Ingersoll-Rand HL1500K, HL4500K, HL6000K, HL1000K, HL1000KR Parts, Operation And Maintenance Manual

...

Form P6587

PARTS, OPERATION AND MAINTENANCE MANUAL

for

AIR CHAIN HOIST MODELS*

HL1000K HL1000KR HL1500K

1000 kg (1 ton) 1000 kg (1 ton) 1500 kg (1-1/2 ton)

Spark Resistant

HL2000K HL3000K HL4500K HL6000K

2000 kg (2 ton) 3000 kg (3 ton) 4500 kg (4-1/2 ton) 6000 kg (6 ton)

* Capacities of hoists are in metric tons (1 metric ton = 2,200 lbs.)

READ THIS MANUAL BEFORE USING THESE PRODUCTS. This manual

contains important safety, installation, operation and maintenance

information. Make this manual available to all persons responsible for

the operation, installation and maintenance of these products.

WARNING

Do not use this hoist for lifting, supporting, or transporting people or lifting or

supporting loads over people.

Always operate, inspect and maintain this hoist in accordance with American National

Standards Institute Safety Code (ASME B30.16) and any other applicable safety codes

and regulations.

Refer all communications to the nearest Ingersoll-Rand Material Handling Office or

Distributor.

Form P6587

Edition 6

May 1997

03531837

©

1997 Ingersoll-Rand Company

1

TABLE OF CONTENTS

Safety Information

Danger, Warning, Caution and Notice .............................................................................................................................................................. 3

Safety Summary ................................................................................................................................................................................................. 3

Safe Operating Procedures ................................................................................................................................................................................ 4

Warning Tags and Labels ................................................................................................................................................................................... 4

Specifications

Model Code Explanation ................................................................................................................................................................................... 6

Installation

Hoist Checks ...................................................................................................................................................................................................... 7

Hoist Mounting .................................................................................................................................................................................................. 7

Chain Container ................................................................................................................................................................................................. 8

Air System ..................................................................................................................... ..................................................................................... 8

Pendant Control Adjustments ............................................................................................................................................................................ 9

Storing the Hoist ................................................................................................................................................................................................ 9

Operation

Initial Operating Checks .................................................................................................................................................................................. 10

Hoist Controls .................................................................................................................................................................................................. 10

Pendant Controls.............................................................................................................................................................................................. 10

Pull Chain Control ........................................................................................................................................................................................... 11

Inspection

Records and Reports ........................................................................................................................................................................................ 12

Load Chain Reports ......................................................................................................................................................................................... 12

Frequent Inspection ......................................................................................................................................................................................... 12

Periodic Inspection .......................................................................................................................................................................................... 13

Hoists Not in Regular Use ............................................................................................................................................................................... 14

Inspection and Maintenance Report ................................................................................................................................................................ 15

Troubleshooting .............................................................................................................................................................................................. 16

Lubrication

General Lubrication ......................................................................................................................................................................................... 17

Maintenance

Load Chain Care .............................................................................................................................................................................................. 18

Initial Chain Installation .................................................................................................................................................................................. 19

Chain Replacement .......................................................................................................................................................................................... 22

Servicing the Filter and Strainer...................................................................................................................................................................... 23

Disassembly ..................................................................................................................................................................................................... 23

Cleaning, Inspection and Repair ..................................................................................................................................................................... 25

Assembly .......................................................................................................................................................................................................... 25

Load Test .......................................................................................................................................................................................................... 31

Assembly Drawings and Parts Lists..................................................................................................................................................... 33 - 61

Assembly Drawing and Parts List Table of Contents ..................................................................................................................................... 32

Parts Ordering Information

Return Goods Policy ........................................................................................................................................................................................ 62

Disposal ............................................................................................................................................................................................................ 62

Warranty Information ................................................................................................................................................................................... 63

Offices and Addresses.................................................................................................................................................................................... 64

2

SAFETY INFORMATION

DANGER

This manual provides important information for all personnel

involved with the safe installation, operation and proper

maintenance of this product. Even if you feel you are familiar

with this or similar equipment, you should read this manual

before operating the product.

Danger, Warning, Caution and Notice

Throughout this manual there are steps and procedures which, if

not followed, may result in a hazard. The following signal words

are used to identify the level of potential hazard.

Danger is used to indicate the presence

of a hazard which will cause severe

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION

NOTICE

Warning is used to indicate the presence

of a hazard which can cause severe

injury, death, or substantial property

damage if the warning is ignored.

Caution is used to indicate the presence

of a hazard which will or can cause

minor injury or property damage if the

warning is ignored.

Notice is used to notify people of

installation, operation, or maintenance

information which is important but not

hazard-related.

Safety Summary

WARNING

• Do not use this hoist or attached equipment for lifting,

supporting, or transporting people or lifting or supporting

loads over people.

• Powered hoists are designed to provide a 5 to 1 safety

factor. The supporting structures and load-attaching devices

used in conjunction with this hoist must provide adequate

support to handle all hoist operations plus the weight of the

hoist and attached equipment. This is the customer’s

responsibility. If in doubt, consult a registered structural

engineer.

NOTICE

• Lifting equipment is subject to different regulations in each

country. These regulations may not be specified in this

manual.

The National Safety Council, Accident Prevention Manual for

Industrial Operations, Eighth Edition and other recognized

safety sources make a common point: Employees who work near

cranes or assist in hooking on or arranging a load should be

instructed to keep out from under the load. From a safety

standpoint, one factor is paramount: conduct all lifting

operations in such a manner that if there were an equipment

failure, no personnel would be injured. This means keep out

from under a raised load and keep out of the intended path of

any load.

Ingersoll-Rand Material Handling hoists are manufactured in

accordance with the latest ASME B30.16 standards.

The Occupational Safety and Health Act of 1970 generally

places the burden of compliance with the user, not the

manufacturer. Many OSHA requirements are not concerned or

connected with the manufactured product but are, rather,

connected with the final installation. It is the owner’s and user’s

responsibility to determine the suitability of a product for any

particular use. It is recommended that all applicable industry,

trade association, federal, state and local regulations be checked.

Read all operating instructions and warnings before operation.

Rigging: It is the responsibility of the operator to exercise

caution, use common sense and be familiar with proper rigging

techniques. See ASME B30.9 for rigging information,

American National Standards Institute, 1430 Broadway, New

York, NY 10018.

This manual has been produced by Ingersoll-Rand to provide

dealers, mechanics, operators and company personnel with the

information required to install, operate, maintain and repair the

products described herein.

It is extremely important that mechanics and operators be

familiar with the servicing procedures of these products, or like

or similar products, and are physically capable of conducting the

procedures. These personnel shall have a general working

knowledge that includes:

1. Proper and safe use and application of mechanic’s common

hand tools as well as special Ingersoll-Rand or

recommended tools.

2. Safety procedures, precautions and work habits established

by accepted industry standards.

Ingersoll-Rand cannot know of, or provide all the procedures

by which product operations or repairs may be conducted and

the hazards and/or results of each method. If operation or

maintenance procedures not specifically recommended by the

manufacturer are conducted, it must be ensured that product

safety is not endangered by the actions taken. If unsure of an

operation or maintenance procedure or step, personnel should

place the product in a safe condition and contact supervisors

and/or the factory for technical assistance.

3

SAFE OPERATING PROCEDURES

The following warnings and operating instructions have been

adapted in part from American National (Safety) Standard

ASME B30.16 and are intended to avoid unsafe operating

practices which might lead to injury or property damage.

Ingersoll-Rand recognizes that most companies who use hoists

have a safety program in force in their plants. In the event you

are aware that some conflict exists between a rule set forth in

this publication and a similar rule already set by an individual

company, the more stringent of the two should take precedence.

Safe Operating Instructions are provided to make an operator

aware of dangerous practices to avoid and are not necessarily

limited to the following list. Refer to specific sections in the

manual for additional safety information.

1. Only allow personnel instructed in safety and operation on

this product to operate and maintain the hoist.

2. Only operate a hoist if you are physically fit to do so.

3. When a “DO NOT OPERATE” sign is placed on the hoist

controls, do not operate the hoist until the sign has been

removed by designated personnel.

4. Read the manufacturer’s operating instructions before

operating the hoist.

5. Never lift a load greater than the rated capacity of the hoist

(unless for test purposes).

6. Never use the load chain as a sling.

7. Never operate the hoist with twisted, kinked, "capsized" or

damaged chain.

8. Be certain the load is properly seated in the saddle of the

hook.

9. Do not use load chain as a ground for welding. Do not

attach a welding electrode to a hoist or sling chain.

10. Do not use the up and down stops as a means of stopping a

hoist. The up and down stops are emergency devices only.

11. Do not leave a load suspended for extended periods.

12. Always stand clear of the load path.

13. Never use the hoist for lifting or lowering people, and

never stand on a suspended load.

14. Never carry loads over people.

15. Before each shift, check the hoist for wear or damage.

Check brakes, limit stops, etc.

16. Periodically, inspect the hoist thoroughly and replace worn

or damaged parts.

17. Follow the lubrication instructions.

18. Do not attempt to repair load chain or hooks. Replace them

when they become worn or damaged.

19. Never operate a hoist when the load chain is not centered

under the hook. Do not “side pull” or “yard”.

20. Always rig the hoist properly and carefully.

21. Ease the slack out of the load chain when starting a lift. Do

not jerk the hoist load.

22. Keep the load chain clean and well lubricated. Do not drag

the load chain or hook on the floor.

23. Be certain there are no objects in the way of a moving load.

24. Be certain the air supply is shut off before performing

maintenance on the hoist.

25. Do not swing a suspended load.

26. Keep the load block overhead when not in use.

27. After use, or when in a non-operational mode, the winch

should be secured against unauthorized and unwarranted

use.

28. Avoid collision or bumping of hoists.

29. Pay attention to the load at all times when operating a hoist.

30. Never splice a hoist chain by inserting a bolt between links

or by any other means.

31. Do not force a chain or hook into place by hammering, and

never insert the point of the hook into a chain link.

32. Do not allow the chain to be exposed to extremely cold

weather. Do not apply loads to a cold chain.

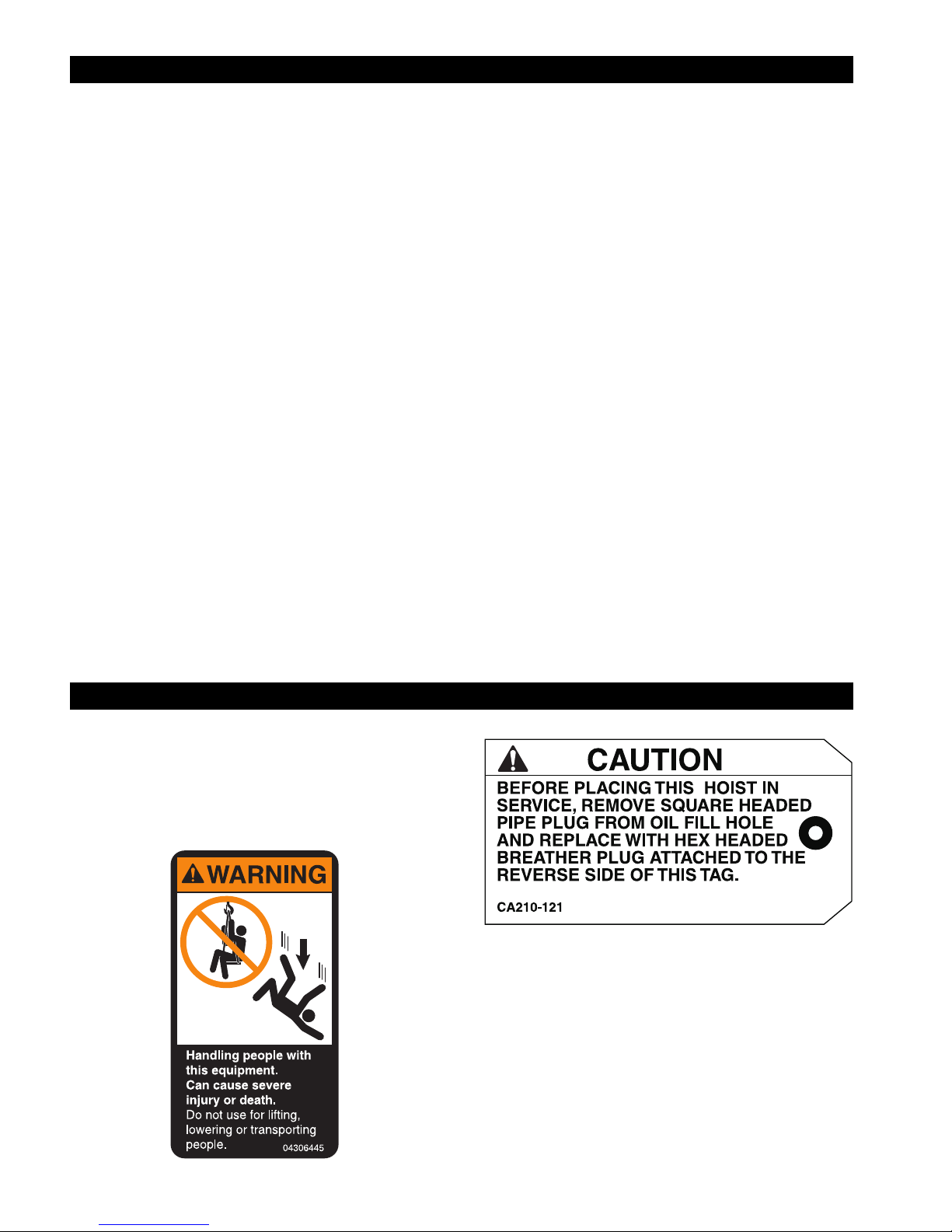

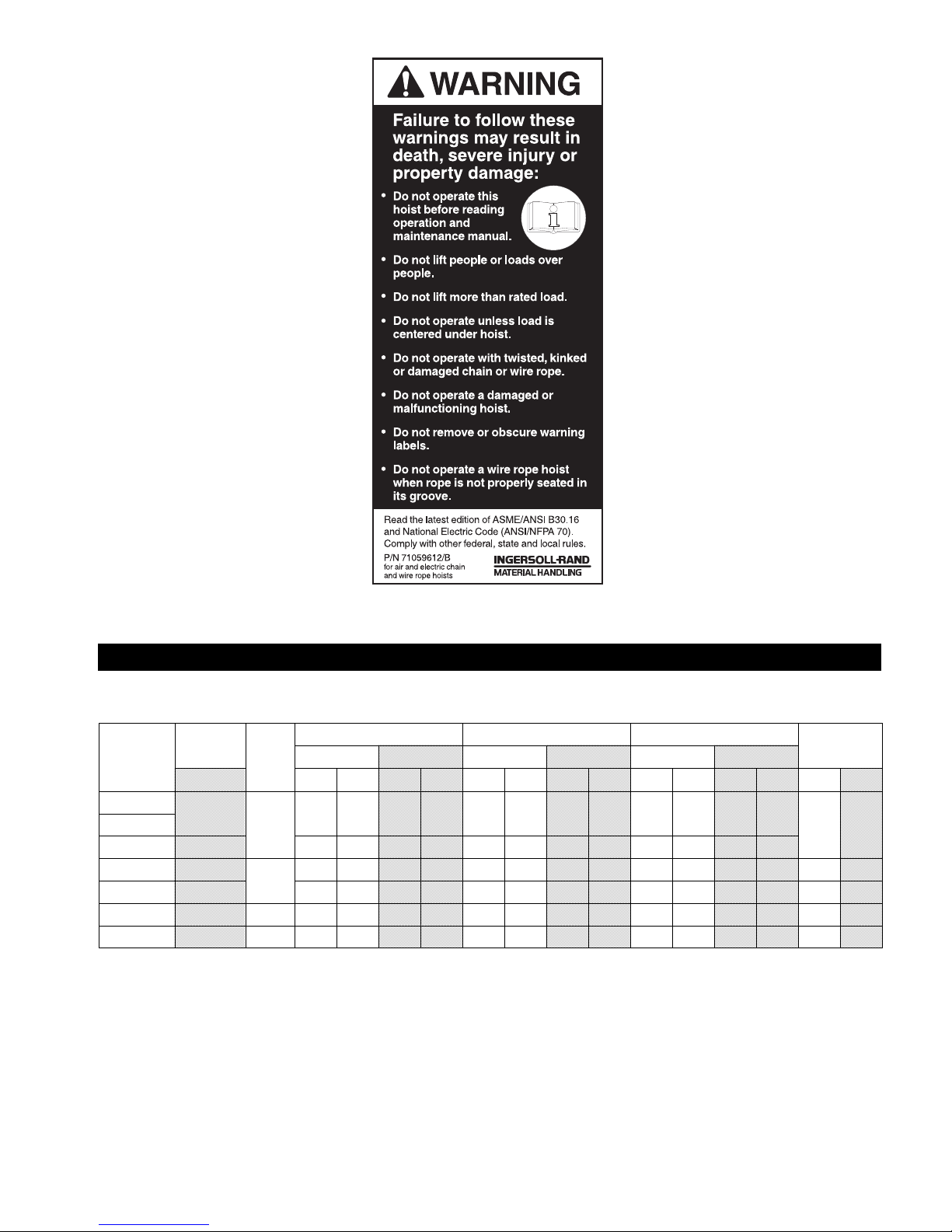

WARNING TAGS AND LABELS

Each hoist is supplied from the factory with the warning tags

and labels shown. If the tags or labels are not attached to your

hoist, order new tags or labels and install. See parts list in parts

section. Read and obey all warnings and other safety

information attached to this hoist. Tags and labels are not shown

actual size.

4

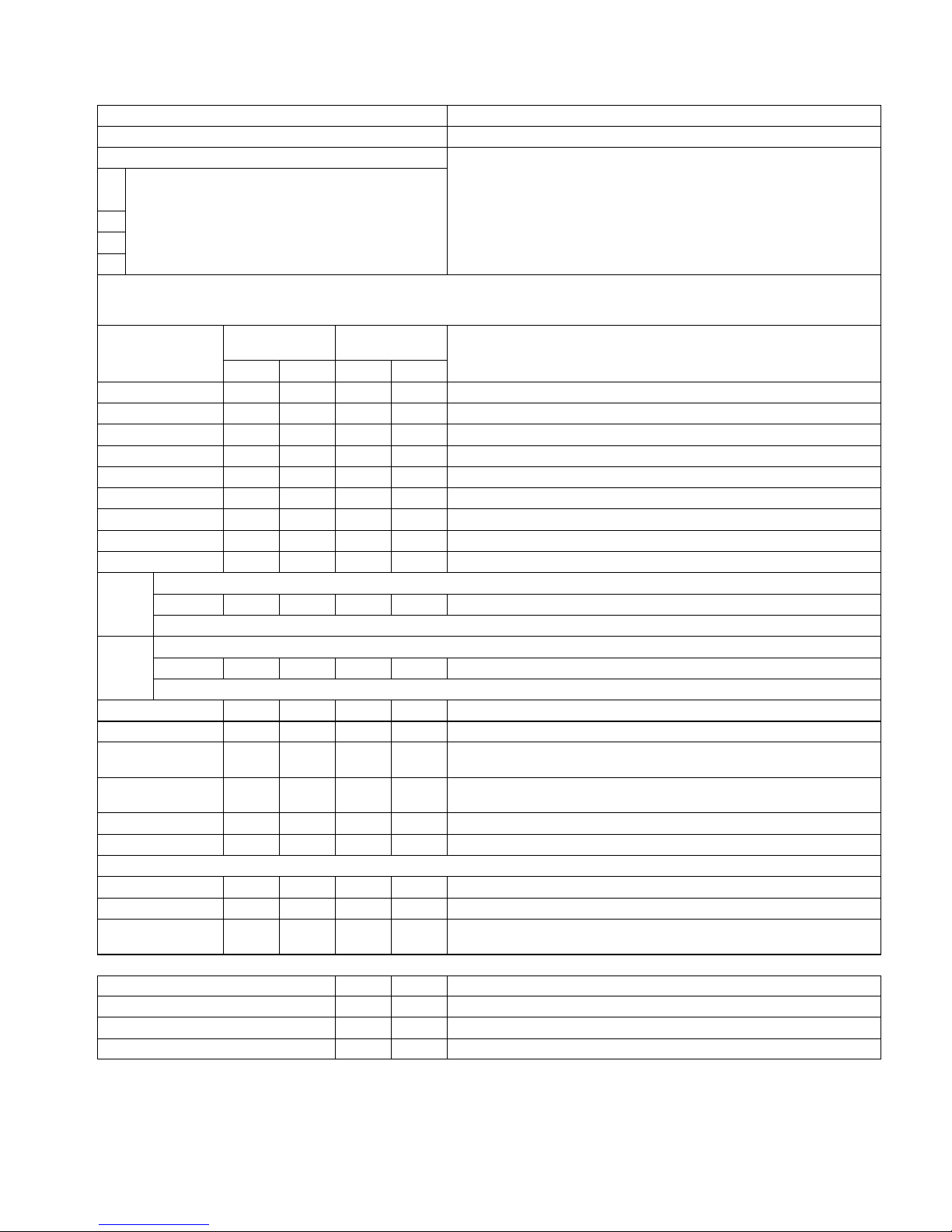

Table 1

SPECIFICATIONS

Hoist

Model No.

HL1000K

HL1500K 1500 16 26 4.9 7.9 22 22 6.7 6.7 28 16 8.5 4.9

HL2000K 2000

HL3000K 3000 8 13 2.4 4.0 11 11 3.4 3.4 14 8 4.3 2.4 129 58.5

HL4500K 4500 3 4.6 10 1.4 3.0 7.5 8.4 2.3 2.6 10.5 6.6 3.2 2.0 193 87.5

HL6000K 6000 4 3.5 7.6 1.0 2.3 5.8 6.2 1.8 1.9 8.4 4.8 2.6 1.5 248 112.5

Notes:

Based on hook mounted hoist with standard 10 ft (3 m) lift and one motor pendant control.

*

**

Performance figures based on 70 SCFM (1.96 cu m/min) at 90 psig (6.3 bar/630 kPa) air supply at hoist inlet. Pendant control

models use approximately 4 SCFM (0.11 cu m/min) more air.

Rated

Capacity

(kg) up down up down up down up down up down up down lb kgs

1000

No.

Chain

Falls

Speed with Rated Load Speed with Half Load Speed with No Load

fpm m/m fpm m/m fpm m/m

26 37 7.9 11.3 31 30 9.4 9.1 40 26 12.2 7.9

1

13 18 4.0 5.5 15 15 4.6 4.6 20 13 6.1 4.0 125 56.6

2

Hoist

Weight*

84 38.1HL1000KR

5

Model Code Explanation

Example: HL1000K-2C10-C6S H L 1000K - 2 C 10 - C 6 S

=

Series:

Chain Type:

L

Base Model:

1000K

1000KR = 1000 kg 1 metric ton (2,200 lbs) Spark Resistant

1500K = 1500 kg 1-1/2 metric tons (3,300 lbs)

2000K = 2000 kg 2 metric tons (4,400 lbs)

3000K = 3000 kg 3 metric tons (6,600 lbs)

4500K = 4500 kg 4-1/2 metric tons (10,000 lbs)

6000K = 6000 kg 6 metric tons (13,200 lbs)

Control:

0=

1=Pull Chain

2

3=

4=

Suspension (1):

A=

B=

C

R=

DA =

DD =

FXXA (2) =

FXXD (2) = Hand Geared Trolley (universal wheels “D” flange)

HA = Vane Motor Powered Trolley (universal wheels “A” flange)

HD = Vane Motor Powered Trolley (universal wheels “D” flange)

Length of Lift:

10

XX =

Lower Hook:

B=

C=

R=

Length of Pull Chain or Pendant Control Hose Drop: *

6

XX =

Options:

E=

M=

P=

S

U=

CE =

Notes:

H

=

Link

=

1000 kg 1 metric ton (2,200 lbs)

No control provided

=

Single Motor Pendant

Two Motor Pendant

Three Motor Pendant

Fixed Lug

Bullard Hook (self closing)

Swivel Steel Snap Hook

=

Bronze Snap Hook

Plain Rigid Trolley (universal wheels “A” flange)

Plain Rigid Trolley (universal wheels “D” flange)

Hand Geared Trolley (universal wheels “A” flange)

=

10 feet (3 metres) Standard

Specify Length

Bullard Hook (self closing)

Steel Snap Hook

Bronze Snap Hook

=

6 feet (1.8 metres) Standard

Specify Length (in feet)

Epoxy Paint

Manual Release Brake Kit

Piped Away Exhaust

Steel Chain Container

=

Fabric Chain Container

Compliance with European Machinery Directive: CE adds Pendant Emergency Stop, Main Air Shut Off Valve and

Overload Protection Device

(1) Refer to page 58 for Flange Adjustment.

(2) XX = Specify length of hand chain required. Example: "08" = 8 feet, standard.

(3) Order hose lengths in feet. Metric sizes listed for reference only.

6

NOTICE

WARNING

INSTALLATION

Prior to installing the hoist, carefully inspect it for possible

shipping damage.

Hoists are supplied fully lubricated from the factory. Lubrication

of the load chain is recommended before initial hoist operation.

CAUTION

• Owners and users are advised to examine specific, local or

other regulations, including American National Standards

Institute and/or OSHA Regulations which may apply to a

particular type of use of this product before installing or

putting hoist to use.

WARNING

• A falling load can cause injury or death. Before installing,

read “SAFETY INFORMATION”.

• The supporting structures and load-attaching devices used

in conjunction with this hoist must provide adequate support

to handle all hoist operations plus the weight of the hoist and

attached equipment. This is the customer’s responsibility. If

in doubt, consult a registered structural engineer.

Hoist Checks

Make certain your hoist is properly installed. A little extra time

and effort in so doing can contribute toward preventing

accidents and helping you get the best service possible.

Always make certain the supporting member from which the

hoist is suspended is strong enough to support the weight of the

hoist plus the weight of a maximum rated load plus a liberal

safety factor.

Trolley Mounted Hoist Installation

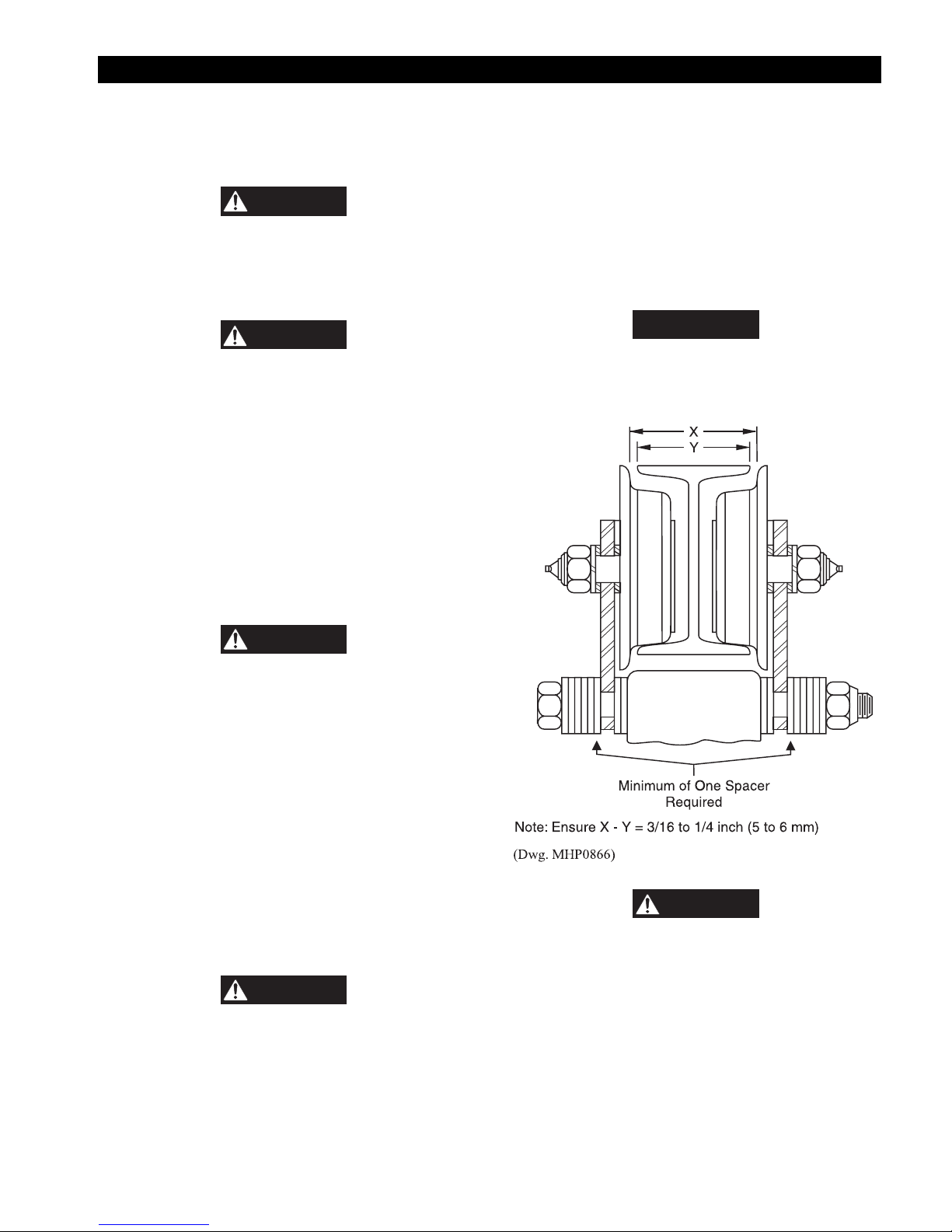

Refer to Dwg. MHP0866

When installing a trolley on a beam, measure the beam flange

and temporarily install the trolley on the hoist to determine the

exact distribution and arrangement of the spacers. The total

distance between the wheel flanges should be 3/16 to 1/4 inch (5

to 6 mm) greater than the width of the beam flange. The number

of spacers between the trolley side plate and the mounting lug

on the hoist must be the same in all four locations in order to

keep the hoist centered under the I-beam. The remaining spacers

must be equally distributed on the outside of the trolley side

plates.

• For specific information relating to trolley installation refer

to the manufacturers’ manual supplied with the trolley.

HLK Hoist Plain Rigid Trolley

CAUTION

• Before placing this hoist in service, remove square headed

pipe plug from oil fill hole and replace with hex headed

breather plug attached to caution tag CA210-121.

1. Remove the solid shipping plug located on top of the hoist

and install the attached breather plug prior to using the

hoist.

2. With the hoist placed in its normal level position check that

the gear case oil level is at the check plug on the side of the

gear box.

Hoist Mounting

Hook Mounted Hoist Installation

Place hook over mounting structure. Ensure hook is large

enough to properly fit on structure. Make sure hook latch is

engaged.

Ensure the supporting member rests completely within the

saddle of the hook and is centered directly above the hook

shank. Hoist must freely hang from hook without restriction.

CAUTION

• The supporting member must position on the saddle of the

hook. Ensure hoist does not tilt to one side or the other.

• A minimum of one adjusting spacer must be placed on the

outside of the trolley side plates. Ensure correct installation

as described in the parts, operation and maintenance manual

provided with the trolley.

Trolley bolt nuts (207) and (220) torque requirements:

On HL1000K, HL1500K, HL2000K and HL3000K hoists

torque to 150 ft lbs (203 Nm).

On HL4500K and HL6000K hoists torque to 250 ft lbs (339

Nm).

7

NOTICE

CAUTION

CAUTION

When installing the hoist and trolley on the beam, make certain

the side plates are parallel and vertical. After installation,

operate the trolley over the entire length of the beam with rated

load suspended 4 to 6 inches (100 to 150 mm) off the floor.

CAUTION

• To avoid an unbalanced load which may damage the

trolley, the hoist must be centered under the trolley.

NOTICE

• Trolley wheels ride on the top of the lower flange of the

beam.

Ensure beam stops are installed prior to operating hoist and

trolley.

Chain Container

Refer to Dwgs. TPC451-3 and MHP1029 and the

“MAINTENANCE” section for detailed assembly and

disassembly information.

NOTICE

• Make certain to adjust the container support such that the

chain container does not contact the load chain or hook.

• Operate the hoist to naturally pile chain into the chain

container. Piling the chain carelessly into the container by

hand may lead to kinking or twisting that may cause chain to

jam the hoist.

1. Check the chain container size to make sure the length of

load chain is within the capacity of the chain container.

Replace with a larger chain container, if required.

2. Attach the chain container to the hoist.

3. Run bottom block to lowest point and run hoist in up

direction to feed the chain back into the container.

WARNING

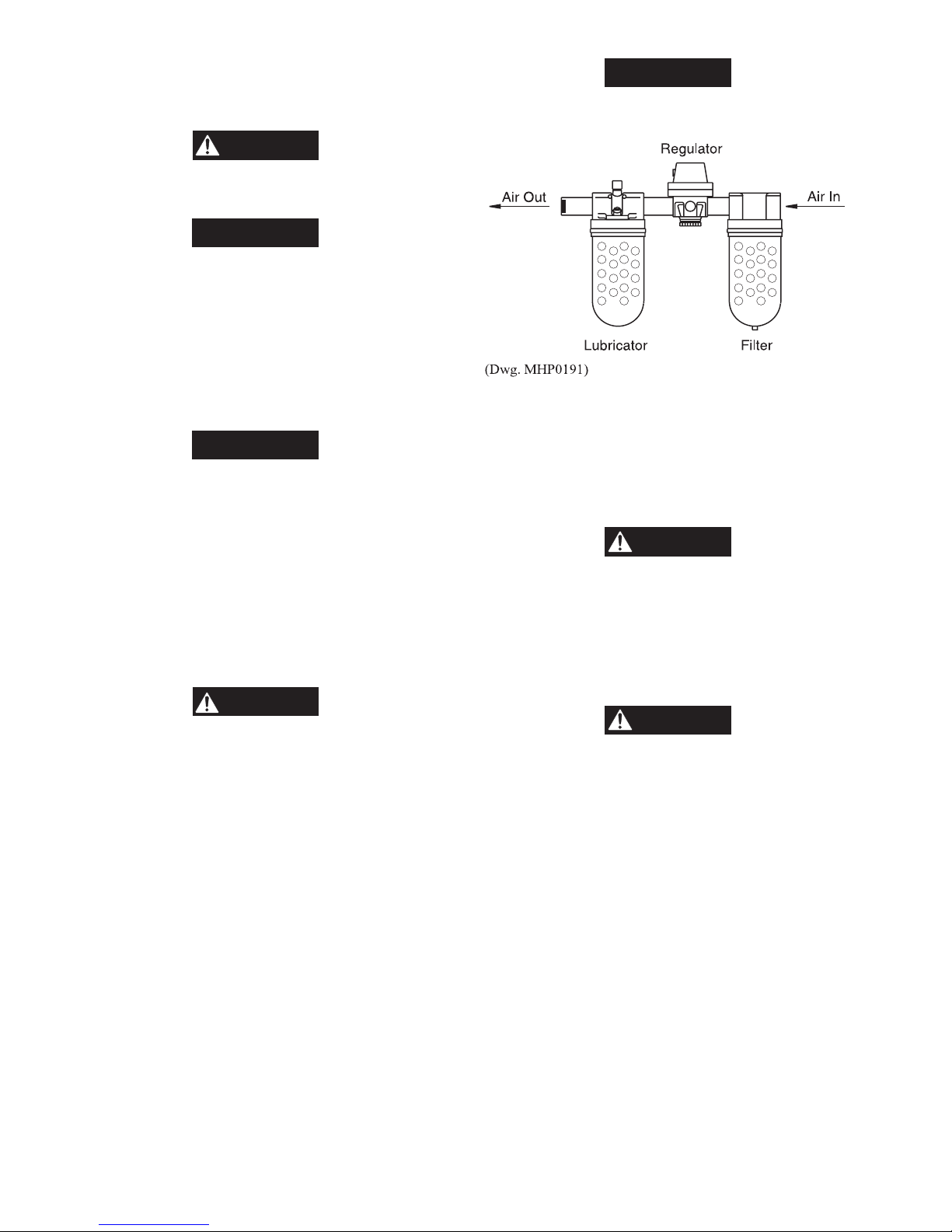

• Always use an air line filter and lubricator with an HLK

hoist.

Air Line Lubricator

Refer to Dwg. MHP0191.

Always use an air line lubricator with these hoists. Use a

lubricator having an inlet and outlet at least as large as the inlet

on the hoist motor. Install the air line lubricator as close to the

air inlet on the hoist motor as possible. Refer to

“ACCESSORIES” in the parts section for the recommended

Filter-Lubricator-Regulator.

• Lubricator must be located no more than 10 ft (3 metres)

from the hoist motor.

• Shut off air supply before filling air line lubricator.

The air line lubricator should be replenished daily and set to

provide lubrication at a minimum rate of 1 to 3 drops per minute

adjusted at maximum hoist speed, of SAE 10W oil or a good

grade of hydraulic oil.

• Disconnect the hoist from the air supply before installing a

chain container kit.

Air System

The supply air must be clean, lubricated and free from water or

moisture. A minimum air supply of 70 scfm (1.96 cu. m/m) at 90

psig (6.3 bar/630 kPa) at the hoist motor inlet is required, during

operation to provide rated hoist performance.

Air Lines

The inside diameter of the hoist air supply lines must not be

smaller than 1/2 in (13 mm) for up to 12 ft (4 m) lengths and 3/4

in (19 mm) for up to 50 ft (15 m) lengths between the air supply

and the hoist. Contact the factory for recommended air line sizes

for distances greater than 50 ft (15 m). Before making final

connections, all air supply lines should be purged with clean,

moisture free air before connecting to unit inlet. Supply lines

should be as short and straight as installation conditions will

permit. Long transmission lines and excessive use of fittings,

elbows, tees, globe valves, etc. cause a reduction in pressure due

to restrictions and surface friction in the lines. Fittings used at

the inlet of the hoist must have at least a 3/8 in (10 mm) air

passage. Use of smaller fittings will reduce performance.

• Do not use automotive type detergent oil. Detergents will

delaminate the motor vanes and cause premature failure.

Air Line Filter

Refer to Dwg. MHP0191

It is recommended that an air line strainer/filter be installed as

close as practical to the motor air inlet port to prevent dirt from

entering the motor. The strainer/filter should provide 10 micron

filtration and include a moisture trap. Clean the strainer/filter

monthly to maintain its operating efficiency. Refer to

"ACCESSORIES" in the parts section for the recommended

Filter-Lubricator-Regulator.

Moisture in Air Lines

Moisture that reaches the air motor through the supply lines is

the chief factor in determining the length of time between

service overhauls. Moisture traps can help to eliminate moisture.

Other methods, such as an air receiver which collects moisture

before it reaches the motor or, an aftercooler at the compressor

that cools the air prior to distribution through the supply lines,

are also helpful.

The swivel inlet assembly (includes items 23 through 24C) must

be installed on the hoist. Failure to do so may result in a hoist

malfunction.

8

Pendant Control Adjustments

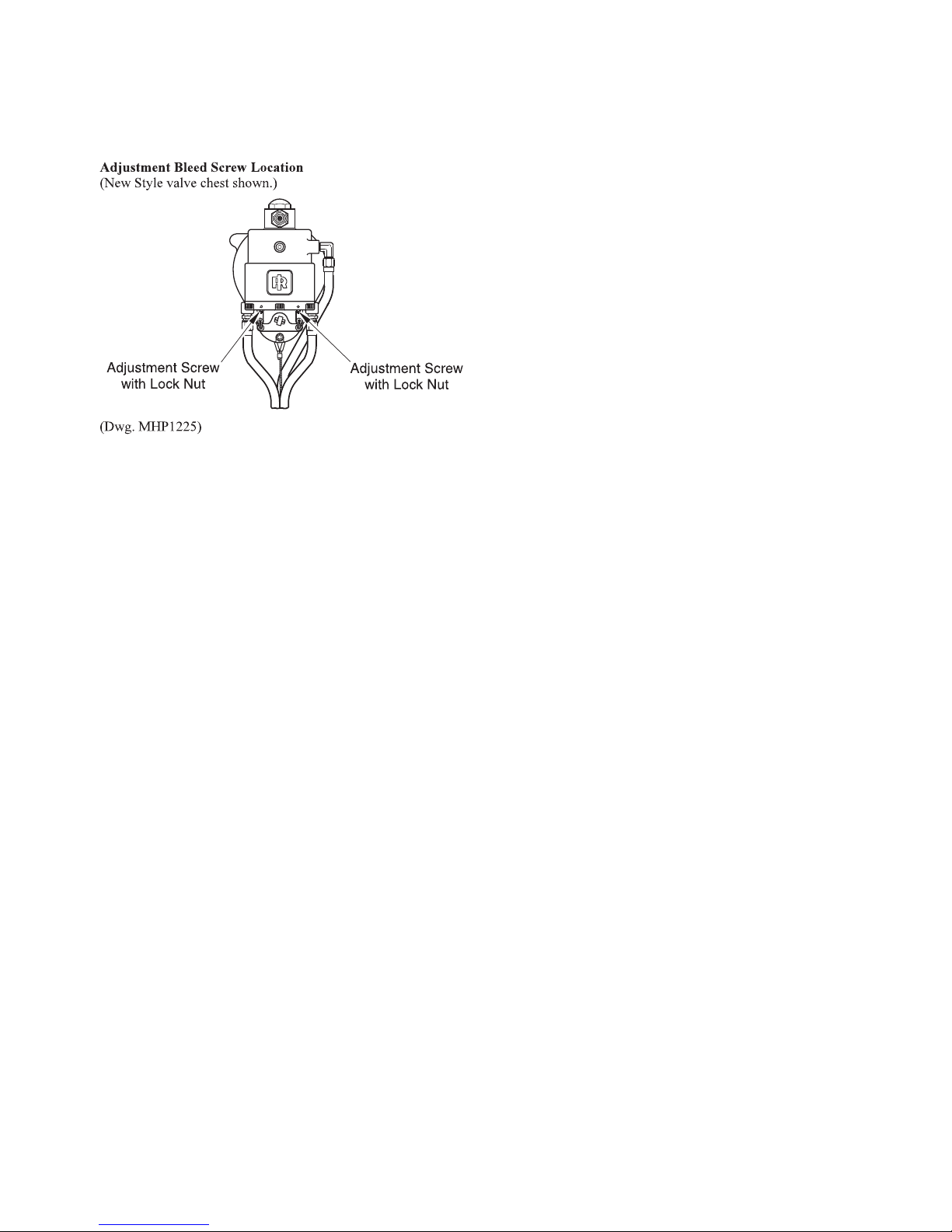

The bleed adjustment screws (19) or (336 [old style]) used on

hoists with a pendant control are factory adjusted to provide

optimum control at 90 psig (6.3 bar/630 kPa) air pressure. If the

hoist is used with other air supply pressures, the bleed

adjustment screws may require readjustment.

For maximum performance and control, adjust the bleed screws

(19) or (336 [old style]) as follows:

1. Loosen the adjustment screw locknut (21) or (337 [old

style]).

2. Turn the adjustment screw (19) or (336 [old style])

counterclockwise approximately one third (1/3) of a turn.

3. Fully depress the pendant throttle lever (165) and hold in

depressed position. Turn the adjustment screw clockwise

until the piston rod fully retracts. This adjustment will

provide a good balance of spotting control and maximum

hoist speed. If better spotting control is desired, slowly

back out the adjustment screw a little at a time until the

spotting control is suitable.

4. When adjustment is complete, hold the adjustment screw in

position and tighten the adjustment screw locknut (21) or

(337 [old style]).

5. Repeat steps 1 through 4 for opposite pendant throttle

lever.

Storing the Hoist

1. Always store the hoist in a no load condition.

2. Wipe off all dirt and water.

3. Oil the load chain, hook pins and hook latch.

4. Place in a dry location.

5. Plug hoist air inlet port.

6. Before returning hoist to service follow instructions for

‘Hoists not in Regular Service’ in the “INSPECTION”

section.

9

OPERATION

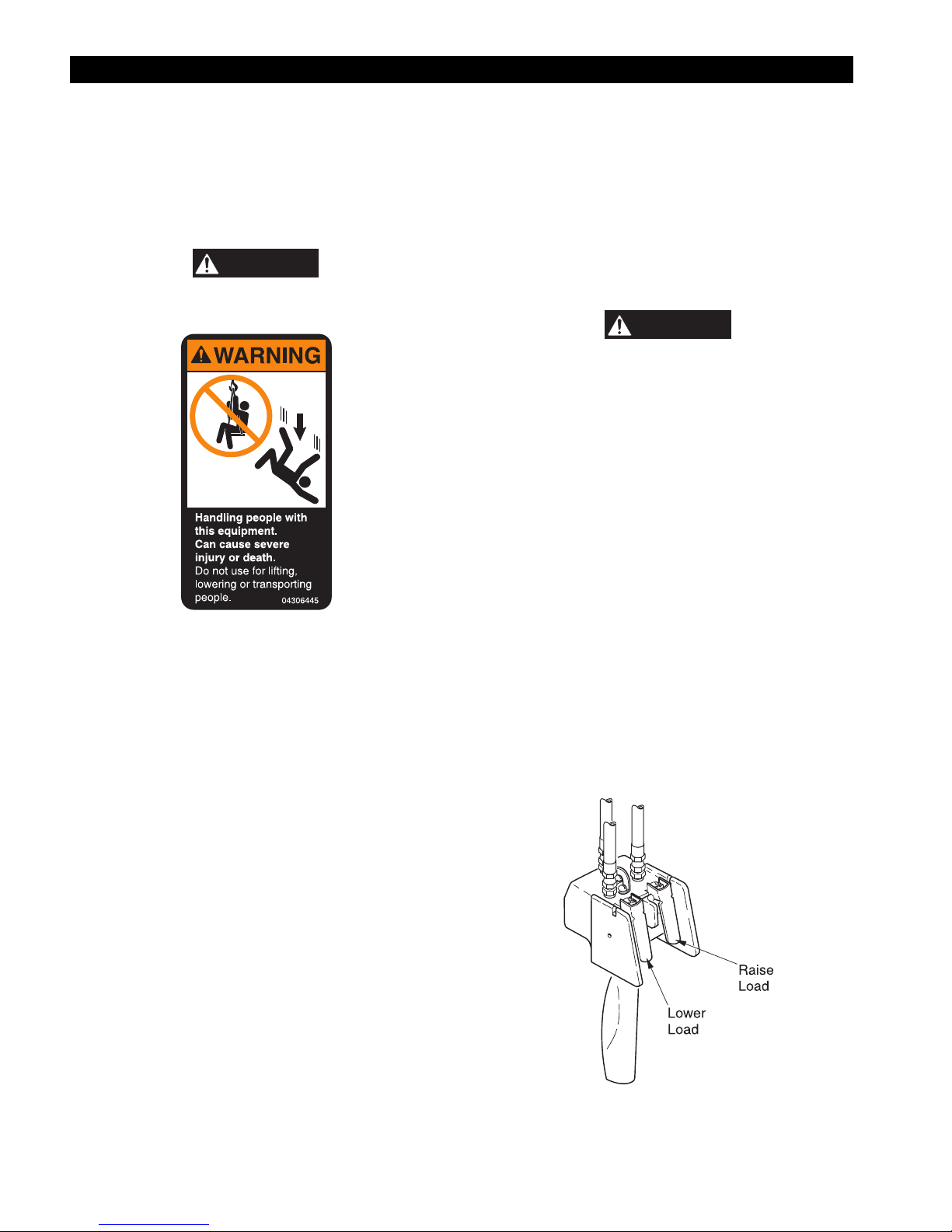

WARNING

The four most important aspects of hoist operation are:

1. Follow all safety instructions when operating hoist.

2. Allow only people instructed in safety and operation on this

product to operate hoist.

3. Subject each hoist to a regular inspection and maintenance

procedure.

4. Be aware of the hoist capacity and weight of load at all

times.

WARNING

• Do not use this hoist for lifting, supporting or transporting

people or lifting or supporting loads over people.

Operators must be physically competent. Operators should have

no health condition which might affect their ability to react, and

they must have good hearing, vision and depth perception. The

hoist operator must be carefully instructed in his duties and must

understand the operation of the hoist, including a study of the

manufacturer’s literature. The operator must be aware of proper

methods of hitching loads and should have a good attitude

regarding safety. It is the operator's responsibility to refuse to

operate the hoist under unsafe conditions.

Initial Operating Checks

Hoists are tested for proper operation prior to leaving the

factory. Before the hoist is placed into service the following

initial operating checks should be performed.

1. After installation of trolley mounted hoists, check to ensure

the hoist is centered below the trolley.

2. Check for air leaks in the supply hose and fittings to

pendant, and from pendant to manifold.

3. When first running the hoist or trolley motors a small

amount of light oil should be injected into the inlet

connection to allow good lubrication.

4. When first operating the hoist and trolley it is

recommended that the motors be driven slowly in both

directions for a few minutes.

5. Operate the trolley along the entire length of the beam.

6. Inspect hoist and trolley performance when raising, moving

and lowering test load(s). Hoist and trolley must operate

smoothly and at rated specifications prior to being placed in

service.

7. Check that trolley (if equipped) and hook movement is the

same direction as arrows or information on the pendant

control.

8. Raise and lower a light load to check operation of the hoist

brake.

9. Check hoist operation by raising and lowering a load equal

to the rated capacity of the hoist 4 to 6 inches (100 to 150

mm) off the floor.

10. Check operation of limit devices.

11. Check to see that the hoist is directly over the load. Do not

lift the load at an angle (side pull or “yard”).

12. Check to see that the hoist is securely connected to the

overhead crane, monorail, trolley or supporting member.

13. Check to see that the load is securely inserted in the hook,

and that the hook latch is engaged.

• The hook latch is intended to retain loose slings or devices

under slack conditions. Hook latches are not intended to be

an antifouling device, so caution must be used to prevent the

latch from supporting any of the load.

Hoist Controls

Pendant Controls

The HLK hoist can be supplied with an optional manual pull

chain control or a one, two or three function pendant depending

on application. For detailed information on these products refer

to Ingersoll-Rand Manual Form Number P6778 or contact your

nearest distributor or the factory.

Operation of the hoist is the same for all pendants listed in this

section:

1. To lift a load, depress the hoist pendant raise lever.

2. To lower a load depress the hoist pendant lower lever.

3. To throttle lift or lowering speed, regulate the amount the

pendant lever is depressed. Depress lever completely for

maximum speed; depress lever partially for slower speeds.

4. To stop lift or lowering function, release the lever. Lever

will spring return to off and hoist motor will stop.

Single Function, Two Lever Pendant

Refer to Dwg. MHP0427.

The two lever pendant is the standard pendant supplied with the

HLK and is designed to provide hoist operation only. Hoist

operation must correspond to the directions indicated by the

arrows located on the pendant levers.

(Dwg. MHP0427)

10

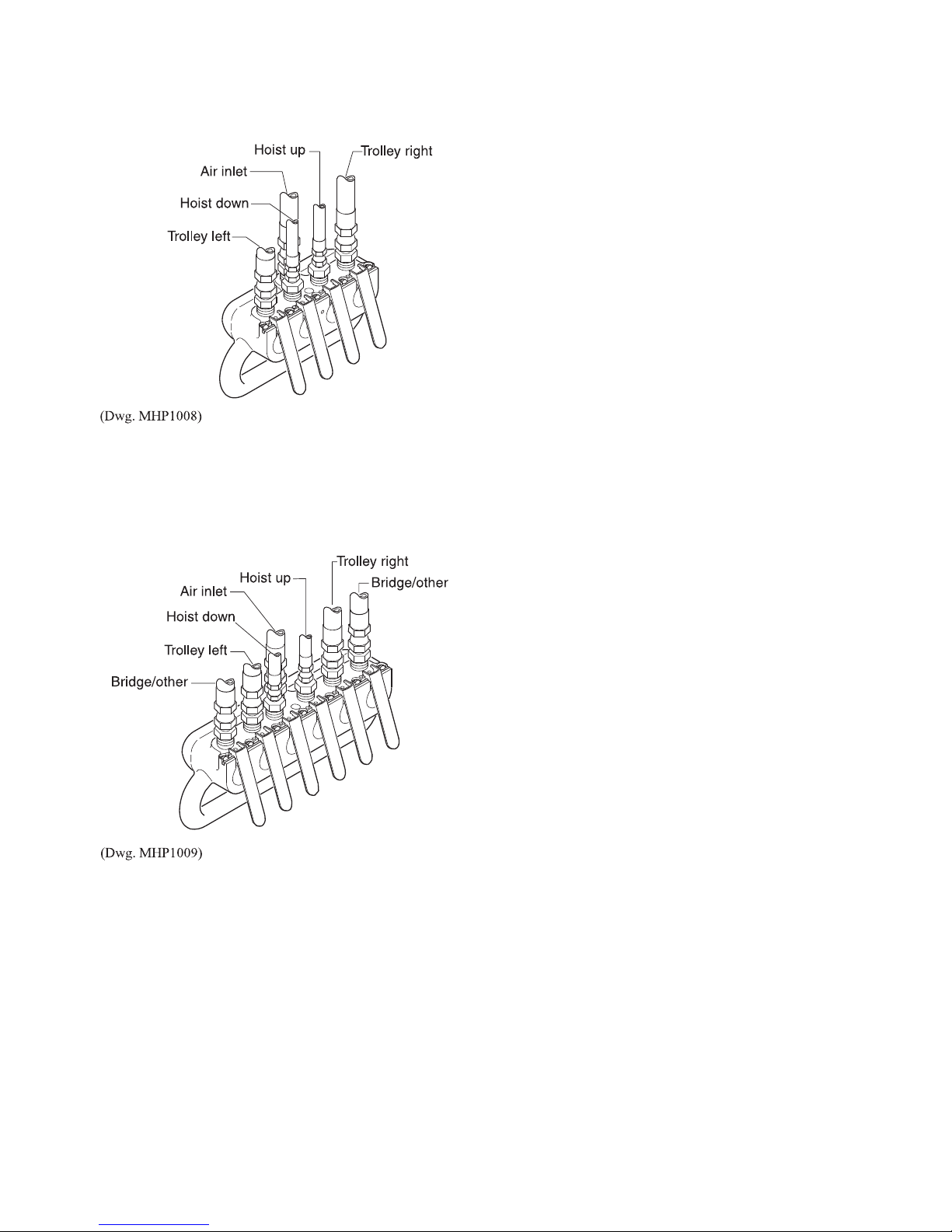

Two Function, Four Lever Pendant

The four lever pendant is designed to provide a single station for

control of hoist and trolley operations.

Refer to Dwg. MHP1008 for pendant lever function and hose to

component connections.

Three Function, Six Lever Pendant

The six lever pendant is designed to provide a single station for

control of the hoist, the trolley and a third related component

(bridge/runway) operation.

Refer to Dwg. MHP1009 for pendant lever function and hose to

component connections.

Pull Chain Control

The pull chain provides the operator with a local hoist operating

station. The following operating directions are as viewed from

the motor end of hoist, facing the pull chains.

1. To lift a load pull down on the right pull chain.

2. To lower a load pull down on the left pull chain.

3. To throttle lift or lowering speed regulate the distance the

pull chain travels. Pull chain to full travel for maximum

speed; pull chain partially for slower speeds.

4. To stop lift or lowering of load, release the pull chain.

Hoist motor will stop.

11

INSPECTION

WARNING

• All new, altered or modified equipment should be inspected

and tested by personnel instructed in safety, operation and

maintenance of this equipment to ensure safe operation at

rated specifications before placing equipment in service.

• Never use a hoist that inspection indicates is damaged.

Frequent and periodic inspections should be performed on

equipment in regular service. Frequent inspections are visual

examinations performed by operators or service personnel and

include observations made during routine equipment operation.

Periodic inspections are thorough inspections conducted by

personnel trained in the safety, operation and maintenance of

this equipment. ASME B30.16 states inspection intervals

depend upon the nature of the critical components of the

equipment and the severity of usage.

The inspection intervals recommended in this manual are based

on intermittent operation of the hoist eight hours each day, five

days per week, in an environment relatively free of dust,

moisture and corrosive fumes. If the hoist is operated almost

continuously or more than eight hours each day, more frequent

inspections will be required.

Careful inspection on a regular basis will reveal potentially

dangerous conditions while still in the early stages, allowing

corrective action to be taken before the condition becomes

dangerous.

Deficiencies revealed through inspection, or noted during

operation, must be reported to designated personnel trained in

safety, operation and maintenance of this equipment. A

determination as to whether a condition constitutes a safety

hazard must be decided, and the correction of noted safety

hazards accomplished and documented by written report before

placing the equipment in service.

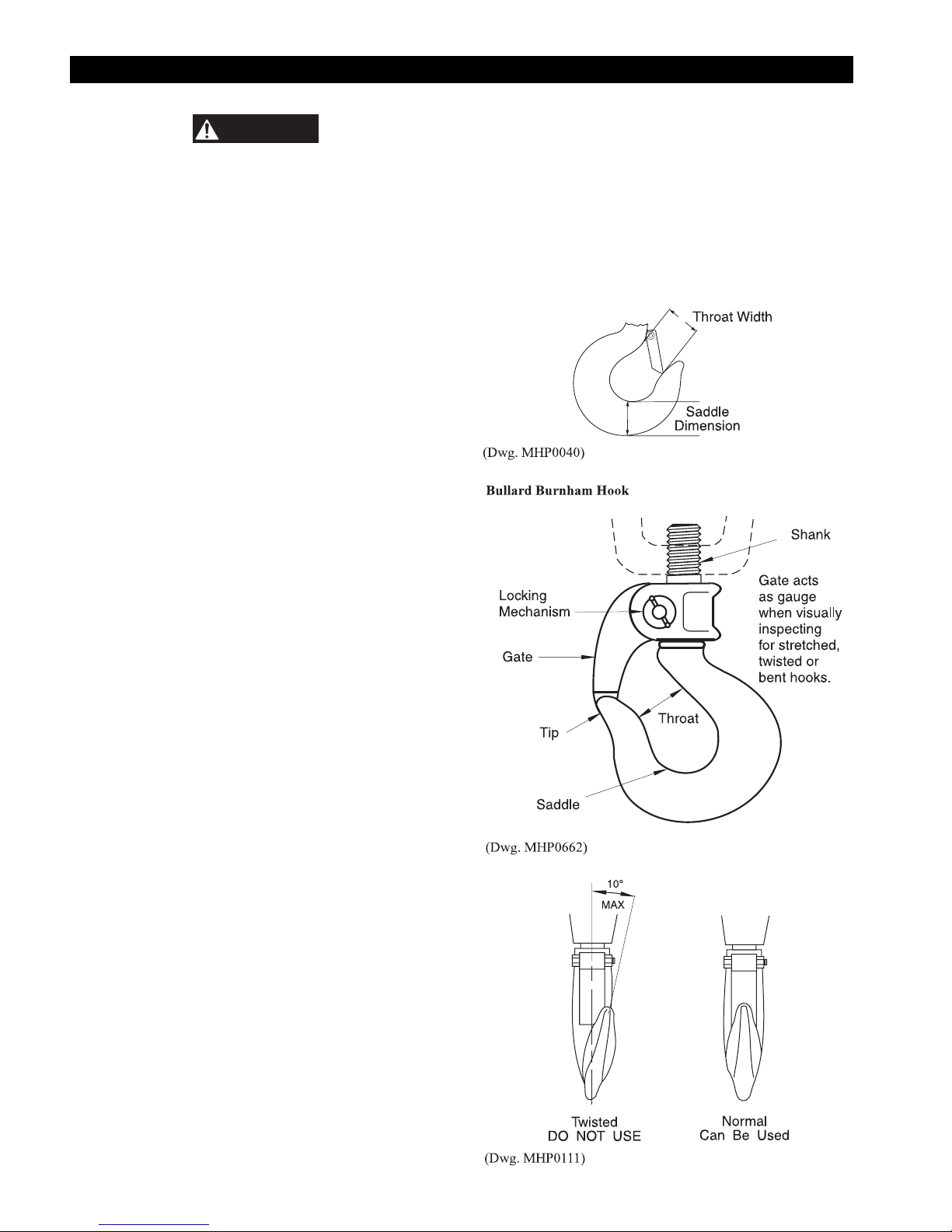

2. HOOKS. Check for wear or damage, increased throat

width, bent shank or twisting of hook. Replace hooks

which exceed the throat opening and/or saddle dimension

discard widths specified in Table 2 (refer to Dwg.

MHP0040) or exceed a 10° twist (refer to Dwg.

MHP0111). If the hook latch snaps past the tip of the hook,

the hook is sprung and must be replaced. Replace Bullard

Burnham hooks if the gate no longer contacts the hook tip.

Refer to Dwg. MHP0662. Refer to the latest edition of

ASME B30.10 “HOOKS” for additional information.

Check hook support bearings for lubrication or damage.

Ensure they swivel easily and smoothly.

Records and Reports

Inspection records, listing all points requiring periodic

inspection should be maintained for all load bearing equipment.

Written reports, based on severity of service, should be made on

the condition of critical parts as a method of documenting

periodic inspections. These reports should be dated, signed by

the person who performed the inspection, and kept on file where

they are readily available for review.

Load Chain Reports

Records should be maintained documenting the condition of

load chain removed from service as part of a long-range load

chain inspection program. Accurate records will establish a

relationship between visual observations noted during frequent

inspections and the actual condition of the load chain as

determined by periodic inspection methods.

Frequent Inspection

On hoists in continuous service, frequent inspection should be

made by operators at the beginning of each shift. In addition,

visual inspections should be conducted during regular operation

for any damage or evidence of malfunction (such as abnormal

noises).

1. OPERATION. Check for visual signs or abnormal noises

(grinding etc.) which could indicate a potential problem.

Make sure controls function properly and return to neutral

when released. Check load chain feed through the hoist and

bottom block. If chain binds, jumps, is excessively noisy or

"clicks", clean and lubricate the chain. If problem persists,

replace the chain. Do not operate the hoist until all

problems have been corrected.

12

3. UPPER AND LOWER LIMIT DEVICE. Test operation

with no load slowly to both extremes of travel. Upward

travel must stop when the bottom block or stop ring on

chain hits hoist limit arm. Downward travel must stop when

the loop at the unloaded end of the chain decreases and

activates the limit arm.

4. AIR SYSTEM. Visually inspect all connections, fittings,

hoses and components for indication of air leaks. Repair

any leaks found. Check and clean the filter in the inlet stud

(24) and the inlet strainer (24C) if equipped.

5. CONTROLS. During operation of hoist, verify response to

pendant, or pull chain, is quick and smooth. Ensure that the

controls return to neutral and hoist operation stops when

released. If hoist responds slowly or movement is

unsatisfactory, do not operate hoist until all problems have

been corrected.

6. HOOK LATCH. Make sure the hook latch or gate is

present and operating. Replace if necessary.

CAUTION

• Do not use hoist if hook latch or gate is missing or damaged.

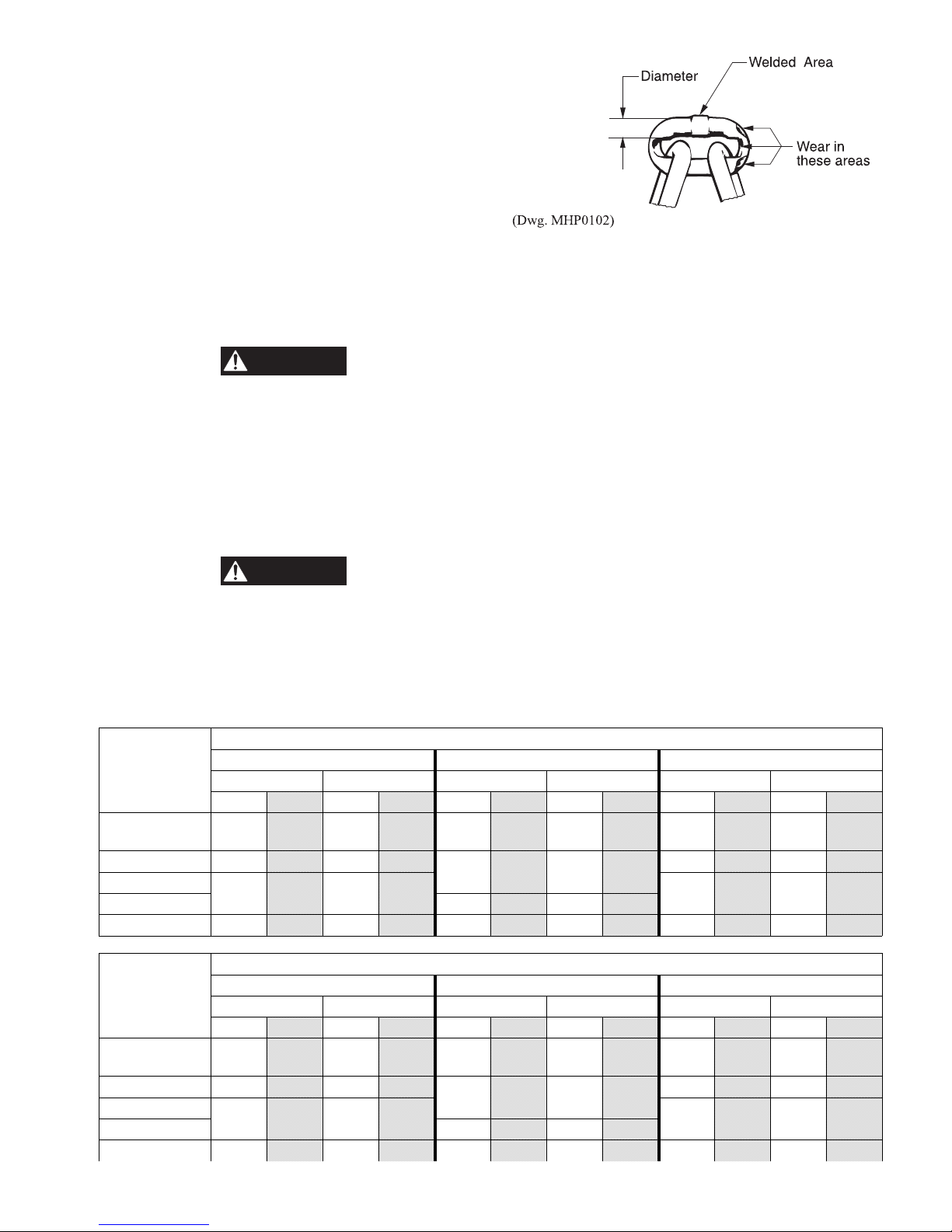

7. LOAD CHAIN. Examine each link for bending, cracks in

weld areas or shoulders, traverse nicks and gouges, weld

splatter, corrosion pits, striation (minute parallel lines) and

chain wear, including bearing surfaces between chain links

(refer to Dwg. MHP0102). Replace a chain that fails any of

the inspections. Check chain lubrication and lubricate if

necessary. Refer to ‘Load Chain’ in “LUBRICATION”

section.

CAUTION

• The full extent of load chain wear cannot be determined by

visual inspection. At any indication of load chain wear

inspect chain and chain wheel in accordance with

instructions in ‘Load Chain’ listed in “Periodic Inspection”

section.

8. LOAD CHAIN REEVING. Ensure welds on standing links

are away from the powered chain wheel. Reinstall chain if

necessary. On hoists with multiple chain falls, make sure

load chain is not capsized, twisted or kinked. Adjust as

required.

Periodic Inspection

Frequency of periodic inspection depends on the severity of

usage:

NORMAL HEAVY SEVERE

yearly semiannually quarterly

Disassembly may be required for HEAVY or SEVERE usage.

Keep accumulative written records of periodic inspections to

provide a basis for continuing evaluation.

Inspect all the items in "Frequent Inspection". Also inspect the

following:

1. FASTENERS. Check all rivets, split pins, capscrews and

nuts. Replace if missing or tighten if loose.

2. ALL COMPONENTS. Inspect for wear, damage,

distortion, deformation and cleanliness. If external evidence

indicates the need, disassemble. Check gears, shafts,

bearings, sheaves, chain guides, springs and covers.

Replace worn or damaged parts. Clean, lubricate and

reassemble.

Table 2

Hoist

Model

HL1000K and

HL1500K

HL2000K

HL3000K

HL4500K

HL6000K

Hoist

Model

HL1000K and

HL1500K

HL2000K

HL3000K

HL4500K

HL6000K

Throat Width (with Latch installed)

Standard Bronze Bullard Burnham

New Hook Discard Hook New Hook Discard Hook New Hook Discard Hook

in mm in mm in mm in mm in mm in mm

1.12 28.4 1.21 30.7 1.06 26.9 1.14 29.0 1.37 34.8 1.48 37.6

1.06 26.9 1.14 29.0

1.50 38.1 1.62 41.1 1.87 47.5 2.02 51.3

1.75 44.5 1.89 48.0 2.75 69.9 2.97 75.4 3.00 76.2 3.24 82.3

Standard Bronze Bullard Burnham

New Hook Discard Hook New Hook Discard Hook New Hook Discard Hook

in mm in mm in mm in mm in mm in mm

1.12 28.4 1.21 30.7 1.44 36.6 1.56 39.6 1.34 34.0 1.45 36.8

1.44 36.6 1.56 39.6

1.81 46.0 1.95 49.5 1.87 47.5 2.02 51.3

2.25 57.2 2.43 61.7 2.97 75.4 3.21 81.5 2.75 69.9 2.97 75.4

1.50 38.1 1.62 41.1

1.75 44.5 1.89 48.0

Saddle Dimension

1.81 46.0 1.95 49.5

2.25 57.2 2.43 61.7

1.50 38.1 1.62 41.1

1.50 38.1 1.62 41.1

13

3. HOOKS. Inspect hooks carefully for cracks using magnetic

particle or other suitable nondestructive method. Inspect

hook retaining parts. Tighten or repair, if necessary.

4. LOAD CHAIN WHEELS. Check for damage or excessive

wear. Replace if necessary. Observe the action of the load

chain feeding through the hoist. Do not operate a hoist

unless the load chain feeds through the hoist and hook

block smoothly and without audible clicking or other

evidence of binding or malfunctioning.

5. MOTOR. If performance is poor, disassemble the motor

and check for wear or damage to bearings and shafts. The

parts should be cleaned, lubricated and reassembled.

Replace worn or damaged parts.

6. BRAKE. Raise a load equal to the rated capacity of the

hoist 4 to 6 inches (100 to 150 mm) off the floor. Verify

hoist holds the load without drift. If drift occurs,

disassemble. Remove brake discs as described in the

“MAINTENANCE” section. Check and clean the brake

parts each time the hoist is disassembled. Replace the brake

discs if the thickness is less than 0.090 inch (2.29 mm).

7. SUPPORTING STRUCTURE. Check for distortion, wear

and continued ability to support load.

8. TROLLEY (if equipped). Check that the trolley wheels

track the beam properly and clearance between each wheel

flange and beam is correct, 3/32 to 1/8 in. (2 to 3 mm).

Check that wheels and beam are not excessively worn.

Inspect side plates for spreading due to bending. Do not

operate the hoist until any problems have been determined

and corrected.

9. LABELS AND TAGS. Check for presence and legibility.

Replace if necessary.

10. LOAD CHAIN END ANCHORS. Ensure both ends of load

chain are securely attached. Secure if loose, repair if

damaged, replace if missing.

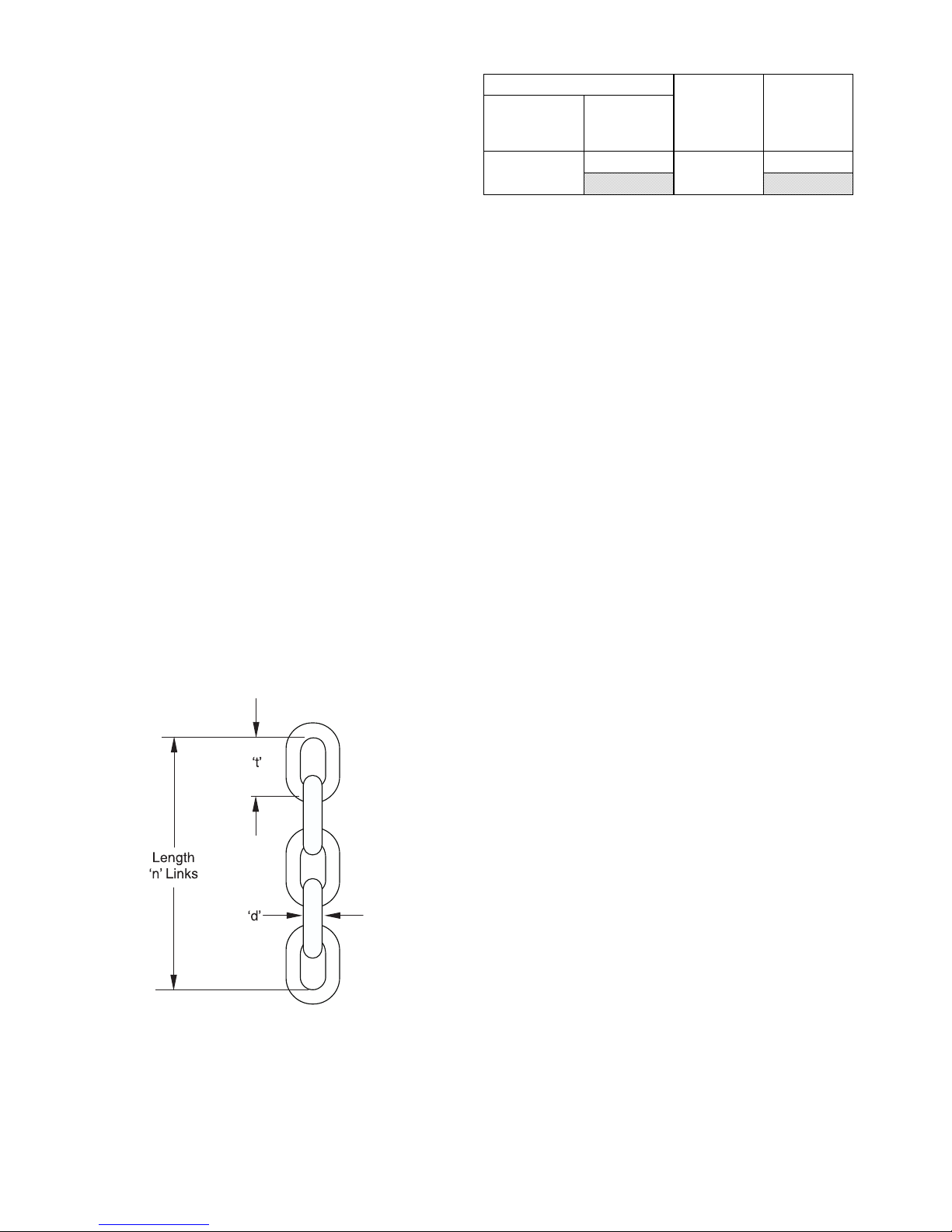

11. LOAD CHAIN. Measure the load chain for wear over a

five link section as shown in Dwg. MHP1291. Pay

particular attention to the most frequently reeved links.

When any five links in the working length reaches or

exceeds the discard length shown in Table 3, replace the

entire chain. Always use a genuine Ingersoll-Rand

Material Handling replacement chain.

Table 3 Load Chain Length

Dimensions Of Link

Nominal Wire

Diameter

(d)

3/8

Zinc plated load chain is standard on HLK hoists built after

January 1996. Always use stainless steel load chain on

HL1000KR Spark Resistant Hoists.

12. CHAIN CONTAINER. Check for damage or excessive

wear and that chain container is securely attached to the

hoist. Secure or replace if necessary.

13. LIMIT ASSEMBLY. Check throttle lever moves freely. To

limit hook downward travel the loop in the slack chain side

must contact the throttle lever. To limit hook upward travel

the bottom hook block, or stop ring, must contact the

throttle lever.

To test “UP” and “DOWN” travel limits first run hoist

slowly with no load to verify proper function. Repeat test at

full speed with no load to verify proper function. On Hoist

Models HL4500K and HL6000K the throttle lever (35)

may require minor adjustment to provide adequate

clearance with the upper suspension block.

Pitch

(t)

1.012 in

25.7 mm 131.4 mm

Number Of

Links

(n)

5

Discard

Length

(n)

Links

5.175 in

Hoists Not in Regular Use

1. A hoist which has been idle for a period of one month or

more, but less than one year, should be given an inspection

conforming with the requirements of “Frequent Inspection”

prior to being placed into service.

2. A hoist which has been idle for a period of more than one

year should be given an inspection conforming with the

requirements of “Periodic Inspection” prior to being placed

into service.

3. Standby hoists should be inspected at least semiannually in

accordance with the requirements of “Frequent Inspection”.

In abnormal operating conditions hoists should be

inspected at shorter intervals.

(Dwg. MHP1291)

14

INSPECTION AND MAINTENANCE REPORT

Ingersoll-Rand HLK Air Chain Hoist

Model Number: Date:

Serial Number: Inspected by:

Reason for Inspection: (Check Applicable Box)

1. Scheduled Periodic Inspection:

____ Quarterly ____Semiannually ____Yearly

2. Discrepancy(ies) noted during Frequent Inspection

3. Discrepancy(ies) noted during maintenance

4. Other: ____________________________

Refer to the Parts, Operation and Maintenance Manual “INSPECTION” section for general inspection criteria. Refer to appropriate National Standards and

Codes of practice. If in doubt about an existing condition contact the nearest Ingersoll-Rand Distributor or the factory for technical assistance.

Operating Environment:

_____ Normal _____ Heavy _____ Severe

COMPONENT

Fasteners

Gears

Shafts

Bearings - - Load Bearing Sheaves

Chain Guides

Springs - - Covers

Hooks:

Actual Hook Throat Width: __________ inches / __________ mm (Refer to Table 2 for minimum/maximum acceptable widths.)

Top

Hook Twist - - - (maximum 10%)

Hook Crack Test Method Used: _____ Dye Penetrant _____ Magnetic Particle _____ Other: ____________________

Actual Hook Throat Width: __________ inches / __________ mm (Refer to Table 2 for minimum/maximum acceptable widths.)

Bottom

Hook Latch (Standard) - - Hook Gate (Bullard) - - Brakes

(10% Load Test)

Brakes

(Visual Inspection)

Tail Pin (End Anchor)

Load Chain: - - -

Supporting Structure

Labels and Tags - - Other Components

(list in NOTES section)

Hook Twist - - - (maximum 10%)

Hook Crack Test Method Used: _____ Dye Penetrant _____ Magnetic Particle _____ Other: ____________________

Working length(s) maximum wear: __________ inches / __________ mm (Refer to Table 3)

CONDITION

Pass Fail Repair Replace

CORRECTIVE

ACTION

- - -

NOTES

Testing: Pass Fail NOTES

Operational (No Load)

Operational (10% Load)

Operational (Maximum Test Load *)

* Refer to the Parts, Operation, and Maintenance Manual ‘Load Test’ in the “MAINTENANCE” section to determine Maximum Test Load.

This page may be photocopied and used by inspectors or maintenance personnel.

15

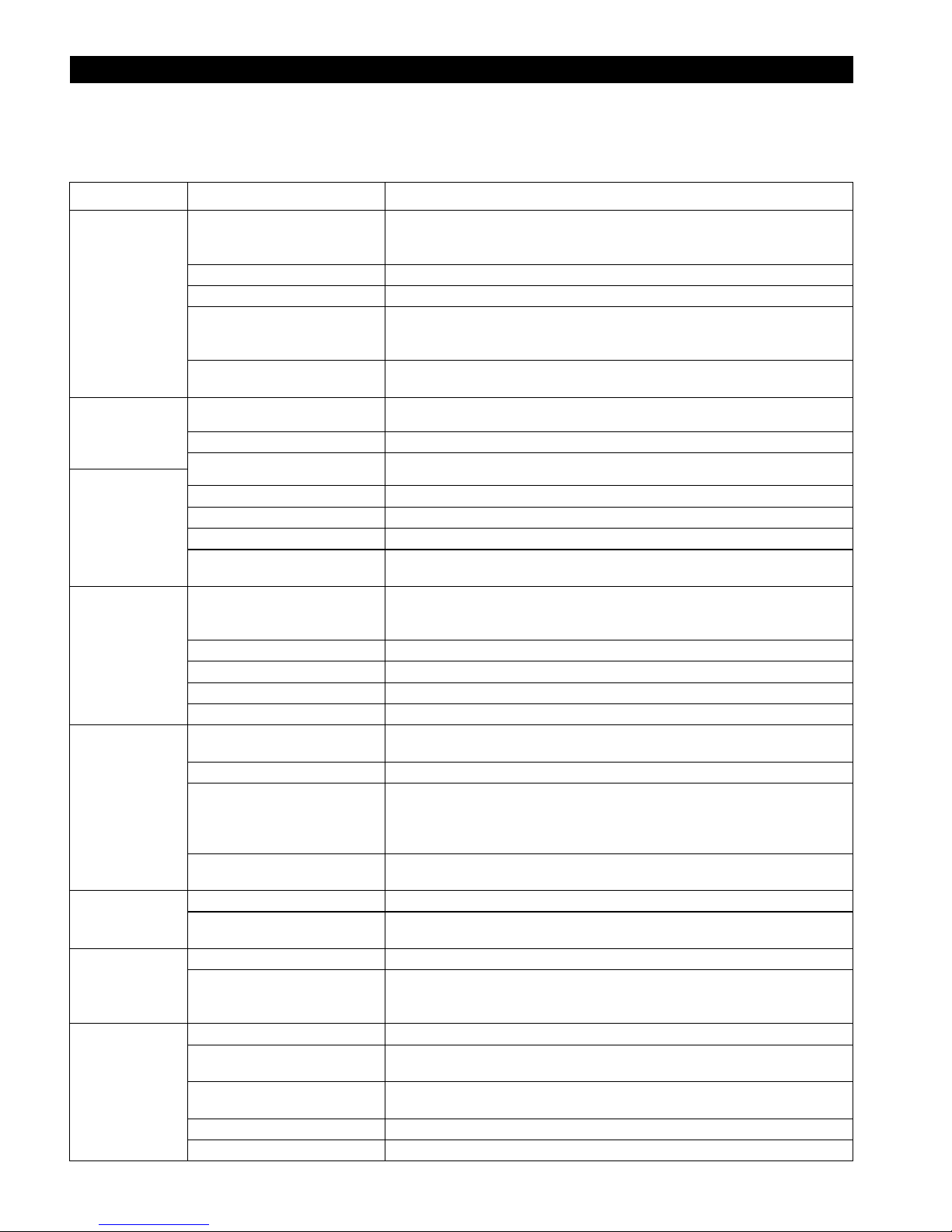

TROUBLESHOOTING

This section provides basic troubleshooting information. Specific causes to problems are best identified by thorough inspections

performed by personnel instructed in safety, operation and maintenance of this equipment. The chart below provides a brief guide to

common hoist symptoms, probable causes, and remedies.

SYMPTOM CAUSE REMEDY

Hoist will not

operate.

Load continues to

move when hoist is

stopped (UP

direction).

Load continues to

move when hoist is

stopped (DOWN

direction).

Hoist does not lift

load.

Reduced speed

and/or capacity.

Hoist operates in

LOWER direction

but will not LIFT.

Hoist operates in

LIFT direction but

will not LOWER.

Load chain jumps

on sheave or makes

a “snapping”

sound.

No air supply to hoist, or too little

flow or pressure.

Hoist is overloaded. Reduce load to within rated capacity.

Motor is damaged. Disassemble, inspect and replace parts. Refer to “MAINTENANCE” section.

Pendant malfunction. Check pendant throttle lever for free movement. Check air pressure at pendant.

Brake not releasing. Check brake release circuit and pressure. Minimum operating pressure at brake

Valve or throttle lever sticking. Check pendant throttle lever for free movement. Lubricate or repair as required.

Dump valves not releasing. Check pendant hose dump valves.

Pendant lever sticking. Check pendant throttle lever for free movement.

Dump valves not releasing. Check pendant hose dump valves.

Hoist is overloaded. Reduce load to within rated capacity.

Valve or throttle lever sticking. Check pendant throttle lever for free movement.

Brake is slipping. Check brake springs and brake disc linings for wear. Refer to “MAINTENANCE”

No air supply to hoist, or too little

flow or pressure.

Hoist is overloaded. Reduce load to within rated capacity.

Main air travel is restricted. Check throttle lever and linkage for free, unobstructed movement.

Exhaust restricted. Inspect vents and replace mufflers. Refer to “MAINTENANCE” section.

Motor is damaged. Disassemble, inspect and replace parts. Refer to “MAINTENANCE” section.

Inlet stud (24) screen plugged,

restricting air flow.

Lubricator oil level low. Fill lubricator.

No air supply to hoist, or too little

flow or pressure.

Bleed screws out of adjustment. Adjust bleed screws as described in ‘Bleed Screw Adjustment’ procedure in

Hoist is overloaded. Reduce load to within rated capacity.

Pendant malfunction. Check pendant throttle lever for free movement. Check air pressure at pendant.

Brake piston seals leaking. Install new seals. Refer to “MAINTENANCE” section.

No air supply to hoist, or too little

flow or pressure.

Dirty or lack of oil on load chain. Clean and lubricate load chain. Refer to “LUBRICATION” section.

Worn or rusted load chain. Inspect load chain. Refer to “INSPECTION” section. Clean and lubricate load

Worn load sheave or incorrectly

reeved load chain.

Capsized hook. Correct as described in “MAINTENANCE” section.

Hoist not in-line with load. Align hoist with load. Do not side pull or “yard”.

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance.

Minimum operating pressure in pendant line must be 55 psig (3.8 bar/380 kPa).

Check lubricator oil level. Fill if low.

inlet must be 55 psig (3.8 bar/380 kPa).

section.

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance.

Replace old style inlet stud with screen with new style (without screen), or

remove screen.

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance. Check pendant

control adjustment as described in the “INSTALLATION” section.

“INSTALLATION” section.

Minimum operating pressure in pendant line must be 55 psig (3.8 bar/380 kPa).

Check air supply line connections and hoses. Check supply air at hoist motor

inlet. A minimum of 70 scfm (1.96 cu. m/m) air flow at 90 psig (6.3 bar/630 kPa)

at hoist motor inlet is required to provide rated performance.

chain. Refer to “LUBRICATION” section.

Check load chain is correctly reeved. Disassemble, inspect and replace worn

parts. Refer to “MAINTENANCE” section.

16

LUBRICATION

WARNING

To ensure continued satisfactory operation of the hoist, all

points requiring lubrication must be serviced with the correct

lubricant at the proper time interval as indicated for each

assembly. Correct lubrication is one of the most important

factors in maintaining efficient operation.

The lubrication intervals recommended in this manual are based

on intermittent operation of the hoist eight hours each day, five

days per week. If the hoist is operated almost continuously, or

more than the eight hours each day, more frequent lubrication

will be required. The lubricant types and change intervals are

based on operation in an environment relatively free of dust,

moisture, and corrosive fumes. Use only those lubricants

recommended. Other lubricants may affect the performance of

the hoist. Approval for the use of other lubricants must be

obtained from your Ingersoll-Rand Technical Support

Department or distributor. Failure to provide proper lubrication

may result in damage to the hoist and/or its associated

components.

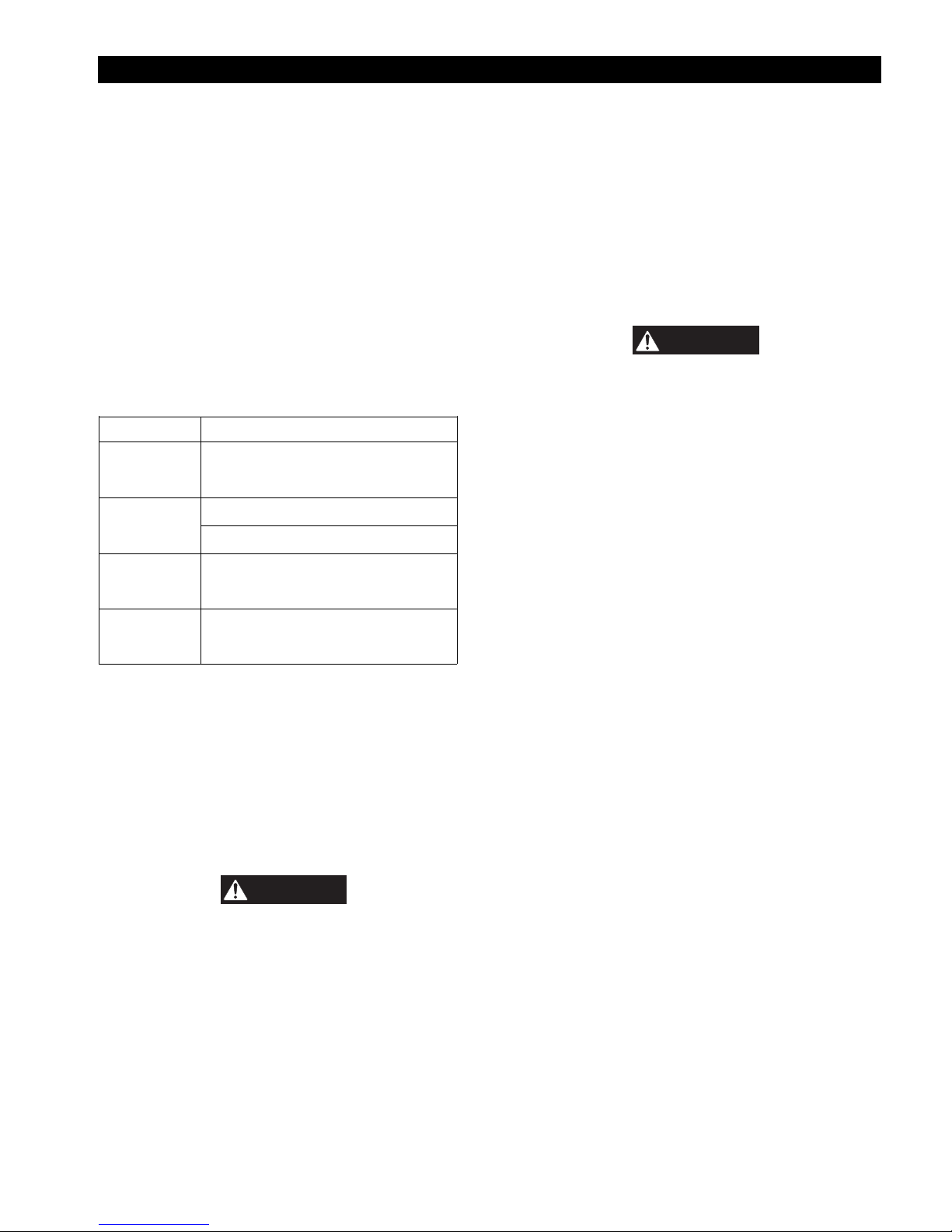

INTERVAL LUBRICATION CHECKS

Start of each

shift

(Operator)

Weekly

(Maintenance

personnel)

Monthly

(Maintenance

personnel)

Yearly

(Maintenance

personnel)

Note: Intervals are based on hoist operation in a normal

environment as described in the “INSPECTION” section. In

HEAVY or SEVERE operating conditions adjust lubrication

intervals accordingly.

General Lubrication

Whenever a Series HLK Hoist is disassembled for overhaul or

replacement of parts, lubricate as follows:

1. Coat all motor parts with a light film of Ingersoll-Rand

Pneu-Lube® Medium Oil No. 50 or a good quality

hydraulic oil before assembling.

Check flow and level of air line lubricator

(1 to 3 drops per minute) when operating

hoist at maximum motor speed.

Clean and lubricate load chain.

Lubricate hook latch and pivot points.

Inspect and clean or replace air line filter.

Drain and replace housing oil.

CAUTION

• Do not use automotive type detergent oil. Detergents will

delaminate the motor vanes and cause premature failure.

2. Apply a coating of Ingersoll-Rand No. 70 Grease or

multipurpose grease to the throttle shaft bearings (2) before

assembly.

3. Fill the gear case to the level plug on the side of the

housing (1) with Ingersoll-Rand No. 62 oil, or Texaco

Meropa No. 220. Replace oil level plug and vent plug after

filling.

4. The top and bottom hooks are supported by thrust bearings.

These bearings must be packed with Ingersoll-Rand No.

68 grease or a standard No. 2 multipurpose grease at

regular intervals. Neglect of proper lubrication will lead to

bearing failure.

In Line Lubricator

Lubricate the motor with Ingersoll-Rand Pneu-Lube

Oil No. 10 (or SAE 10), or No. 50 (SAE 20 or 20W) nondetergent motor oil from an in-line lubricator. The use of

detergent oil may cause premature failure.

Load Chain

• Failure to maintain clean and well lubricated load chain

will result in rapid load chain wear that can lead to chain

failure which can cause severe injury, death or substantial

property damage.

1. Lubricate each link of the load chain weekly. Apply new

lubricant over existing layer.

2. In severe applications or corrosive environments, lubricate

more frequently than normal.

3. Lubricate hook and hook latch pivot points with same

lubricant used on the load chain.

4. If required, clean chain with acid free solvent to remove

rust or abrasive dust buildup and lubricate the chain.

5. Use Ingersoll-Rand LUBRI-LINK-GREEN

to 90 EP oil.

Hook and Suspension Assemblies

1. Lubricate the hook and hook latch pivot points. Hook and

latch should swivel/pivot freely.

2. Use Ingersoll-Rand LUBRI-LINK-GREEN® or a SAE 50

to 90 EP oil.

3. On HL4500K and HL6000K hoists lubricate the idler

wheel bearings (107) in the upper suspension housing

(101) and lower hook block (123) with Ingersoll-Rand No.

68 Grease or a good quality No. 2 multipurpose grease.

4. On HL4500K and HL6000K hoists after each 300 hours of

operation or more frequently if hoist is operating in a

contaminated atmosphere, inject 2 or 3 shots of grease from

a grease gun into grease fittings (111) in the end of the idler

wheel shafts (110).

Housing

Remove the oil level plug from the side of the housing (1). If the

oil level is below the tapped hole, remove the vent plug and add

a sufficient amount of Ingersoll-Rand No. 62 oil (Texaco

Meropa No. 3 or Texaco Meropa No. 220). Reinstall the oil

level plug and vent plug.

Other System Components

Refer to the “LUBRICATION” section in the manufacturer’s

manual provided with the system component for lubrication

requirements.

Medium

®

or a SAE 50

®

17

CAUTION

MAINTENANCE

WARNING

• Never perform maintenance on the hoist while it is

supporting a load.

• Before performing maintenance, tag controls:

• Only allow personnel instructed in service and repair of this

hoist to perform maintenance.

• After performing any maintenance on the hoist,

dynamically test hoist to 100% of its rated capacity, in

accordance with ASME B30.16 standards, before returning

hoist to service. Testing to more than 100% of rated capacity

may be required to comply with standards and regulations

set forth in areas outside of the USA.

• Shut off air system and depressurize air lines before

performing any maintenance.

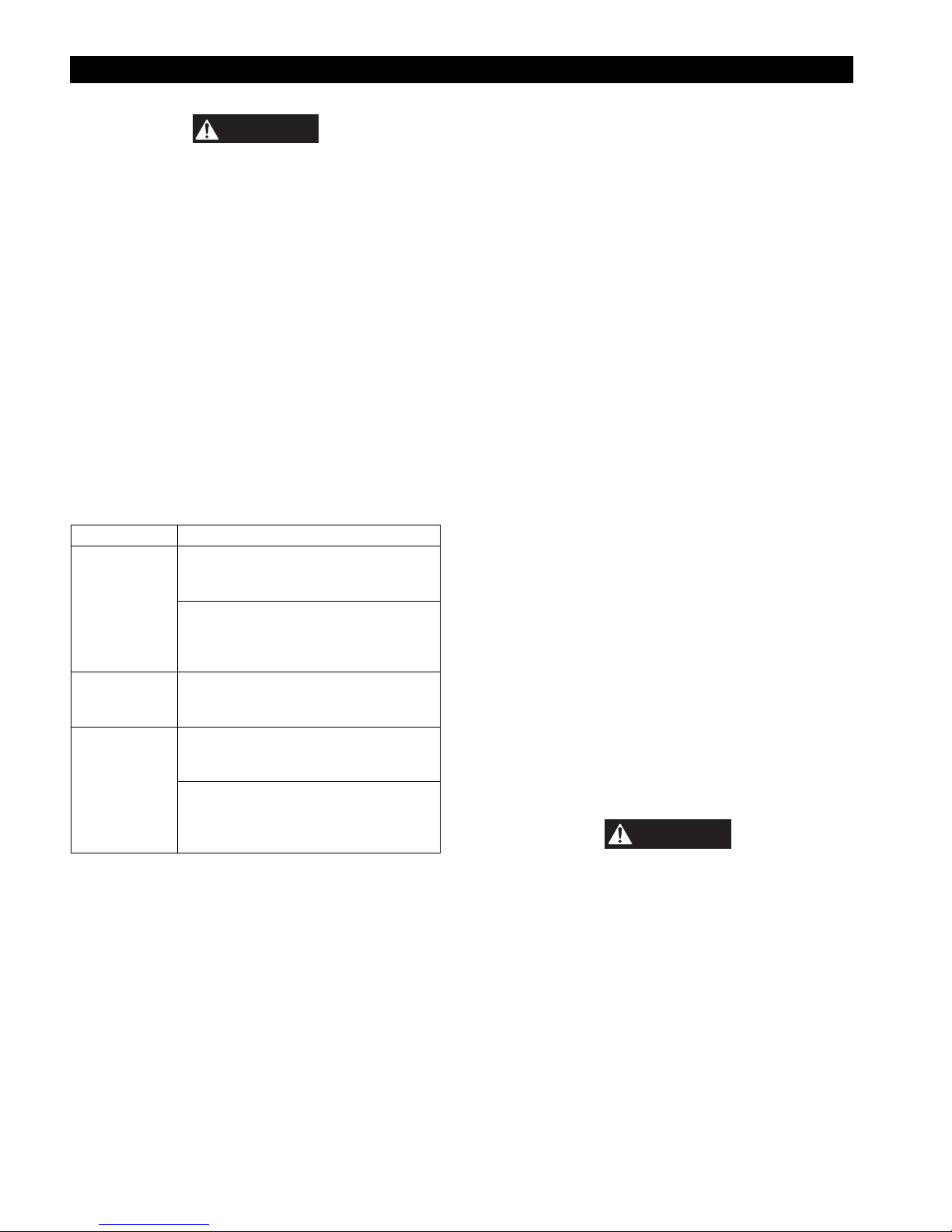

Maintenance Intervals

The maintenance interval chart is based on intermittent

operation of the hoist eight hours each day, five days per week,

in an environment relatively free of dust, moisture and corrosive

fumes. If the hoist is operated almost continuously or more than

eight hours each day, more frequent maintenance should be

performed.

INTERVAL MAINTENANCE CHECK

Start of each shift

(Operator or

Maintenance

Personnel)

Semiannually

(Maintenance

Personnel)

Yearly

(Maintenance

Personnel)

DANGER - DO NOT OPERATE -

EQUIPMENT BEING REPAIRED.

Make a thorough visual inspection of the

hoist for damage. Do not operate the hoist if

damaged.

Operate the hoist in both directions. Hoist

must operate smoothly without sticking,

binding or abnormal noises. Check the

operation of the brake.

Inspect the brake. Clean or replace parts as

required. Adjust brake as necessary.

Inspect the hoist gearing, shafts and bearings

for wear and damage. Repair or replace as

necessary.

Check all the supporting members, including

the suspension, fasteners, nuts, sheaves and

rigging, etc. for indications of damage or

wear. Repair or replace as required.

2. Never disassemble the hoist any further than is necessary to

accomplish the needed repair. A good part can be damaged

during the course of disassembly.

3. Never use excessive force when removing parts. Tapping

gently around the perimeter of a cover or housing with a

soft hammer, for example, is sufficient to break the seal.

4. Do not heat a part with a flame to free it for removal, unless

the part being heated is already worn or damaged beyond

repair and no additional damage will occur to other parts.

In general, the hoist is designed to permit easy disassembly and

assembly. The use of heat or excessive force should not be

necessary.

5. Keep the work area clean to prevent dirt and other foreign

matter from getting into bearings and other moving parts.

6. All seals, gaskets and ‘O’ rings should be discarded once

they have been removed. New seals, gaskets and ‘O’ rings

should be used when assembling the hoist.

7. When grasping a part in a vise, always use leather or

copper covered vise jaws to protect the surface of the part

and help prevent distortion. This is particularly true of

threaded members, machined surfaces and housings.

8. Do not remove any part which is press fit in or on a

subassembly unless the removal of the part is necessary for

repairs or replacement.

9. To avoid damaging bearings during hoist assembly or

disassembly always tap or press on the bearing inner race

for shaft fit bearings or the outer race for bore fit bearings.

10. If repair work can only be conducted above body height,

suitable working platforms or ladders should be made

available.

Load Chain Care

Keep the chain well lubricated as instructed in the

“LUBRICATION” section. Never operate a hoist when the load

chain does not flow freely and smoothly into and out of the

chain wheel(s), or when it makes noises indicative of binding or

other malfunctions.

If the chain is visibly damaged replace the chain and examine

the chain wheel and chain guard. Install a new chain wheel if the

old one is visibly worn. Install a new guard if the old one is

broken or distorted.

Refer to “INSPECTION” section for information on load chain

inspection.

General Maintenance Instructions

All maintenance work performed on the hoist must be recorded

with the date in the inspection report.

Proper use, inspections and maintenance increase the life and

usefulness of your Ingersoll-Rand equipment. During assembly,

lubricate gears, nuts, capscrews and all machined threads with

applicable lubricants. Use of antiseize compound and/or thread

lubricant on capscrew and nut threaded areas prevents corrosion

and allows for ease of disassembly of components.

It is recommended that all maintenance work on the hoist be

performed on a bench in a clean, dust free work area. During the

process of disassembling the hoist, observe the following:

1. Turn off air system and depressurize air lines before

performing any maintenance. Disconnect air line from

hoist.

• The full extent of load chain wear cannot be determined by

visual inspection. At any indication of load chain wear

inspect chain and chain wheel. Refer to “INSPECTION”

section.

The standard chain provided with this hoist is case hardened to a

depth of 0.010 to 0.012 inch (0.25 to 0.35 mm). When the outer

hardened case layer is worn through, additional wear will

progress rapidly and the strength of the chain will be

considerably reduced.

Additionally, the chain will no longer fit the pockets in the hoist

chain wheel properly causing the chain wheel to wear rapidly.

This will greatly increasing the chance of hoist malfunction and

chain breakage.

The hoist chain wheel is designed to outlast several chain

replacement cycles if the chain is replaced as recommended.

18

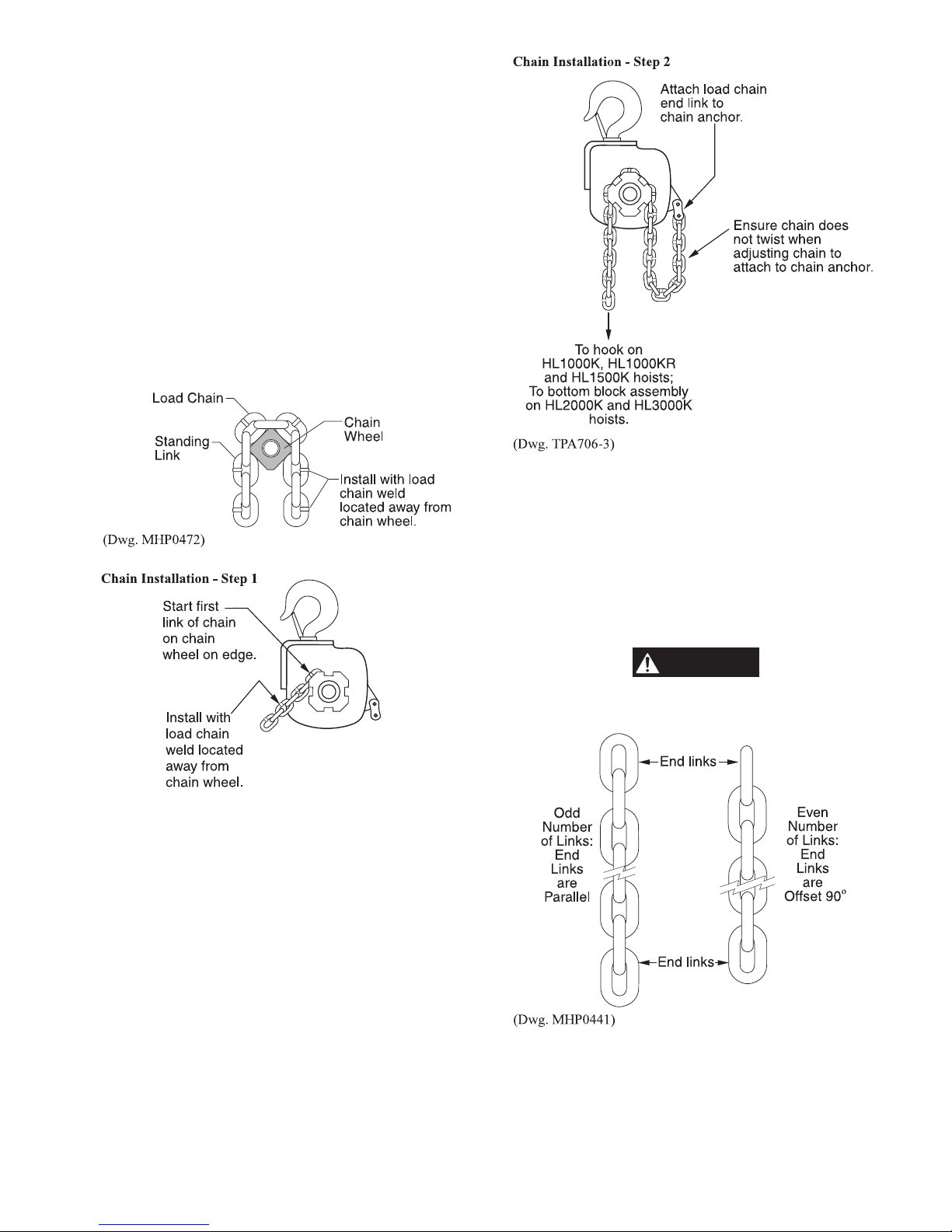

Initial Chain Installation

WARNING

The following instructions apply to hoists that do not have load

chain installed. For hoists with load chain installed, that must be

replaced, refer to the ‘Chain Replacement’ section. When

directed to remove or install hoist sections or subassemblies to

assist in chain installation, refer to the applicable ‘Disassembly’

or ‘Assembly’ section for specific requirements.

HL1000K, HL1000KR and HL1500K

The following steps describe the initial installation of chain on

single fall hoists that do not have load chain installed.

1. Remove the brake spring and piston housing, brake discs

and brake plates to expose the brake driver.

2. From the side of the chain wheel opposite the chain anchor

bolt, engage the first link of load chain in a pocket of the

chain wheel on edge. Refer to Dwg. TPA706-4, ‘Chain

Installation - Step 1.’ The weld on the load chain link must

face away from the powered chain wheel. Refer to Dwg.

MHP0472.

3. Rotate the brake driver by hand to feed the load chain

through the hoist.

5. Attach free end of load chain to hook. Inspect chain while

operating hoist slowly. Ensure chain feeds through chain

wheel smoothly, without sticking or binding. Repeat

operation in the opposite direction.

(Dwg. TPA706-4)

4. Keep the load chain straight and do not twist it. Attach the

free end of the load chain to the connecting link. Refer to

Dwg. TPA706-3, ‘Chain Installation - Step 2.’ Clean,

inspect and install the brake spring, brake discs, brake

plates and piston housing on hoist.

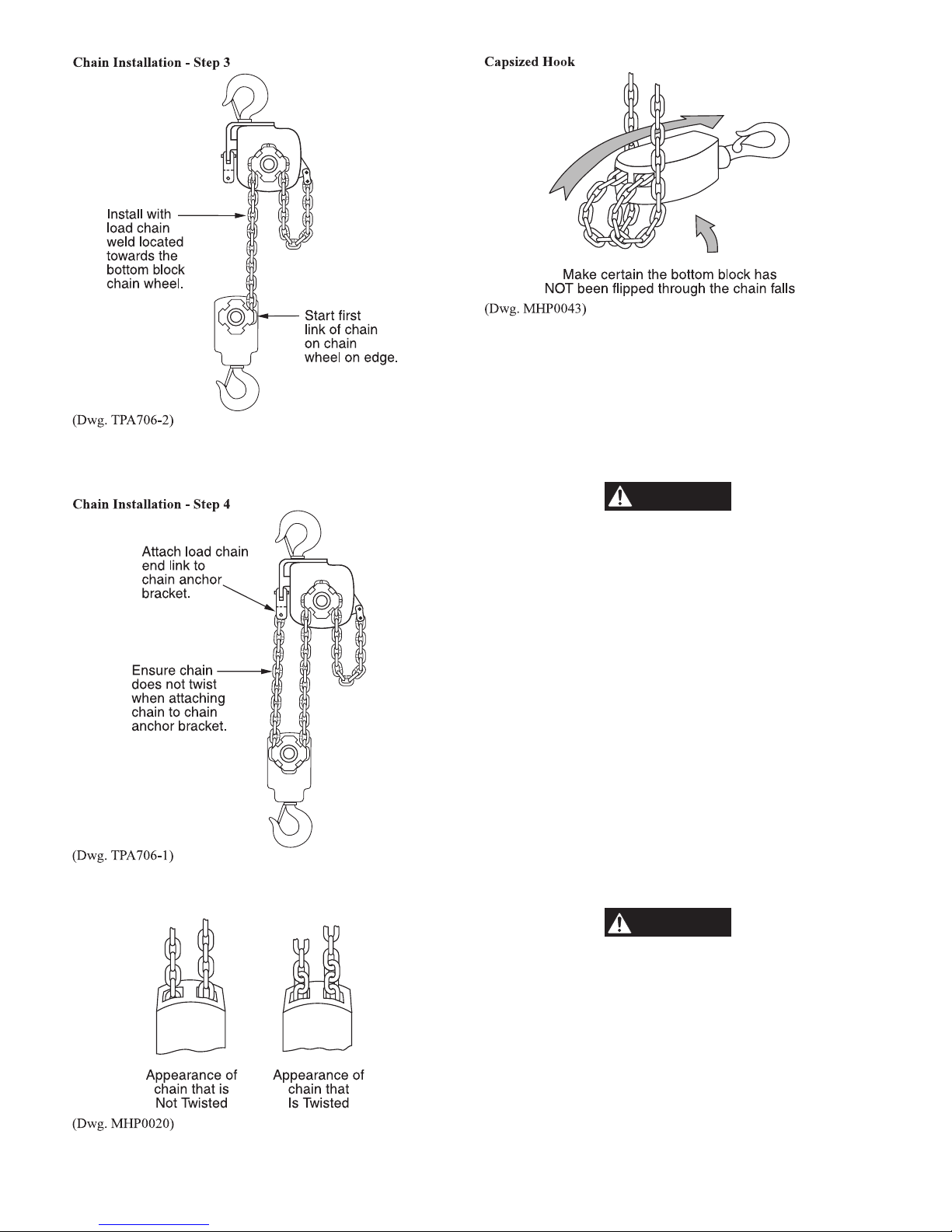

HL2000K and HL3000K

The following steps describe the initial installation of chain on

double fall hoists that do not have load chain installed.

1. Complete steps 1 through 4 of “HL1000K, HL1000KR and

HL1500K Chain Installation” section. Refer to MHP0472,

TPA706-4, and TPA706-3.

• Replacement chain for an HLK double fall hoist must have

an ODD number of total links. Refer to Dwg. MHP0441.

2. Ensure the chain is straight and feed the end through the

bottom hook chain wheel with the first link on edge with

the weld to the inside of the idler chain wheel. Refer to

Dwg. TPA706-2, ‘Chain Installation - Step 3.’

19

3. Ensure the chain is straight and attach the free end to the

CAUTION

WARNING

chain anchor bracket. Refer to Dwg. TPA706-1, ‘Chain

Installation - Step 4.’

HL4500K and HL6000K

The following steps describe the initial installation of chain on

three or four fall hoists that do not have load chain installed.

1. Remove the brake spring and piston housing, brake discs

and brake plates to expose the brake driver.

2. Place the edge of the first link of load chain in a pocket of

the hoist powered chain wheel. Refer to Dwg. MHP0472.

The weld on the load chain link must face away from the

powered chain wheel pocket.

• Improper installation of the load chain will cause

premature wear of the chain wheels resulting in damaged

equipment, which can cause injury or property damage.

3. Rotate the brake driver by hand to feed the load chain

through the hoist in the direction of the dead end chain

anchor (raise direction).

4. Keep the load chain straight, do not twist it. Attach the free

end of the load chain to the connecting link. Refer to Dwg.

TPA1056 for HL4500K and Dwg. TPA1057 for HL6000K.

Clean and inspect the brake parts and assemble.

5. On HL6000K hoists, slide the limit stop tube onto the load

chain.

6. Keeping the load chain straight, complete the load chain

installation as described in either the HL4500K or

HL6000K ‘Hoist Load Chain Reeving’ section.

4. Inspect to ensure chain is not twisted, kinked or “capsized”.

Refer to Dwg. MHP0020 and MHP0043.

HL4500K Hoist Load Chain Reeving

Refer to Dwg. TPA1056.

After the load chain has been correctly installed onto the hoist

powered chain wheel it must be carefully routed through the

lower block idler chain wheel, the upper suspension idler chain

wheel and secured to the bottom block housing as described in

this section.

• Twisted load chain can jam as it passes over the chain

wheel causing damage to the hoist or breaking the load chain

which can cause injury or property damage.

1. Raise the bottom hook block to a position near the hoist

where it can be properly supported and restrained from

movement.

2. Ensure the load chain remains straight. Feed load chain

through bottom block idler chain wheel.

20

Loading...

Loading...