Page 1

OPERATOR’S MANUAL

www.ingersollrandproducts.com

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

1” DIAPHRAGM PUMP

1:1 RATIO (METALLIC)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Refer to Model Description Chart to match the pump material options.

637397 for air section repair (see page 6).

637401-XX for fluid section repair (see page 4). NOTE: This kit also con-

tains several air motor seals which will need to be replaced.

637390-3 major air valve assembly (see page 7).

PUMP DATA

Models see Model Description Chart for “-XXX”..............

Pump Type Metallic Air Operated Double Diaphragm..........

Material see Model Description Chart..............

Weight 26.2 lbs (11.9 kgs).........................

Maximum Air Inlet Pressure 120 p.s.i.g. (8.3 bar).........

Maximum Material Inlet Pressure 10 p.s.i.g. (0.69 bar).....

Maximum Outlet Pressure 120 p.s.i.g. (8.3 bar)..........

Maximum Flow Rate

Displacement / Cycle @ 100 p.s.i.g. 0.234 gal. (0.89 lit.)...

Maximum Particle Size 1/8” dia. (3.3 mm)............

Maximum Temperature Limits (diaphragm / ball / seal material)

E.P.R. / EPDM -60_ to 280_ F(-51_ to 138_ C)...........

HytrelR -20_ to 150_ F(-29_ to 66_ C)...............

Nitrile 10_ to 180_ F(-12_ to 82_ C).................

SantopreneR -40_ to 225_ F(-40_ to 107_ C)...........

PTFE 40_ to 225_ F(4_ to 107_ C).................

VitonR -40_ to 350_ F(-40_ to 177_ C)................

Dimensional Data see page 8................

Mounting Dimension 5.9375” x 8.75” (150.8 mm x 222.3 mm)....

Noise Level @ 70 p.s.i., 60 c.p.m. 80.6 db(A)

Thepump sound pressure levels published here have been updated to an Equivalent

Continuous Sound Level (L

ROP S5.1 using four microphone locations.

NOTICE: All possible options are shown in the chart, however, certain

combinations may not be recommended, consult a representative or the

factory if you have questions concerning availability.

(flooded inlet) 60.0 g.p.m. (227.1 l.p.m.)....

{.....

) to meet the intent of ANSI S1.13-1971, CAGI-PNEU-

Aeq

CENTER SECTION MATERIAL

A - Aluminum

FLUID CONNECTION

A - Inlet - 1-1/2 -- 11-1/2 N.P.T.F. - 1

Outlet - 1-1/4 -- 11-1/2 N.P.T.F. - 1

FLUID CAPS & MANIFOLD MATERIAL

A - Aluminum

HARDWARE MATERIAL

P - Plated Steel

S - Stainless Steel

SEAT MATERIAL

A - Santoprene F - Aluminum

C - Hytrel G - Nitrile

BALL MATERIAL

A - Santoprene T - PTFE

C - Hytrel V - Viton

G - Nitrile

DIAPHRAGM MATERIAL

A - Santoprene T - PTFE / Santoprene

C - Hytrel V - Viton

G - Nitrile

PW10A-X-X

RELEASED: 3-11-04

REVISED: 5-19-10

(REV. 05)

Figure 1

MODEL DESCRIPTION CHART

PW10 A -A A X -X X X

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET BRYAN, OHIO 43506

(800) 276-4658 D FAX (800) 266-7016

E2010 CCN 15207962

FLUID SECTION SERVICE KIT SELECTION

EXAMPLE: MODEL # PW10A-AAP-AAA

FLUID SECTION SERVICE KIT # 637401-AA

PW10A - AAX - X X X

637401 - X X

DiaphragmBall

Page 2

OPERATING AND SAFETY PRECAUTIONS

READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE.

EXCESSIVE AIR PRESSURE

STATIC SPARK

WARNING

al injury, pump damage or property damage.

EXCESSIVE AIR PRESSURE. Can cause person-

HAZARDOUS MATERIALS

HAZARDOUS PRESSURE

S Do not exceed the maximum inlet air pressure as stated on the

pump model plate.

S Be sure material hoses and other components are able to with-

stand fluid pressures developed bythis pump. Check all hoses

for damage or wear. Be certain dispensing device is clean and

in proper working condition.

WARNING

severe injury or death. Ground pump and pumping system.

STATIC SPARK.Can cause explosion resulting in

S Sparks can ignite flammable material and vapors.

S The pumping system and object being sprayed must be

grounded when it is pumping, flushing, recirculating or spraying flammable materials such as paints, solvents, lacquers,

etc. or used in a location where surrounding atmosphere is

conducive to spontaneous combustion. Ground the dispensing valve or device, containers, hoses and anyobject to which

material is being pumped.

S Secure pump, connections and all contact points to avoid

vibration and generation of contact or static spark.

S Consult local building codes and electrical codes for specific

grounding requirements.

S Aftergrounding, periodically verify continuity ofelectrical path

to ground. Test with an ohmmeter from each component (e.g.,

hoses, pump, clamps, container, spray gun, etc.) to ground to

insure continuity. O hmmeter should show 0.1 ohms or less.

S Submerse the outlet hose end, dispensing valve or device in

the material being dispensed if possible. (Avoid free streaming

of material being dispensed.)

S Use hoses incorporating a static wire.

S Use proper ventilation.

S Keep inflammables away from heat, open flames and sparks.

S Keep containers closed when not in use.

WARNING

causesevere injury. Pipeexhaust awayfrom workarea and personnel.

Pump exhaust may contain contaminants. Can

S In the event of a diaphragm rupture, material can be forced out

of the air exhaust muffler.

S Pipe the exhaust to a safe remote locationwhen pumping haz-

ardous or inflammable materials.

S Use a grounded 3/8” minimum i.d. hose between the pump and

the muffler.

WARNING

injury or property damage. Do not service or clean pump,

hoses or dispensing valve while the system is pressurized.

HAZARDOUS PRESSURE. Can result in serious

S Disconnect air supply line and relieve pressure from the sys-

tem by opening dispensing valve or device and / or carefully

and slowly loosening and removing outlet hose or piping from

pump.

WARNING

jury or property damage. Do not attempt to return a pump to the

factory or service center that contains hazardous material.

Safe handling practices must comply with local and national

laws and safety code requirements.

HAZARDOUSMATERIALS.Can cause seriousin-

S Obtain Material Safety Data Sheets on all materials from the

supplier for proper handling instructions.

WARNING

num wetted parts cannot be used with III.-Trichloroethane,Methylene Chloride or other Halogenated Hydrocarbon solvents

which may react and explode.

EXPLOSION HAZARD. Models containing alumi-

S Check pump motor section, fluid caps, manifolds and all

wetted parts to assure compatibility before using with solvents

of this type.

WARNING

containing aluminum wetted parts with food products for human consumption. Plated parts can contain trace amounts of

lead.

CAUTION

wetted parts and the substance being pumped, flushed or recirculated. Chemical compatibility may change with temperature and concentration of the chemical(s) within the

substances being pumped, flushed or circulated. For specific

fluid compatibility, consult the chemical manufacturer.

CAUTION

cal stress only. Certain chemicals will significantly reduce

maximum safe operating temperature. Consult the chemical

manufacturer for chemical compatibility and temperature limits.RefertoPUMPDATAonpage1ofthismanual.

CAUTION

been trained for safe working practices, understand it’s limitations, and wear safety goggles / equipment when required.

CAUTION

the piping system. Be certain the system components are

properly supported to prevent stress on the pump parts.

MISAPPLICATION HAZARD. Do not use models

Verify the chemical compatibility of the pump

Maximum temperatures are based on mechani-

Be certain all operators of this equipment have

Do not use the pump for the structural support of

S Suction and discharge connections should be flexibleconnec-

tions (such as hose), not rigid piped, and should be compatible

with the substance being pumped.

CAUTION

not allow pump to operate when out of material for long periods

of time.

Prevent unnecessary damage to the pump. Do

S Disconnect air line from pump when system sits idle for long

periods of time.

CAUTION

sure compatible pressure rating and longest service life.

NOTICE

TION. Creep of housing and gasket materials may cause fasteners to loosen. Re-torque all fasteners to insure against fluid

or air leakage

WARNING

CAUTION

NOTICE

Use only genuine ARO replacement parts to as-

RE-TORQUEALL FASTENERSBEFORE OPERA-

= Hazards or unsafe practices which could

result in severe personal injury, death or

substantial property damage.

= Hazards or unsafe practices which could

result in minor personal injury, product

or property damage.

= Important installation, operation or

maintenance information.

PW10A-X-XPage 2 of 8

Page 3

GENERAL DESCRIPTION

OPERATING INSTRUCTIONS

The ARO diaphragm pump offers high volume delivery even at low air

pressure and a broad range of material compatibility options available.

Refer to the model and option chart. ARO pumps feature stall resistant

design, modular air motor / fluid sections.

Air operated double diaphragm pumps utilize a pressure differential in

the air chambers to alternately create suction and positive fluid pressure

in the fluid chambers, ball checks insure a positive flow of fluid.

Pump cycling will begin as air pressure is applied and it will continue to

pump and keep up with the demand. It will build and maintain line pressure and will stop cycling once maximum line pressure is reached (dispensing device closed) and will resume pumping as needed.

AIR AND LUBE REQUIREMENTS

WARNING

damage, personal injury or property damage.

EXCESSIVE AIR PRESSURE. Can cause pump

S A filter capable offiltering out particles larger than 50 microns should

be used on the air supply.There is no lubrication required other than

the “O” ring lubricant which is applied during assembly or repair.

S If lubricated air is present, make sure that it is compatible with the

Nitrile seals in the air motor section of the pump.

INSTALLATION

S Verify correct model / configuration prior to installation.

S Retorque all external fasteners per specifications prior to start up.

S Pumps are tested in water at assembly. Flush pump with compatible

fluid prior to installation.

S When the diaphragm pump is used in a forced-feed (flooded inlet)

situation, it is recommended that a “Check Valve” be installed at the

air inlet.

S Material supply tubing should be at least the same diameter as the

pump inlet manifold connection.

S Material supply hose must be reinforced, non-collapsible type com-

patible with the material being pumped.

S Piping must be adequately supported. Do not use the pump to sup-

port the piping.

S Use flexible connections (such as hose) at the suction and dis-

charge. These connections should not be rigid piped and must be

compatible with the material being pumped.

S Secure the diaphragm pump legs to a suitable surface (level and

flat) to insure against damage by vibration.

S Pumps that need to be submersed must have both wet and non-wet

components compatible with the material being pumped.

S Submersed pumps must have exhaust pipe above liquid level. Ex-

haust hose must be conductive and grounded.

S Flooded suction inlet pressure must not exceed 10 p.s.i.g. (0.69

bar).

S Always flush the pump with a solvent compatible with the material

being pumped if the material being pumped is subject to “setting up”

when not in use for a period of time.

S Disconnect the air supply from the pump if it is to be inactive for a few

hours.

PARTS AND SERVICE KITS

Refer to the part views and descriptions as provided on page 4 through 7

for parts identification and Service Kit information.

S Certain ARO “Smart Parts” areindicated which should be available

for fast repair and reduction of down time.

S Service kits are divided to service two separate diaphragm pump

functions:1.AIRSECTION,2.FLUIDSECTION.TheFLUIDSECTION is divided further to matchtypical part MATERIAL OPTIONS.

MAINTENANCE

S Provide a clean work surface to protect sensitive internal moving

parts from contamination from dirt and foreign matter during service

disassembly and reassembly.

S Keep good records of service activity and include pump in preven-

tive maintenance program.

S Before disassembling, empty captured material in the outlet man-

ifold by turning the pump upside down to drain material from the

pump.

FLUID SECTION DISASSEMBLY

1. Remove (61) outlet manifold, (60) inlet manifold.

2. Remove (22) balls, (19 and 33) “O” rings (if applicable) and (21)

seats.

3. Remove (15) fluid caps.

NOTE: Only PTFE diaphragm models use a primary diaphragm (7) and

a backup diaphragm (8). Refer to the auxiliary view in the Fluid Section

illustration.

4. Remove the (14) screw, (6) diaphragm washer, (7) or (7 / 8) diaphragms, and (5) backup washer.

NOTE: Do not scratch or mar the surface of (1) diaphragm rod.

FLUID SECTION REASSEMBLY

Reassemble in reverse order. Refer to the torque requirements on

S

page 5.

S Clean and inspect all parts. Replace worn or damaged parts with

new parts as required.

S Lubricate (1) diaphragm rod and (144) “U” cup with LubriplateR

FML-2 grease (94276 grease packet is included in service kit).

S For models with PTFE diaphragms: Item (8) Santoprene diaphragm

is installed with the side marked “AIRSIDE” towards the pump center body. Install the PTFE diaphragm (7) with the side marked

“FLUID SIDE” towards the (15) fluid cap.

S Re-check torque settings after pump hasbeen re-started and run a

while.

S VitonR and HytrelR are trademarks of the DuPont Company, S KynarR is a registered trademark of Penwalt Corp. S LoctiteR is a registered trademark of Henkel Loctite Corporation S

S SantopreneR is a registered trademark of Monsanto Company, licensed to Advanced Elastomer Systems, L.P., S LubriplateR is a registered trademark of Lubriplate Division (Fiske Brothers) S

Page 3 of 8PW10A-X-X

Page 4

PARTS LIST / PW10A-X-X FLUID SECTION

L 637401-XX FLUID SECTION SERVICE KITS INCLUDE: BALLS (see Ball Option, refer to -XX in Service Kit chart below), DIAPHRAGMS

(see Diaphragm Option, refer to -XX

in Service Kit chart below),and items 19, 70, 144 and 175 (listed below) plus 174 and 94276Lubri-

plate FML-2 grease (page 6).

SEAT OPTIONS

PW10A-XXX-XXX

“21”

-XXX Seat Qty [Mtl] -XXX Ball Qty [Mtl]

-AXX 96152-A (4) [SP] -XAX 93278-A (4) [SP]

-CXX 96152-C (4) [H] -XCX 93278-C (4) [H]

-FXX 96156 (4) [A] -XGX 93278-2 (4) [B]

BALL OPTIONS

PW10A-XXX-XXX

L “22” (1-1/4” dia.)

MATERIAL CODE

[A] = Aluminum

[B] = Nitrile

[C] = Carbon Steel

[Co] = Copper

[E] = E.P.R.

[H] = Hytrel

[SP] = Santoprene

[SS] = Stainless Steel

[T] = PTFE

[V] = Viton

-GXX 96152-G (4) [B] -XTX 93278-4 (4) [T]

-XVX 93278-3 (4) [V]

DIAPHRAGM OPTIONS PW10A-XXX-XXX

L Service Kit L “7” L “8” L “19” L “33”

-XX = (Ball)

-XXX

-XXA 637401-XA 96267-A (2) [SP] ----- --- --- 93280 (4) [E] 93279 (4) [E]

-XXC 637401-XC 96267-C (2) [H] ----- --- --- Y327-225 (4) [V] Y327-220 (4) [V]

-XXG 637401-XG 96267-G (2) [B] ----- --- --- Y325-225 (4) [B] Y325-220 (4) [B]

-XXT 637401-XT 96146-T (2) [T] 96145-A (2) [SP] 93282 (4) [T] 93281 (4) [T]

-XXV 637401-XV 95989-3 (2) [V] ----- --- --- Y327-225 (4) [V] Y327-220 (4) [V]

-XX

= (Diaphragm) Diaphragm Qty [Mtl] Diaphragm Qty [Mtl] Gasket Qty [Mtl] Gasket Qty [Mtl]

NOTE: Gasket items 19 and 33 are not required with seat options -AXX, -CXX and -GXX.

EXTERNAL HARDWARE OPTIONS PW10A-XXX-XXX

PW10A-XXP- PW10A-XXS-

Item Description (size) Qty Part No. [Mtl] Part No. [Mtl]

26 Screw (M8x1.25-6gx30mm) (8) 95880-1 [C] 95880 [SS]

27 Screw (M8x1.25-6gx40mm) (20) 95896-1 [C] 95896 [SS]

29 Nut (M8x1.25-6h) (20) 95879-1 [C] 95879 [SS]

COMMON PARTS

Item Description (size) Qty Part No. Mtl Item Description (size) Qty Part No. Mtl

1 Rod (1) 95995 [C]

5 Backup Washer (2) 95990-3 [C]

6 Diaphragm Washer (2) 95990-3 [C]

9 Washer (0.505” i.d.) (2) 93189-1 [SS]

14 Screw (M12x1.75-6gx25mm) (2) 95997 [SS]

15 Fluid Cap (2) 95935 [A]

43 Ground Lug (1) 93004 [Co]

60 Inlet Manifold (1) 96154 [A]

61 Outlet Manifold (1) 96155 [A]

n Air Section Service Kit Parts, see page 6.

68 Air Cap (1) 95994-2 [A]

69 Air Cap (1) 95994-1 [A]

Ln70 Gasket (2) 95843 [B]

131 Screw (M8x1.25-6gx95mm) (4) 96001 [C]

Ln144 “U” Cup (3/16” x 1-1/8” o.d.) (2) Y186-49 [B]

Ln175 “O” Ring (3/32” x 13/16” o.d.) (2) Y325-114 [B]

n 180 Washer (4) 96006 [Co]

195 Nut (M8x1.25-6h) (4) 96005 [SS]

PW10A-X-XPage 4 of 8

Page 5

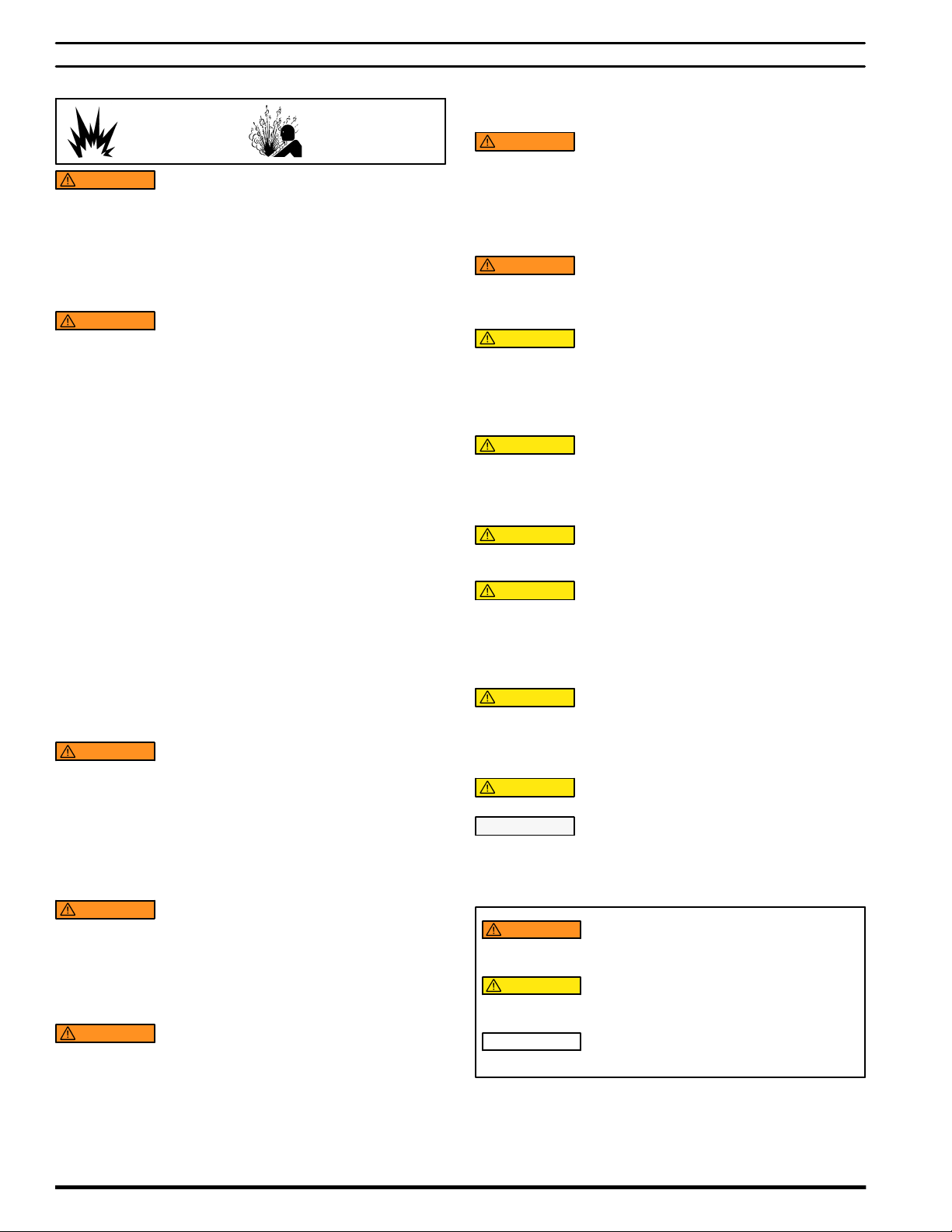

PARTS LIST / PW10A-X-X FLUID SECTION

COLOR CODE

DIAPHRAGM BALL

MATERIAL COLOR COLOR

HYTREL Cream Cream

NITRILE Black Red (S)

SANTOPRENE Tan Tan

SANTOPRENE Green N / A

(Backup)

PTFE White White

VITON Yellow (-) Yellow (S)

(-) Dash (S)Dot

68

70 k

3

5

9

7

2

Torque Sequence

61

26 , U

144 k

1

8

(14) screw, tighten to 25 - 30 ft lbs (33.9 - 40.7 Nm).

(26) screws, 20 - 25 ft lbs (27.1 - 33.9 Nm).

10

6

4

(29) nuts, 15 - 20 ft lbs (20.3 - 27.1 Nm).

(131) screws, 12 - 17 ft lbs (16.3 - 23.0 Nm).

k Apply Lubriplate FML-2 Grease to all “O” rings, “U”

x Apply LoctiteR 242 to threads at assembly.

- Apply PTFE tape to threads at assembly.

~ Apply Loctite 271 to threads at assembly.

U Apply anti-seize compound to threads at assembly.

Y Not used with PW10A-AAX-AXX, -CXX and -GXX.

Z Lubriplate FML-2 is a white food grade petroleum grease.

FOR THE

AIR MOTOR SECTION

SEE PAGES 6 & 7

x

131 ,

70 k 69

29 ,

. TORQUE REQUIREMENTS ,

NOTE: DO NOT OVERTIGHTEN FASTENERS.

ALL FASTENERS ARE METRIC.

LUBRICATION / SEALANTS

Cups & mating parts.

7

9195

22

175 k

144 k

View of two piece PTFE diaphragm

43

175 k

26 , U

60

1 k 5

180 k27 U

Figure 2

6

14 , ~

19 Y

21

33 Y

27 U

15

29 ,

22

19 Y

21

33 Y

Santoprene 8

PTFE 7

Page 5 of 8PW10A-X-X

Page 6

PARTS LIST / PW10A-X-X AIR SECTION

n Indicates parts included in 637397 Air Section Service Kit shown below and items (70), (144), (175) and (180) shown on page 4.

AIR MOTOR PARTS

Item Description (size) Qty Part No. [Mtl] Item Description (size) Qty Part No. [Mtl]

101 Center Body (1) 95888 [A]

103 Bushing (1) 96000 [D]

105 Screw (M6 x 1 - 6g x 16 mm long) (4) 95991 [SS]

111 Spool (1) 95835 [D]

118 Actuator Pin (2) 95999 [SS]

121 Sleeve (2) 95123 [D]

128 Pipe Plug (1/8 - 27 N.P.T. x 0.27”) (1) Y17-50-S [SS]

n 132 Gasket (1) 96170 [B]

133 Washer (1/4”) (3) Y117-416-C [C]

134 Screw (M6x1-6gx20mm) (4) 95887 [SS]

135 Valve Block (1) 95942-1 [Z]

136 End Cap (1) 95941 [Z]

n 137 Gasket (1) 95844 [B]

n 138 “U” Cup (3/16” x 1-5/8” o.d.) (1) Y186-53 [B]

n 139 “U” Cup (3/16” x 1-1/8” o.d.) (1) Y186-49 [B]

140 Valve Insert (1) 95838 [AO]

141 Valve Plate (1) 95837 [AO]

n 166 Gasket (1) 96171 [B]

n 167 Pilot Piston (includes 168 and 169) (1) 67164 [D]

168 “O” Ring (3/32” x 5/8” o.d.) (2) 94433 [U]

169 “U” Cup (1/8” x 7/8” o.d.) (1) Y240-9 [B]

170 Piston Sleeve (1) 94081 [Br]

n 171 “O” Ring (3/32” x 1-1/8” o.d.) (1) Y325-119 [B]

n 172 “O” Ring (1/16” x 1-1/8” o.d.) (1) Y325-22 [B]

n 173 “O” Ring (3/32” x 1-3/8” o.d.) (2) Y325-123 [B]

Kn 174 “O” Ring (1/8” x 1/2” o.d.) (2) Y325-202 [B]

n 176 Diaphragm (check valve) (2) 95845 [SP]

181 Roll Pin (5/32” o.d. x 1/2” long) (4) Y178-52-S [SS]

n 200 Gasket (1) 96172 [B]

201 Muffler (1) 350-568 --233 Adapter Plate (1) 95832 [P]

L n Lubriplate FML-2 Grease (1) 94276

Lubriplate Grease Packets (10) 637308

K Fluid Section Service Kit Parts, see page 4.

AIR MOTOR SECTION SERVICE

Service is divided into two parts - 1. Pilot Valve, 2. Major Valve.

GENERAL REASSEMBLY NOTES:

S Air Motor Section Service is continued from Fluid Section repair.

S Inspect and replace old parts with new partsas necessary. Look for

deep scratches on surfaces, and nicks or cuts in “O” rings.

S Take precautions to prevent cutting “O” rings upon installation.

S Lubricate “O” rings with Lubriplate FML-2 grease.

S Do not over-tighten fasteners, refer to torque specification block on

view.

S Re-torque fasteners following restart.

S SERVICE TOOLS -- To aid in the installation of (168) “O” rings onto

the (167) pilot piston, use tool # 204130-T, available from ARO.

PILOT VALVE DISASSEMBLY

1. A light tap on (118) should expose the opposite (121) sleeve, (167)

pilot piston and other parts.

2. Remove (170) sleeve, inspect inner bore of sleeve for damage.

PILOT VALVE REASSEMBLY

1. Clean and lubricate parts not being replaced from service kit.

2. Install new (171 and 172) “O” rings, replace (170) sleeve.

3. Install new (168) “O” rings and (169) seal - Note the lip direction. Lubricate and replace (167).

4. Reassemble remaining parts, replace (173 and 174) “O” rings.

MAJOR VALVE DISASSEMBLY

1. Remove (135) valve block and (233) adapter plate, exposing (132

and 166) gaskets and (176) checks.

2. Insert a small flat bladescrewdriver into the notch in the side of (135)

valve block and push in ontab to remove (233) adapter plate, releasing (140) valve insert, (141) valve plate, (200) gasket.

3. Remove (136) end cap and (137) gasket, releasing (111) spool.

MAJOR VALVE REASSEMBLY

1. Install new (138 and 139) “U” cups on (111) spool -- LIPS MUST

FACE EACH OTHER.

2. Insert (111) spool into (135) valve block.

3. Install (137) gasket on (136) end cap and assemble end cap to (135)

valve block, securing with (105) screws. NOTE: Tighten (105)

screws to 35 - 40 in. lbs (4.0 - 4.5 Nm).

4. Install (140) valve insert and (141) valve plate into (135) valve block.

NOTE: Assemble (140) valve insert with “dished”side toward (141)

valve plate. Assemble (141) valve plate with part numberidentification toward (140) valve insert.

5. Assemble (200) gasket and (233) adapter plate to (135) valve block.

NOTE: Assemble (233) adapter plate with notched side down.

6. Assemble (132 and 166) gaskets and (176) checks to (101) body.

7. Assemble (135) valve block and components to (101) body, securing with (134) screws. NOTE: Tighten (134) screws to 40 - 50 in. lbs

(4.5 - 5.6 Nm).

PW10A-X-XPage 6 of 8

Page 7

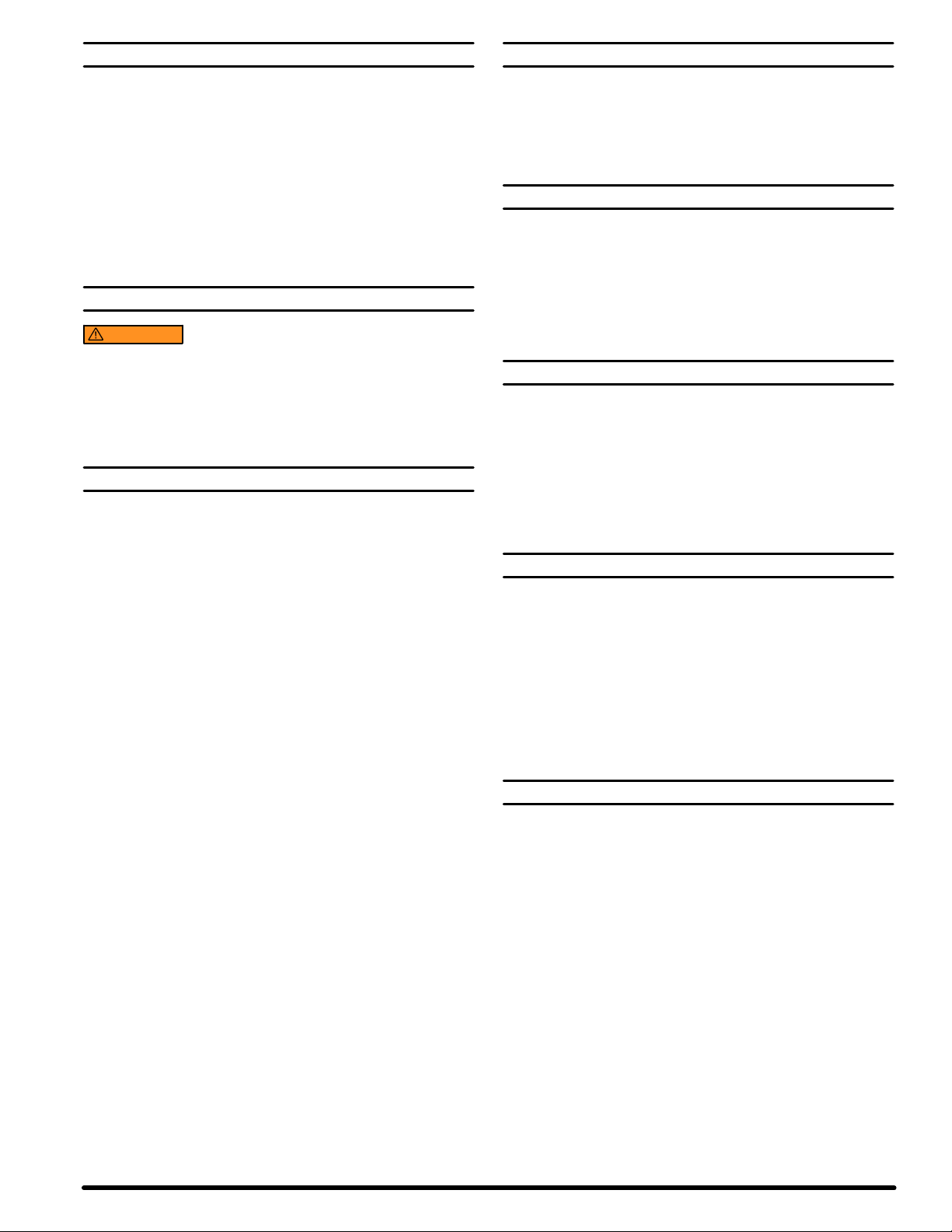

PARTS LIST / PW10A-X-X AIR SECTION

135

133

U . 134

k 138

111

k 139

k 174

121

167

140

118

173 k

141 k

169 k

168 k

172 k

171 k

170

166 k

233

Notch

200 k

Insert screwdriver here to remove (233) adapter plate.

132 k

176 k

101

181 103 201

PILOT VALVE

PART GROUP

173 k

121

118

174 k

k 137

- 128

MAJOR

VALVE

136

U . 105

. TORQUE REQUIREMENTS ,

NOTE: DO NOT OVERTIGHTEN FASTENERS.

Torque (105) screws to 35 - 40 in. lbs (4.0 - 4.5 Nm).

Torque (134) screws to 40 - 50 in. lbs (4.5 - 5.6 Nm).

k Apply Lubriplate FML-2 grease to “O” rings, “U” Cups & mating parts.

- Apply PTFE tape to threads at assembly.

U Apply anti-seize compound to threads at assembly.

A replacement 637390-3 Major Valve Service Assembly is available separately, which

includes the following: 105 (4), 111,128, 132, 135, 136, 137, 138, 139, 140, 141, 166,

176 (2), 200 and 233.

ALL FASTENERS ARE METRIC.

LUBRICATION / SEALANTS

Figure 3

MATERIAL CODE

[A] = Aluminum

[AO] = Alumina Oxide

[B] = Nitrile

[Br] = Brass

[C] = Carbon Steel

[D] = Acetal

[P] = Polypropylene

[SP] = Santoprene

[SS] = Stainless Steel

[U] = Polyurethane

[Z] = Zinc

Page 7 of 8PW10A-X-X

Page 8

TROUBLE SHOOTING

Product discharged from exhaust outlet.

S Check for diaphragm rupture.

S Check tightness of (14) diaphragm screw.

Air bubbles in product discharge.

S Check connections of suction plumbing.

S Check “O” rings between intake manifold and inlet side fluid caps.

S Check tightness of (14) diaphragm screw.

Motor blows air or stalls.

S Check (176) check valve for damage or wear.

S Check for restrictions in valve / exhaust.

DIMENSIONAL DATA

(Dimensions shown are for reference only, they are displayed in inches and millimeters (mm).

Air Inlet 1/2 - 14 N.P.T.

11-11/16”

(296.4 mm)

Outlet

1-1/ 4 - 11 -1 /2 N. P.T. F. - 1

5-27/32”

(148.2 mm)

Low output volume, erratic flow, or no flow.

S Check air supply.

S Check for plugged outlet hose.

S Check for kinked (restrictive) outlet material hose.

S Check for kinked (restrictive) or collapsed inlet material hose.

S Check for pump cavitation -- suction pipe should be sized at least as

large as the inlet threaddiameter of the pump for proper flowif high

viscosity fluids are being pumped. Suction hosemust be a non-collapsing type, capable of pulling a high vacuum.

S Check all joints on the inlet manifolds and suction connections.

These must be air tight.

S Inspect the pump for solid objects lodged in the diaphragm chamber

or the seat area.

Exhaust Port 3/4 - 14 N.P.T.

14-1/32”

(356.2 mm)

8-1/8”

(206.4 mm)

16-7/8”

(428.6 mm)

8-1/16”

(204.7 mm)

2-15/32”

(62.7 mm)

Inlet

1/2” (12.7 mm)

8-3/4”

(222.3 mm)

3/8” (9.5 mm)

1-1/ 2 - 11 -1 /2 N. P.T. F. - 1

5-15/16”

(150.8 mm)

7-21/32” (194.5 mm)

Figure 4

PN 97999-1078

PW10A-X-XPage 8 of 8

Loading...

Loading...