

the on-line / off-line control, but also provides for throttling of the inlet flow up to the off-line air

pressure set point value. By applying line pressure to an adjustable modulator valve, the throttling

position of the inlet valve is controlled, thus allowing the modulator to ”trim” the inlet valve position as

dictated by the line pressure.

The modulating pressure range is about 0.3 bar (4.0 psid) and the modulator normally should be set

to straddle the compressor rated pressure. Modulation begins when the line pressure reaches about

99 percent of the compressor rated pressure and continues as/if the line pressure rises. Modulation

becomes stable when the compressor output equals the plant air demand. When the modulation is at

the factory setting, the maximum capacity reduction will be approximately 60 percent of the

compressor rated capacity (as indicated in Figure 1).

43

Page 44

MODULATE CONTROL VALVE ADJUSTMENT

Ensure that the compressor is isolated from the compressed air system by closing the isolation valve and

venting pressure from the drip leg. Ensure that the main power disconnect switch is locked open and tagged.

1. Put the compressor in the MODULATION mode.

2. Connect a pressure gauge to outlet port of modulation valve with 1/4” tubing tee.

3. Loosen the adjustment screw locknut and back out adjusting screw 3 turns. See Figure 2

4. Put the main power disconnect switch in the ON position.

5. Open the isolation valve and start the compressor.

6. Adjust the isolation valve to bring the discharge air pressure to the rated discharge pressure (100, 125, or

140 psig).

7. While maintaining the rated discharge pressure, turn the adjustment screw on the modulation valve (see

Figure 2) so that the test pressure gauge reads:30 psig for modulate 60% capacity Tighten the adjustment

screw locknut.

8. Press UNLOADED STOP. Wait for sump pressure to go 0 psig.

Close the isolation valve or vent off all system air.

9. Put the compressor in the desired control mode.

10.Remove the test pressure gauge and replace 1/4” plastic plug.

Table 12

44

Page 45

Standard S3 Menu Structure and Parameters

Table 12

45

Page 46

Standard S3 Menu Structure and Parameters

Table 12

46

Page 47

Standard S3 Menu Structure and Parameters

Table 12

47

Page 48

Standard S3 Menu Structure and Parameters

Td – Air Temp High Level Trip Fixed Value 109 C 109 C 109 109

Table 13

48

Page 49

Modbus Register Listing

49

Page 50

Table 13

Modbus Register Listing

50

Page 51

Motor PTC Open (High Motor Temperature)

Here is a list of trip codes that are very handy to carry with you on a service call.

51

Page 52

Appendix 1 Thermistor 2ATT -34 to 124 °C (255 F) Air end Discharge

52

Page 53

53

Page 54

54

Page 55

55

Page 56

56

Page 57

57

Page 58

General Specifications for Eiger Packages

58

Page 59

59

Page 60

60

Page 61

61

Page 62

62

Page 63

63

Page 64

64

Page 65

65

Page 66

66

Page 67

67

Page 68

68

Page 69

69

Page 70

70

Page 71

71

Page 72

72

Page 73

73

Page 74

74

Page 75

75

Page 76

76

Page 77

77

Page 78

78

Page 79

79

Loading...

Loading...