Ingersoll-Rand QA6 series, QA8 series Maintenance Information

16601056

April 2008

Air Angle Wrench and

Nut Runner

QA6 and QA8 Series

Maintenance Information

Edition 1

Save These Instructions

2 16601056_ed1

WARNING

∙ Always wear eye protection when operating or performing maintenance on this tool.

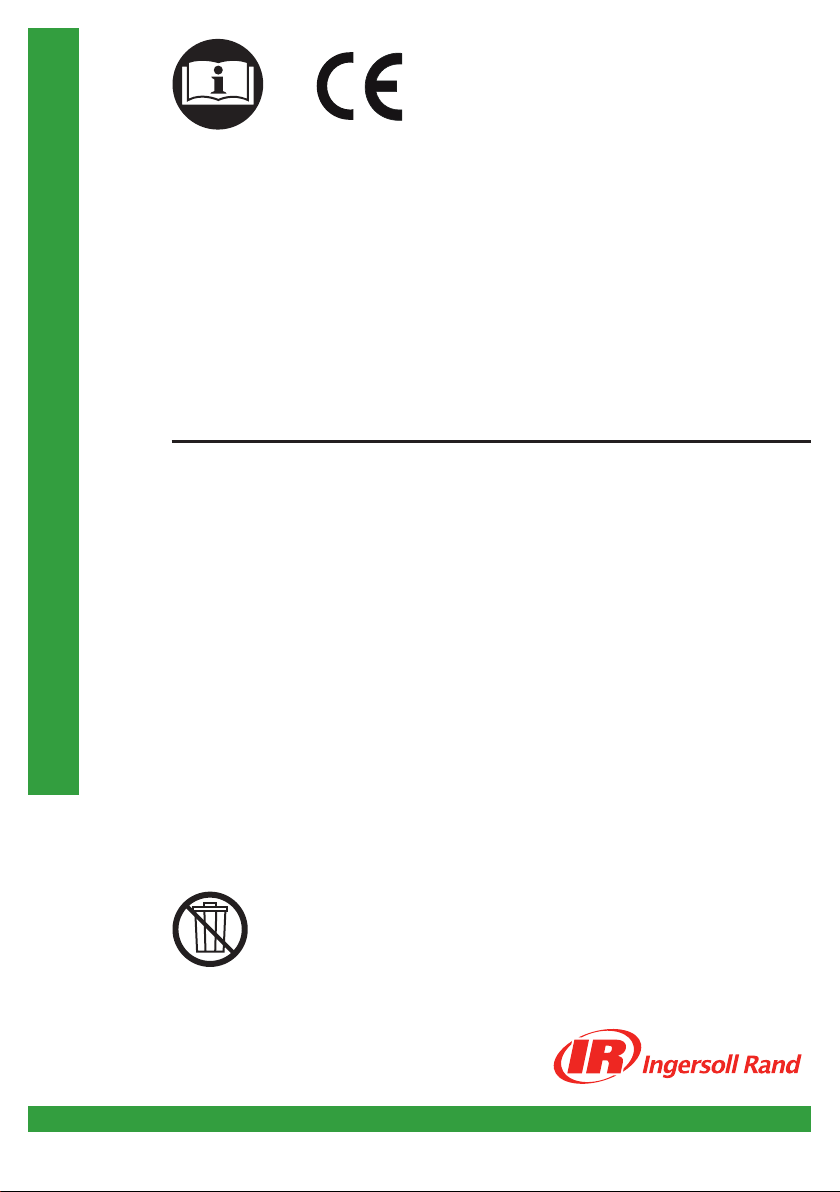

13

4

3

1

10

5

2

6

8

7

9

12

11

∙ Always turn o the air supply and disconnect the air supply hose before installing, removing or adjusting any accessory on this tool

or before performing any maintenance on this tool.

ASSEMBLY DISASSEMBLY INSTRUCTIONS

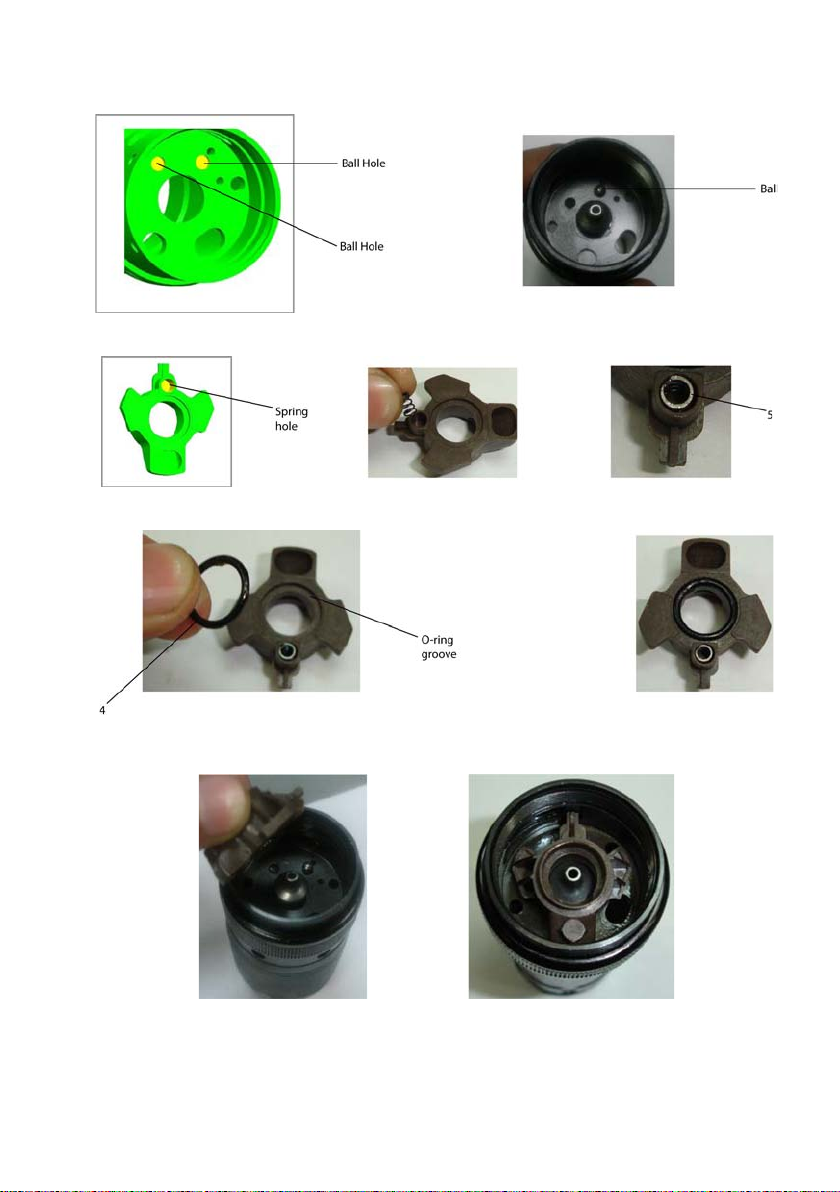

Throttle Housing

(Dwg. RG_80223480)

Throttle Housing Module

Item Part Description Part Number

Throttle Housing Module QA6-NPT-A231 QA6-BSP-A231 QA8-NPT-A231 QA8-BSP-A231

1 Throttle Housing

2 Ball Seat 12 mm

3 Throttle Pin

4 O-Ring 3.4 mm

5 Ball 12 mm

6 Ball Spring

7 Muer Black QA8-311 (1) QA8-311 (1) QA8-311 (2) QA8-311 (2)

8 Muer White QA6-311 (2) QA6-311 (2)

9 Diuser Plate

10 Pin 2 mm

11 Chip Holder Assembly QA4-A528 QA4-A528 QA4-A528 QA4-A528

12 Inlet Bushing Assembly QA6-NPT-A465 QA6-BSP-A465 QA6-NPT-A465 QA6-BSP-A465

13 Lever Assembly QA6-A93 QA6-A93 QA6-A93 QA6-A93

Tooling Required

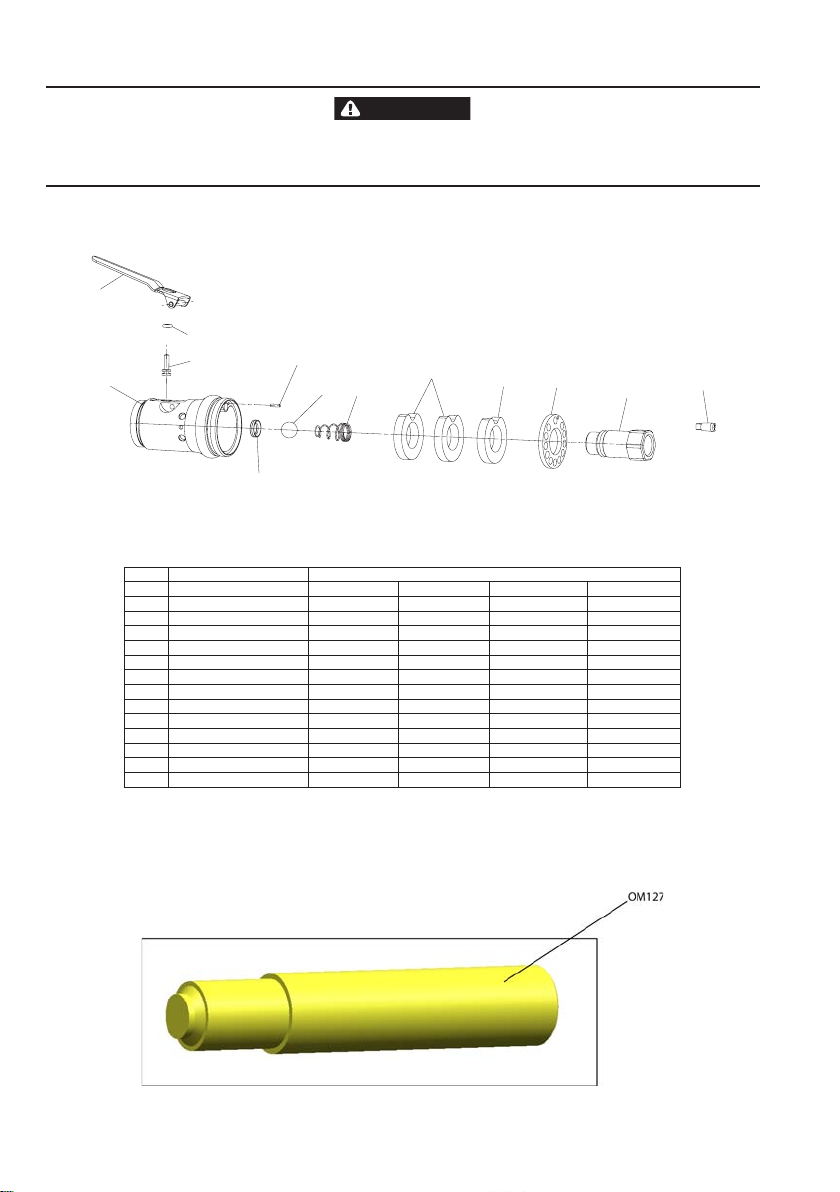

Specic Tooling

Ball Seat Assembly tool (OM127): This tool Is Required to Press Ball Seat (2) Into Throttle Housing (1).•

Standard tools and Products

O-Ring 11 mm

Inlet Bushing

Screen

O-ring Lube (Ingersoll Rand No. 68)

•

Vice

•

Needle Nose Pliers

•

Spanner Wrench

•

torque Wrench

•

Punch

•

Hammer

•

Subassemblies

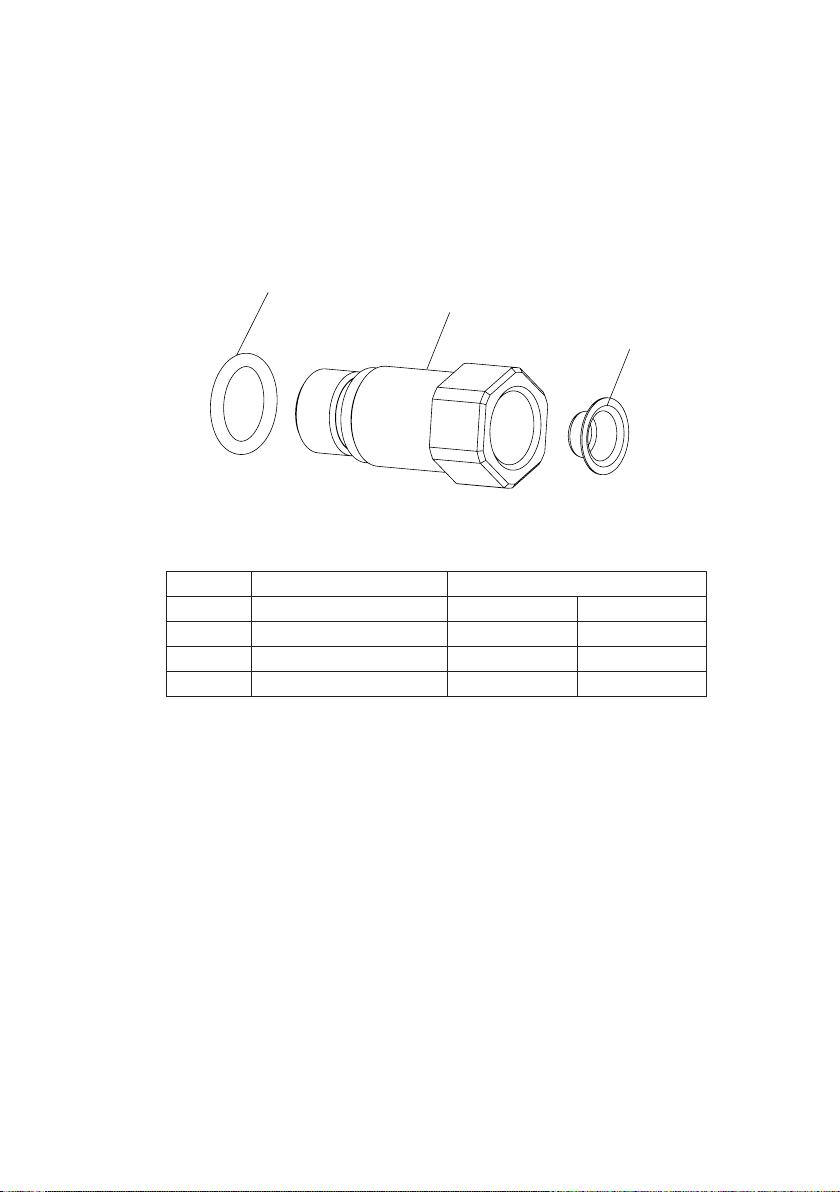

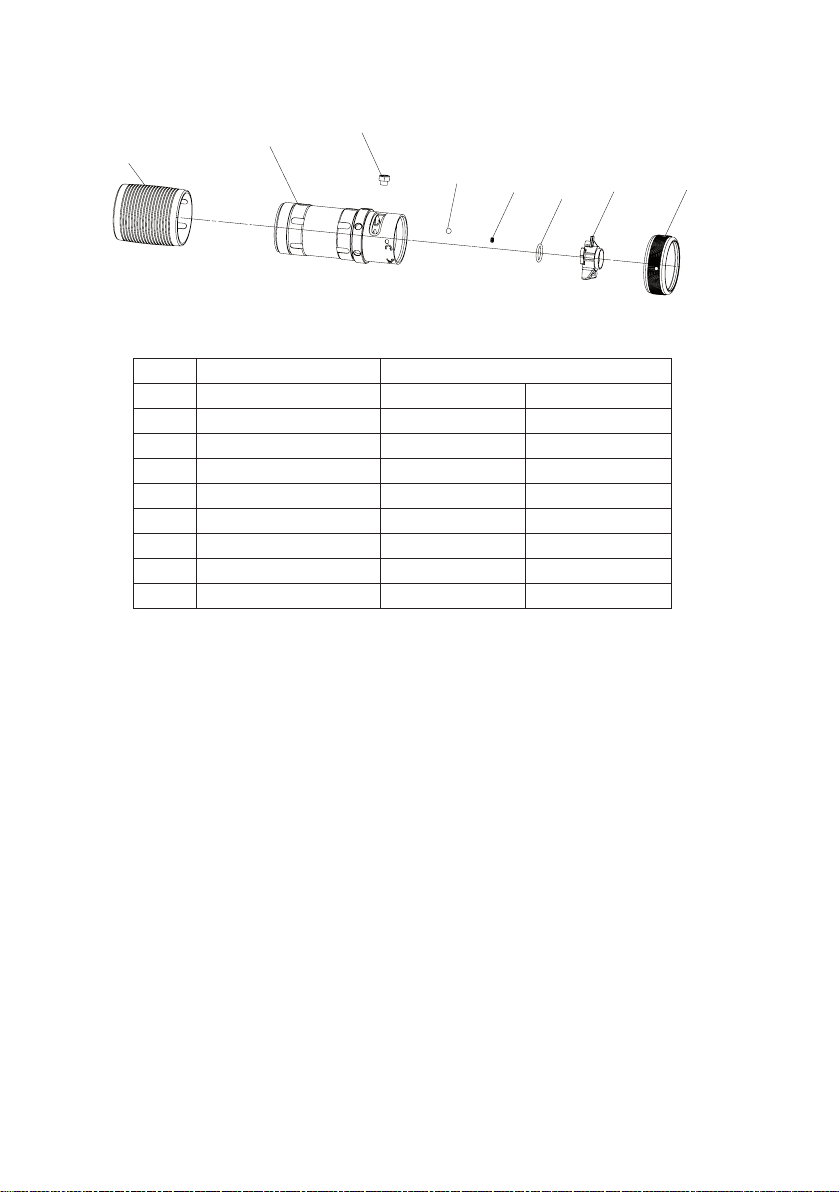

Inlet Bushing Assembly Exploded View

(Dwg. RG_45504578)

Inlet Bushing Assembly Parts List

Item Part Description Part Number

12 Inlet Bushing Assembly QA6-NPT-A465 QA6-BSP-A465

12A Inlet Bushing Assembly

12B O-Ring 11 mm

12C Screen

16601056_ed1 3

4 16601056_ed1

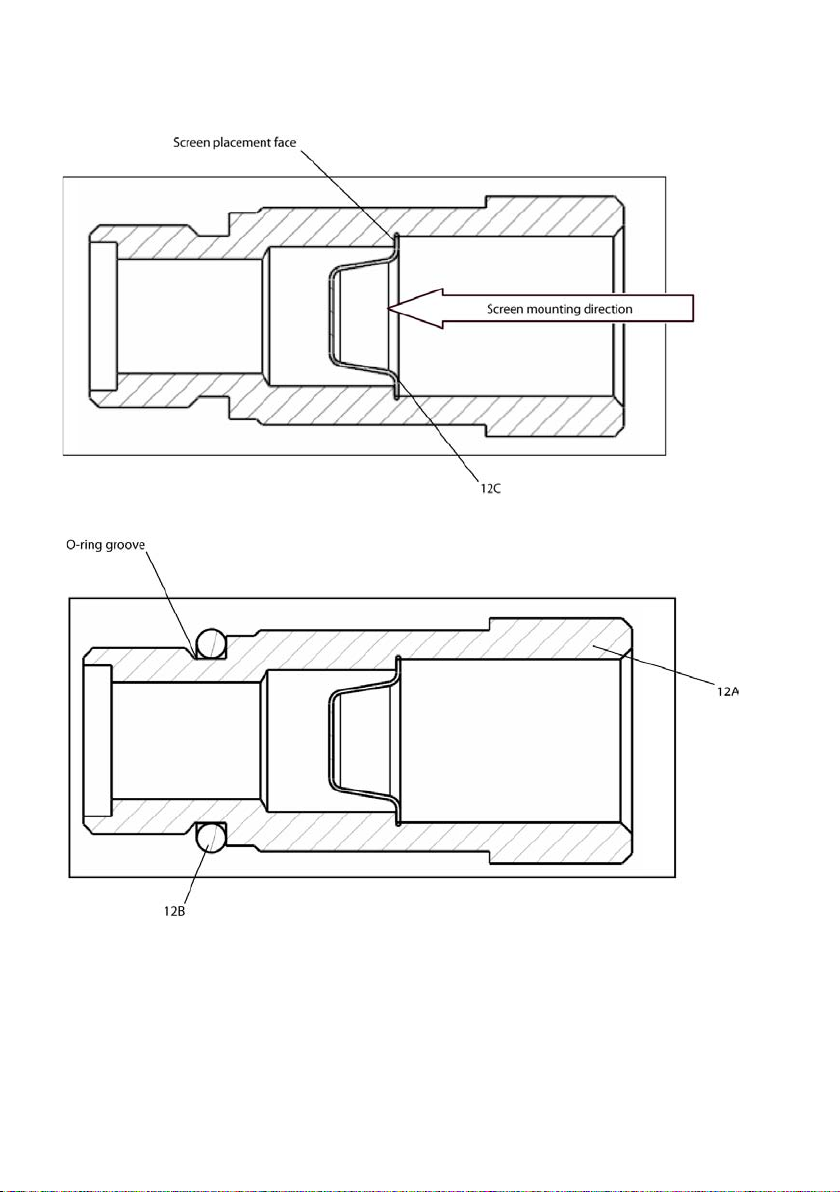

Inlet Bushing Assembly Instructions

Mount screen (12C) into inlet bushing (12A) screen placement face. See section view for the proper placement.

1.

2. Coat o-ring (12B) with o-ring lube and mount on inlet bushing (12A) O-ring groove. See section view for the proper placement.

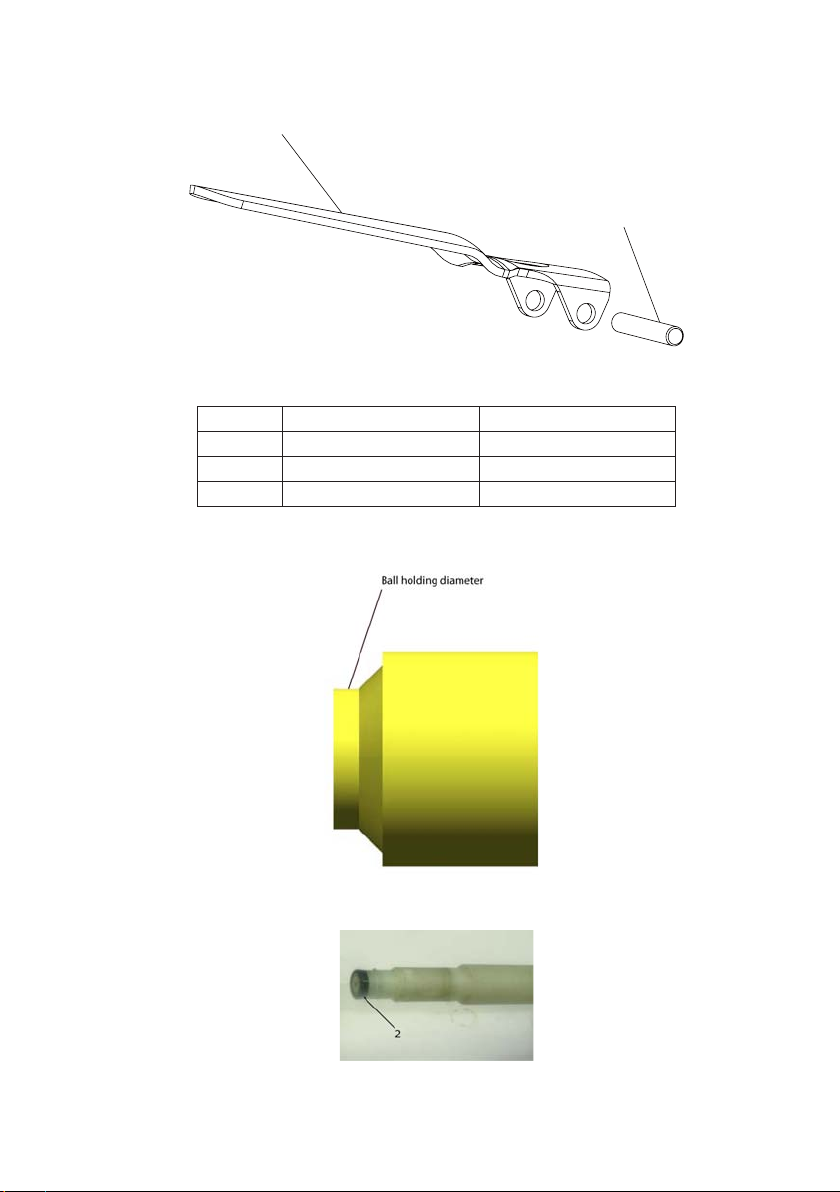

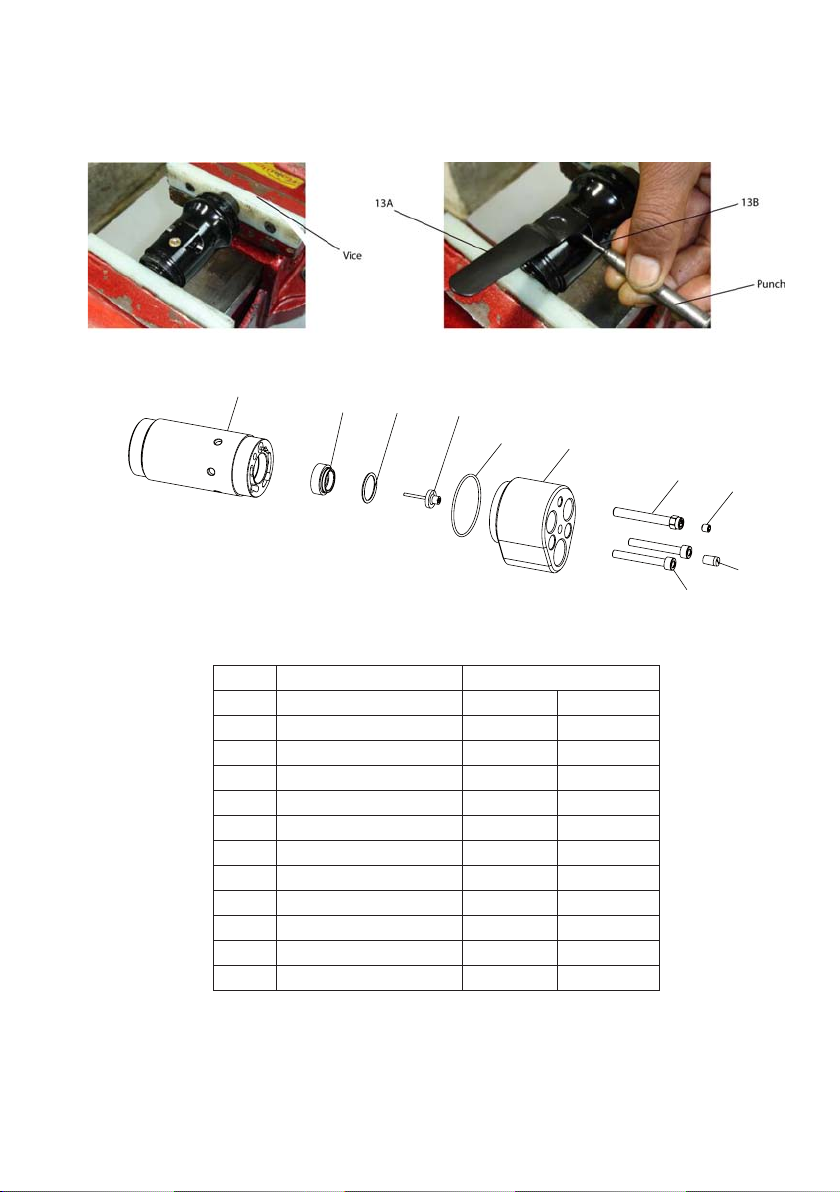

Lever Assembly Exploded View

Lever

Pin 3.5 mm

(Dwg. RG_45504586)

Lever Assembly Parts List

Item Part Description Part Number

13 Lever QA6-A93

13A Lever

13B Pin 3.5 mm

Throttle Housing Module Assembly Instructions

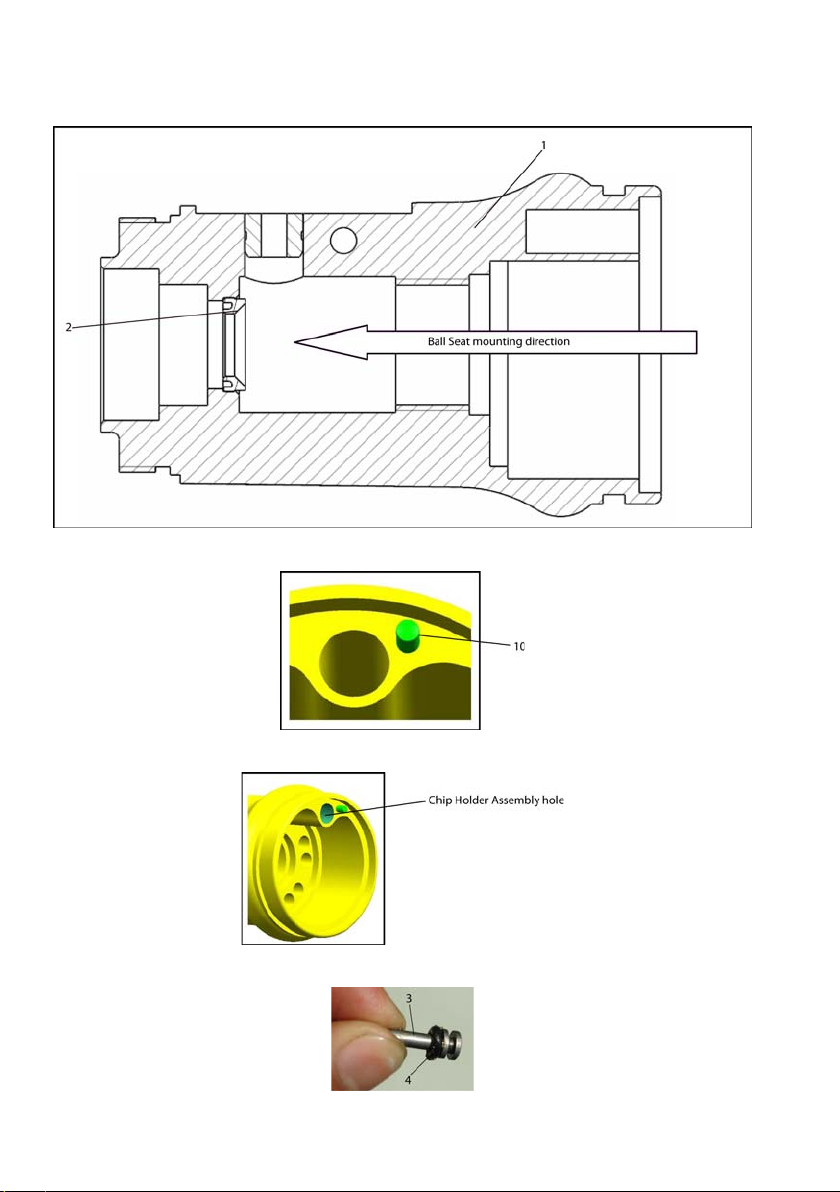

Coat Ball Seat holding diameter of tool (OM127) with O-ring Grease.

1.

2. Hold Ball Seat (2) on Ball Seat Assembly tool (OM127) as shown in picture below.

16601056_ed1 5

6 16601056_ed1

3. Press Ball Seat (2) with Ball Seat Assembly tool into Throttle Housing by using manual press. See Section view for the proper placement.

4. Insert pin (10) into pin hole in throttle housing and press to full depth by manual press, or hammer and punch.

5. Put chip holder assembly (11) into Chip holder assembly hole in throttle housing (1) so that leads are showing.

6. Coat O-ring (4) with O-ring lube and place over Throttle Pin (3).

7. Install throttle pin (3) with O-ring in throttle housing (1) using needle nose pliers. Adjust to get throttle pin into throttle bush. Throttle pin

must be visible from outside over throttle housing bush area.

8. Insert ball (5) in Throttle Housing (1). Make sure, ball sits under Throttle Pin (3).

16601056_ed1 7

8 16601056_ed1

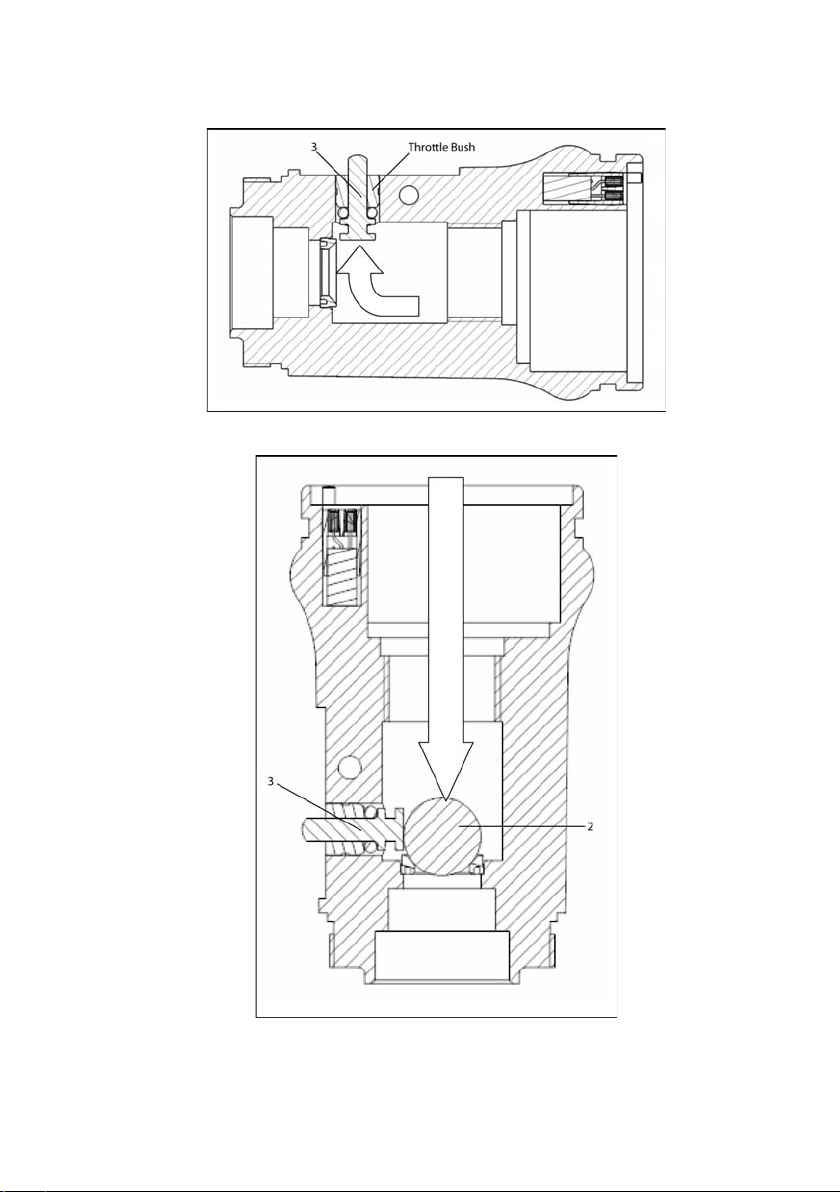

9. for QA6

Note: Muer (7) must face Input of tool.

Place Muer (8), Qty # 2 and Muer (7), Qty # 1 in the Throttle Housing (1). Align Muers to match Throttle Housing Prole.

For QA8

Place Muer (7), Qty # 2 in the Throttle Housing (1). Align Muers to match Throttle Housing prole.

10. Place Diuser Plate (9) on Throttle Housing. Align Pin (10) in Throttle Housing with Diuser Plate Pin Hole.

11. Grease Ball Spring (6) Ground Face and Mount on Inlet Bushing Assembly (12) Mounting Face.

12. Align Ball Spring above Ball (5) and Thread into Throttle Housing (1).

7

3

4

5

6

1

8

10

2

9

13. Align Ball Spring above Ball (5) and Thread into Throttle Housing (1).

14. Hold Throttle Housing on vice. Place Lever (13a) over Throttle Housing and Assemble Pin (13b) using a Punch and Hammer.

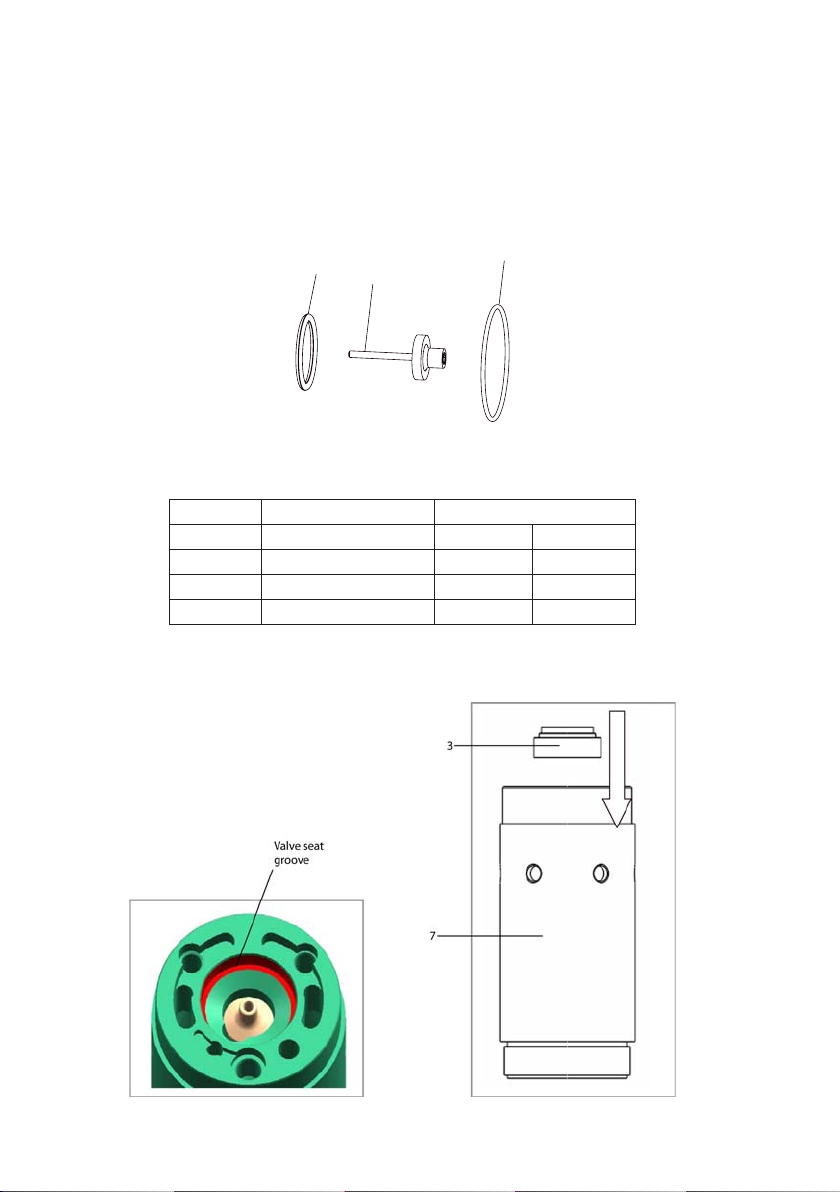

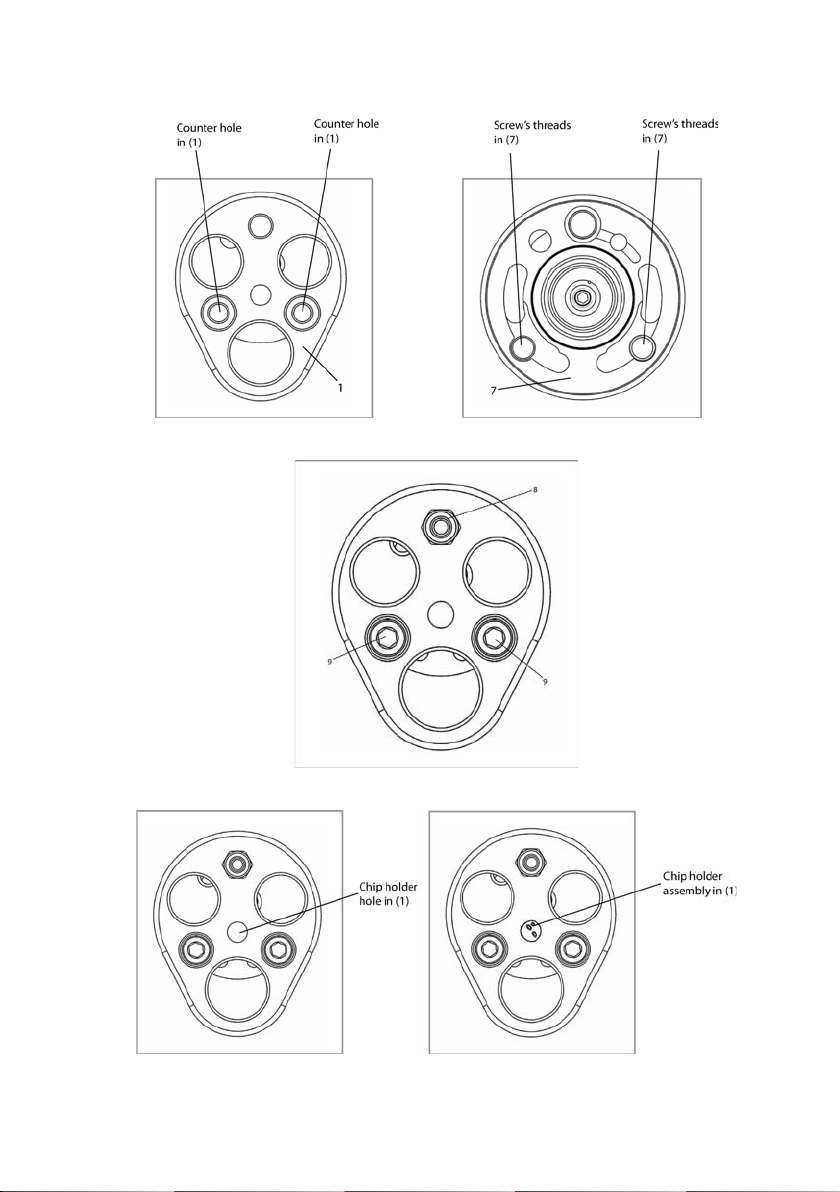

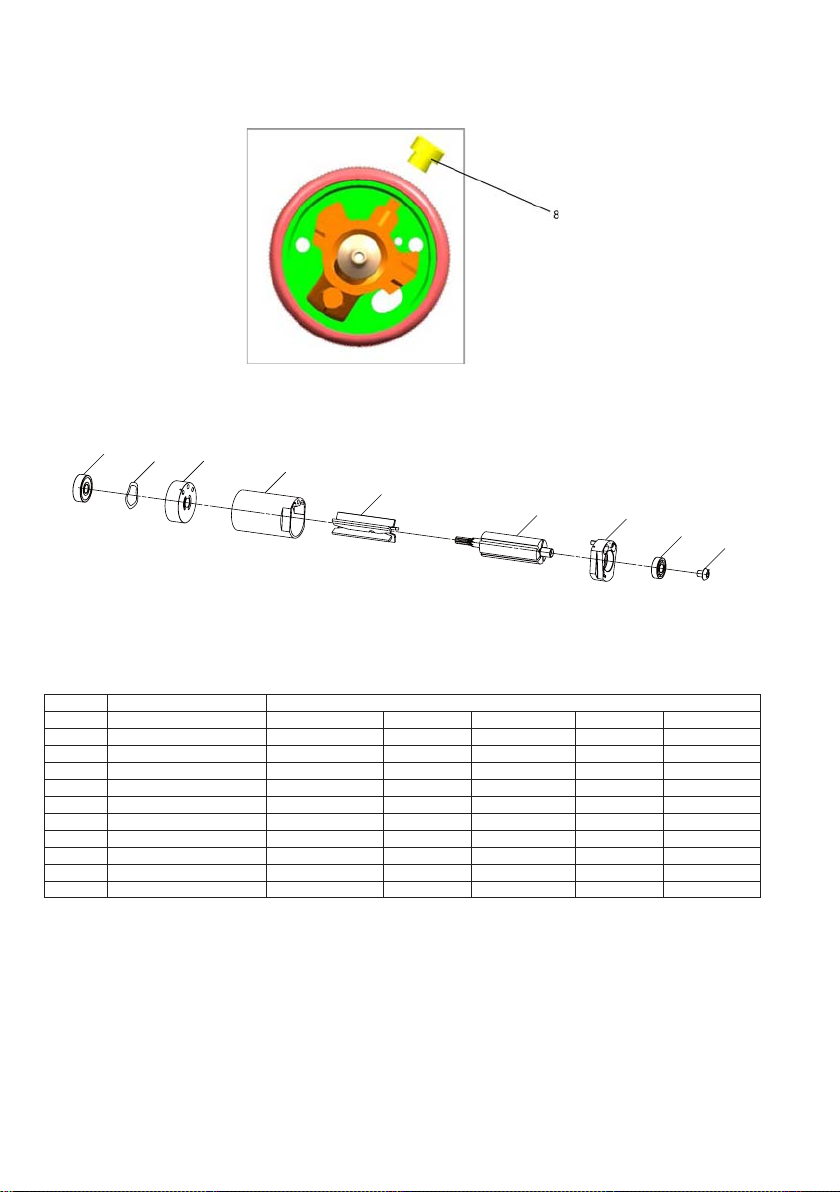

Remote Housing Module Exploded View

(Dwg. RG_45500816)

Remote Housing Module Parts List

Item Part Description Part Number

Remote Housing Assembly QA6-R-A40 QA8-R-A40

1 Remote Start Housing

2 Chip Holder Assembly QA4-A528 QA4-A528

3 Valve Seat

* Remote housing Tune Up kit QA6-1R-K40 QA8-1R-K40

4 O-Ring 15.6 mm

5 Shut o Valve 131128 131128

6 O-Ring 40 mm

7 Remote Motor Housing

8 Remote Screw M6 QA6-439 QA6-439

9 Screw M5 QA6-439-1 (2) QA6-439-1 (2)

10 Set Screw M5

16601056_ed1 9

10 16601056_ed1

Tooling Required

4

5

6

Standard tools and Products:

Ingersoll Rand # 68 Grease

•

torque Wrench

•

Subassemblies

Remote Housing Tune Up Kit Exploded View

(Dwg. RG_45513520)

Remote Housing Tune Up Kit Parts List

Item Part Description Part Description

Remote housing Tune Up kit QA6-1R-K40 QA8-1R-K40

4 O-Ring 15.6 mm

5 Shut o Valve 131128 131128

6 O-Ring 40 mm

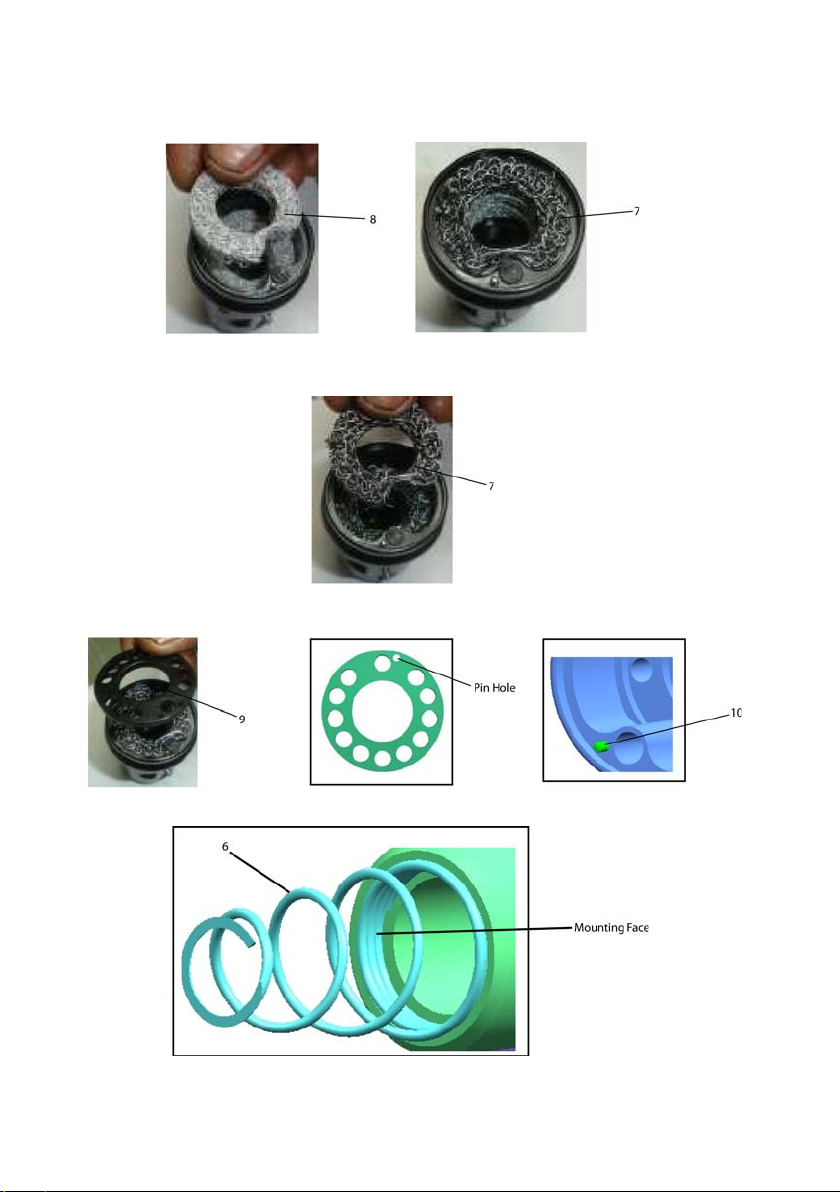

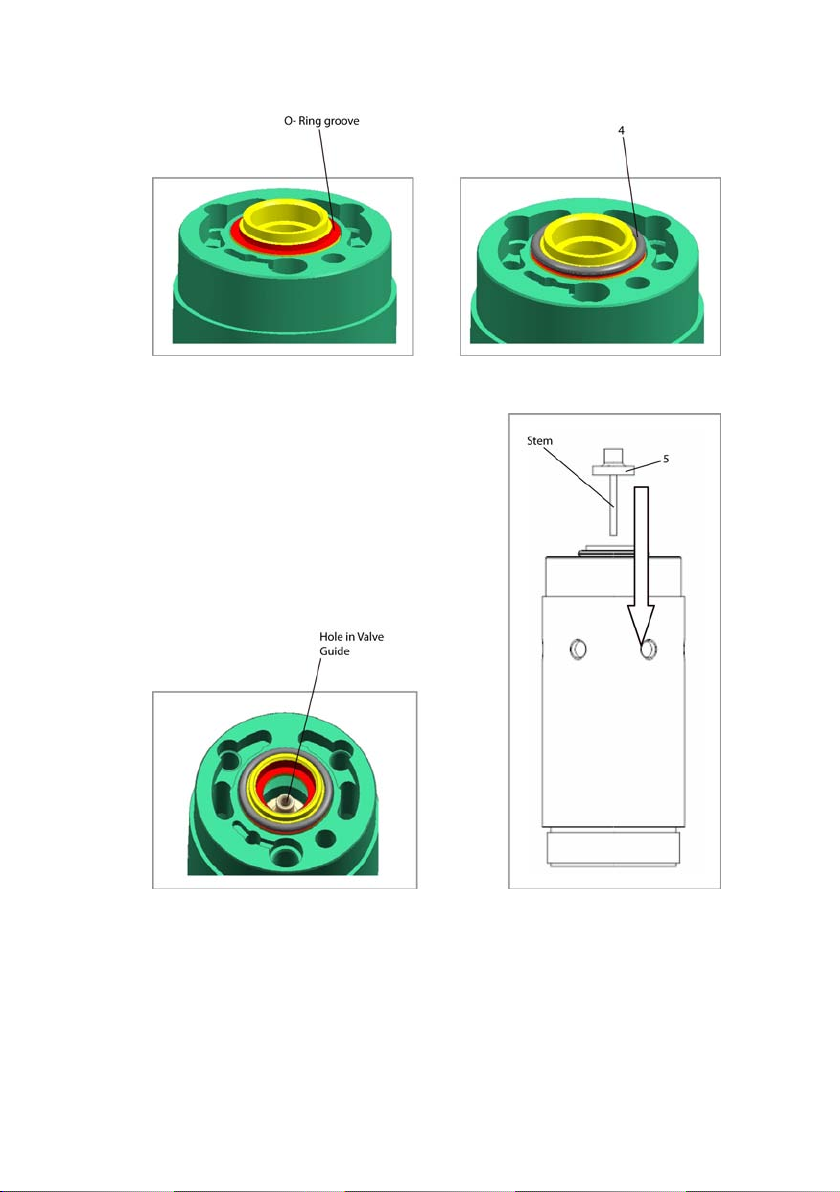

Assembly Instructions for Remote Housing Module

Place Valve Seat (3) in remote Motor Housing’s (7) valve seat groove.

1.

2. Grease O-ring (4) with Ingersoll Rand # 68 Grease and Mount on the Valve Seat’s (3) O-ring Groove in above Assembly.

3. Place Shut-o Valve (5) on Valve Seat’s (3) Step Diameter. Make Sure That Stem of Shut-o Valve Passes Through The Hole In Valve Guide In

Remote Motor Housing.

16601056_ed1 11

12 16601056_ed1

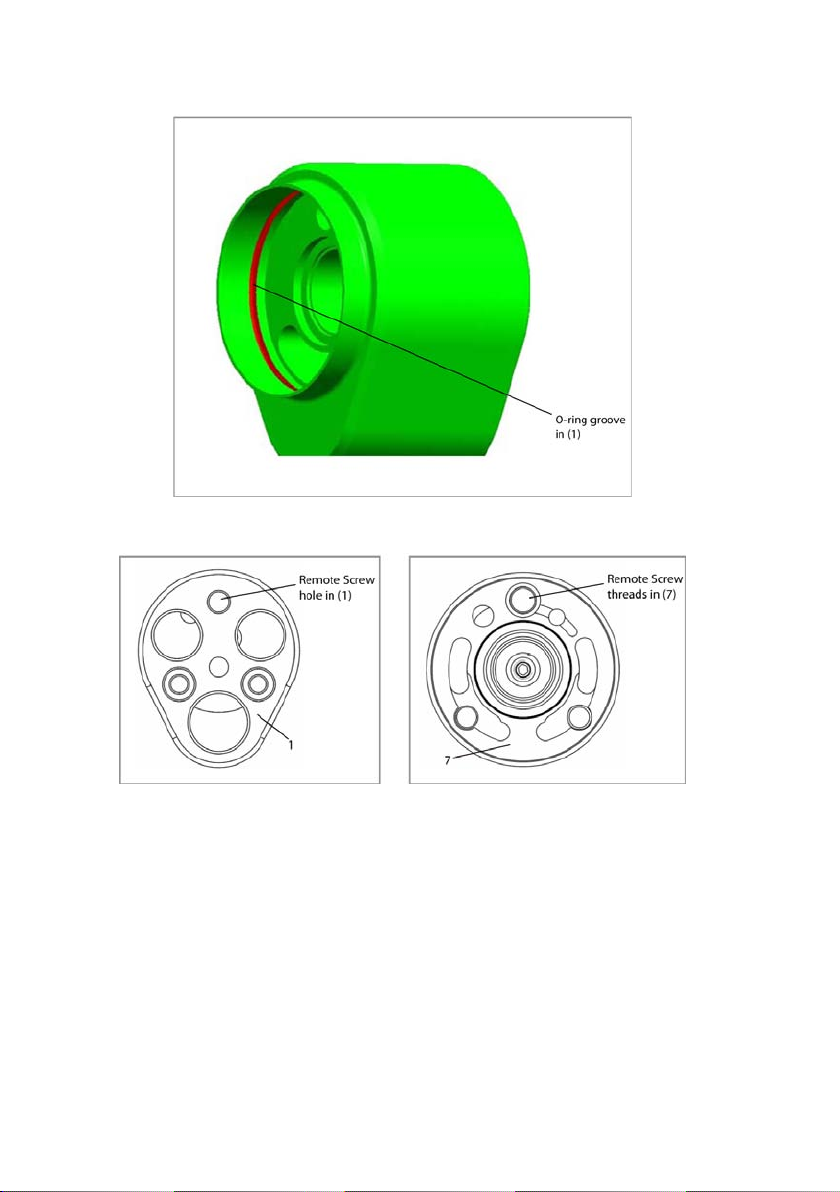

4. Grease O-ring (6) with Ingersoll Rand # 68 Grease and Mount in Remote Start Housing (1) Internal Groove.

5. Insert Remote Screw (8) in the Remote Screw Hole of Remote Housing. Slide this Assembly onto Remote Motor Housing (7). Tighten this

Screw onto Remote Screw’s threads in Remote Motor Housing by hand rst.

6. Insert Screw (9), Qty 2 in the counter holes in remote start housing of above assembly and tighten screws onto screw’s threads in remote

motor housing by hand rst.

7. Tight screw (8) clockwise to 5 nm (3.7 Ft-lb) and screws (9) clockwise to 6 nm (4.5 Ft-lb) assembled in step 5 and 6 by using a torque wrench.

8. Insert Chip Holder Assembly (2) into the chip holder hole in remote start housing (1).

16601056_ed1 13

14 16601056_ed1

Motor Housing Module Exploded View

2

1

8

6

5

4

3

7

(Dwg. RG_45504602)

Motor Housing Module Parts List

Item Part Description Part Number

Motor Housing Assembly QA6-A40 QA8-A40

1 M otor Housing

2 Grip QA6-145 QA6-145

3 Reverse Valve QA6-329 QA6-329

4 O-Ring 14.8 mm

5 Spring 3.6 mm

6 Ball

7* Reverse Ring Assembly QA6-A273 QA6-A273

8 Reverse Screw M8 131069 131069

* See Subassembly Exploded View and Parts List for Detail.

Tooling Required

Standard tools and Products

O-ring Lube ( Ingersoll Rand # 68)

•

Loctite # 542

•

Allen Key 4mm

•

Subassemblies

7A

7A

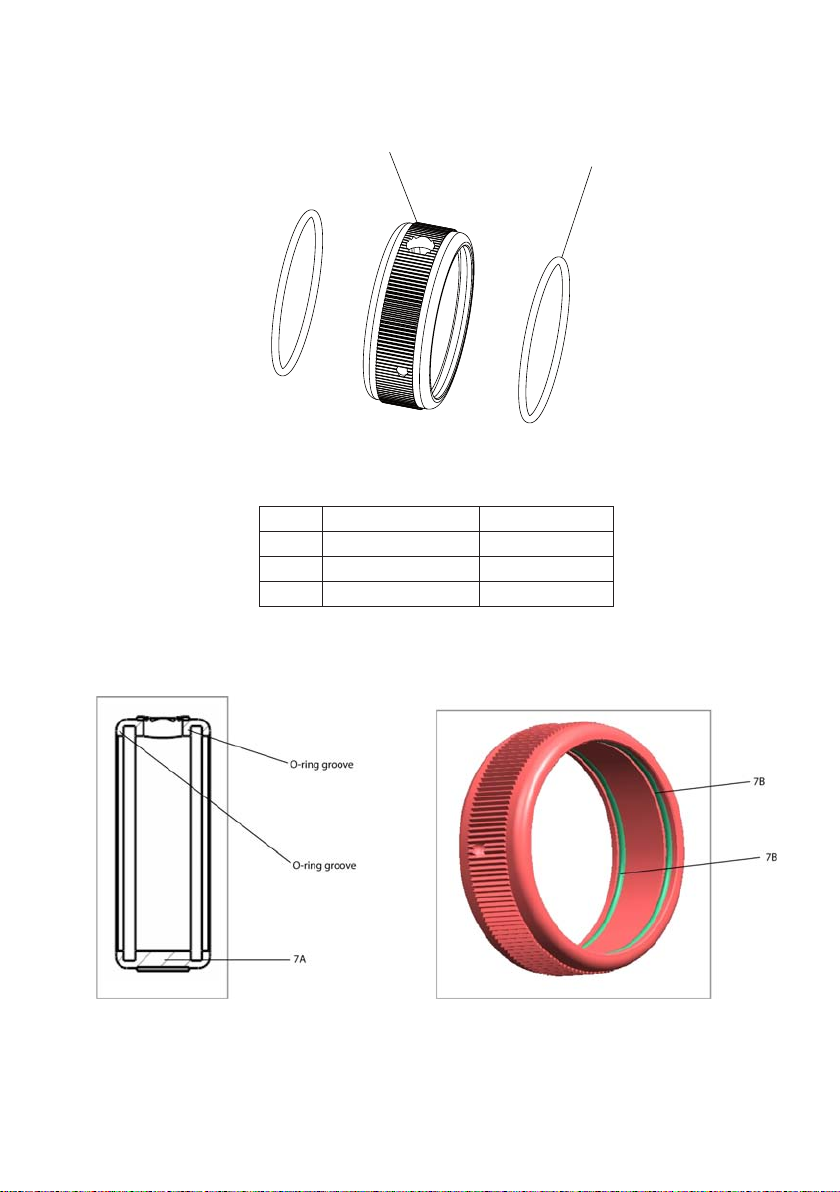

Reverse Ring Assembly Exploded View

(Dwg. RG_45503844)

Reverse Ring Assembly Parts List

Item Part Description Part Number

7 Reverse Ring Assembly QA6-A273

7A Reverse Ring

7B O-ring 38 mm (2)

Assembly Instructions for Reverse Ring Assembly

Coat O-ring (7b), Qty#2 with O-ring lube and mount in Reverse Ring (7a) grooves, one each. See section view for the proper placement.1.

16601056_ed1 15

16 16601056_ed1

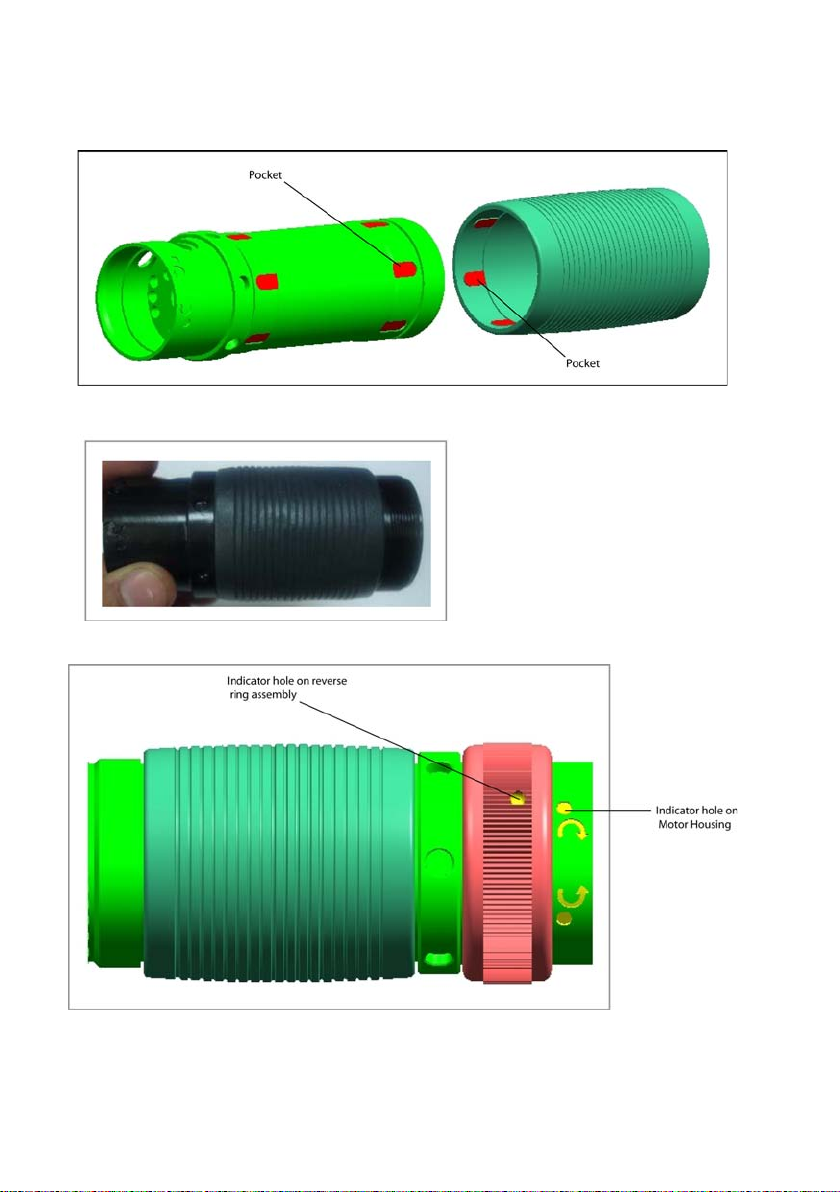

Assembly Instructions for Motor Housing Module

Slide Grip (2) on motor housing (1). Make sure to align motor housing pockets with grip pockets.

1.

Note: Do not use oil or other lubricants, heat slightly to soften the grip if required.

2. Orient Reverse Ring Assembly (7) with indicator hole closer to indicator hole on motor housing (1).

3. Coat Ball (6) with o-ring grease and place onto either ball hole in motor housing.

4. Coat Spring (5) with o-ring grease and place onto reverse valve (3) spring hole.

5. Coat O-ring (4) with o-ring lube and place on the groove in reverse valve (3).

6. Place above reverse valve assembly onto motor housing. Make sure that ball spring in reverse valve sits over ball placed in motor housing.

See Step 3 above.

16601056_ed1 17

18 16601056_ed1

7. Coat Reverse Screw (8) Threads with loctite # 542. Tighten reverse screw fully with allen key on reverse ring assembly placed on motor

6

3

9

8

2

1

7

5

4

housing and then back o 1 / 4 turn. Make sure that screw sits over reverse valve edge. Remove the excess loctite.

Motor Module Exploded View

(Dwg. RG_80221583)

Motor Module Parts List

Item Part Description Part Number

1 Rotor QA6-53-8 QA6-53-10 QA6-53-11 QA8-53-10 QA8-53-11

2* Vane Pack QA6-42-5 QA6-42-5 QA6-42-5 QA8-42-5 QA8-42-5

* Motor Kit QA6-1-K53 QA6-1-K53 QA6-1-K53 QA6-1-K53 QA6-1-K53

3 Wave Washer

4 Adjustment Screw M5

5 Rear End Bearing 17x7x5

6 Front End Bearing 22x7x7

7* Rear Endplate Assembly QA6-A12 QA6-A12 QA6-A12 QA6-A12 QA6-A12

8* Cylinder Assembly QA6-A3 QA6-A3 QA6-A3 QA8-A3 QA8-A3

9 Front Endplate QA6-11 QA6-11 QA6-11 QA6-11 QA6-11

* See Subassembly Exploded View & Parts List for Detail.

Motor Assembly QA6-A53-8 QA6-A53-10 QA6-A53-11 QA8-A53-10 QA8-A53-11

Tooling Required

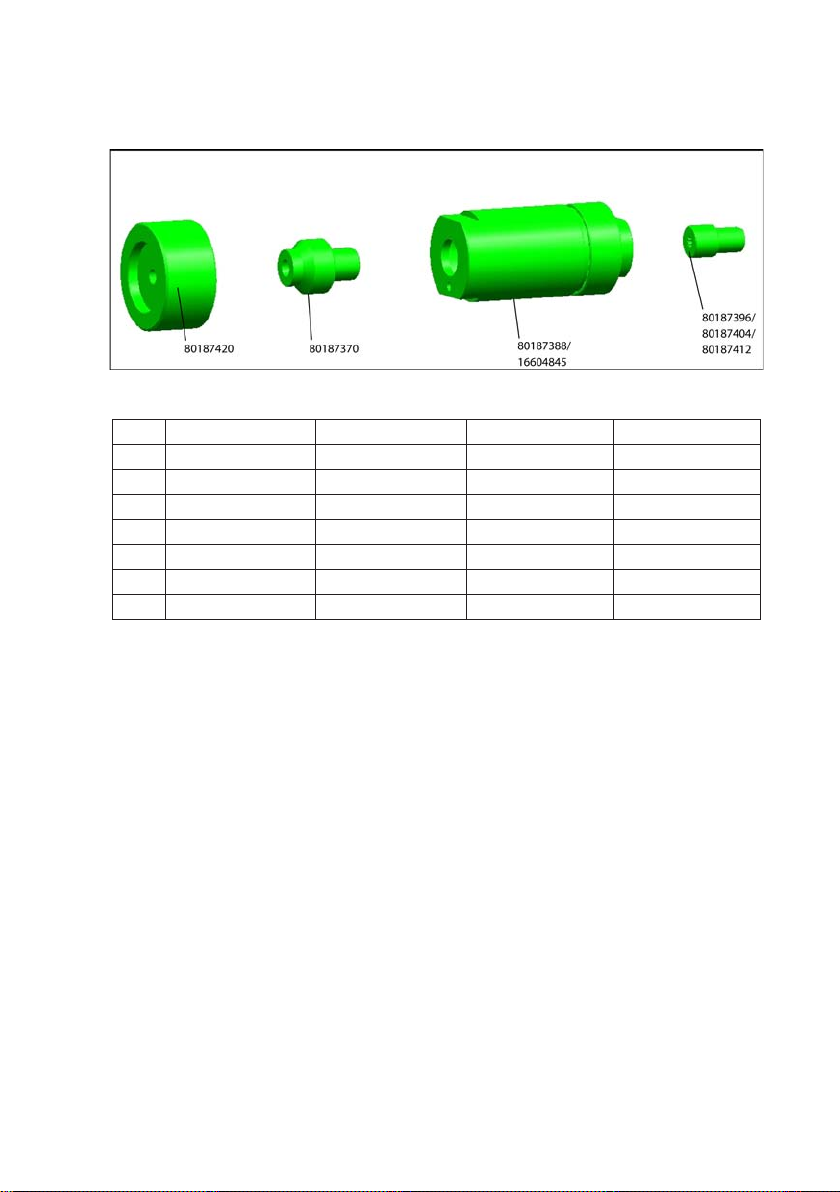

Specic Tooling Exploded View

Specic Tooling Parts Lists

Item Part Description Part Number Usage For Model

1 Rotor Spline Adaptor 80187396 8 Teeth Motor spacing QA6 { }

2 Rotor Spline Adaptor 80187404 10 Teeth Motor spacing QA6 { }, QA8 { }

3 Rotor Spline Adaptor 80187412 11 Teeth Motor spacing QA6 { }, QA8 { }

4 Motor Clamp tool 80187388 Motor spacing QA6 { }

5 Motor Clamp tool 16604845 Motor spacing QA8 { }

6 Motor Press Assembly 80187370 Motor Back Bearing Press QA6 { }, QA8 { }

7 Motor Assembly tool 80187420 Motor Back Bearing Press QA6 { }, QA8 { }

Standard tools and Products

Loctite # 243

•

Vice

•

3mm Hex Key

•

Ingersoll Rand # 10 Oil

•

Ingersoll Rand # 68 Grease

•

Heat Gun – for Disassembly

•

Soft Mallet

•

Manual Arbor Press

•

16601056_ed1 19

20 16601056_ed1

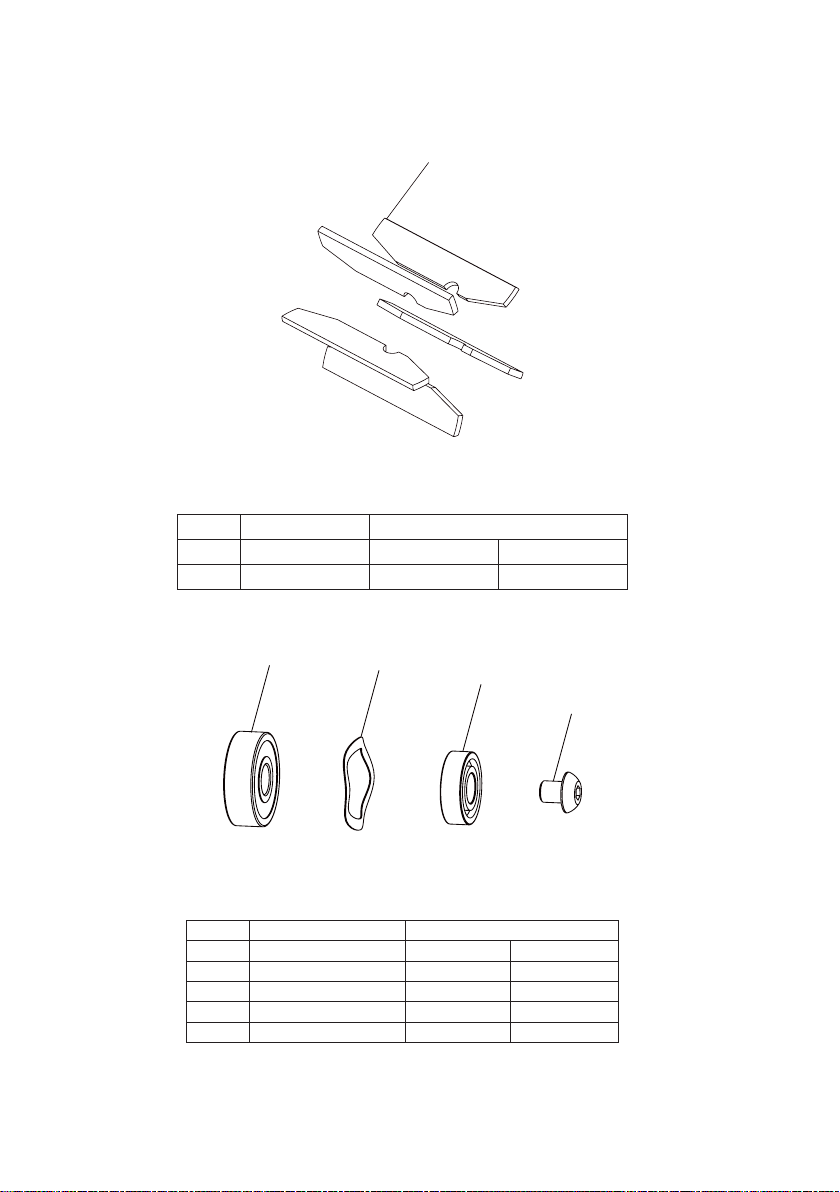

Subassemblies

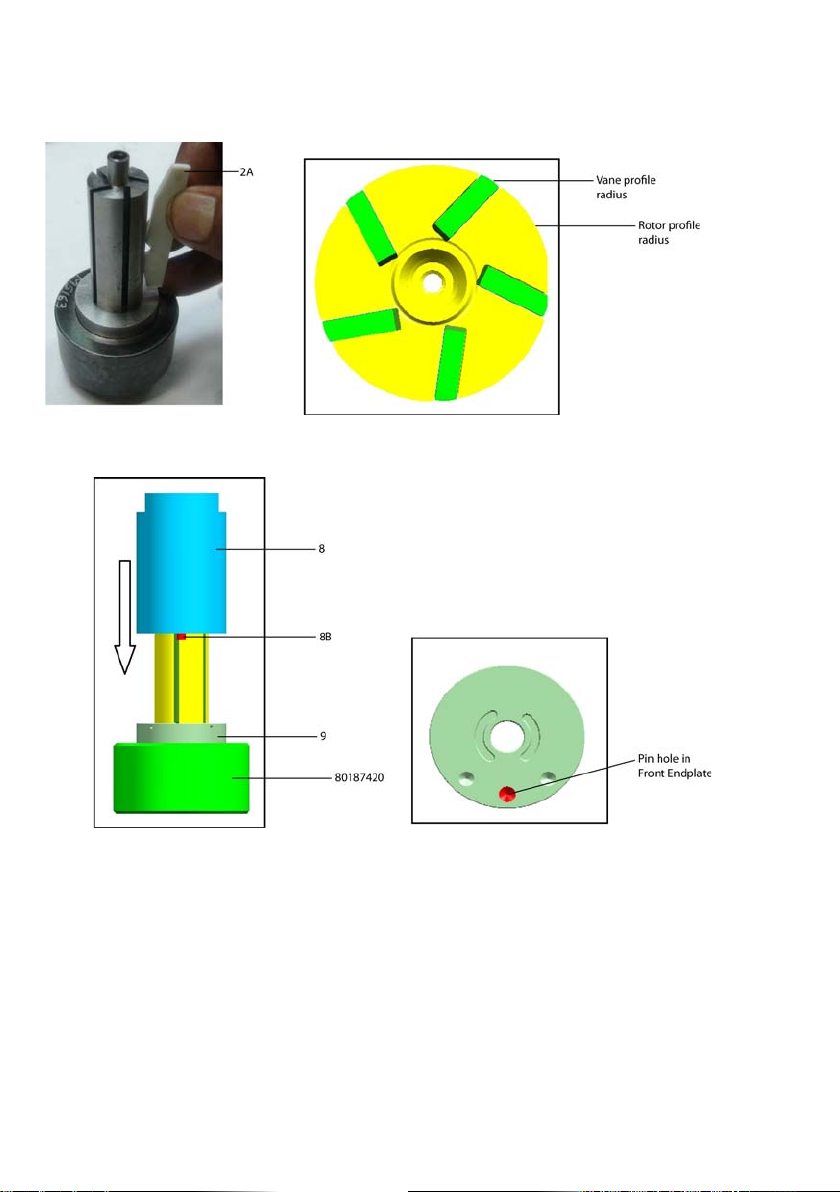

2A

6

3

5

4

Vane Pack Exploded View

(Dwg. RG_45492162)

Vane Pack Parts List

Motor Kit Exploded View

Item Part Description Part Number

2 Vane Pack QA6-42-5 QA8-42-5

2A Vane (5) (5)

(Dwg. RG_45513546)

Motor Kit Parts List

Item Part Description Part Number

* Motor Kit QA6-1-K53 QA6-1-K53

3 Wave Washer

4 Adjustment Screw M5

5 Rear End Bearing 17x7x5

6 Front End Bearing 22x7x7

Rear Endplate Assembly Exploded View

7A

7B

(Dwg. RG_80238579)

Rear Endplate Assembly Parts List

Item Part Description Part Number

7 Rear Endplate Assembly QA6-A12

7A Rear Endplate

7B Roll Pin 19 mm Y178-41

Assembly Instructions for Rear Endplate Assembly

Insert Roll Pin (7B) in rear endplate (7A) hole and press to maintain pin projection of 2.5Mm. See views below for the proper placement.1.

16601056_ed1 21

22 16601056_ed1

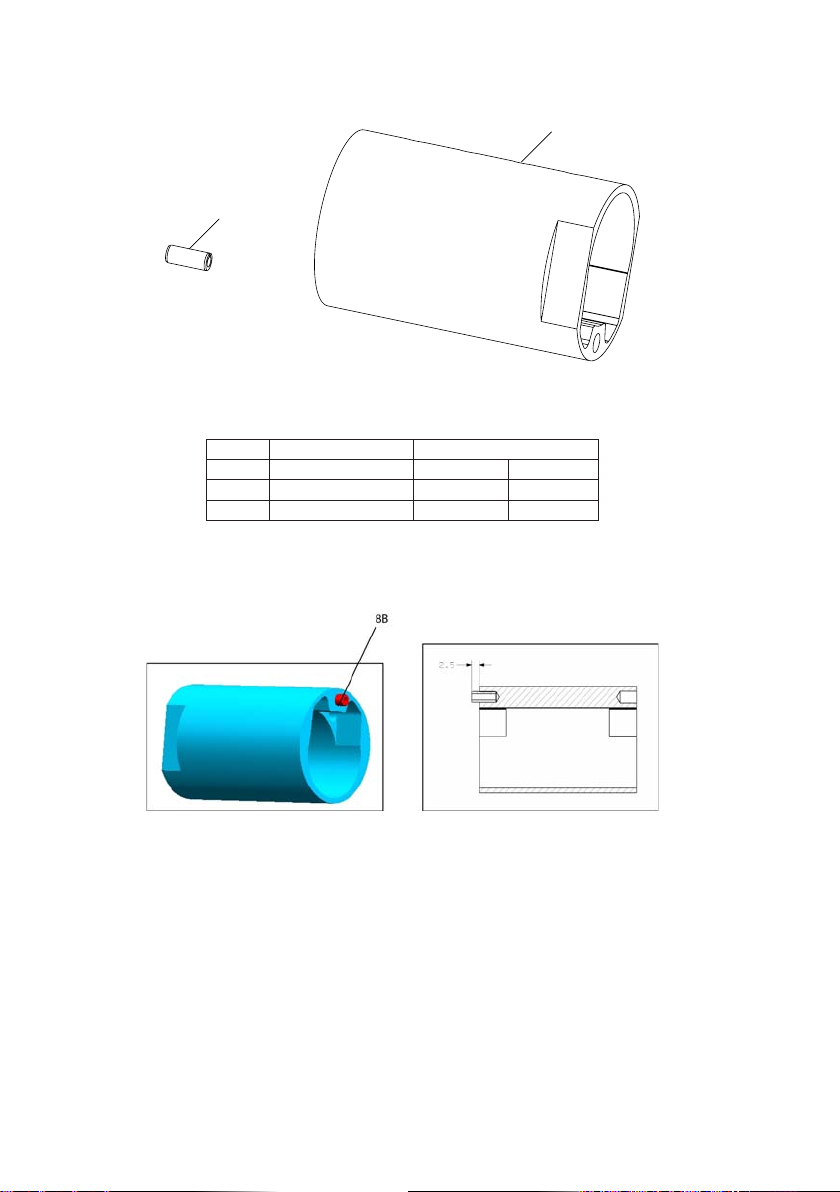

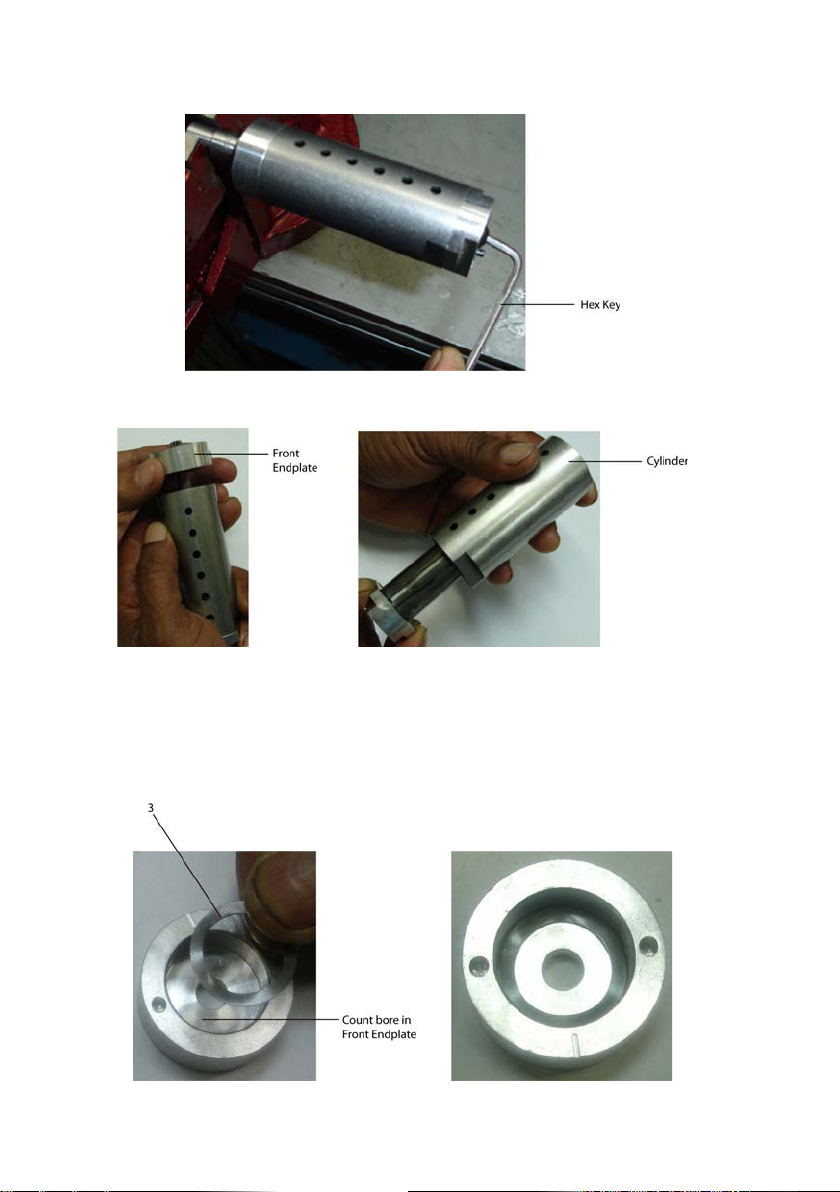

Cylinder Assembly Exploded View

8B

8A

(Dwg. RG_45492139)

Cylinder Assembly Parts List

Item Part Description Part Number

8 Cylinder Assembly QA6-A3 QA8-A3

8A Cylinder

8B Roll Pin Y178-191 Y178-191

Assembly Instructions for Cylinder Assembly

Insert Roll Pin (8B) into Cylinder (8A) Pin Hole and Press Pin on Manual Press to Maintain Pin Projection of 2.5mm. See views below for the

1.

proper placement.

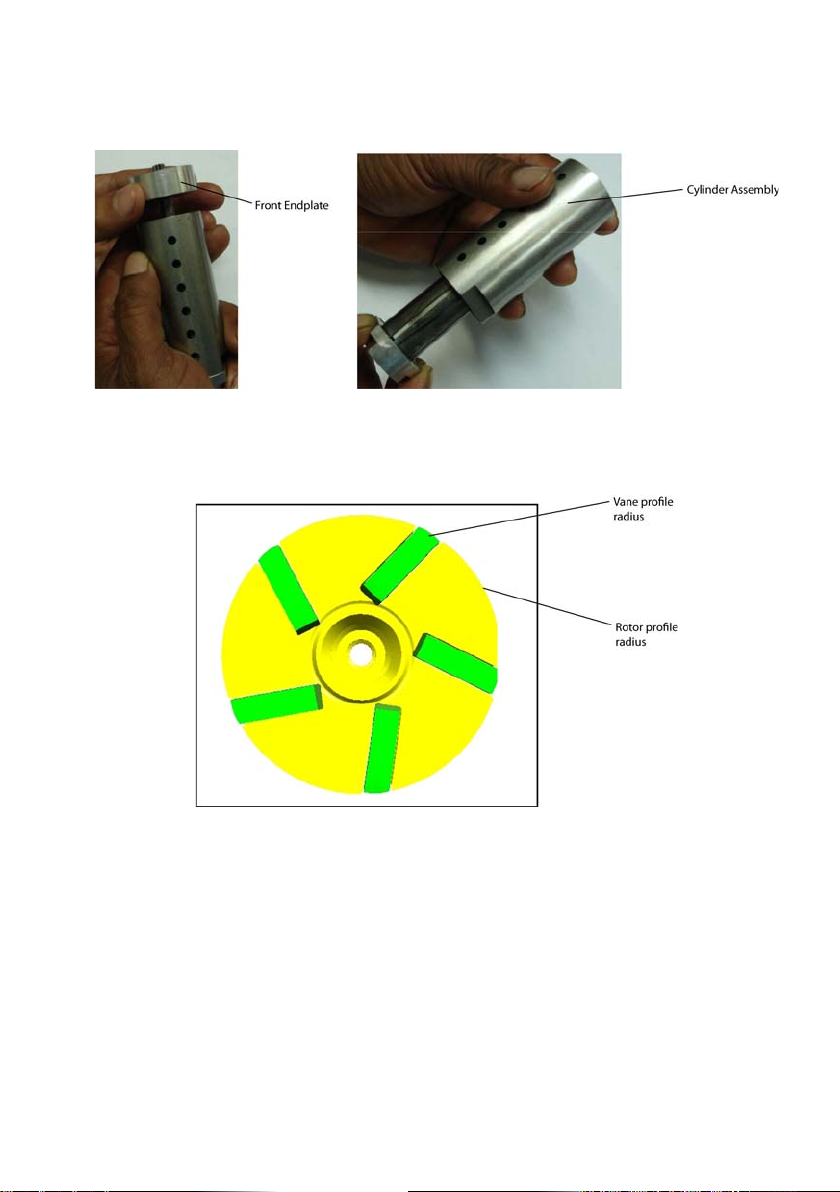

Replacement of Vanes

Hold Motor rmly in hand, strike mallet on rotor spline to drive rotor (1) and rear endplate assembly out of front endplate (9). Remove front

1.

endplate (with wave washer and bearing) and cylinder assembly from motor module.

2. Remove Vanes (2A) qty # 5 from rotor and using degreaser clean all surfaces of rotor and endplates. Make sure not to get degreaser in

bearing or it may be damaged.

3. Oil all surfaces of new vanes (qty # 5) with ingersoll rand # 10 oil. Place them one at a time in rotor (1) slots. Make sure to match vane prole

radius with rotor prole radius. See view below.

Note: Motor will run without lubrication but oil is used for maximum vane life.

16601056_ed1 23

24 16601056_ed1

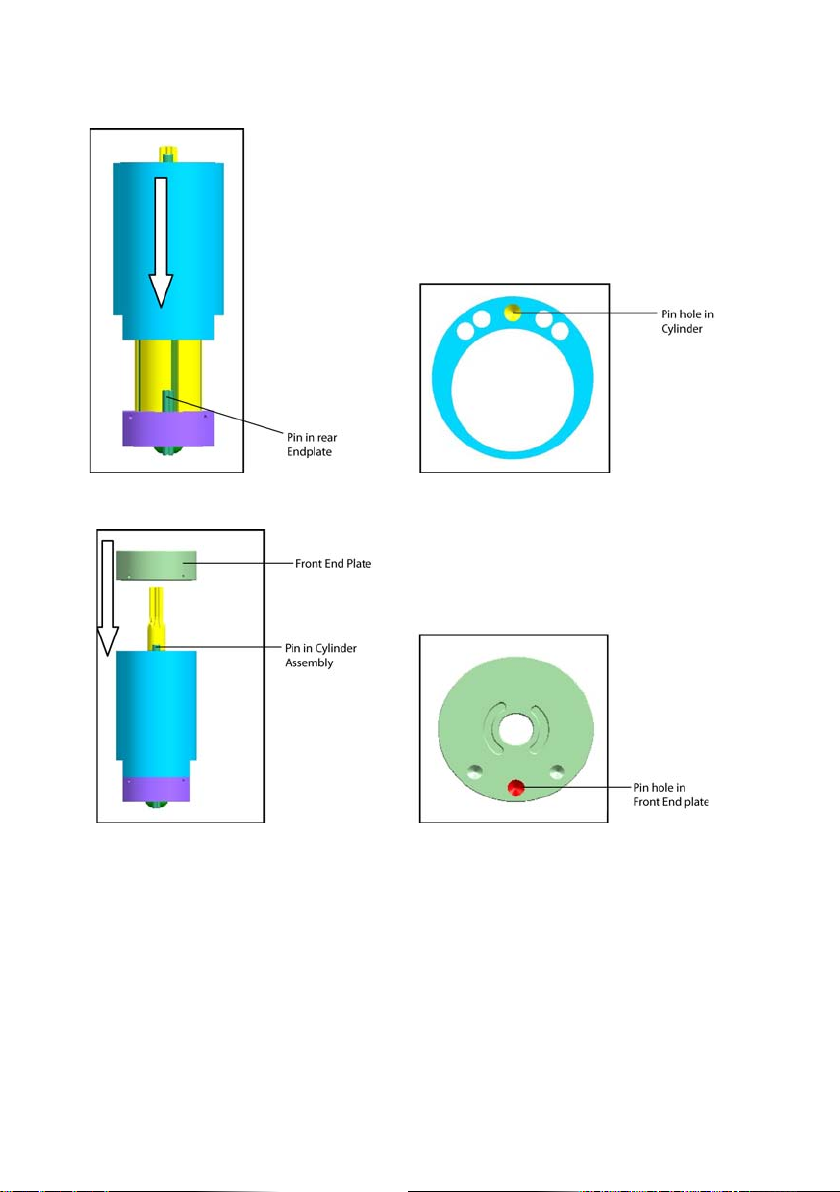

4. Mount Cylinder Assembly in above assembly. Align pin in rear endplate with pin hole in cylinder assembly.

Note: Hold assembly in straight upward direction otherwise vanes will walk out.

5. Place Front Endplate (with Wave Washer and Bearing) assembly onto rotor shaft. Align roll pin (8b) in cylinder assembly with pin hole in

front endplate.

6. Place Fixture 80187420 on top of motor, then press until bearing (6) is properly spaced.

Notes:

1. Make sure to clear adjustment screw (4) and roll pin (7b) in rear endplate assembly from pressing.

2. Bearing should be pressed at least 0.025mm below the surface of the end plate, and not exceeding 0.2mm. The front bearing press

xture 80187420 provides this spacing.

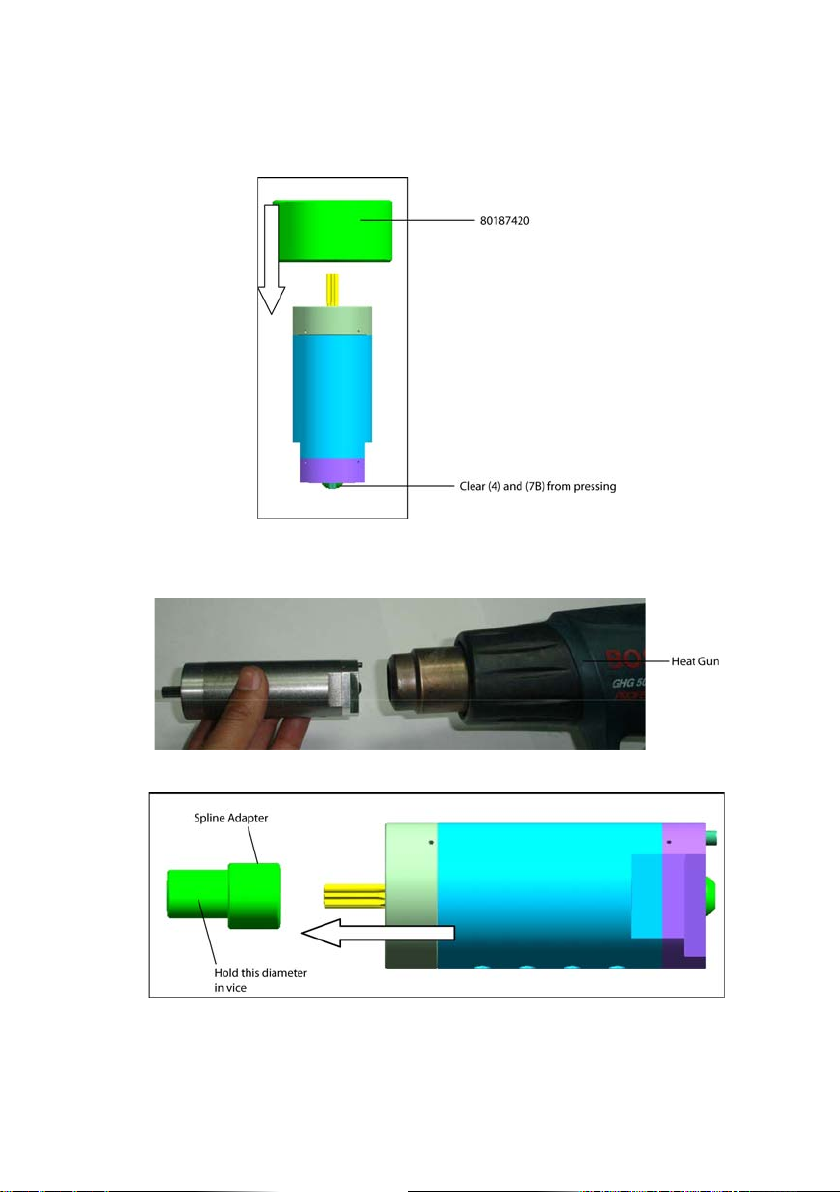

Disassembly of Motor Module

Heat Adjustment Screw (4) screwed in the rear of motor with heat gun.

1.

Note: Adjustment Screw has loctite. Heat is used to break that bonding.

2. Hold Spline Adaptor in vice. Insert rotor splines into adaptor’s (80187396 / 80187404 / 80187412 depending on rotor teeth) spline.

16601056_ed1 25

26 16601056_ed1

3. Using 3mm Hex key, unscrew adjusting screw.

4. Hold Motor rmly in hand, strike mallet on rotor spline to drive rotor (1) and rear endplate assembly out of front endplate (9). Remove front

endplate (with wave washer and bearing) and cylinder assembly from motor module.

5. Remove Vanes (2A) Qty # 5 from rotor and using degreaser clean all surfaces of rotor and endplate.

6. Remove rear endplate assembly (7) from rotor.

Note: It is not a hard press, so gently press out rotor with a pin<7mm from endplate.

Assembly Instructions for Motor Module

Note: Replacement of motor parts may change shut o operation of tool. We recommend ordering new pushrod (132017).

1. Completely clean rotor and cylinder with a degreaser agent, it may be necessary to use a light brush to clean rotor and pin with degreaser.

2. Place Wave washer (3) in front end plate (9) counter bore.

3. Place Bearing (6) over wave washer in front endplate counter bore.

4. Place above assembly in the counter bore of xture 80187420. Kidney slot side of front endplate must be upward.

Note: Fixture provides proper placement of front endplate and bearing. Bearing must be pressed a minimum of 0.025mm below front

endplate surface after nal motor spacing adjustment. Heat build up and bearing failure may occur if not properly spaced.

5. Place Rotor onto front endplate bore. Hold xture 80187370 in manual press and press rotor in front endplate.

16601056_ed1 27

28 16601056_ed1

6. Oil all surfaces of new vanes (Qty # 5) with Ingersoll Rand # 10 oil. Place them one at a time in rotor (1). Make sure to match vane prole

radius with prole radius of rotor.

Note: Motor will run without lubrication but oil is used for maximum vane life.

7. Slide Cylinder Assembly (8) over rotor and front endplate. Align roll pin (8b) in cylinder assembly with front endplate pin hole.

Note: Hold Assembly in straight upward direction otherwise vanes will walk out.

8. Put Rear Endplate Assembly onto rotor shaft. Align roll pin (7B) in rear endplate assembly with cylinder pin hole.

Note: Counter Bore side of rear endplate assembly must be upward.

9. Grease Bearing (5) with Ingersoll Rand # 68 Grease and place onto Rotor Shaft and Rear Endplate Assembly counter Bore. Press Bearing

Using Fixture 80187370 Until Assembly is tight and will not rotate.

Note: Rear Endplate press xture 80187370 presses the bearing inner race. Pressing outer race may damage bearing.

16601056_ed1 29

Loading...

Loading...