Page 1

---

OPERATOR's MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

SELF-FEED DRILL

Models

8670-(

)-1( ) and 8670-(

)-3( )

SECTlON

MANUAL

M105

40

Released: 4/77

Revised: 8- 30-96

Form:

1022-2

FEATURES:

MODULAR DESIGN FOR EASY MAINTENANCE

OUTER HOUSING OF DUCTlLE IRON FOR RlGlDlTY

DUPLEX BEARING MOUNTED FRONT SPINDLE TO REDUCE RUN-OUT

DWELL CONTROL - ADJUSTABLE FROM 0 TO 7 SECONDS

TO-DEPTH AND FULL RETRACT SIGNAL PORTS

REMOTE START AND RETRACT SIGNAL PORTS

MANUAL START AND RETRACT VALVES

EXTERNAL RETRACT FEED RATE ADJUSTMENT

DIRECT READING STROKE SCALE ON REAR COVER

ADJUSTABLE TRIP BRACKET

HYDRAULIC CHECK WlTH 3-POSlTlON MOUNTING

5/8”-16 THREADED SPINDLE FOR CHUCK MOUNTlNG

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

INDEX

MODEL IDENTlFlCATlON

GENERAL DESCRIPTION AND OPERATlON

MOUNTING AND SET-UP PROCEDURE

................................................................

..................................................

...............................................

PAGE

2

2

3

AIR AND LUBE

MAINTENANCE

DISASSEMBLY AND ASSEMBLY ..................................................

TOOL CROSS SECTION

ACCESSORIES

RECOMMENDED POWER INLET SYSTEM

REMOTE CONTROL ClRCUlTlNG

TROUBLE SHOOTING ..................................................................

DIMENSIONAL DATA

For parts and service information, contact your local ARO distributor, or the Customer Service Dept. of the Ingersoll-Rand Distribution Center, White House, TN at PH: (615) 672-0321, FAX: (615) 672-0801.

ARO Tool Products

Ingersoll-Rand Company

1725 U.S. No. 1 North l P.O. Box 8000 l Southern Pines, NC 28388-8000

©1996 THE ARO CORPORATION. PRINTED IN U.S.A.

REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.........................................................................

................................................................

................................................................

...............................................

.................................................

...................................................................

4 and 15

4

4 thru 10

11

12 thru 14

15

16 and 17

18

19

Page 2

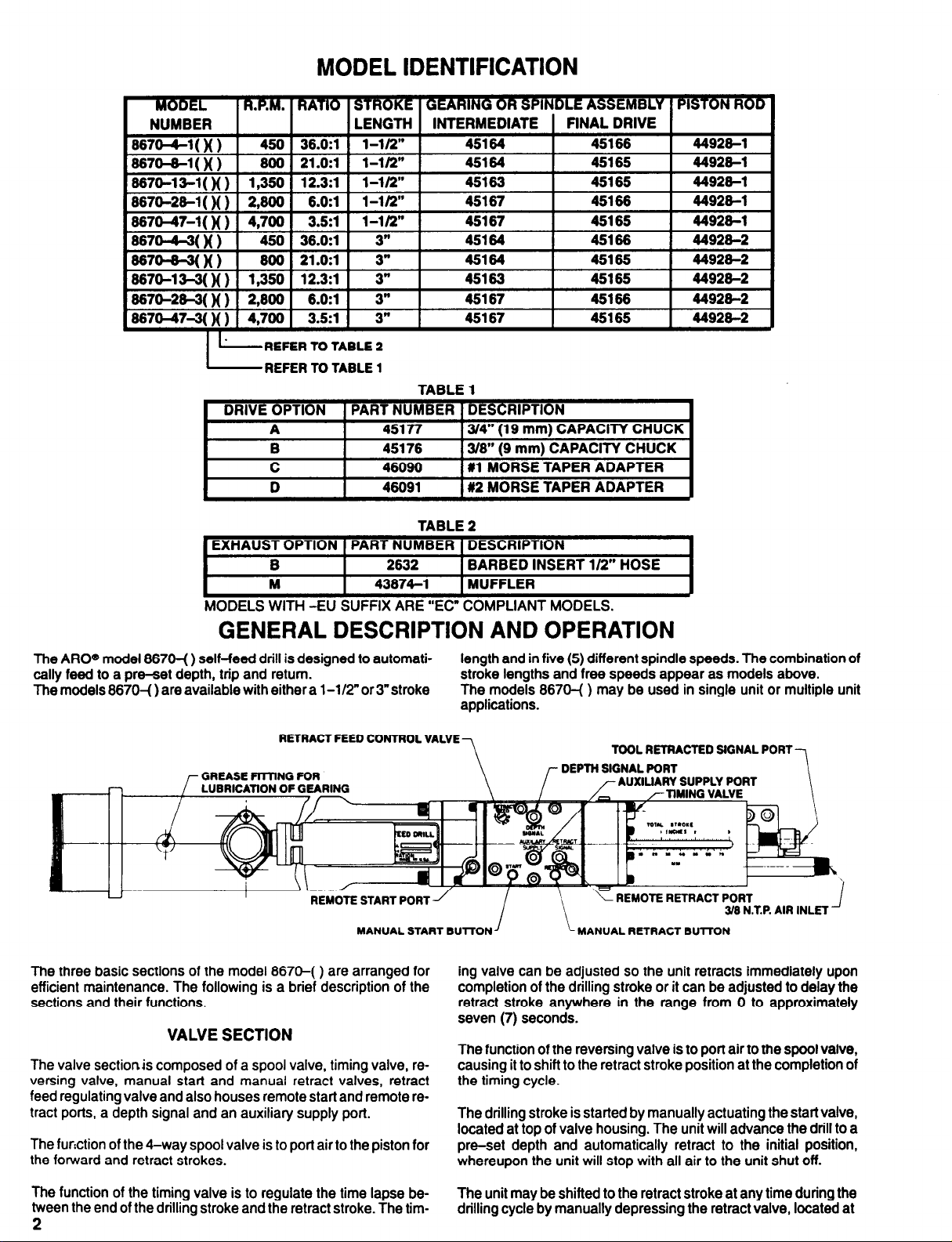

MODEL IDENTIFICATION

TABLE 2

The ARO@ model 8670-( ) self-feed drill is designed to automatitally feed to a pre-set depth, trip and return.

The models 8670-( ) are available with either a 1 -1/2” or 3” stroke

RETRACT FEED CONTROL VALVE

The three basic sections of the model 8670-( ) are arranged for

efficient maintenance. The following is a brief description of the

sections and their functions.

VALVE SECTION

The valve section is composed of a spool valve, timing valve, reversing valve, manual start and manual retract valves, retract

feed regulating valve and also houses remote start and remote retract ports, a depth signal and an auxiliary supply port.

The function of the 4-way spool valve is to port air to the piston for

the forward and retract strokes.

length and in five (5) different spindle speeds. The combination of

stroke lengths and free speeds appear as models above.

The models 8670-( ) may be used in single unit or multiple unit

applications.

7

TOOL RETRACTED SIGNAL PORT

UARY SUPPLY PORT

EMOTE RETRACT PC

ing valve can be adjusted so the unit retracts immediately upon

completion of the drilling stroke or it can be adjusted to delay the

retract stroke anywhere in the range from 0 to approximately

seven (7) seconds.

The function of the reversing valve is to port air to the spool valve,

causing it to shift to the retract stroke position at the completion of

the timing cycle.

The drilling stroke is started by manually actuating the start valve,

located at top of valve housing. The unit will advance the drill to a

pre-set depth and automatically retract to the initial position,

whereupon the unit will stop with all air to the unit shut off.

The function of the timing valve is to regulate the time lapse be-

tween the end of the drilling stroke and the retract stroke. The tim2

The unit may be shifted to the retract stroke at any time during the

drilling cycle by manually depressing the retract valve, located at

Page 3

top of valve housing. The unit will immediately retract to the initial

position, whereupon the unit will stop with all air to the unit shut off.

The needle type retract feed control valve regulates the flow of air

from the piston, thus regulating the rate of retraction of the unit.

The model 8670-( ) is furnished with a hydraulic check to control

the rate of forward feed of the unit-see page 12 for set-up procedure.

SPECIAL NOTE: There are two needle valves (34617) contained

in the valve block. One needle valve is for the retract feed control.

The other needle valve [visible only after the removal of the name-

plate (45184)) should not be adjusted or removed. If this needle

valve should ever be removed, the correct assembled position is

-the top of the needle valve flush with the top of the valve block.

The unit may be operated remotely thru the use of the start and

retract signal ports located in top of the valve housing, using recommended fittings, tubing and valves - see page 16.

The auxiliary supply port is pressurized whenever air is present at

the air inlet of the tool.

The depth signal port is momentarily pressurized at the comple-

tion of the forward feed stroke when the retract valve (44981) is

actuated and can be used to activate a remote valve for the purpose of starting another tool or an accessory function.

M105

40

The tool retracted signal port is located in rear of piston rod

(44928-). The port is pressurized when motor starts and remains

pressurized during the drilling cycle, until motor shuts off when

unit is fully retracted.

The valve section can be easily removed from tool for servicing

and replaced with a spare unit, eliminating excessive down-time

of tool. See page 4 for removal instructions.

MOTOR AND GEARING SECTION

The motor and gearing section has been designed into a single

unit that can be easily removed from tool and replaced with a

spare unit while it is being serviced or repaired, eliminating excessive down-time of tool. See page 4 for removal from tool.

HOUSING AND VALVE SECTION

The housing and valve section consists of a main housing, which

houses the piston section and motor and gearing section, and the

valve housing, which houses the retract valve that is actuated by

the adjustment screw contained in the trip bracket. The retract

valve components are accessible by removing striker plate

(44987) from rear of valve housing. The piston and components

are accessible by separating the main housing from the

housing. See page 4 for disassembly procedure.

valve

MOUNTING

The nose end of tool housing is provided with 2-7/8”-16 I.h.

threads and a 2.873” x 2-1/4” long pilot diameter for fixture mounting. A foot type mounting bracket and nose housing are available

SET-UP PROCEDURE

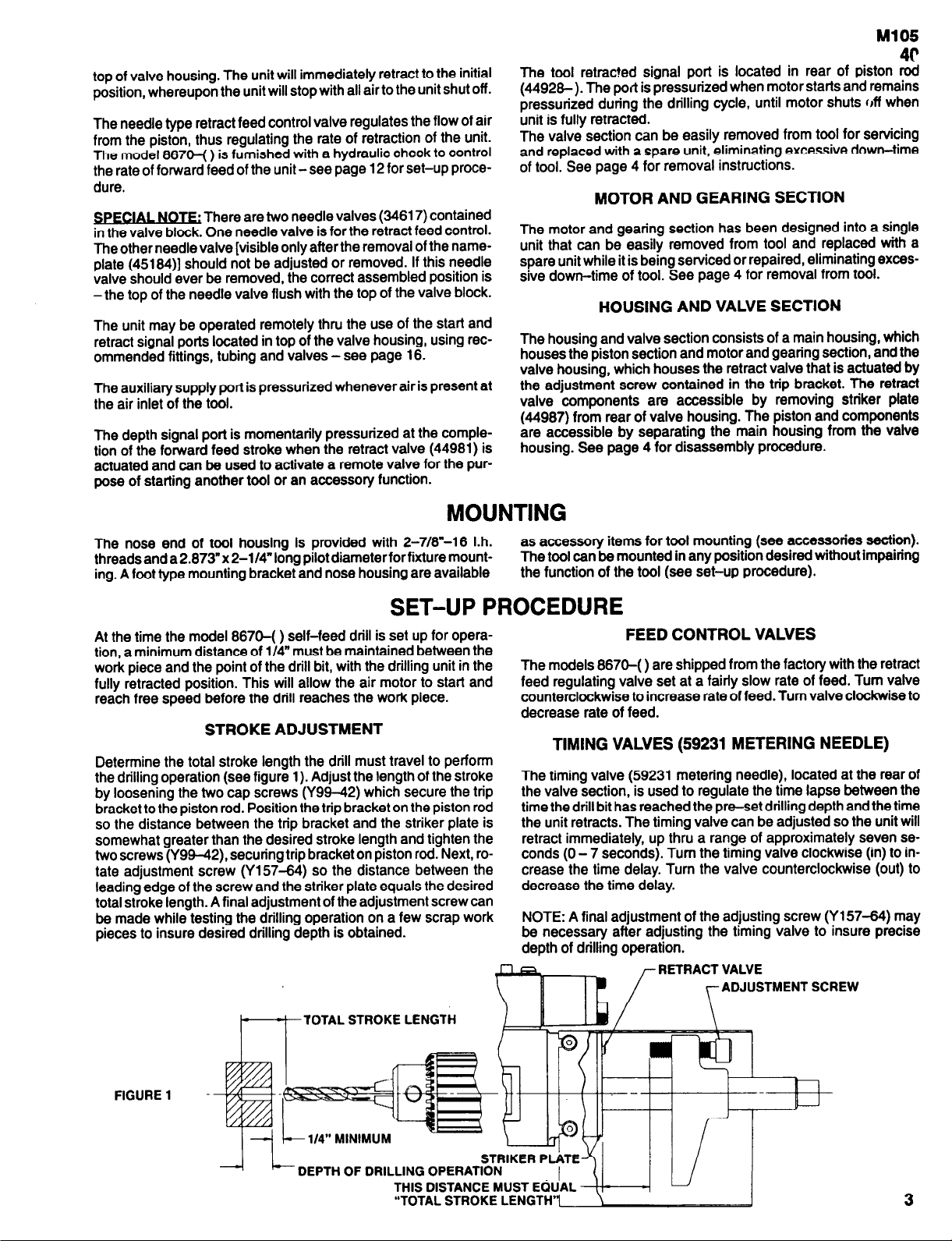

At the time the model 8670-( ) self-feed drill is set up for operation, a minimum distance of 1/4” must be maintained between the

work piece and the point of the drill bit, with the drilling unit in the

fully retracted position. This will allow the air motor to start and

reach free speed before the drill reaches the work piece.

STROKE ADJUSTMENT

Determine the total stroke length the drill must travel to perform

the drilling operation (see figure 1). Adjust the length of the stroke

by loosening the two cap screws (Y99-42) which secure the trip

bracket to the piston rod. Position the trip bracket on the piston rod

so the distance between the trip bracket and the striker plate is

somewhat greater than the desired stroke length and tighten the

two screws (Y99-42), securing trip bracket on piston rod. Next, rotate adjustment screw (Y157-64) so the distance between the

leading edge of the screw and the striker plate equals the desired

total stroke length. A final adjustment of the adjustment screw can

be made while testing the drilling operation on a few scrap work

pieces to insure desired drilling depth is obtained.

as accessory items for tool mounting (see accessories section).

The tool can be mounted in any position desired without impairing

the function of the tool (see set-up procedure).

FEED CONTROL VALVES

The models 8670-( ) are shipped from the factory with the retract

feed regulating valve set at a fairly slow rate of feed. Turn valve

counterclockwise to increase rate of feed. Turn valve clockwise to

decrease rate of feed.

TIMING VALVES (59231 METERING NEEDLE)

The timing valve (59231 metering needle), located at the rear of

the valve section, is used to regulate the time lapse between the

time the drill bit has reached the pm-set drilling depth and the time

the unit retracts. The timing valve can be adjusted so the unit will

retract immediately, up thru a range of approximately seven se-

conds (0 - 7 seconds). Turn the timing valve clockwise (in) to in-

crease the time delay. Turn the valve counterclockwise (out) to

decrease the time delay.

NOTE: A final adjustment of the adjusting screw (Y157-64) may

be necessary after adjusting the timing valve to insure precise

depth of drilling operation.

RETRACT VALVE

ADJUSTMENT SCREW

TOTAL STROKE LENGTH

3

Page 4

AIR AND LUBE REQUIREMENTS

Air pressure of 90 p.s.i.g. (6 bar) at the air inlet of the tool is required for maximum motor efficiency. If necessary, an air regulator

should be installed to maintain this pressure when tool is in operation.

Filtered and oiled air will allow the tool to operate more efficiently

and yield a longer life to operating parts and mechanisms. A line

filter capable of filtering particles larger than 50 microns should be

used with a line oiler.

Filter-Regulator-Lubricator (F-R-L) assembly model RECOMMENDED LUBRICANTS: Spindle oil 29665, 1 qt. (.9 liter)

C28241-810 is recommended for use with this air tool. The ca- container for oiler and air inlet; Grease 33153, 5 lb. (2.3 kg) can for

pacity of the individual filter-lubricator is adequate to provide gears and bearings; “0” ring lubricant 36460, 4 oz. (113 g) tube for

clean (40 micron) oiled and regulated air for the tool. lubrication and installation of “0” rings.

Inject 33153 grease (3 to 4 strokes) thru grease fitting located at

top of main housing after each 160 hours of operation, or as experience indicates, for lubrication of gearing and spindle bearings.

NOTE: Be sure tool is in the fully retracted position when injecting

grease thru fitting. CAUTION: An excessive amount of lubricant in

a tool will affect the speed and power.

RECOMMENDED HOSE SIZE: 1/2” (13 mm) nominal inside diameter.

MAINTENANCE

Air tools are made of precision parts and should be handled with

reasonable care when servicing. Excessive pressure exerted by

a holding device may cause distortion of a part. Apply pressure

evenly when disassembling (or assembling) parts which have a

press fit. When removing or installing bearings, apply pressure to

the bearing race that will be press fit to the mating part; if this is not

practiced, Brinelling of the bearing races will occur, making replacement necessary. It is important that the correct tools and fixtures are used when servicing this air tool.

Disassembly should be done on a clean work bench with a clean

cloth spread to prevent the loss of small parts. After disassembly

is completed, all parts should be thoroughly washed in a clean solvent, blown dry with air and inspected for wear levels, abuse and

contamination.

Double sealed or shielded bearings should never be placed in

solvent unless a good method of relubricating the bearing is available. Open bearings may be washed but should not be allowed to

spin while being blown dry. When replacement parts are necessary, consult drawing containing the part for identification.

Before reassembling, lubricate parts where required. Use 33153

grease, or equivalent, in bearings. Use 36460 lubricant for “0

ring assembly. When assembling “0” rings, care must be exercised to prevent damage to the rubber sealing surfaces. A small

amount of grease will usually hold steel balls and other small parts

in place while assembling.

When ordering parts, be sure to list part number, part name, model

number and serial number of tool. Use only genuine ARO© replacement parts.

DISASSEMBLY AND ASSEMBLY OF TOOLS

Disconnect air supply from tool or shut off air supply and drain line

of compressed air before performing maintenance or service to

tool.

Before starting to disassemble or assemble this tool (any part or

completely), be sure to read “Maintenance” section.

To minimize the possibility of parts damage and for convenience,

the steps for disassembly or assembly listed on the following

pages are recommended.

The basic sections and instructions for removing them from the

tool are as follows:

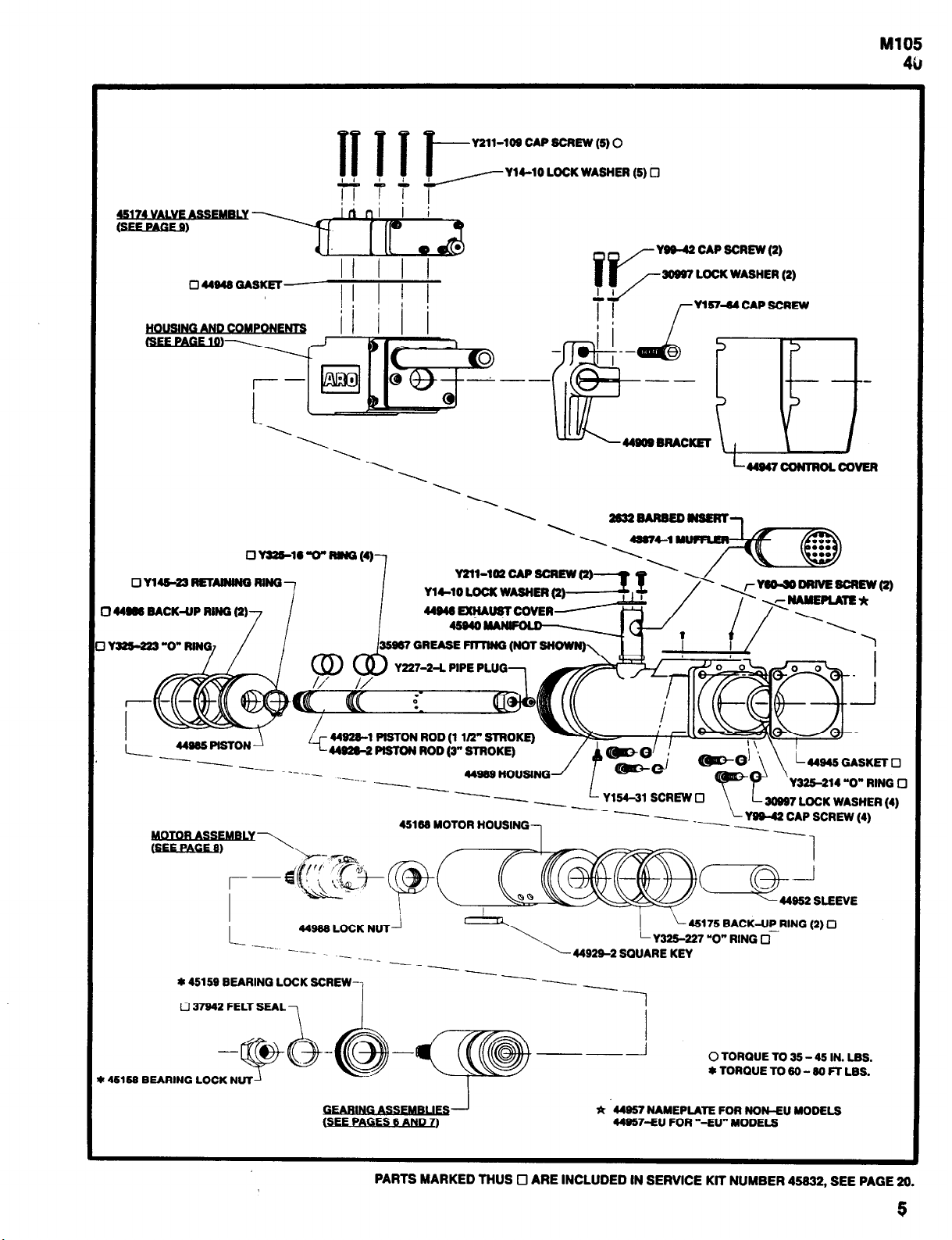

VALVE SECTION

First, disconnect tubing from ports if any is being used. Remove

five screws (Y211-109) with washers (Y14-10), and lift valve

section (45174) off valve housing (44919). For disassembly of

valve section, see page 8.

MOTOR AND GEARING SECTION

Loosen four screws (Y211-102) and remove control cover

(44947) off rear of tool. Using a wrench on flats at end of piston rod

(44928-), unthread piston rod from nut (44988) which secures

piston rod to motor and gearing section. Do not attempt to remove

piston rod from housing at this time. The main housing and valve

housing must be separated for removal of rod (see “Housing and

Valve” section). Next, remove screw (Y 154-31) and remove mo-

tor and gearing section from main housing and key (44929-2).

For disassembly of gearing, see pages 6 and 7. For disassembly

of motor, see page 8.

HOUSING AND VALVE SECTION

To remove piston rod (44928- ) and to gain access to piston

(44985), loosen four screws (Y211-1 02) and remove control cover (44947). Loosen two screws (Y99-42) and slip trip bracket

(44909) off end of piston rod. Unthread piston rod (44928-) from

nut (44988) using a wrench on flats at rear end of rod. Main housing and valve housing must be separated before rod can be removed. Remove four screws (Y99-42) with washers (30997)

and separate valve housing (44919) from main housing (44989).

Use reasonable care when removing valve housing off piston rod

so as not to damage rod or components in valve housing. The retract valve (44981) and components are accessible after removing control cover, trip bracket, three screws (Y211-102) and

washers (Y14-10) and striker plate (44987). See page 10 for

complete disassembly.

4

Page 5

M105

40

----

*

44957

NAMEPLATE FOR NON-EU MODELS

44957-EU FOR “-EU” MODELS

PARTS MARKED THUS - ARE INCLUDED IN SERVICE KIT NUMBER 45832, SEE PAGE 20.

5

Page 6

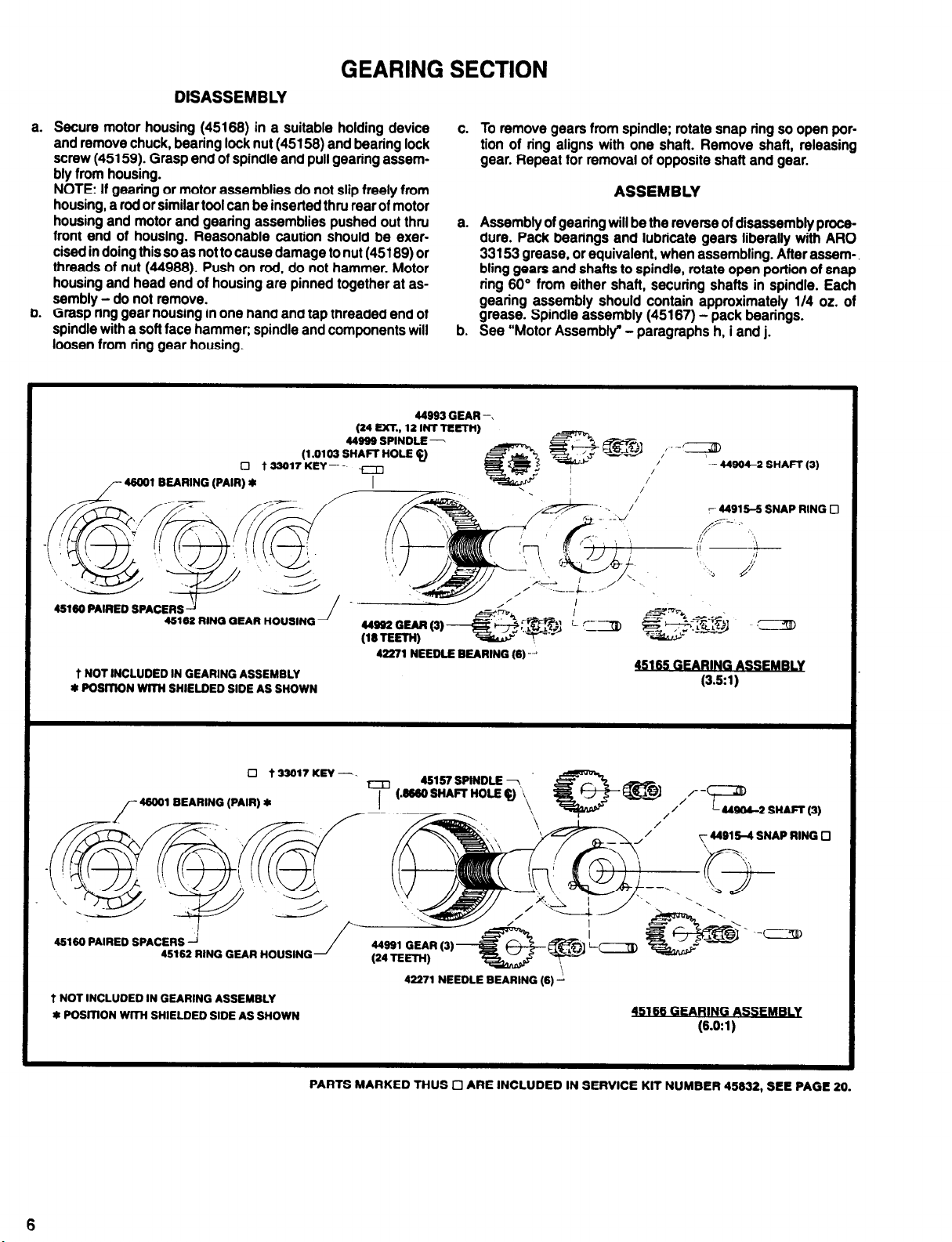

DISASSEMBLY

GEARING SECTION

a. Secure motor housing (45168) in a suitable holding device

and remove chuck, bearing lock nut (45158) and bearing lock

screw (45159). Grasp end of spindle and pull gearing assembly from housing.

NOTE: If gearing or motor assemblies do not slip freely from

housing, a rod or similar tool can be inserted thru rear of motor

housing and motor and gearing assemblies pushed out thru

front end of housing. Reasonable caution should be exercised in doing this so as not to cause damage to nut (45189) or

threads of nut (44988). Push on rod, do not hammer. Motor

housing and head end of housing are pinned together at assembly - do not remove.

b. Grasp ring gear housing in one hand and tap threaded end of

spindle with a soft face hammer; spindle and components will

loosen from ring gear housing.

c. To remove gears from spindle: rotate snap ring so open por-

tion of ring aligns with one shaft. Remove shaft, releasing

gear. Repeat for removal of opposite shaft and gear.

ASSEMBLY

a. Assembly of gearing will be the reverse of disassembly proce-

dure. Pack bearings and lubricate gears liberally with ARO

33153 grease, or equivalent, when assembling. After assembling gears and shafts to spindle, rotate open portion of snap

ring 60° from either shaft, securing shafts in spindle. Each

gearing assembly should contain approximately 1/4 oz. of

grease. Spindle assembly (45167) - pack bearings.

b. See “Motor Assembly” - paragraphs h, i and j.

~- 44994-2 SHAFT (3)

6

45162 RING GEAR HOUSING

Page 7

15161

M105

40

PARTS MARKED THUS ARE INCLUDED IN SERVICE KIT NUMBER 45632, SEE PAGE 20.

* POSlTlON BEARINGS WITH SHIELDED SIDE AS SHOWN.

7

Page 8

MOTOR SECTION

DISASSEMBLY

Remove motor from tool as outlined on page 4. Remove motor

a.

assembly from housing as outlined in paragraph “a” of gearing disassembly.

Remove retaining ring (Y145-18) retainer nut (45189) and

b.

nut (44980).

NOTE: It is suggested that brass blocks be used in a vise or

some other suitable fixture to clamp on splines of rotor to keep

from turning while removing or tightening nut (44980). Care

must be exercised so as not to damage splines of rotor shaft.

Grasp cylinder in one hand and tap splined end of rotor with a

c.

soft face hammer; motor will come apart.

ASSEMBLY

Pack bearings with ARO 33153 grease, or equivalent, and as-

a.

semble bearing (34690) to end plate (44974) with shielded

side out.

b. Assemble end plate (44974), with bearing and spacer

(33555), to rotor and secure with nut (44980). Torque nut to 26

- 30 ft Ibs. Bearings are press fit on rotor.

Coat i.d. of cylinder with ARO 29665 spindle oil and assemble

c.

cylinder over rotor, aligning air inlet and roll pin of cylinder with

holes in end plate.

d. Assemble blades into slots in rotor.

Assemble spring washer (35963) to end plate (44975), with

e.

large diameter of washer facing out, and assemble bearing

(Y65-12) to end plate. Assemble end plate to rotor and cylinder and secure with retaining ring (Y145-18). Bearing is press

fit on rotor.

f. Assemble retainer nut (45189) to end plate and torque to 9 -

12 ft Ibs.

g. Be sure rotor does not bind and assemble motor to housing.

NOTE: Be certain nut (44988) is properly positioned in hous-

ing before assembling motor to housing.

h.

Assemble spacer (44994) and gearing assemblies to housing

and secure with bearing lock screw (45159) with seal (37942)

and bearing lock nut (45158).

NOTE: When assembling gearing to motor housing, be sure

key (33017) is properly positioned in ring gear and aligned

with slot in housing.

i.

Lube “0” ring (Y325-227) attached to rear head of motor

housing with ARO 36460 “0” ring lube and assemble motor

and gearing section with key (449292)to main housing and

secure key into housing with screw (Y154-31). NOTE: When

assembling key, be sure hole thru key is properly positioned

and aligned with hole in housing to accept screw (Y154-31).

j.

Thread piston rod into nut (44988) securing motor and gearing section into main housing. Using a wrench on flats at rear

of piston rod, tighten rod securely but do not overtighten.

44977 MOTOR ASSEMBLY

PARTS MARKED

VALVE SECTION

DISASSEMBLY

To gain access to timing valve (metering needle 59231) and/

a.

or reversing valve (actuator 59572) and components, remove

four screws (Y154-38) with washers (Y79-6) cover plate

(44954) and valve body (44953) from valve block (44927).

Use reasonable care when removing cover plate (44954) so

as not to cause damage to metering needle (59231) or components. After removal of cover plate, insert (59597) and components can be removed from valve body. To disassemble

components from insert, remove retaining ring (Y147-1). Unthread metering needle (59231) to remove from insert.

After removal of cover plate, diaphragm (58037) and valve ac-

b.

tuator (59572) can be removed from valve body. To remove

valve seat (44955) and components, remove retaining ring

(Y247-75).

Spool valve (44978) can be removed from valve block after re-

c.

moving the end cap (44949) and cover plate (44954) and

valve body (44953). To remove end cap, remove three screws

8

THUS Cl ARE

(Y154-32) and one screw (Y154-34) with washers (Y79-6).

Push spool valve out thru block.’

To remove needle valves (34617) unthread from valve block

d.

(44927).

e.

To

(Y14743) and (44106).

To remove rubber ball(s) (44967) remove retaining ring(s)

f.

(Y147-1), washer(s) (59230) and spring(s) (39679).

Assembly of the valve assembly (45174) will be the reverse of

a.

the disassembly procedure. Lubricate all “0” rings with ARO

36460 “0” ring lube, or equivalent, upon assembly. It is recommended that “0” rings be replaced whenever a part containing

good repair and assembled in the proper position.

INCLUDED IN SERVICE

remove valve stem (36602), remove retaining ring

KIT NUMBER

45632,

SEE PAGE 20.

ASSEMBLY

"0"

rings has been disassembled. Be sure gaskets are in

Page 9

NOTE: When assembling needle valves (34617), install with

top of needle valve flush with top of valve block (44927).

b.

Assemble valve assembly (45174) to valve housing (44919)

with gasket (44948) and nameplate (45184) and secure with

five screws (Y211-109) and washers (Y14-10)

44979 VALVE SLEEVE

M105

40

NOTE: When replacing gaskets, torque cap screws to 20 in.

Ibs and re-torque after 24 hours to remove gasket set.

/

45174 VALVE ASSEMBLY

PARTS MARKED THUS ARE INCLUDED IN SERVICE KIT NUMBER

45632, SEE PAGE 20.

9

Page 10

HOUSING AND VALVE SECTION

DISASSEMBLY

a. Remove three cap screws (Y211-102), with lock washers

(Y14-10), and remove striker plate (44987).

Grasp end of valve stem (44981) and pull valve components

b.

from housing.

Remove bushing (44982) from housing for access to two “0”

c.

rings (Y325-210) and washer (F21-38). Other “0” ring

(Y325-210) is accessible thru front of housing.

ASSEMBLY

Lubricate all “0” rings with ARO 36480 “0” ring lube, or equiv-

a.

alent, upon assembly.

NOTE: It is recommended that “0” rings be replaced whenev-

era part containing “0” rings has been disassembled.

b.

Assemble one “0” ring (Y325-210) into “0” ring groove thru

front of housing. Assemble washer (F21-38), two “0” rings

(Y325-210) and bushing (44982) into position at rear of hous-

ing.

c. Assemble one “0” ring (Y325-11) into bottom of hole in hous-

ing provided for valve body and assemble two “0” rings

(Y325-11) to valve body. Assemble “0” rings (Y325-8) and

(44938) to valve stem and assemble valve stem to valve body.

Assemble valve body into housing and secure with striker

plate (44987), washers (Y14-10) and cap screws

(Y211-102).

10

Y211-102 CAP SCREW (3)

Page 11

TYPICAL CROSS SECTION OF TOOL

11

Page 12

ACCESSORIES

HYDRAULIC CHECK

TRIP BRACKET

44910 MOUNTING BRACKET

(3 POSITION ADJUSTMENT)

NOTE: Hydraulic check assembly (44969-1) is furnished with

models 8670( )-1 and 44969-2 is furnished with models 8670-(

)-3.

HYDRAULIC CHECK: The hydraulic check assembly is a

hermetically sealed unit with a frictionless diaphragm. The hydraulic fluid need not be replenished.

MOUNTING INSTRUCTIONS

Assemble mounting bracket (44910) with hydraulic check

(38922-), to the valve housing with three screws (Y99-45) and

washers (30997).

SET-UP PROCEDURES

TO CONTROL RATE OF FEED:

Measure distance from drill point to work piece (distance “Y”).

1.

Distance “X” between the hydraulic check plungerand the trip

2.

bracket must be less than distance “Y” to prevent damage to

the drill point when it approaches the work piece. This can be

adjusted by selecting the most suitable mounting of the

,

’ Y99-45 CAP SCREW (3)

39997 WASHER (3)

3-position mounting feature when attaching mounting bracket to tool housing and/or positioning of the adjustable trip

bracket. Re-tighten screws before operating unit.

3.

The hydraulic feed rate adjustment is located at the nameplate end of the hydraulic check. Rotate extended spindle until

the slot on spindle is located midway between the highest and

the lowest settings.

4.

Start tool and the drill will advance at a rapid rate, until the trip

bracket contacts the plunger of the hydraulic check.

5.

Slowly rotate the hydraulic feed rate counterclockwise toward

the zero (0) on the nameplate until the drill advances at the desired rate.

Set-up procedure for the tool will be the same as explained in

“Set-Up Procedure” on page 3.

TO CONTROL BREAKTHROUGH:

1. When controlled breakthrough is required, the hydraulic

check must be set up so the distance between the plungerand

the trip bracket (distance “X”) is less than the distance from the

drill point to the opposite side of the work piece (distance “W).

Set-up procedure for the tool will be the same-as explained in

2.

“Set-Up Procedure” on page 3.

12

Page 13

DOUBLE HYDRAULIC CHECK ASSEMBLIES 46133-( )

46132 BRACKET

Y99-43 CAP SCREW (2)

Ml05

40

HYDRAULlC

CHECK

ASSEMBLY NO.

46133-11

46133-12

46133-13

46133-22

46133-23

I

38133-33 38922-2 38922-2

HYDRAULIC CHECK NO. 38922 = 1”

HYDRAULlC HYDRAULIC

CHECK

"A"

38922

38922

30922 38922-2

38922-1

38922-1

CHECK "B"

38922

38922-1

30922-1

38922-2

I

STROKE, 38922-1 = 2” STROKE.

The dual hydraulic check assembly (46133- ) is an accessory

item used to replace the standard hydraulic check when additional thrust control during the drilling operation and/or at breakthrough is required.

The dual system can be used when two different thrust control requirements are needed - for example, a 2” stroke length check

and a 1” stroke length check. When used together, the 2” stroke

length check controls the initial part of the drilling operation and

the 1” stroke is set to give additional control at breakthrough.

MOUNTING INSTRUCTIONS

Remove hydraulic check assembly supplied with tool.

Determine which of the three mounting positions on housing is

best suited for the operation to be performed and assemble

mounting bracket (46130) to housing using the three 1/4”- 20 x

5/8” long cap screws (Y99-458) and tighten securely. Insert hydraulic checks thru mounting bracket, positioning for desired

stroke and secure with the two 1/4”-20 x 1-114” long cap screws

(Y99-43) and two washers (30997).

Remove trip bracket (44909) from tool and remove the two clamping screws (Y99-42) and washers (30997) and the adjusting

46133-11

AS-

screw (Y157-64) from the trip bracket for use with the new trip

bracket (46132).

Assemble adapter plate (48131) to trip bracket (46132) and secure with the two 1/4”- 20 x 1/2” long cap screws (Y94-40) and

two washers (30997). Assemble the two clamping screws

(Y9942) with washers (30997) and the adjusting screw

(Y157-64) to trip bracket and assemble the trip bracket to tool.

Position trip bracket on piston rod for desired stroke and tighten

the two screws (Y99-42), securing trip bracket on piston rod.

SET-UP PROCEDURE

Basically, the set-up procedure for the dual hydraulic checks is

the same as for the single hydraulic check, except you will be doing each step of the set-up twice. After the stroke length set-up is

made, synchronize the two checks more or less by rotating the

feed rate adjustment of each check to approximately the same

number. This is when two checks of the same stroke lengths are

being used to control thrust.

When using two checks of different stroke lengths, testing set-up

on a few scrap work pieces will be the best way in determining

proper rates of feed.

.

46253 SPANNER WRENCH

FOR REMOVAL OF 45159 BEARING LOCK SCREW,

AVAILABLE AT EXTRA COST.

13

Page 14

ACCESSORIES

45185 FOOT MOUNT ASSEMBLY

45188 NOSE HOUSING

?

14

/

Page 15

RECOMMENDED POWER AIR INLET SYSTEM

M105

40

Your ARO self-feed tool is designed to deliver specific horsepowerand thrust to achieve high rates of work. To assure the unit will develop this

power, care must be taken that the power air Inlet system Is correctly sized to permit the proper rate of air flow. Shown above is a system for a

single tool that will supply correct dellvery.

IMPORTANT: The tool is power-rated when 90 p.s.i. is present at the tool during operation. To check operating air pressure at the tool, a pressure

gauge may be installed in a 1/8” n.p.t. port marked “Auxiliary Supply”. CAUTION: This port Is pressurized when tool Is connected to air supply.

Shown below Is the same system in schematic form.

If two units are to be Installed, each unit should be supplied with a system like that shown below or use two systems Iike that above.

15

Page 16

BASIC REMOTE CONTROL FOR START

AND EMERGENCY RETRACT FUNCTIONS

REMOTE OPERATION

Remote operation of the unit may be achieved by connecting a 3-way valve to the remote start and/or remote retract ports, as shown above.

TO START: Depress the remote start button momentarily. The unit will advance the drill to a pre-set depth and automatically retract to the initial

position, whereupon the unit will stop with all air to the unit shut off.

EMERGENCY RETRACT: Depress the emergency retract button momentarlly. This signal to the unit will shift the built-in pressure operated

valve, commanding the unit to retract immediately to the initial position, whereupon the unit will stop with all air to the unit shut off.

NOTE: Manual start and emergency retract buttons on the tool are fully operatlonal even when remote control Is used. The manually operated

buttons can be used when set-up is required.

Shown below Is the same system In schematic form.

16

Page 17

# 3 PORT (EXHAUST)

REMOTE VALVE

I

(DUPLICATE FOR REMOTE RETRACT CIRCUIT, EXCEPT USE MODEL 461-2 PALM VALVE WITH RED BUTTON)

WHEN MORE THAN EIGHT (6 TOOLS ARE REQUIRED PROVIDE ANOTHER 29192 VALVE AND 37750 MANIFOLD. THE SECOND SET OF

TOOLS CAN BE ACTUATED

FROM THE SAME 3-WAY PALM VALVE.

Page 18

TROUBLE SHOOTING

LISTED BELOW ARE SOME OF THE MOST COMMON CAUSES FOR THE SELF-FEED DRILL TO MALFUNCTION. MALFUNCTIONS BEYOND THE SCOPE OF THIS

MANUAL SHOULD BE BROUGHTTO THE ATTENTlON OF YOUR ARO REPRESENTATIVE OR RETURN THE TOOL TO THE FACTORY FOR REPAIR.

LOW SPEED OR

FAILURE TO OPER-

ATE.

MOTOR DOES NOT

SHUT OFF AFTER

COMPLmON OF

CYCLE.

IRREGULAR OR ER-

RATlC FEED.

FAILURE TO FEED

FORWARD.

FAILURE TO RETRACT.

POSSIBLE CAUSE

1. INADEQUATE AIR SUPPLY.

IMPROPER LUBRlCATlON OF UNIT

2.

(MOTOR

MOTOR (ROTOR BLADES STICKING,

ETC.), OR BROKEN OR BADLY WORN

ROTOR BLADES OR BEARINGS IN

MOTOR.

MOTOR NOT TlGHTENED DOWN OR

3.

IMPROPERLY SPACED.

WORN OR DAMAGED “0” RINGS IN

1.

VALVE HOUSING (44919).

1. INADEQUATE AIR SUPPLY.

FEED CONTROL NEEDLE VALVES

2.

(34817) IMPROPERLY ADJUSTED OR

RESTRICTED WlTH FOREIGN MATERIAL.

WORN OR DAMAGED “0” RINGS ON

3.

SPOOL VALVE (44978).

WORN OR DAMAGED “0” RINGS ON

0.

PISTON (44965), IN HOUSING (44989)

OR VALVE HOUSING (44919).

LEAKING OR DAMAGED GASKETS

i.

(44948, 44950, 44956 OR 42639).

TlMlNG VALVE (69231) IMPROPERLY

6.

ADJUSTED OR RESTRICTED (DIRTY).

SEE ITEMS 1 THRU 3 OF ERRATIC

1.

FEED.

LEAKING OR DAMAGED GASKET

2.

(44950).

IMPROPER SET-UP OF ACCESSORY

3.

HYDRAULIC CHECK (38922-)

I. SEE ITEMS 1 THRU 3 OF ERRATIC

FEED.

2. LEAKING OR DAMAGED GASKET

(44958 OR 42639).

L IMPROPER ALIGNMENT OR CON-

TACT OF STROKE ADJUSTMENT

SCREW (Y157-64) AND RETRACT

VALVE STEM (44981).

0. BADLY WORN OR DAMAGED “0”

RING ON RETRACT VALVE STEM

(44981).

AN/OR

GEARING), DIRTY

CORRECTIVE ACTION

1. CHECK AIR SUPPLY FOR CORRECT REGULATOR ADJUSTMENT (96 P.S.I.G. MAX. WHEN TOOL IS OPERATING).

2. BE SURE LUBRICATOR IS FULL OF OIL AND GEARING IS LUBRICATED REGULARLY, REFER TO PAGE 4. DISASSEMBLE,

CLEAN, INSPECT, REPLACE WORN OR DAMAGED PARTS, LUBRICATE. REFER TO PAGES 4, 6 AND 8

3. BE SURE BEARING LOCK SCREW (44898) IS SUFFICIENTLY

TIGHTENED. INSURE PROPER INSTALLATION OF MOTOR. REFER TO PAGE 8.

DISASSEMBLE, CLEAN, INSPECT, REPLACE “0” RINGS. REFER

1.

TO PAGES 4 AND 10.

CHECK AIR SUPPLY FOR CORRECT REGULATOR ADJUST-

1.

MENT (90 P.S.I.G. MAX. WHEN TOOL IS OPERATING).

DISASSEMBLE, CLEAN, INSPECT, REPLACE “0” RINGS IF NEC-

2.

ESSARY. REFER TO PAGES 4, 8 AND 9.

DISASSEMBLE, CLEAN, INSPECT, REPLACE “0” RINGS. REFER

3.

TO PAGES 4, 8 AND 9.

DISASSEMBLE, CLEAN. INSPECT, REPLACE “0” RINGS. REFER

1.

TO PAGES 4, 5, 8, 9 AND 10.

CHECK TORQUE ON CAP SCREWS. BE SURE ALL SCREWS

i.

ARE PROPERLY TIGHTENED. REPLACE GASKET(S), IF NECESSARY.

DISASSEMBLE, CLEAN, INSPECT TIMING VALVE AND BALL

6.

CHECK AREAS. REFER TO PAGES 3, 4, 6 AND 9.

SEE ITEMS 1 THRU 3 OF ERRATIC FEED.

I.

BE SURE SCREWS IN END CAP (44949) ARE PROPERLY TIGHT-

2.

ENED. REPLACE GASKET IF NECESSARY.

BE SURE PROPER SET-UP AND ADJUSTMENT PER INSTRUC-

3.

TIONS ON PAGE 12.

SEE ITEMS 1 THRU 3 OF ERRATIC FEED.

I.

CHECK TORQUE ON CAP SCREWS (Y154-38). REPLACE GAS-

!.

KET IF NECESSARY.

BE SURE TRIP BRACKET (44909) IS PROPERLY POSITIONED

I.

ON PISTON ROD, ALLOWING STROKE ADJUSTMENT SCREW

TO ALIGN AXIALLY WITH VALVE STEM. REFER TO SET-UP

PROCEDURE, PAGE 3.

DISASSEMBLE AND REPLACE “0” RING. PAGE 10.

1.

MAINTENANCE TOOL FURNISHED WITH EACH MODEL

Y106-3 ALLEN WRENCH (1/8”)

Y106-5 ALLEN WRENCH (3/16”)

Y106-8 ALLEN WRENCH (5/16”)

Y106-21 ALLEN WRENCH (7/64”)

Page 19

“TOOL RETRACTED” PORT

Page 20

SERVICE KIT NO. 45832

Qty

5

1

1

1

1

3

1

1

1

2

1

2

2

1

1

1

1

3

1

2

2

5

PART

NUMBER

15066

33017

34690

35963

37942

39679

41795

41799

41954

42321

42639

44915-4

44915-5

44945

44948

44950

44956

44967

44968

44986

45175

45364

DESCRIPTION

“0” RING

KEY

BEARING 5

SPRING WASHER

SEAL

SPRING

MOTOR OIL 3

GEAR LUBE

“0” RING LUBE

SPRING

GASKET 2

SNAP RING

SNAP RING 2

GASKET

GASKET 3

GASKET

GASKET

BALL

“0” RING

BACK-UP RING

BACK-UP RING

ROTOR BLADE

Qty

2

1

1

2

1

11

3

1

1

1

1

1

4

1

1

1

1

PART

NUMBER

59230

59378

Y14-10

Y65-12

Y145-18

Y145-23

Y147-1

Y147-43

Y147-75

Y178-18

Y325-6

Y325-7

Y325-8

Y325-10

Y325-11

Y325-16

Y325-210

Y325-214

Y325-223

Y325-227

59105

Y154-31

DESCRIPTION

WASHER

“0” RING

LOCKWASHER

BEARING

RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

RETAINING RING

ROLL PIN

“0” RING

“0” RING

“0” RING

“0” RING

“0” RING

“0” RING

“0” RING

“0” RING

“0” RING

“0” RING

“0” RING

SCREW

20

PN 49999-071

Loading...

Loading...