Ingersoll-Rand QX Series User Manual

QX Series Display

User Manual

48619852

Edition 1

July 2012

EN

User Manual

ES

Manual de usuario

FR

Manuel d’utilisation

IT

Manuale per l’uente

DE

Benutzerhandbuch

NL

Gebruikershandleiding

DA

Brugervejledning

SV

Bruksanvisning

NO

Brukerhåndbok

FI

Käyttöopas

PT

Manual do Utilizador

EL

Εγχειρίδιο Χρήστη

SL

Uporabniški priročnik

SK

Používateľská príručka

CS

Návod pro uživatele

ET

Kasutusjuhend

HU

Felhasználói kézikönyv

LT

Naudotojo vadovas

LV

Lietotāja rokasgrāmata

PL

Podręcznik użytkownika

BG

Ръководство на потребителя

RO

Manual de utilizare

RU

Руководство пользователя

ZH

用户手册

JA

ユーザー マニュアル

KO

사용자 설명서

Save These Instructions

EN

Purpose of the document:

This document provides details about dierent menu screens, their description and how to edit those screens in display

module, required for the operation of QX Series Hand Tool.

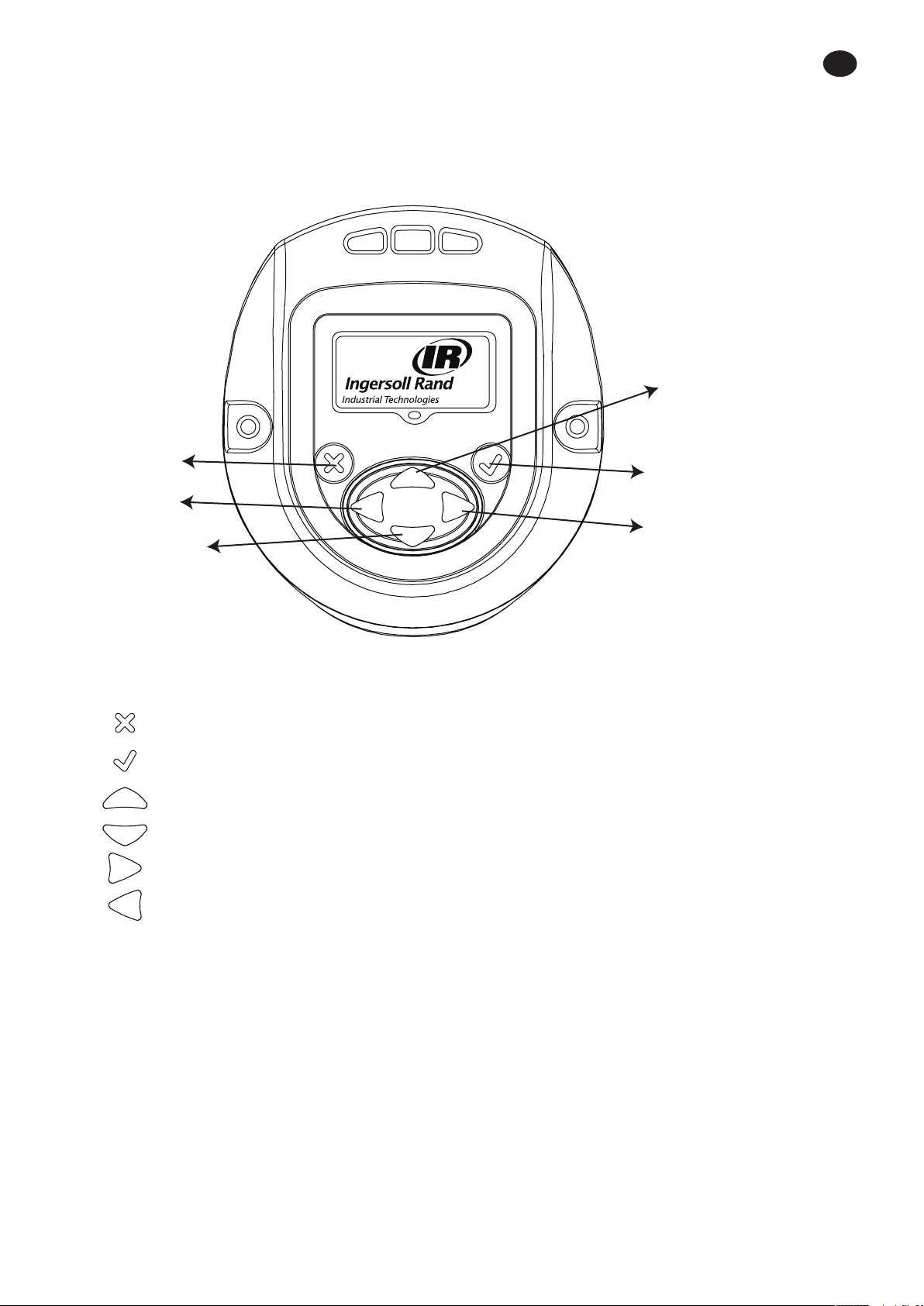

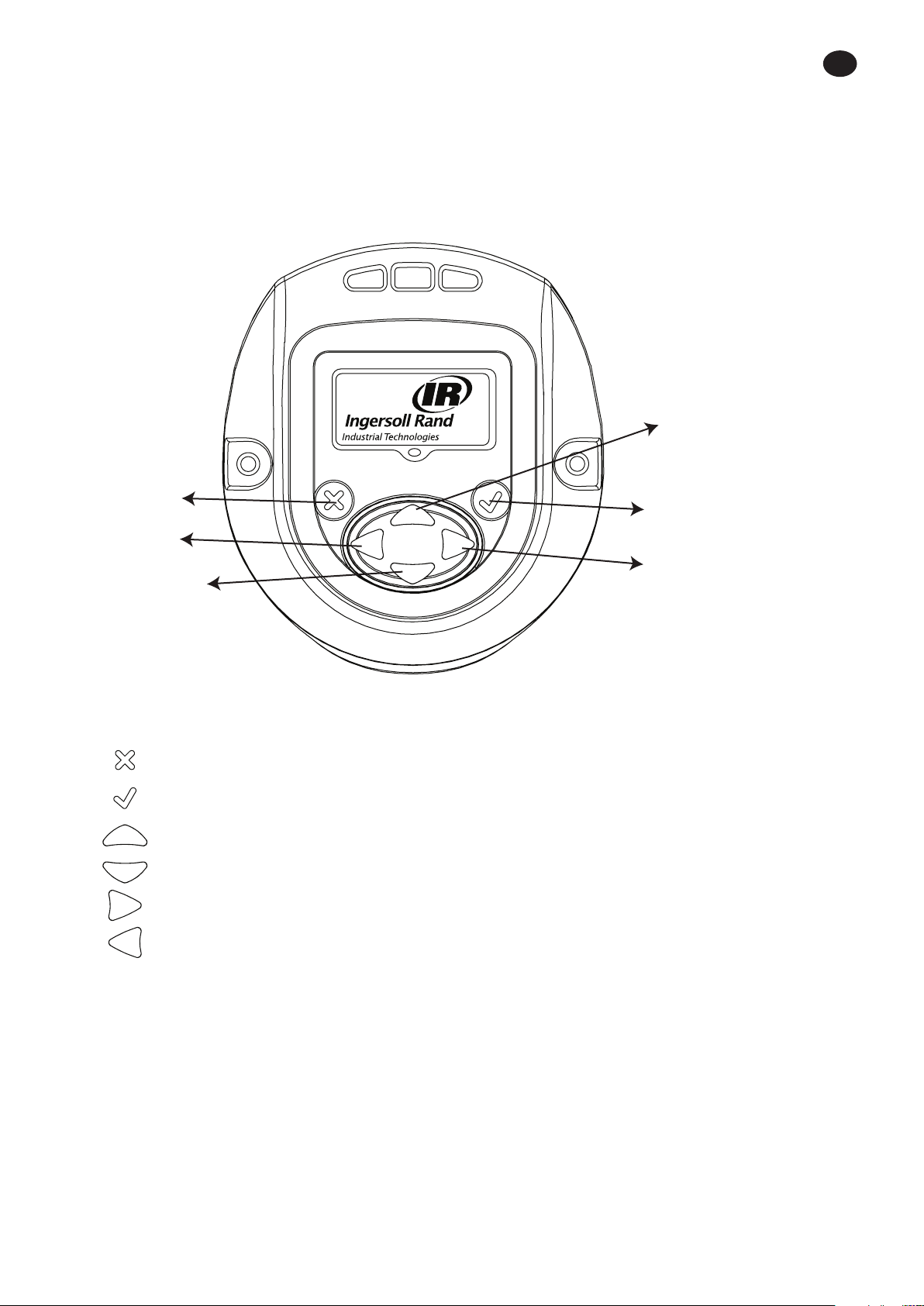

The image Below shows the display of QX Series display module with descriptions of the programming keys.

UP

ESCAPE

LEFT

DOWN

Symbol Function

Escape / Exit

Enter / Edit

UP

DOWN

RIGHT

LEFT

ENTER

RIGHT

48619852_ed1 EN-1

EN

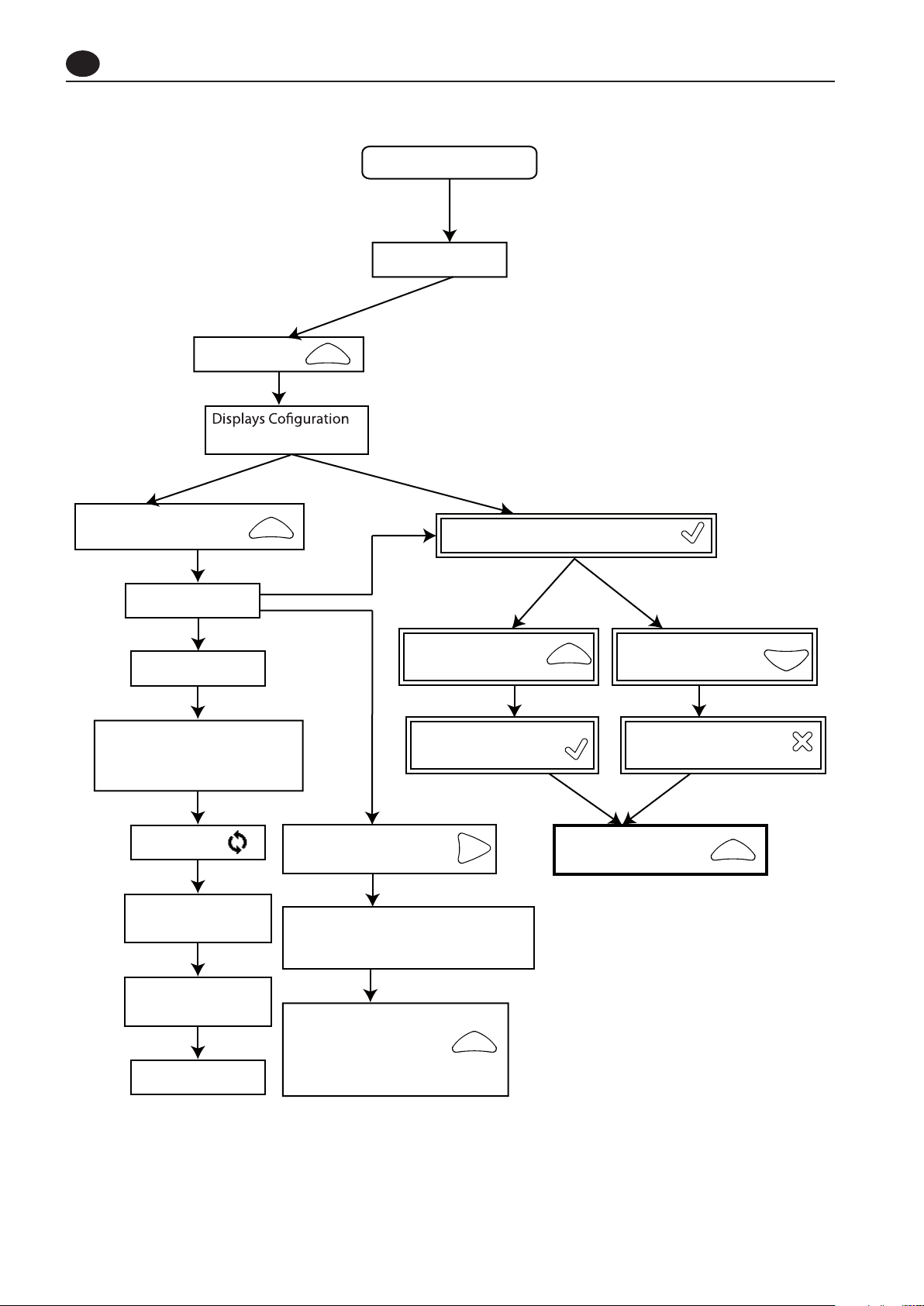

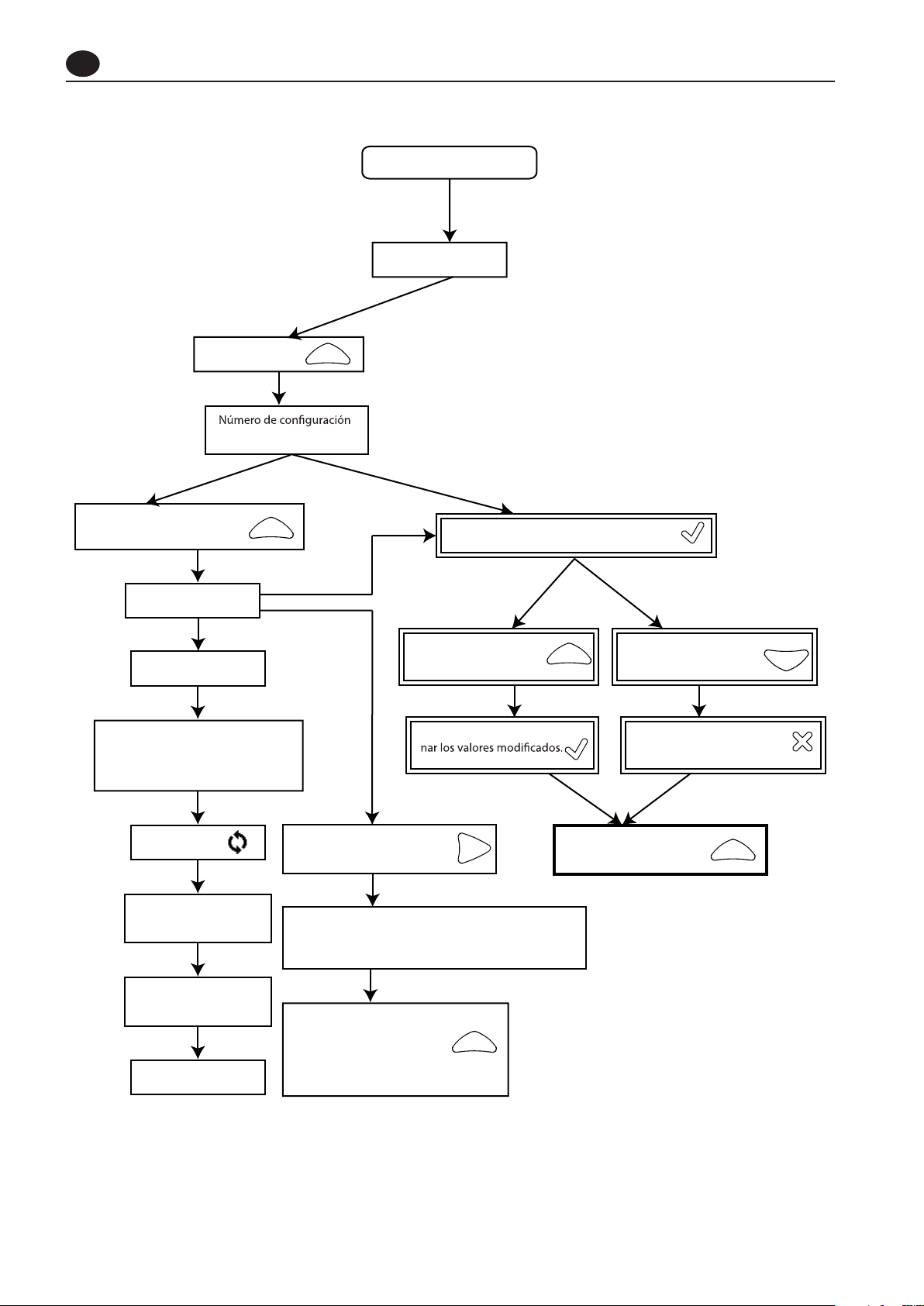

Power up QX Series tool

RUN SCREEN

Press “UP” key

Number being used

Always Press “UP” key to

go to next screen

Press “ENTER” to enter “EDIT” mode

Password screen

Current fault

Status screen with shunt

cal, wireless strength and

battery level.

Cycle Count

Target Angle, Low

and High screen

Target Torque Low

and High screen

RUN SCREEN

Press “UP” key to

increment the value

Press “DOWN” key to

decrement the value

Press “ENTER” to select

the changed values.

Press “ESC” to undo and

keep the old values.

After display is unlocked

Press “RIGHT” Key

Press “UP” key to go to

next screen

Save or Ignore changes. If not on

Save screen, use the up or down

key to scroll to the Save screen.

Press “UP” key to scroll

on one by one to get

below editable screens

in seriesscreen.

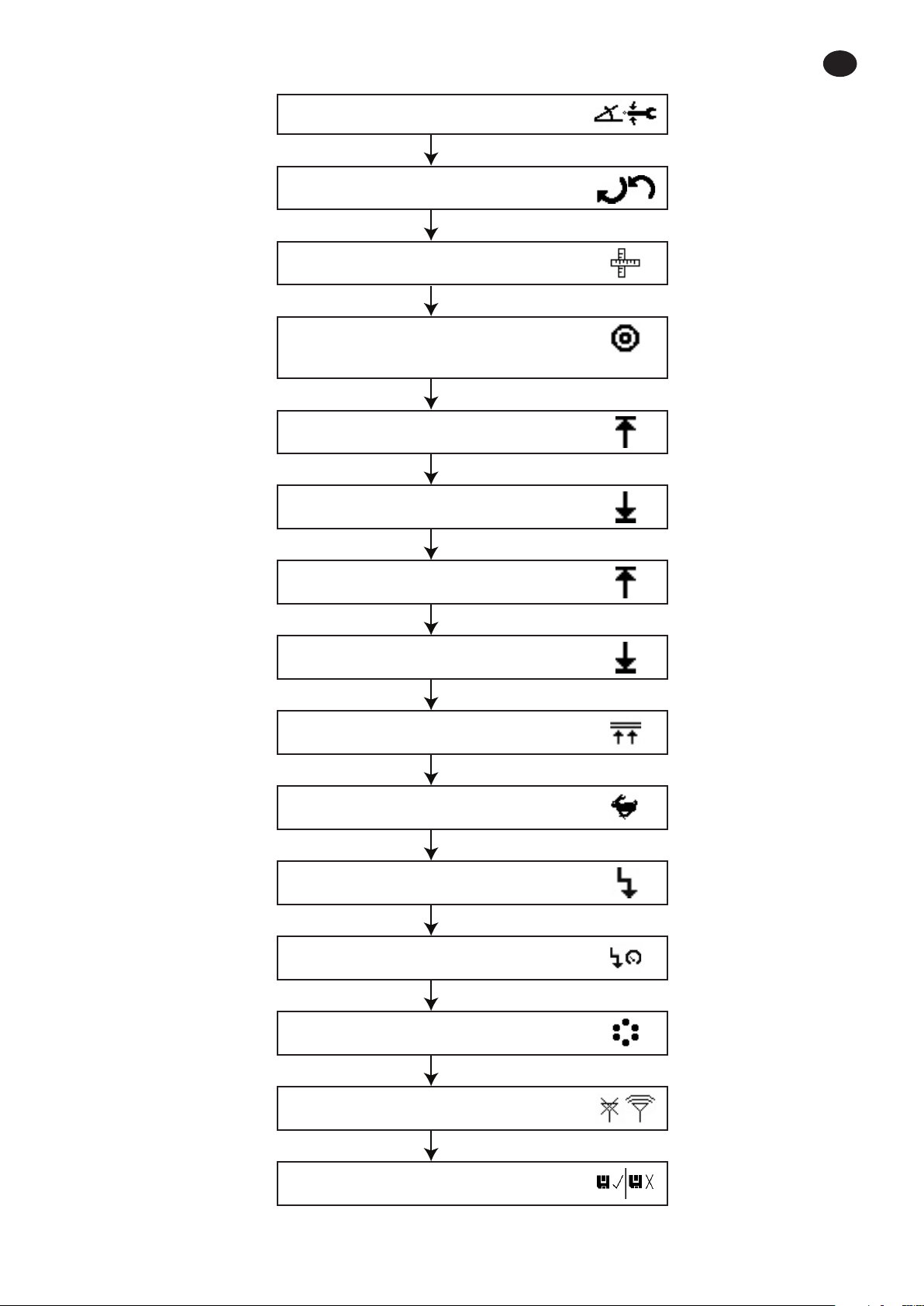

1. Overview of dierent Menu screens

EN-2 48619852_ed1

EN

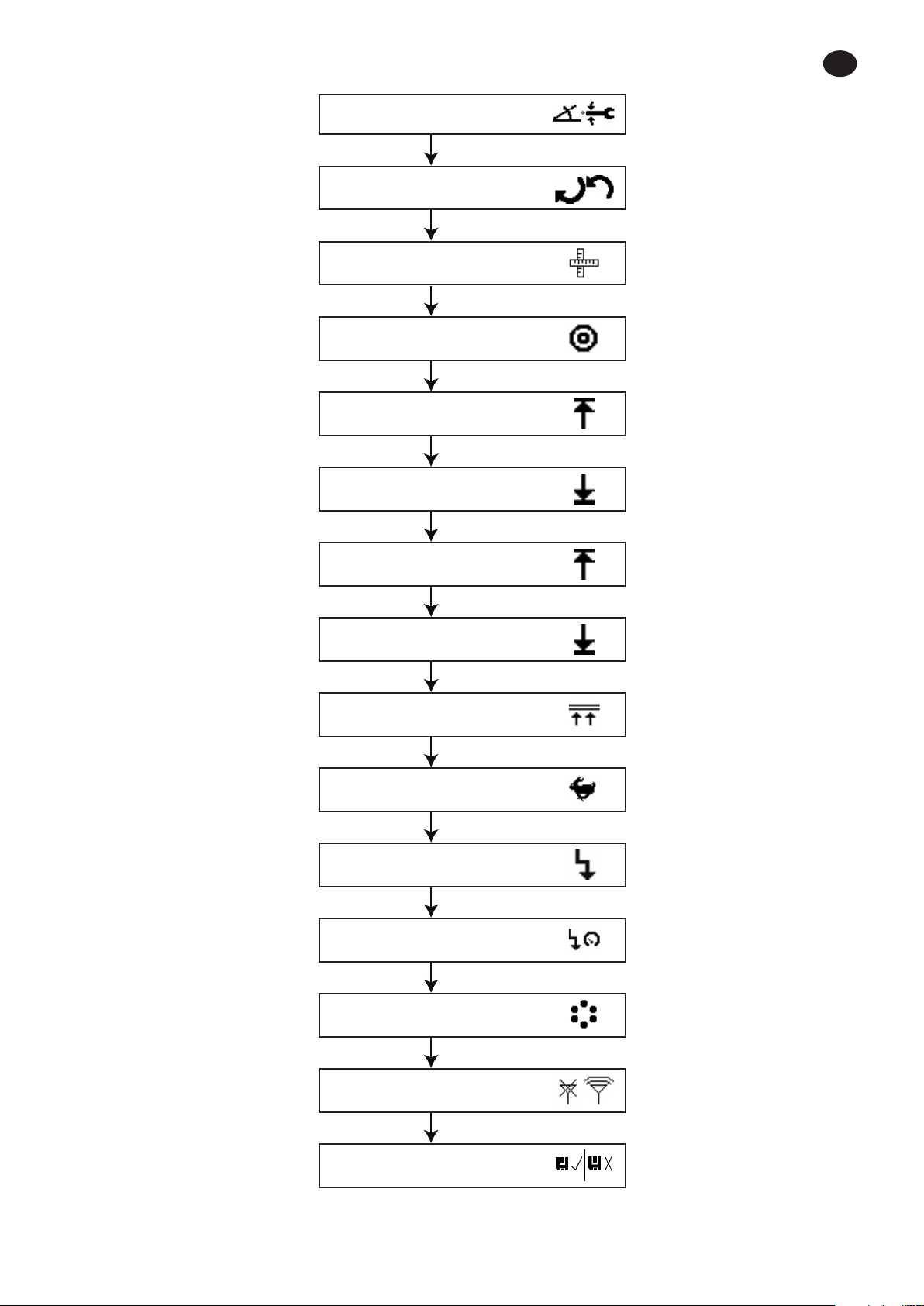

Strategy – Angle or Torque

Direction – Clock wise or anti

clockwise

Unit of Torque

Target Angle (Angle strategy) OR

Target torque (Torque strategy)

Torque High

Torque Low

Angle High

Angle Low

Torque threshold

Free Speed

Shift down torque

Shiftdown Speed

Gang count

Enable / disable RF module

Save / ignore the changes

settings

48619852_ed1 EN-3

EN

2. Description of the Display screen in detail

There are three sections in the QX Series display screen, one “PRIMARY” on the top and two “SECONDARY” which are on

left and right bottom of the display.

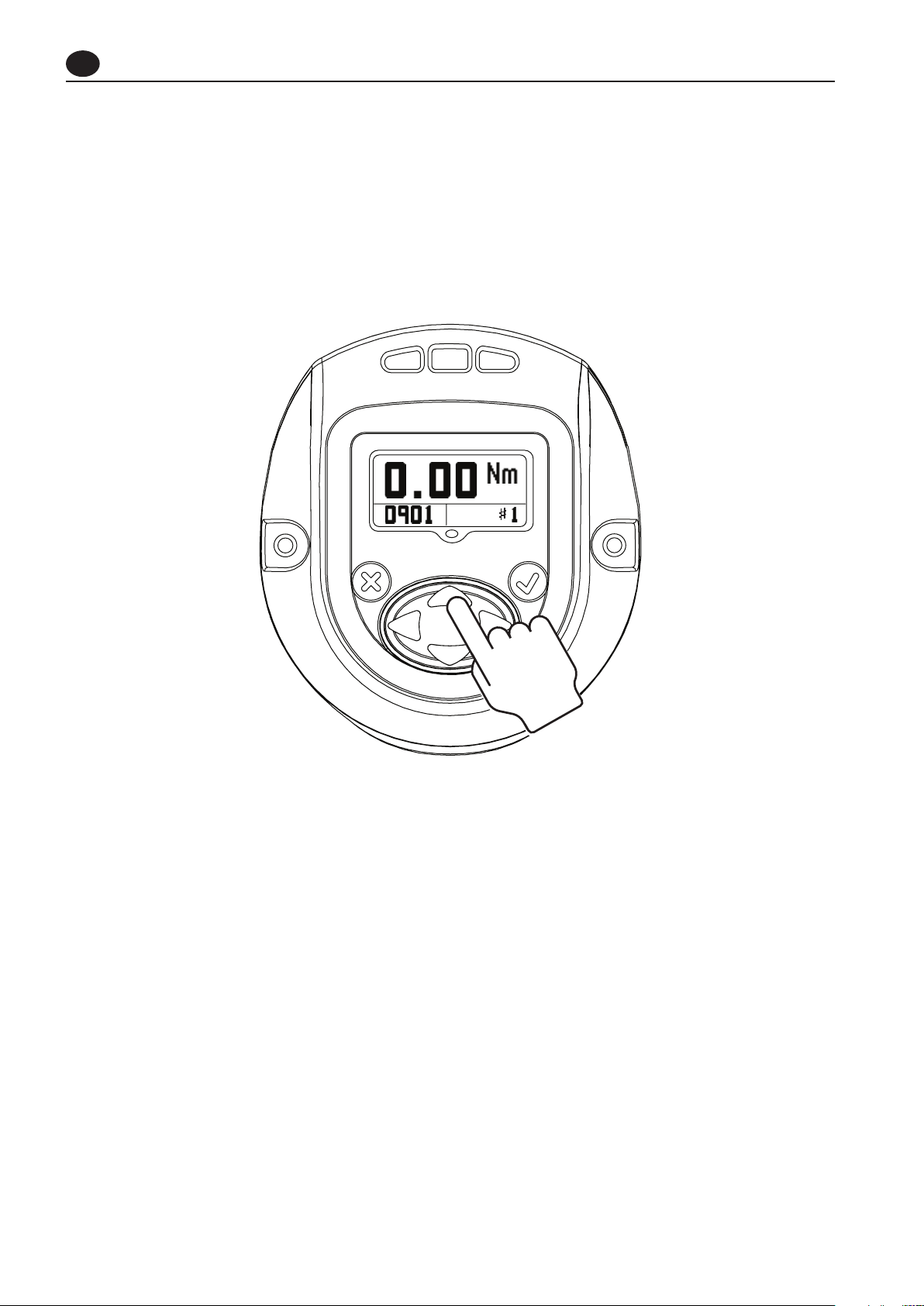

2.1. Run Screen

Pressing “ENTER” key after switching on the display will show this image.

PRIMARY Section - shows latest peak torque (for a torque strategy) or the latest peak angle (for an angle strategy), with

units.

The SECONDARY LEFT - shows the cycle count or gang count, if gang count is programmed.

The SECONDARY RIGHT - shows the active conguration number.

EN-4 48619852_ed1

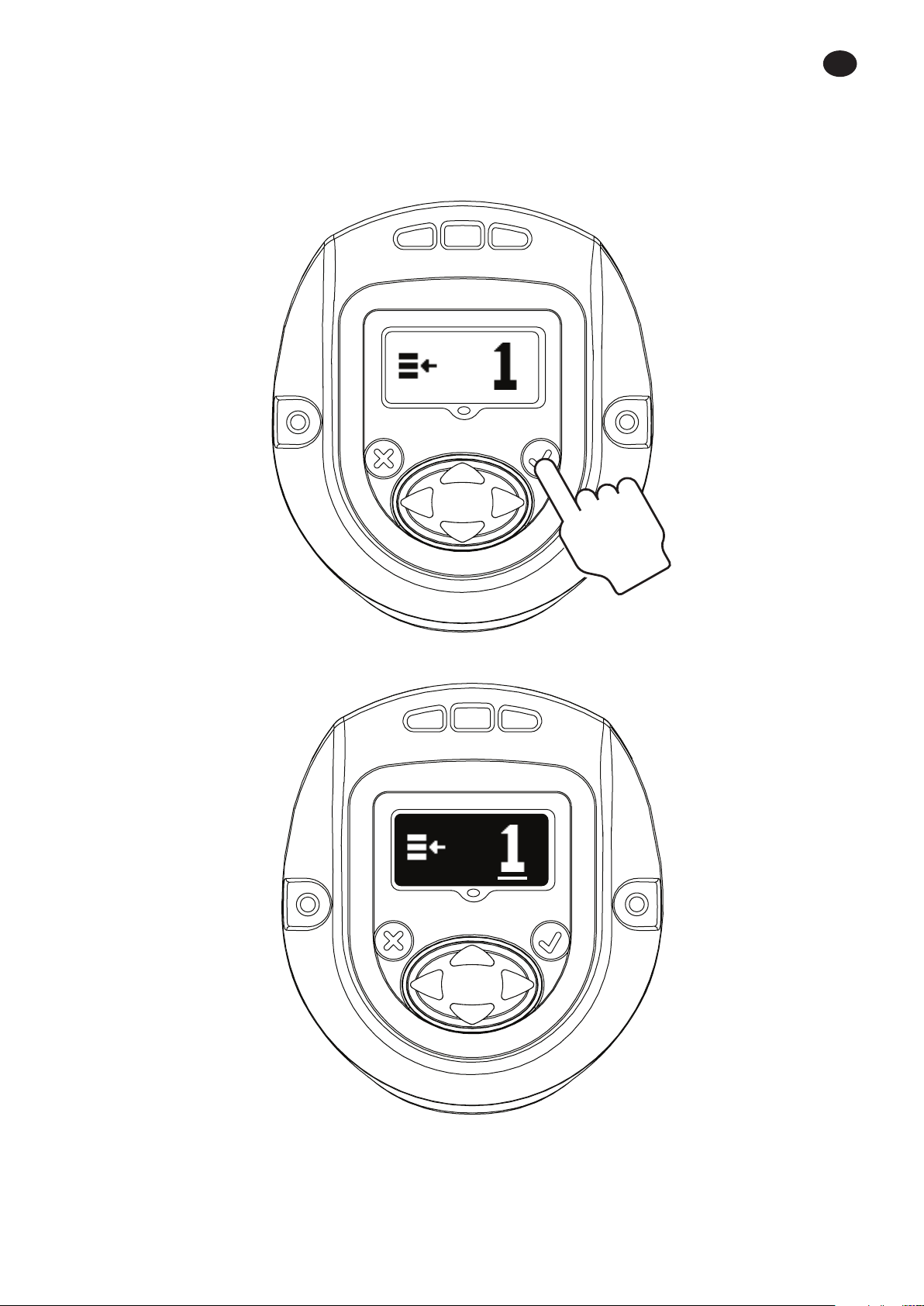

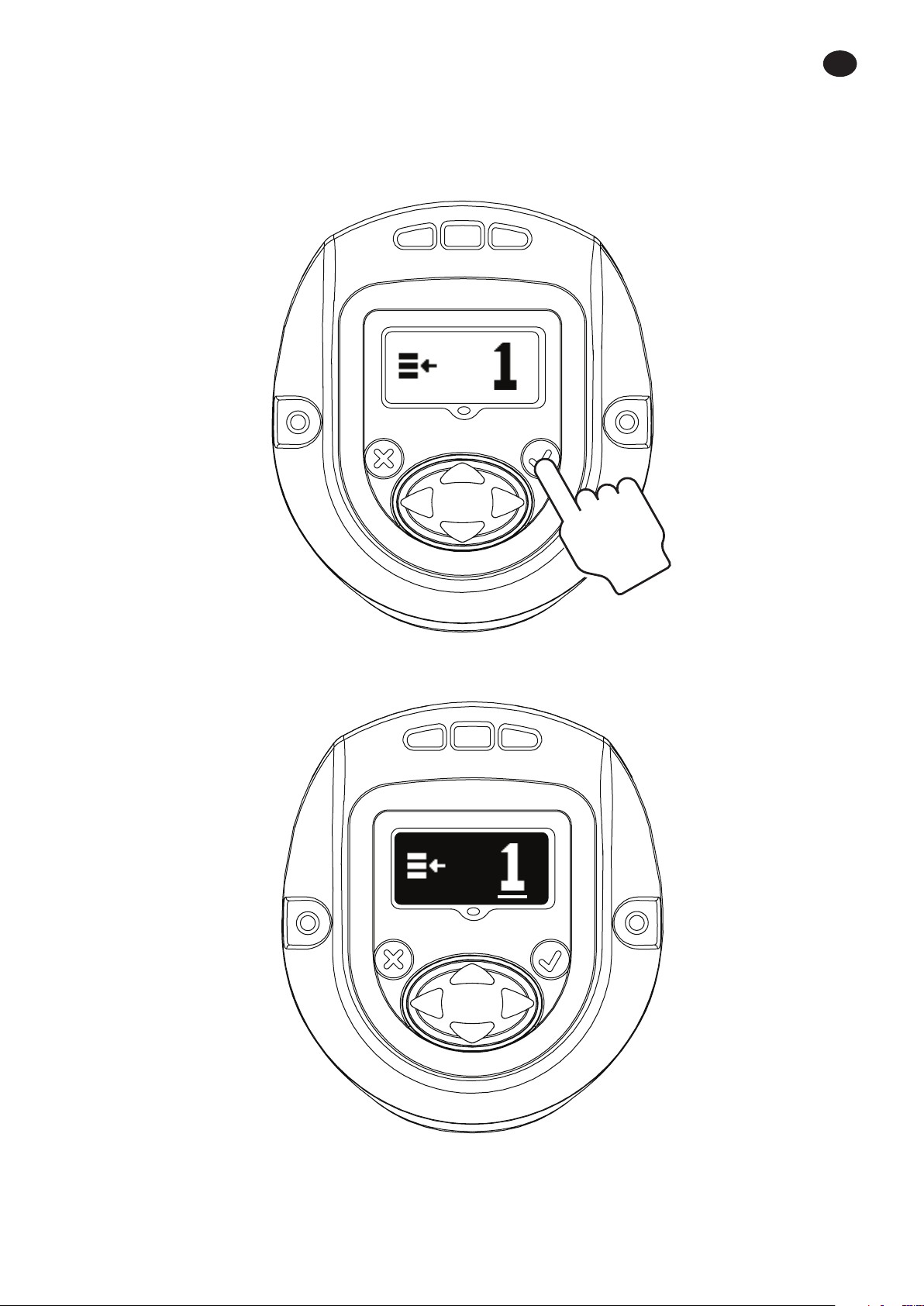

2.2. Conguration

Pressing “UP” will advance to next screen.

Screen shows CONFIGURATION setting used in the tool.

NOTE: Only Conguration 1 can be programmed through the display module.

EN

Pressing “ENTER” will enable the “EDIT MODE” (This procedure to enter “EDIT MODE” is same for all settings update).

48619852_ed1 EN-5

EN

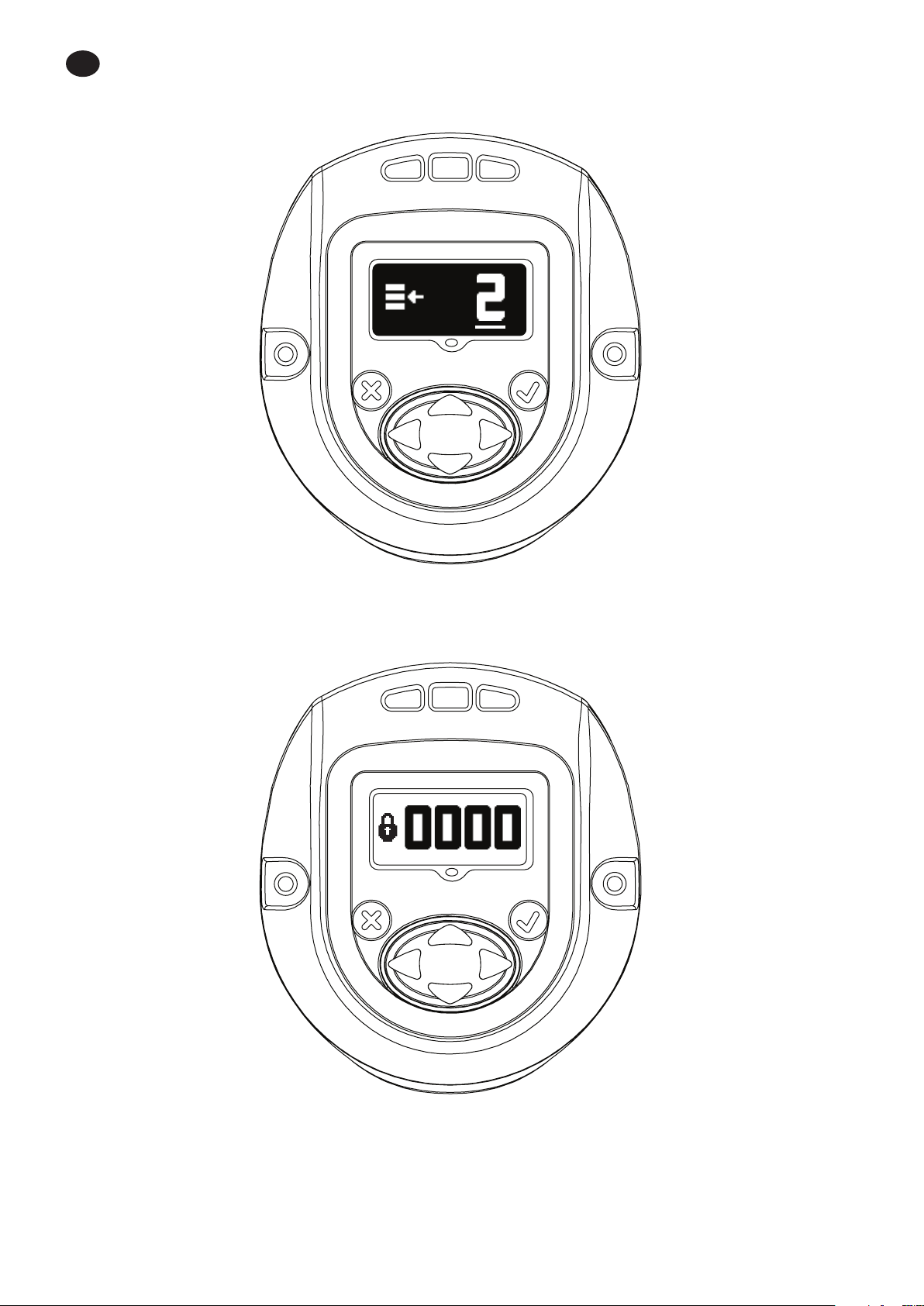

“UP” or “DOWN” key can be used to update the conguration. Pressing “ENTER” again will select the modied

conguration.

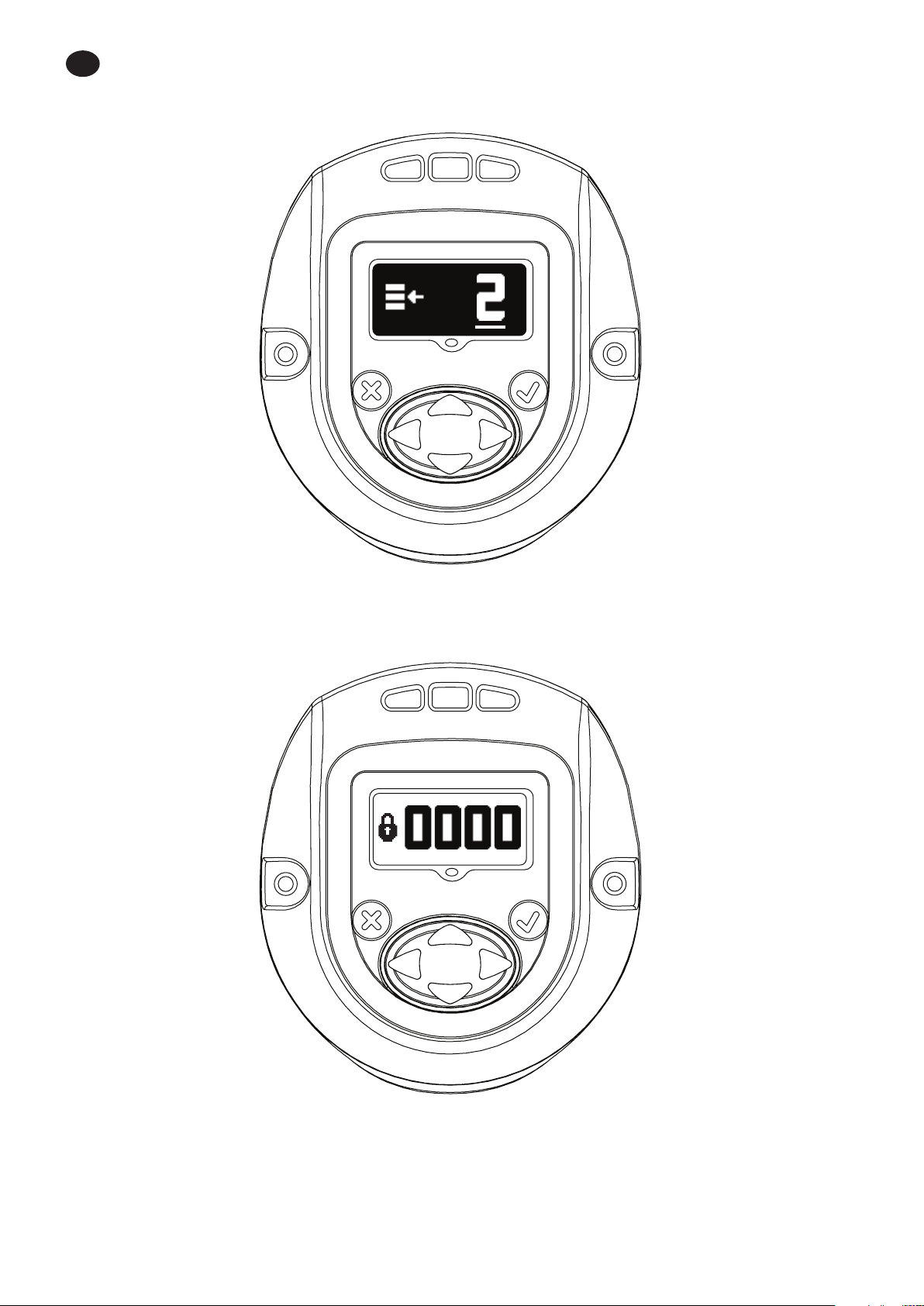

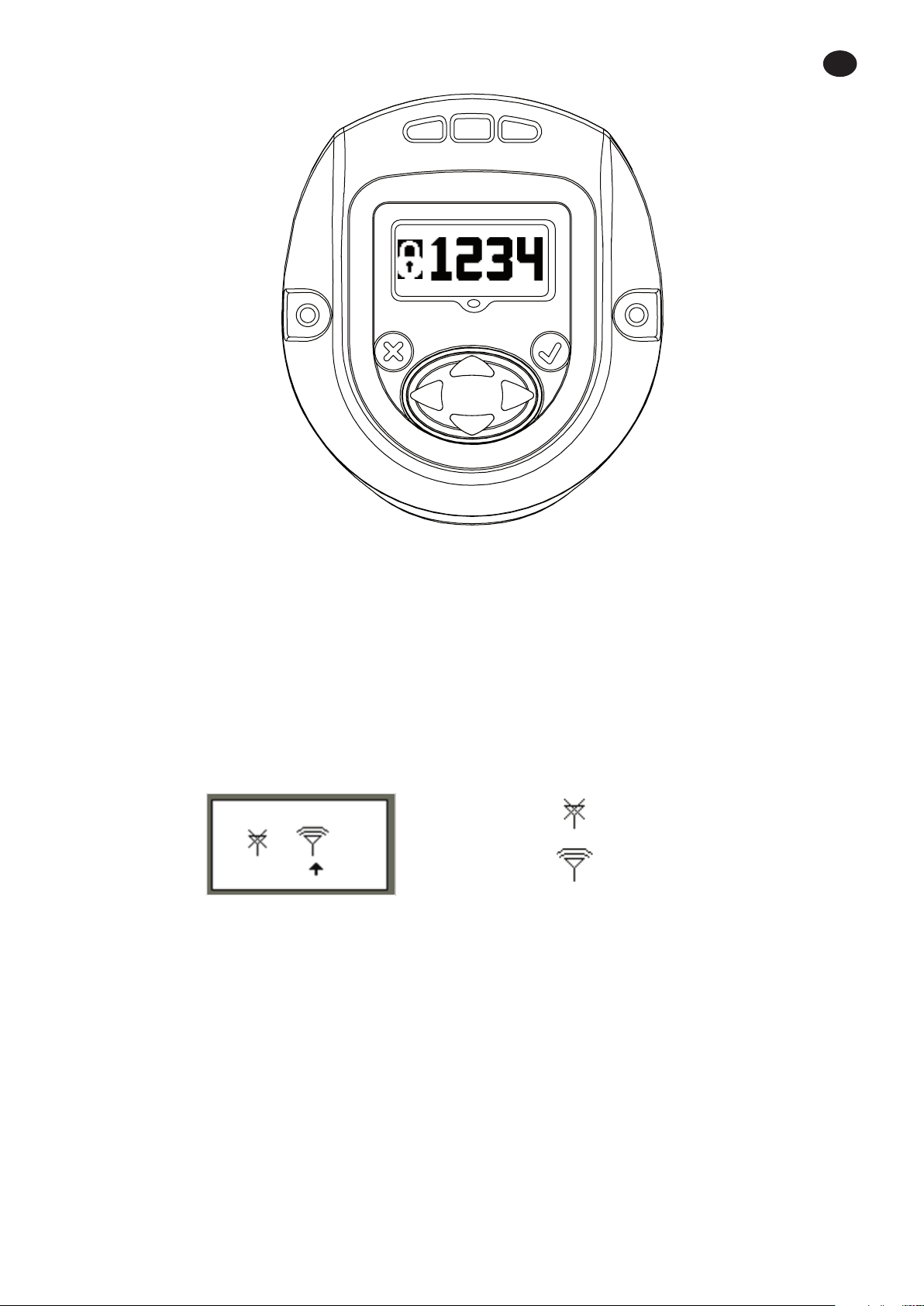

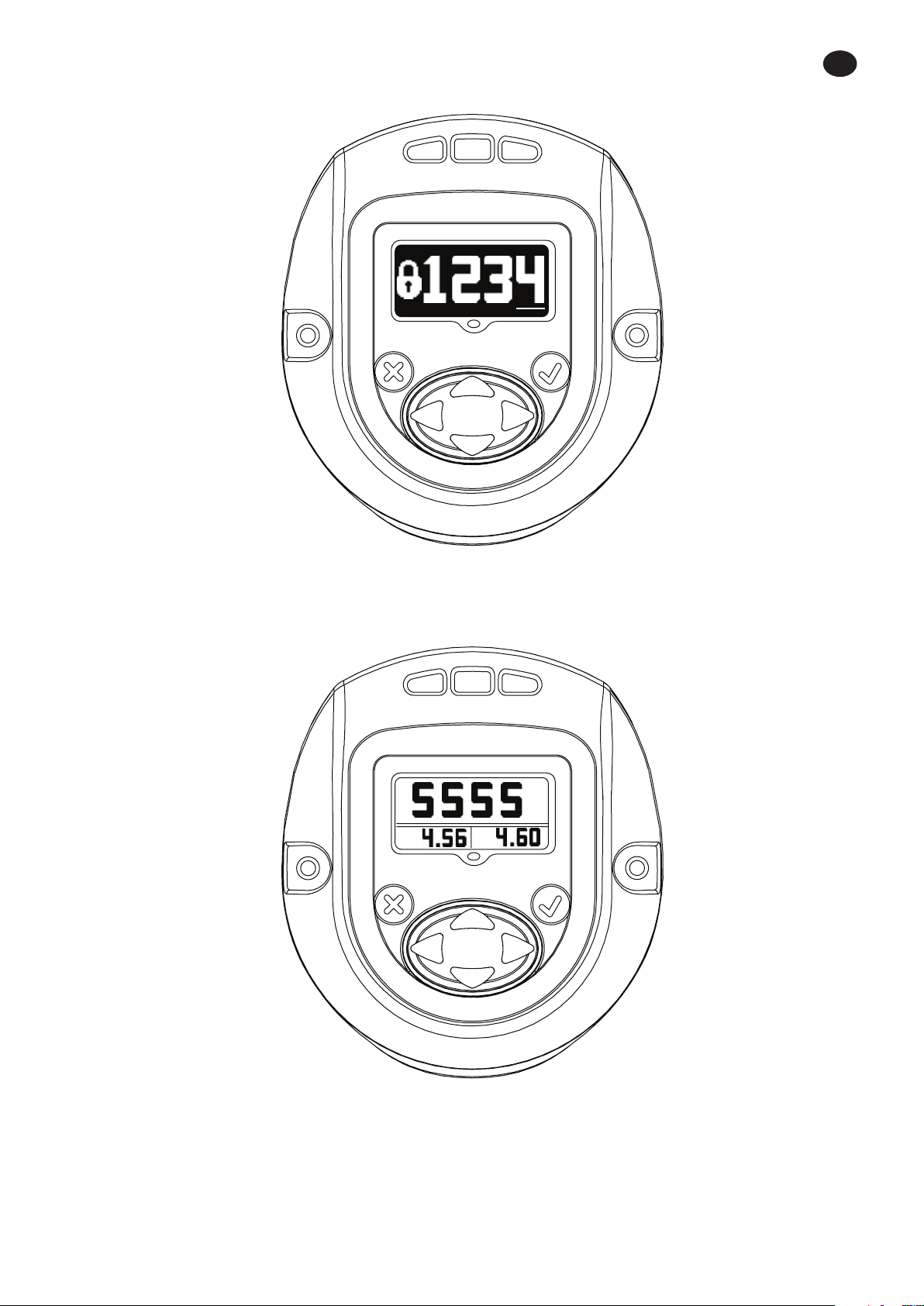

2.3. Password

The password screen shows whether the display is locked or unlocked. If the display is locked the parameters of the QX

Series Hand tool cannot be edited.

EN-6 48619852_ed1

Password can be changed by entering into “EDIT MODE” and using “UP” or “DOWN” key.

EN

If “1234” is entered on the Password screen, the user may use the left arrow to go to the Tool ID and software version

page.

The Primary Display is the “Tool Location ID”.

Lower Secondary Right is the “Display Firmware” Version.

Lower Secondary Left is the “Motor Controller Firmware” Version.

48619852_ed1 EN-7

EN

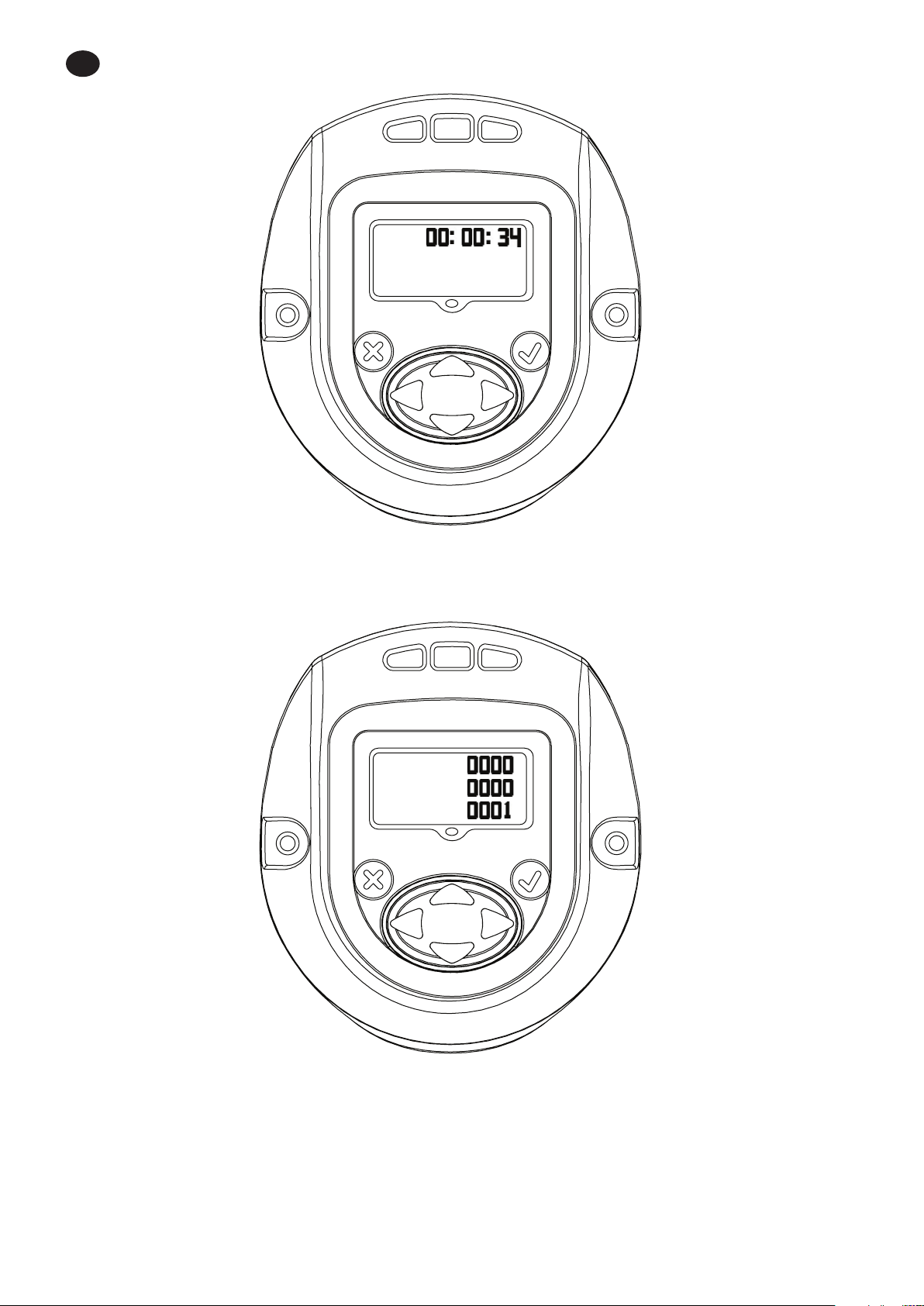

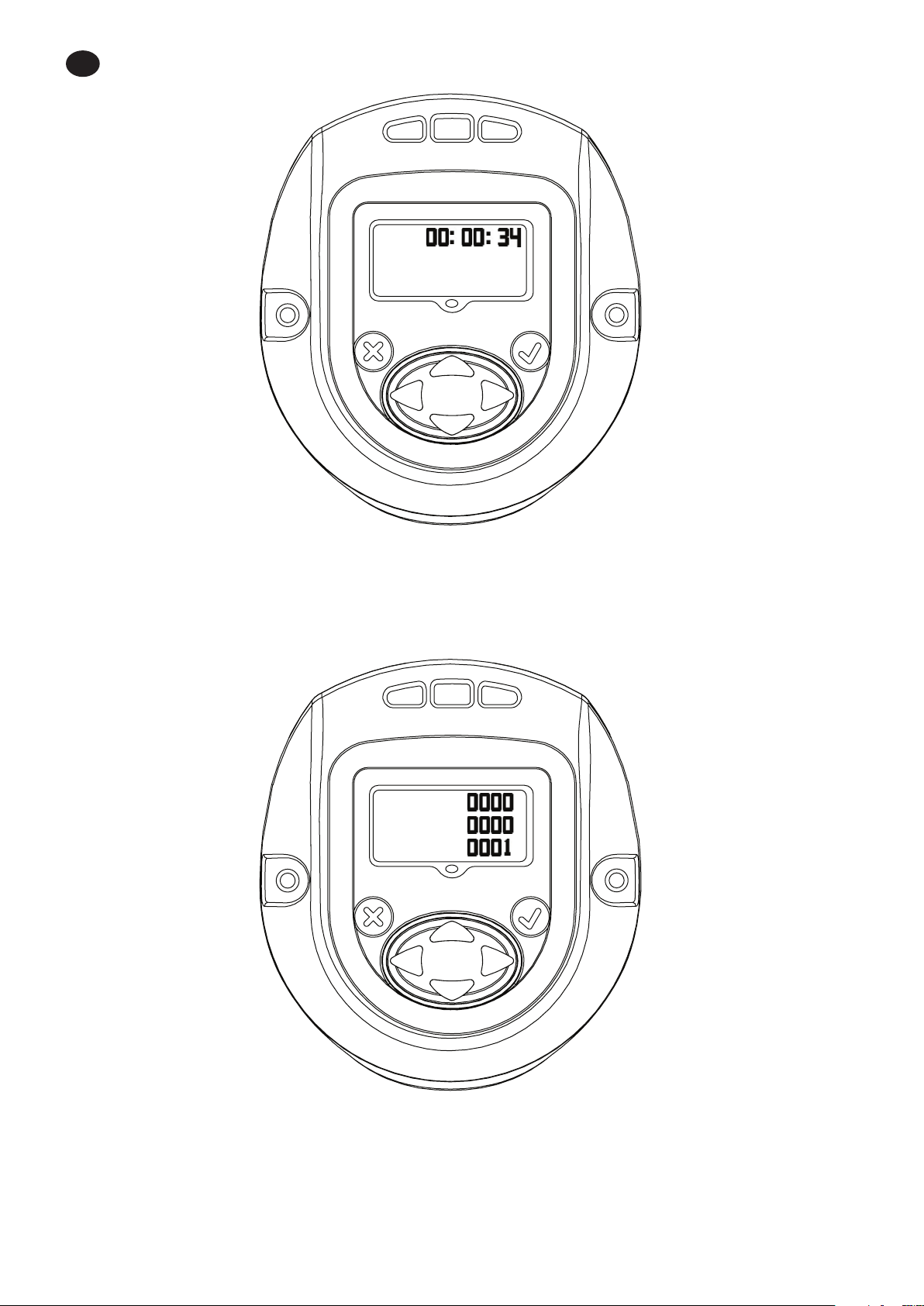

Displays Tool time in HH:MM:SS format. Press the Down key to display the tool time in HH:MM:SS format.

Remaining screens are for internal use only to view log location. Press the Down key to display a screen for internal use

only to view log location. Press the Down key again to display a second log screen.

Press the Down key again to return to the Tool ID page. Pressing the right arrow from this page exits back to the

password display.

EN-8 48619852_ed1

EN

Press ‘ENTER’ to enter the ‘EDIT’ mode. Enter the appropriate password to unlock the tool. Press ‘ENTER’ to exit the ‘EDIT’

mode.

2.3.1. Updating parameters of the QX Series tool

After display is unlocked with a valid password, Pressing “RIGHT” key will advance to following settings that can be

modied as required.

The settings can be modied by entering “EDIT MODE” and using “UP” or “DOWN” key or “RIGHT” or “LEFT” key as

required.

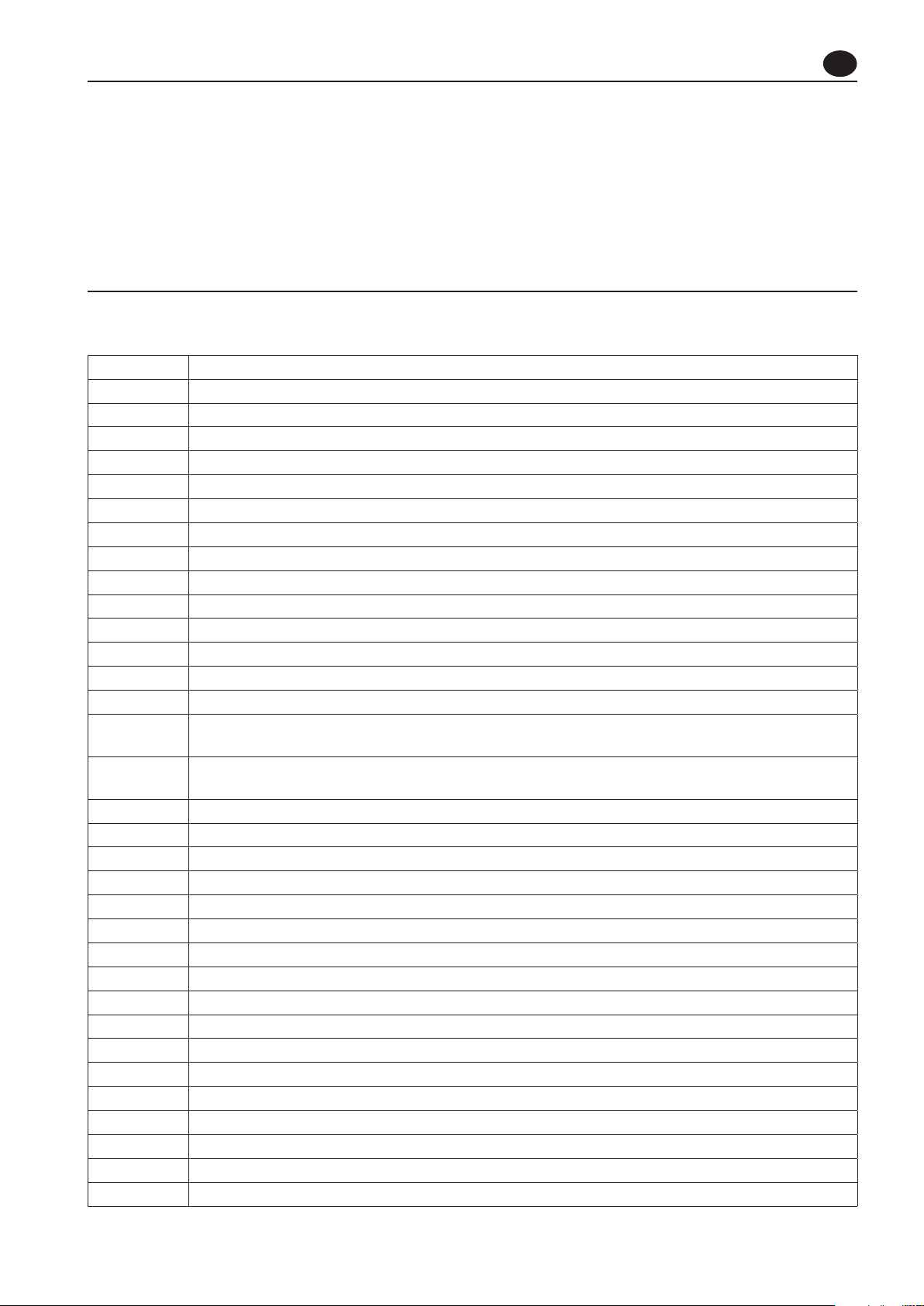

2.3.2. Radio Enable/Disable

This screen allows the user to enable or disable the radio module. The selection on the left disables the radio module

and the selection on the right enables the radio module.

RADIO DISABLED

RADIO ENABLED

48619852_ed1 EN-9

EN

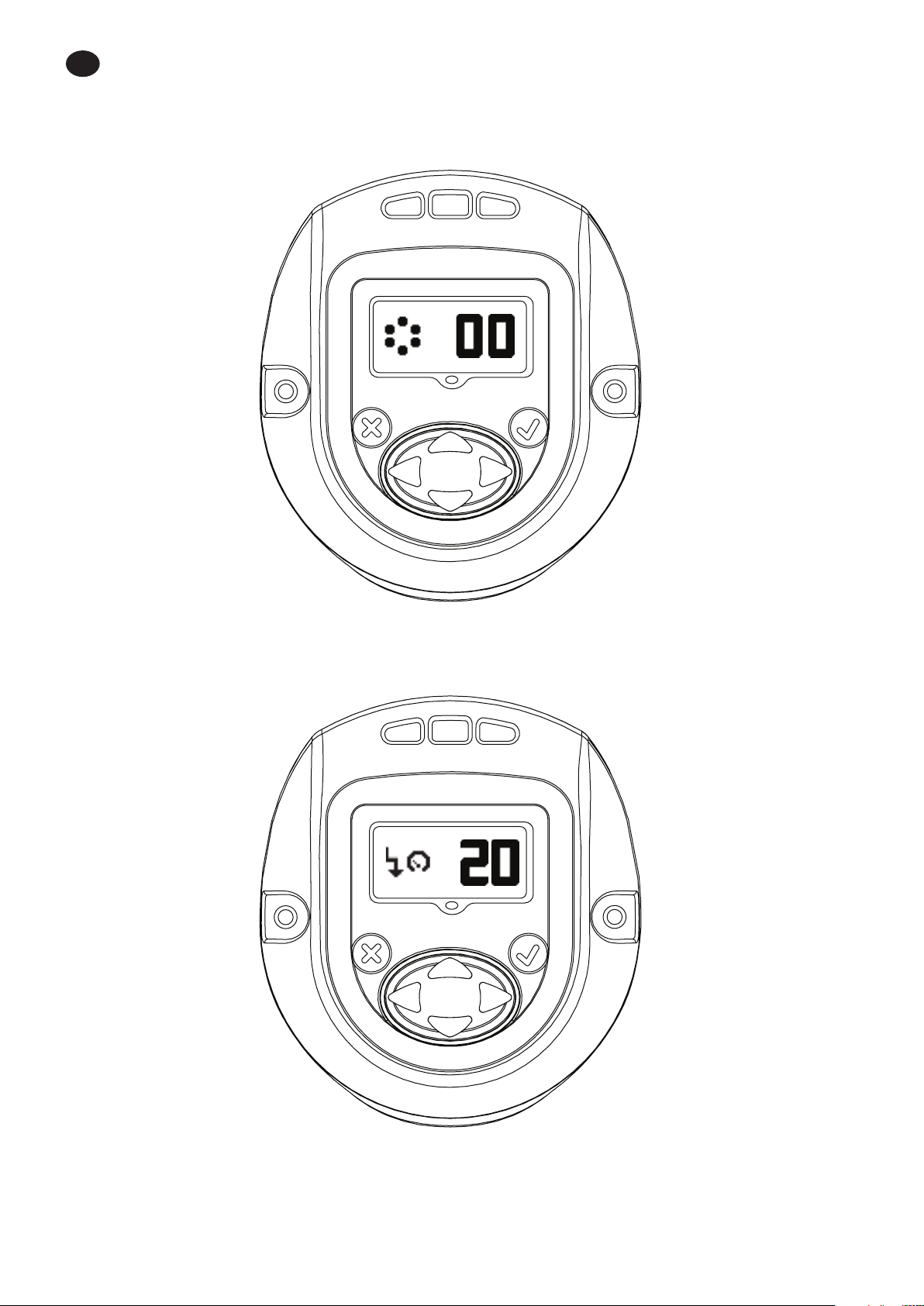

2.3.3. Gang count

The below screen shows the gang count number of bolts to be fastened per Group, Gang, or Set for Conguration 1.

This can be modied by entering “EDIT MODE”.

2.3.4. Shiftdown Speed

This screen indicates shiftdown speed of the QX Series tool. Shiftdown speed can be edited by entering “EDIT MODE”

and updating using UP and DOWN arrow. Programmed speed is a percentage of tool maximum speed.

EN-10 48619852_ed1

2.3.5. Shiftdown Point Cong

This screen indicates “Torque Threshold for shiftdown point”. This can be changed by entering “EDIT MODE” and

updating using “UP” or “DOWN” key.

EN

2.3.6. Free Speed

The below screen indicates free speed of the QX Series tool. The value can be edited by entering “EDIT” mode and using

“UP” and “DOWN” arrow. Programmed speed is a percentage of tool maximum speed.

48619852_ed1 EN-11

EN

2.3.7. Torque Threshold

The Torque at which reading of the angle will be started. The value can be edited by entering “EDIT” mode and using

“UP” and “DOWN” arrow.

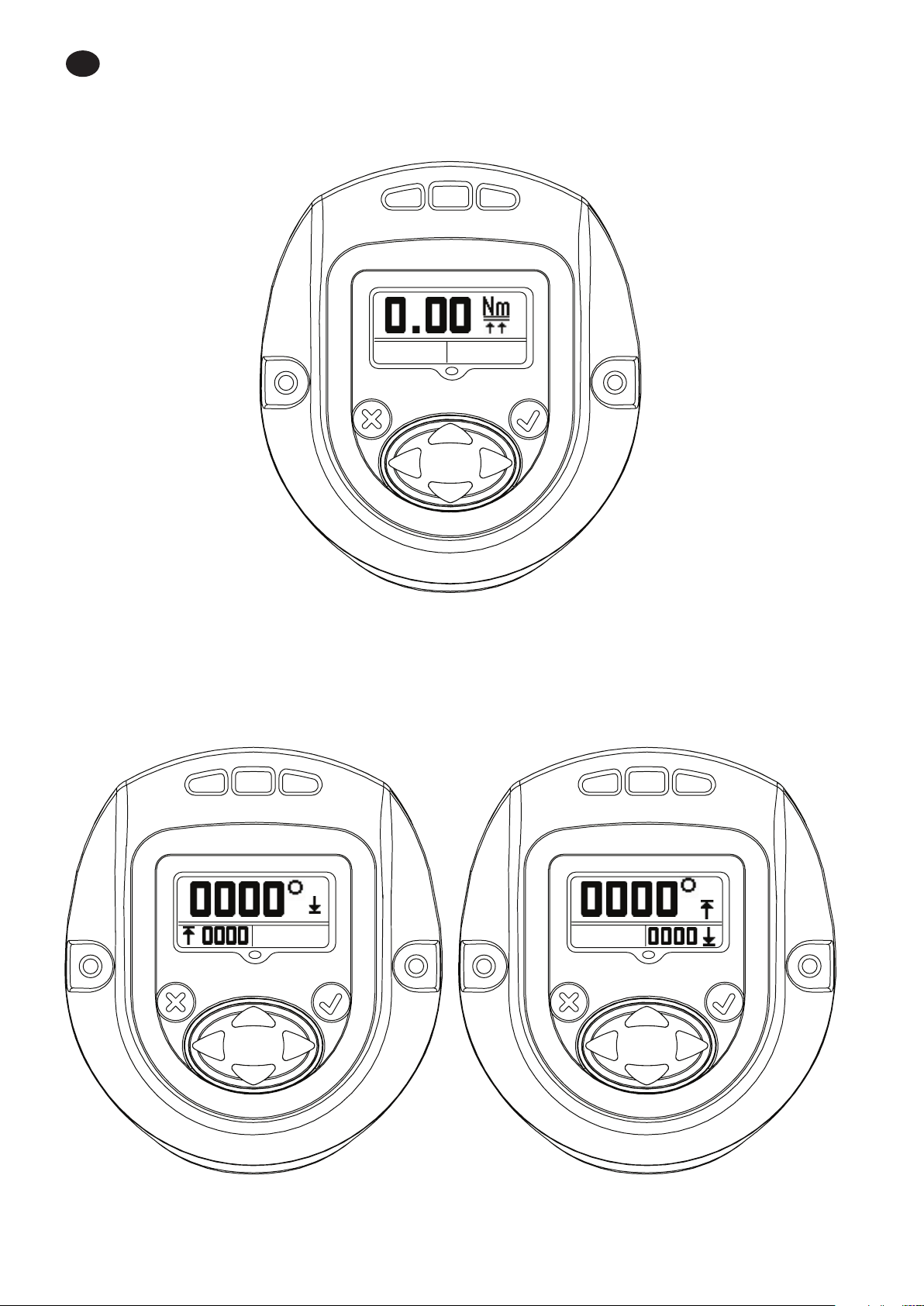

2.3.8. Angle

Angle “LOW” Display

Angle “LOW” can be modied in this mode by

entering “EDIT” mode and using “UP or “DOWN” key.

Angle “HIGH” Display

Angle “HIGH” can be modied in this mode by

entering “EDIT” mode and using “UP or “DOWN” key.

EN-12 48619852_ed1

2.3.9. Torque

EN

Torque “LOW” Display

Torque “LOW” can be modied in this mode by

entering “EDIT” mode and using “UP or “DOWN” key.

Torque “HIGH” Display

Torque “HIGH” can be modied in this mode by

entering “EDIT” mode and using “UP or “DOWN” key.

Torque “TARGET” Display.

Torque “TARGET” can be modied in this mode by entering “EDIT” mode and using “UP or “DOWN” key.

48619852_ed1 EN-13

EN

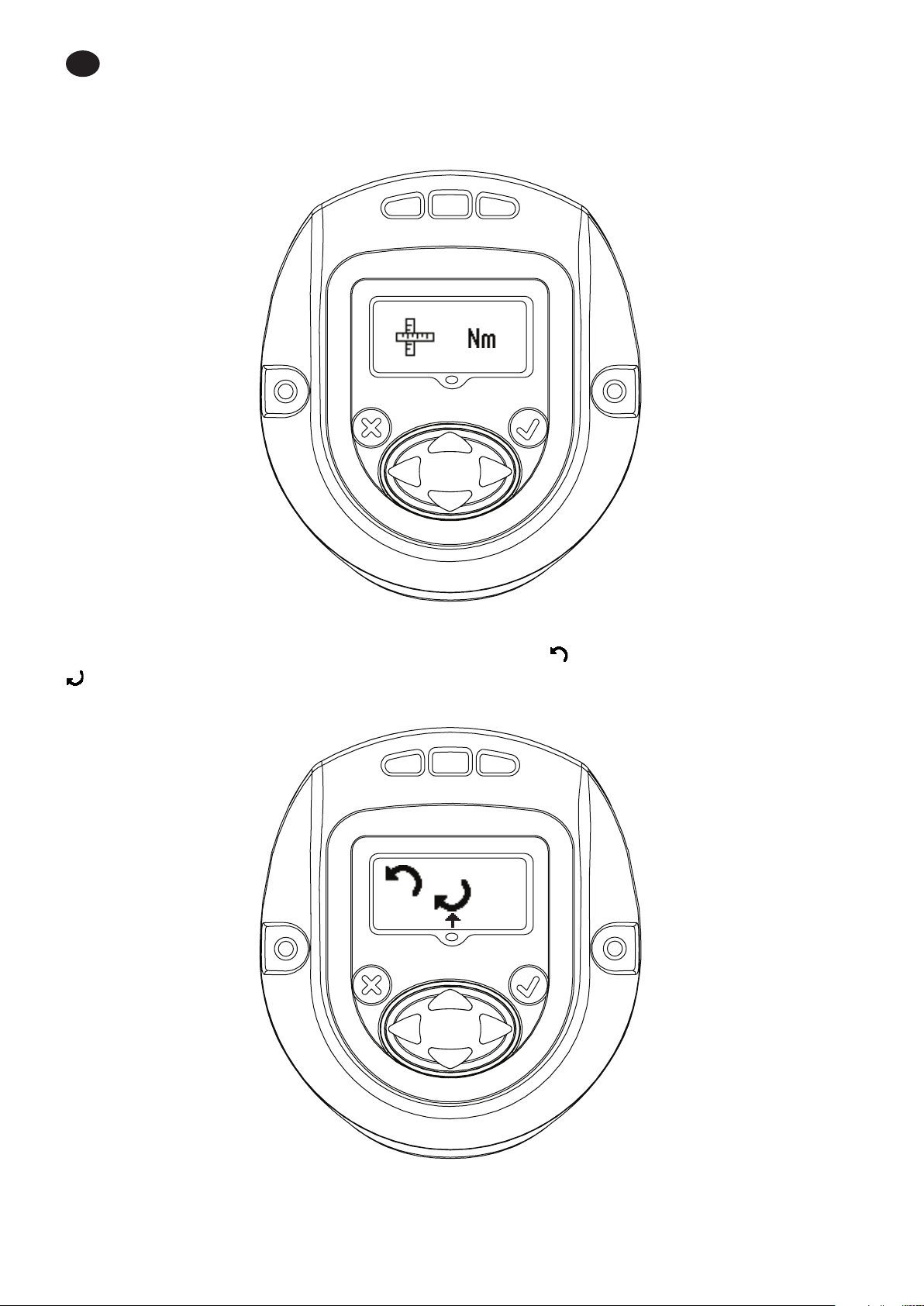

2.3.10. Unit of the Torque

Indicates unit of the Torque displayed in Conguration 1.

This can be changed by entering “EDIT MODE” and updating using “UP” or “DOWN” key.

2.3.11. Direction of Rotation

Image shows direction of rotation in which the QX Series hand tool rotates. Indicates counter clock wise rotation.

Indicates clock wise rotation

This can be changed by entering “EDIT MODE” Key and updating using “RIGHT” or “LEFT” key.

EN-14 48619852_ed1

2.3.12. Strategy

This screen indicates conguration strategy being used.

Left – Angle, Right – Torque.

The pointing arrow indicates the present conguration being used.

This can be changed by entering “EDIT MODE” and using “RIGHT” or “LEFT” key.

EN

2.3.13. Save / Ignore Settings

After all the required changes are completed, Press enter to highlight the save settings box on the left. Press the right or

left arrow key to select cancel on the right. Pressing enter a second time causes the tool to leave edit mode.

SAVE SETTINGS

CANCEL SETTINGS

48619852_ed1 EN-15

EN

2.4. Warning Screen

This is the next screen obtained after pressing “UP” key when QX Series displays the Password screen.

2.5. Shunt Calibration, RF Signal Strength and Battery level

This is the next screen obtained after pressing “UP” key when QX Series displays password screen.

Primary display indicates Shunt Calibration Value.

Secondary display on left indicates RF signal strength and the one on the right indicates Battery Level.

EN-16 48619852_ed1

EN

2.6. Cycle count

This value shows number of cycles run by the QX Series tool, Since the last time it was changed.

With the tool unlocked, press ‘ENTER” key to edit this screen. Press either the ‘UP’ or ‘DOWN’ key to clear the cycle count.

For this change to be retained a cycle must be run before removing power to the tool. Otherwise, the old cycle count is

restored.

2.7. Angle

Primary display – Target Angle.

Secondary Display on left - Angle low.

Secondary Display on right - Angle High.

48619852_ed1 EN-17

EN

2.8. Torque

Primary Display -Target Torque.

Secondary display on left - Torque low.

Secondary display on Right - Torque high.

Pressing “UP” advances back to “RUN SCREEN”, the rst display screen.

EN-18 48619852_ed1

Appendix 1 : Status LED Denitions

There are four LEDs on the display module. 3 on the top and 1 below the display screen.

The Status LEDs shall be used as follows:

Red -- The last tightening cycle exceeded its high limit.

Yellow -- The last tightening cycle ended below its low limit.

Green -- The last tightening cycle ended between its high and low limits.

Blue -- The tool has an active fault condition.

Appendix 2 : Tool Fault codes

The tool shall report the following fault codes for the listed conditions:

F-01 Tool Disabled (by external control)

F-02 Rapid Trigger pull – trigger was pulled before conguration delay was complete

1-FF USB enumeration fault

A-10 Motor controller communication timeout

A-55 A display software version update was detected

B-01 Failure to update Motor Controller Software

B-85 RF ACK Timeout (we did not get a serial ACK messages from the transceiver)

B-E1 RF Transmit NAK–“Channel Access Failure”

B-E5 RF Transmit NAK–“Frame Too Long”

B-E9 RF Transmit NAK–“No ACK Received”

C-01 Conguration ID value is 0 or greater than 8

C-02 Number of conguration steps is greater than 8

C-03 Current Step ID is greater than the current number of steps

C-04 Total Gang is greater than 8

C-05 Current Gang count is greater than Total Gang

C-06 Current Torque High Limit is greater than the Tool’s maximum Torque value (Tool’s max torque value

is congured in the Factory Set Points) OR Current Torque High Limit is less than 0

C-07 Current Torque Low Limit is greater than the Tool’s maximum Torque value OR Current Torque Low

Limit is less than

C-08 Current Torque High Limit is less than Current Torque Low Limit

C-09 Current Torque Low Limit is greater than Current Torque High Limit (Fault code to be removed)

C-0A Current Angle High Limit is greater than the Tool’s maximum Angle value (to be set to 9999)

C-0B Current Angle Low Limit is greater than the Tool’s maximum Angle value (to be set to 9999)

C-0C Current Angle High Limit is less than Current Angle Low Limit

C-0D Current Angle Low Limit is greater than Current Angle High Limit (Fault code to be removed)

C-0E

C-0F

C-10 Tool conguration step is not set for either Angle or Torque

C-11

C-12 Current Free Speed is greater than maximum motor speed

C-13 Current Shiftdown Speed is greater than maximum motor speed

C-14 Current display unit value is unsupported

C-15 Torque Threshold exceeds target (with torque target) or max torque (with Target Angle)

C-55 Invalid Conguration selection

E-00 Battery Fault

E-01 Invalid Hall State

Tool conguration step is a Target torque and the target value is outside the torque high and low limits

Tool conguration step is an Target Angle and the target value is outside the angle high and low limits

Current Threshold value is greater than the maximum tool torque OR Current Threshold value is less than 0

EN

48619852_ed1 EN-19

EN

E-02 I2T Fault

E-03 Motor Stall

E-04 Over Current

E-05 Over Temperature

E-06 Current O set Fault

E-07 Shunt Calibration Fault

E-08 Torque Oset Fault

E-09 Transducer Fault

E-0A Step Execution Timeout

E-0B Conguration Execution Timeout

E-0C Over Torque Limit

E-0D Over Angle Limit

E-0E Current Plausibility High

E-0F Under Torque

E-10 Under Angle

E-11 Current Plausibility Low

E-12 Early trigger Release

E-13 Motor Controller Watch dog Reset

E-14 Brake Timeout

E-18 Missed Run Steps (Prevailing Torque conguration did not complete)

E-1B Battery Cell Fault (detected by Motor Controller)

E-1C Low Battery Fault (detected by Motor Controller)

E-1D Critical Battery Fault (detected by Motor Controller)

E-1E Motor Controller is shutting down

E-1F Wakeup Code received (but not expected)

E-81 The conguration ID in the Motor controller’s EOR did not match the currently selected conguration

2-<Alarm ID> PM Alarm Time Fault for corresponding Alarm ID normally congured by the user

3-<Alarm ID> PM Alarm Cycle Fault for corresponding Alarm ID normally congured by the user

C-16 Number of conguration steps is set to 0

Parts and Maintenance

Original instructions are in English. Other languages are a translation of the original instructions.

Tool repair and maintenance should only be carried out by an authorized Service Center.

Refer all communications to the nearest Ingersoll Rand Oce or Distributor.

EN-20 48619852_ed1

ES

Finalidad del documento:

Este documento proporciona información detallada sobre las diferentes pantallas de los menús, su descripción y la

edición de dichas pantallas en el módulo de la pantalla de visualización, necesario para utilizar la herramienta manual

de la serie QX.

La imagen incluida a continuación muestra el módulo de la pantalla de visualización de la serie QX con descripciones

de las teclas de programación.

ARRIBA

ESCAPE

IZQUIERDA

ABAJO

Símbolo Función

Escape / salida

ENTRAR / EDICIÓN

ARRIBA

ABAJO

DERECHA

IZQUIERDA

ENTRAR

DERECHA

48619852_ed1 ES-1

ES

Encendido de la herramienta de

la serie QX

PANTALLA DE

EJECUCIÓN

Pulse la tecla

“ARRIBA”

de las pantallas en uso

Pulse siempre la tecla

“ARRIBA” para pasar a la

siguiente pantalla

Pulse “ENTRAR” para acceder al modo de

“EDICIÓN”

Pantalla de la

contraseña

Fallo de corriente

Pantalla de estado con la

calibración por derivación, la

intensidad inalámbrica y el

nivel de la batería

Recuento de

ciclo

Pantalla de ángulo

objetivo inferior y

superior

Pantalla de par de

torsión objetivo inferior y

superior

PANTALLA DE

EJECUCIÓN

Pulse la tecla “ARRIBA”

para incrementar el valor

Pulse la tecla “ABAJO”

para reducir el valor

Pulse “ENTRAR” para seleccio-

Pulse “ESC” para deshacer

el cambio y conservar los

valores antiguos.

Una vez desbloqueada

la pantalla, pulse la tecla

“DERECHA”

Pulse la tecla “ARRIBA” para

pasar a la siguiente pantalla

Guarde o ignore los cambios. Si no se encuentra en la

pantalla de guardado, utilice la tecla arriba o abajo para

desplazarse hasta dicha pantalla.

Pulse la tecla “ARRIBA” para

desplazarse por las pantallas

una a una y obtener las

pantallas editables siguientes

en serie

1. Descripción general de las pantallas de los distintos menús

ES-2 48619852_ed1

ES

Estrategia: ángulo o par de torsión

Dirección: en el sentido de las aguja del reloj

o en sentido contrario a las agujas del reloj

Unidad del par de torsión

Ángulo objetivo (estrategia de ángulo) O

par de torsión objetivo (estrategia de par de

torsión)

Par de torsión superior

Par de torsión inferior

Ángulo superior

Ángulo inferior

Umbral del par de torsión

Velocidad libre

Par de torsión de desaceleración

Velocidad de desaceleración

Recuento de grupo

Habilitar/deshabilitar el módulo de

radiofrecuencia

Guardar/ignorar la conguración de los

cambios

48619852_ed1 ES-3

ES

2. Descripción de la pantalla de visualización en detalle

Existen tres secciones en la pantalla de visualización de la serie QX, una “PRINCIPAL” situada en la parte superior y dos

“SECUNDARIAS” situadas a la izquierda y a la derecha de la parte inferior de la pantalla.

2.1. Pantalla de ejecución

Al pulsar la tecla “ENTRAR” tras encender la pantalla, se mostrará esta imagen.

Sección PRINCIPAL: muestra el último par de torsión máximo (para una estrategia de par de torsión) o el último ángulo

máximo (para una estrategia de ángulo), con sus unidades.

Sección SECUNDARIA IZQUIERDA: muestra el recuento de ciclo o el recuento de grupo, si se ha programado este último.

Sección SECUNDARIA DERECHA: muestra el número de conguración activo.

ES-4 48619852_ed1

2.2. Conguración

Al pulsar la tecla “ARRIBA”, se pasará a la siguiente pantalla.

La pantalla muestra el ajuste de CONFIGURACIÓN utilizado en la herramienta.

NOTA: solo puede programarse la Conguración 1 a través del módulo de la pantalla de visualización.

ES

Al pulsar la tecla “ENTRAR”, se habilitará el “MODO DE EDICIÓN” (este procedimiento de acceso al “MODO DE EDICIÓN” es

el mismo para la actualización de todos los parámetros de conguración)

48619852_ed1 ES-5

ES

Las teclas “ARRIBA” o “ABAJO” pueden utilizarse para actualizar la conguración. Al volver a pulsar la tecla “ENTRAR”, se

seleccionará la conguración modicada.

2.3. Contraseña

La pantalla de la contraseña indica si la pantalla se encuentra bloqueada o desbloqueada. Si la pantalla está bloqueada,

no es posible editar los parámetros de la herramienta manual de la serie QX.

ES-6 48619852_ed1

La contraseña puede modicarse accediendo al “MODO DE EDICIÓN” y utilizando las teclas “ARRIBA” o “ABAJO”.

ES

Si introduce “1234” en la pantalla de la contraseña, el usuario puede utilizar la echa izquierda para acceder a la página

de la versión del software y el Id. de la herramienta

La pantalla principal corresponde al “Id. de ubicación de la herramienta”.

La pantalla secundaria inferior derecha corresponde a la versión del “rmware de la pantalla”.

La pantalla secundaria inferior izquierda corresponde a la versión del “rmware del controlador del motor”.

48619852_ed1 ES-7

ES

Muestra la hora de la herramienta en el formato HH:MM:SS. Pulse la tecla Abajo para visualizar la hora de la herramienta

en el formato HH:MM:SS.

Las pantallas restantes se restringen al uso interno para ver la ubicación del registro. Pulse la tecla Abajo para visualizar

una pantalla para uso interno únicamente para ver la ubicación del registro. Vuelva a pulsar la tecla Abajo para

visualizar una segunda pantalla de registro.

Pulse de nuevo la tecla Abajo para regresar a la página del Id. de la herramienta. Al pulsar la tecla derecha desde esta

página, regresará a la pantalla de la contraseña.

ES-8 48619852_ed1

Loading...

Loading...